Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

772results about How to "Guaranteed vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

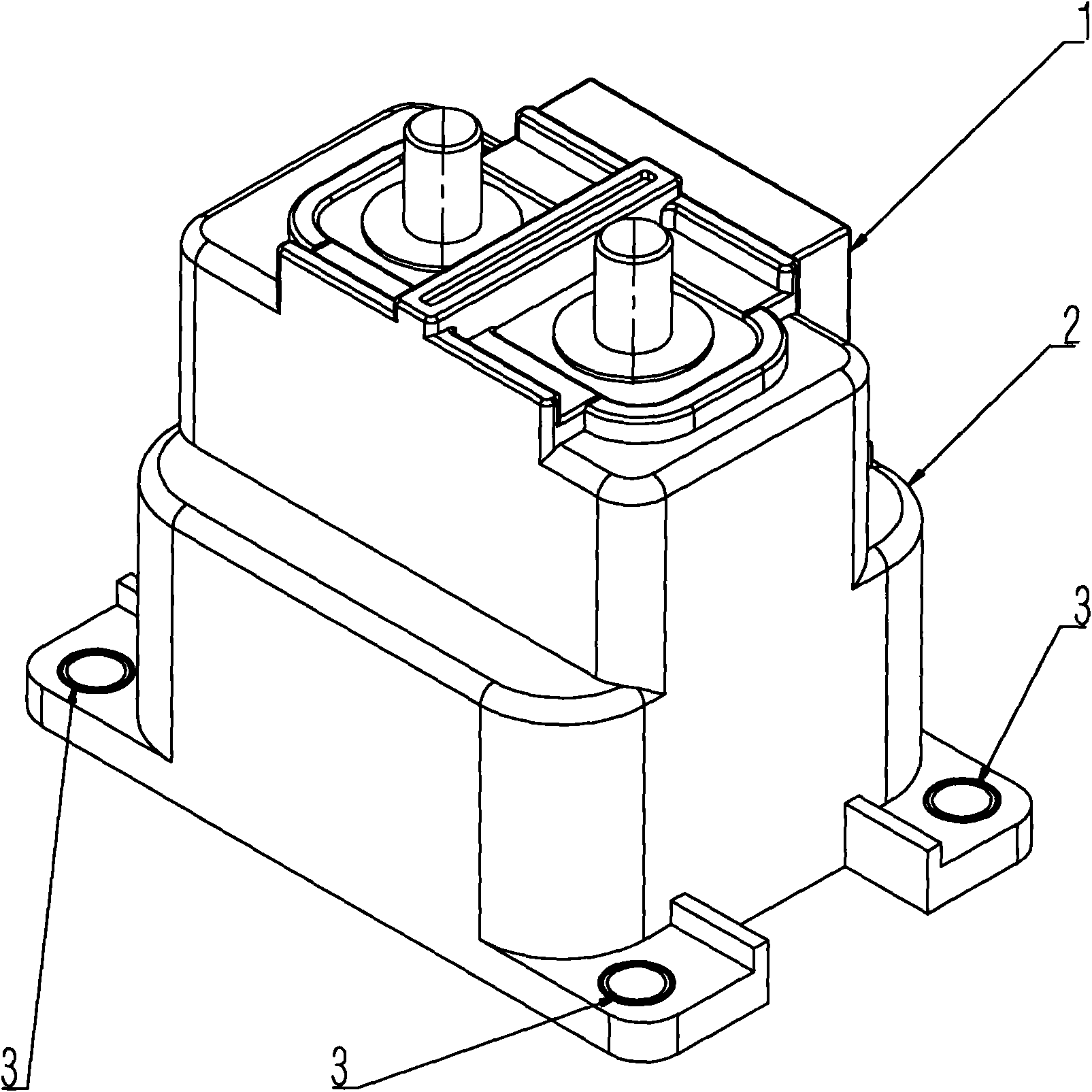

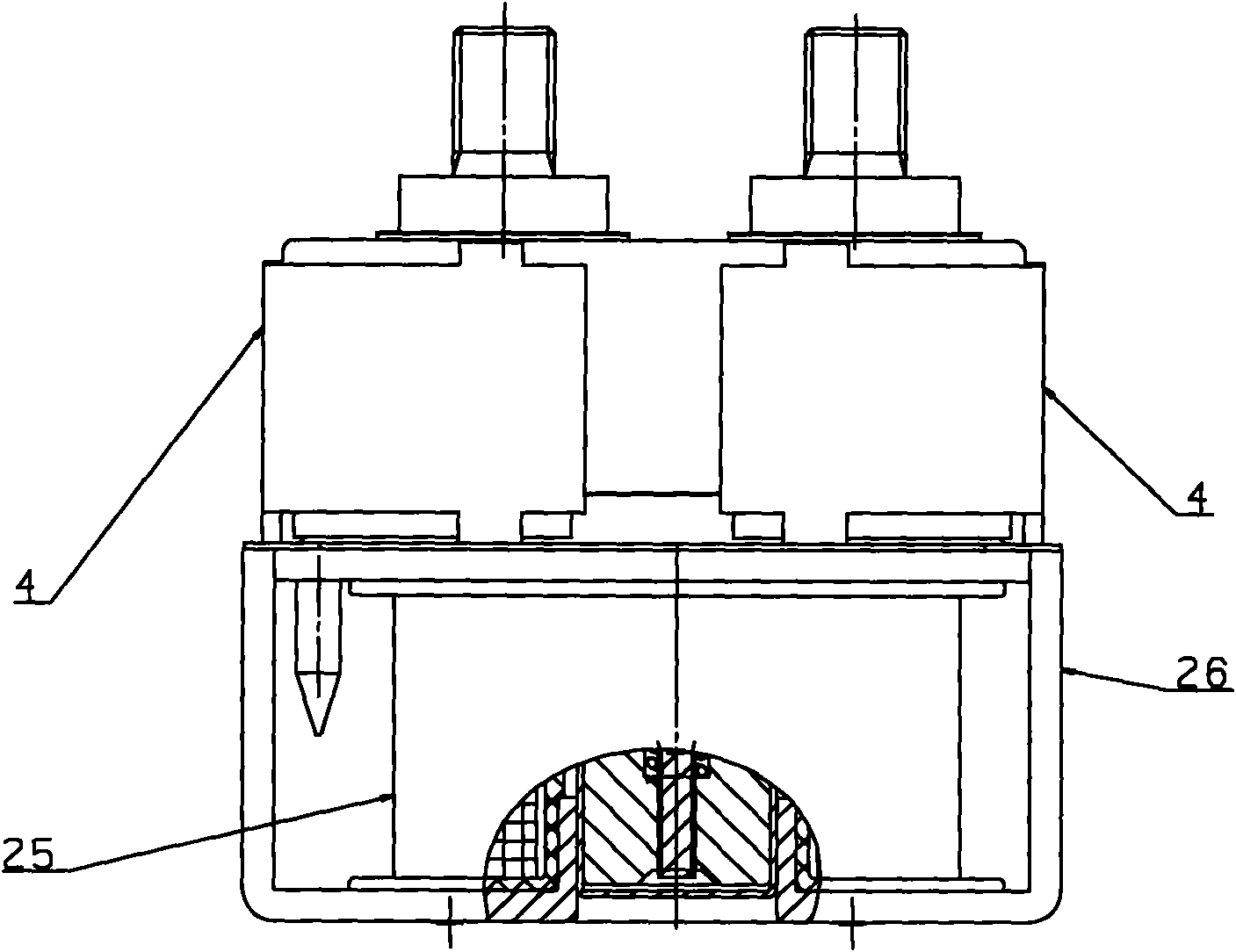

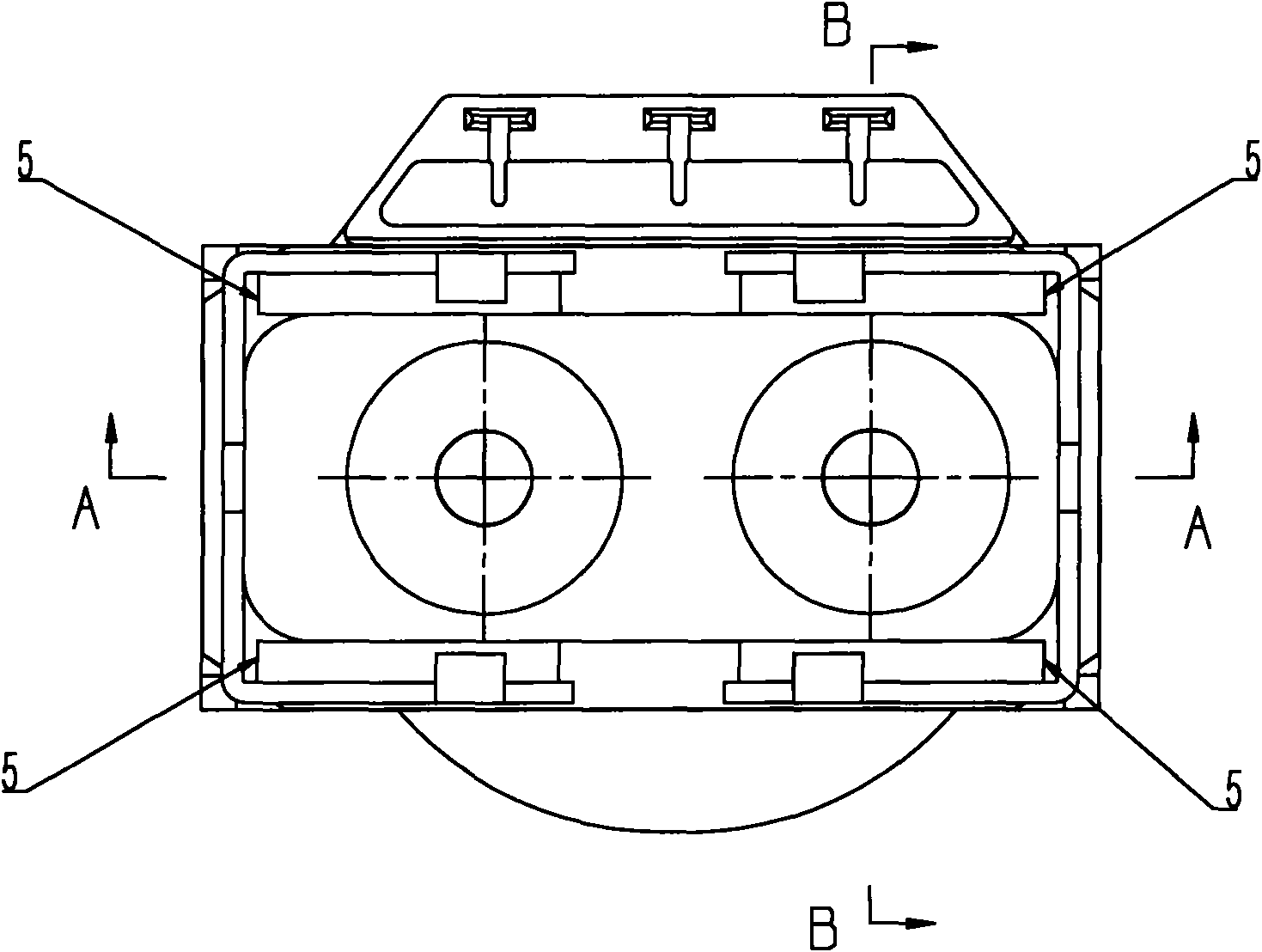

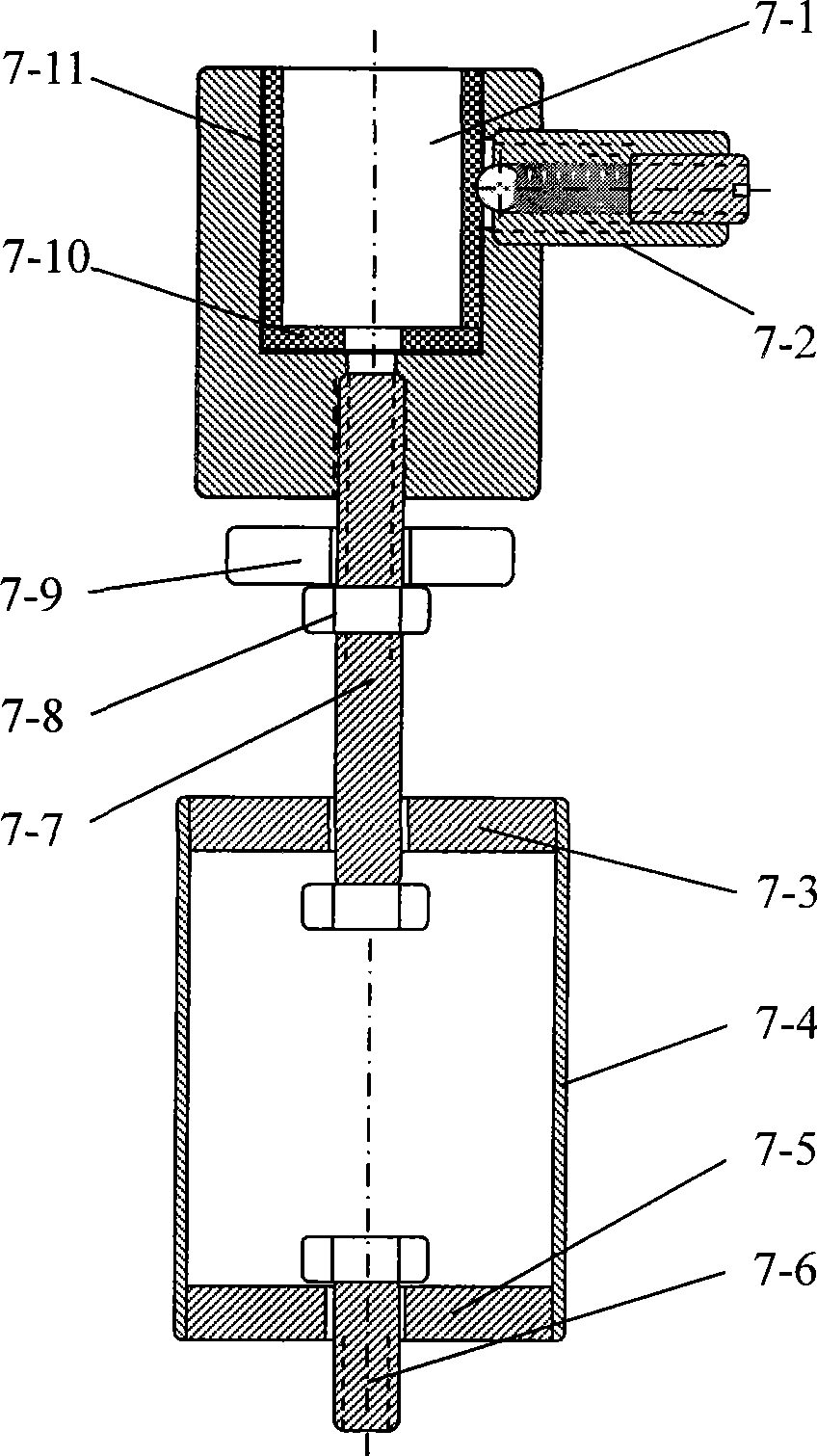

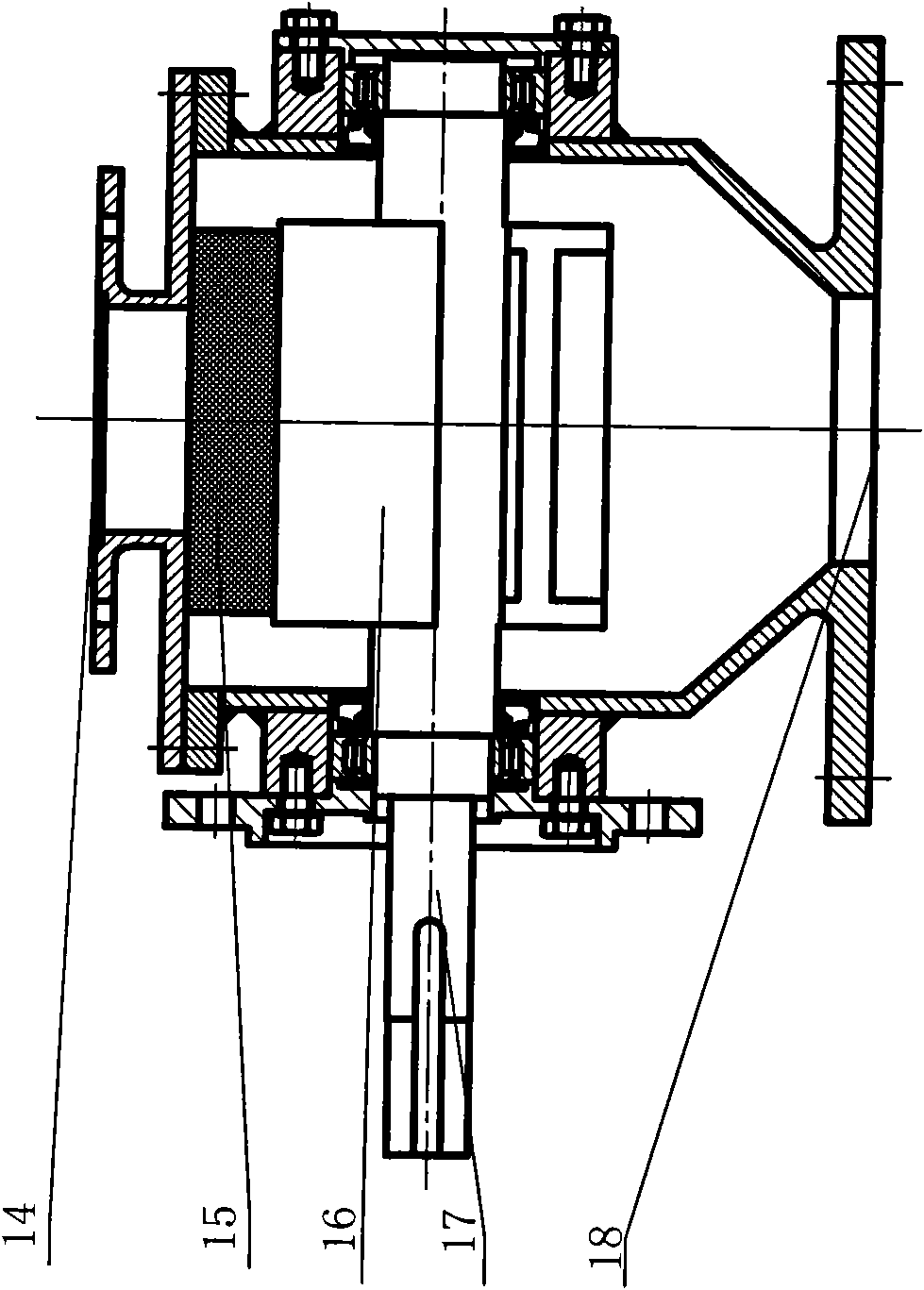

High voltage DC vacuum relay with high reliability and long service life

ActiveCN101677044AGuaranteed arc breaking capabilityImprove insulation performanceElectromagnetic relay detailsNon-polarised relaysShock resistanceHigh pressure

The invention discloses a high voltage DC vacuum relay with high reliability and long service life, which is arranged inside a vacuum cavity body that is sealed and connected by meal and ceramic; a ceramic insulator is connected between a movable contact component and a push rod in a sliding way; the good vacuum performance and electric insulation performance of the ceramic insulator can be utilized to lead the movable contact and a fixed contact to main good electric insulation together with a magnetic circuit system formed by a magnetic guide yoke iron plate of the relay, an iron core and the like no matter in a state of connection or disconnection, so that current interruption capability of the relay can be guaranteed when DC high-voltage load is switched; a vacuum chamber body and allparts in side the vacuum chamber body formed by the high voltage DC vacuum relay have low enough saturated vapor pressure and are treated by high temperature baking exhaust, so that the vacuum degreein the vacuum chamber body can ensure the work demand of the relay on switching heavy current and the DC high-voltage load for a long time; furthermore, the relay also has the advantages of simple andcompact structure, small volume, light weight, strong shock resistance and impact resistance, simple technique process, low production cost and large batch production.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

Silica gel based carbon material oriented heat conduction interface material and production method thereof

The invention relates to a silica gel based carbon material oriented heat conduction interface material. The material comprises components in percentage by weight as follows: 9.5%-20% of siloxane-based resin with the viscosity being 200 cp-2,000 cp, 19.5%-35% of heat conductive filler, 35%-70% of an anisotropic carbon material and 1%-10% of an auxiliary agent and is prepared with a stirring and curing production method. The silica gel based carbon material oriented heat conduction interface material has the advantages as follows: according to the heat conductive interface material prepared by mixing the siloxane-based resin with the viscosity being 200 cp-2,000 cp, the heat conductive filler, the anisotropic carbon material and the auxiliary agent, the anisotropic carbon material mixed in gel is orientated through electric fields on upper and lower surfaces, longitudinal orientation of the carbon material is realized, the conduction path of the heat conductive material is in the direction where the large heat conduction coefficient is large, and the heat conduction performance is realized to the maximum; with the addition of the heat conductive filler, the defect that the heat conduction performance of the carbon material in direction, perpendicular to the orientation direction, of the carbon material, namely, in the horizontal direction of mixed gel, is poor after the anisotropic carbon material is orientated is overcome, balanced conduction of heat is guaranteed, and a production method is simple.

