High voltage DC vacuum relay with high reliability and long service life

A vacuum relay, high-voltage DC technology, applied in relays, electrodeless relays, electromagnetic relays and other directions, can solve the problems of increased contact temperature rise, increased contact voltage drop, reduced relay performance and reliability of use, etc., to achieve reliable contact, Excellent electrical insulation performance, ensuring the effect of arc breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

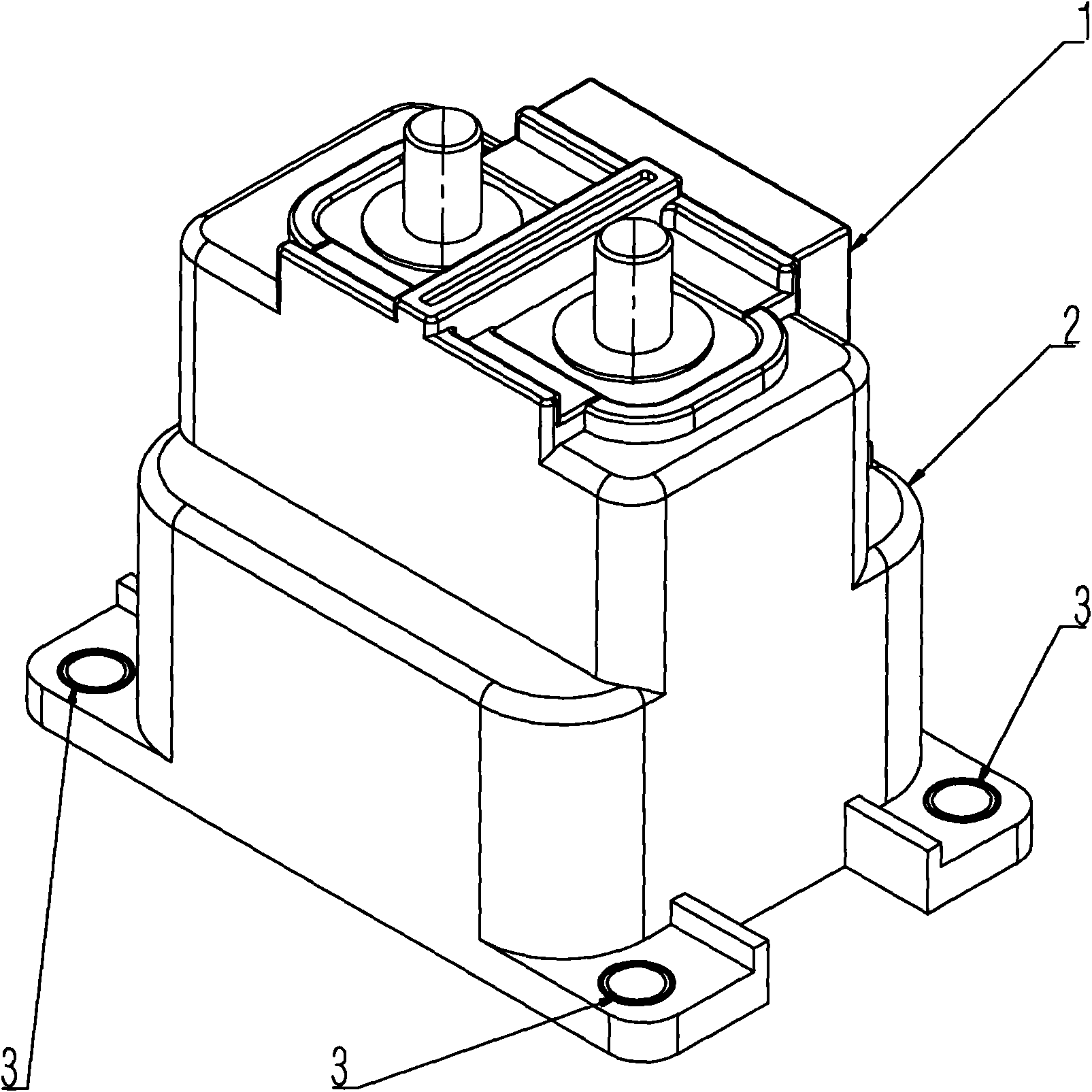

