Embedded vacuum rolling method of titanium/steel laminated metal

A vacuum rolling and embedded technology, applied in the field of vacuum rolling where clad titanium metal is embedded, can solve the problems of energy consumption, large waste of titanium metal, increased cost, etc., to ensure vacuum degree and purity, improve Productivity, the effect of avoiding plate bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

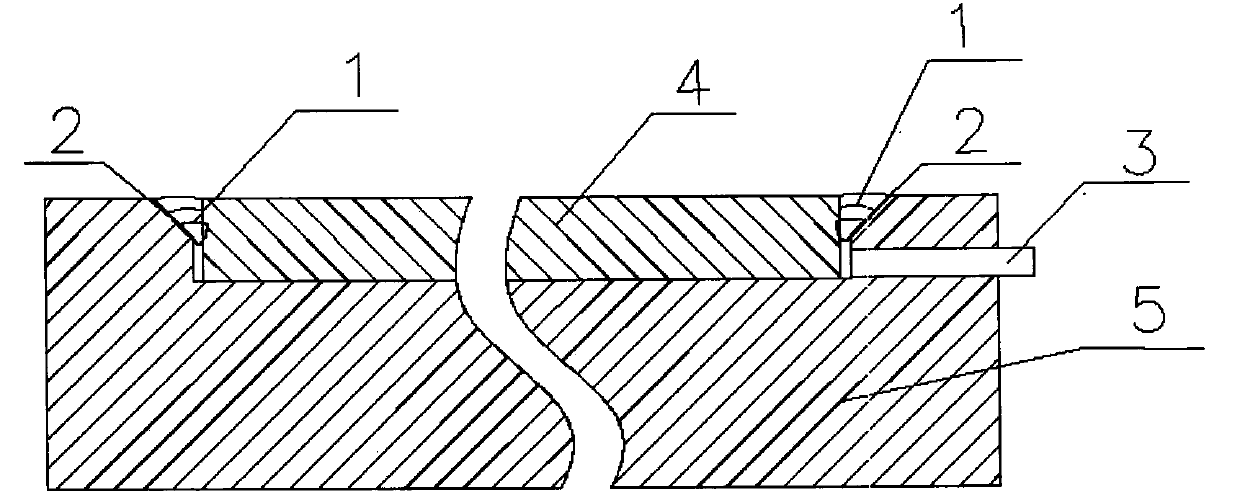

[0028] Single-rolled single-sided composite titanium / steel clad plate, the material is TA2+Q235B, the base plate size is 38×1060×1500mm, and the TA2 plate size is 4×1000×1440mm.

[0029] 1) Use a gantry milling machine to mill a rectangular groove of 4×1001×1441 mm on one side of the substrate, and process the right-angled side of the rectangular groove into a 2×45° chamfer.

[0030] 2) Check around the titanium plate to ensure it is straight.

[0031] 3) Clean the chamfer of the rectangular groove of the substrate, and surfacing a layer of V metal on the chamfer surface by argon tungsten arc welding with a thickness of 0.1mm. Sand the vertical faces of the rectangular slot smooth.

[0032] 4) Clean each surface of the rectangular groove of the substrate to remove surface oil; mechanically polish and polish the surface to be compounded of the titanium plate. The titanium plates are respectively embedded in the rectangular grooves of the substrate, and the space formed by the...

Embodiment 2

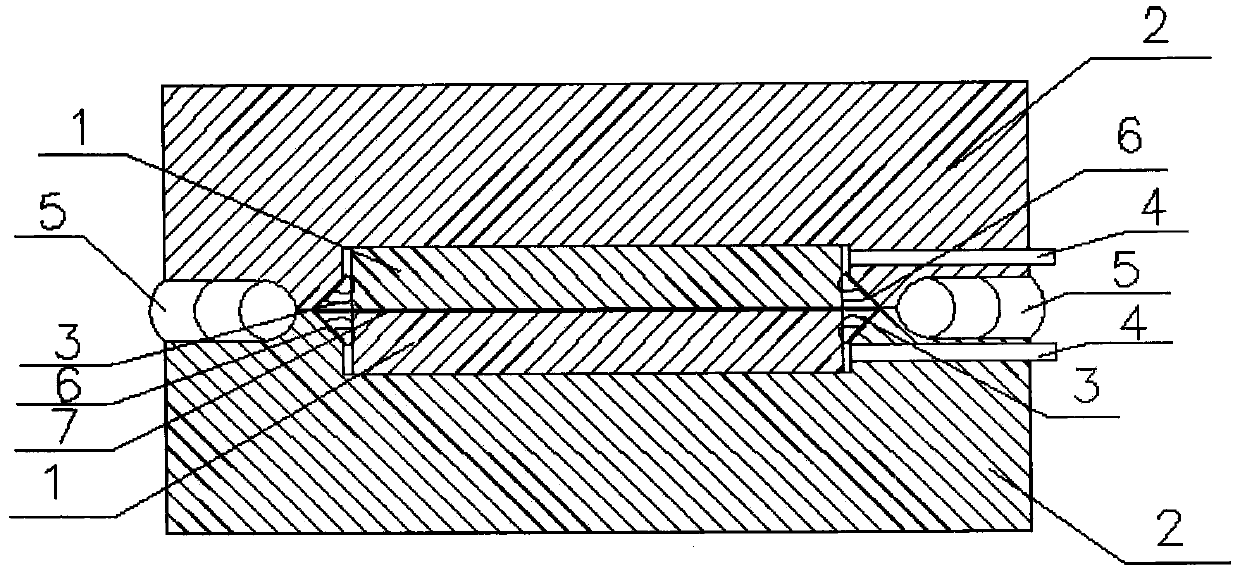

[0037] Double-rolled single-sided composite titanium / steel clad plate, the material is TA2+Q235B, the size of the base plate is 56×2060×2500mm, and the size of TA2 plate is 6×2000×2440mm.