Owner:PINGHU ALLIED IND

Steam type spraying-dead steam direct absorption type compound heat pump system

InactiveCN104390388AEfficient use ofReduce pump powerMechanical apparatusFluid circulation arrangementSteam pressureNet return

The invention discloses a steam type spraying-dead steam direct absorption type compound heat pump system. The steam type spraying-dead steam direct absorption type compound heat pump system comprises an absorber, a generator, a condenser and a spraying device; low-temperature dead steam is directly introduced into the absorber and is absorbed by a working medium in the absorber; a working medium outlet of the absorber is connected with a working medium inlet of the generator by a pipeline; a working medium outlet of the generator is connected with a working medium inlet of the absorber by a pipeline to form a working medium loop; heat net returned water is heated by the absorber and the condenser in sequence and is used as heat net supply water to be output. According to the steam type spraying-dead steam direct absorption type compound heat pump system, the spraying device is introduced, and middle-pressure steam formed by low-pressure steam generated by utilizing a high pressure inlet steam to inject the generator is used as driving steam of a heat pump so that the operation unsafety problem of the system, caused by the fact that the steam pressure is too high is avoided; meanwhile, the efficient utilization of steam energy is realized; the heat pump system is used for directly absorbing the low-temperature dead steam and an evaporator link in a traditional heat pump system is saved; the system investment is reduced; meanwhile, a middle heat exchanging process is reduced so that the system performance is greatly improved.

Owner:XI AN JIAOTONG UNIV

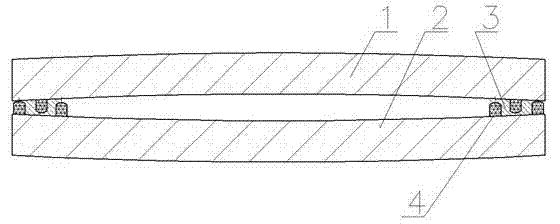

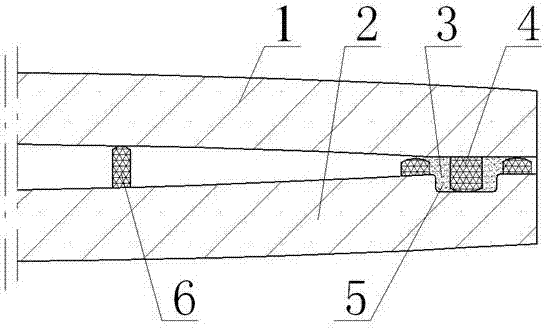

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

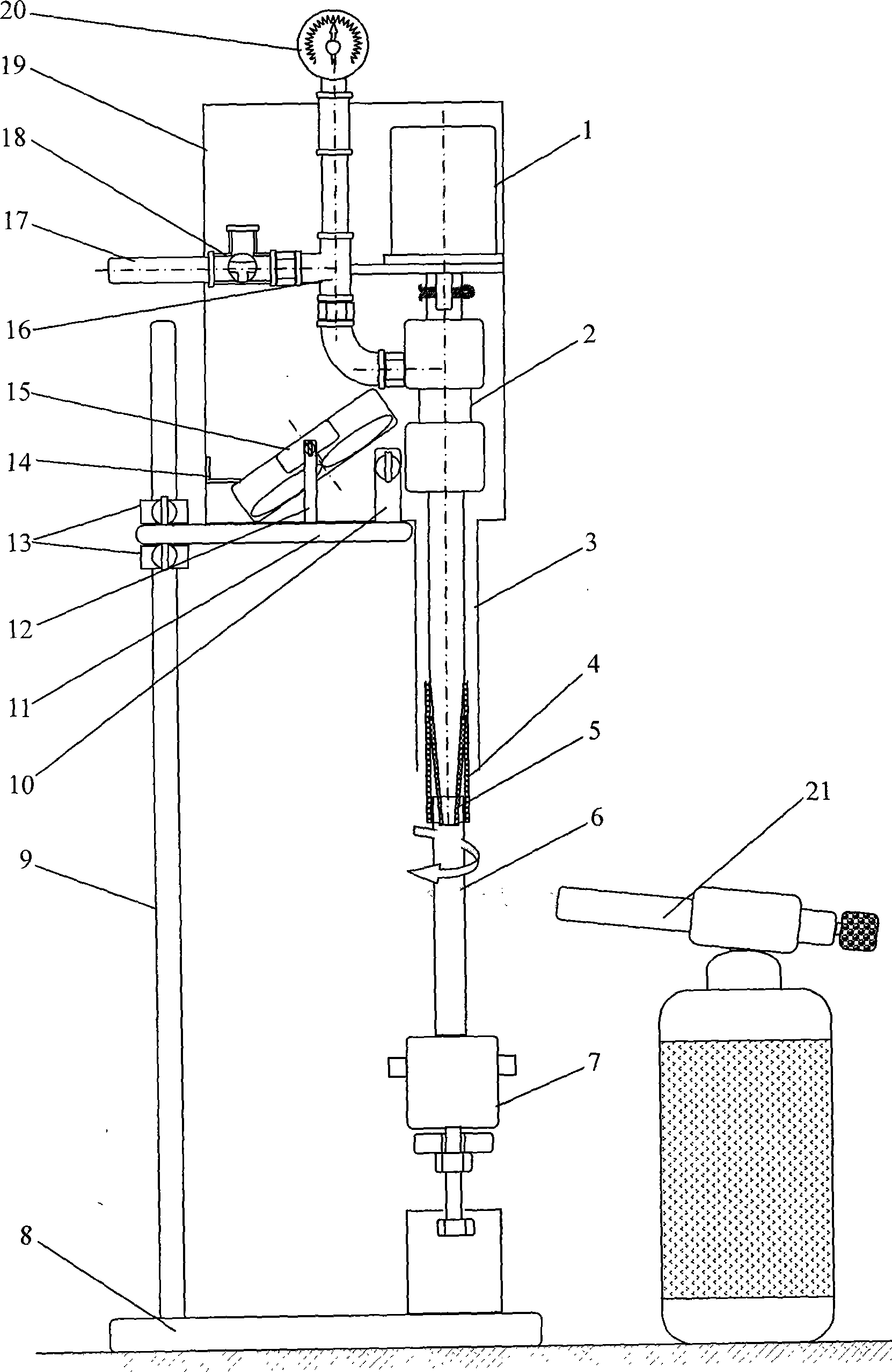

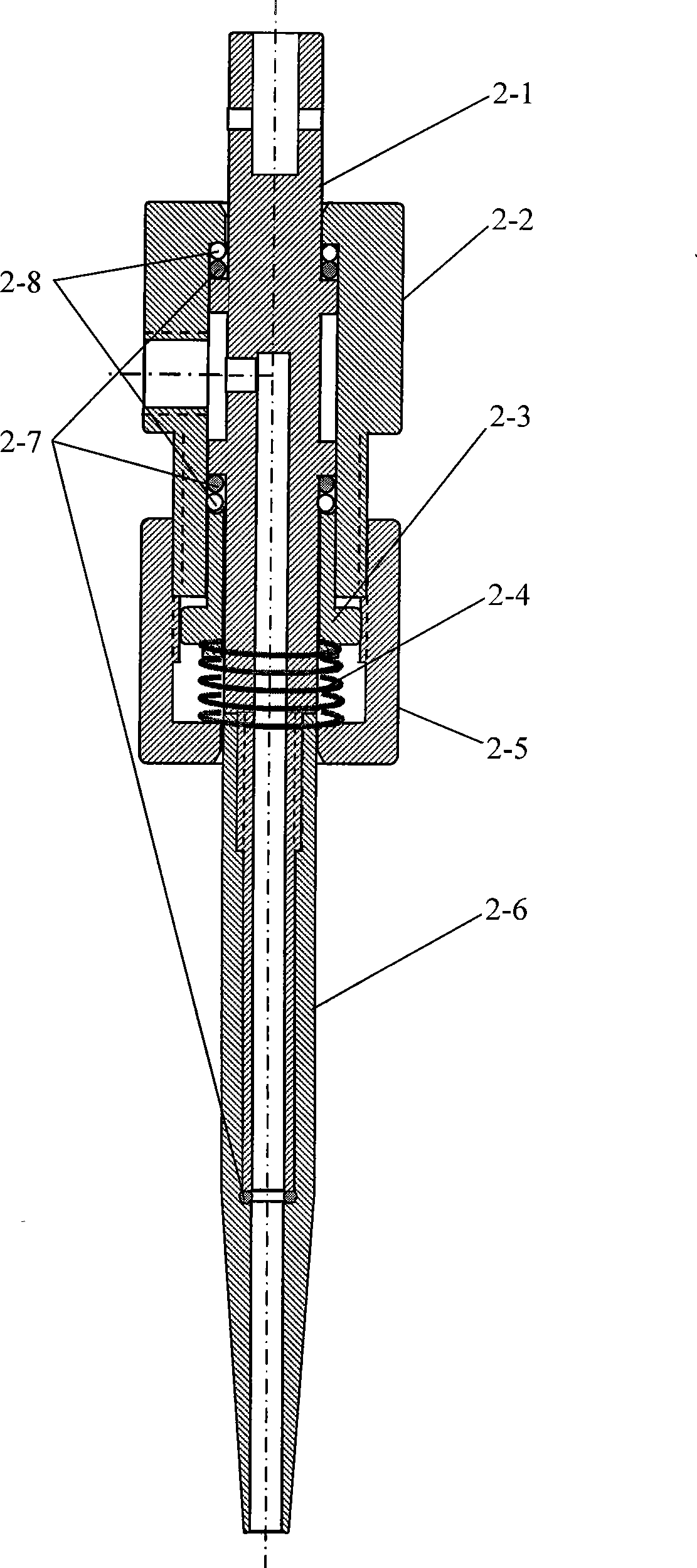

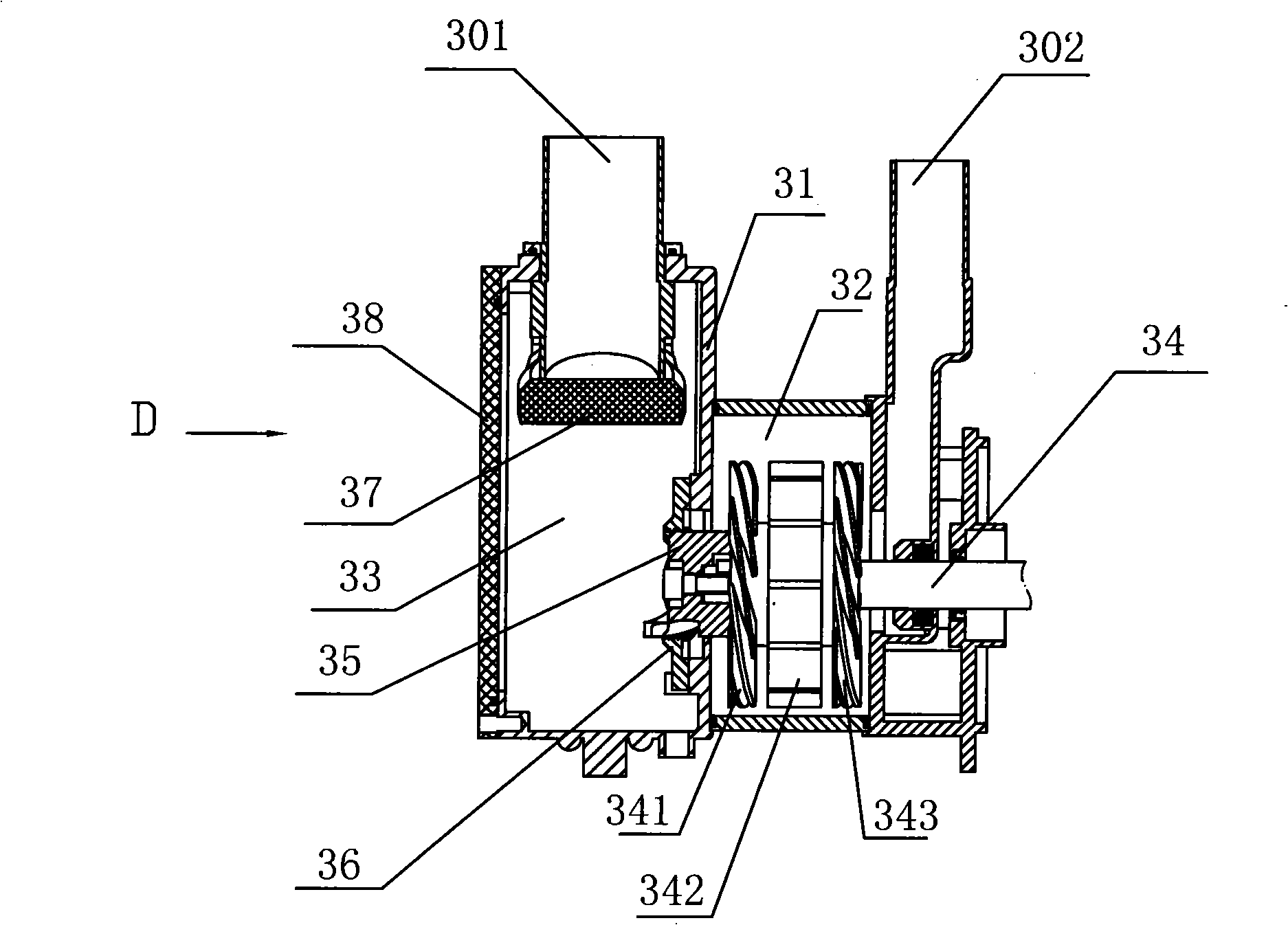

Vacuum ampoule fusion sealing machine

InactiveCN101475303AGuaranteed vacuumGuaranteed drynessGlass reforming apparatusFlavorWhole blood product

The invention provides a vacuum ampoule sealing machine, and relates to the technical field of biochemical experiment equipment. The vacuum ampoule sealing machine mainly comprises a rotary type vacuum connector, a rotary drawing ampoule or a test tube clamp, a lifting bracket and a sealing and heating device. The vacuum ampoule sealing machine has the advantages that the vacuum ampoule sealing machine overcomes the defects of the prior art, has the characteristics of simple structure, convenient operation, high efficiency, good sealing quality and high qualification rate (as high as 100 percent), is particularly suitable for long-term oxygen isolation sealing preservation of little biochemical products or samples which are easily oxidized, decomposed, denatured and inactivated in air and frozen and dried in an ampoule or a test tube, such as microbe strains, animal and plant cells or tissues, vaccine, viable bacteria preparation, enzyme preparation, active protein, blood products, flavor food, health-care food and biochemical drugs, and suitable for vacuum sealing preservation of all oxygen-sensitive biological and chemical substances.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

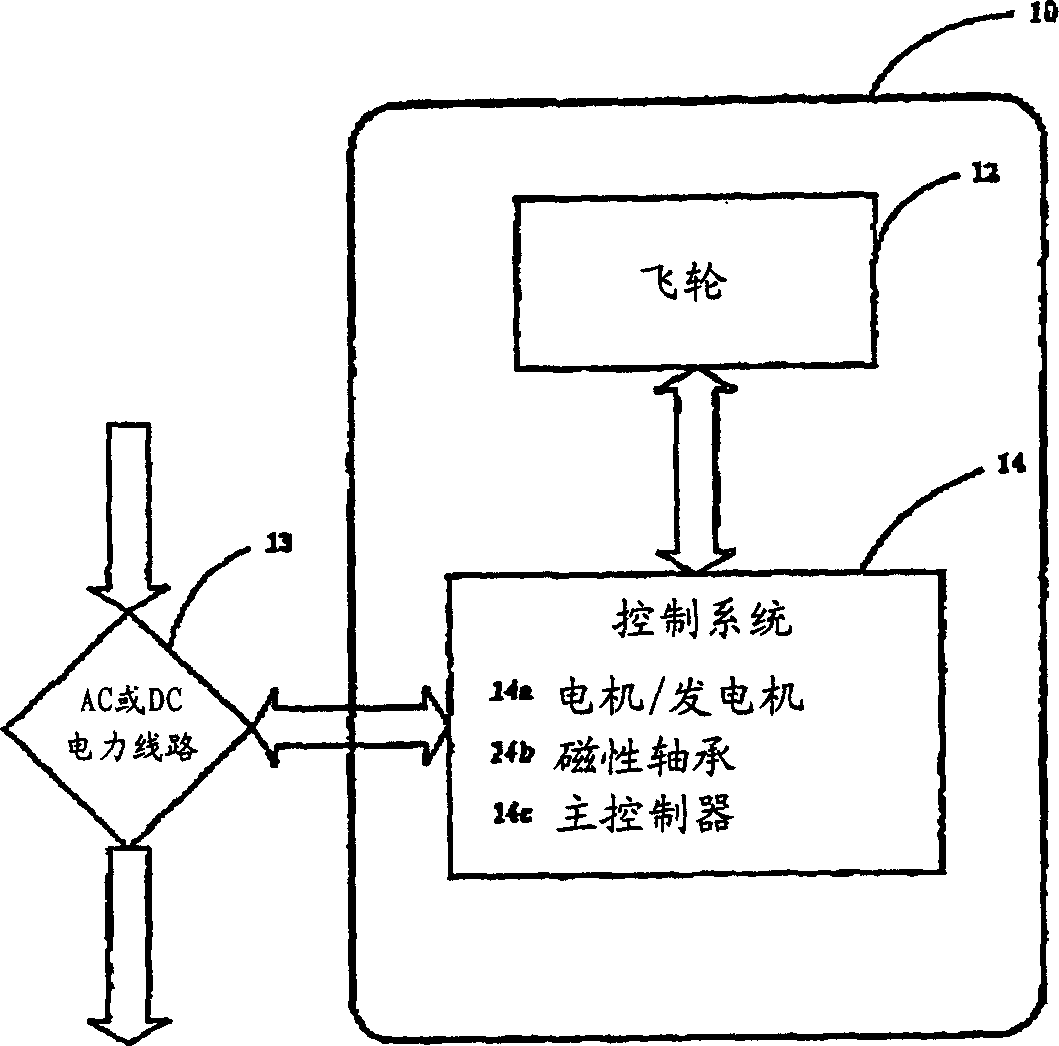

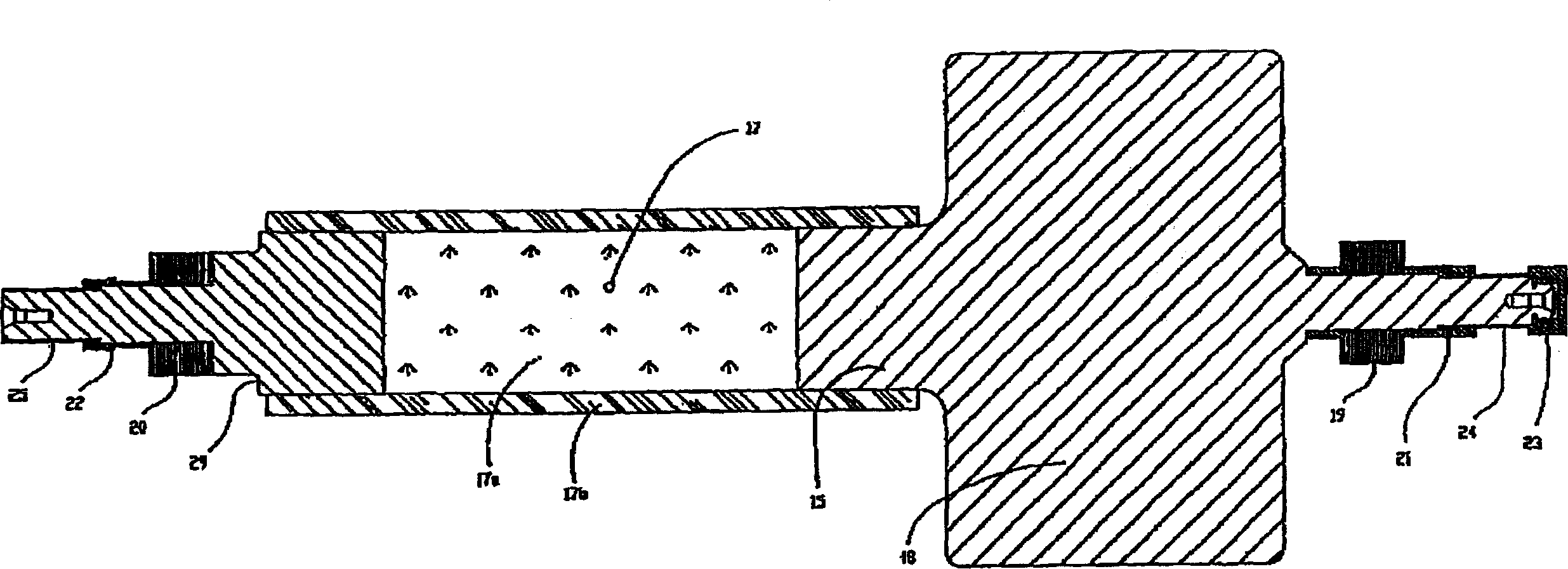

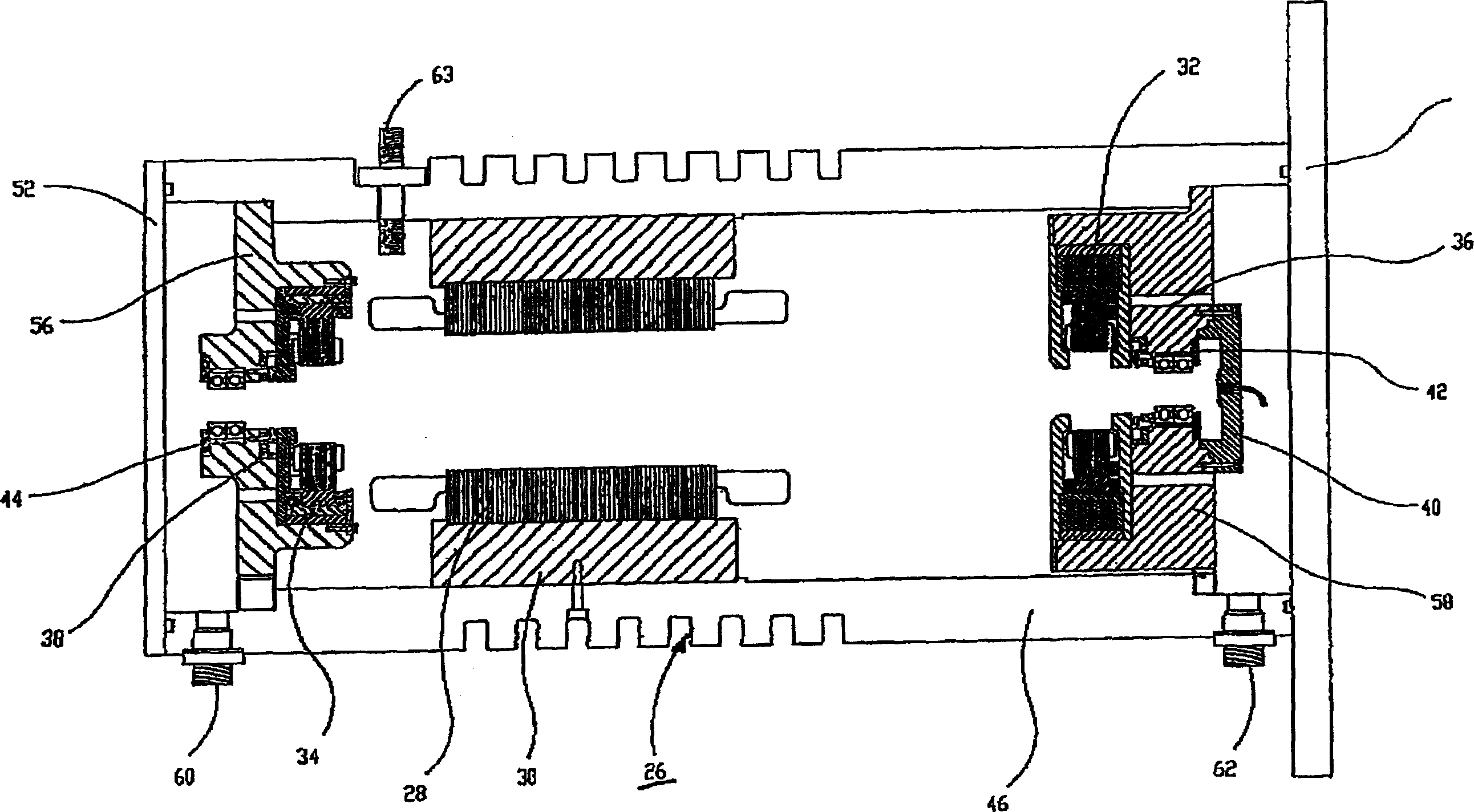

Energy storage flywheel with minimum power magnetic bearing and motor/generator

InactiveCN1759518AImprove power densityLow costMagnetic circuit rotating partsEngine componentsMagnetic bearingElectric machine

An optimized flywheel energy storage system utilizing magnetic bearings, a high speed permanent magnet motor / generator, and a flywheel member. The flywheel system is constructed using a high strength steel wheel for kinetic energy storage, high efficiency magnetic bearings configured with dual thrust acting permanent magnet combination bearings, and a high efficiency permanent magnet motor generator. The steel wheel provides a cost effective, high speed construction for the energy storage rotor.

