Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "Does not affect machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire electrode for WEDM-LS electrical discharge machining and preparation method of wire electrode

ActiveCN103537768ADoes not affect machining accuracyFast processingElectrical-based machining electrodesZincOxide

The invention discloses a wire electrode for WEDM-LS electrical discharge machining and a preparation method of the wire electrode. The wire electrode comprises a core portion, a transition layer, a covering layer and an oxide layer. The core portion is made of brass alloy or red copper. The transition layer covers the outer layer of the core portion and comprises a continuous portion and an interruption portion formed by beta-phase pinchbeck alloy protruding from the continuous portion. The covering layer is formed by the interruption portion formed by the beta-phase pinchbeck alloy, cracked gamma-phase pinchbeck alloy inlaid on the interruption and gaps. The inevitable oxide layer is formed on the surface of the covering layer. The zinc content at the joint between the core portion and the transition layer and the zinc content at the joint between the transition layer and the covering layer are distributed in a linear increase mode. According to the wire electrode with the special tissue structure, the gasification capacity of zinc can be adjusted in the cutting process, cutting efficiency and cutting accuracy are promoted, cost is saved to the largest degree and machining quality is improved.

Owner:NINGBO BODE HIGHTECH CO LTD

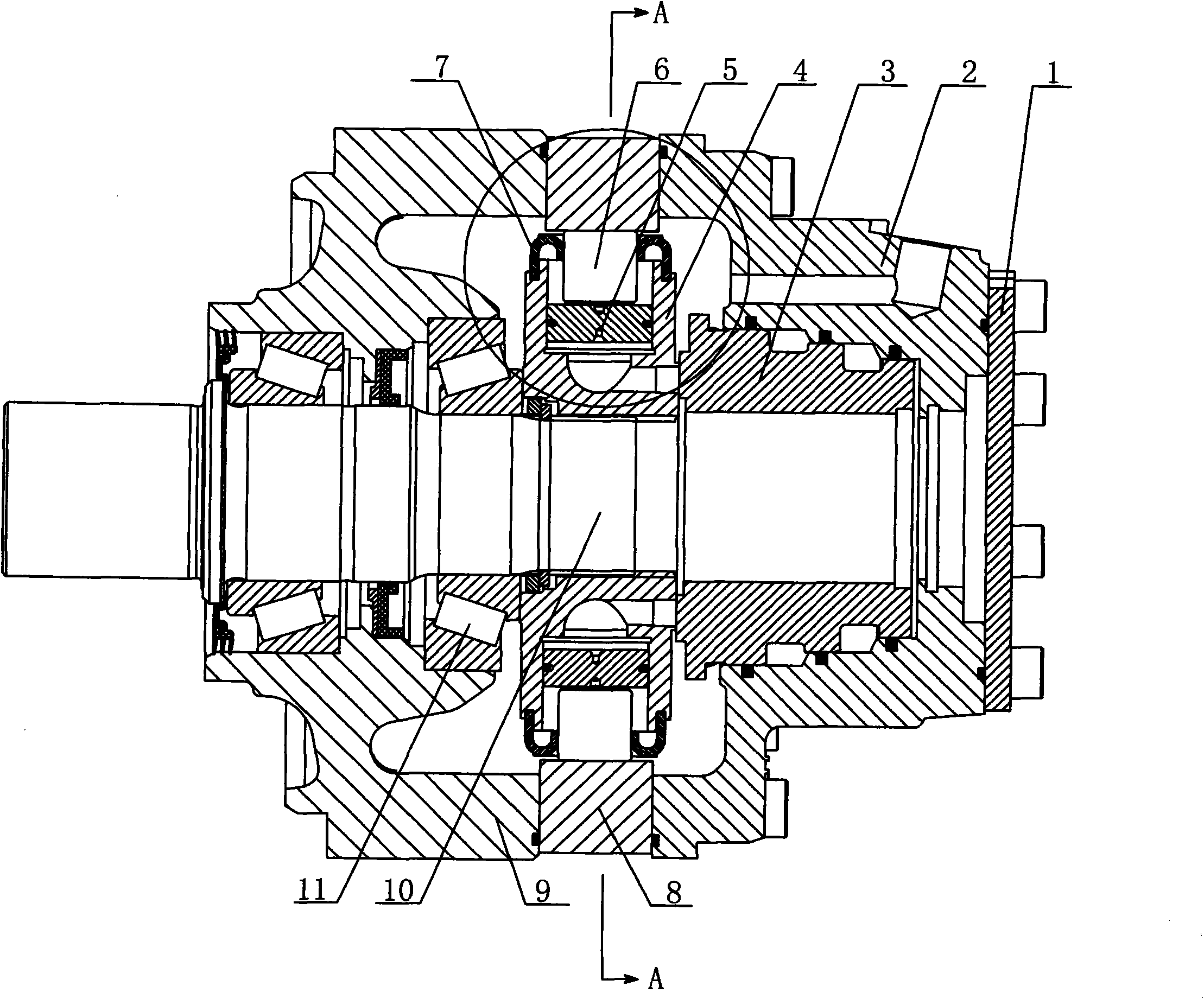

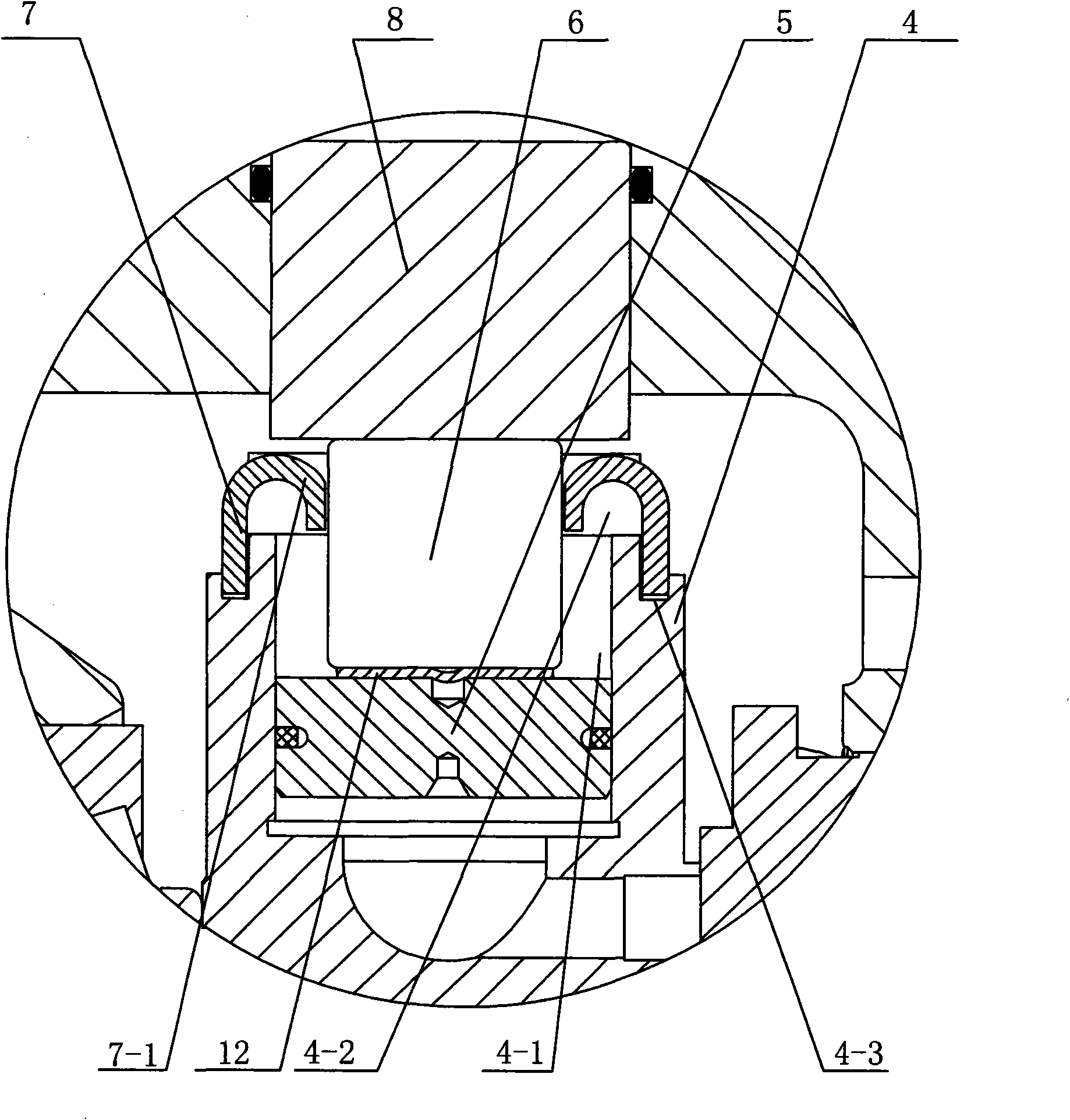

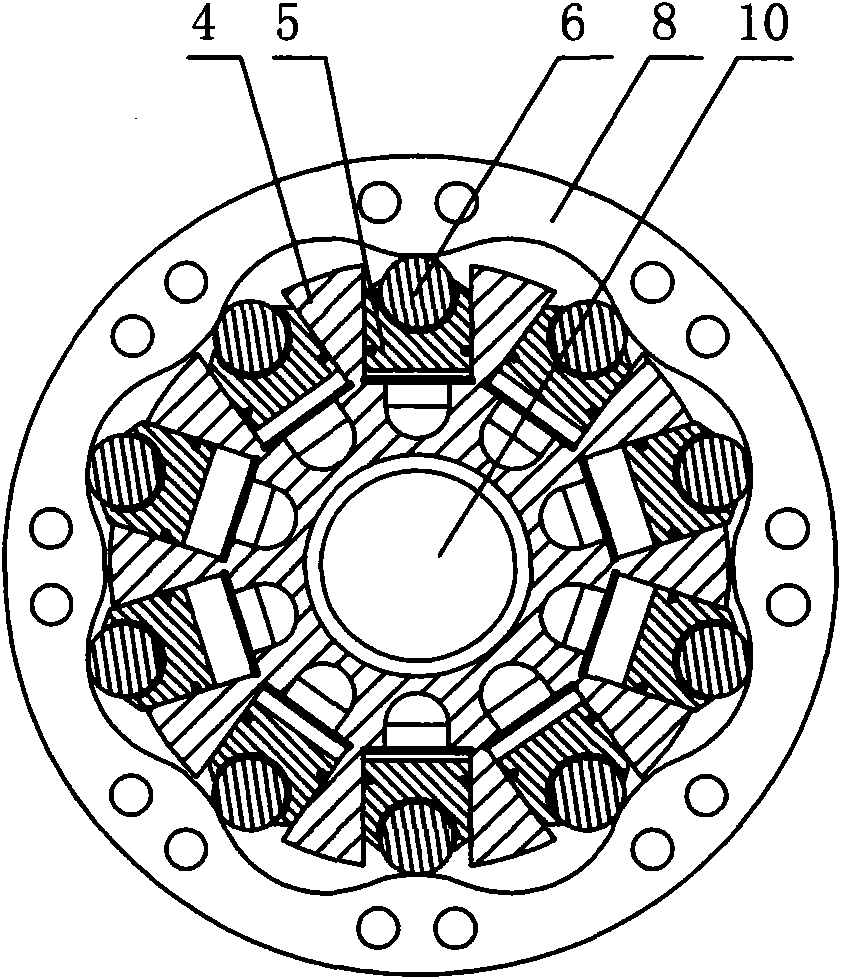

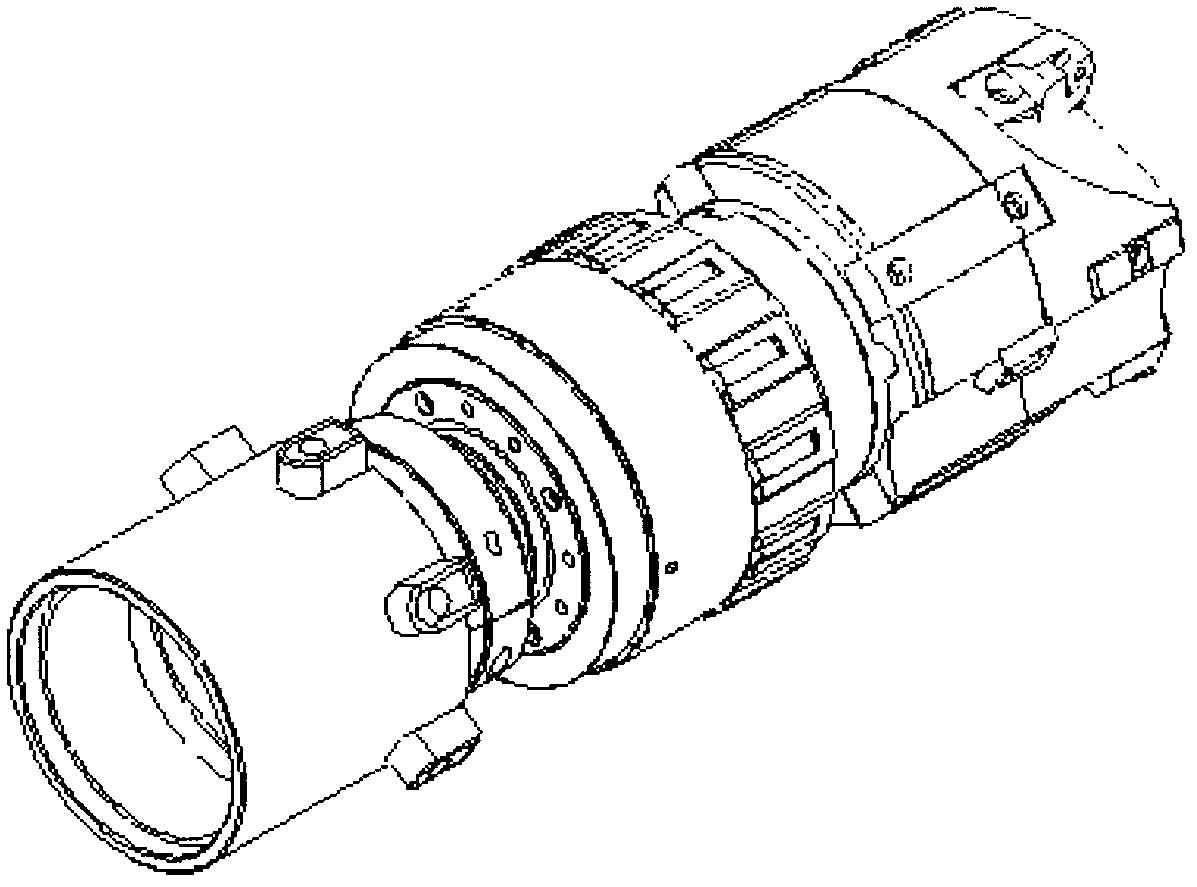

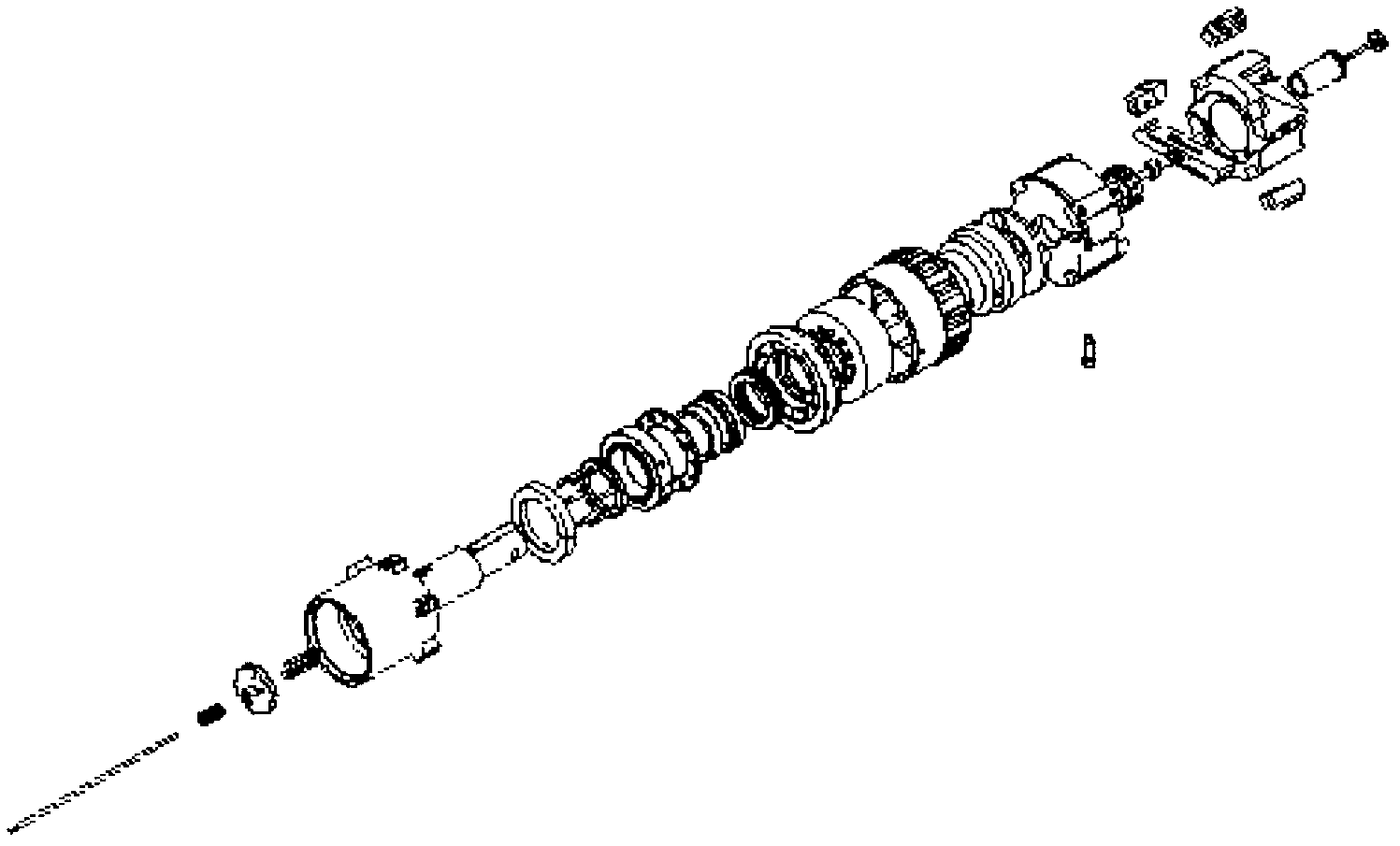

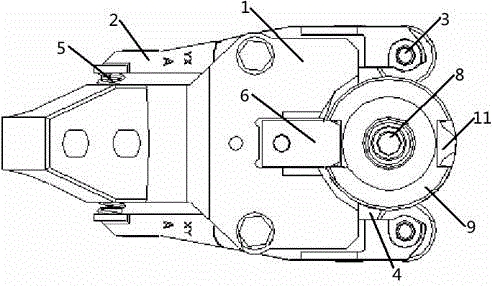

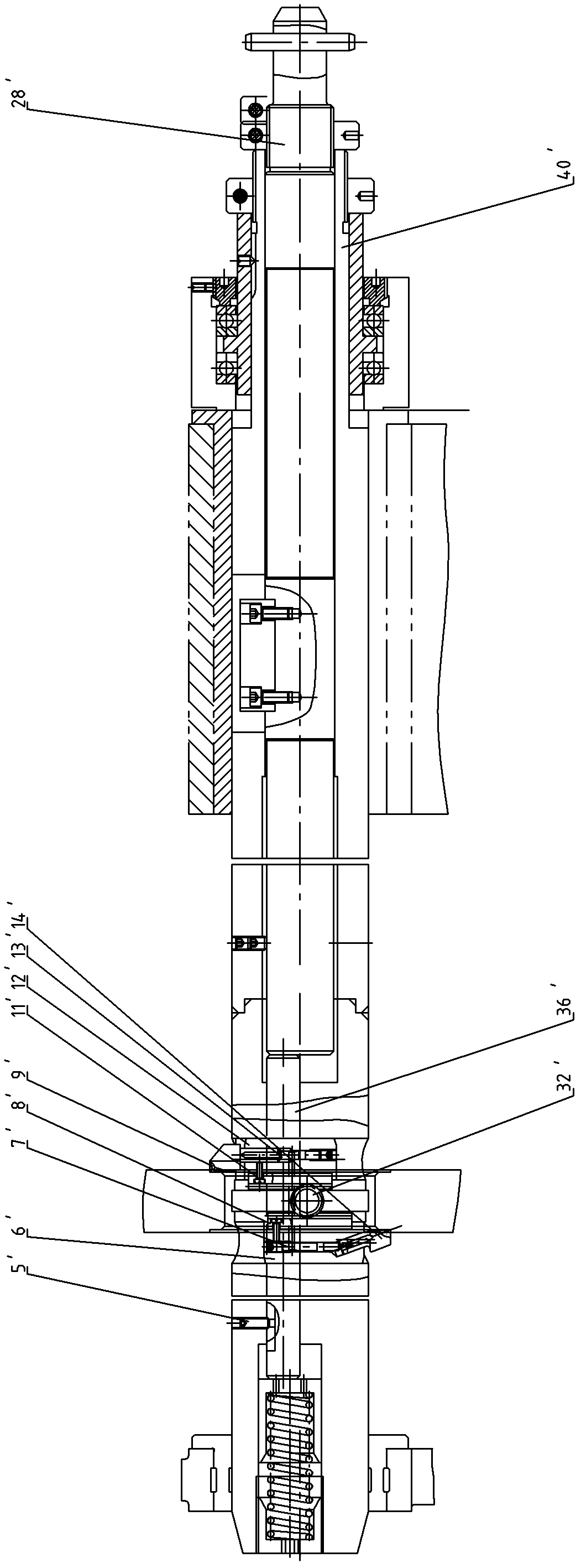

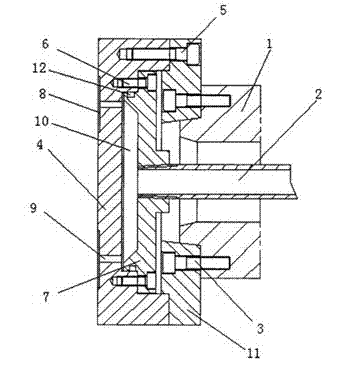

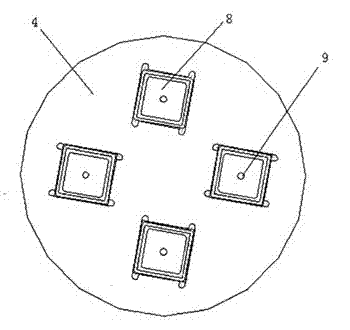

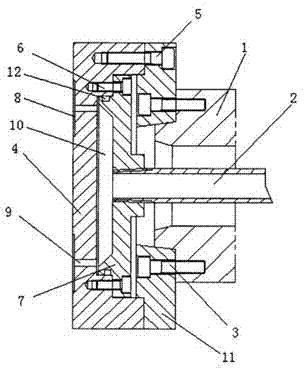

Innercurve multiple-action radial plunger type hydraulic motor

InactiveCN101858300ASimplify processing difficulty and costIncrease productivityRotary piston enginesRetaining ringEngineering

The invention provides an innercurve multiple-action radial plunger type hydraulic motor, wherein, the plunger holes of a rotator are connected with rollers, a sliding bearing, a plunger and elastic retaining rings; the elastic retaining rings are evenly distributed with claw elbows in a circumference direction; two ends of the outer surface of the rotator are provided with a groove respectively; two end surfaces of the rotator are provided with notches which are communicated with the plunger holes and have the same number as the plunger holes; the elastic retaining rings are clamped in the two grooves on the outer surface of the rotator; the claw elbows on the elastic retaining rings are in clearance fit with the two end surfaces of the roller in each plunger hole; and the rollers are clamped in the middle of two claw elbows. Each elastic retaining ring is of an integral structure, thus the ring does not need to be assembled in each plunger hole independently; and only two elastic retaining rings are clamped in the grooves on the rotator so as to limit the rollers in all the plunger holes to axially move, thereby leading even stress on the rollers, enabling a hydraulic energy conversion part to work stably, improving the mechanical efficiency and the reliability of the hydraulic motor, and prolonging the service life of the hydraulic motor.

Owner:宁波恒通诺达液压股份有限公司

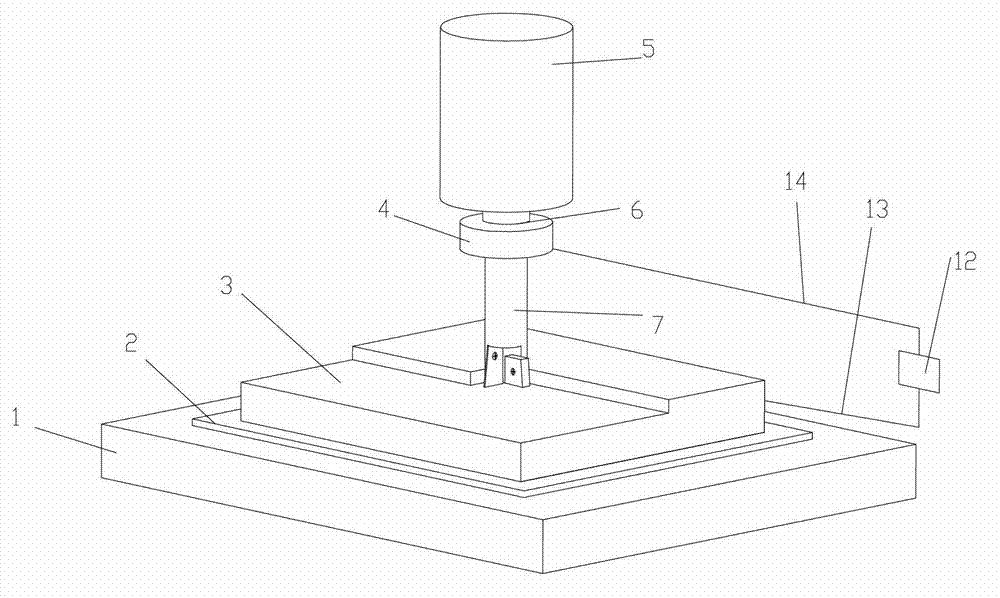

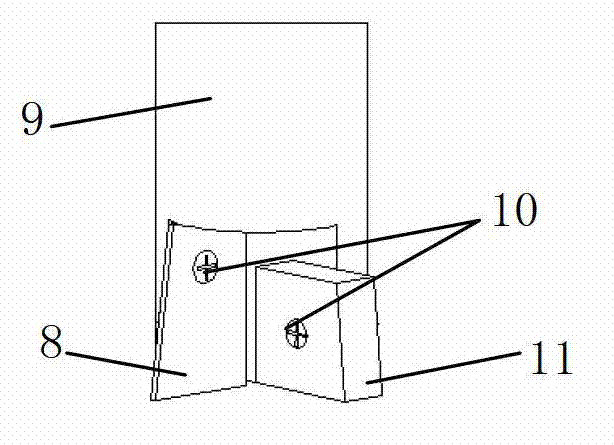

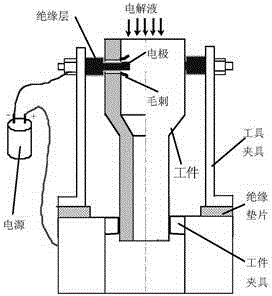

Milling and electrosparking combined machining method

The invention discloses a milling and electrosparking combined machining method, and relates to a mechanical cutting method. An indexable milling tool is chosen, the blade of the indexable milling tool is a non-conducting blade, or arranges an insulating layer on an electrically conductive blade, the insulating layer enables the blade to be insulated with a toolbar, and then one of the blades is replaced with an electrically conductive metal sheet. A bearing matched with the toolbar of the indexable milling tool is chosen to be sleeved on the toolbar, an insulating sleeve is sleeved at the upper end of the toolbar, and then the upper end of the toolbar is clamped on the main shaft of a milling machine, a workpiece is clamped on the workbench of the milling machine, an insulating plate is arranged under the bottom face of the workpiece, two wires are respectively connected with two electrodes of a power supply, one of the wires is pressed on the bottom face of the workpiece, and the other wire is wound on the wall of the bearing outer ring. The rotatable milling tool and the workpiece are enabled to form a return circuit, and are insulated with the milling machine. And after powered on, the milling machine can be run to carry out milling. The electric sparks are used for auxiliary milling, the loss of the milling tool can be greatly reduced, milling efficiency is obviously improved, and the loss of the electrodes does not influence the milling precision of parts.