[0038] 1) Use a gantry milling machine to mill a 6×2000×2440mm rectangular groove on one side of the substrate, process the right-angled side of the rectangular groove into a 3×45° chamfer, and process the periphery of the substrate into a semi-U-shaped bevel.

[0039] 2) Check around the titanium plate to ensure it is straight.

[0040] 3) Clean the chamfer of the rectangular groove of the substrate, and surfacing pure iron metal on the chamfer surface by argon tungsten arc welding with a thickness of 0.2 mm. Sand the vertical faces of the rectangular slot smooth.

[0041] 4) Clean each surface of the rectangular groove of the substrate to remove surface oil; mechanically polish and polish the surface to be compounded of the titanium plate. The titanium plates are respectively embedded i...

Embodiment 3

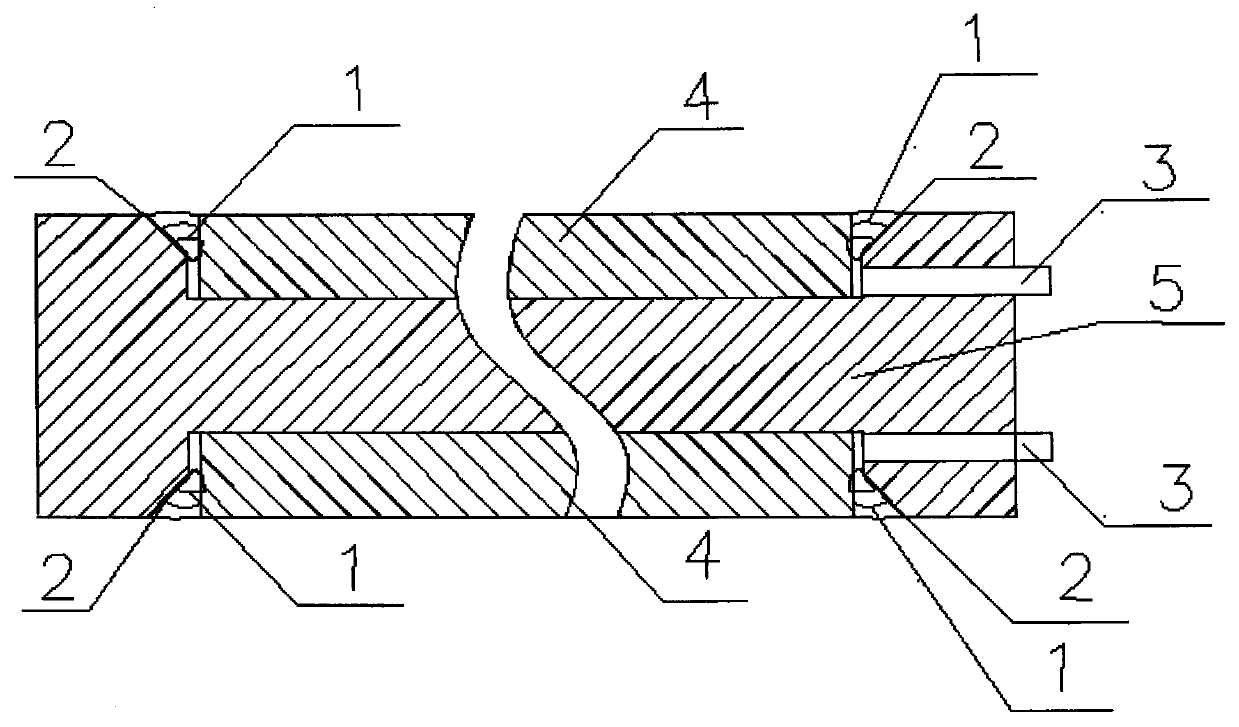

[0048]Single rolling double-sided composite titanium / steel clad plate, the material is TA2+Q235B, the base plate size is 62×1060×1500mm, and the TA2 plate size is 6×1000×1440mm.

[0049] 1) Use a gantry milling machine to mill a rectangular groove of 6×1001×1441 mm on the front and back of the substrate, and process the right-angled side of the rectangular groove into a 3×45° chamfer.

[0050] 2) Check around the titanium plate to ensure it is straight.

[0051] 3) The chamfer of the rectangular groove of the substrate is cleaned, and a layer of Nb metal with a thickness of 0.1 mm is surfacing on the chamfer surface by argon tungsten arc welding. Sand the vertical faces of the rectangular slot smooth.

[0052] 4) Clean each surface of the rectangular groove of the substrate to remove surface oil; mechanically polish and polish the surface to be compounded of the titanium plate. The titanium plates are respectively embedded in the rectangular grooves of the substrate, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com