Owner:帕特里克·T·麦克马伦 +1

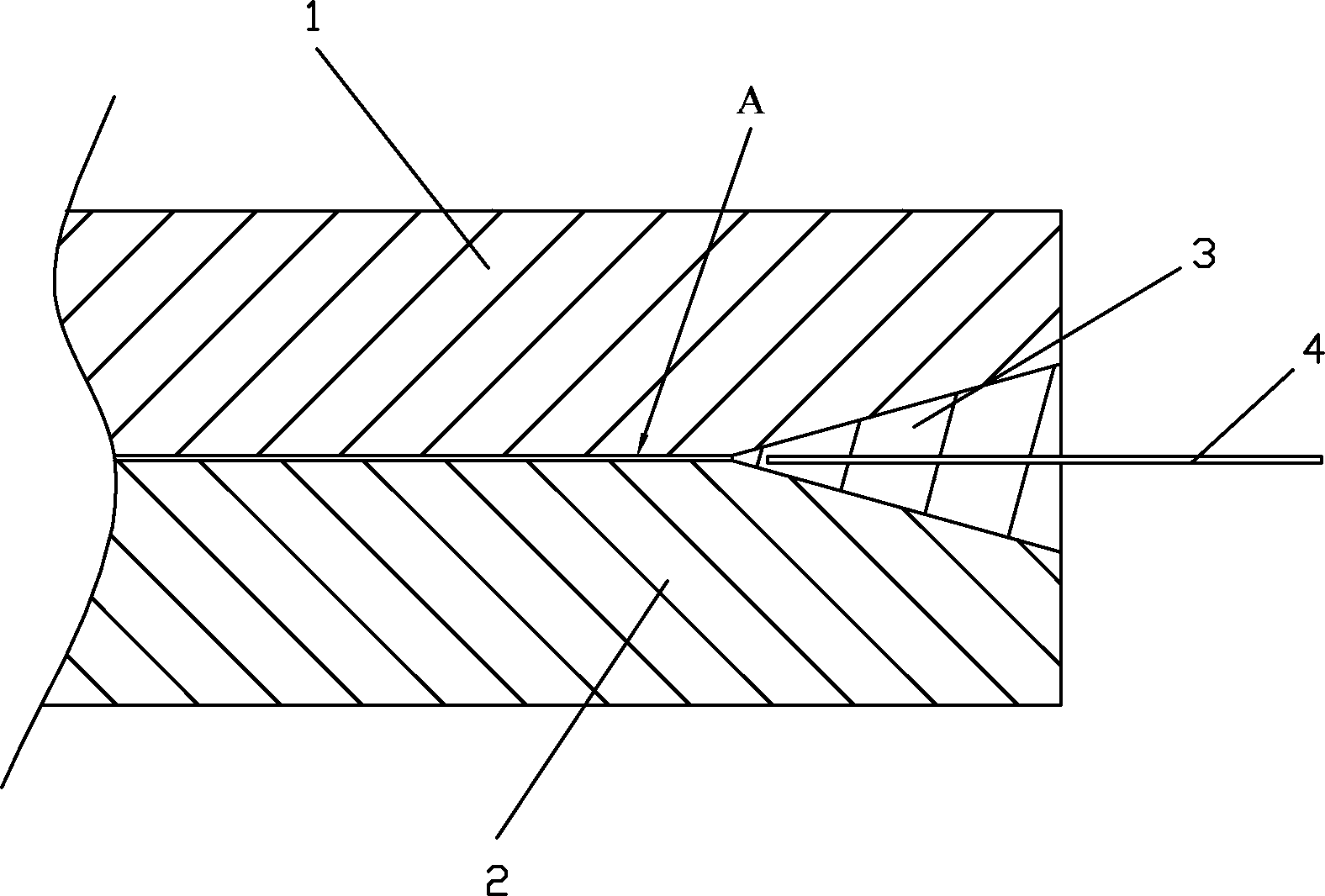

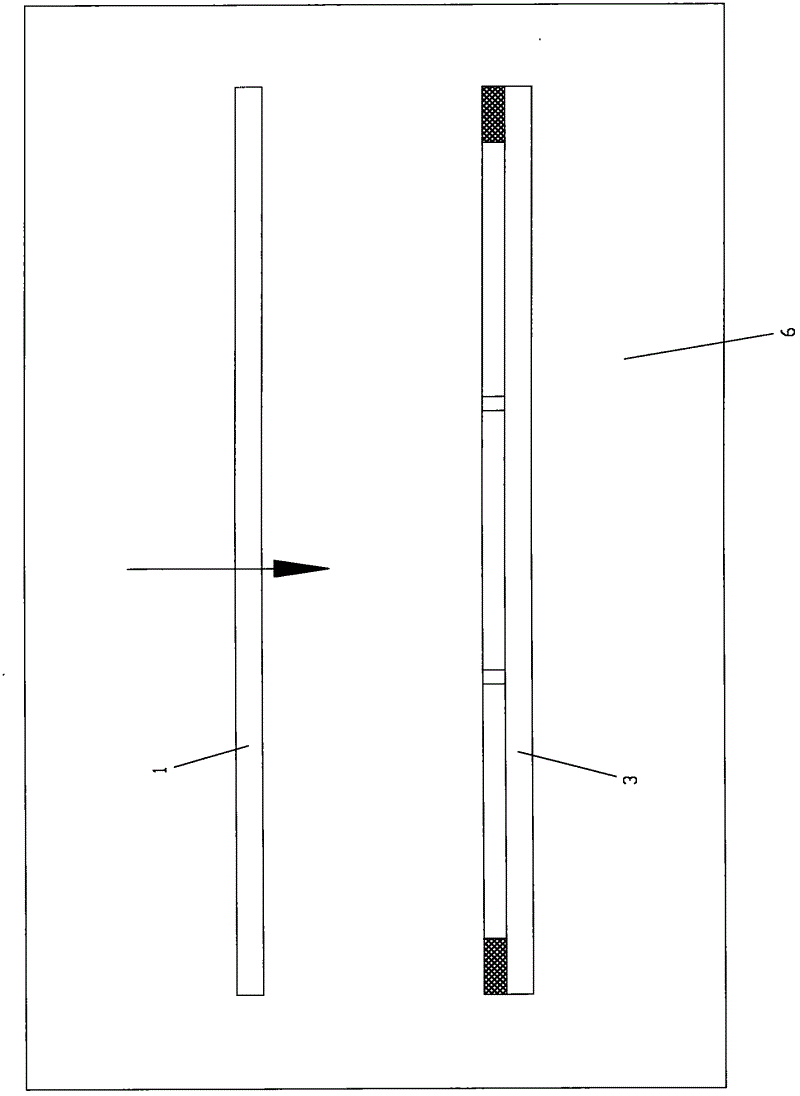

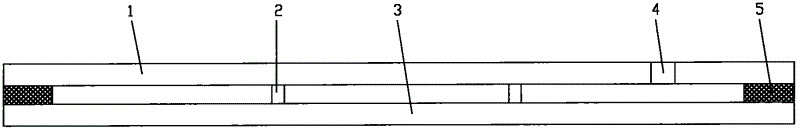

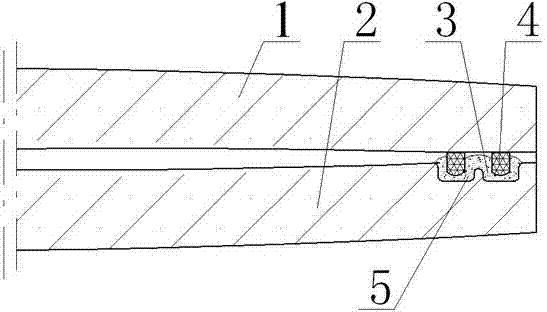

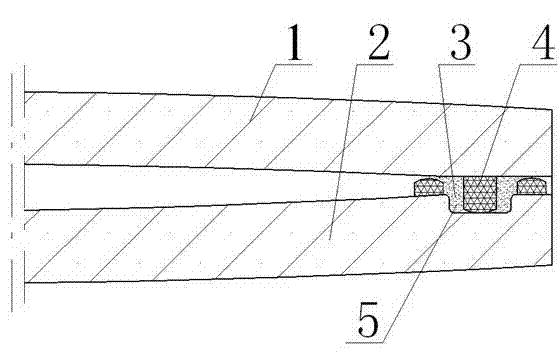

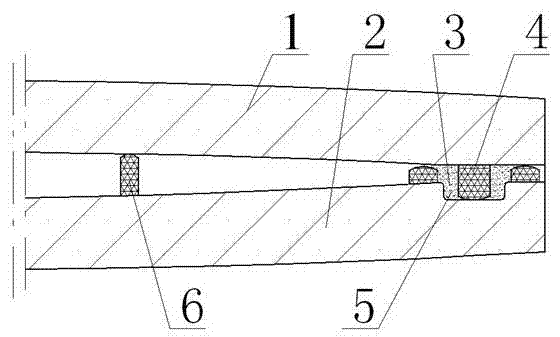

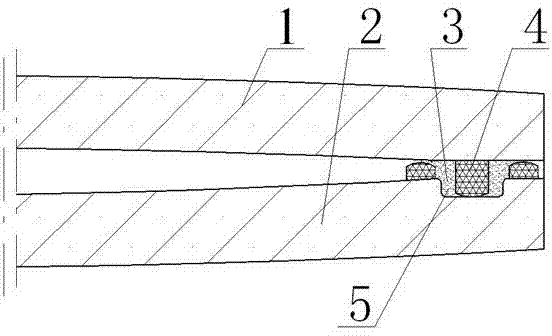

Manufacture method of all-optical fiber heavy pressure gas chamber based on hollow photon crystal optical fibre

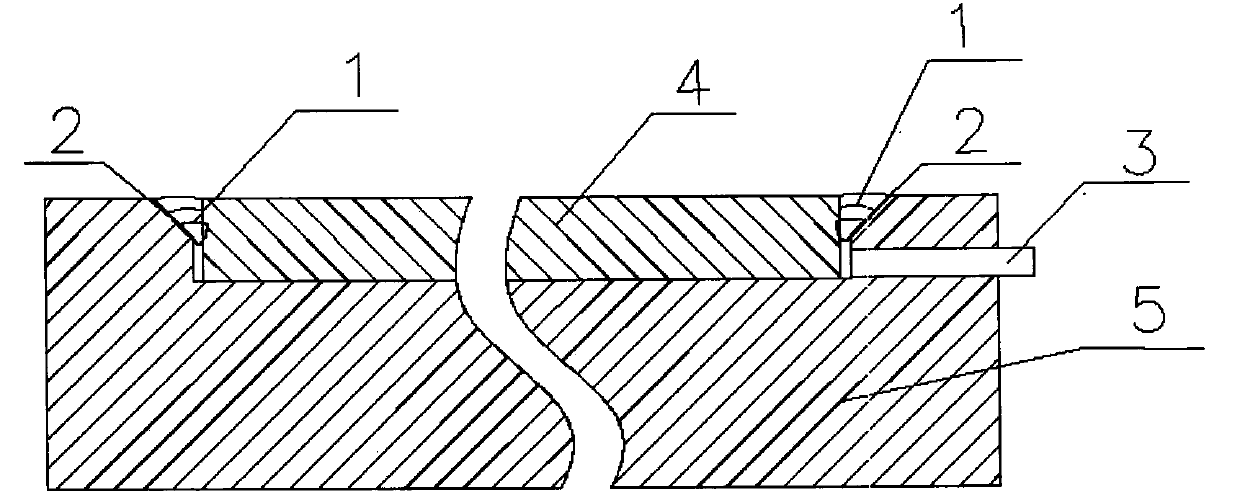

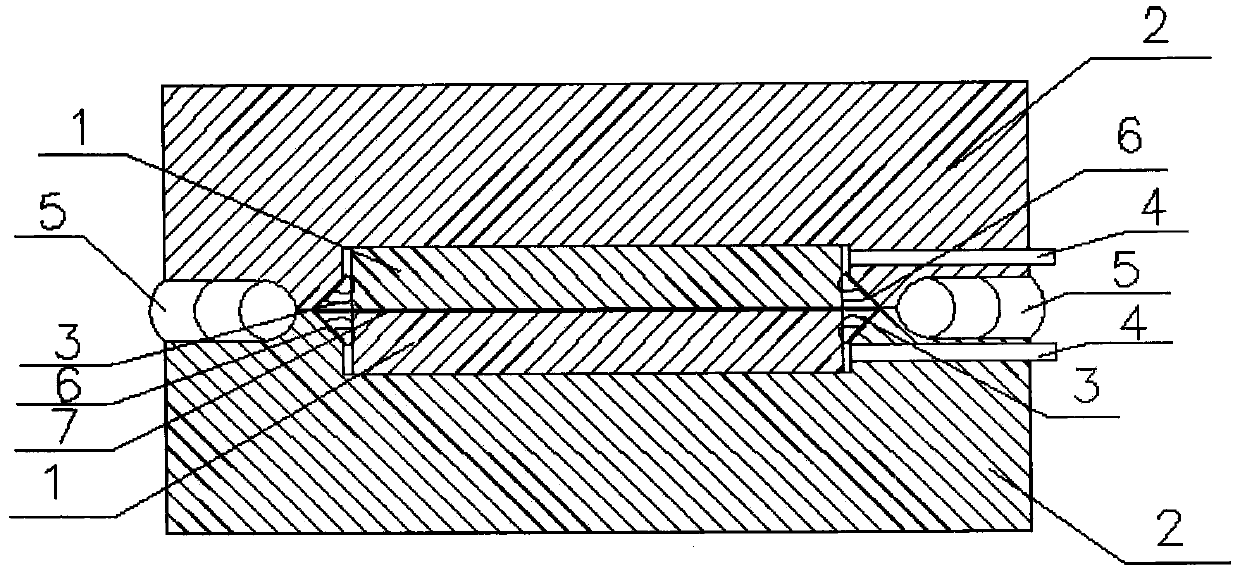

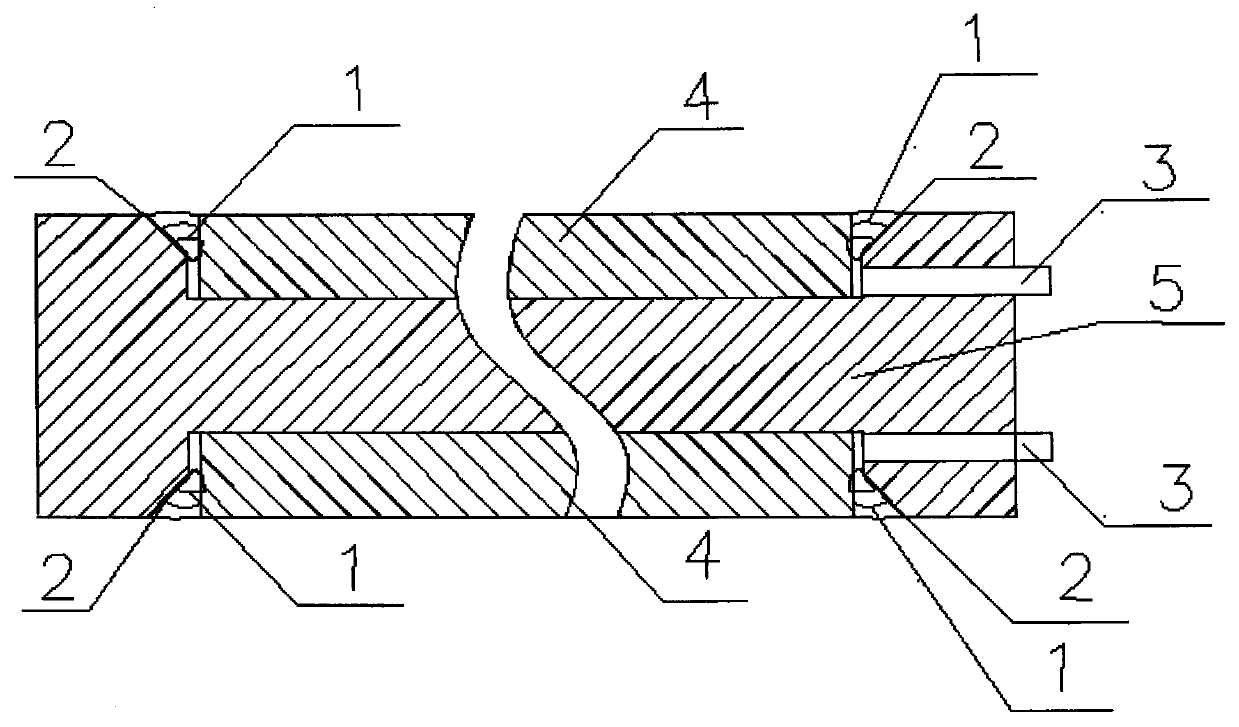

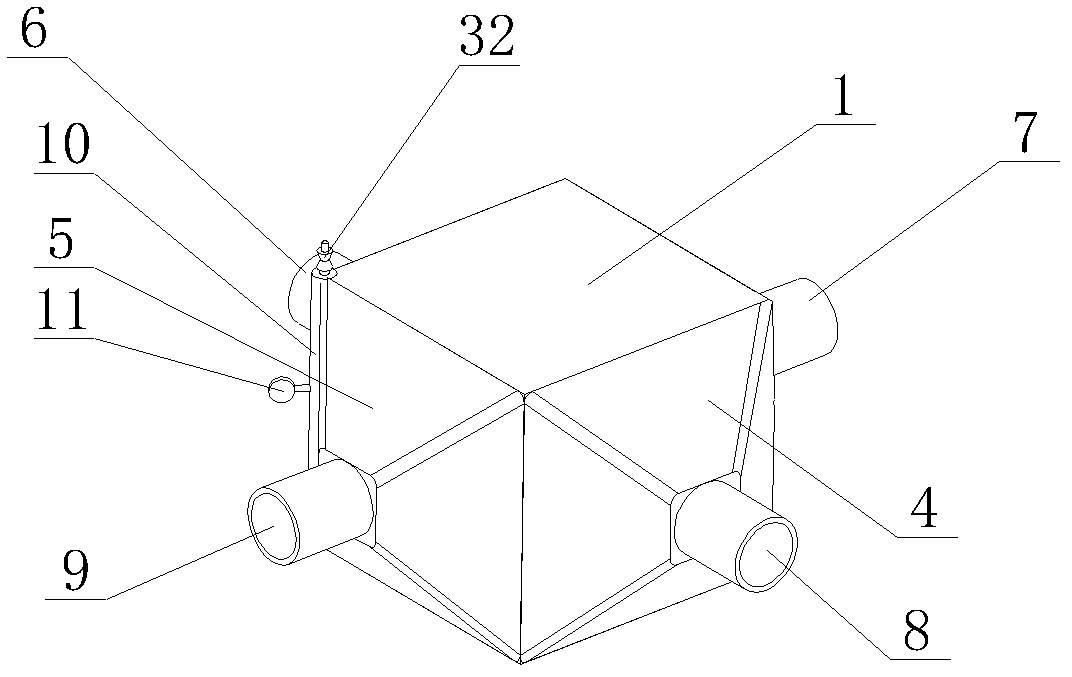

InactiveCN101285908AGuaranteed certaintyGuaranteed vacuumCladded optical fibreOptical waveguide light guideDistillationEngineering