Owner:XIAMEN UNIV

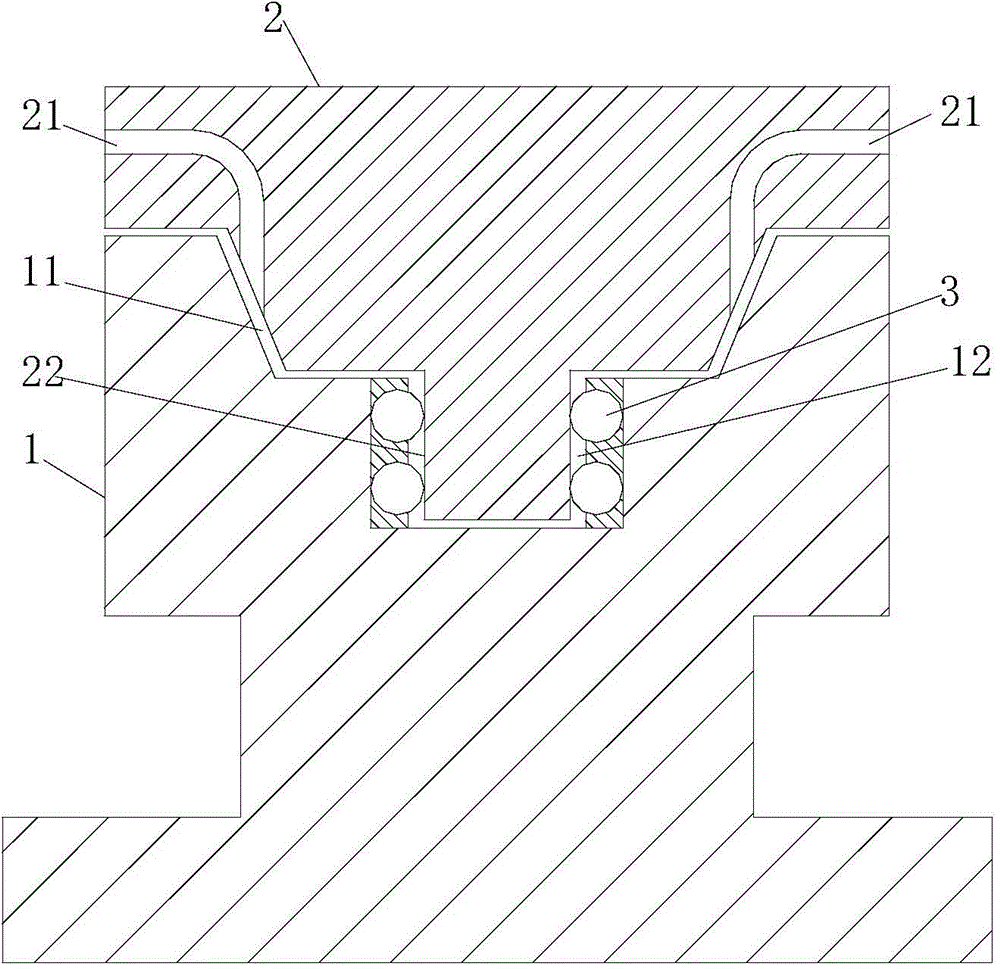

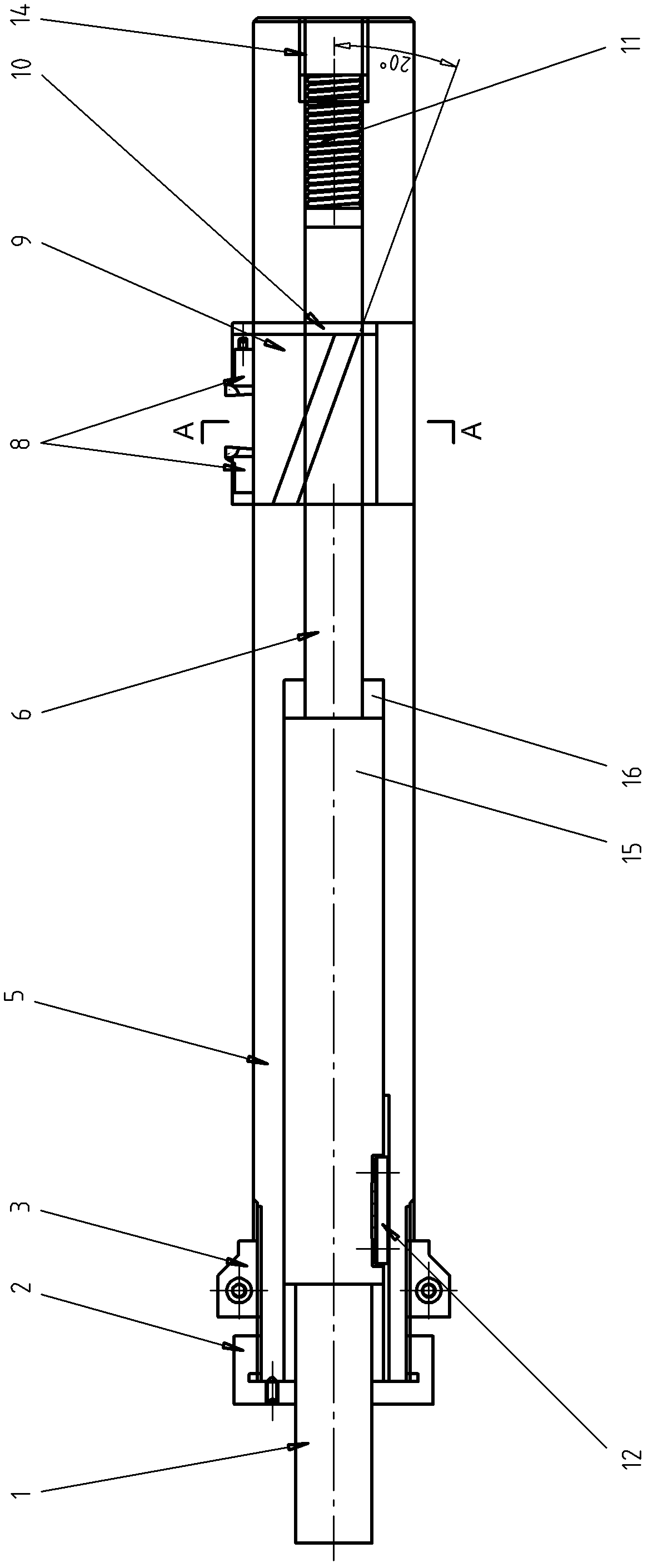

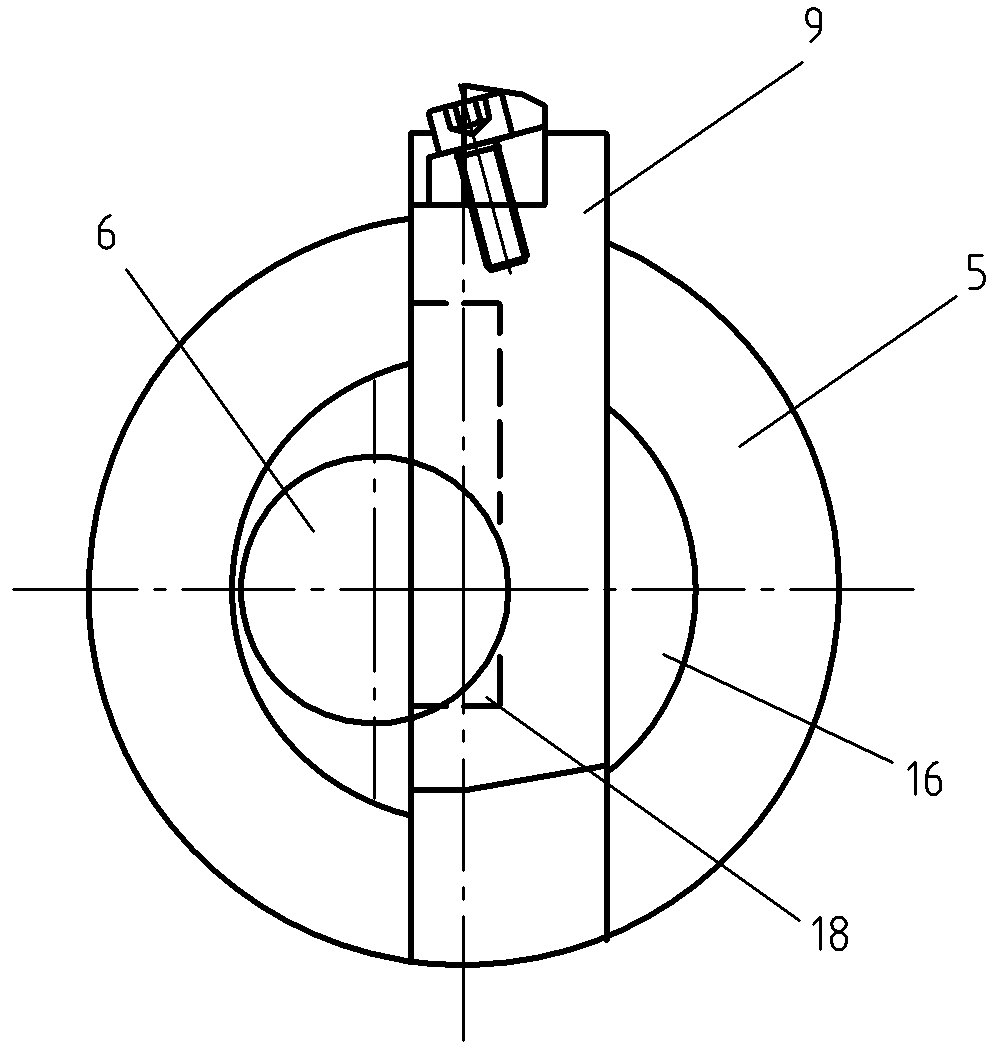

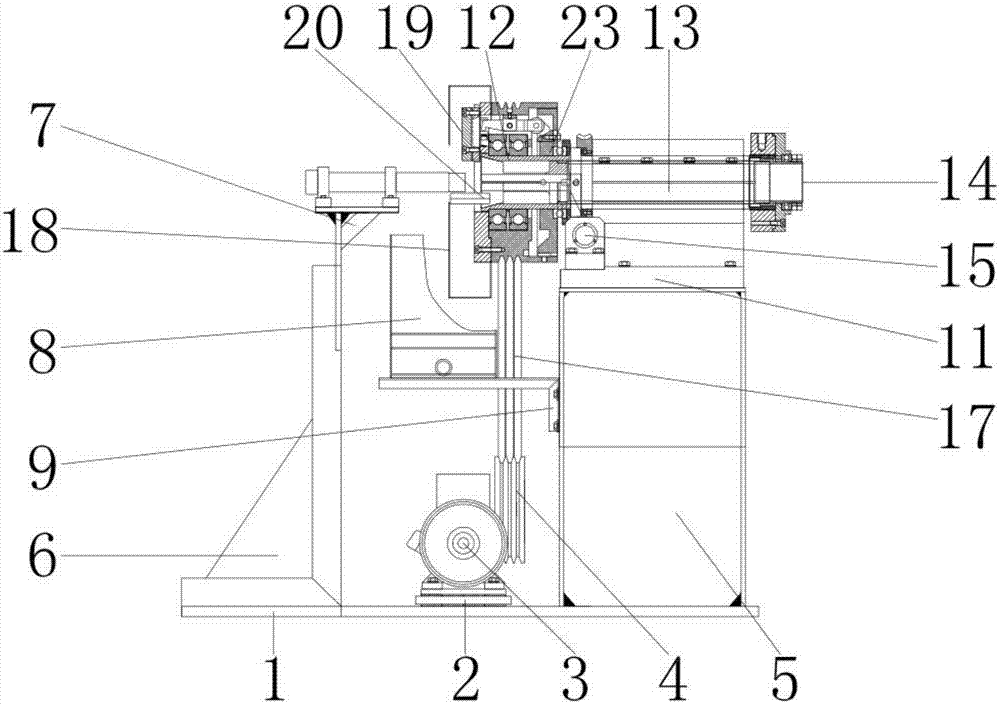

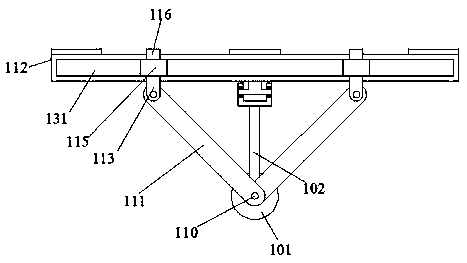

Automatically expanding and shrinking scraping-rolling combined deep hole cutter

ActiveCN102152118AImprove static stiffnessImprove dynamic stiffnessOther manufacturing equipments/toolsBoring headsMatched pairEngineering

The invention discloses an automatically expanding and shrinking scraping-rolling combined deep hole cutter. A scraping part of the cutter comprises at least one pair of scrapers, a top block, and a reset device; the top block is positioned in the centre of a thick boring head body and is provided with a taper structure, and a corresponding conical surface is jacked by an endocentric end of the scraper; and the reset device is arranged between each matched pair of scrapers for resetting the scrapers; and a rolling part of the cutter comprises a rolling path and a keeper. The combined boring head also comprises a manipulating device which comprises a first driving part and a second driving part, wherein the first driving part drives the keeper to move axially along a spindle, and the second driving part penetrates a centre hole and acts on the top block in order to drive the top block to move axially along the spindle. The cutter disclosed by the invention is compact in structure, high in processing precision, convenient to use, and can expand and shrink automatically.

Owner:德州普利森机床有限公司

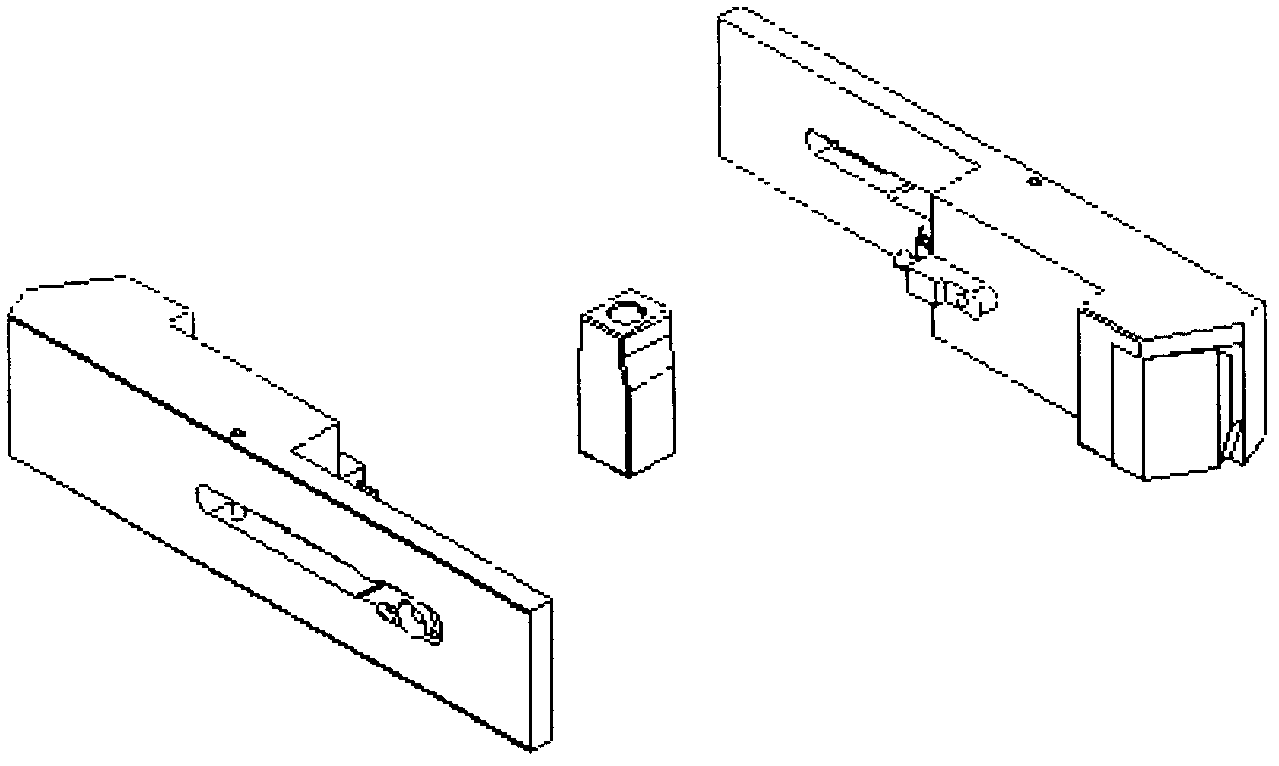

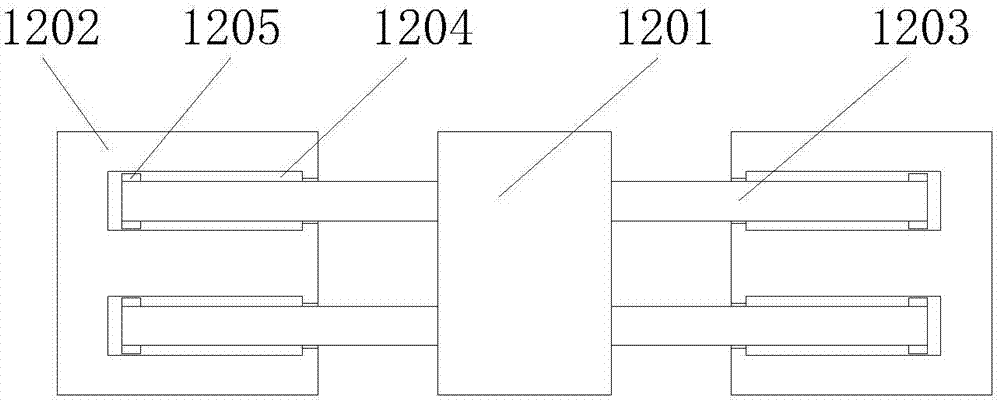

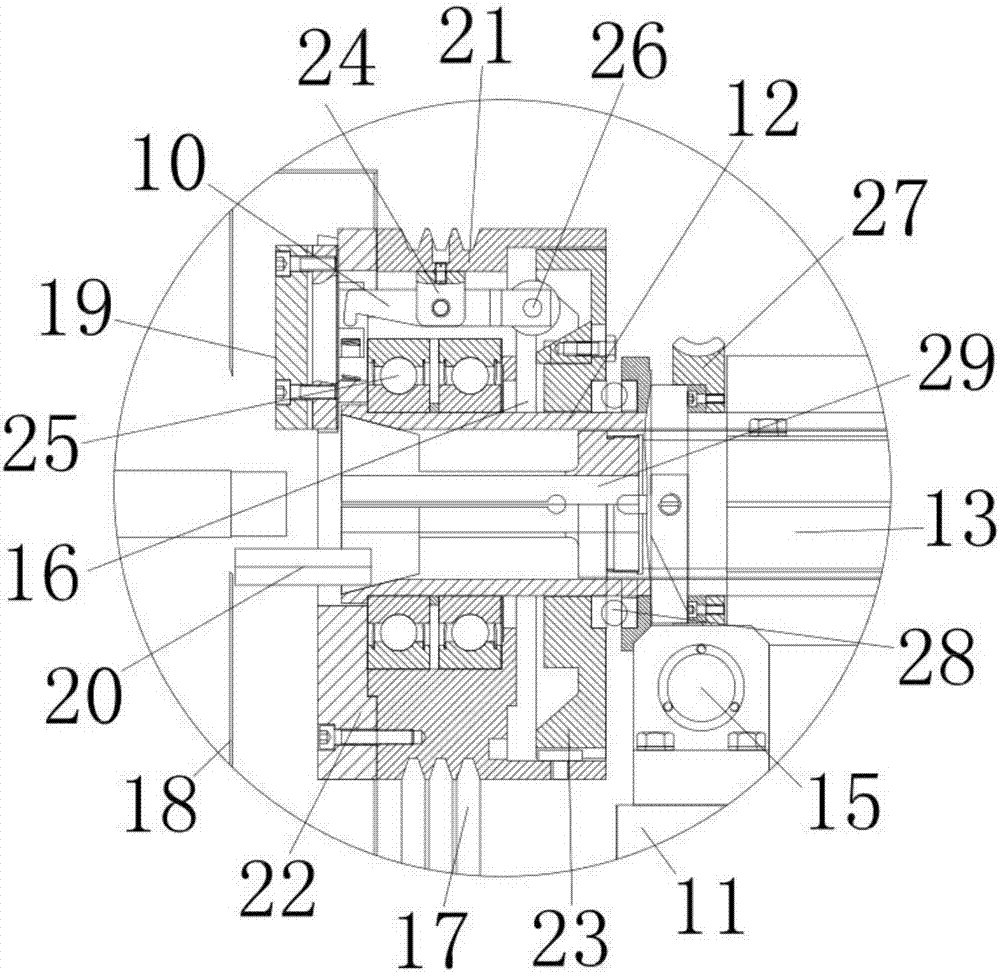

Tool magazine tool clamping device

InactiveCN104551807AAvoid damageExtended service lifePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a tool magazine tool clamping device comprising a clamping seat. Lever mechanisms are arranged at the upper end and the lower end of the clamping seat symmetrically, each lever mechanism is fixed on the clamping seat through bolts, a roller is mounted at one end of the lever mechanism, and a clamping seat groove is formed among the rollers and the clamping seat. The tool magazine tool clamping device is characterized in that a spring is mounted on the clamping seat, located between the lever mechanisms and fixedly connected with the lever mechanisms, and the spring and the rollers are located at two ends of the lever mechanism respectively. The spring is arranged between the lever structures, collision force between the clamping seat and a tool is buffered through the spring during tool changing, so that damage to the clamping seat due to tool changing collision is reduced, service life of the clamping seat is prolonged, and frequency of maintenance of the clamping seat is lowered.

