Vacuum heat-insulating plate

A vacuum heat insulation board and vacuum pumping technology, applied in heat exchange equipment, through heat insulation to protect pipelines, heat preservation, etc., can solve the problems of low heat transfer performance, low thermal conductivity, etc., and achieve good heat insulation performance and barrier air leakage , Reduce the effect of edge thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

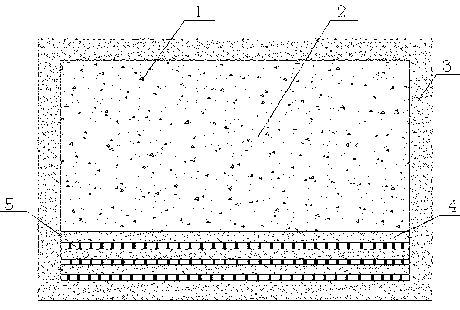

[0008] Such as figure 1 As shown, the present invention is A vacuum insulation panel, a getter 1 is placed in a polystyrene foam 2, sealed with a multi-layer polyester base film 3, and a high vacuum space is formed after vacuuming, and a thermal radiation layer is placed in the vacuum insulation panel to prevent heat The radiation layer is composed of aluminum foil or aluminized film 4 and nylon mesh 5 .

[0009] The heat radiation protection layer is placed inside the vacuum insulation panel, which adopts a two-layer or multi-layer structure, with 5 compartments of nylon mesh.

[0010] The anti-heat radiation layer is sandwiched between the multi-layer polyester base film 3 and the polystyrene foam 2, and is located on the side of the vacuum insulation panel with heat radiation.

[0011] The multilayer polyester base film 3 is processed by folding and heat sealing three sides and welding.

[0012] Aluminum foil or aluminized film 4 use one deck polyethylene film as heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com