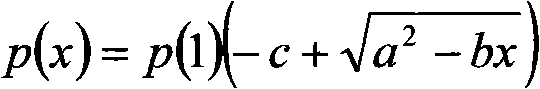

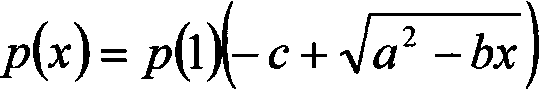

The invention discloses a manufacturing method for a full optical fiber high-pressure gas chamber based on a hollow-core photon crystal fiber. The steps of the invention are as follows: a) two ends of a hollow-core photon crystal fiber (1) are respectively communicated with an airtight A chamber (2) and an airtight B chamber (3), and one end of gas distribution equipment (4) is communicated with the airtight B chamber (3), and the other end of the gas distribution equipment (4) is respectively connected with a vacuum pump (5) and a gas source (6) to be inflated; b) the airtight B chamber (3) is connected with the vacuum pump (5) through the gas distribution equipment (4) first, after the required vacuum degree is achieved, the airtight B chamber (3) is connected with the gas source (6) to be inflated again through the gas distribution equipment (4) until air pressure of the airtight A chamber (2) is more than or equal to one atmospheric pressure; c)the two ends of the hollow-core photon crystal fiber (1) are successively welded with a standard single film fiber (10) within a range of less than or equal to 1.5 min; d) a distillation function p(x) of air pressure of a fiber core in the hollow-core photon crystal fiber (1) is derived from a formula p(x)=p(1)(-c+a2-bx); e) a final air pressure value of the full optical fiber high-pressure gas chamber is calculated by more than one p(x). The p(x) can accurately determine the air pressure value of the full optical fiber high-pressure gas chamber.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

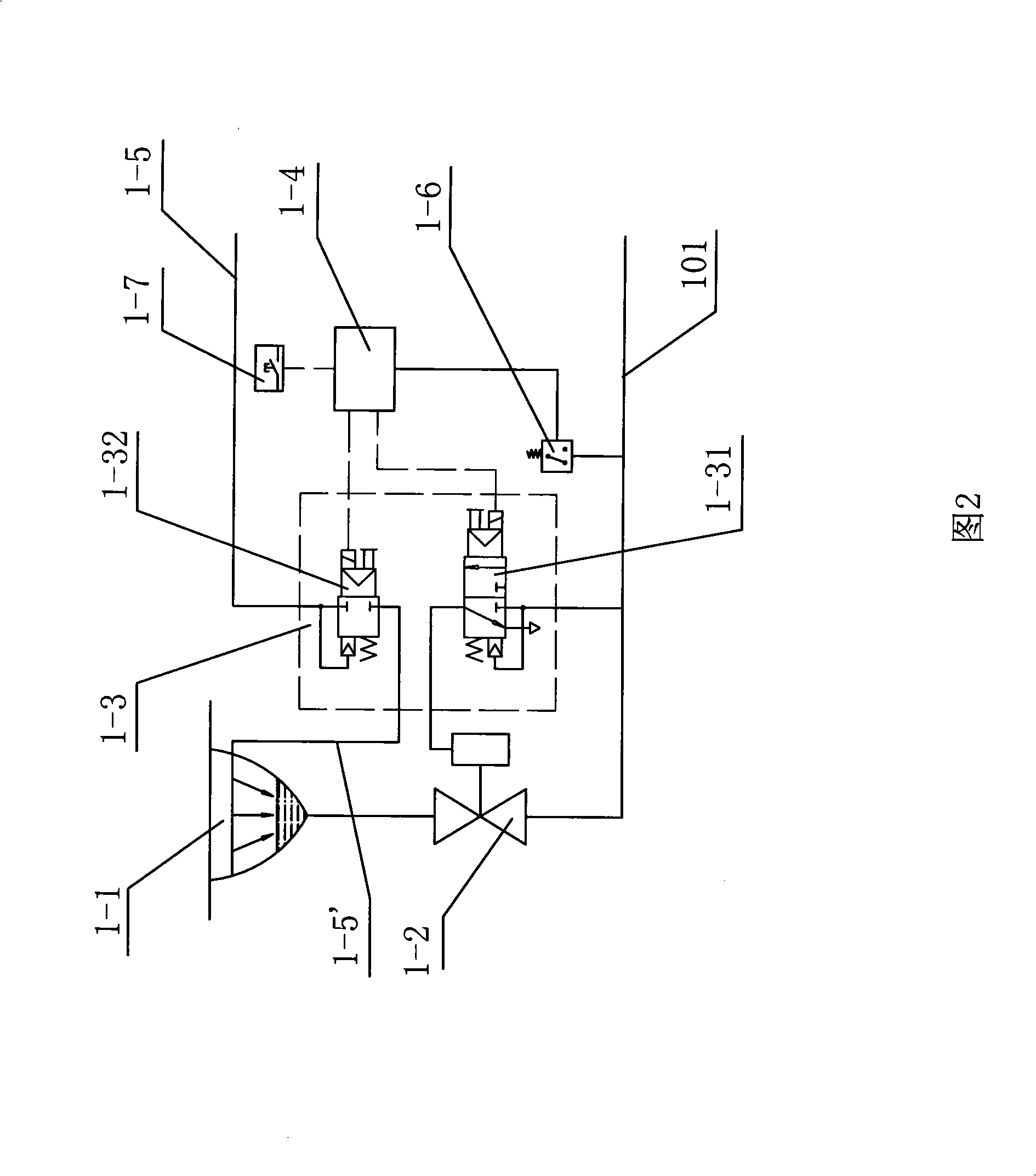

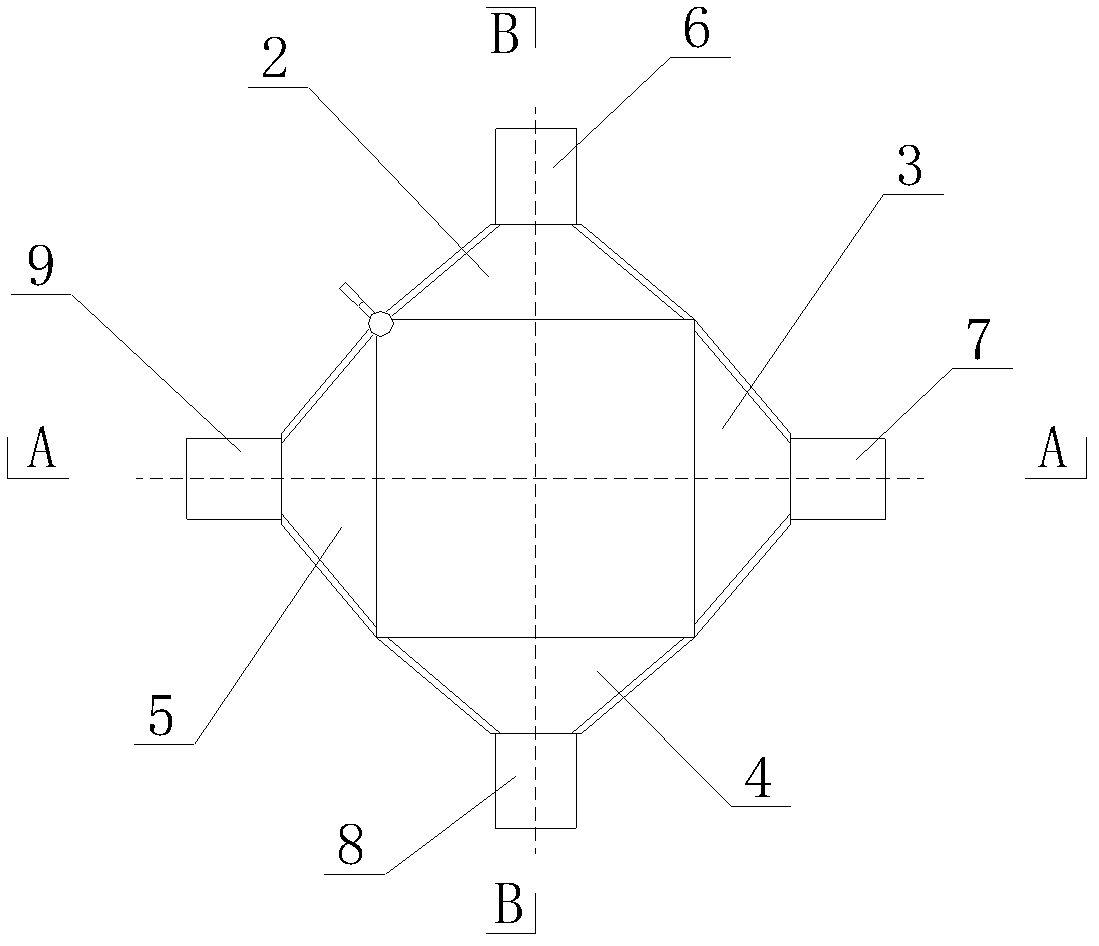

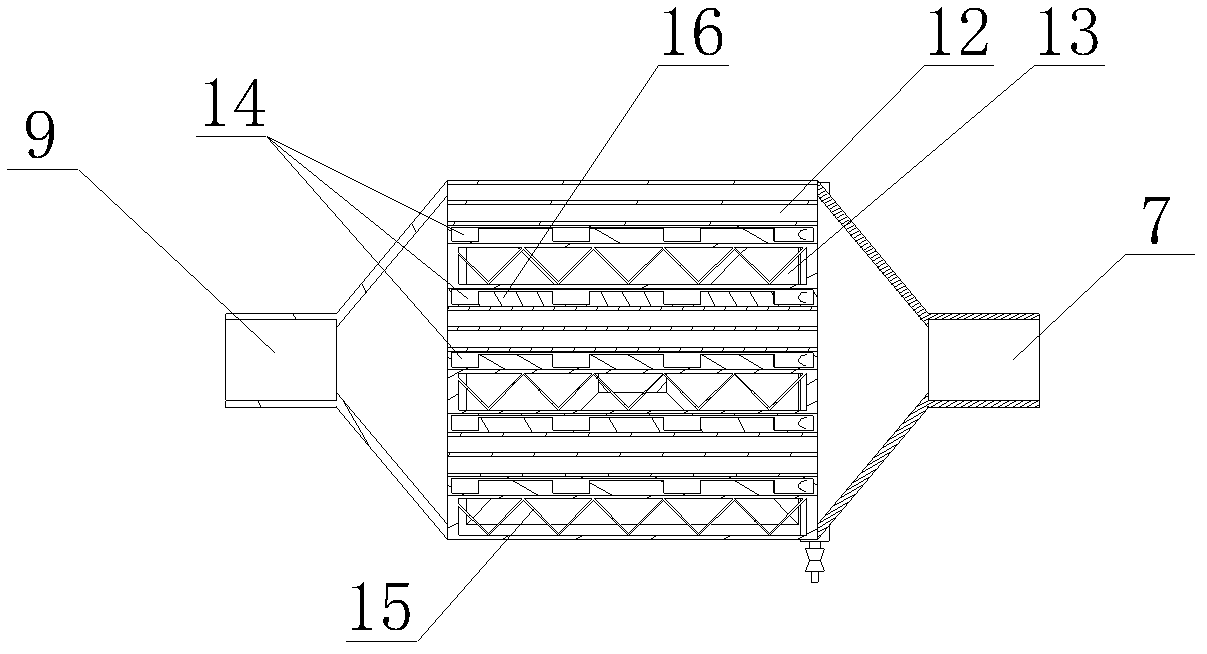

Vacuum system

ActiveCN101349072AGuaranteed vacuumOptimize layoutRotary piston pumpsSewage drainingElectricityWater source

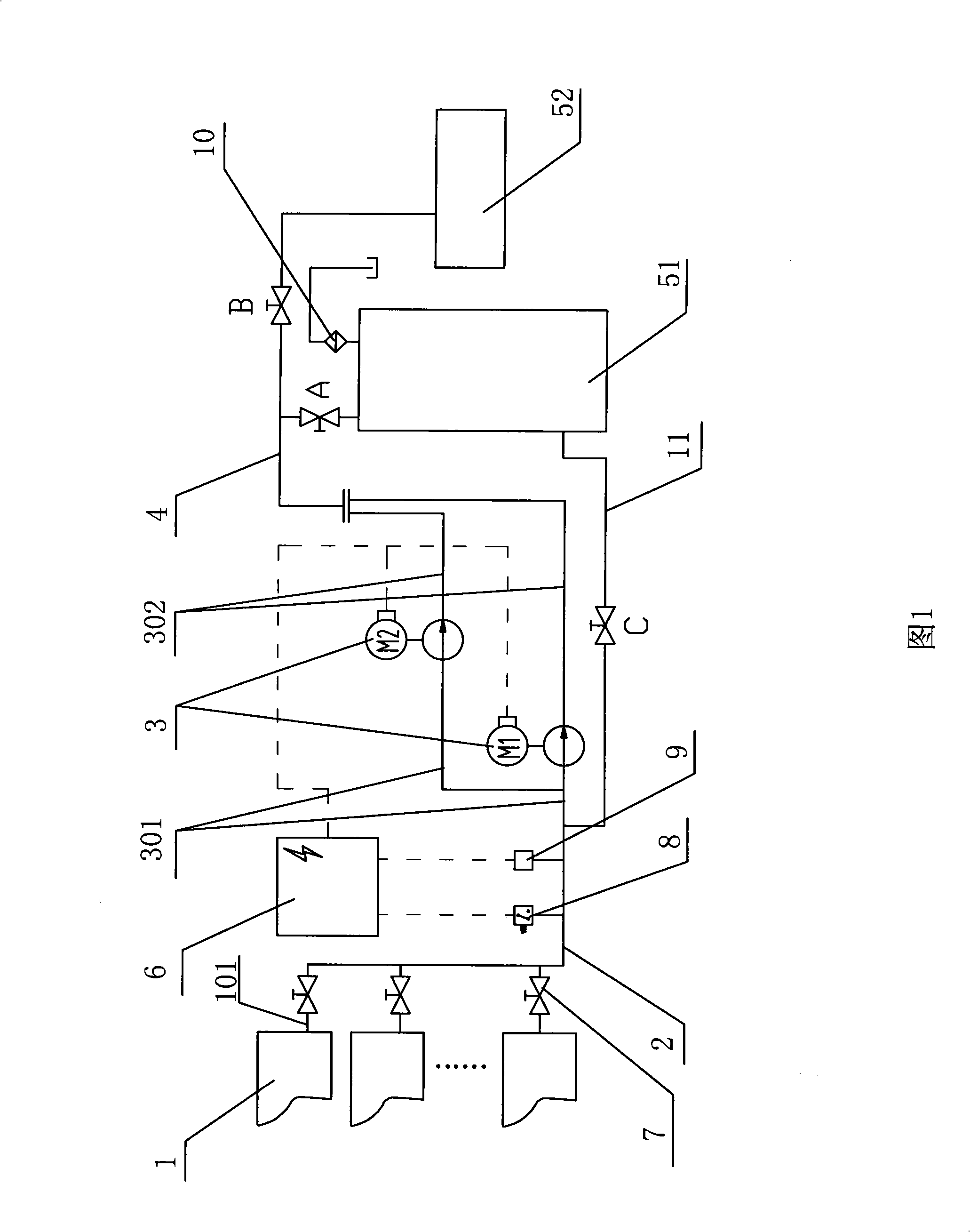

The invention relates to a vacuum system which comprises a plurality of drainage sources, a plurality of vacuum conveying pumps, a sewage collecting part and a control center. Each sewage source comprises a drainage pool with a sewage outfall, a vacuum release valve, a vapor integrated double electromagnetic valve and a control device; and the sewage outfall of the drainage pool is connected with a discharge pipe of the sewage source by the vacuum release valve. The discharge pipe of the sewage source is connected with a sewage suction pipe by an isolation ball valve; the sewage suction pipe is connected with an inlet pipe of each vacuum conveying pump; and an outlet pipe of each vacuum conveying pump is connected with a sewage discharge pipe which is connected to the sewage collecting part. A pressure detection device in electric connection with the control center is arranged on the sewage suction pipe; and the vacuum conveying pump and the control center are in electric connection. In the vacuum system, the control center carries out intelligent control that one or a plurality of the vacuum conveying pumps are opened according to the detected vacuum degree of the sewage suction pipe; the vacuum system can ensure the vacuum degree of the sewage suction pipe to make sewage discharging smooth, effectively saves energy, has simple control, reduces cost, improves the reliability of the system and is convenient to maintain.

Owner:湖南真创环保科技有限公司

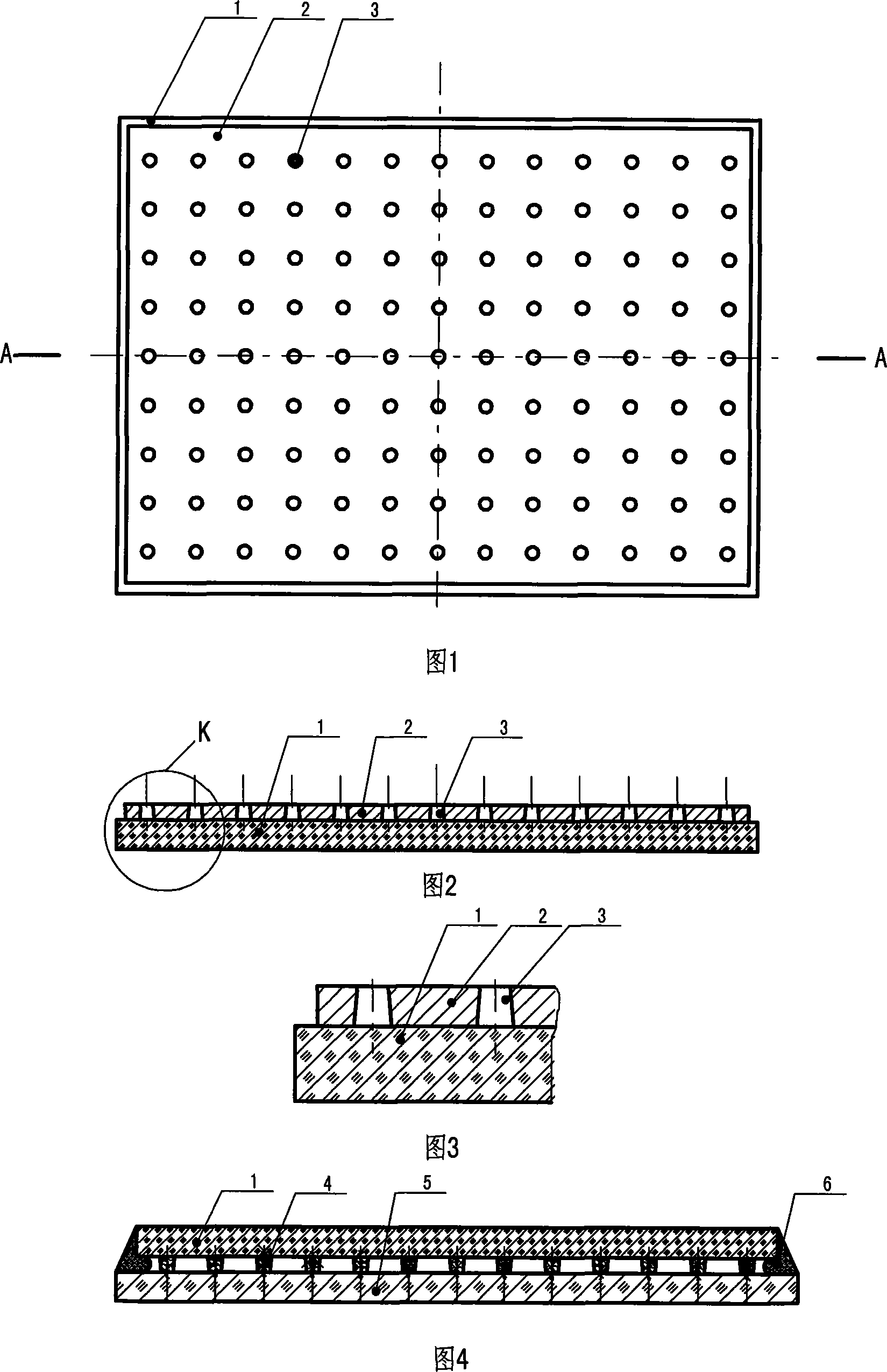

Method for preparing vacuum glass

ActiveCN101215076AImprove molding qualityImprove molding efficiencyGlass reforming apparatusPulp and paper industryHeating furnace

The invention relates to a process for preparing vacuum glass. The steps of the process are, (1) keeping a leaking plate mould flat on a glass substrate, on which die orifices are equispaced and compartmentally prepared, (2) coating the supporting pulp on the leaking plate mould to form backstops which are distributed compartmentally and have the same height, inverting the glass substrate on bottom glass, (3) preparing an opening which is inserted in a suction glass tube on the glass, and adopting supporting pulp to seal edges, (4) putting the glass into a heating furnace and treating, (5) connecting the suction glass with a vacuum device until vacuum degree in the vacuum glass reaches 10-2-10-4Pa, hot fusing and sealing the glass tube, thereby obtaining vacuum glass finished products. The invention has the advantages of simple preparation technology, easy operation, lower investment, lower rejection rate, perfect quality and higher production efficiency. Further, the invention adopts mechanical separator system to replace manual operation, which effectively reduces costs of vacuum glass and is applicable for industrial production.