Owner:HUBEI YIXING INTELLIGENT EQUIP CO LTD

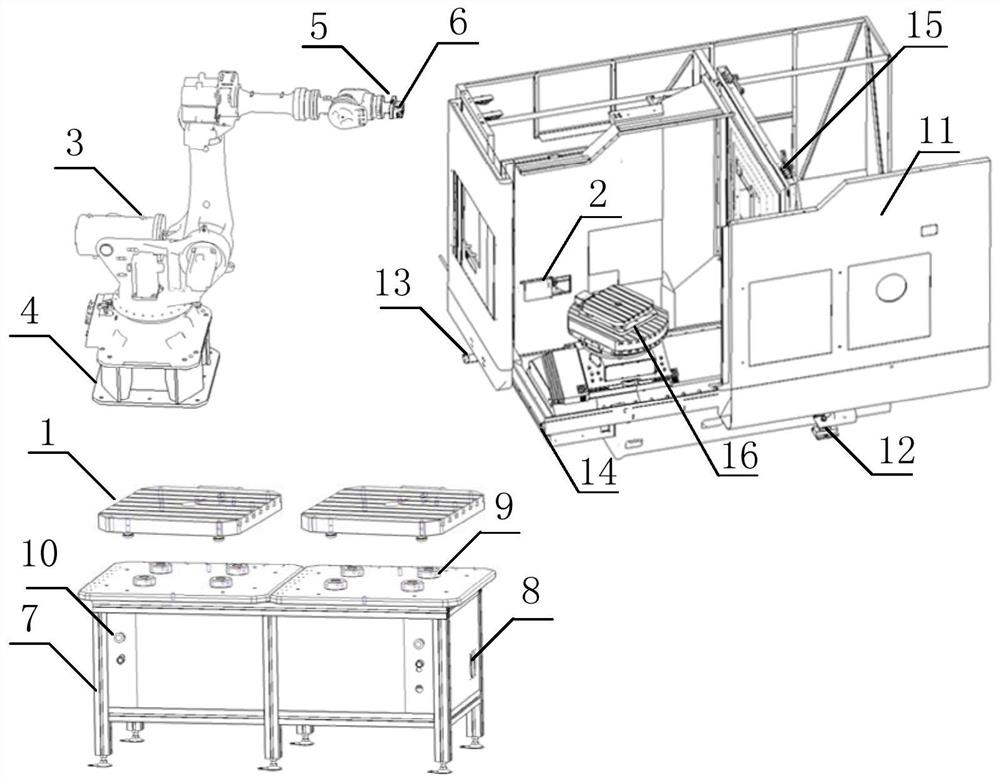

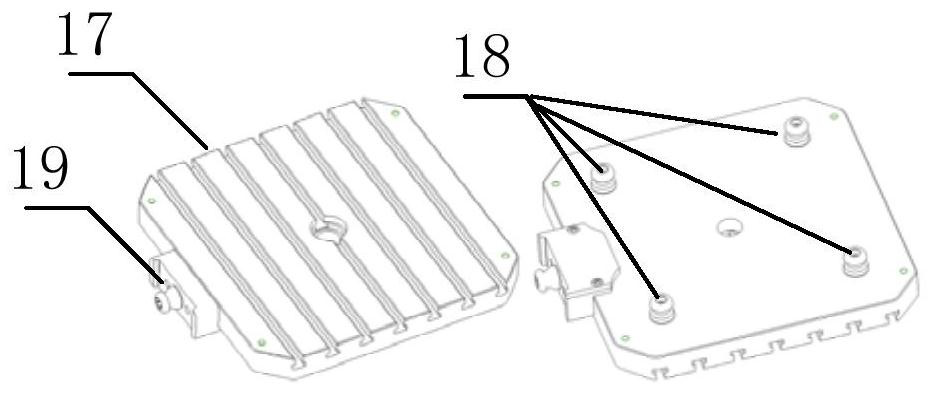

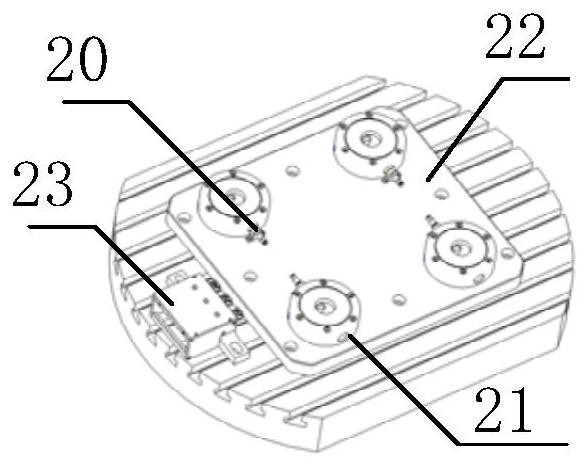

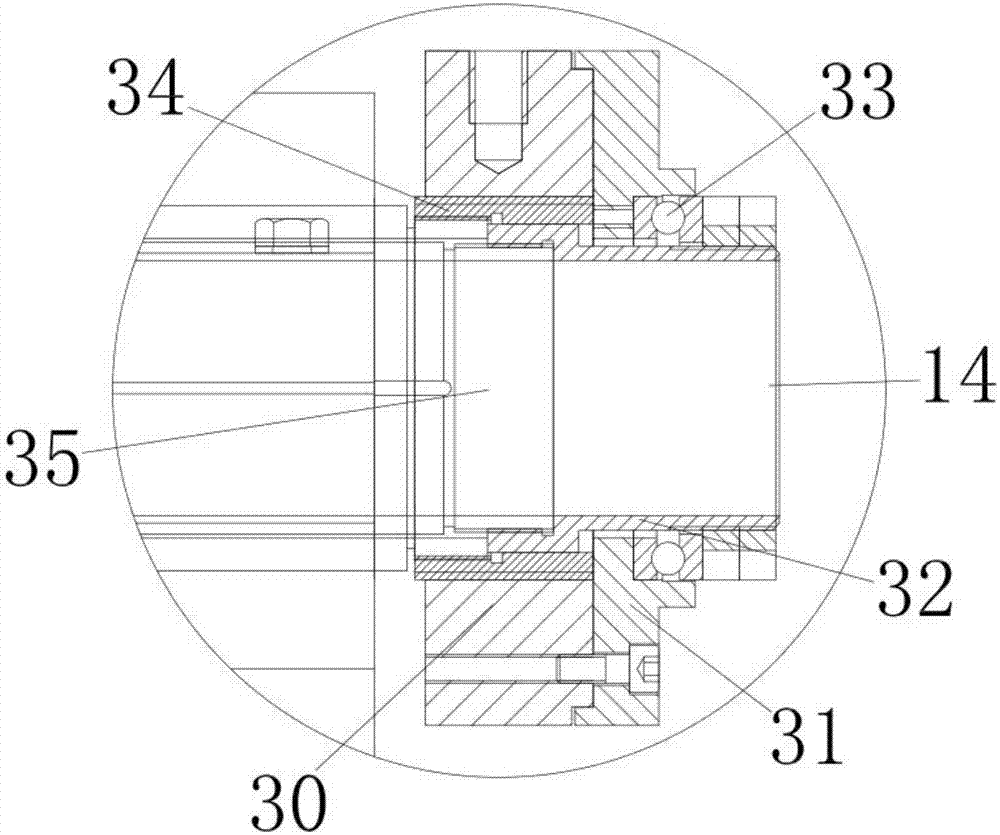

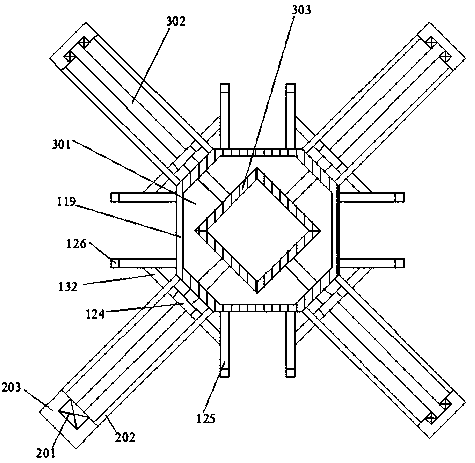

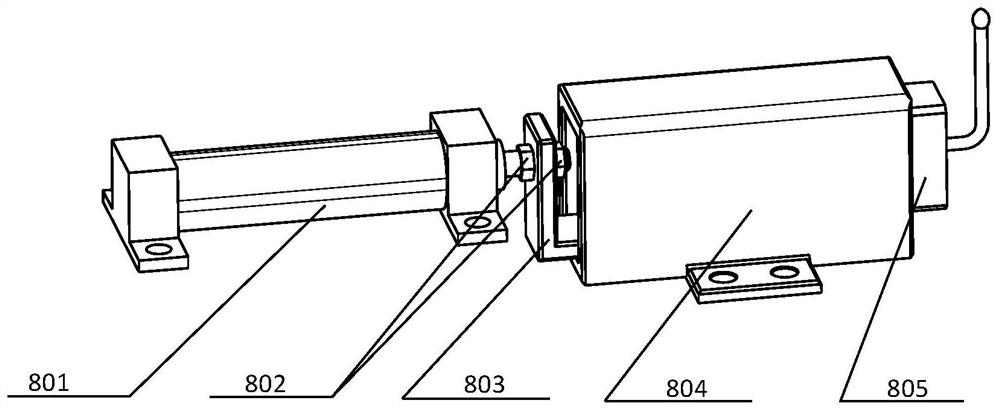

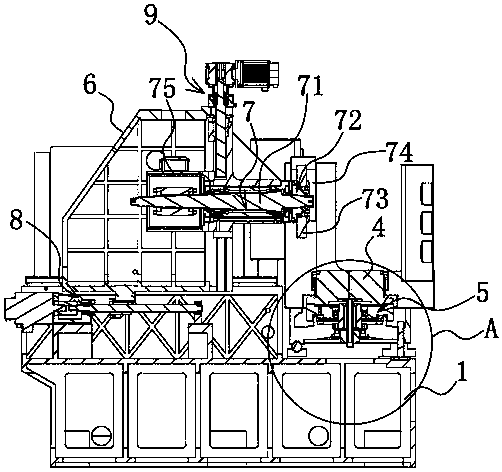

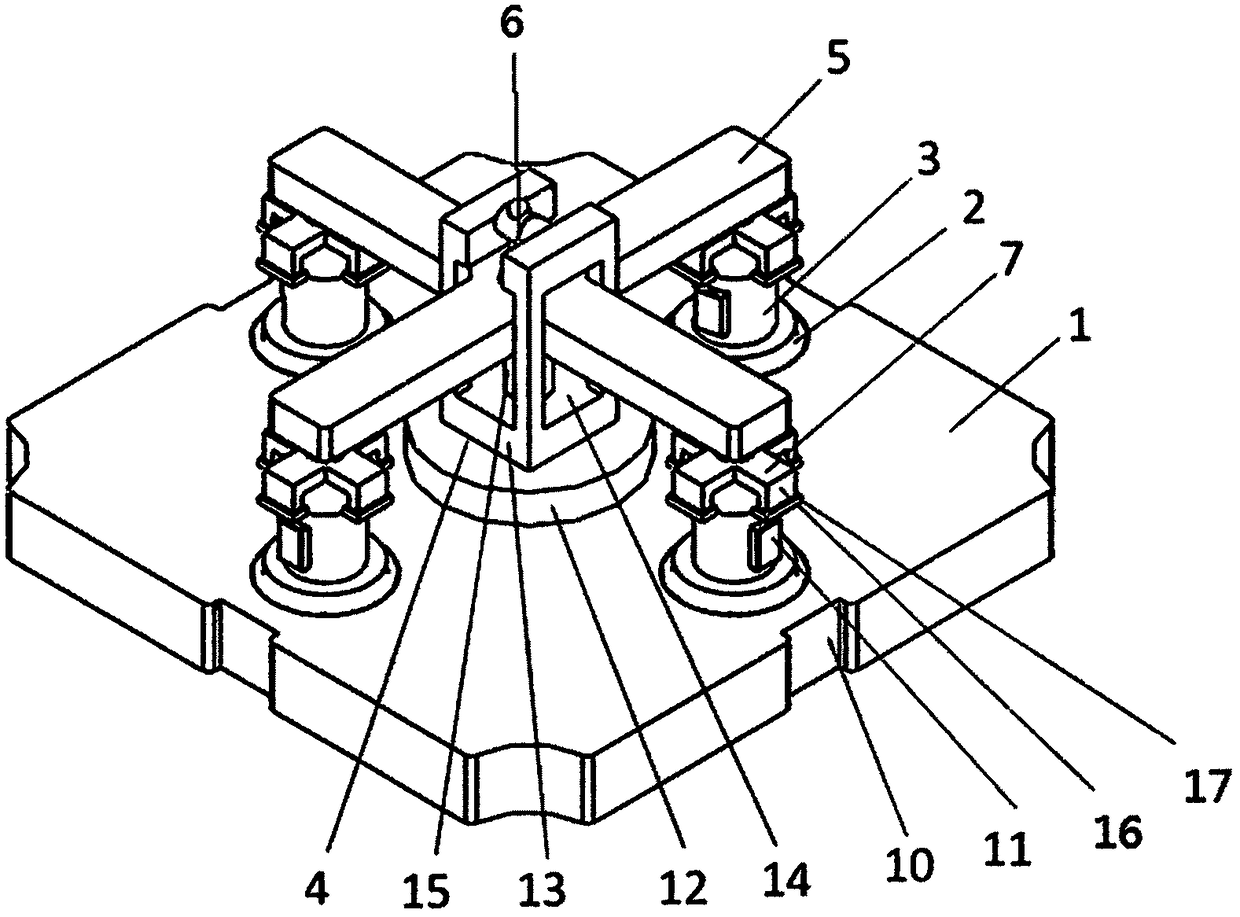

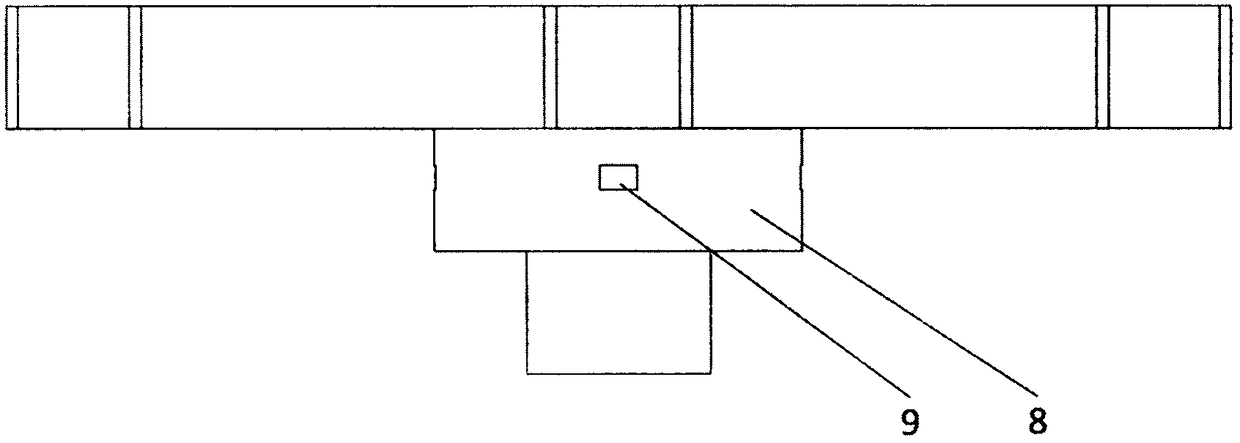

System and method for rapid replacement and clamping based on zero point positioning

ActiveCN113245884ASolve the needs of special characteristicsShorten assembly timeVehicular energy storagePositioning apparatusControl systemControl engineering

The invention relates to a system and a method for rapid replacement and clamping based on zero point positioning, in particular to a process method for single and small-batch spaceflight component machining, and belongs to the technical fields of machining and automatic detection. According to the system and the method, the rapid replacement and clamping of workpieces is achieved by adopting a zero point positioning technology and an automation module. Through the adoption of the process layout and the automation module design, the system which is used for the rapid replacement and clamping of a machining center, is based on the zero point positioning technology, and has an off-line clamping alignment function is provided; and through the adoption of the basic principle of a zero point positioning module, the cooperative use with a transfer robot is achieved, the machine tool table top positioning is transformed, an automated gas circuit butt-joint device is arranged, an off-line rapid replacement and clamping alignment platform is added, an I / O expansion module is adopted for communication connection to a master control PLC, the signal integration and control operation is performed in a robot control system, and finally the rapid replacement and clamping of the machining center is achieved.

Owner:BEIJING SATELLITE MFG FACTORY

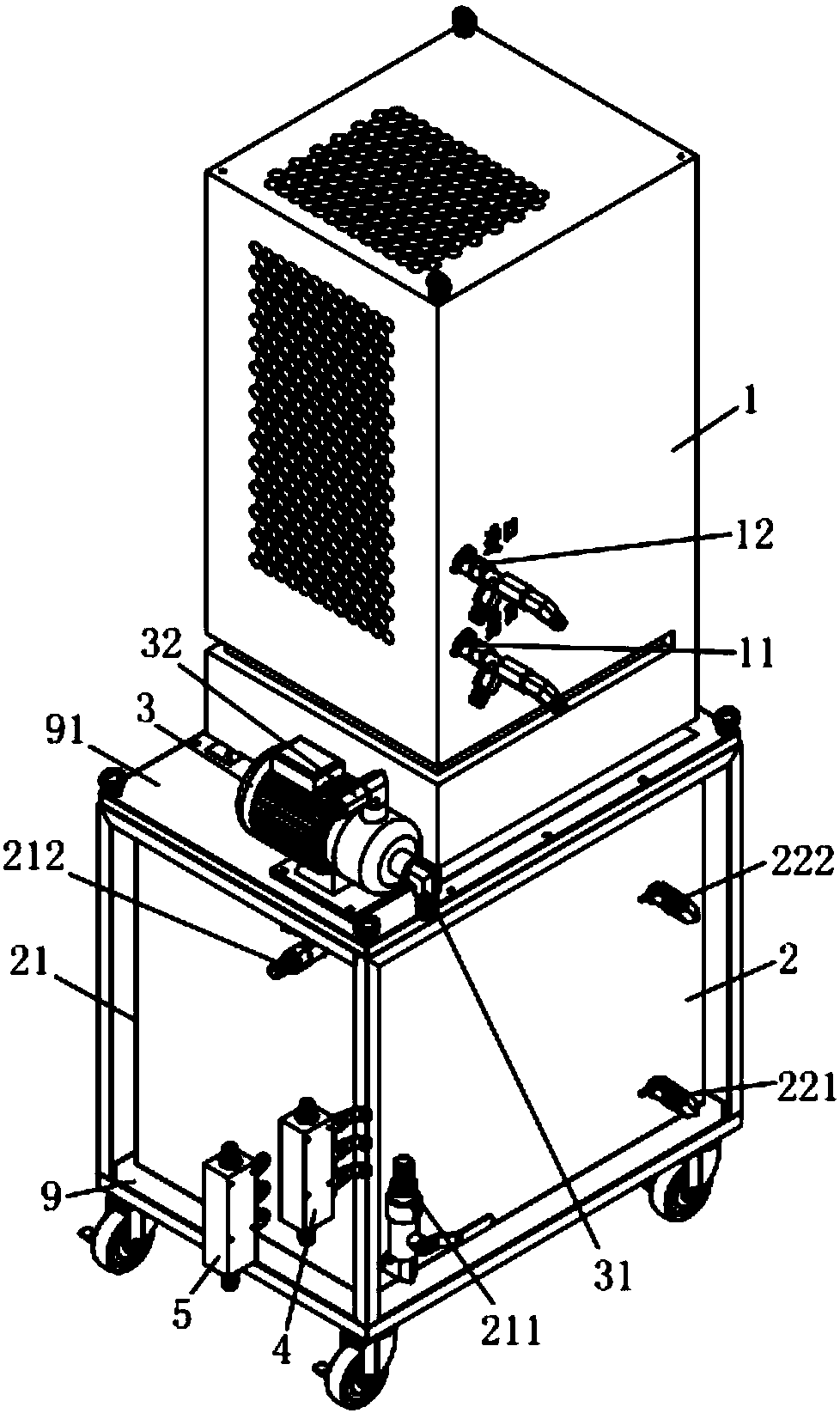

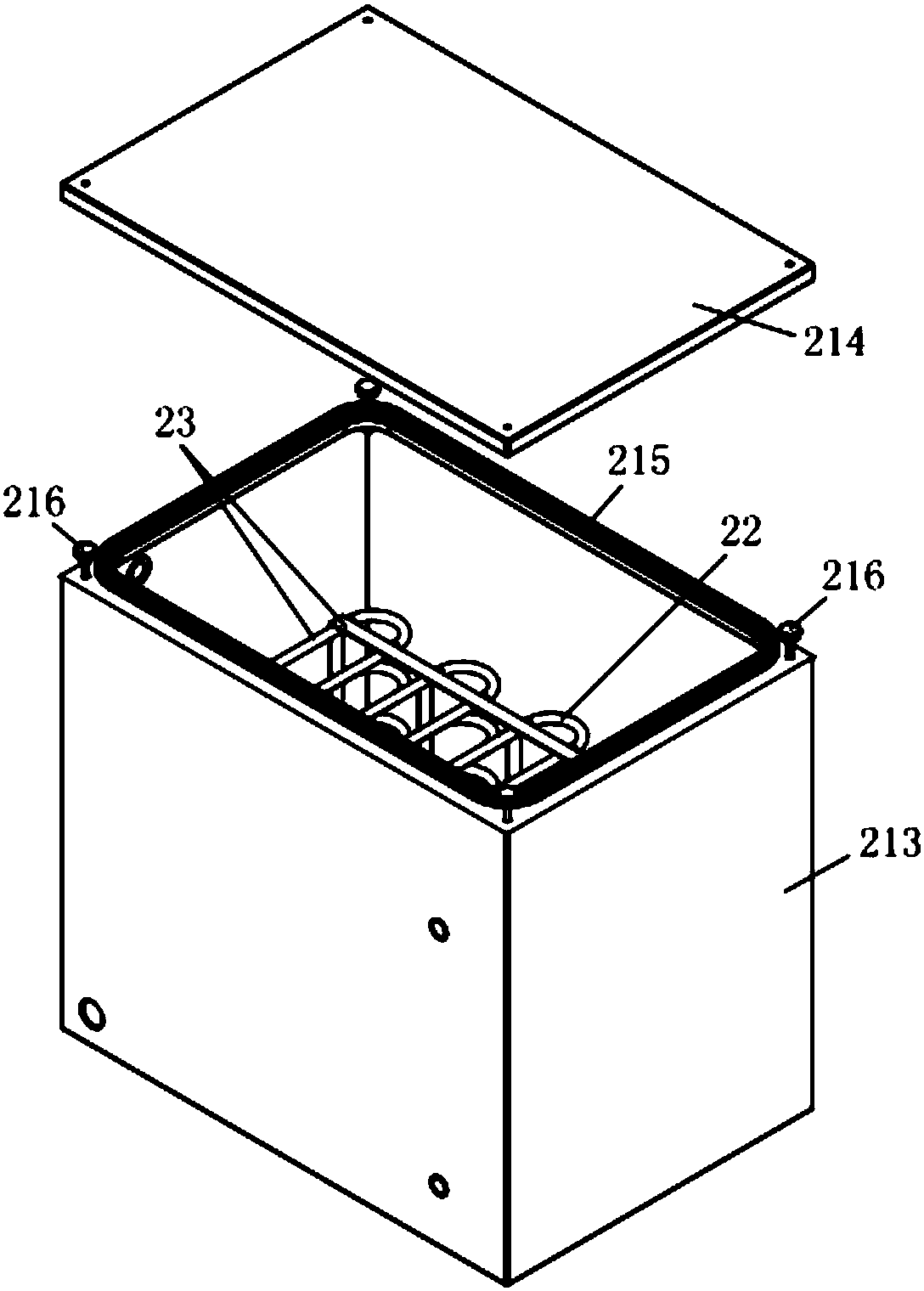

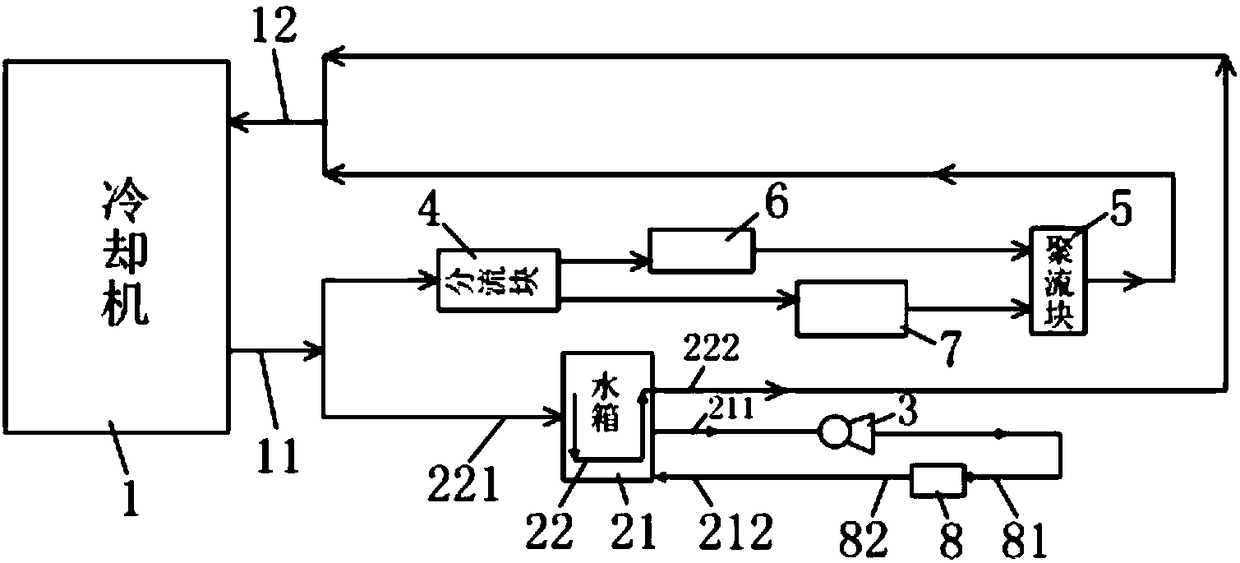

Constant-temperature cooling system of high-precision numerical control machining tool

PendingCN108397964ADoes not affect machining accuracyReduce use costLighting and heating apparatusCooling fluid circulationNumerical controlEngineering

The invention relates to the technical field of numerical control machining, in particular to a constant-temperature cooling system of a high-precision numerical control machining tool. The constant-temperature cooling system comprises a cooler, a cooling water tank assembly, a water pump, a flow dividing block and a flow gathering block, wherein the cooling water tank assembly is connected with the cooler; the water pump is connected with the cooling water tank assembly; the flow dividing block and the flow gathering block are connected with the cooler; the cooler is equipped with a cooling liquid outlet and a cooling liquid inlet; a three-way valve is connected with both the cooling liquid outlet and the cooling liquid inlet; the cooling water tank assembly comprises a water tank and a cooling copper pipe; the water tank is used for accommodating water; the cooling copper pipe is arranged in the water tank; both a copper pipe inlet and a copper pipe outlet of the cooling copper pipeextend out of the water tank; and the water tank is equipped with a water-tank water outlet and a water-tank water inlet. The constant-temperature cooling system of the high-precision numerical control machining tool has the advantages of being low in cost and high in stability, and then the product machining yield can be improved.

Owner:巨冈精工(广东)股份有限公司

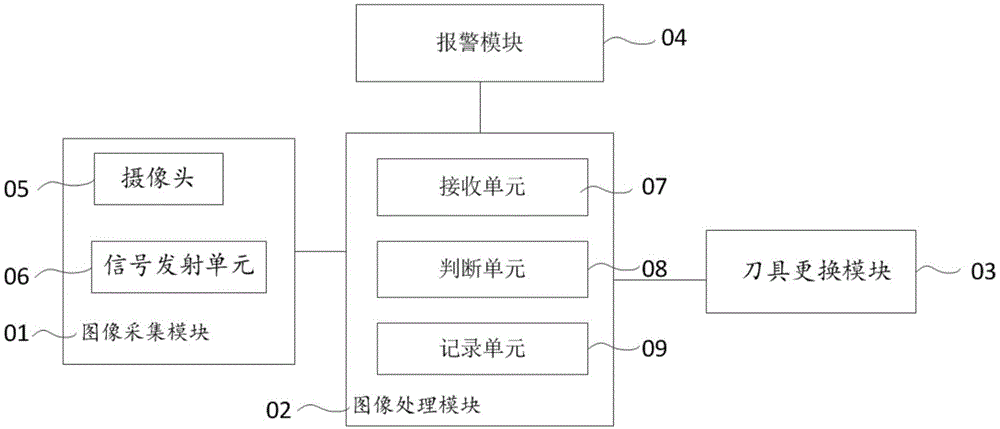

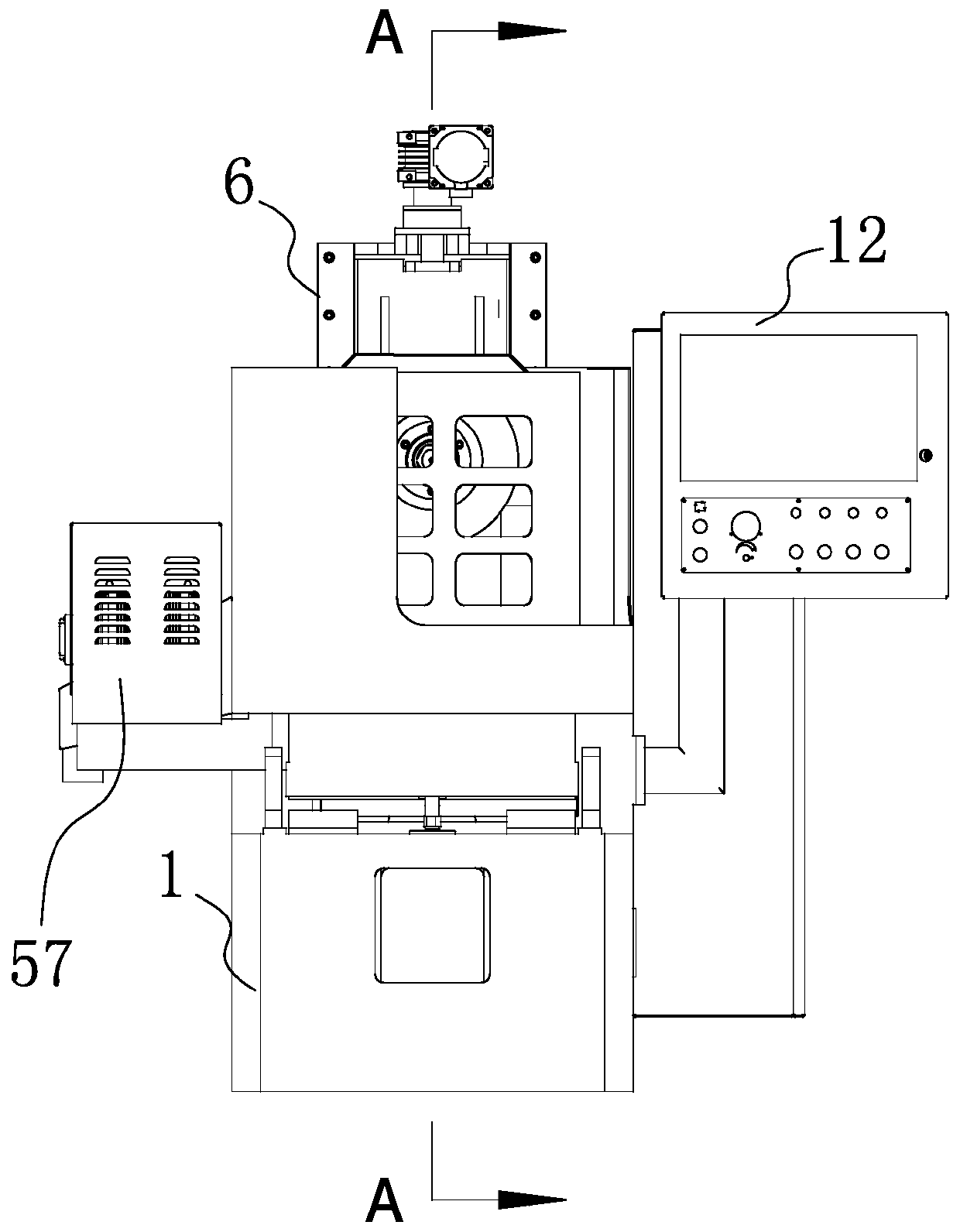

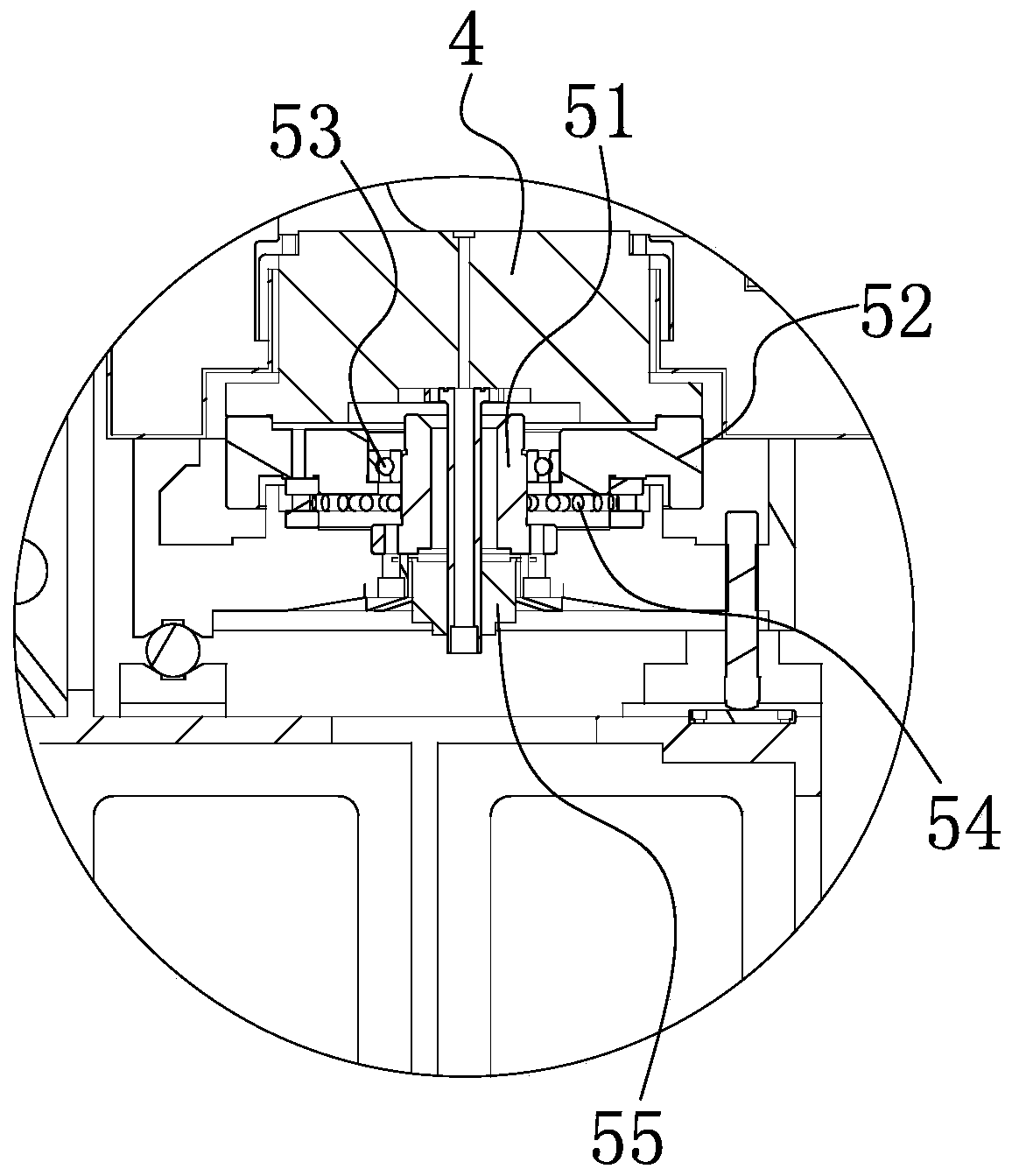

Automatic cutter changing system for numerically-controlled machine tool

InactiveCN103551900ADoes not affect machining accuracySimple structureMeasurement/indication equipmentsPositioning apparatusNumerical controlImaging processing

