Vacuum sucking disc device of novel numerical control machine tool

A vacuum suction cup, CNC machine tool technology, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of affecting processing accuracy, deformation of metal sheets, scrap of metal sheets, etc. The effect of improving the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

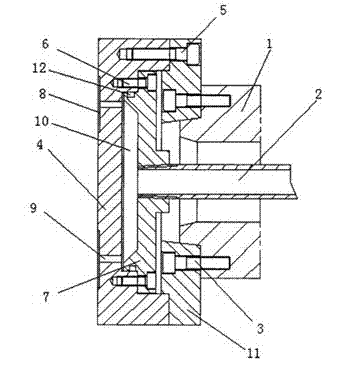

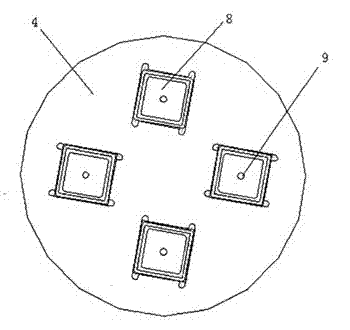

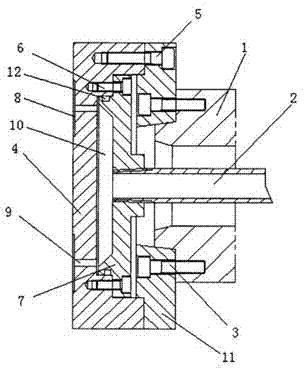

[0012] Such as figure 1 , 2 As shown, this embodiment consists of a clamp 4 , a vacuum tube 2 , a sealing block 7 and a connecting block 11 . Wherein, the connection block 11 is directly connected to the machine tool spindle 1 through the spindle screw 3, the clamp 4 is covered on the connection block 11, the clamp 4 and the connection block 11 are connected by the clamp screw 5, and the clamp 4 and the clamp 4 are arranged between the clamp 4 and the connection block 11. Closely connected sealing block 7, the sealing block 7 is connected with the fixture 4 through sealing screws, the sealing block 7 is provided with a sealing strip 12, the space between the sealing block 7 and the fixture 4 is a vacuum groove 10, and the sealing strip 12 ensures the vacuum groove 10 degrees of vacuum. The vacuum tube 2 is arranged in the main shaft 1 of the machine tool, one end of the vacuum tube 2 communicates with the device for vacuuming, and the other end communicates with the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com