Owner:天津沽上创新真空玻璃有限公司

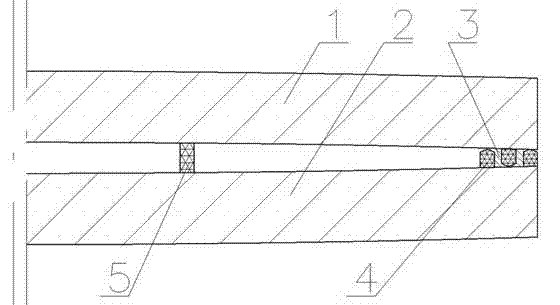

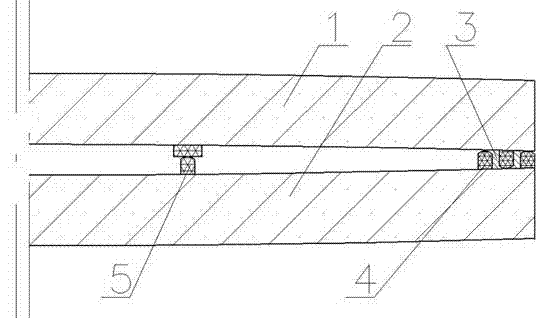

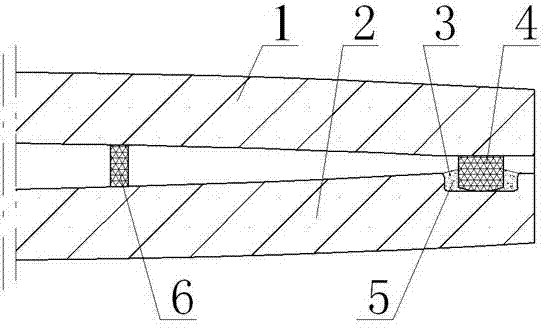

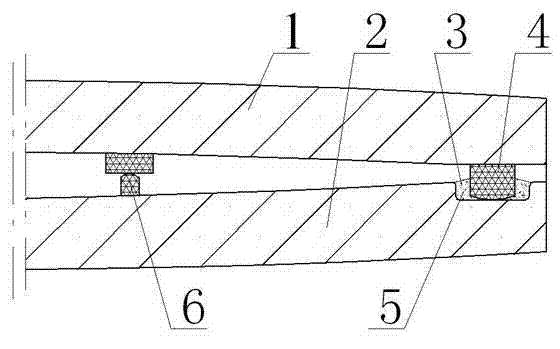

Method for achieving vacuum in composite blank assembly welding process

ActiveCN104209659APrevent welding oxidationPromote dissipationMetal working apparatusWelding apparatusOxideWelding joint

The invention provides a method for achieving vacuum in the composite blank assembly welding process. The method includes the following steps that firstly, plates are prepared, namely, two plate blanks are taken, oxide scales on the surfaces of the plate blanks are completely removed, chamfers are machined in the peripheries of the combined surfaces of the plate blanks, and then grooves are formed; secondly, earlier-stage closed sealing is conducted, namely, the grooves of the two plate blanks are welded for at least three layers; thirdly, vacuumization is carried out, namely, a mechanical vacuum pump enters the position between the two plate blanks from a connecting hole reserved in a welding joint to conduct vacuumization, the vacuum degree is below 10 Pa after extraction, and then a molecular vacuum pump is used for continuous vacuumization until the vacuum degree is below 0.01 Pa; fourthly, two-step welding control is conducted under the vacuum condition. Vacuum between the two assembled plate blanks can be guaranteed, oxygen molecules adsorbed to the combined surface of the plate blanks are fewer, and then the composite quality of combined interfaces after composite rolling is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing novel vacuum insulated panel

ActiveCN102873959AImprove insulation performanceLow thermal conductivityLaminationLamination apparatusWoven fabricCarbon black

The invention discloses a method for producing a novel vacuum insulated panel. The method comprises the following steps of: material mixing: putting fumed silica, microsilica, carbon black, fibers and a vacuum active stabilizer into a mixer for complete mixing; drying: drying the uniformly stirred mixture; core material molding: putting the dried mixture and a getter into a mold, and putting the mold into a pressing machine for extrusion forming; packing: taking the formed core plate out of the mold and wrapping the core plate with a layer of non-woven fabric to obtain the core plate of the vacuum insulated panel; putting the core plate into a high-resistance air film bag for vacuuming until a vacuum degree is 0.02-20 Pa, and sealing the high-resistance air film bag. The method has the advantages that the fumed silica, the microsilica and the fibers are mixed together so that the strength of the insulated panel is improved, the insulation performance is improved and low heat conductivity is obtained, and the fumed silica, the microsilica and the fibers are inorganic materials and are difficultly combusted. The carbon black has large specific surface area, can absorb residual moisture in the core material and can assist the vacuum active stabilizer in maintaining vacuum in the bag.

Owner:ANHUI KERUIKE INSULATION MATERIAL

Infrared focal plane array detector

InactiveCN102997999AReduce volumeReduce packaging costsRadiation pyrometryFocal plane detectorSemiconductor

The invention relates to the field of semiconductor photoelectrons, in particular to an infrared focal plane array detector which comprises an encapsulation casing, an infrared optical window and a buffering ring. The encapsulation casing, the infrared optical window and the buffering ring form a closed vacuum cavity. The buffering ring is positioned between the encapsulation casing and the infrared optical window. An electrical activation getter and an infrared focal plane detector chip are arranged in the vacuum cavity. The encapsulation casing comprises a bottom surface, wherein the infrared focal plane detector chip is arranged on the bottom surface. A welding plate is arranged on the side of the bottom surface, a metal pin is arranged outside the bottom surface, the welding plate is electrically communicated with the metal pin, and the electrical activation getter is electrically communicated with the metal pin. A metal welding plate is arranged on the infrared focal plane detector chip and connected with the welding plate through a metal wire. The encapsulation structure of the infrared focal plane array detector is simplified, the size of the infrared focal plane array detector is reduced, and the encapsulation cost of the infrared focal plane array detector is reduced.

Owner:YANTAI RAYTRON TECH

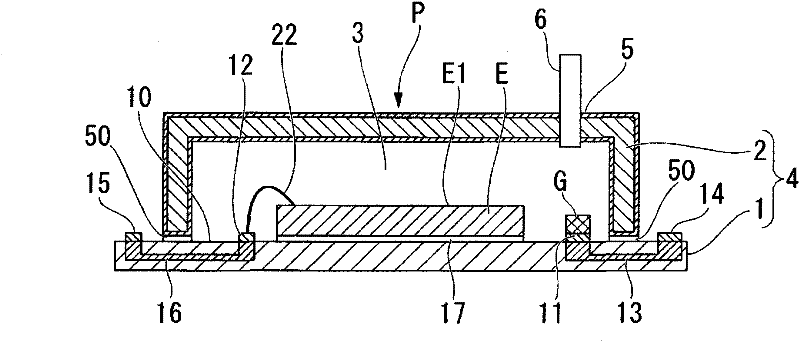

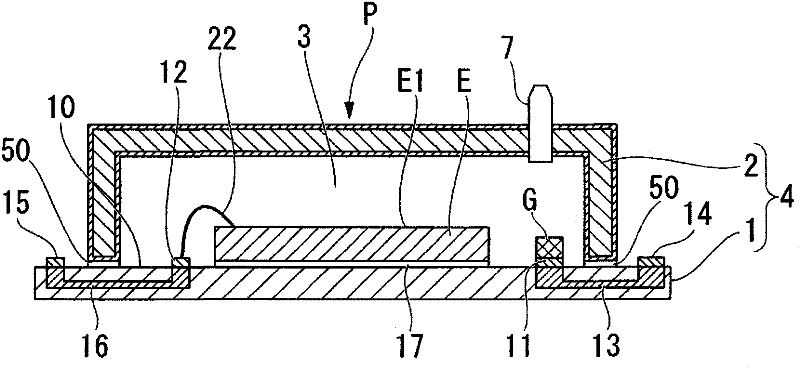

Vacuum sealed package, printed circuit board having vacuum sealed package, electronic device, and method for manufacturing vacuum sealed package

InactiveCN102318060AGuaranteed vacuumReduce vacuumRadiation pyrometrySemiconductor/solid-state device detailsElectrical conductorHeat conducting

Disclosed is a vacuum sealed package which comprises a package main body in which a first main body part and a second main body part are joined together with a hollow part interposed therebetween, and a getter material and an electronic device which are provided within the hollow part. The vacuum sealed package is obtained by sealing the package main body with a sealing member, while maintaining the hollow part in an evacuated state by means of a through hole by which the inside and the outside of the hollow part are communicated with each other. The getter material and the electronic device are connected with a first conductor pad and a second conductor pad. The first conductor pad is connected with a third conductor pad through a heat conducting material, and the second conductor pad is electrically connected to a fourth conductor pad that is on a wiring substrate.

Owner:NEC CORP

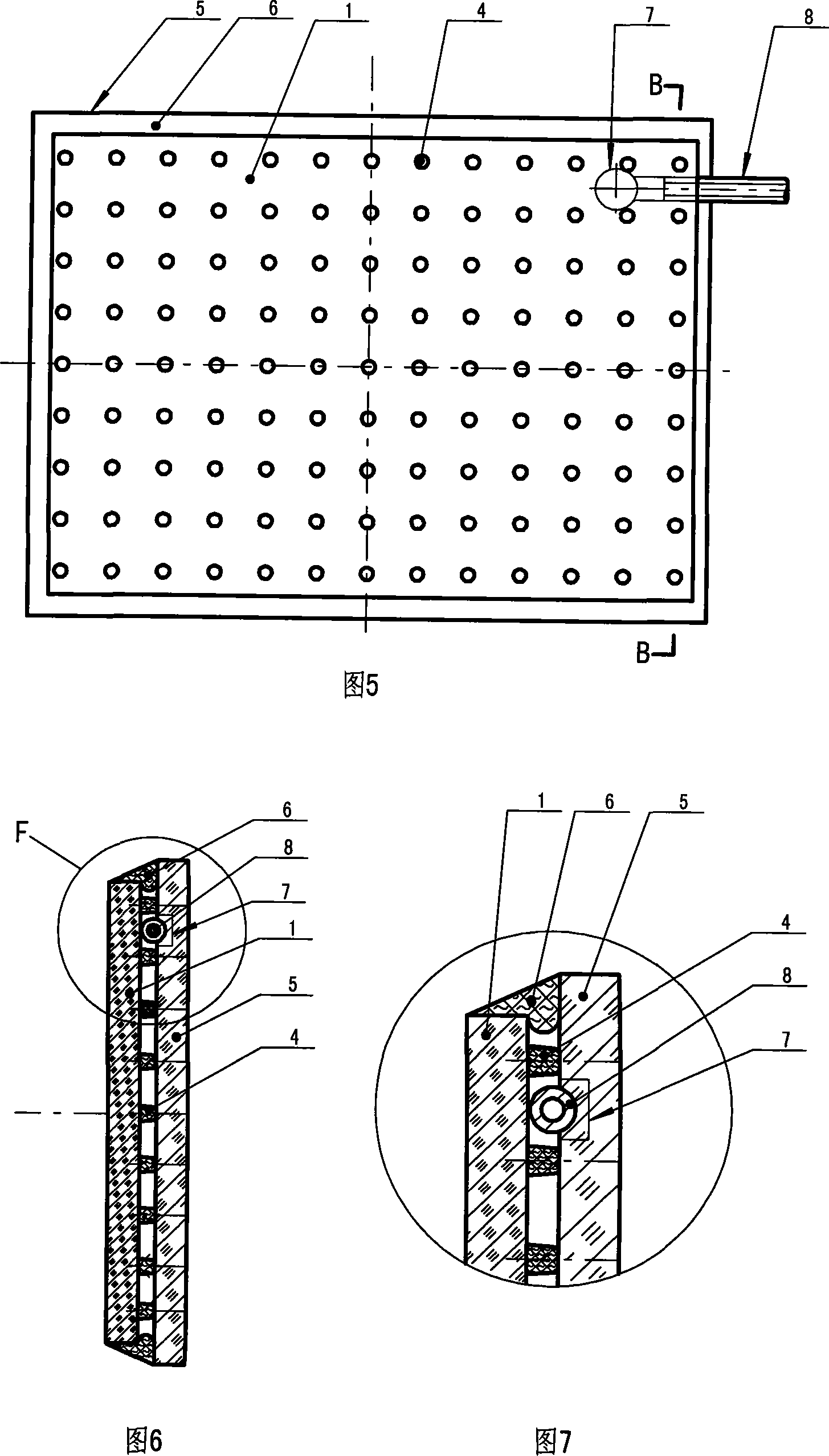

Method for acquiring vacuum during making vacuum glass member

ActiveCN102617025AGuaranteed vacuumImprove processing efficiencyDoors/windowsWindows/door improvementEngineeringGlass sheet

The invention discloses a method for acquiring vacuum during making a vacuum glass member, which is characterized in that in the vacuum environment possessing required vacuum degree, each sheet of glass plates capable of forming the vacuum glass member is assembled and finally sealed, before the assembly, each sheet of the glass plates are mutually independently positioned in the vacuum environment, the vacuum space in the assembled vacuum glass member possesses completely same vacuum degree with the vacuum environment. According to the invention, the assembly process of the glass plate is placed in the vacuum environment, the glass plates are placed at intervals with each other by the spacers before the assembly, the vacuum degree around each sheet of the glass plates is same with the vacuum degree of whole vacuum environment, therefore, the vacuum degree of the vacuum environment is need to be controlled, the vacuum degree of the processed vacuum glass member can be ensured, the existing problem in the prior art can be avoided, the processing efficiency of the vacuum glass member can be enhanced, and the quality of the vacuum glass member can be guaranteed.

Owner:洛阳兰迪真空玻璃科技有限公司

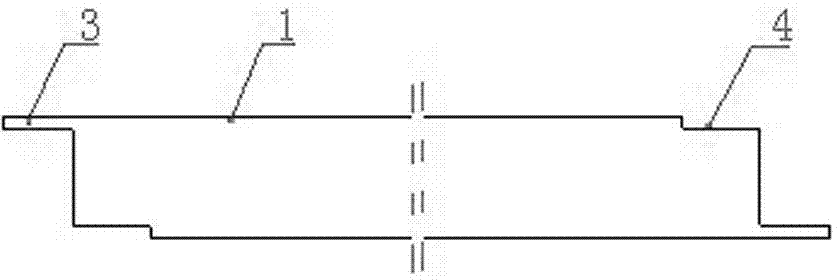

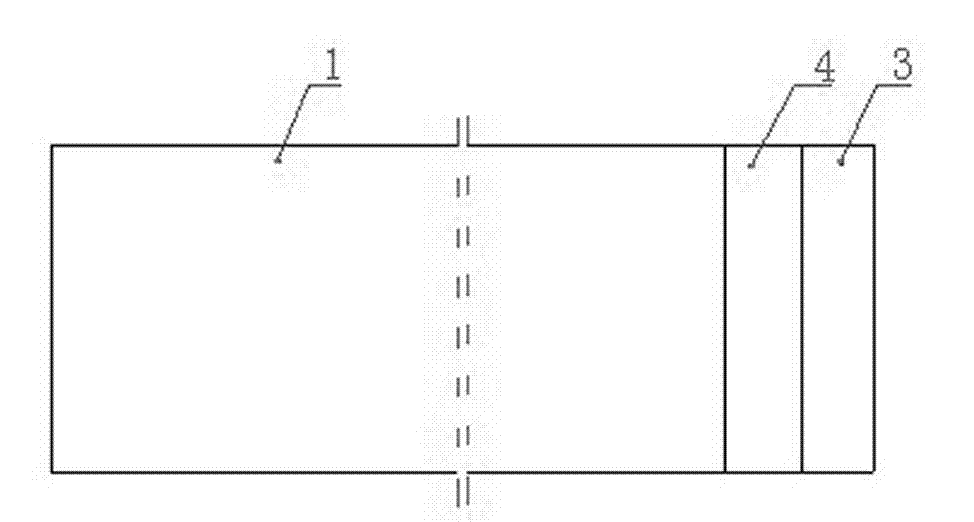

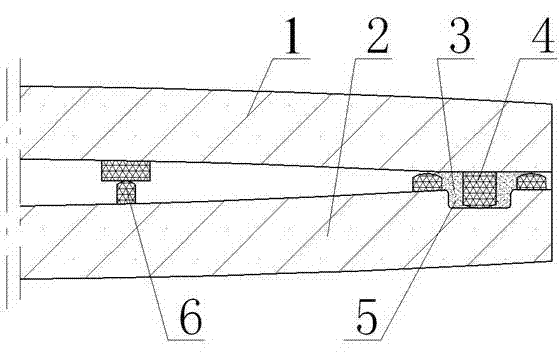

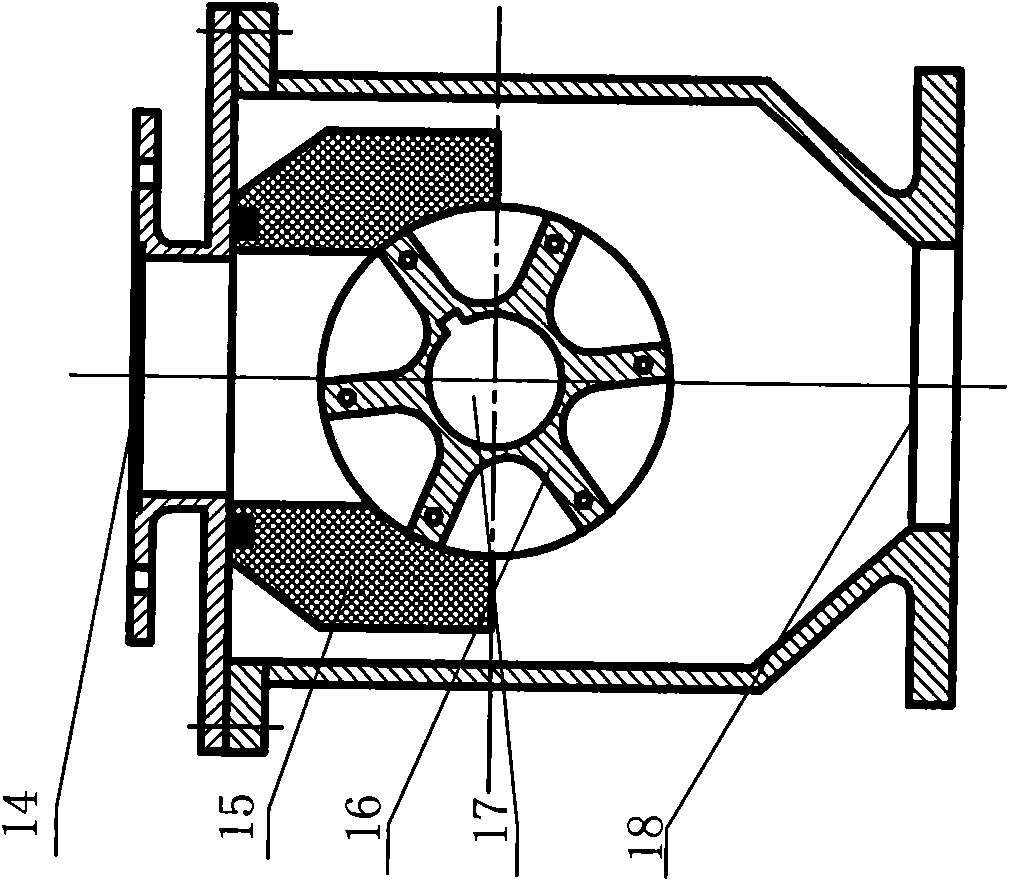

Convex vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951803AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideEngineering

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

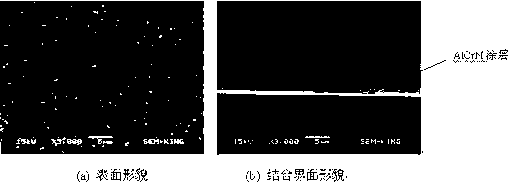

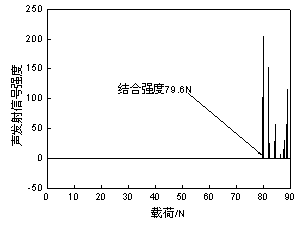

Treatment of diabetes mellitus by taking insulin PEGylation derivative as active component

ActiveCN103132026AImprove wear resistanceGood anti-adhesionVacuum evaporation coatingSputtering coatingDiabetes mellitusPharmacology

The invention discloses treatment of diabetes mellitus by taking insulin PEGylation derivative as an active component, which is characterized in that a drug delivery mode of single injection can be changed, and the patient tolerance is increased. After PEGylation of insulin, the renal clearance is reduced, the enzymolysis speed is reduced, the retention time of insulin in human body is increased, the drug delivery cycle is prolonged, and the treatment cost is reduced.