The invention relates to an automatic cutter changing system for a numerically-controlled machine tool. The system comprises an image acquisition module, an image processing module and a cutter changing module which are sequentially connected, wherein the image acquisition module is used for shooting an image of a cutter on a machine tool main body and transmitting the image of the cutter to the image processing module; the image processing module is used for receiving the image of the cutter and judging whether the size of the cutter on the received cutter image reaches a scrap size; and the cutter changing module is used for receiving a cutter changing instruction and selecting the same cutter to replace the scrapped cutter so as to continue a machining process. The system is simple in structure, realizes monitoring of a running state of the cutter, and can automatically change the cutter according to the monitored cutter state when the numerically-controlled machine tool is in an unattended state; the machining precision of a workpiece is not influenced; the machining time is not waste; the machining efficiency is high; and the system is suitable for extensive application in the machining field.

Owner:GUILIN ZHENGLING NO 2 MACHINE

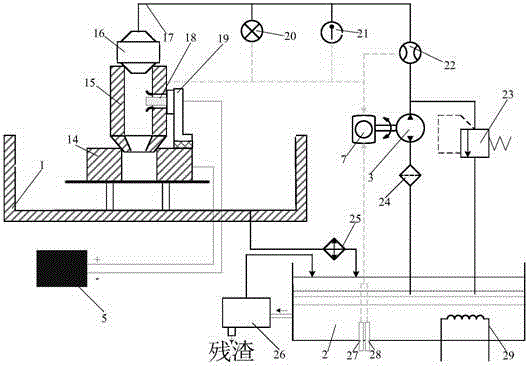

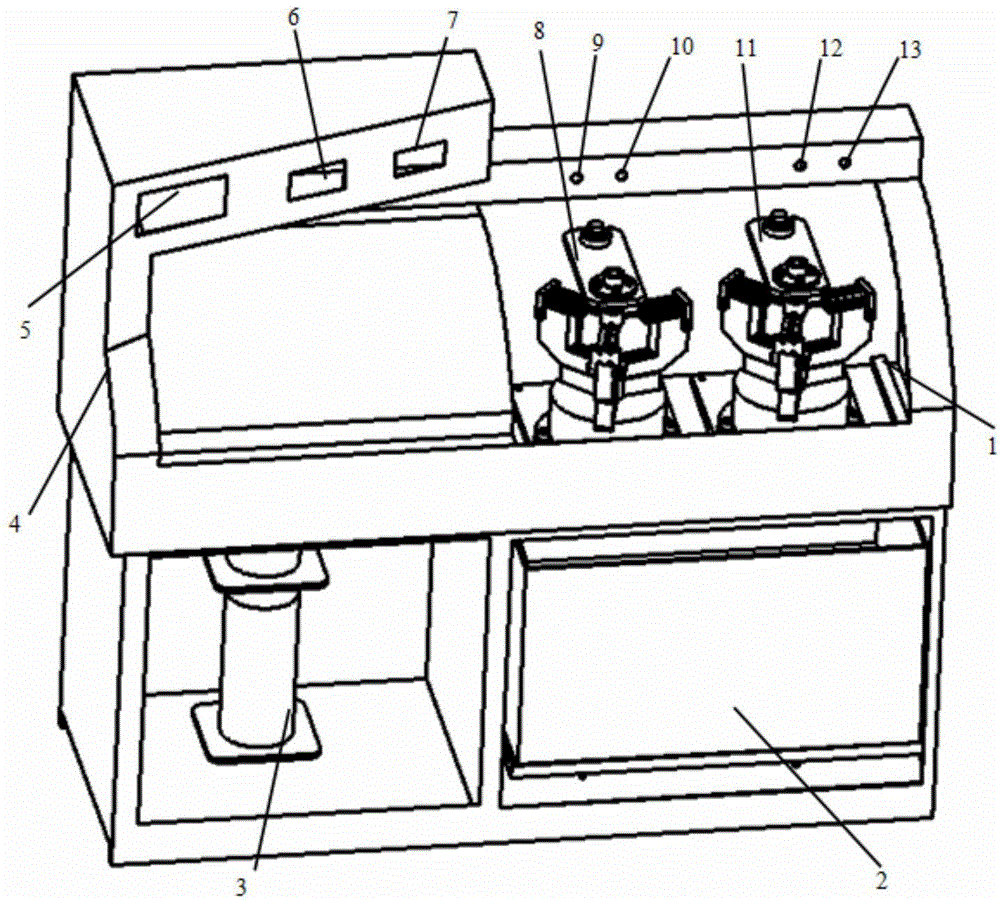

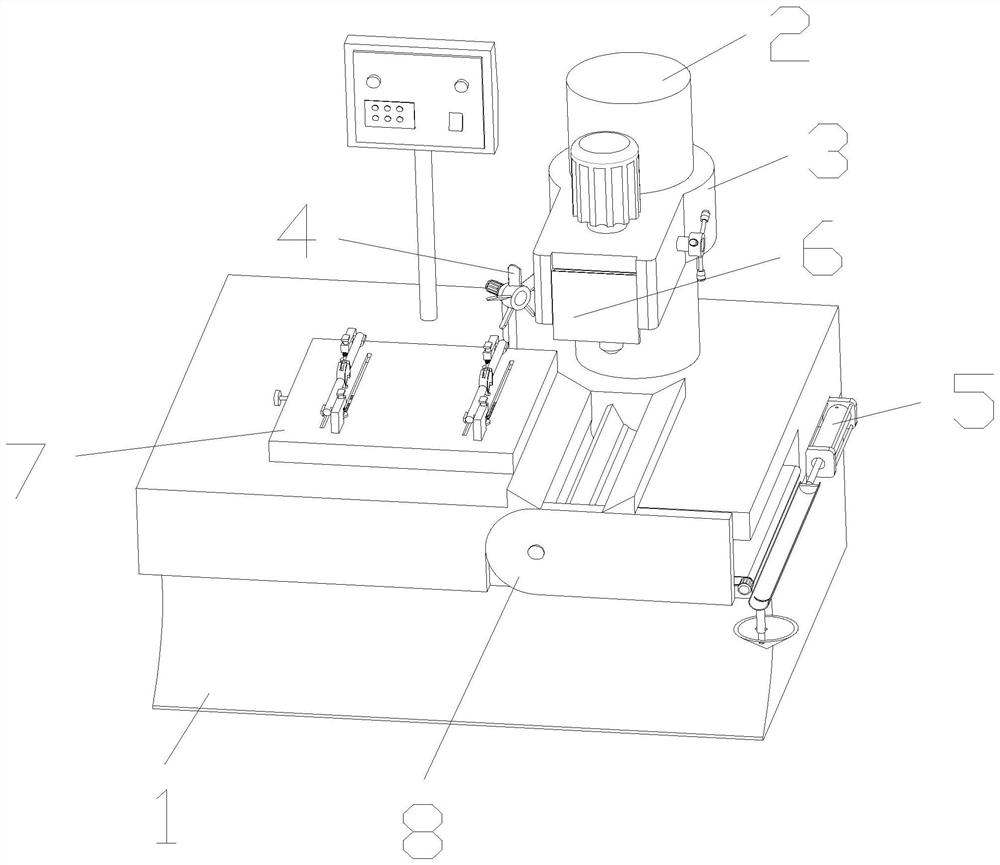

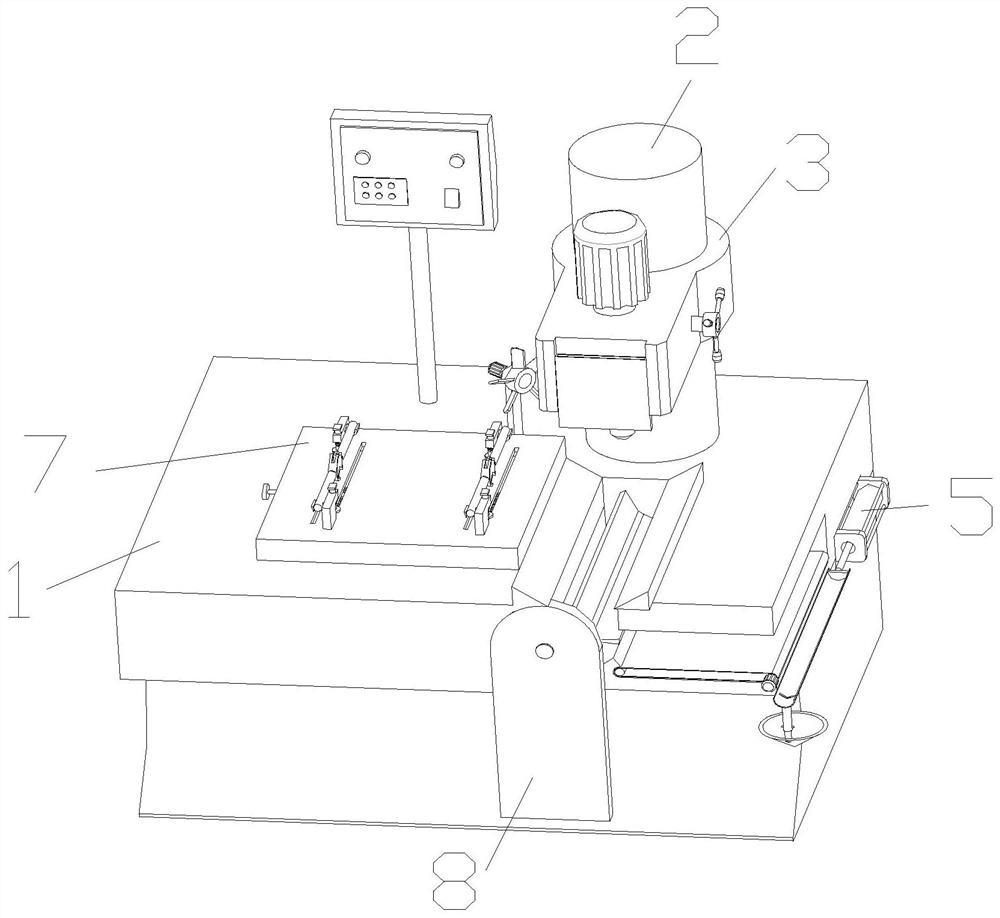

Electrochemical machine tool for removing internal-crossing array small-hole burrs

InactiveCN104607732ASimple structureEasy to clamp and positionMachining working media supply/regenerationElectrical-based auxillary apparatusLoop controlControl system

The invention relates to the technical field of burr processing, in particular to an electrochemical burr-removing machine tool. The machine tool comprises a machine tool body, a power source, a control system, a safety detection loop, an electrolyte circulating system, tool clamps and a ladder electrode. The machine tool body is composed of an upper compartment and a lower compartment, and an electrolyte groove and an electrolyte temperature, pH value and conductivity detection probe are mainly placed on the right side of the lower compartment of the machine tool body; the upper compartment and the lower compartment on the left side of the machine tool body are communicated, and a stainless steel centrifugal pump is arranged on the left side of the machine tool body; the tool clamps, a pneumatic loop control system and a safety detection loop are arranged on the left side of the upper compartment of the machine tool; and a main power source switch, the power source, a detection instrument and a burr removing control system are arranged on the top of the right side of the upper compartment of the machine tool. A stationary cathode machining method is adopted, and an automatic positioning device of an array electrode is designed; it is ensured that the small-hole burrs can be removed from roots, and the problem that when the burrs are removed in the height direction, short circuit is prone to happening is solved; and the electrochemical burr-removing machine tool has the advantages of being high in machining efficiency, convenient to use, and high in similarity of machined small-hoe round angles

