Method for acquiring vacuum during making vacuum glass member

A vacuum glass and component technology, applied in glass molding, glass re-molding, building components and other directions, can solve the problems of long time required, difficulty in obtaining a higher vacuum degree, etc., to achieve the effect of quality assurance and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by taking a vacuum glass member with a two-layer structure as an example.

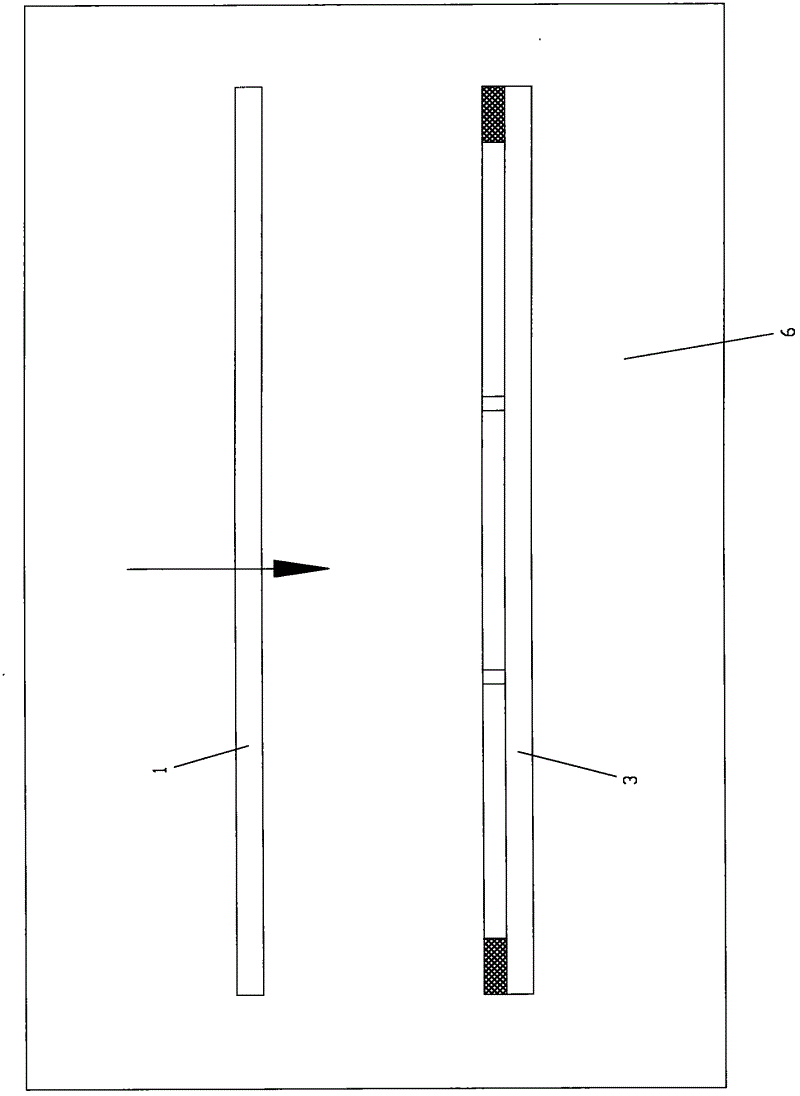

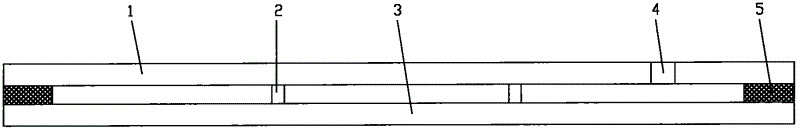

[0018] like figure 2 As shown, when processing a vacuum glass member according to the method of the present invention, at first the two glass plates 1, 3 constituting the vacuum glass member are placed in a vacuum chamber 6, and the two glass plates 1, 3 are placed in a vacuum environment independently of each other , that is, the surroundings of each glass plate have the same vacuum degree as the vacuum environment. At this time, if the vacuum degree in the vacuum chamber 6 reaches the required vacuum degree, the upper glass plate 1 can be pressed according to the arrow in the figure. Direction is placed on the lower glass plate 3, and the two are assembled together, if the required vacuum degree is not reached in the vacuum chamber 6, it is necessary to adjust the vacuum degree to the required value, and then put the two pieces of glass to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com