Owner:江苏腾驰科技有限公司

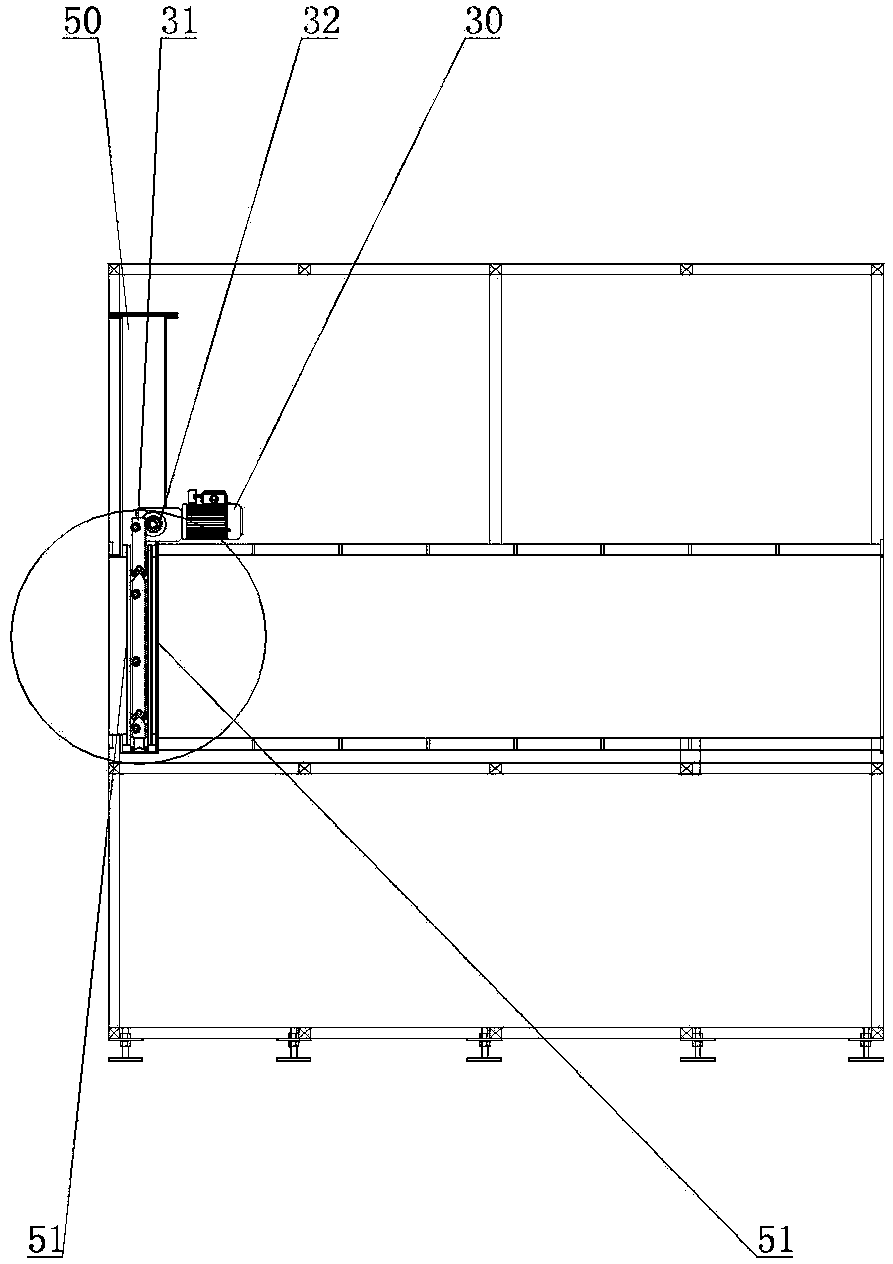

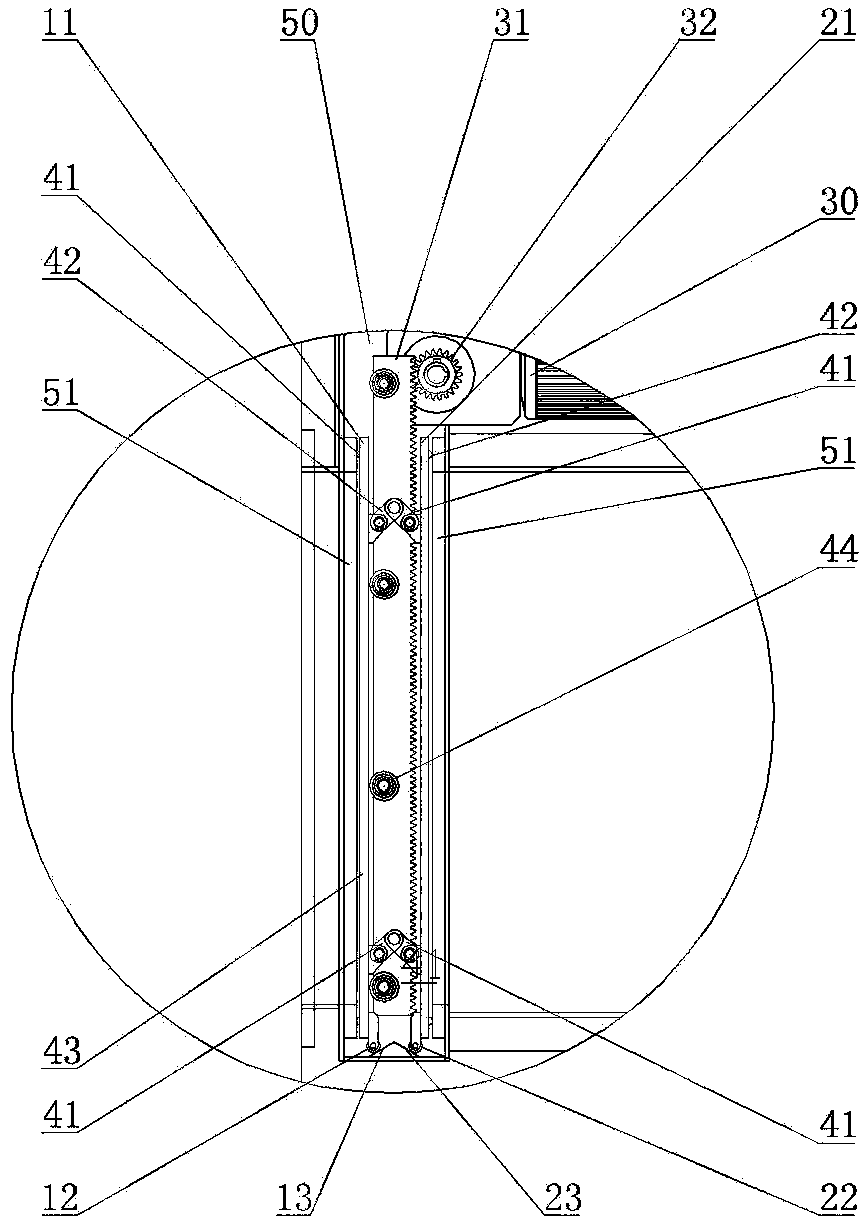

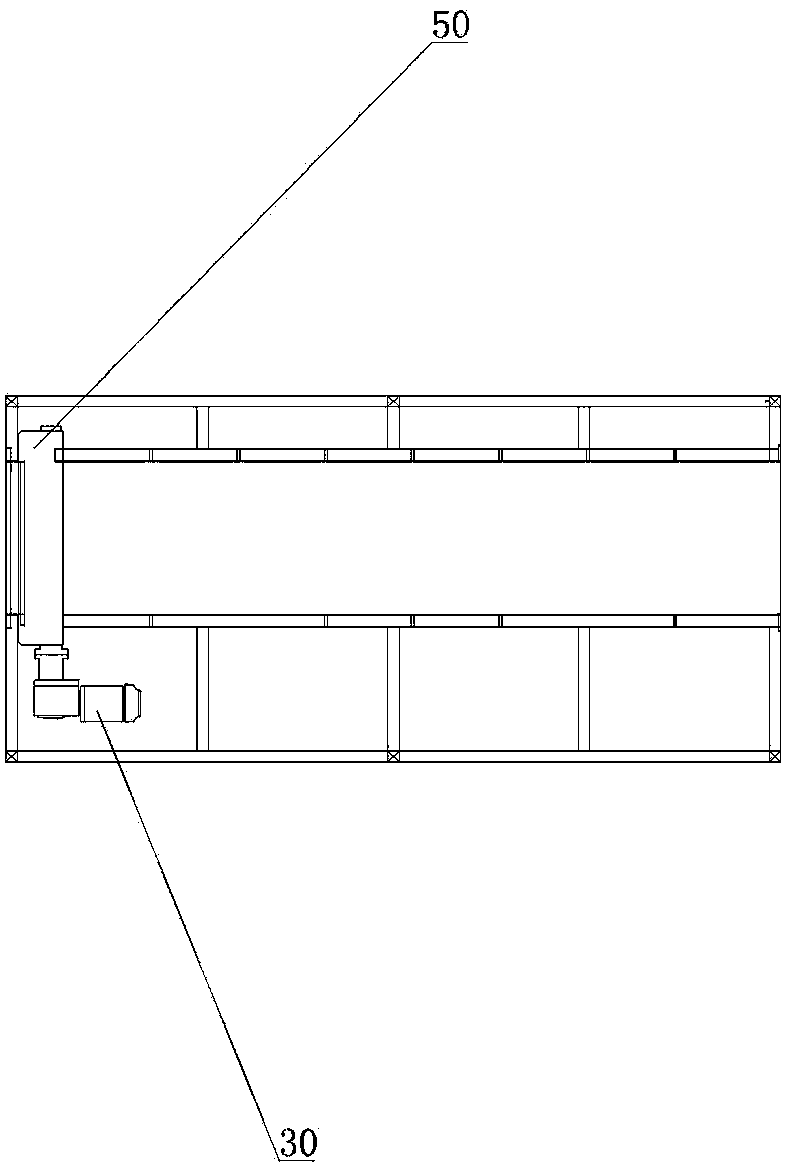

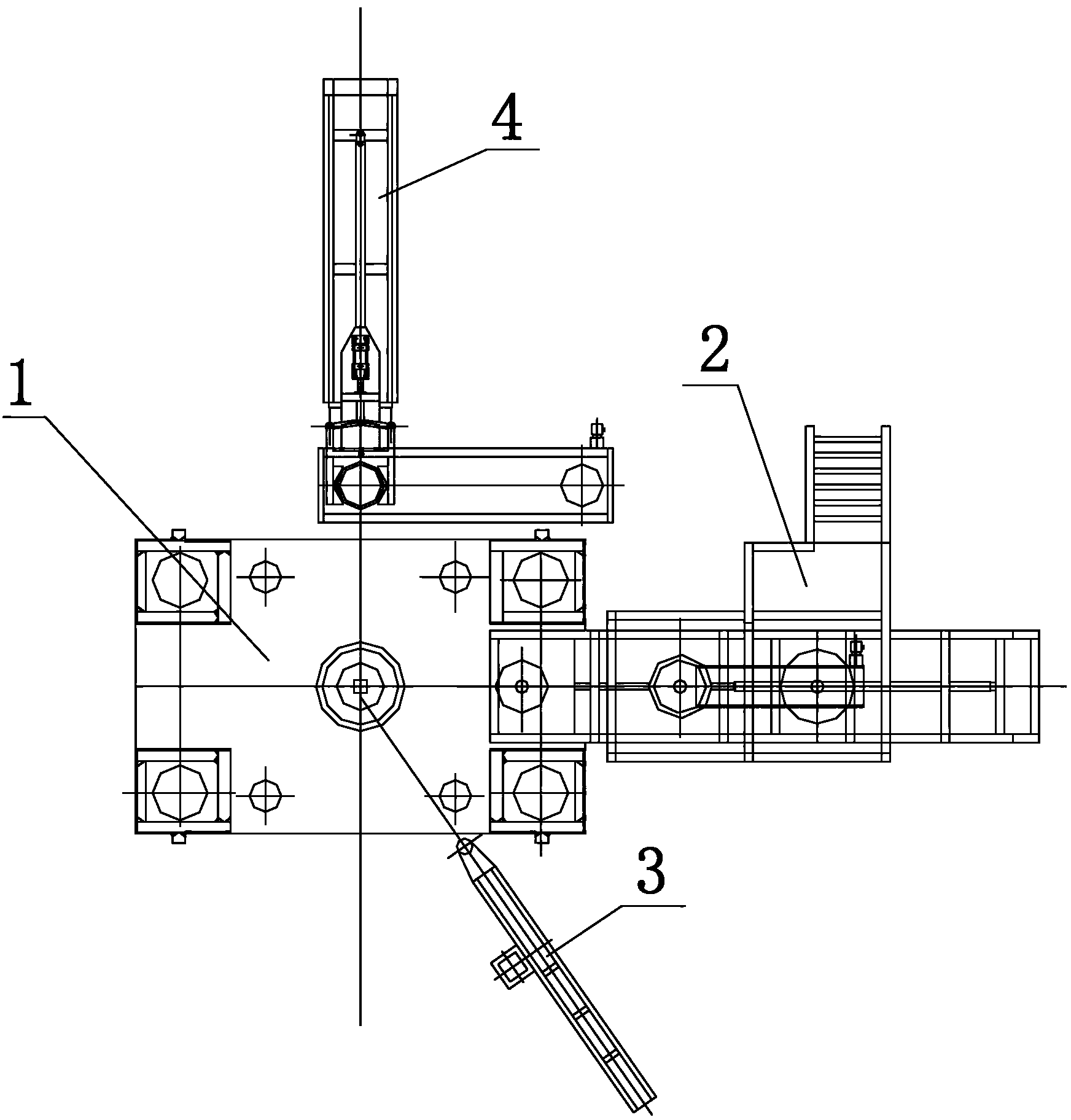

Automatic sealing door

InactiveCN104358494AAchieve sealingGuaranteed sealing performanceDrying chambers/containersSealing arrangementsEngineeringMechanical engineering

An automatic sealing door comprises a first door plate and a second door plate which are arranged in parallel, wherein an elevating mechanism for lifting the first door plate and the second door plate is arranged between the first door plate and the second door plate; at least two articulation pieces are arranged between the first door plate and the elevating mechanism; one end of each of the two articulation pieces is hinged to the first door plate, and the other ends of the articulation pieces are hinged to the elevating mechanism; at least two articulation pieces are arranged between the second door plate and the elevation mechanism; one end of each of the two articulation pieces is hinged to the second door plate, and the other ends of the articulation pieces are hinged to the elevation mechanism; first rolling wheels are arranged at the lower end of the first door plate; a first inclined plate with a left lower end and a higher right end is arranged below the first rolling wheels; second rolling wheels are arranged at the lower end of the second door plate; a second inclined plane with a left higher end and a right lower end is arranged below the second rolling wheels. The automatic sealing door with the structure provided by the invention can realize seamless connection between vacuum drying equipment of a vacuum drying system.

Owner:SHENZHEN TIME HIGH TECH EQUIP

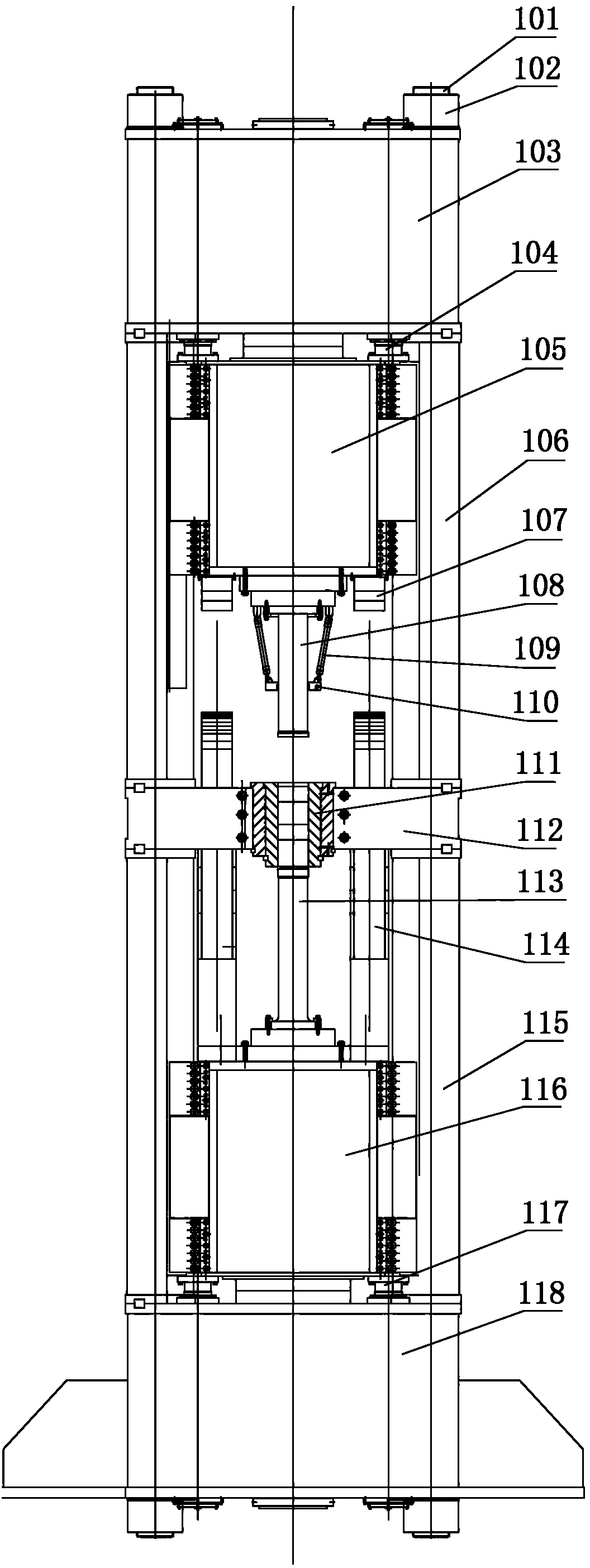

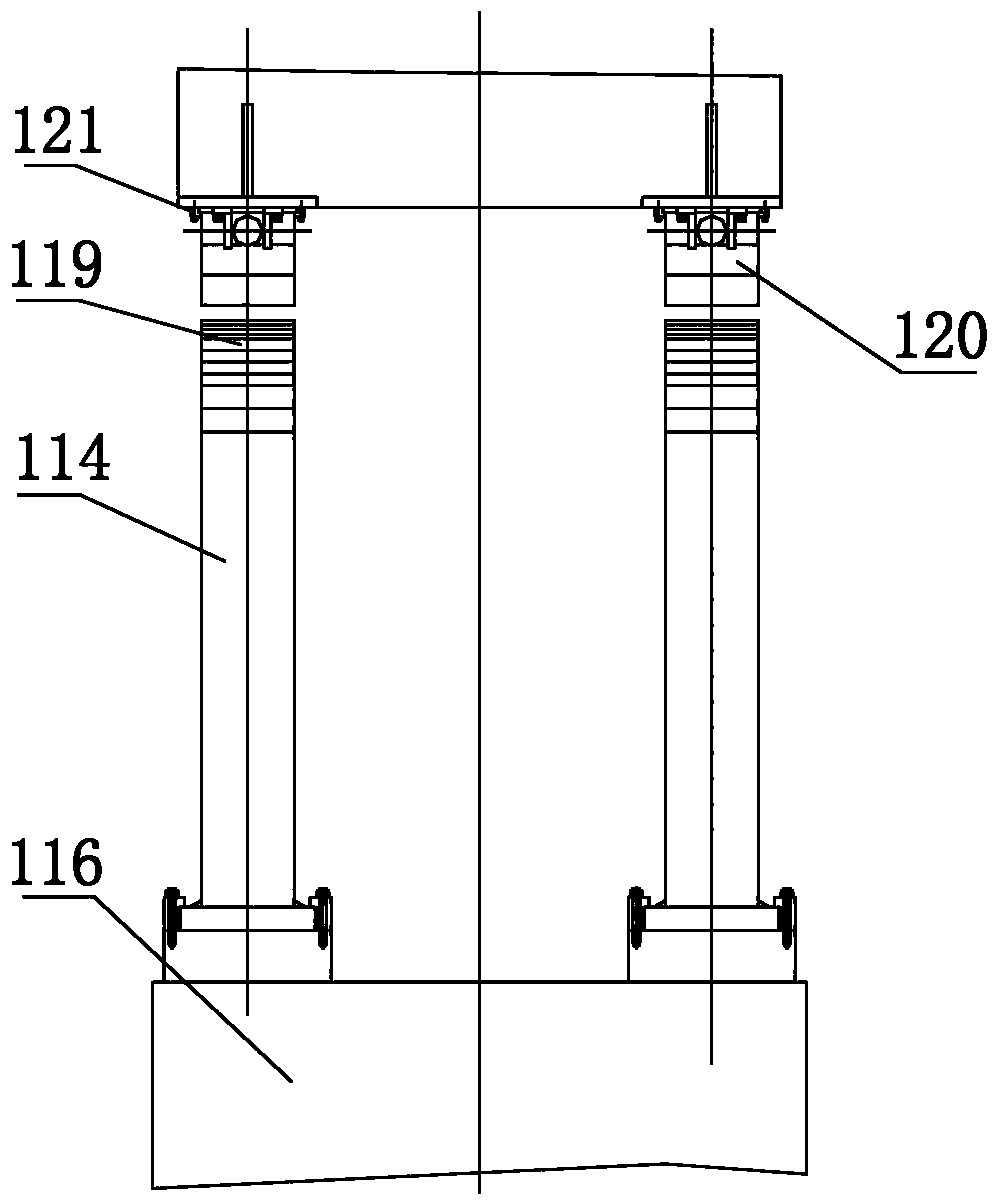

Automatic pressing production line of large explosive column

ActiveCN103265389AIncrease pressureHigh densityExplosive working-up apparatusProduction lineUltimate tensile strength

The invention relates to an automatic pressing production line of a large explosive column. The automatic pressing production line comprises a hydraulic press, which is composed of an upper beam, an upper return cylinder, an upper slide block with a cylinder, an upper punch, a middle girder with a die sleeve, and a lower beam. The automatic pressing production line is characterized by also comprising an automatic weighing and feeding device, a powder smoothing device and an automatic discharge device, which are arranged at the periphery of the hydraulic press; a lower return cylinder is arranged at the upper part of the lower beam; the lower return cylinder is connected with a lower slide block with a cylinder; a lower punch is arranged on the lower slide block with the cylinder; an automatic evacuating device is arranged at the lower part of the upper slide block with the cylinder; and mechanical limiting devices are arranged on the upper slide block with the cylinder and the lower slide block with the cylinder. The automatic pressing production line has the advantages that full-automatic operation of feeding, smoothing, two-way control and discharge of the explosive column can be achieved through the production line; the labor intensity of operating personnel can be greatly reduced; the production efficiency of a large-tonnage hydraulic press is improved; potential safety hazards are avoided; air bubbles of the explosive column in the pressing process can be reduced; the compact evenness and the accuracy of the explosive column are improved; and the product quality is also ensured.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Ultrahigh-modulus magnesium alloy and preparation method thereof

The invention discloses a ultrahigh-modulus magnesium alloy and a preparation method thereof. Nanometer aluminum oxide is dopted in a magnesium alloy to obtain a ultrahigh-modulus magnesium alloy. The magnesium alloy consists of magnesium and zinc elements and nanometer aluminum oxide; the atom ratio of magnesium and zinc is 3: 1-1.5: 1; the average diameter of the aluminum oxide is below 100 nanometers; the average grain of the magnesium alloy is below 100 nanometers; and the elastic modulus of the alloy can reach above 50 MN*M / Kg. The magnesium alloy is prepared through such steps as smelting, doping of nanometer particles, dispersion, cooling and warping deformation.