Owner:NORTHEAST FORESTRY UNIVERSITY +2

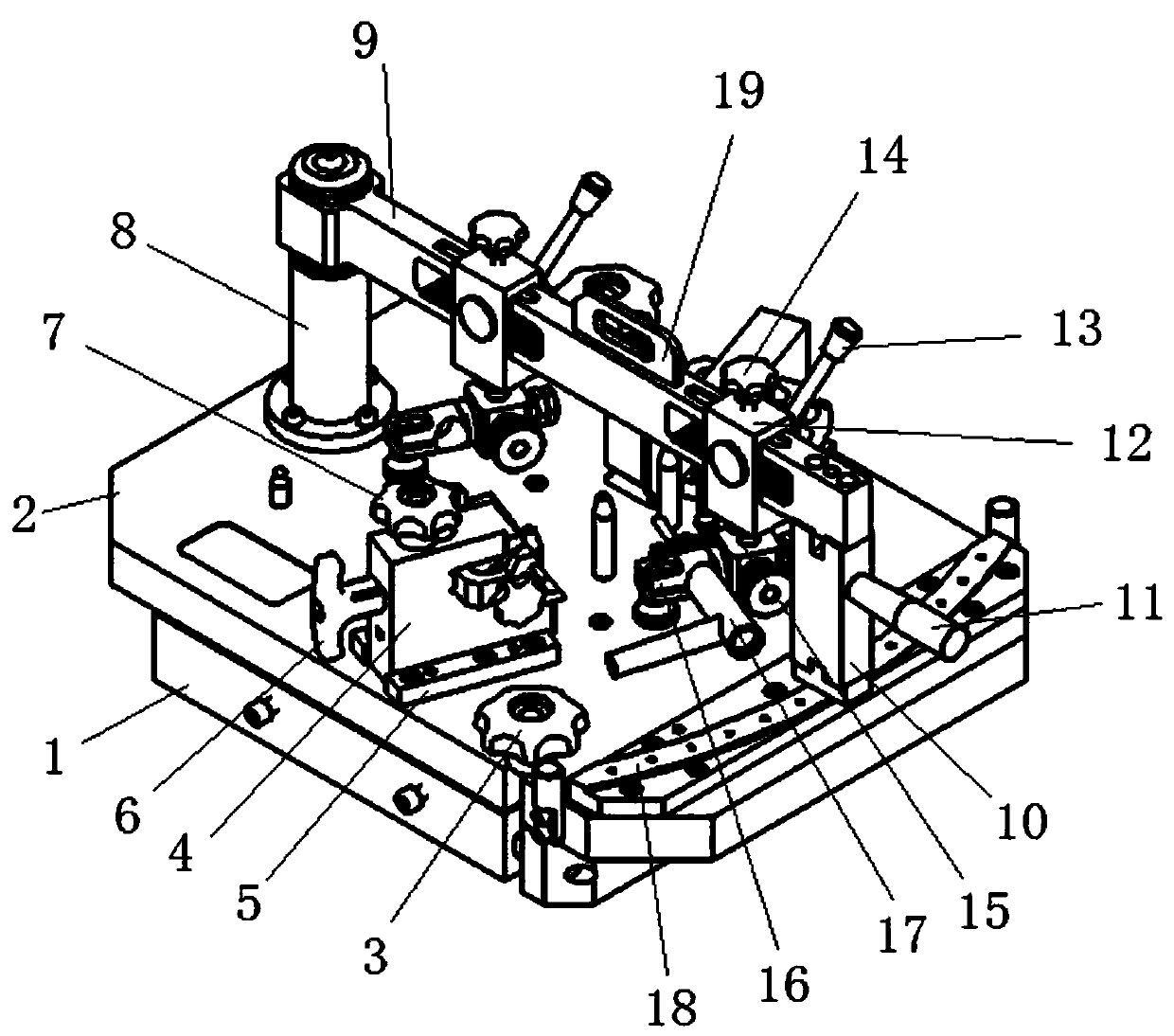

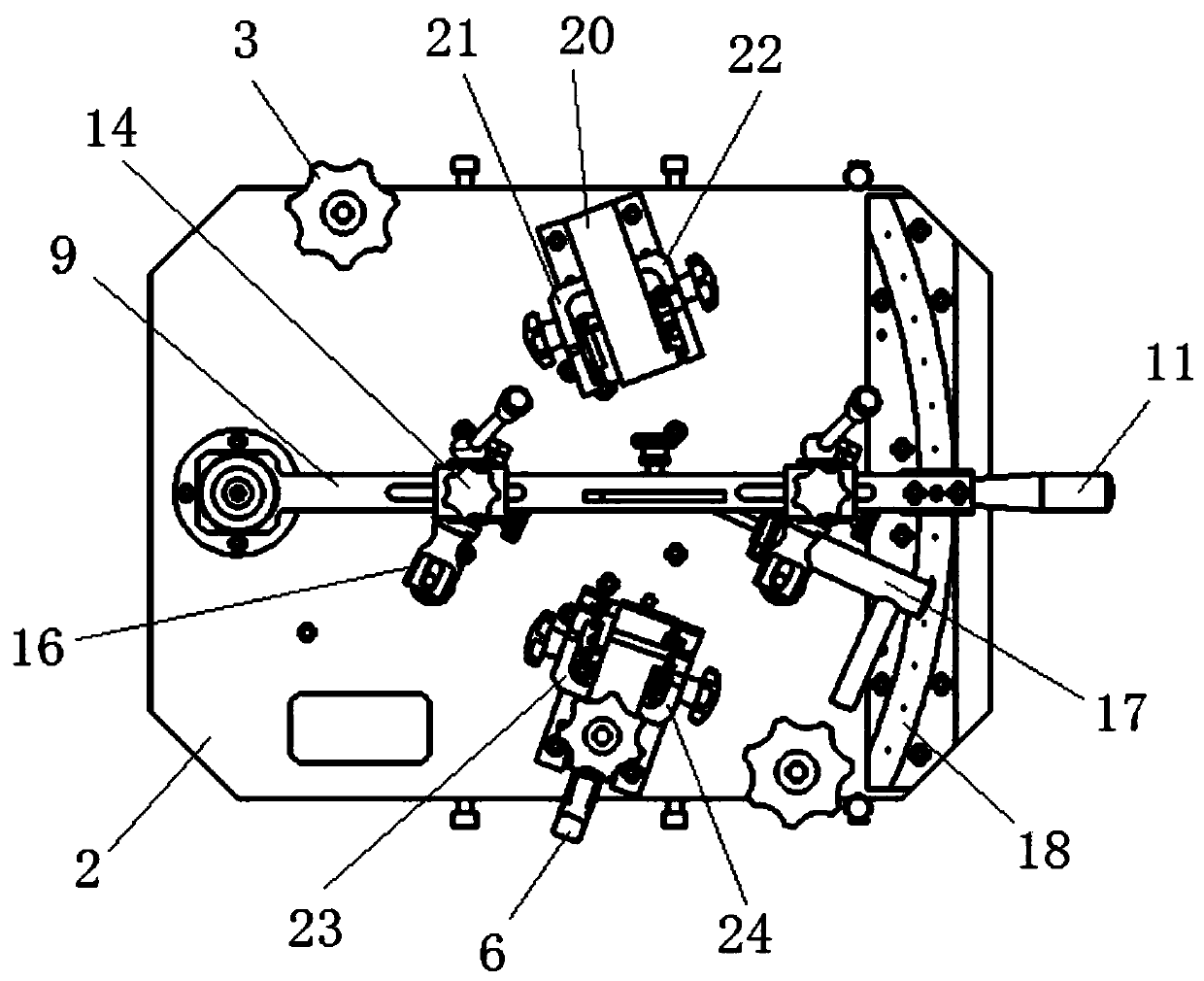

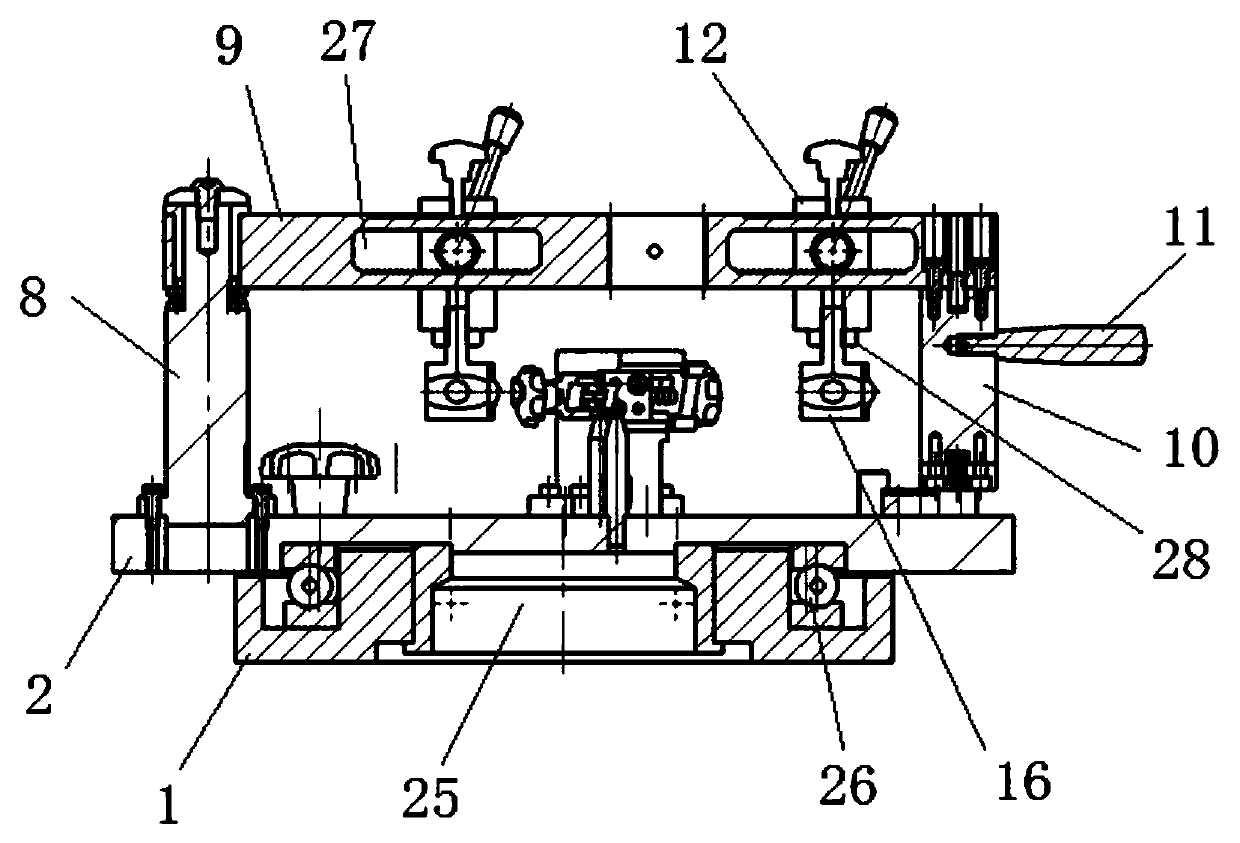

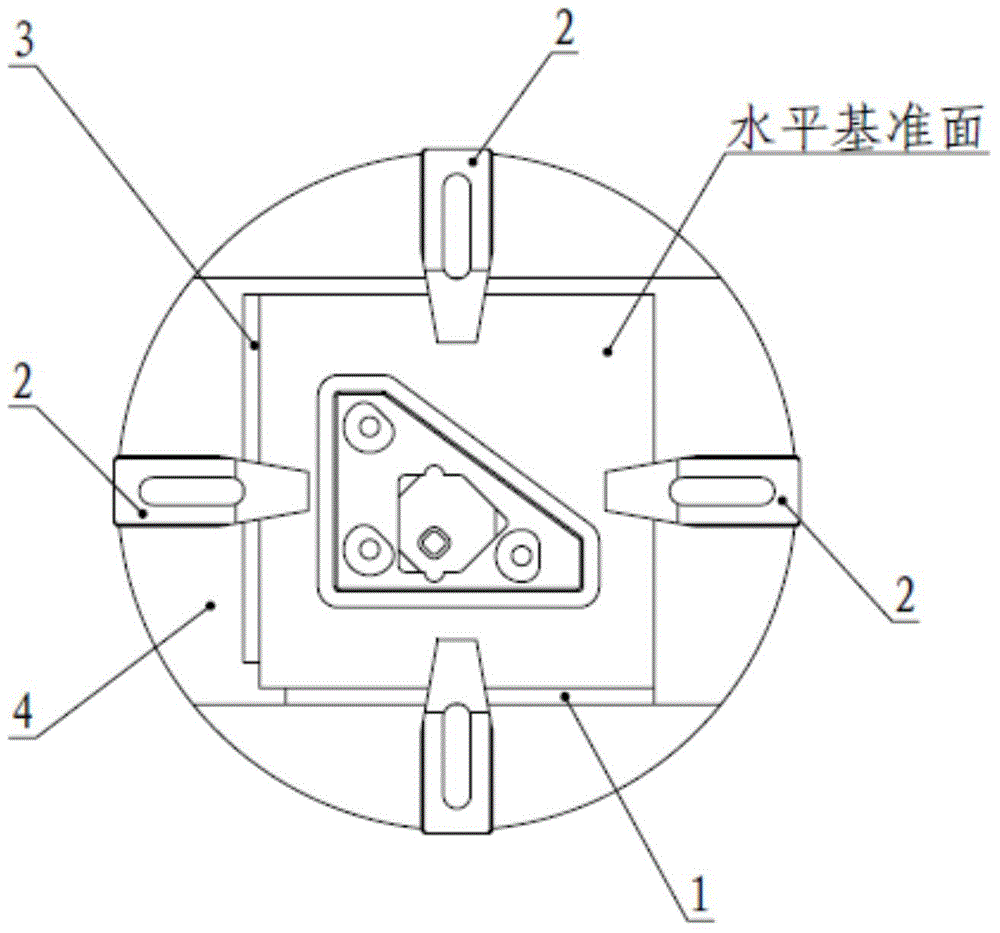

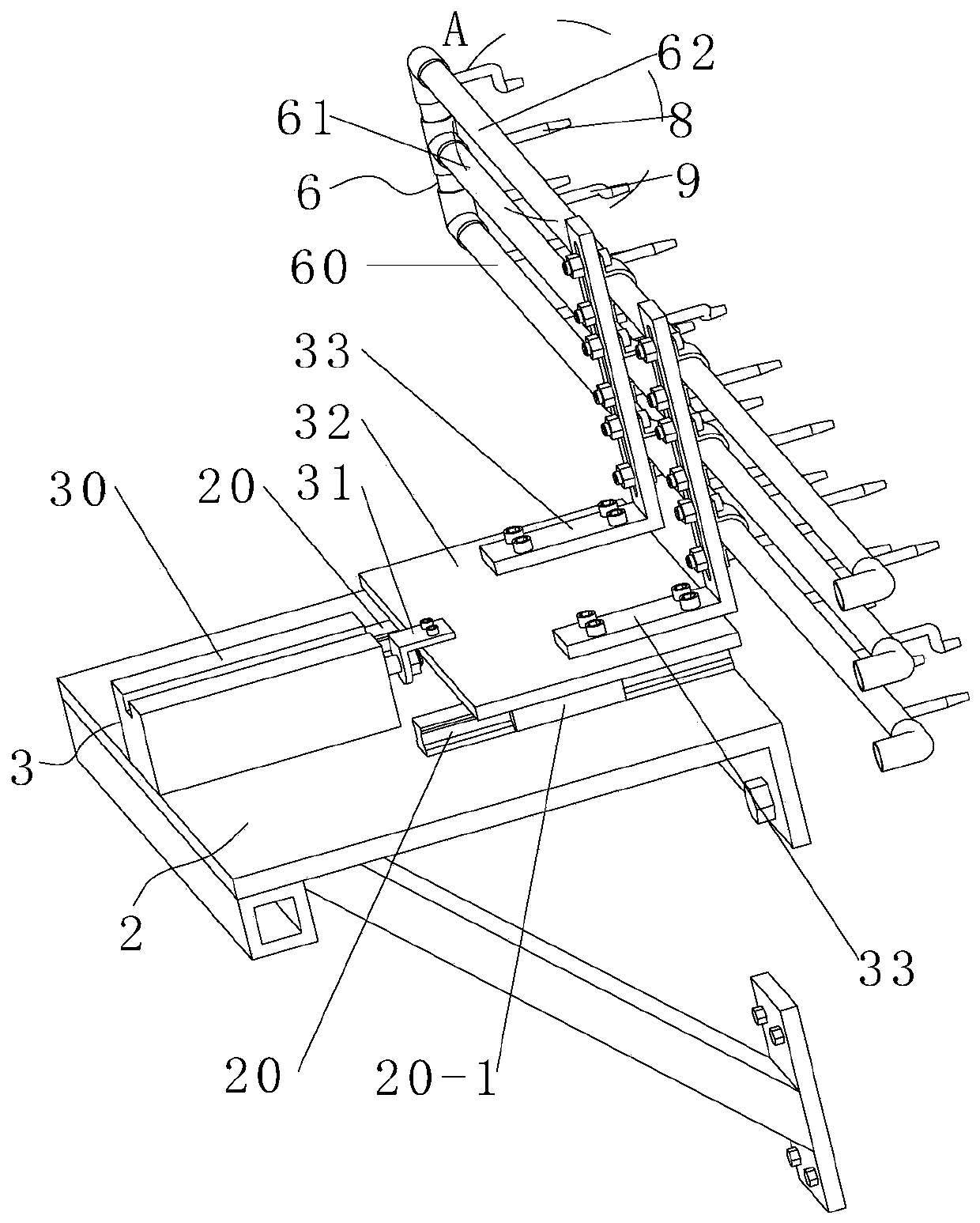

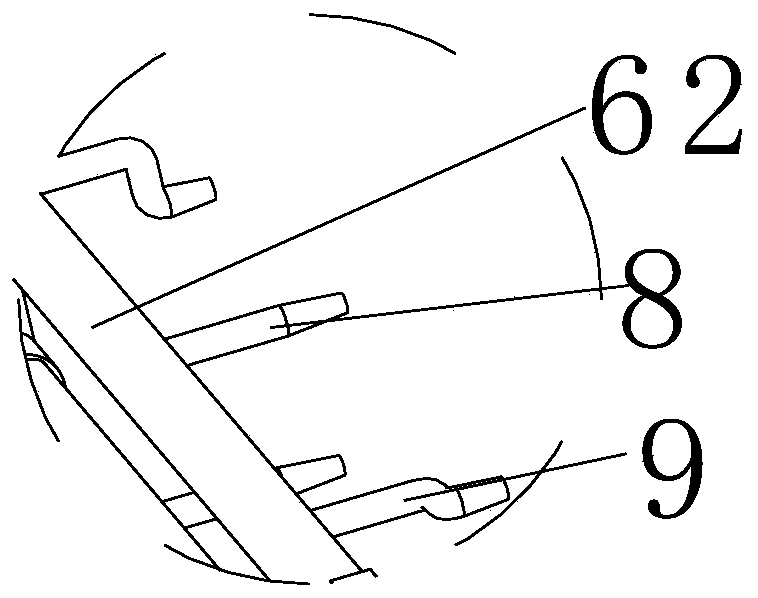

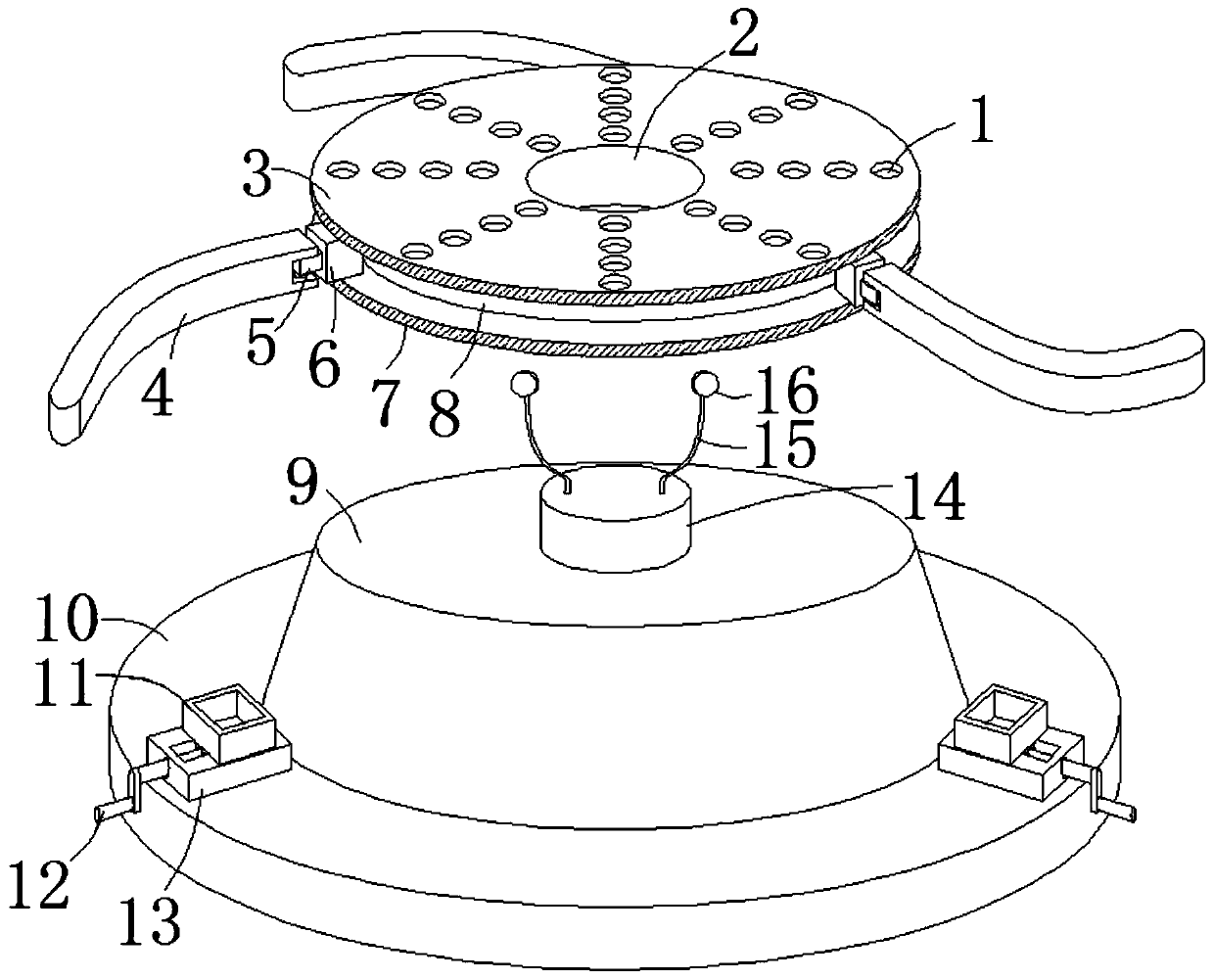

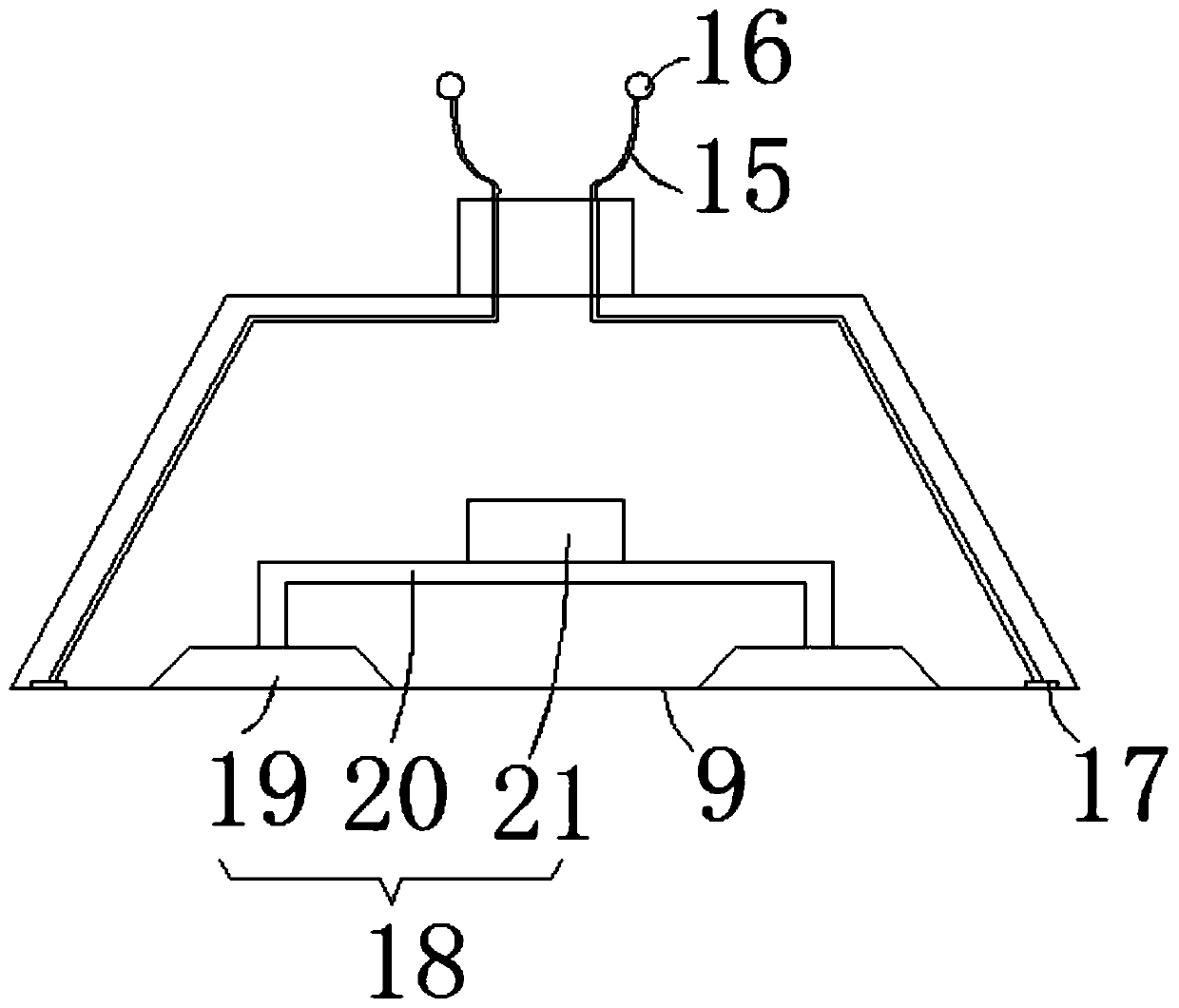

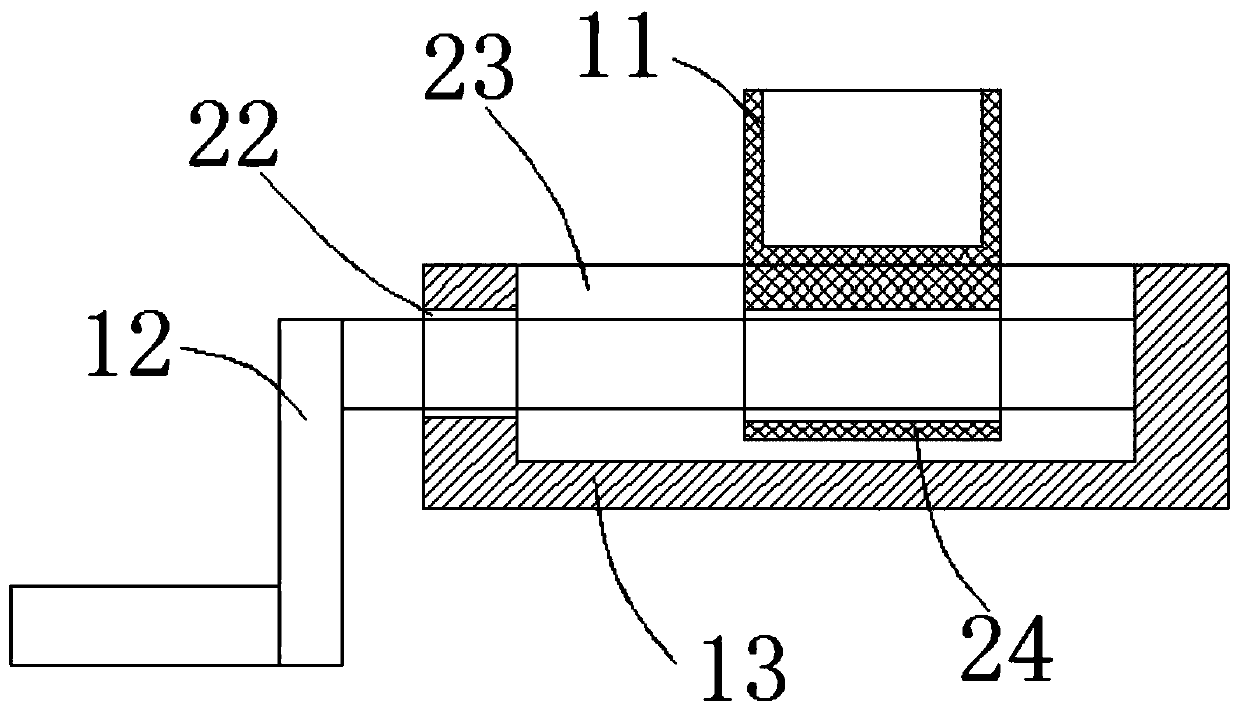

Clamp for assembling aero-engine fan-shaped block assemblies

ActiveCN110936084ASolve the problem of blind spots in spot weldingEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesCantileverAero engine

The invention belongs to the field of mechanical tools, and particularly relates to a clamp for assembling aero-engine fan-shaped block assemblies. According to the technical scheme, the clamp for assembling the aero-engine fan-shaped block assemblies comprises a chassis rotating unit, a positioning pressing unit, a cantilever welding unit and an angular scale plate, wherein the positioning pressing unit, the cantilever welding unit and an angular scale unit are mounted on the chassis rotating unit, the positioning pressing unit is used for pressing and positioning inner runner plate and outerrunner plates of the fan-shaped block assemblies, the cantilever welding unit is used for welding blades of the fan-shaped block assemblies to the inner runner plates and the outer runner plates, andthe angular scale plate is used for angular positioning of the cantilever welding unit. According to the clamp for assembling the aero-engine fan-shaped block assemblies, the assembling size precision and the consistency of positioning welding points can be ensured.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

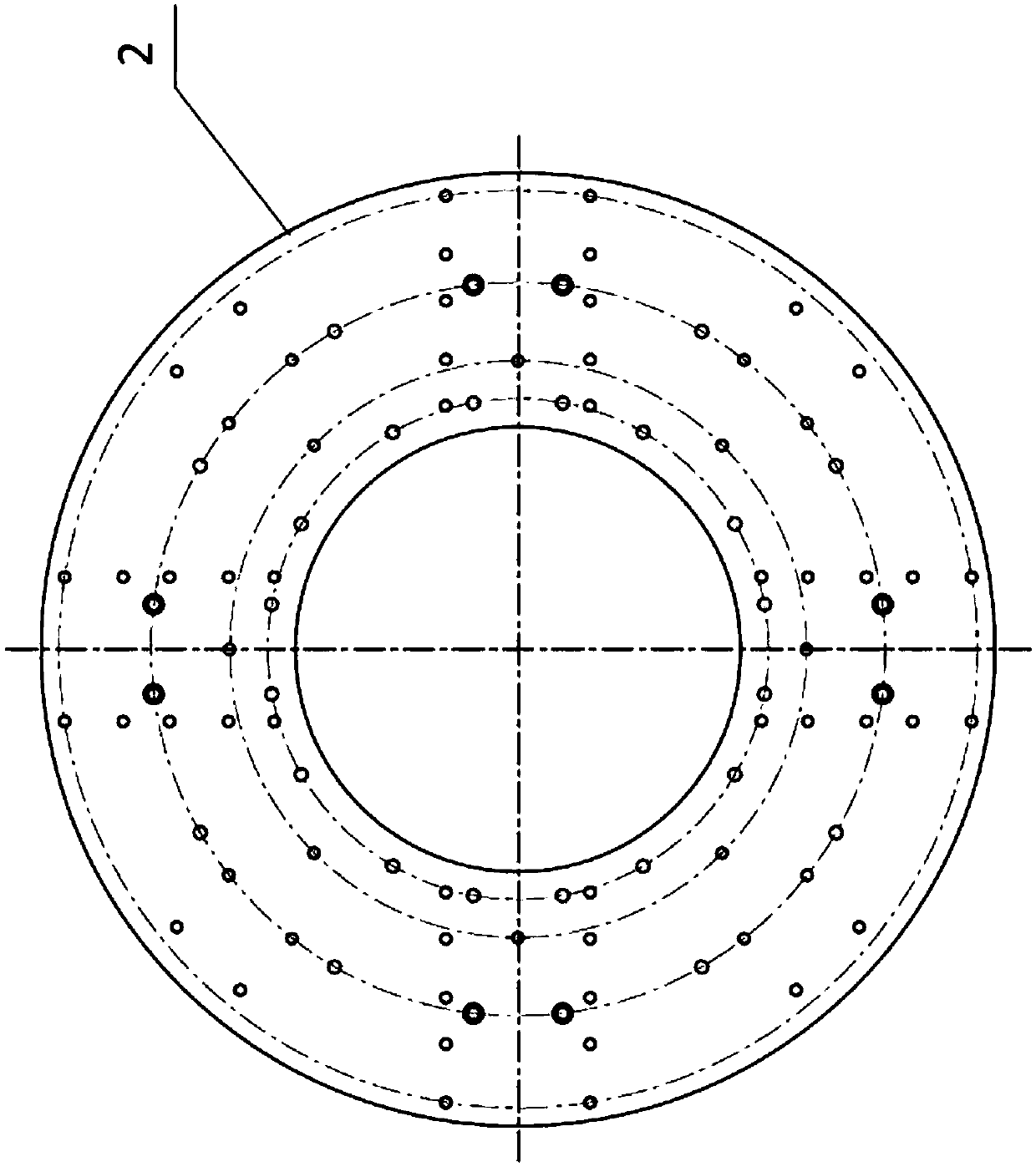

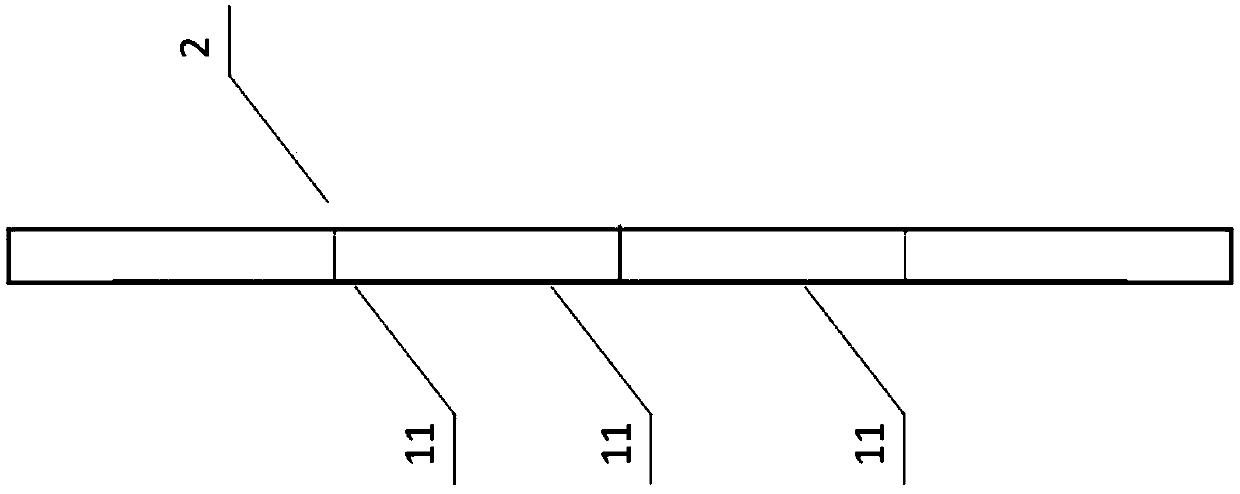

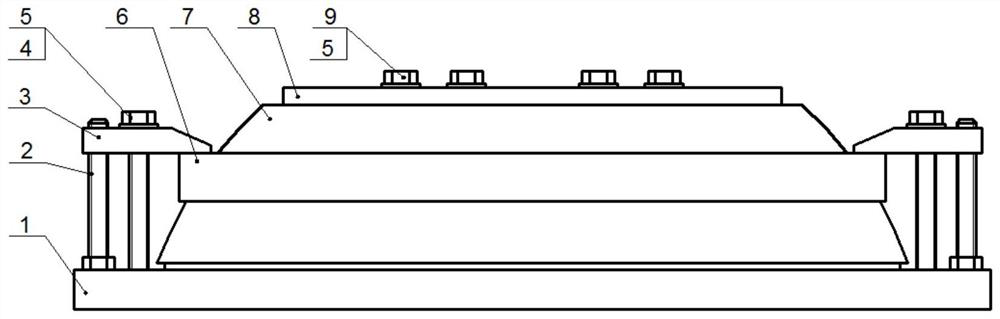

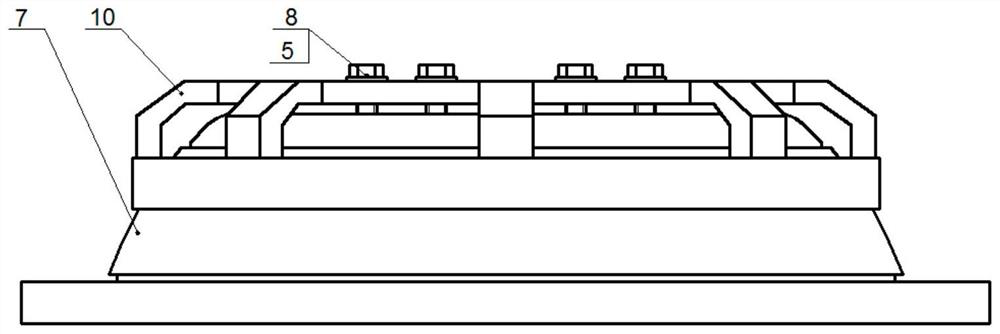

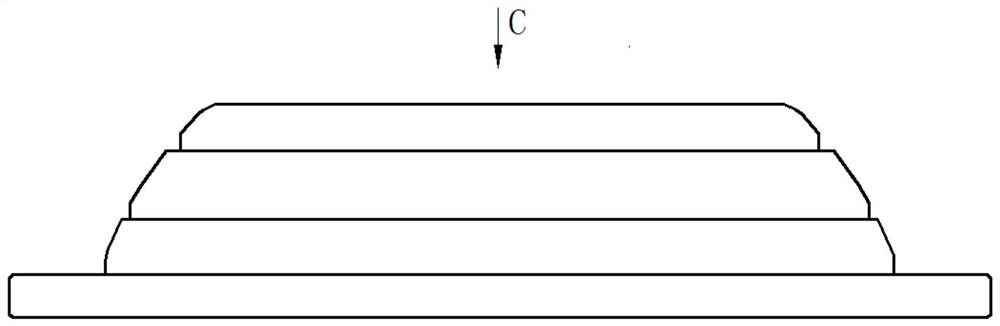

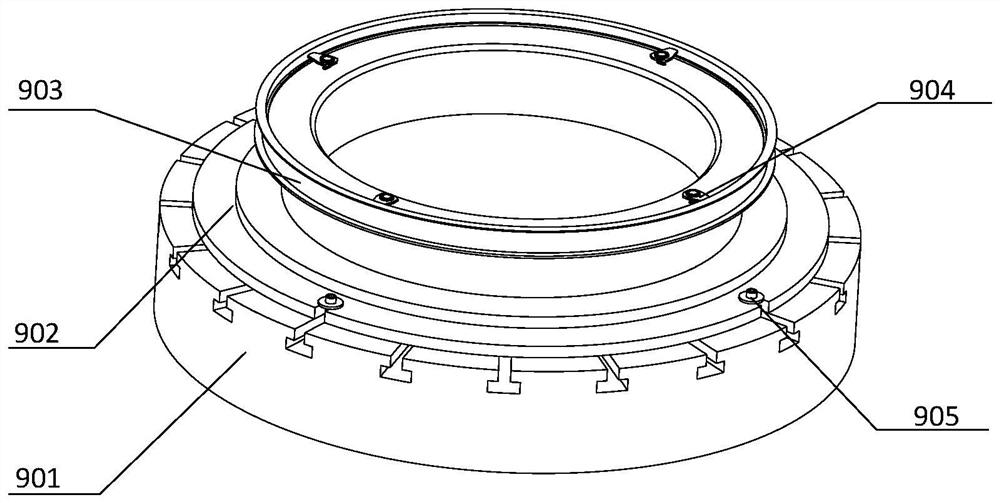

Special tool fixture for vertical type combined machining center

PendingCN107791057AExpand the scope of processingReduce re-clampingPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to the technical field of vertical type combined turning-milling machining, in particular to a special tool fixture for a vertical type combined machining center. The tool fixture comprises a rotary tray 2, clamping jaw high-position supports 3, a plurality of bolt and nut fixing components, an annular sizing block, a center fixing disc of an annular structure, equal-height pads and pressing plates, wherein the rotary tray is of an annular structure, the diameter of the annular outer circle of the rotary tray is smaller than the rotary limit range of a rotary workbench ofthe vertical type combined machining center, and the clamping jaw high-position supports are weld assemblies and are used for heightening the clamping positions of chuck jaws. By means of the specialtool fixture for the vertical type combined machining center, the machining range of the workbench of the vertical type combined machining center can be widened to the maximum extent, and machining precision is not influenced; and in addition, a clamping method of the workbench can be simulated, clamping modes are not only limited to modes provided by the workbench, and more importantly, the clamping modes are diversified. The special tool fixture for the vertical type combined machining center can be widely popularized in the field of machining with machine tools and the like.