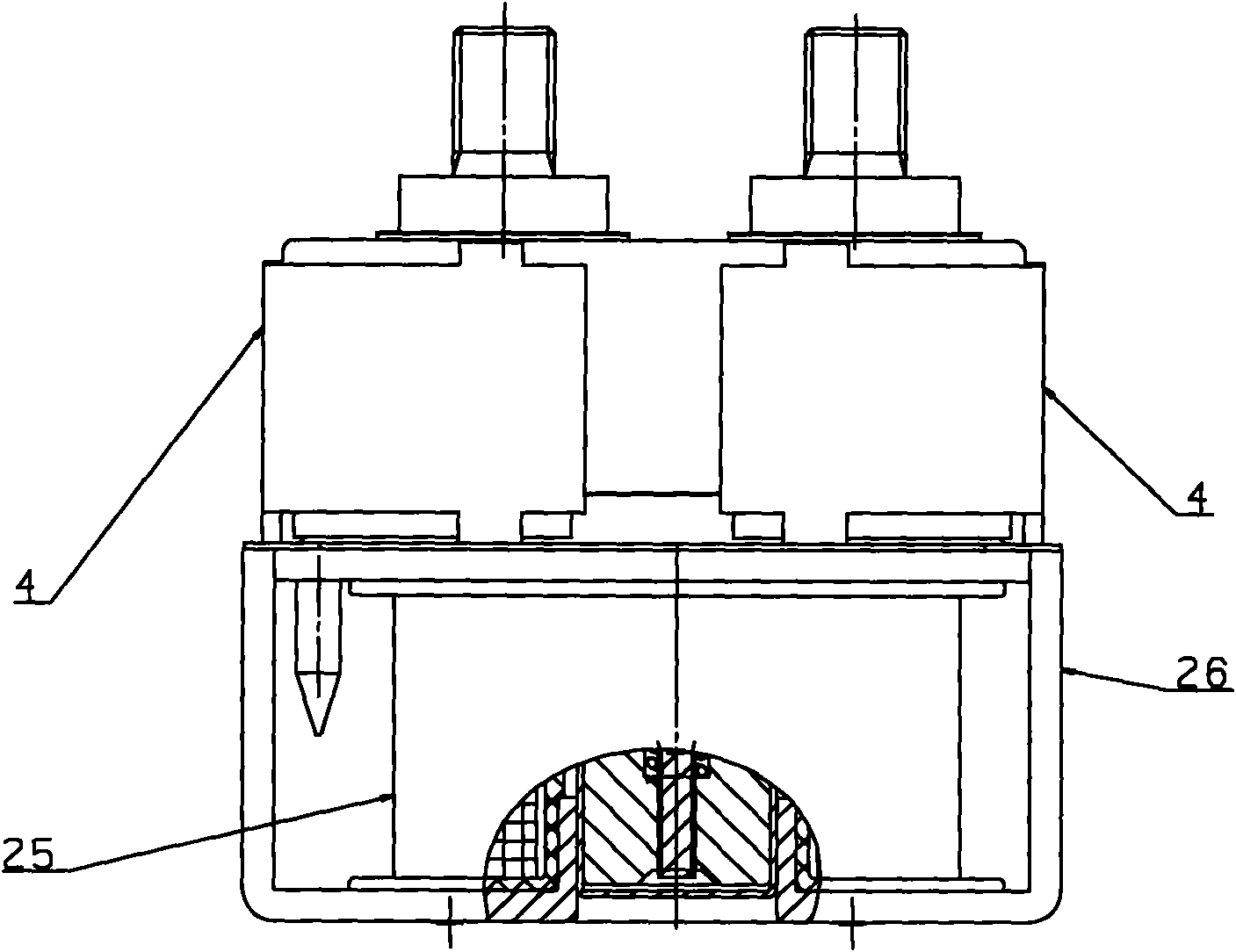

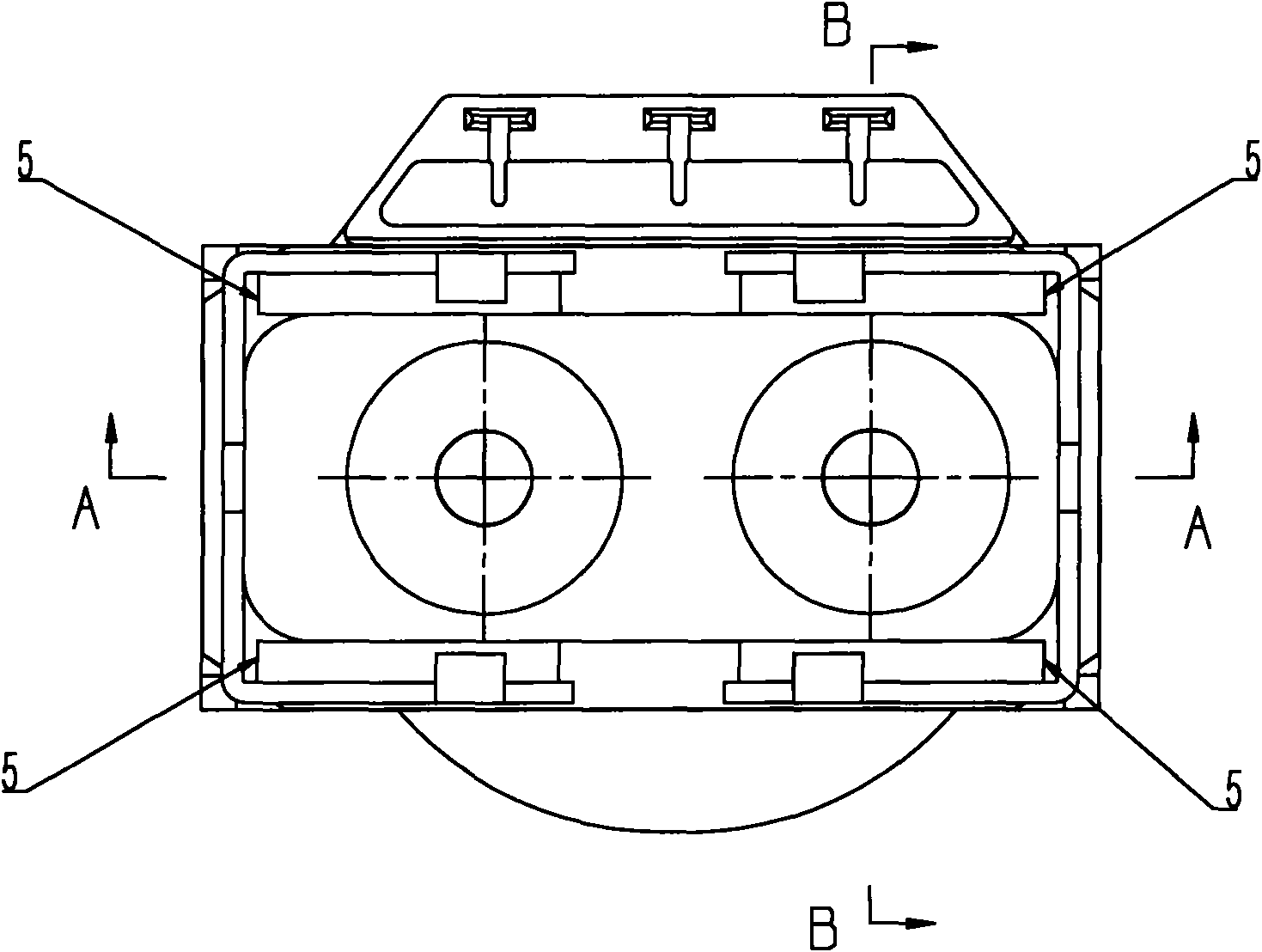

[0035] see Figure 1 to Figure 7 As shown, a high-reliability and long-life high-voltage DC vacuum relay of the present invention includes a moving contact assembly, a static contact assembly, a pushing mechanism containing an iron core, a ceramic cavity, and an external magnetic circuit part; the static contact assembly includes The lead-out 6 and the static contact 7 fixed with the lead-out, the lead-out 6 is installed on the ceramic cavity; the moving contact assembly includes the moving reed 14 and the moving contact 13 fixed with the moving reed; the pushing mechanism It includes a push rod 18 and an iron core that can move the push rod under the action of the external magnetic circuit part; the external magnetic circuit part is installed outside the ceramic cavity; the moving contact assembly, the static contact and the pushing mechanism are completely sealed in the ceramic cavity In the formed vacuum cavity, the moving contact assembly is connected with the first end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com