Owner:西安翱翔新材料科技有限公司

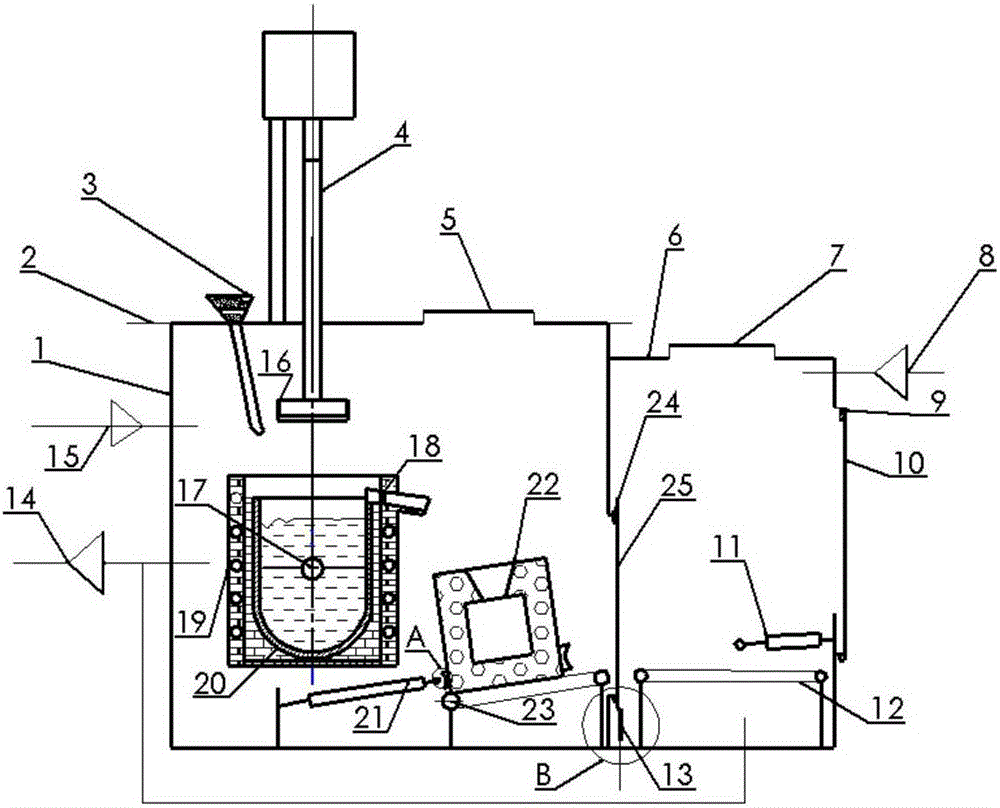

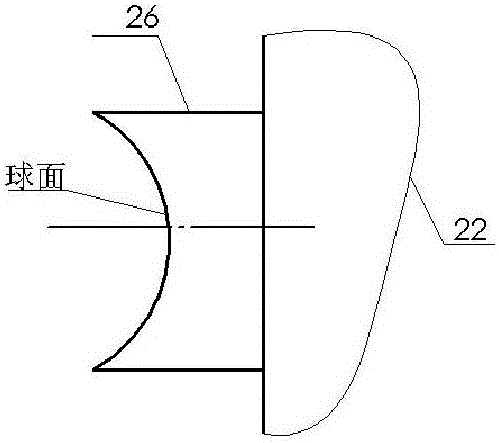

Integrated preparing and forming device for magnesium alloy thin-walled pieces

The invention relates to an integrated preparing and forming device for magnesium alloy thin-walled pieces. The forming device comprises a smelting-pouring tank and a protective atmosphere solidification tank, wherein the smelting-pouring tank and the protective atmosphere solidification tank are used for preparing a magnesium alloy. The smelting-pouring tank and the protective atmosphere solidification tank are both connected with a vacuumizing device and a protective gas injection device. By means of the integrated preparing and forming device, the magnesium alloy can be smelted under the vacuum condition, preparation is completed and pouring is conducted under the condition that the protective gas is injected, and pressurized solidification is conducted under the condition that the protective gas is injected in the protective atmosphere solidification tank. The integrated preparing and forming device is suitable for producing complex and thin-walled magnesium alloy castings, the production safety is high, the surfaces of the castings are free of oxidation defects, internal defects such as slag inclusion, shrinkage porosity and cold shut are basically solved, the structure is compact, performance is good, production requirements are met, the integrated preparing and forming device is easy to popularize, and the yield of the castings is high.

Owner:HENAN POLYTECHNIC UNIV

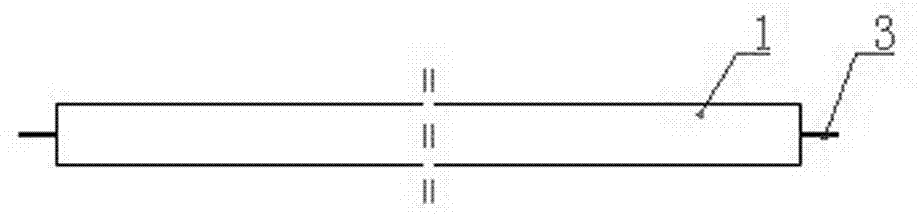

Embedded vacuum rolling method of titanium/steel laminated metal

The invention provides a blank production method for embedded vacuum rolling of a titanium / steel composite plate. The method not only can prevent the oxidation of surfaces, to be compounded, of titanium and steel to obtain the high-quality titanium / steel composite plate, but also is suitable for high-efficiency industrialized production.

Owner:史和生

Safety heat exchanger capable of monitoring leakage in real time

InactiveCN102620582AGuaranteed vacuumImprove heat transfer efficiencyMeasurement of fluid loss/gain rateStationary plate conduit assembliesHeat transfer efficiencyEngineering

The invention relates to a safety heat exchanger capable of monitoring leakage in real time. The safety heat exchanger comprises a cross-flow type shell and a heat exchanger core which is arranged in the cross-flow type shell, wherein a first fluid inlet, a second fluid inlet, a first fluid outlet and a second fluid outlet are respectively formed on a first sealing head, a second sealing head, a third sealing head and a fourth sealing head; a first vacuum layer sealing head is arranged at a joint of the first sealing head and the fourth sealing head; a vacuumizing device and a pressure detector or a material component detector are arranged on the first vacuum layer sealing head; a first vacuum layer is communicated with the first vacuum layer sealing head; a first fluid flow channel is respectively communicated with the first fluid inlet and the first fluid outlet; and a second fluid flow channel is respectively communicated with the second fluid inlet and the second fluid outlet. The safety heat exchanger capable of monitoring the leakage in real time is high in heat transfer efficiency, high in performance and high in equipment safety and can monitor the leakage situation in real time, and production safety and production quality are ensured.

Owner:刘猛

Metal solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951829AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionAlloyMetal

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex glass, an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

Pipeline sprayer

ActiveCN108816602AEasy to moveStable output speedLiquid surface applicatorsLiquid spraying apparatusSprayerEngineering

The invention discloses a pipeline sprayer. The pipeline sprayer comprises a rack, a storage mechanism arranged above the rack and having a pressurization function, a feeding mechanism connected withan output end of the storage mechanism, a drive motor arranged above the feeding mechanism, a transmission mechanism connected with an output end of the drive motor and a paint spraying mechanism connected with an output end of the feeding mechanism, wherein the feeding mechanism comprises a feeding cavity body, a feeding piston arranged in the feeding cavity body and an air-pressure balance device matched with the feeding piston; a crank is rotationally connected to the downward output end of the drive motor; a connection rod is rotationally connected between the feeding piston and the crank;under the co-action of the elasticity of air-pressure balance balls and the elasticity of fluffy fillers, an air pressure in an air cavity and a pressure given to a spray cavity by a pressurizer aremutually balanced, and then stable conveying for a paint is ensured; and moreover, due to the wrapping of the fluffy fillers, the occurrence of the case that the pressure balance balls are broken dueto a too high pressure, is avoided.