Owner:大连诺酉工程技术有限公司

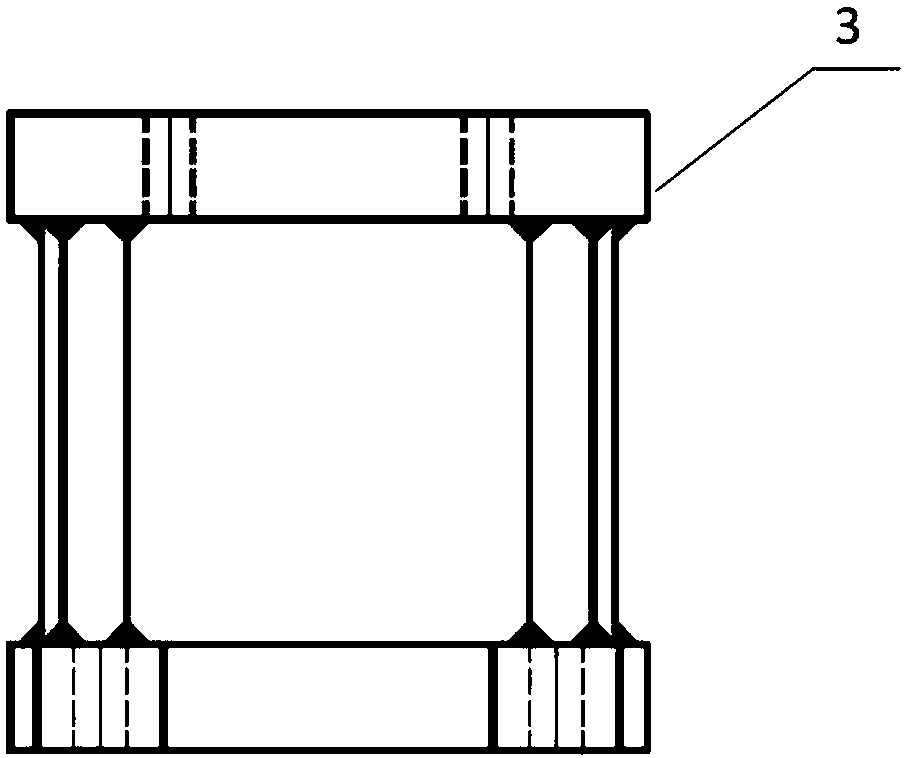

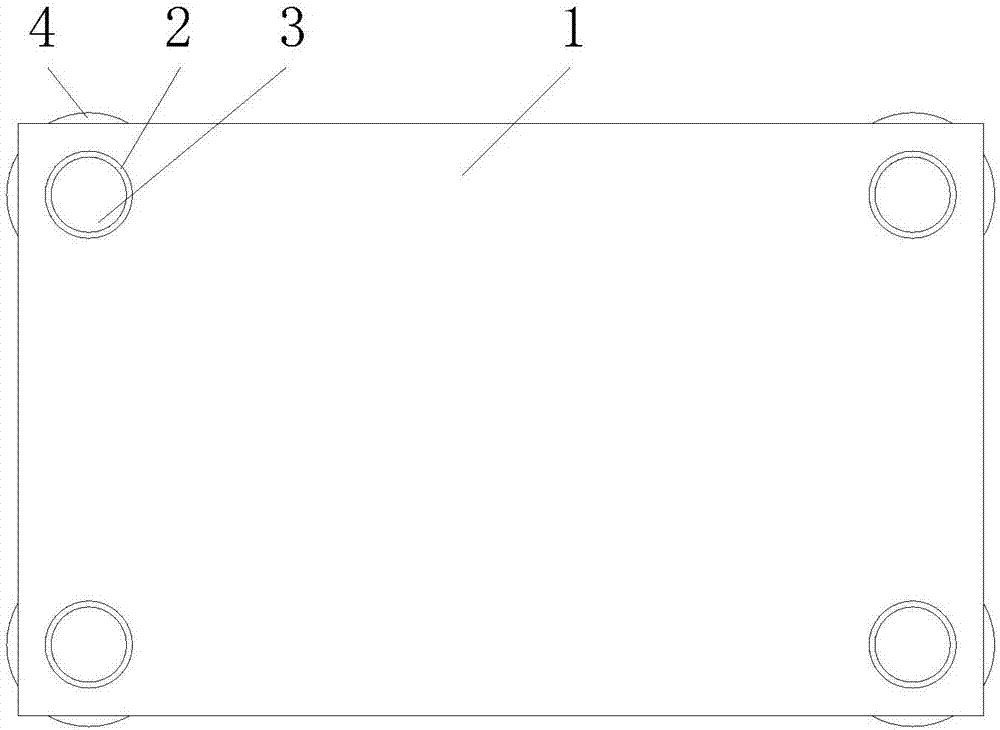

Base device used for numerical-control machine tool

ActiveCN108000222ASolve the problem of not being able to adjust to the size of the machine toolDoes not affect machining accuracyLarge fixed membersMaintainance and safety accessoriesMachine toolHydraulic cylinder

The invention discloses a base device used for a numerical-control machine tool. The base device used for the numerical-control machine tool comprises a supporting base. Adjustment grooves are formedin the four corners of the bottom of the supporting base correspondingly. Threaded columns are arranged in the adjustment grooves. External threads are arranged on the surfaces of the threaded columns. Internal threads matched with the threaded columns for use are arranged on the inner walls of the adjustment grooves. The bottom ends of the threaded columns penetrate through the adjustment groovesand extend out of the adjustment grooves to be fixedly connected with ground feet. According to the base device used for the numerical-control machine tool, a sliding groove, a sliding block, a fixing rod, a hydraulic cylinder, a first supporting block, a second supporting block and a telescopic plate are arranged, so that the problem that a common numerical-control machine tool base cannot be adjusted according to the size of a machine tool is solved; the base device is adjustable so that numerical-control machine tools of different models and types can be fixed to the base device completelyadaptively, and materials and time are greatly saved; and contact stability between the base device and the ground is good, the machining precision of workpieces is not affected, and the base devicecan be widely used in workshops.

Owner:舒能智能装备(长兴)有限公司

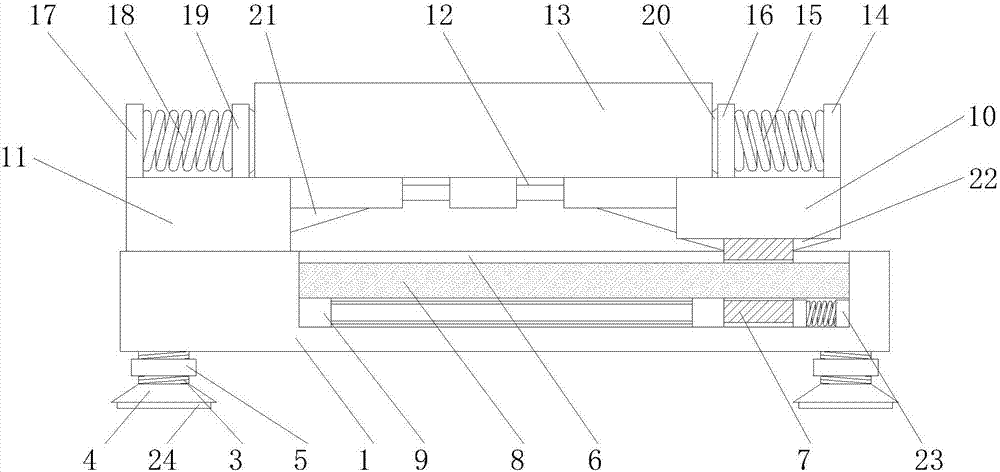

Working table with guide rail

InactiveCN104440131AAvoid offsetDoes not affect machining accuracyLarge fixed membersMaintainance and safety accessoriesFriction lossEngineering

The invention relates to a working table with a guide rail. The working table comprises the guide rail and a working table body, a U-type groove is formed in the upper end face of the guide rail and internally provided with a sliding groove, roll balls are arranged on the two sides of the sliding groove, the working table body is arranged to be of a T-type structure matched with the guide rail, a guide block matched with the sliding groove is arranged at the bottom end of the working table body, makes contact with the roll balls in the sliding groove and slides through rolling of the roll balls, and oil ducts are formed in the two side faces of the working table body and communicated with the side faces of the U-type groove. The working table has the advantages of being simple in structure and convenient to lubricate and will not deflect in the sliding process, and friction loss between the working table body and the guide rail is reduced.

Owner:常州矩阵精密机械有限公司

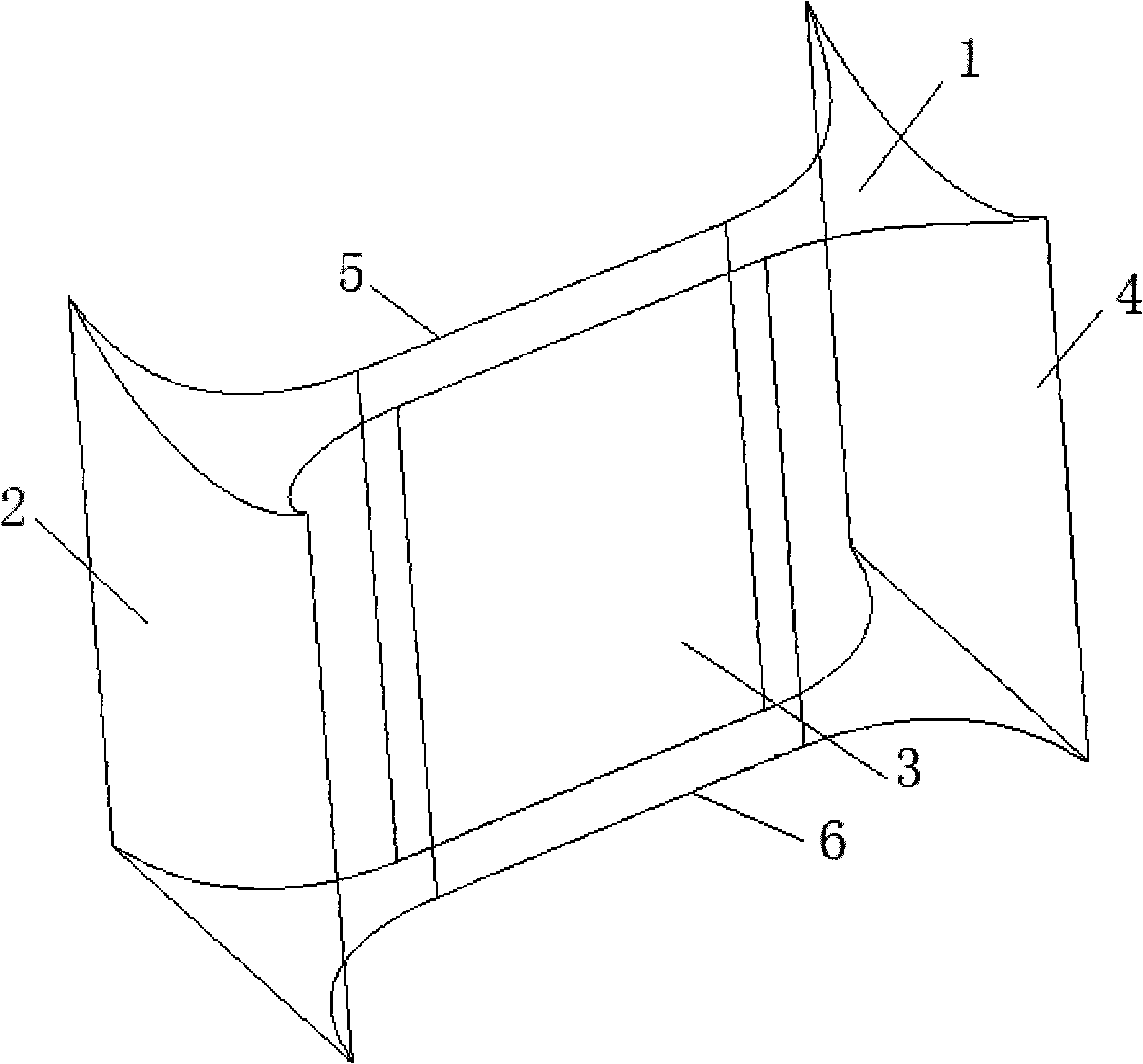

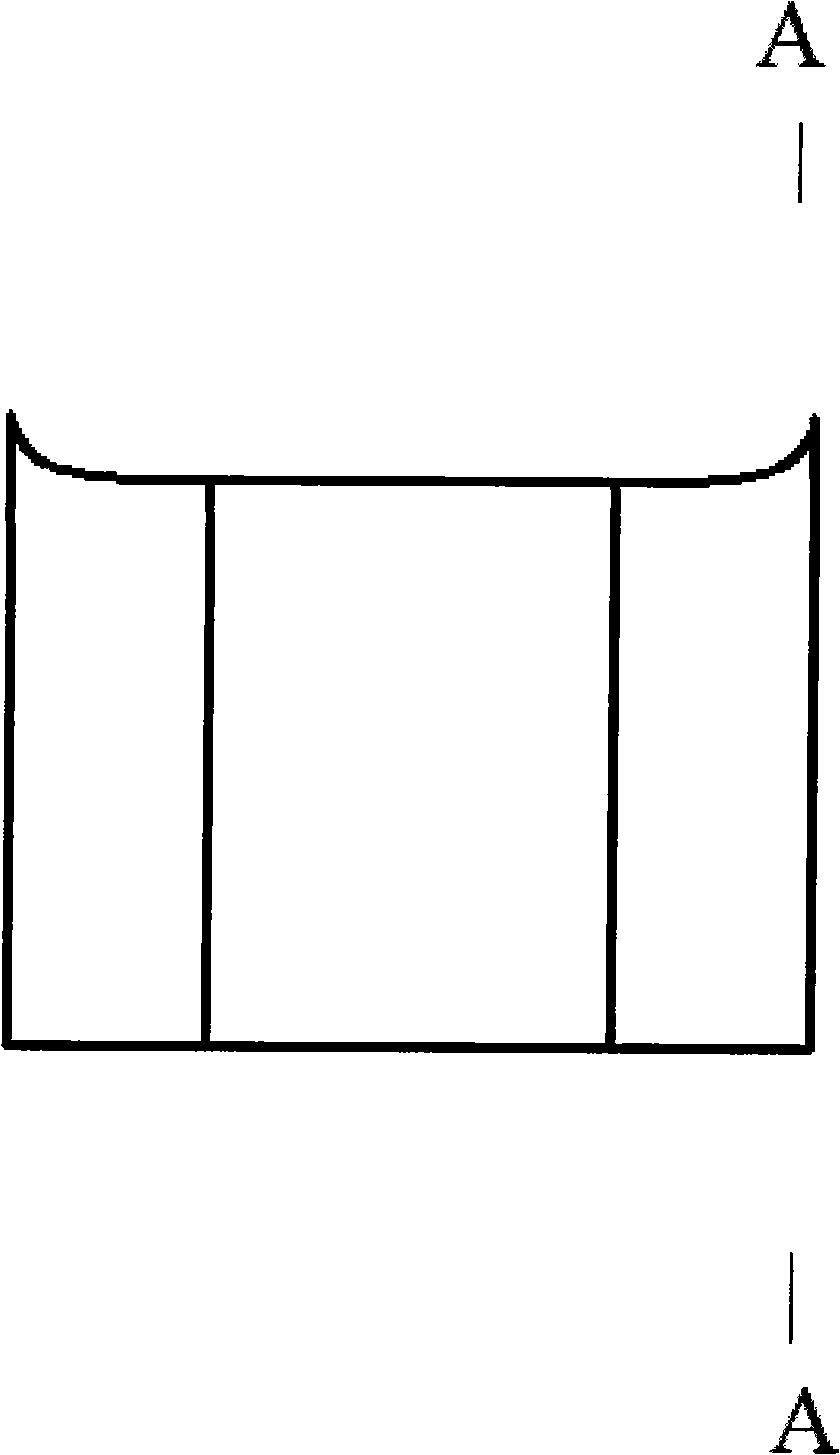

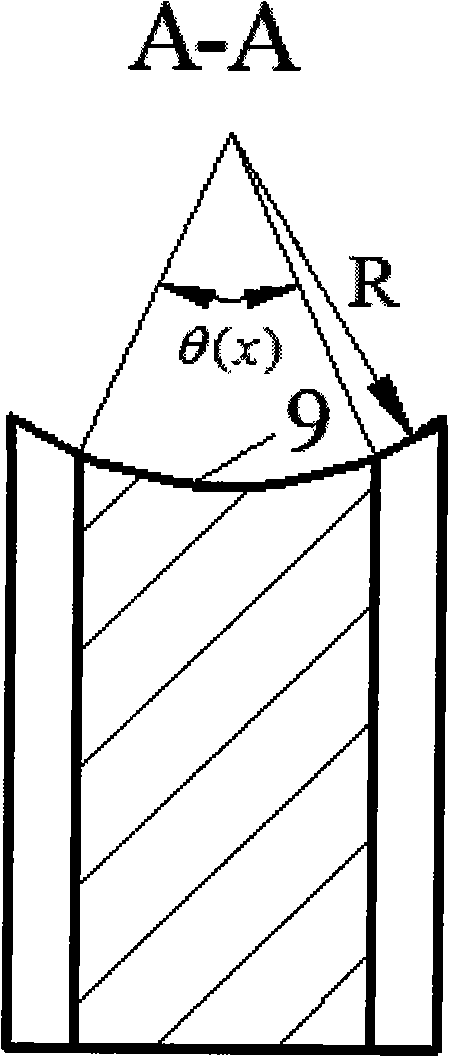

Super grinding whetstone for cylindrical roller with logarithmic camber

InactiveCN101549471ASimple processing equipmentLow costRevolution surface grinding machinesEconomic benefitsEngineering

The invention discloses a super grinding whetstone for cylindrical roller with logarithmic camber. two surfaces of the cuboid whetstone in length direction are composed of symmetrical distributed inwardlydished curved surfaces with same shape; the third surface of the cuboid whetstone in the length direction is an iso-radial concave curved surface with the radius equal to that of the cylindrical roller with logarithmic camber. The grinding theory says: the workpiece cutting amount is proportional to the contact arc length; therefore, the whetstone structure can be designed according to the cutting amount calculated by the logarithmic camber curve, and the whetstone can be used for grinding to obtain the workpiece with requested logarithmic camber. the whetstone with the structure needs simple equipments for machining roller camber, is low in cost, and convenient in operation, solves the problems of high difficulty and high cost in logarithmic camber roller machining, has higher engineering value and economic benefit.

Owner:ZHEJIANG UNIV

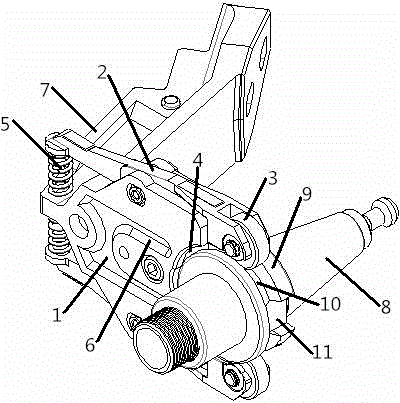

Boring rod component for machining thrust surface of diesel body

InactiveCN102581321AImprove machining accuracyElimination of tool pillows (i.e. sliders)Boring barsTurning toolsTorque transmissionMechanical engineering

The invention discloses a boring rod component for machining a thrust surface of a diesel body, which comprises a driving rod, a push rod, a slider and a return spring. A boring rod is in a hollow structure, a backing positioning nut and a thrust surface axial positioning nut are arranged at the rear end of the boring rod, the driving rod, the push rod and the return spring are sequentially arranged in a hollow cavity of the boring rod, the driving rod is connected with the boring rod through a feather key, and the driving rod is kept in contact with the push rod under the action of the return spring. The slider is arranged on the boring rod and corresponds to an oblique protruding strip on the push rod through an oblique groove, and radial turning tools in pair are arranged at the top of the boring rod. The boring rod component has the advantages that the feather key is used for the driving structure to simply combine torque transmission with feeding, the tool is withdrawn first and then the boring rod is pulled out when the spring is returned, and the push rod is combined with the radial slider through the oblique groove, so that the boring rod component is high in rigidity and machining manufacturability.

Owner:CHINA NAT HEAVY DUTY TRUCK GRP HANGZHOU ENGINE

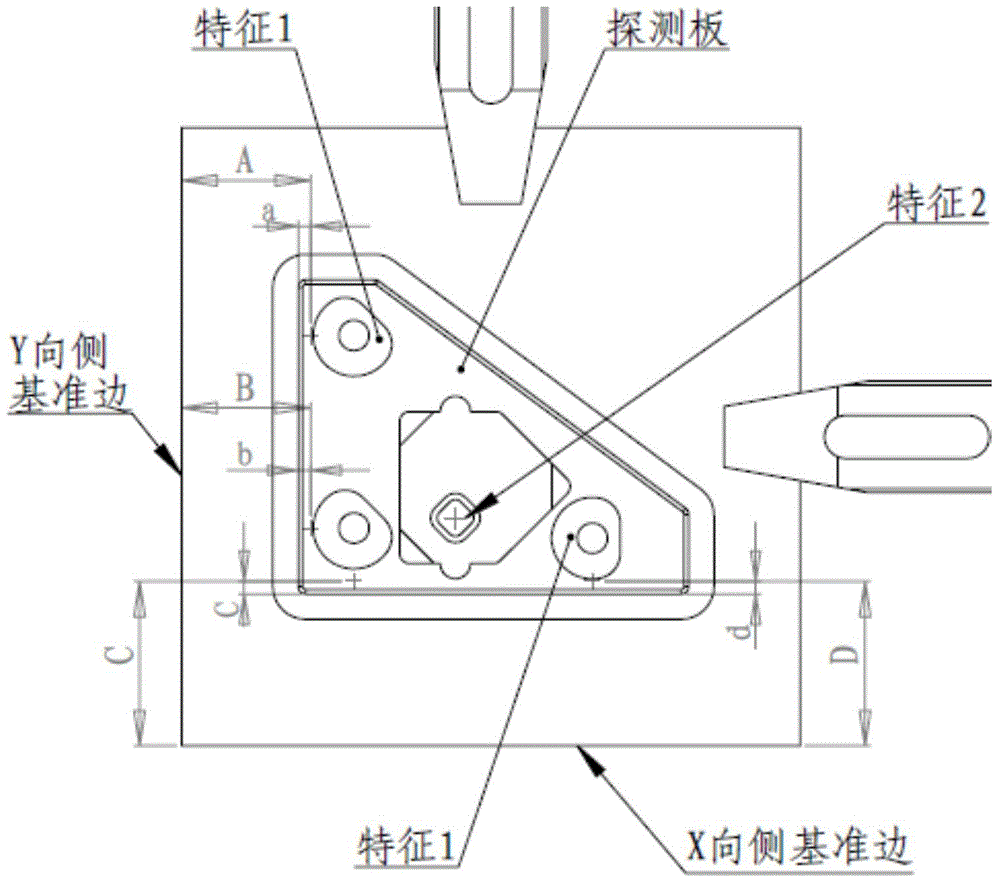

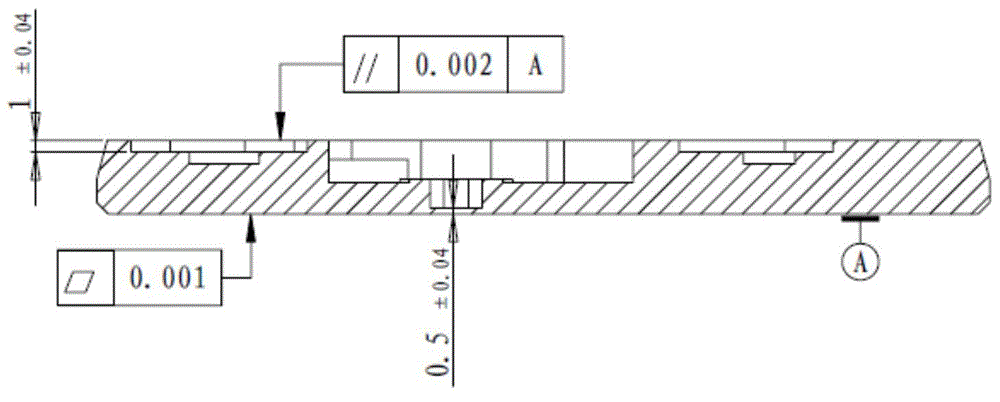

Method for machining detection plate

ActiveCN103558741AStrong dependenceDoes not affect machining accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMachine tool

The invention discloses a machining and manufacturing process for a detection plate of a photo-etching machine, and particularly relates to a method for machining a detection plate. The method comprises the following steps: (1) measuring positioning marks of the detection plate, and processing data; (2) adjusting the reference accuracy of X and Y directions of a machining center machine tool and a clamp, and fixing a workpiece of the detection plate; (3) machining X-direction and Y-direction reference surfaces of the detection plate, and calibrating the accuracy of the reference surfaces and the reference of a cursor; (4) pre-machining all characteristics of the detection plate, and checking and verifying parameters of the machining center machine tool; (5) roughly machining an outline and internal characteristics; and (6) finely machining the outline and the internal characteristics. According to the invention, the rejection rate is reduced, the machined detection plate is high in quality, and requirements of photo-etching are met.

Owner:SHANGHAI MODERN ADVANCED ULTRA PRECISION MFG CENT

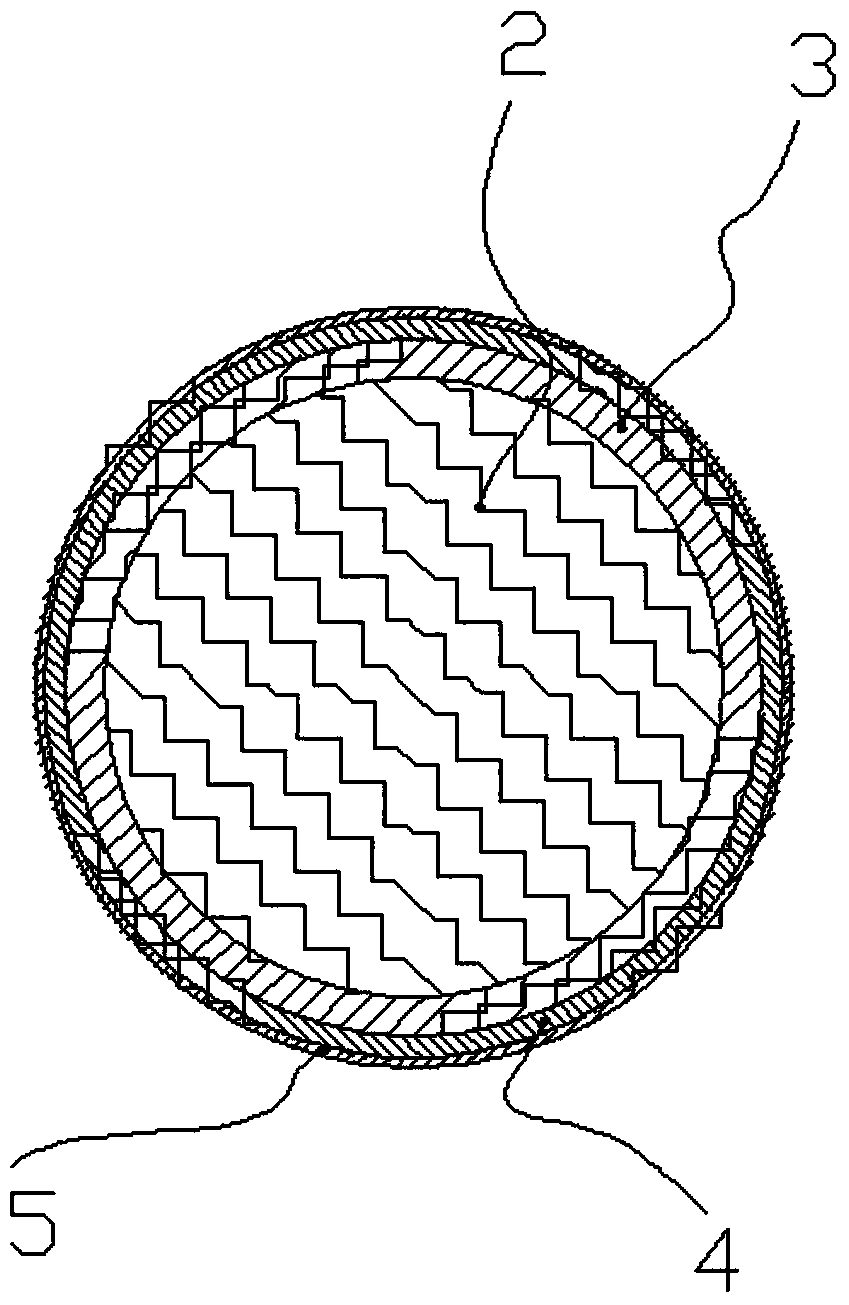

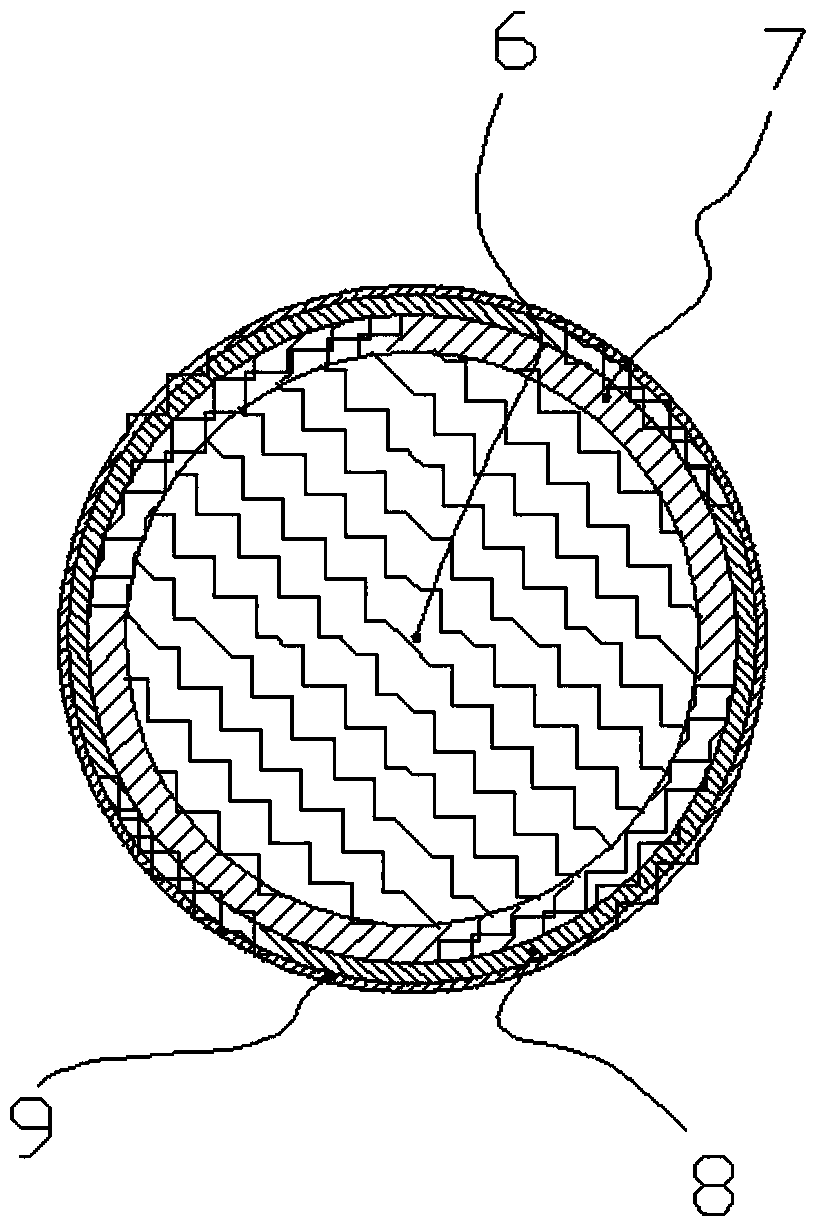

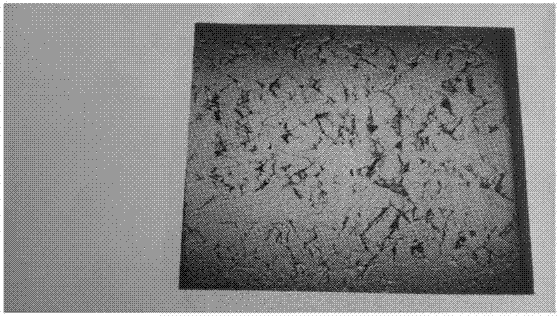

Electrode wire for slow wire electric discharge machining and preparation method thereof

ActiveCN103537768BDoes not affect machining accuracyFast processingElectrical-based machining electrodesElectric dischargeBeta phase

The invention discloses a wire electrode for WEDM-LS electrical discharge machining and a preparation method of the wire electrode. The wire electrode comprises a core portion, a transition layer, a covering layer and an oxide layer. The core portion is made of brass alloy or red copper. The transition layer covers the outer layer of the core portion and comprises a continuous portion and an interruption portion formed by beta-phase pinchbeck alloy protruding from the continuous portion. The covering layer is formed by the interruption portion formed by the beta-phase pinchbeck alloy, cracked gamma-phase pinchbeck alloy inlaid on the interruption and gaps. The inevitable oxide layer is formed on the surface of the covering layer. The zinc content at the joint between the core portion and the transition layer and the zinc content at the joint between the transition layer and the covering layer are distributed in a linear increase mode. According to the wire electrode with the special tissue structure, the gasification capacity of zinc can be adjusted in the cutting process, cutting efficiency and cutting accuracy are promoted, cost is saved to the largest degree and machining quality is improved.

Owner:NINGBO BODE HIGHTECH CO LTD

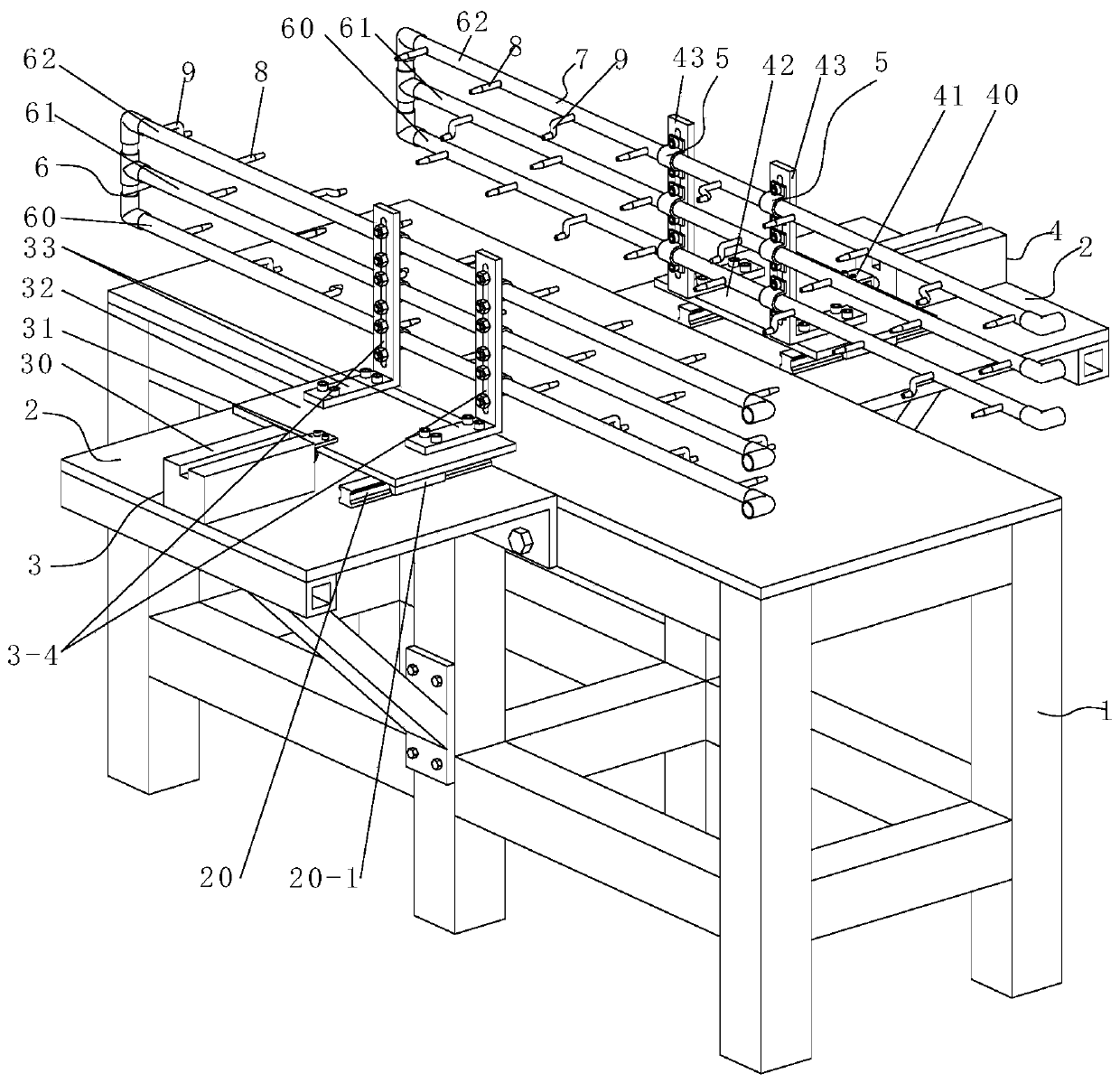

Device for purging tapping scrap iron on engine cylinder head production line

PendingCN110102838AGuaranteed to be properly screwedImprove purge efficiencyThread cutting machinesMaintainance and safety accessoriesProduction lineCylinder head

The invention discloses a device for purging tapping scrap iron on an engine cylinder head production line. The device is located on a purging station workbench and comprises a side platform, a firstdriving system, a second driving system, half buckles, a first purging pipeline system, a second purging pipeline system, a first purging pipe and a second purging pipe, wherein the side platform is fixedly connected with the side edge of the purging station workbench; the first driving system is fixedly connected with the upper end of one side of the side platform; the second driving system is fixedly connected with the upper end of the other side of the side platform; the first purging pipeline system is fixedly connected with a first support through the half buckles; the second purging pipeline system is fixedly connected with a second support through the half buckles; and the first purging pipeline system and the second purging pipeline system respectively communicate with the first purging pipeline system and the second purging pipeline system. The device has the advantages of having no influence on the machining precision of the next process and ensuring normal screwing of boltsduring assembly; labor force is liberated; and the metal dust does not affect the health of workers, the purging is high in efficiency and not forgotten.

Owner:Y & C ENGINE

Vacuum sucking disc device of novel numerical control machine tool

InactiveCN102476303ASolve clamping problemsNo deformationPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a vacuum sucking disc device of a novel numerical control machine tool, and the vacuum sucking disc device belongs to a fixture tool of the numerical control machine tool. The vacuum sucking disc device of the novel numerical control machine tool has the structural characteristics that the vacuum sucking disc device of the novel numerical control machine tool comprises a fixture, a vacuum tube, a sealing block and a connection block, wherein the connection block is connected with a machine tool spindle; the fixture is connected with the connection block; a sealing block is arranged between the fixture and the connection block; the sealing block and the fixture mutually surround to form a vacuum slot; the vacuum slot is communicated with a vacuum hole arranged on the fixture; the position of the vacuum hole on the surface of the fixture is provided with a working slot; the vacuum tube is arranged in the machine tool spindle; one end of the vacuum tube is communicated with the vacuum slot; and the other end of the vacuum tube is communicated with a vacuumized device. The vacuum sucking disc device of the novel numerical control machine tool has the advantages of reasonable structure design, good sealing effect and no vibration under high-speed rotation, and sheet metal is machined at high precision without damage.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

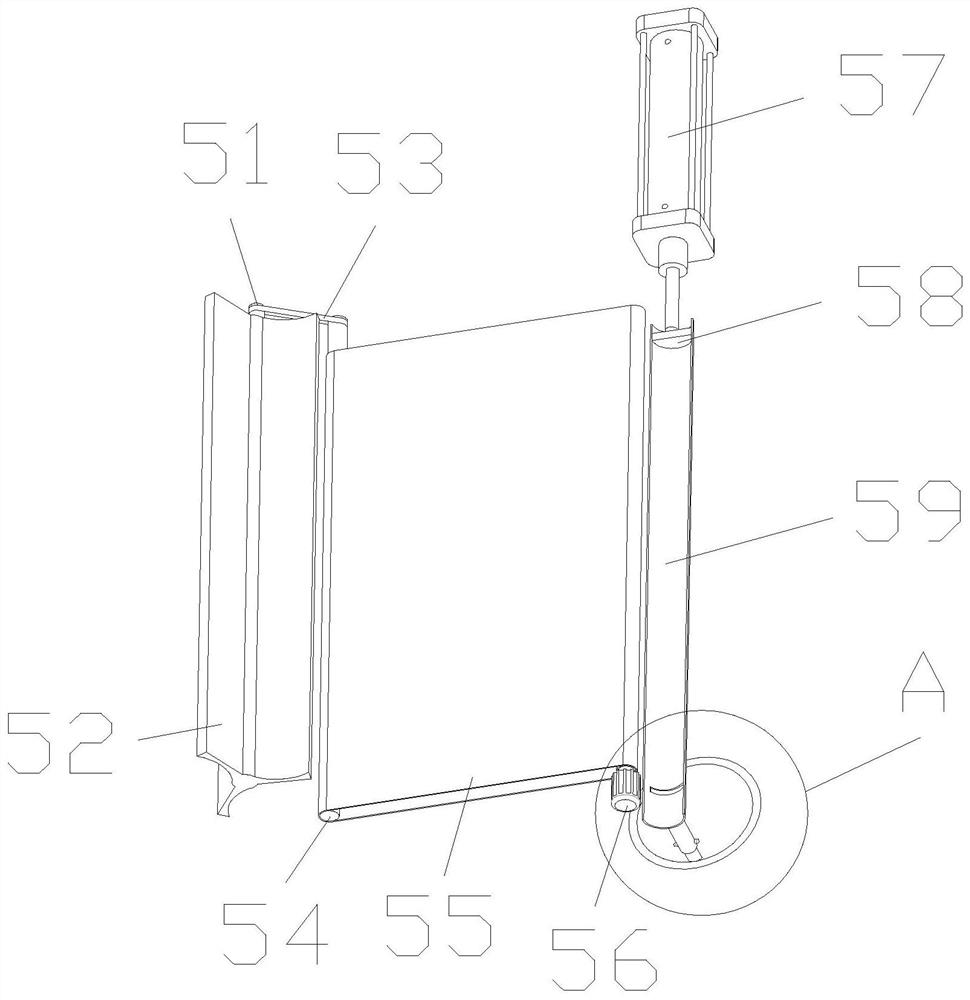

Novel high-power 3D printing cutting machine for steel structure

InactiveCN107962253AImprove the operating environmentGuaranteed uptimeLarge fixed membersDriving apparatusEngineeringProcessing accuracy

The invention discloses a novel high-power 3D printing cutting machine for a steel structure. The novel high-power 3D printing cutting machine comprises a machine body. A motor is arranged on the upper surface of the machine body. The lower surface of the motor is connected with the upper surface of the machine body. A first rotating wheel is mounted on the outer wall of the motor. The inner wallof the first rotating wheel and the outer wall of the motor are connected. A machine box is mounted on the outer wall of the right side of the machine body. The lower surface of the machine box is connected with the upper surface of the machine body. A bracket is mounted on the outer wall of the left side of the machine body. According to the novel high-power cutting machine for the steel structure, through cooperation between the motor, the first rotating wheel, a belt and a second rotating wheel, under the action of a rotating shaft and a rotating rod, the machining speed of cutting blades to a machined part is adjusted, when the thickness of the machined part is large, the rotating speed of the motor can be adjusted, the speed of the motor is increased, the cutting speed is increased, and the machining efficiency is improved; and therefore the defects that a traditional cutting machine for a steel structure is poor in machining precision, and the cutting speed cannot be adjusted areovercome, the machining efficiency is improved, and the machining period is saved.

Owner:HKUST TIANGONG INTELLIGENT EQUIP TECH (TIANJIN) CO LTD

Clamp and method for turning thin-wall dish-shaped part on lathe

PendingCN114055211AWill not deformNo deformationPositioning apparatusMetal-working holdersMachiningProcessing accuracy

The invention discloses a clamp and method for turning a thin-wall dish-shaped part on a lathe, and belongs to the field of machining. The clamp comprises a male die, a support bolt, a first pressing plate, a first pressing bolt, a pressing ring, a second pressing plate, a second pressing bolt and a third pressing plate. The male die is of a spherical crown structure with a bottom, the outline of the spherical crown structure is the same as that of the inner arc face of the thin-wall butterfly-shaped piece, and the thin-wall butterfly-shaped piece is coaxially placed on the male die. When the upper end of the thin-wall butterfly-shaped piece is turned, the workpiece is pressed and fixed through the support bolt, the first pressing plate, the first pressing bolt, the pressing ring, the second pressing plate and the second pressing bolt; when the lower end of the thin-wall butterfly-shaped piece is turned, the workpiece is pressed and fixed through the pressing ring, the second pressing bolt and the third pressing plate; according to the clamp, the thin-wall butterfly-shaped part is clamped on a lathe, the whole workpiece does not deform, meanwhile, the whole workpiece is pressed by the pressing ring during turning, and the workpiece does not vibrate to affect the machining precision. The machining quality of products is guaranteed, and efficient turning of the products is achieved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

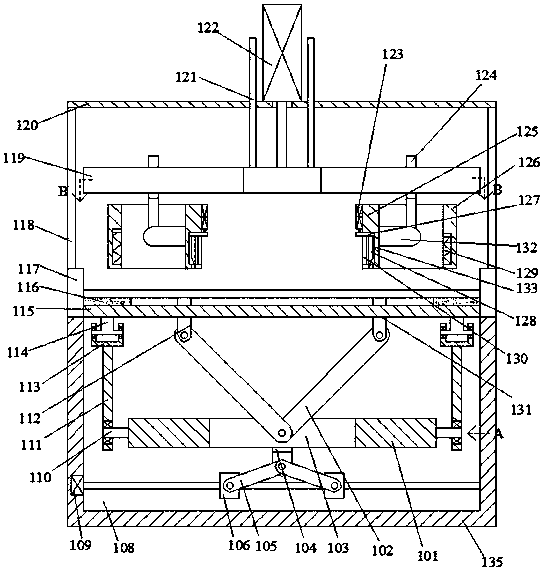

Quick blanking die

ActiveCN109759497ASupport the position of the workpiece so that the force on the workpiece is balancedStable supportProcess efficiencyEngineering

The invention discloses a quick blanking die. The quick blanking die comprises a bottom box, wherein the bottom box is fixedly provided with an inner cavity with an opening, the inner cavity is internally provided with a supporting device used for a lower side support in the blanking process, and the upper end face of the bottom box is provided with a quick blanking device used for blanking and processing. The die is simple in structure; the supporting device is used for adjusting a supporting structure in the blanking process by utilizing the operating mode of a connecting rod, so that the blanking process efficiency is higher; and meanwhile, the blanking interval of a blanking cutter is uniformly changed by using threads of the rapid blanking device, so that the blanking of a plurality of shapes is finished in a single device, the efficiency of the device is improved, the die can be prevented from being taken out and blanked by people for multiple times, and the safety of the equipment is improved.

Owner:武汉博联科技发展有限公司

Metal cutting machine tool convenient for collecting chippings, and using method thereof

InactiveCN113601243AReduce wearExtended service lifePositioning apparatusMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a metal cutting machine tool convenient for collecting chippings, and a using method thereof, and relates to the technical field of cutting machine tool design. The metal cutting machine tool convenient for collecting the chippings comprises a main body, wherein an empty cavity is formed in the main body, a driving rod is fixedly installed on the upper surface of the main body, and a cutting machine head is connected to the outer surface of the driving rod in a sleeved mode; and an electric fan is arranged on the upper surface of the main body, and a chipping removing assembly is arranged on the outer surface of the main body. According to the invention, chippings generated when metal is cut by the cutting machine do not splash all around, the chippings are cleaned through a cleaning assembly, the chippings are prevented from hurting human body and entering the cutting machine, the machining precision is not affected, the abrasion of the cutting machine is reduced, and the service life of the cutting machine is prolonged; and a clamping mechanism of the cutting machine can clamp round and square materials at the same time, the clamping mechanism can be adjusted, the materials of various specifications can be clamped, and a good clamping effect is achieved.

Owner:陈先取

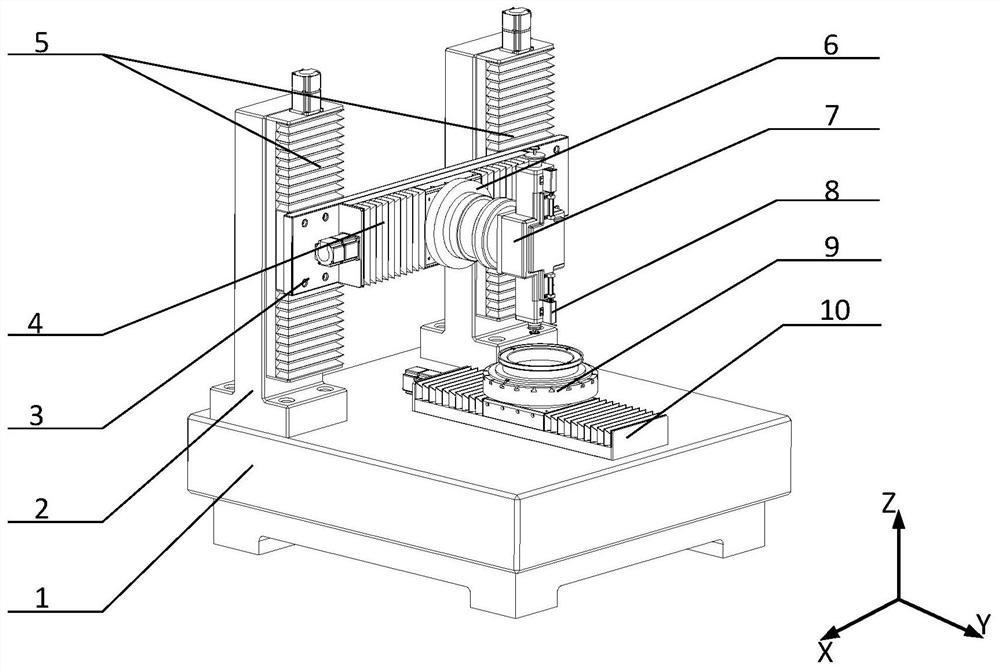

Annular workpiece milling, grinding and measuring integrated machining machine tool and control method thereof

ActiveCN112025315AReduce labor intensityReduce processing stepsProgramme controlComputer controlRotary stageEngineering

The invention discloses an annular workpiece milling, grinding and measuring integrated machining machine tool which comprises a machine tool base, a Z-axis mounting support, an X-axis mounting panel,an X-axis moving device, a Z-axis moving device, a B-axis rotating table, a milling and grinding operation system, a measuring mechanism, a workbench and a Y-axis moving device. The Z-axis mounting support is fixed to the machine tool base, the Z-axis moving device is fixed to the Z-axis mounting support, the X-axis mounting panel is fixed to the Z-axis moving device and is driven by the Z-axis moving device to move up and down in the Z-axis direction, and the X-axis moving device is fixed to the X-axis mounting panel. The B-axis rotating table is fixed to the X-axis moving device and drivenby the X-axis moving device to move leftwards and rightwards in the X-axis direction, the milling and grinding operation system is fixed to the B-axis rotating table, the measuring mechanism is fixedto the end of the milling and grinding operation system, the workbench is fixed to the Y-axis moving device and driven by the Y-axis moving device to move forwards and backwards in the Y-axis direction, and the Y-axis moving device is fixed to the machine tool base. Meanwhile, the invention discloses a control method of the annular workpiece milling, grinding and measuring integrated machining machine tool.