Owner:浦江县冠宏家居用品有限公司

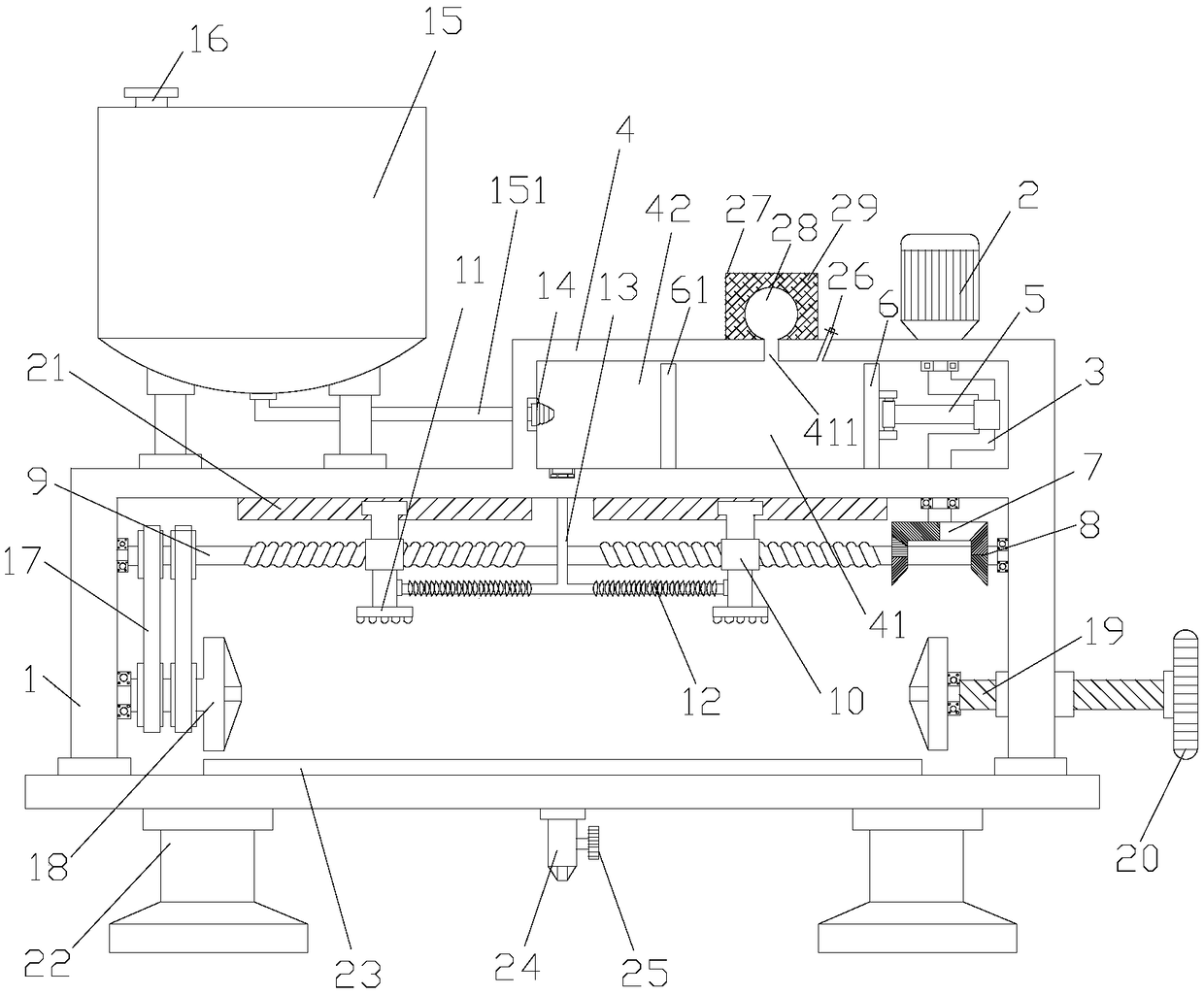

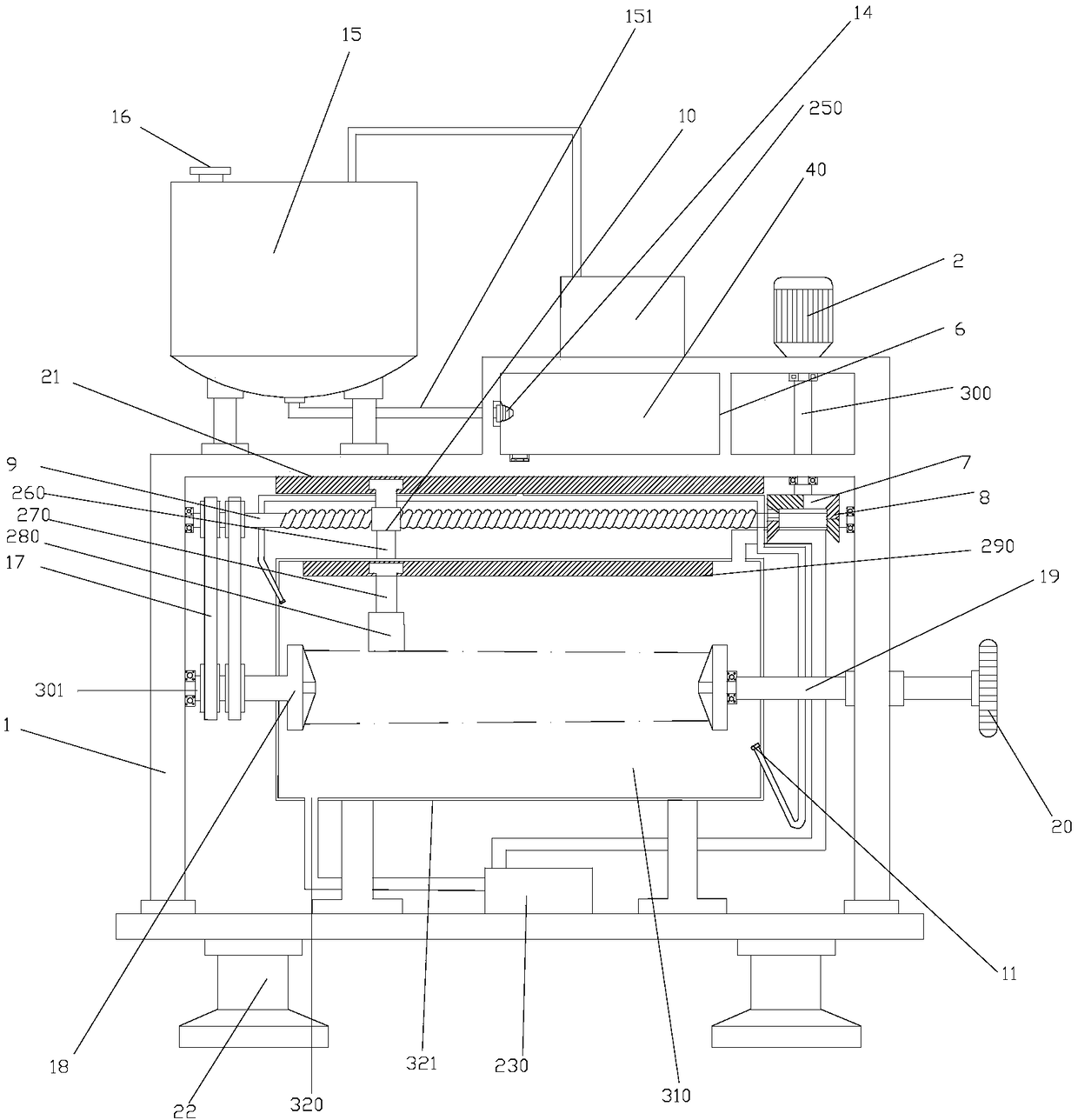

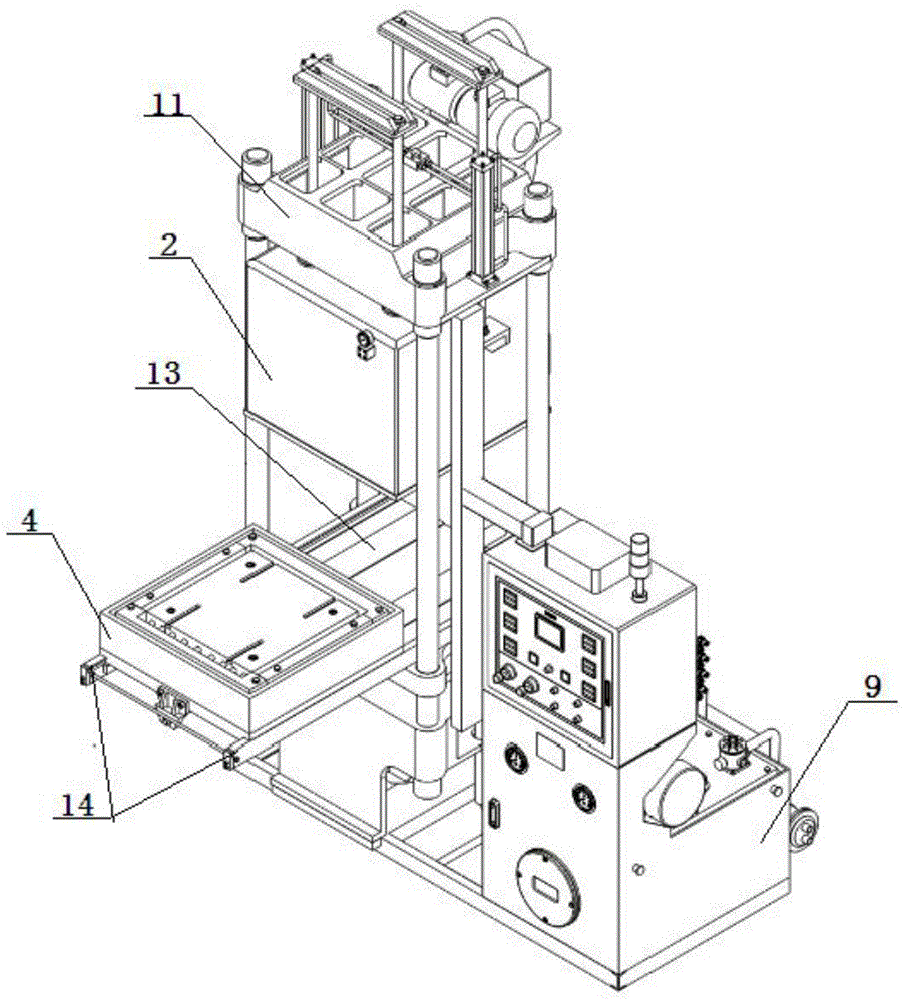

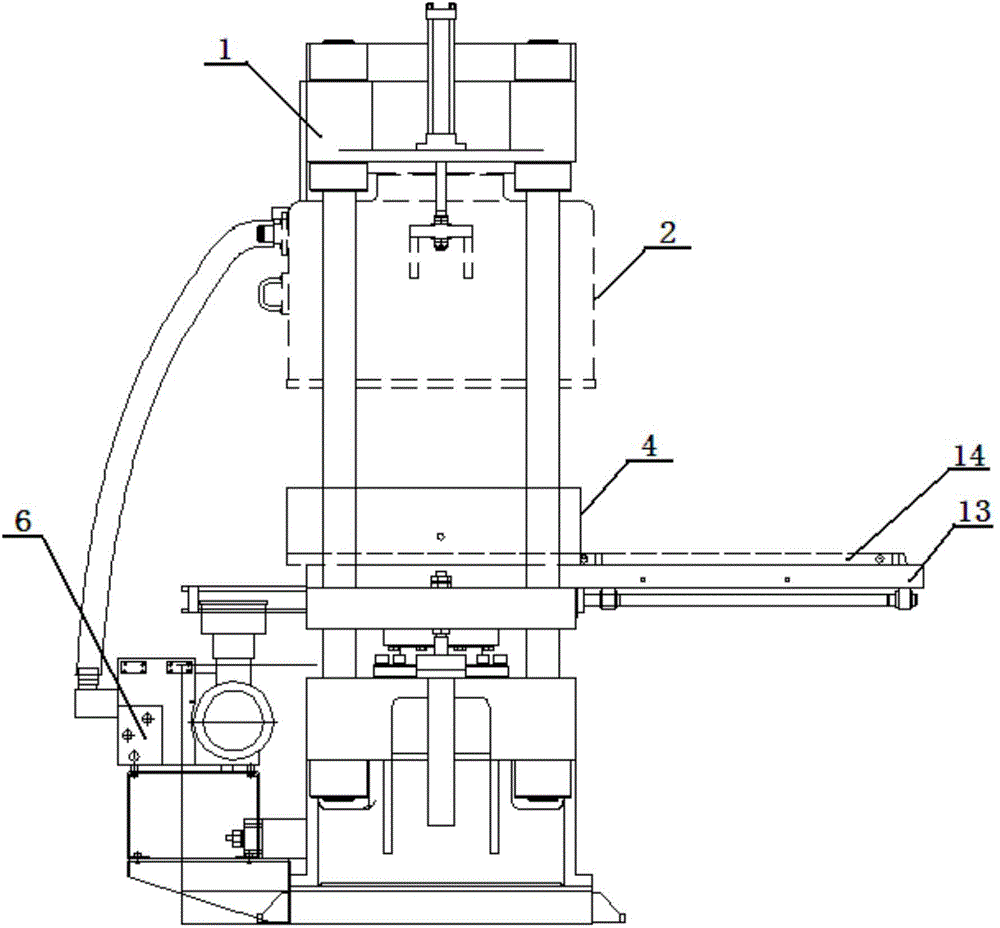

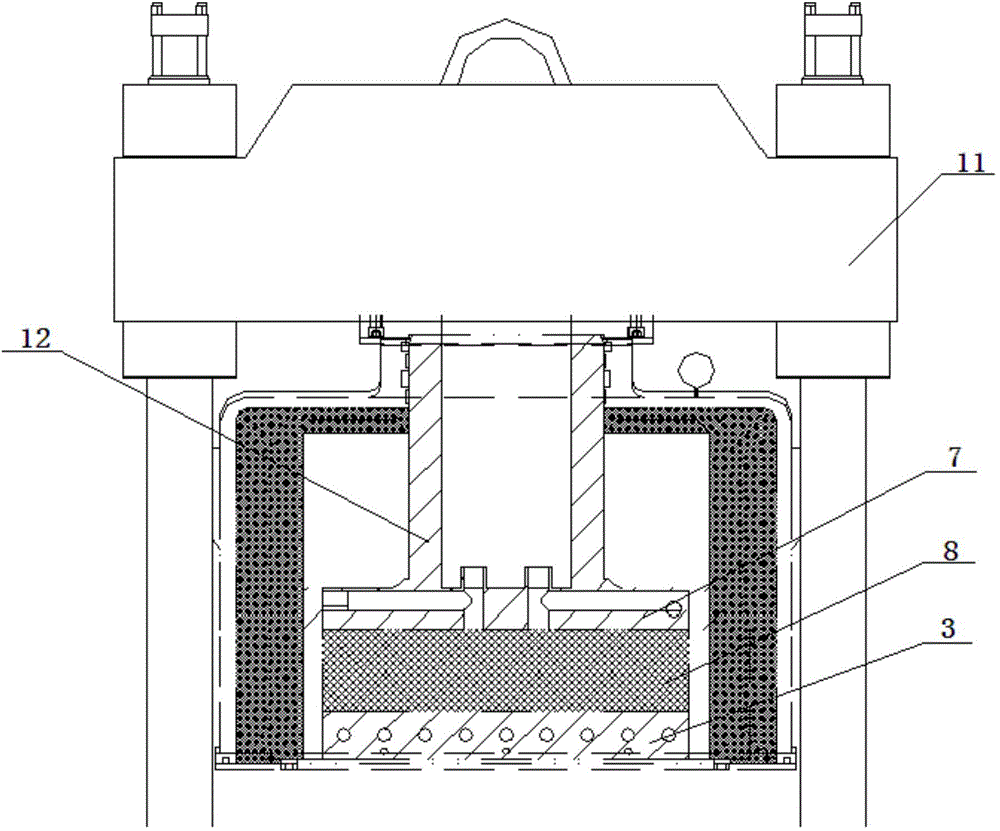

Vacuum high-temperature hot pressing molding machine

The invention discloses a vacuum high-temperature hot pressing molding machine. The vacuum high-temperature hot pressing molding machine comprises a rack (1) for wholly supporting a molding machine, an upper heat-preservation cold-state vacuum cover (2), a lower heat-preservation cold-state vacuum cover (4) corresponding to the upper heat-preservation cold-state vacuum cover (2), and a vacuumizing device (6) connected with the upper heat-preservation cold-state vacuum cover (2) or the lower heat-preservation cold-state vacuum cover (4), wherein the upper heat-preservation cold-state vacuum cover (2) can move up and down and is internally provided with an upper heating plate (3); the lower heat-preservation cold-state vacuum cover (4) can move front and back and up and down; and the lower heat-preservation cold-state vacuum cover (4) is internally provided with a lower heating plate (5) corresponding to the upper heating plate (3). The vacuum high-temperature hot pressing molding machine is simple in structure, reasonable in design, convenient to use, good in vacuum sealing effect, high in molding temperature, good in molding effect and low in heat dissipation.

Owner:大连天能装备制造有限公司

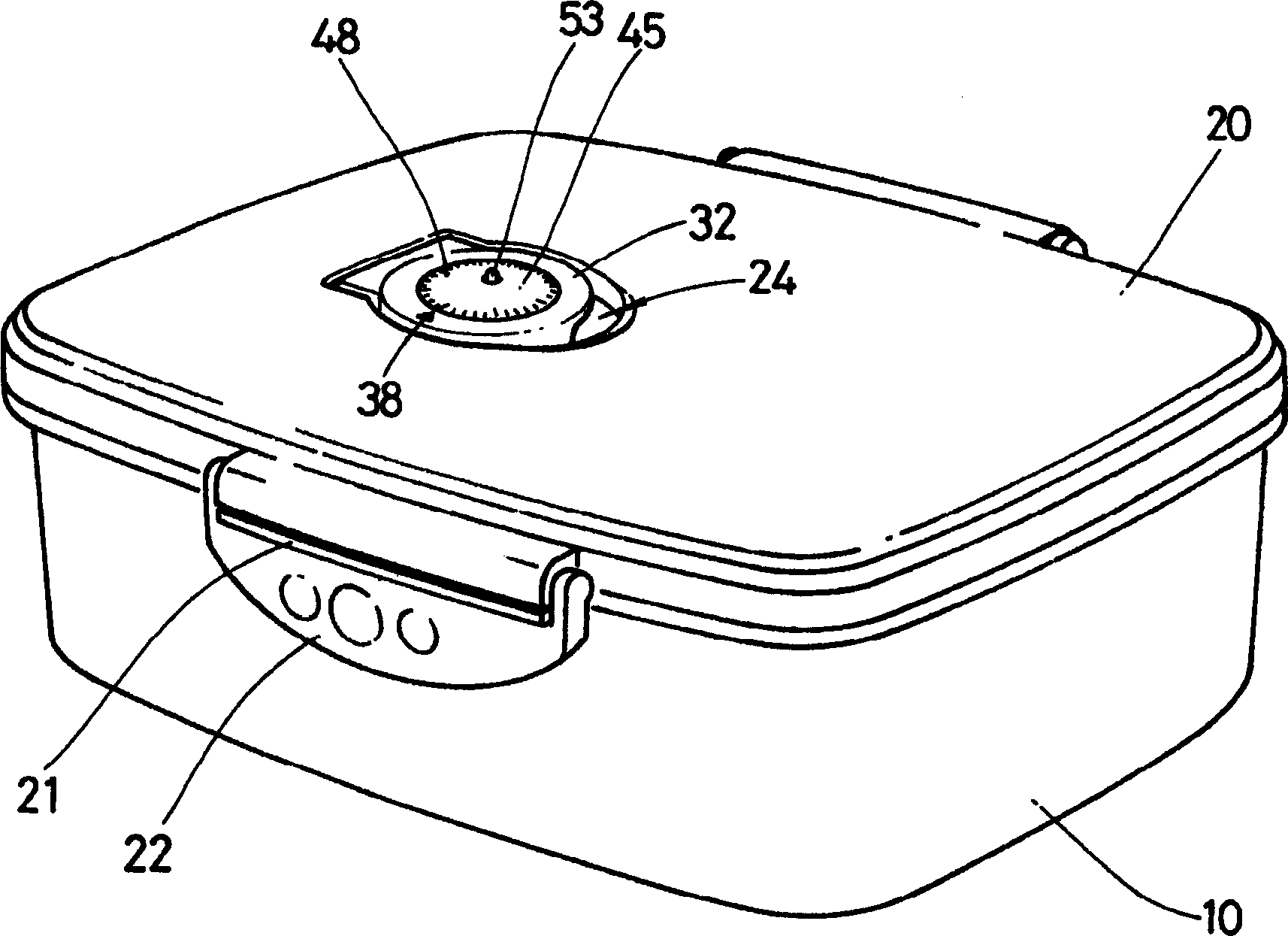

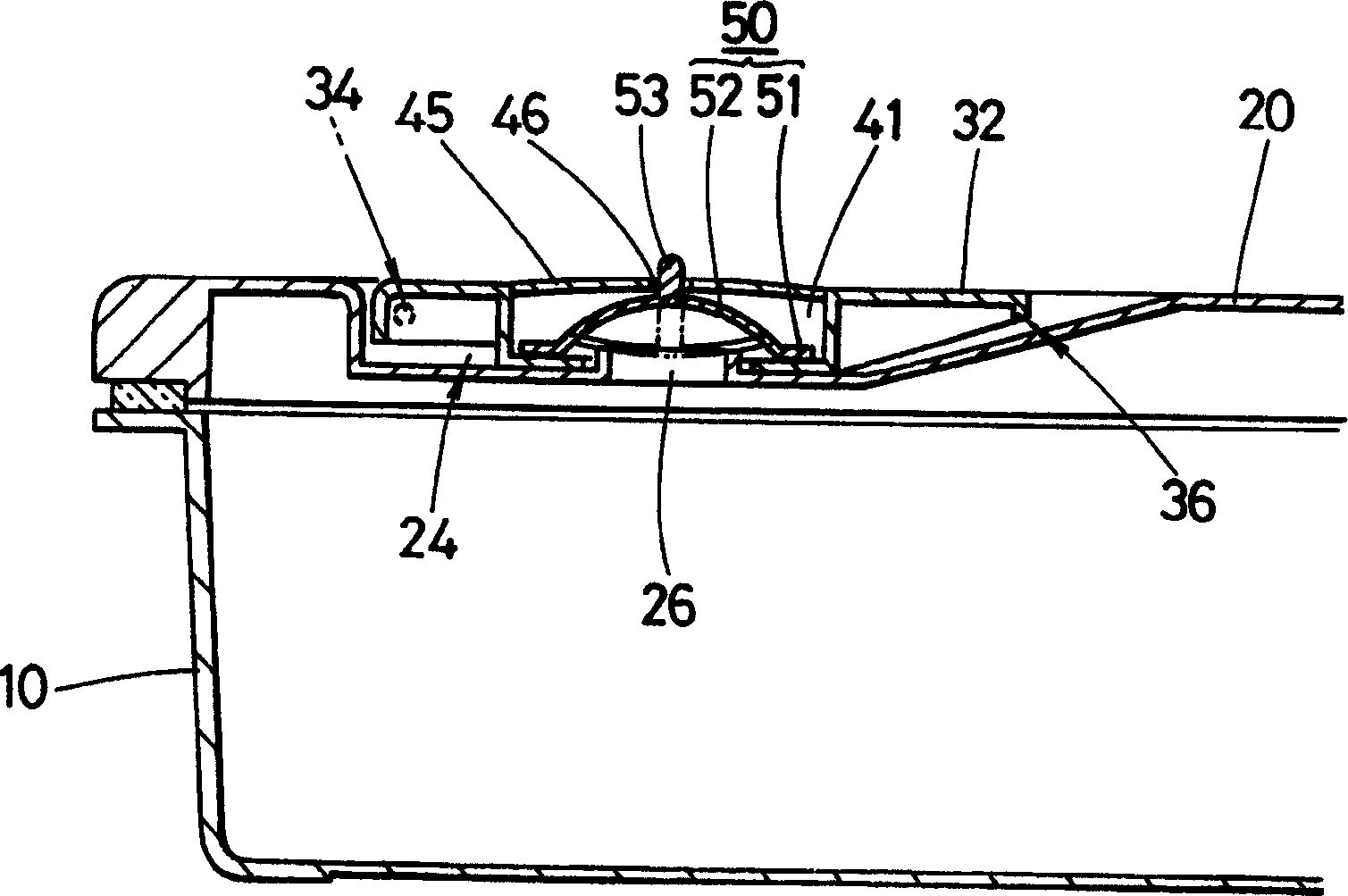

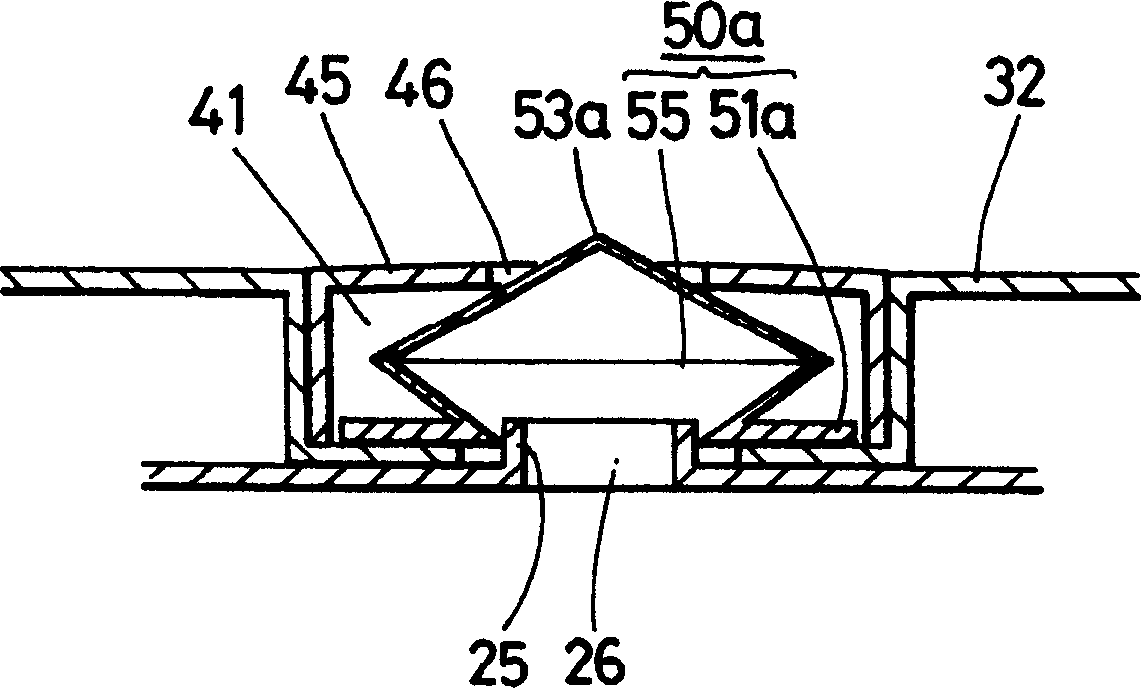

Vacuum valve with vacuum gauge function

Disclosed is a vacuum valve including a lid (20), a depression (24) defined on the lid, a boss (25) formed on the lid at a bottom of the depression, a rotary cover (32) rotatably arranged in the depression, and a closure member detachably coupled to the rotary cover. The vacuum valve comprises a through-hole (26) defined at a center portion of the closure member; a vacuum maintaining member (50) accommodated in the closure member and having an airtightening flange part and a semi-spherical head part, the airtightening flange (51) part being brought into close contact with a portion of the rotary cover, and the semi-spherical head part projecting upward from the airtightening flange part in a rounded manner such that, as the lid of a vacuum container is repeatedly pressed and released, air existing in a container body is discharged to the outside and vacuumization is effected in the vacuum container; and an exposure bar extending upward from the semi-spherical head part by a predetermined length such that the exposure bar can be moved upward and downward through the through-hole of the closure member depending upon a vacuumization degree to allow a user to confirm a vacuumized state of the vacuum container with the naked eye.

Owner:KOREA ALPHALINE CO LTD

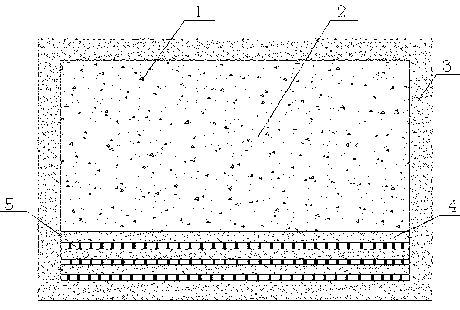

Vacuum heat-insulating plate

InactiveCN103234095AReduce edge heatingGuaranteed vacuumThermal insulationPipe protection by thermal insulationThin membraneAluminium foil

Provided is a vacuum heat-insulating plate. An air absorbing agent (1) is arranged in polystyrene foam (2), the polystyrene foam (2) is sealed by using multiple layers of polyester based films (3) and then vacuumized form a high-vacuum space, and an anti-heat-radiation layer is arranged in the vacuum heat-insulating plate and consists of an aluminium foil or an aluminium coated film (4) and a nylon net (5). The anti-heat-radiation layer consisting of the aluminium foil or the aluminium coated film and the nylon net effectively decreases heat entering the vacuum heat-insulating plate through heat radiation, the edge heat effect of the vacuum heat-insulating plate is reduced, permeation of outside aqueous vapor and air leakage of a heat preserving material can be prevented well, and the vacuum degree of the vacuum heat-insulating plate is guaranteed, so that the heat-insulating performance of the vacuum heat-insulating plate is good.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Glass solder-welded and strip frame-groove-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951821AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionEngineeringEdge banding

Owner:戴长虹

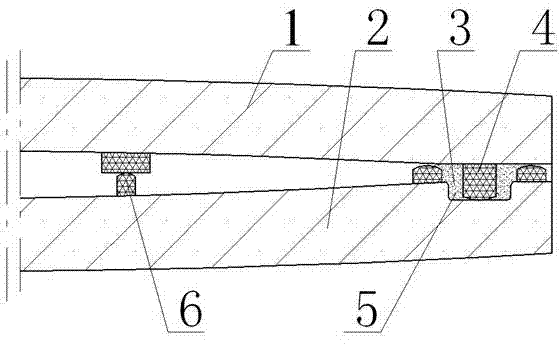

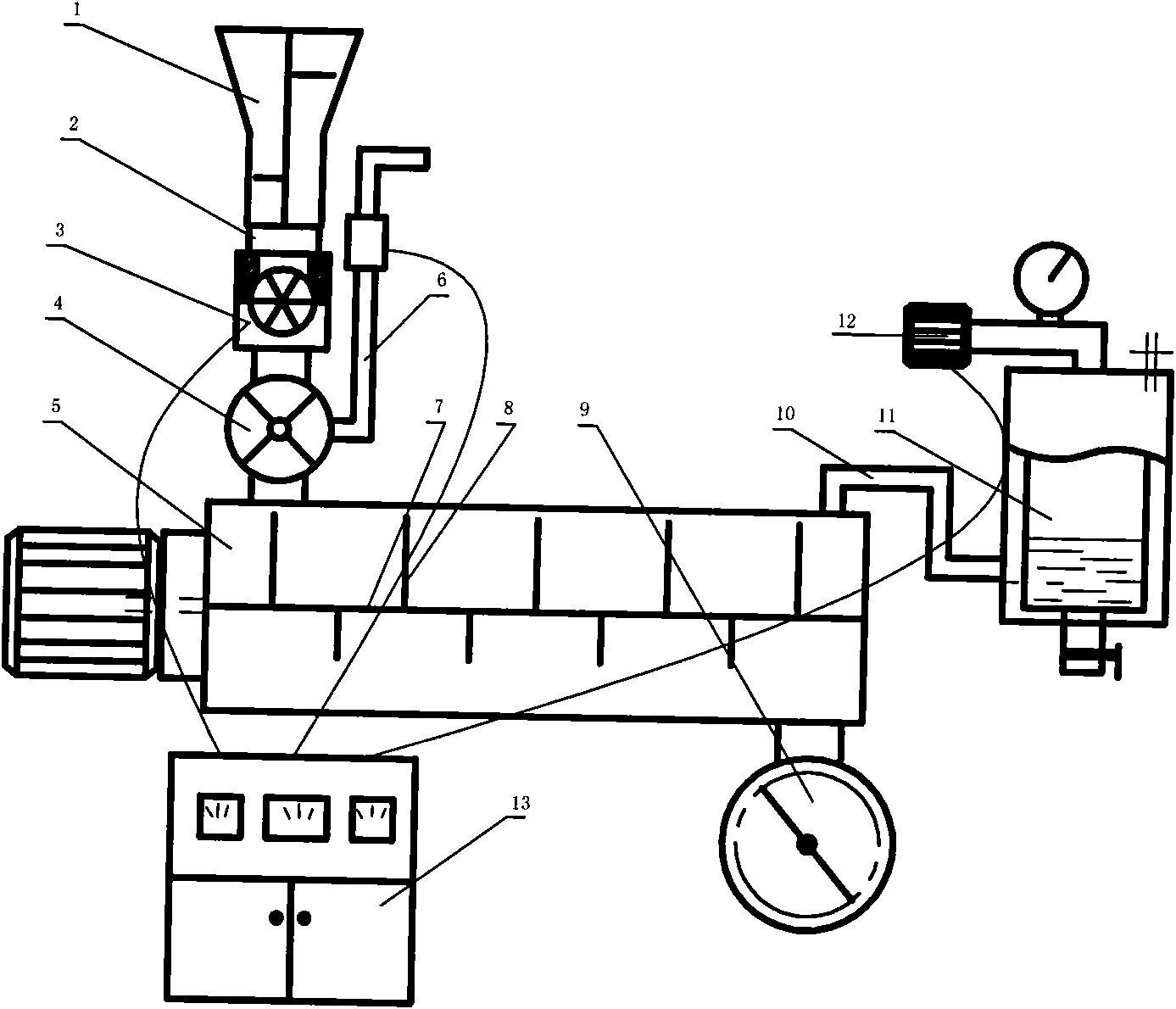

Vacuum flour mixer

InactiveCN101647478AContinuous productionSpeed up the flowMixing/kneading with vertically-mounted toolsEngineeringDrive motor

The invention provides a vacuum flour mixer and relates to a continuous vacuum flour mixer, which comprises a machine frame, a driving motor and a stirring container, wherein the stirring container isarranged on the machine frame and driven by the driving motor, and the inside of the stirring container is provided with a stirrer consisting of a stirring shaft and a stirring paddle. The vacuum flour mixer also comprises a flour feeding device, a water feeding device and a discharging device which are communicated with the stirring container. The vacuum flour mixer is provided with a control device controlling the flour feeding device and the water feeding device. The vacuum flour mixer also comprises a continuous vacuumizing device which is controlled by a circuit and connected with the stirring container, wherein the vacuumizing device comprises a vacuum connecting pipe and a vacuum pump. The vacuum flour mixer is characterized in that: a rotary feeder is arranged between the flour feeding device and the stirring container; the vacuum connecting pipe is provided with a dust filtering device; and the stirring paddle is connected to the stirring shaft through an angle adjusting device. The vacuum flour mixer has the function of insulating pressure to make the inside of the stirring container keep certain vacuum degree all the time so as to ensure the flour mixing quality.

Owner:JIANGSU YINGYANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com