Owner:JILIN UNIV

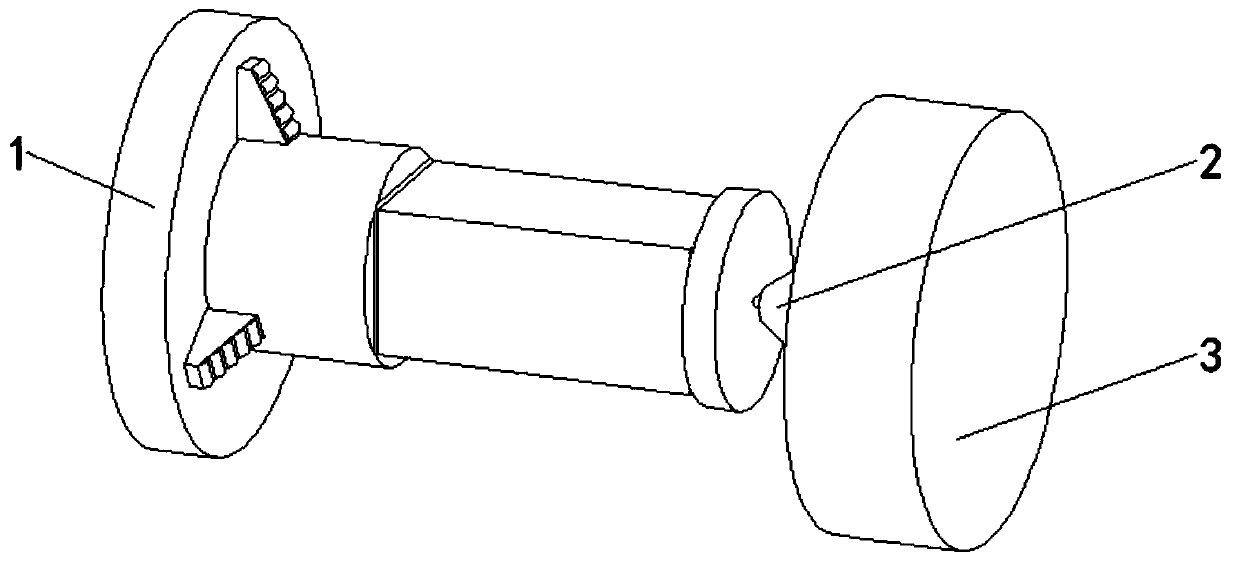

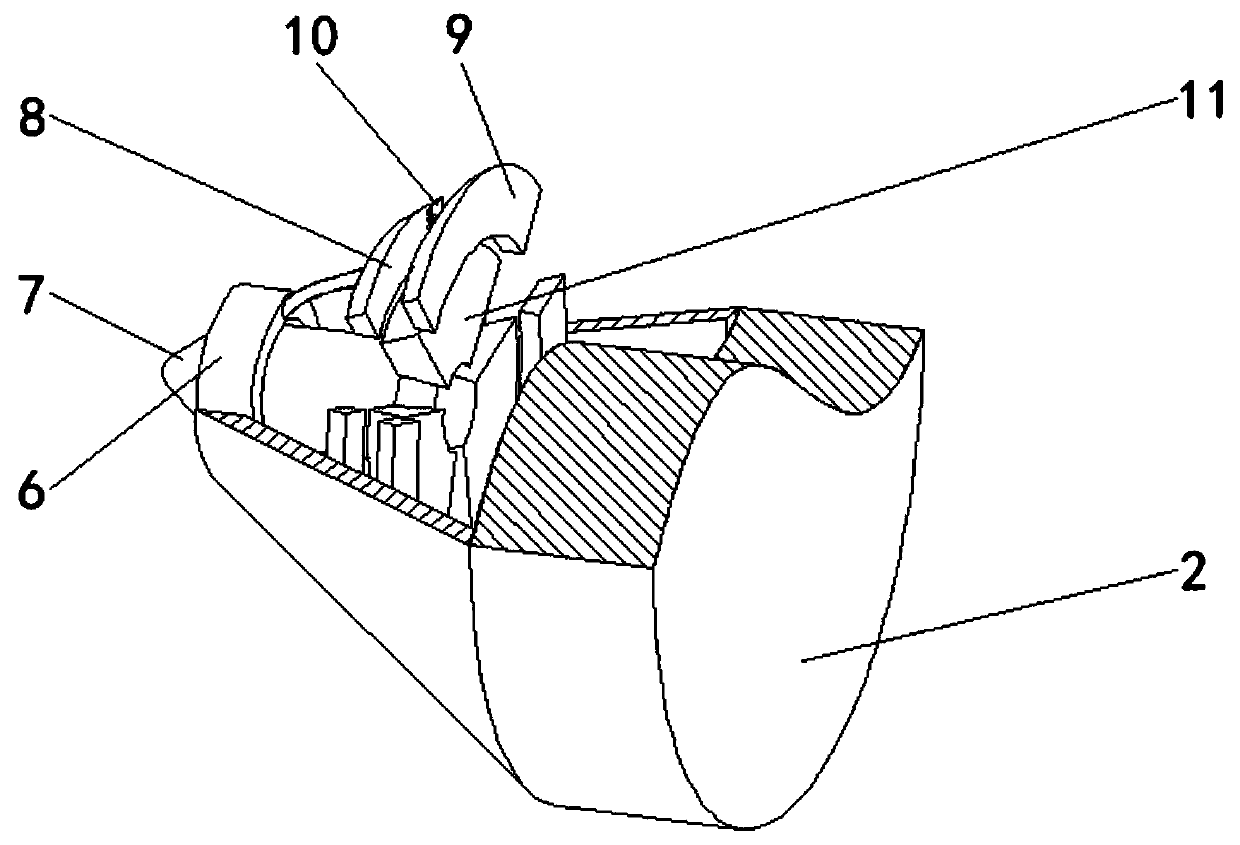

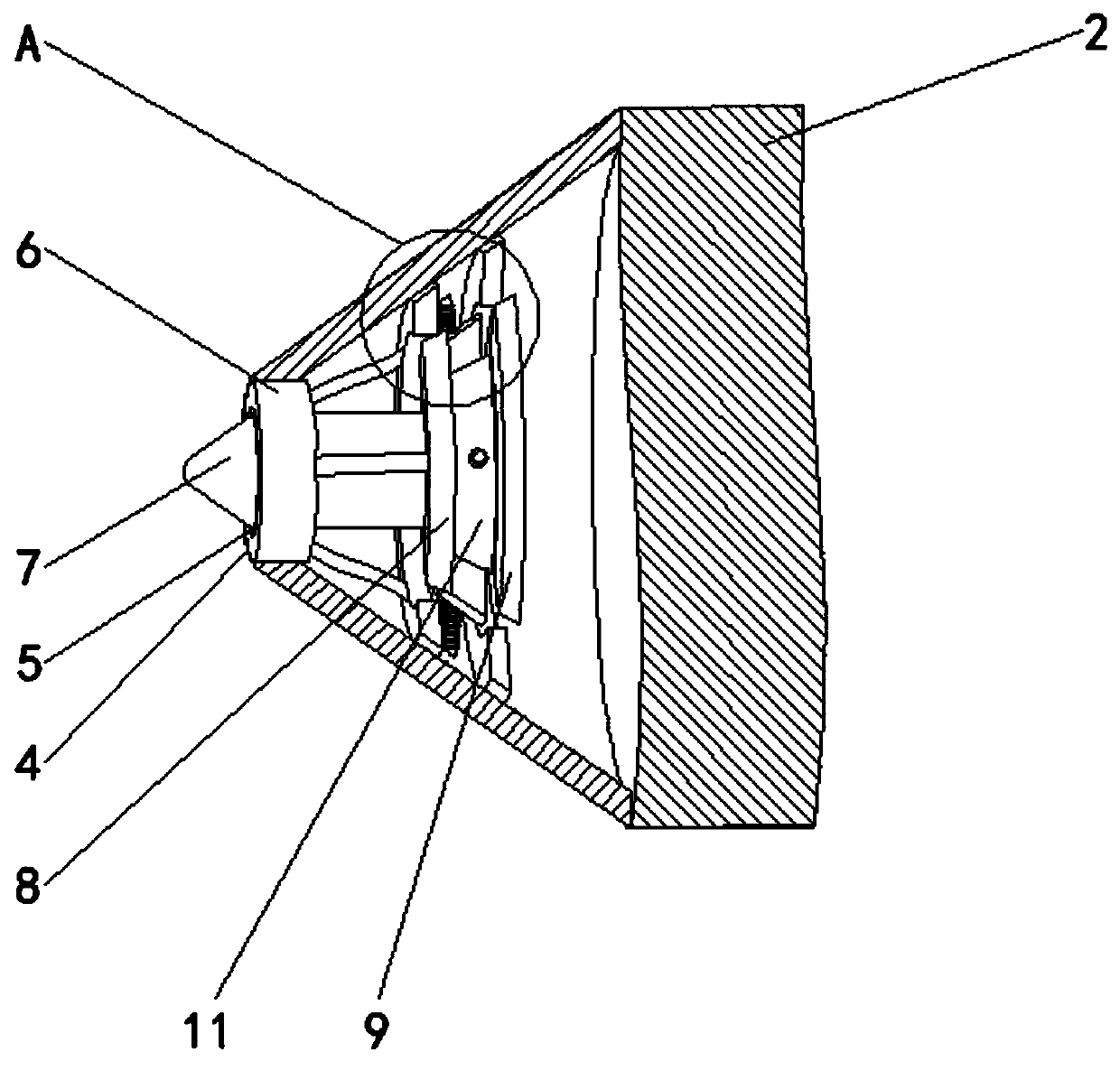

Numerical control multilateral forming machine tool

ActiveCN110722179ADoes not affect machining accuracyExtended service lifeTailstocks/centresLarge fixed membersProcessing accuracyEngineering

The invention relates to the technical field of numerical control machine tools, and discloses a numerical control multilateral forming machine tool. The numerical control multilateral forming machinetool comprises a chuck, a tip and a connecting round plate. The axes of the chuck, the tip and the connecting round plate are located on the same straight line, the chuck is located on the left sideof the tip, the tip is fixedly mounted on the connecting round plate, a ring groove and a thimble groove are formed in one side of the tip, the thimble groove is located in the ring groove, an electromagnet is fixedly mounted in the ring groove, and a thimble is slidingly mounted in the thimble groove. According to the numerical control multilateral forming machine tool, as the thimble does not make contact with a workpiece, the effect of protecting the thimble can be achieved, the service life of the thimble is prolonged, it is guaranteed that during next use, the thimble can continue to achieve the effect of precise positioning, the connecting round plate makes contact with the workpiece, due to the fact that the connecting round plate and the workpiece are in plane contact, even when abrasion is generated, the abrasion is plane abrasion, and the machining precision of the workpiece is not affected.

Owner:营口凌海精密机械制造有限公司

Simplified grinding head movable type horizontal shaft circular truncated cone plane grinding machine

PendingCN110064982AHigh precisionImprove stabilityGrinding carriagesGrinding drivesMovable typeEngineering

The invention relates to a simplified grinding head movable type horizontal shaft circular truncated cone plane grinding machine. The grinding machine solves the technical problems that an existing grinding machine design is not reasonable enough and the like. The machine comprises a lathe body, an adjustable mounting structure, a workbench frame body, a workbench, a rotary driving mechanism, a movable upright post, a grinding machine assembly, a horizontal driving structure and a vertical driving structure; an arc-shaped waterproof cover shell is arranged at the upper end of the workbench frame body, a notch is formed in one side, close to the movable upright post, of the arc-shaped waterproof cover shell, the front end of the grinding machine assembly penetrates through the notch and extends to the inner side of the arc-shaped waterproof cover shell, the side, far away from the movable upright post, of the arc-shaped waterproof cover shell is provided with an operation window, and the operation window is provided with an arc-shaped baffle through a movable connection structure. The grinding machine has the advantages that the lathe body and the movable upright post are designed in a hollowed-out mode, the weight of the machine tool is reduced, the structure of the grinding machine is simplified, so that the grinding machine becomes lighter, and meanwhile, the function characteristics such as the machining precision of the grinding machine are not influenced. The front circular arc-shaped cover is simple and elegant, and the protection area is adjustable.

Owner:德清勤龙磨床制造有限公司

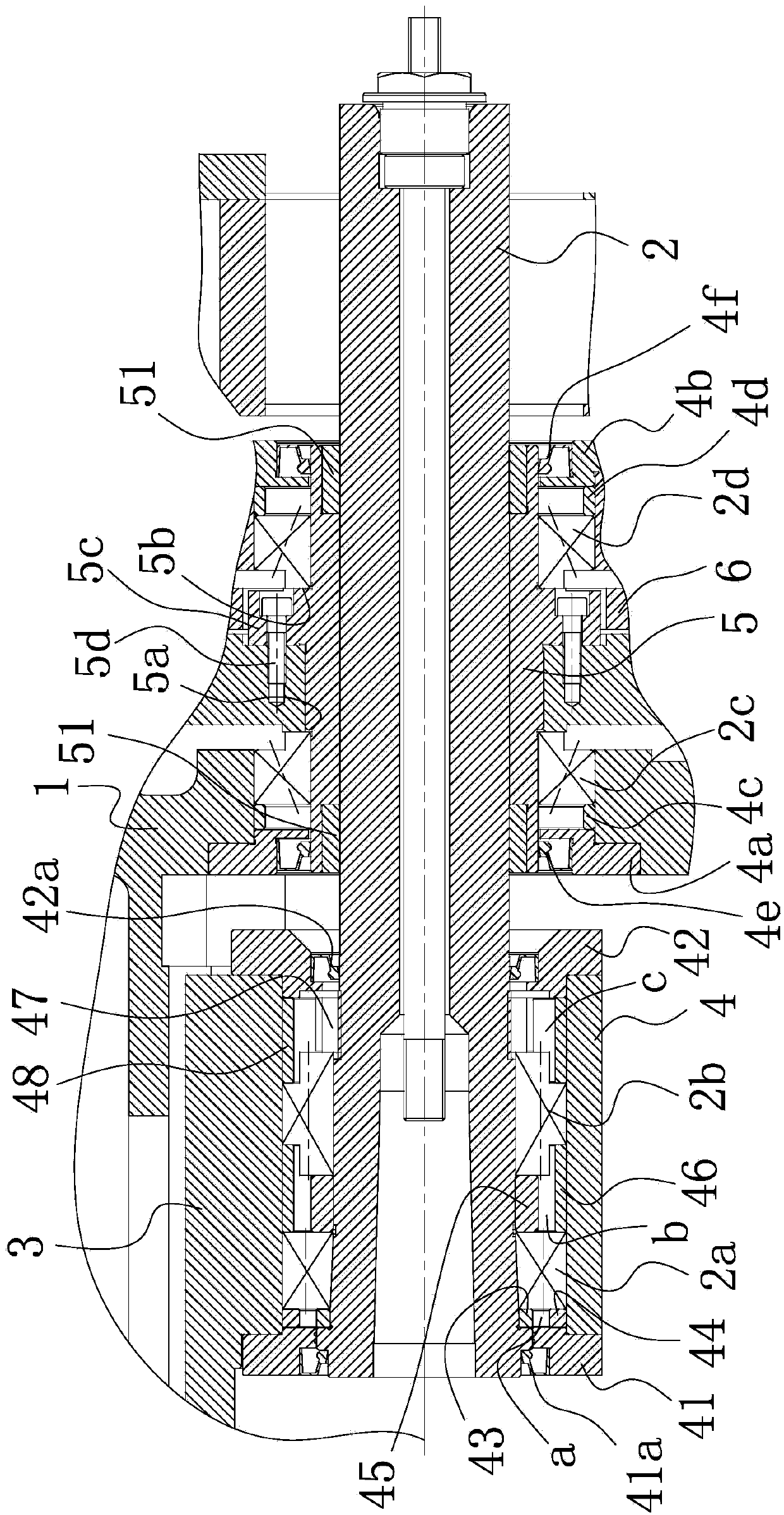

Hobbing cutter main shaft mechanism of CNC gear hobbing machine

InactiveCN103990818AReasonable designImprove structural strengthLarge fixed membersHobbingEngineering

The invention belongs to the technical field of gear hobbing machines, and particularly relates to a hobbing cutter main shaft mechanism of a CNC gear hobbing machine. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine solves the technical problems that practicability is poor in the prior art and the like. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine comprises a cutter rest shell and hobbing cutter main shaft which is arranged in the cutter rest shell in a penetrating mode and can rotate relative to the cutter rest shell, the front end of the hobbing cutter main shaft is inserted into the cutter rest shell and is arranged in a suspending mode, the tail end of the hobbing cutter main shaft penetrates through the cutter rest shell and extends out of the cutter rest shell, a first rolling structure is arranged between the cutter rest shell and the hobbing cutter main shaft, a supporting plate fixedly connected with the cutter rest shell is arranged in the cutter rest shell and is provided with a barrel-shaped locating body which is fixedly connected with the supporting plate and arranged on the periphery of the suspended end of the hobbing cutter main shaft in a sleeved mode, a second rolling structure is arranged between the hobbing cutter main shaft and the barrel-shaped locating body, and an axial locating mechanism used for preventing axial float of the hobbing cuter is further arranged between the hobbing cutter main shaft and the barrel-shaped locating body. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine has the advantages of being high in structural intensity, rigidity and practicability during interrupted cutting.

Owner:浙江嘉力宝精机股份有限公司

Quakeproof support device for industrial robot

InactiveCN110270985AAnti-impact processing and productionReduce vibrationProgramme-controlled manipulatorSupport planeIndustrial robot

The invention discloses a quakeproof support device for an industrial robot. The device comprises a first support plate, a second support plate, a rubber base, a chassis and placing boxes; three turning blocks, distributed in a regular triangle form, are rotationally hinged between the edge positions of the first support plate and the second support plate; rotating blocks are rotationally hinged to the side wall centers of the three turning blocks; the three turning blocks are rotationally hinged with support rods through the rotating blocks; the rubber base is embedded in a placing through hole of the chassis; three adjusting plates, distributed in a regular triangle form, are fixedly welded in the edge position of the top end surface of the chassis; a thread rocking rod penetrates through an adjusting groove, and is rotationally inserted with the back end surface of an inner cavity of the adjusting groove; the thread rocking rod rotationally penetrates through a thread adjusting cylinder through threads; the placing boxes are positioned above the adjusting plates; and the top ends of the three support rods are matched with inner cavities of the three placing boxes. The device conveniently installs the industrial robot, and is high in overall stability, convenient for fine adjustment of the flatness of support planes and convenient to store.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

Working method of milling machine clamp

InactiveCN108296823AShorten the timeReduce auxiliary timePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a working method of a milling machine clamp. The working method of the milling machine clamp includes the following steps that a middle rotating disk is driven to turn, and a pressing connection piece is driven to move to a loading and unloading station, and is kept at the loading and unloading station; a workpiece is replaced; the middle rotating disk is driven to turn, the pressing connection piece is driven to return to a pressing connection station, and the pressing connection piece is kept at the pressing connection station; an adjusting pressing rod is driven to perform downward pressing, and the pressing connection piece is pushed to gradually press the workpiece; a pressure sensor detects a pressure value between the pressing connection piece and the workpiece; when the pressure value is larger than a set value, a lifting driving system stops, and the pressing connection piece is kept at the pressing position; after machining is completed, the adjustingpressing rod is driven to rise, and the workpiece is loosened; and the adjusting pressing rod rises to the set position. The working method of the milling machine clamp can achieve that a plurality ofworkpieces are loaded and disassembled at a time, the basic time and the auxiliary time for workpiece machining are shortened to a great extent, and the production efficiency is effectively improved;and the clamping pressure on the workpiece can be automatically adjusted, and the application range is wide.

Owner:太仓市万丰塑料制品有限公司

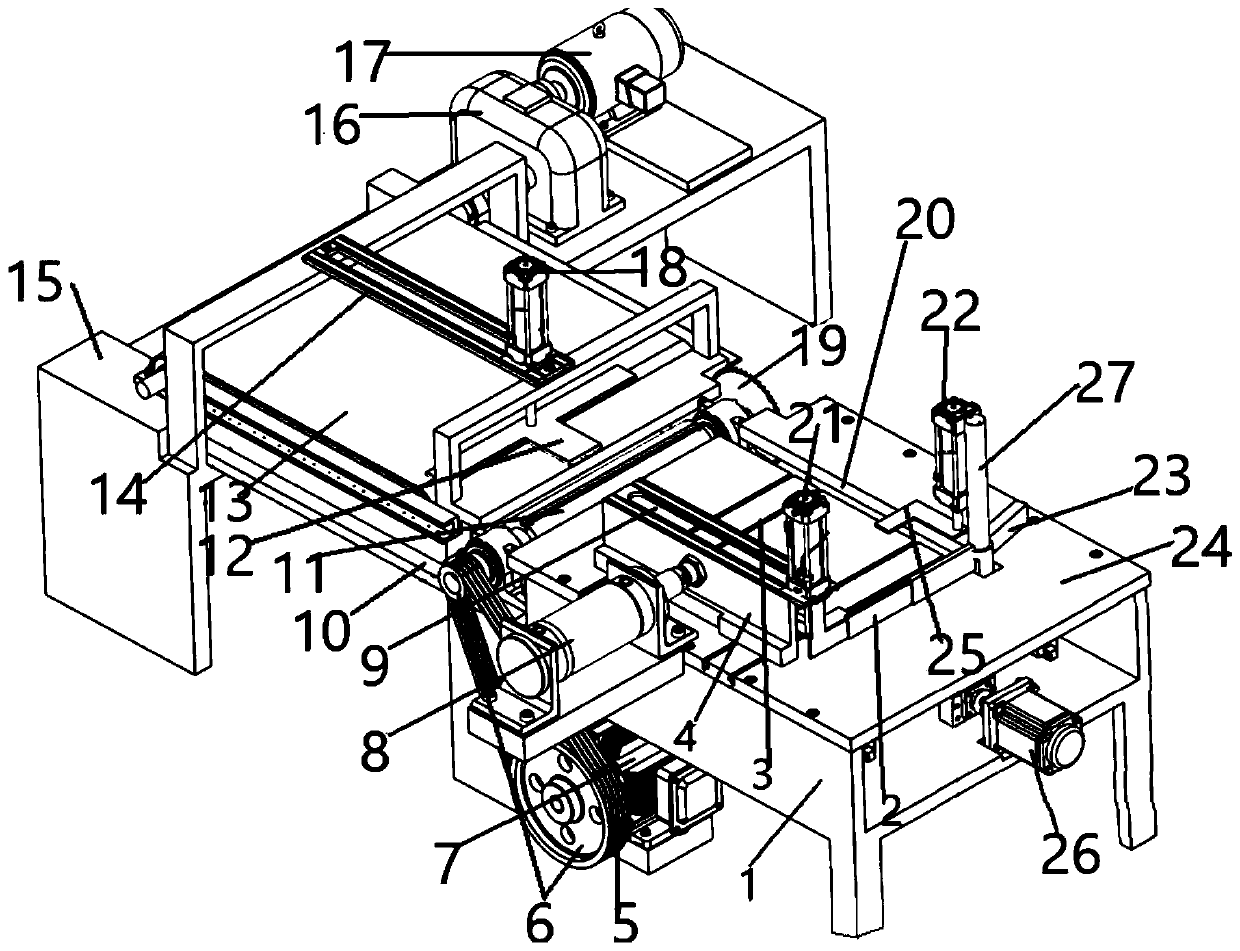

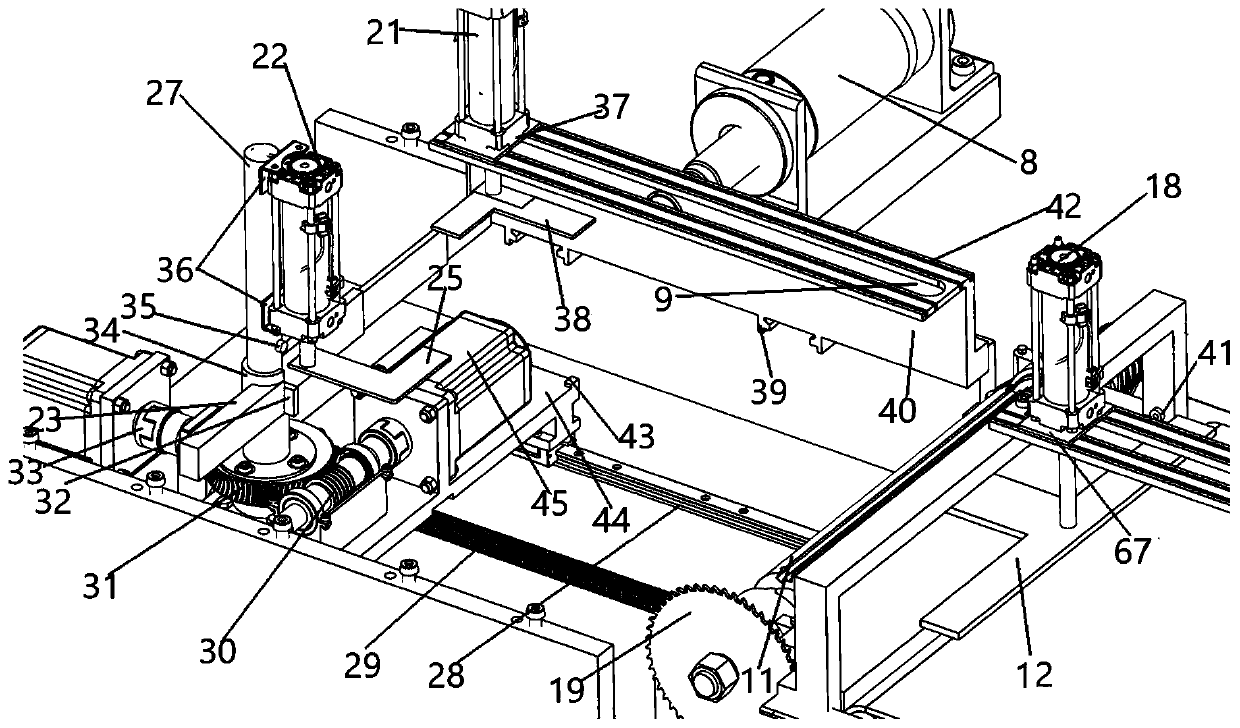

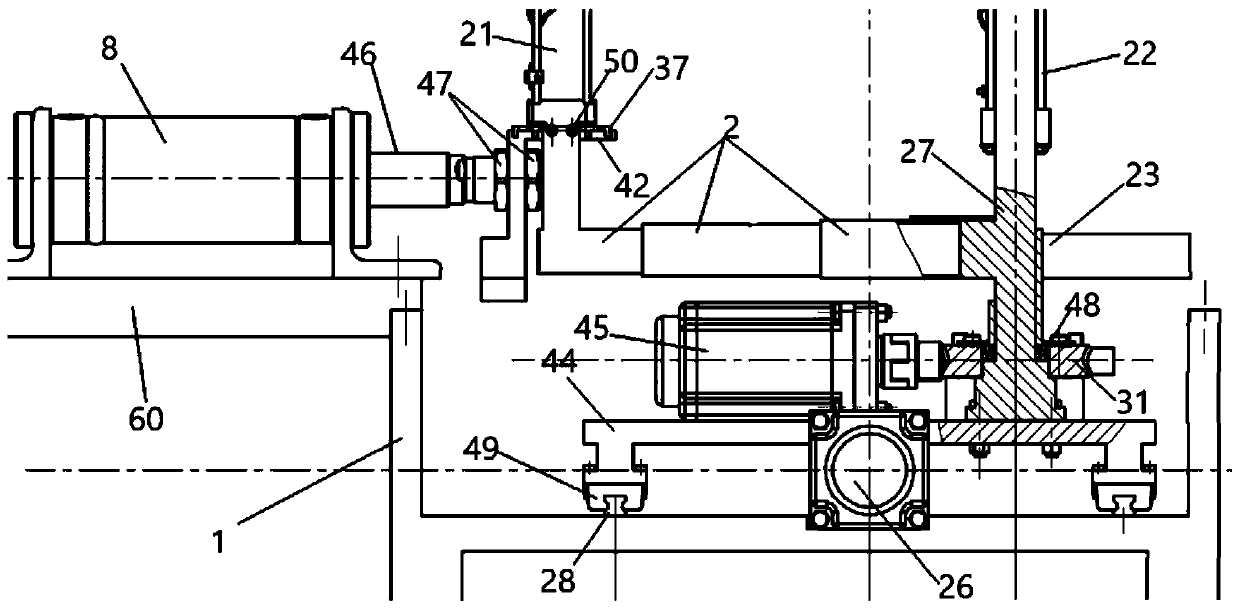

Plate-type wood multifunctional processing machine tool and using method thereof

ActiveCN110340997ADoes not affect machining accuracyWide adaptabilityMulti-purpose machinesCircular sawsPistonProcessing accuracy

The invention discloses a plate-type wood multifunctional processing machine tool and a using method of the plate-type wood multifunctional processing machine tool. The machine tool comprises a machine base, a workbench, a discharge conveyor belt, a cutter device, a wood board longitudinal positioning device, a wood board angle positioning device, a wood board pressing device, a wood board propelling device, a laser sensor and a PLC. The machine tool can be used for straight material planing, straight cutting sawing and angle sawing of wood boards. The machine tool has the beneficial effects that the wood board is pressed on the workbench by a piston pressing plate of an air cylinder in the processing process, and the situation that the wood board changes the direction due to the reactionof cutting force or vibration when sliding on the workbench so as to affect processing precision is avoided; a ball screw is adopted to control the automatic feeding of a pushing plate, the feeding speed can be adjusted according to different working conditions, and the adaptability is wide; by adopting a self-locking worm gear and worm transmission mechanism to position the angle of the wood board, it can be ensured that the positioning angle of the wood board is not changed due to the reaction of cutting force in the sawing process, and the sawing precision of the angle is guaranteed; the automation degree is high, the labor intensity is low, the machining precision is high, and meanwhile, safety accidents caused since two hands mistakenly touch a tool rotating at a high speed during manual feeding can be avoided.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com