Method for machining detection plate

A processing method and detection board technology are applied in the field of lithography machines, which can solve the problems of data deviation, low processing yield, and inability to meet the requirements of 90nm lithography machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

[0116] In order to prevent the solution of the influence of the temperature and humidity of the workshop where the gluing is located on the gluing, the temperature in the clean working room is 20-26°C±0.1°C, the humidity is 50-70%, and it is carried out under standard atmospheric pressure;

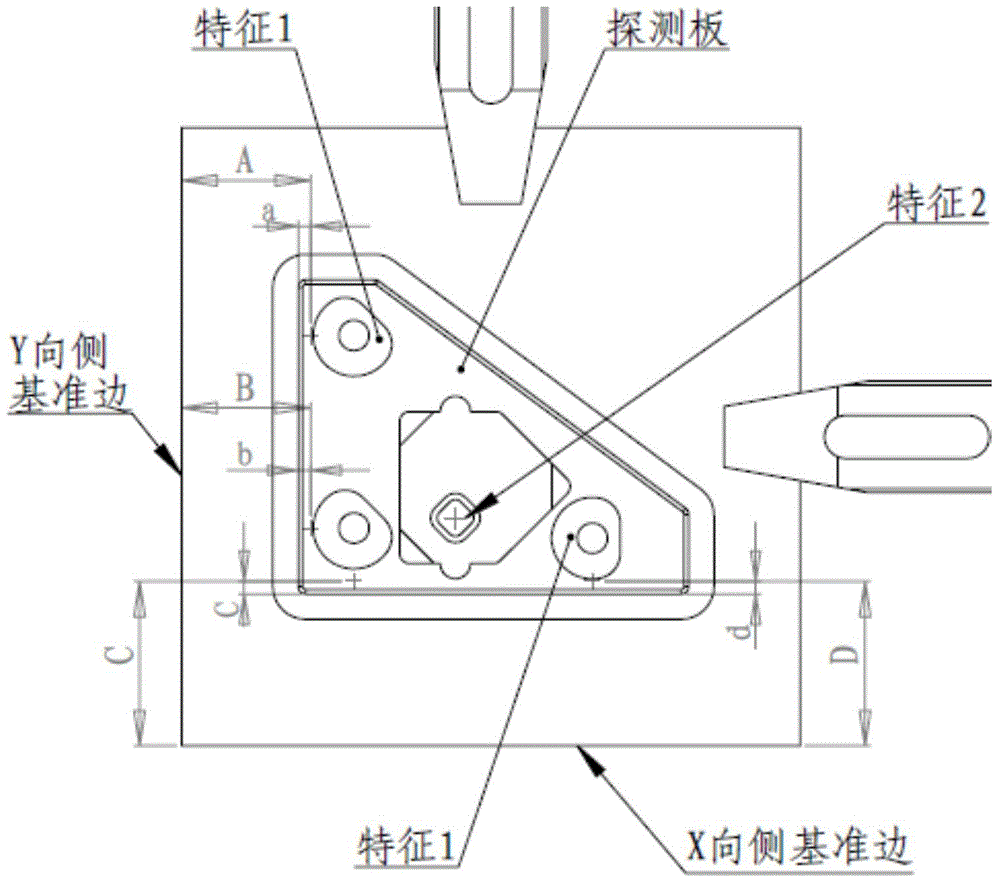

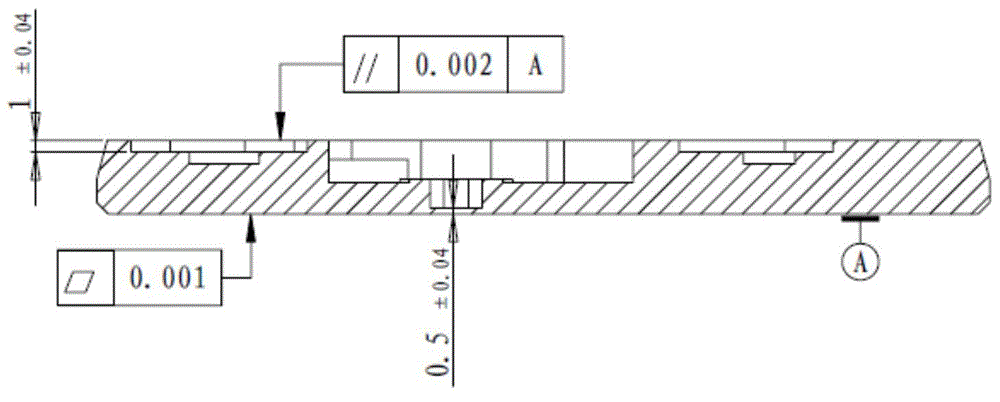

[0117] 1. Carry out the measurement of the positioning mark of the detection board and data processing, and the accuracy of the measured values A, B, C, and D has reached ±0.01, which meets the precision requirements of the processing of the detection board. It is characterized in that the method comprises the following steps:

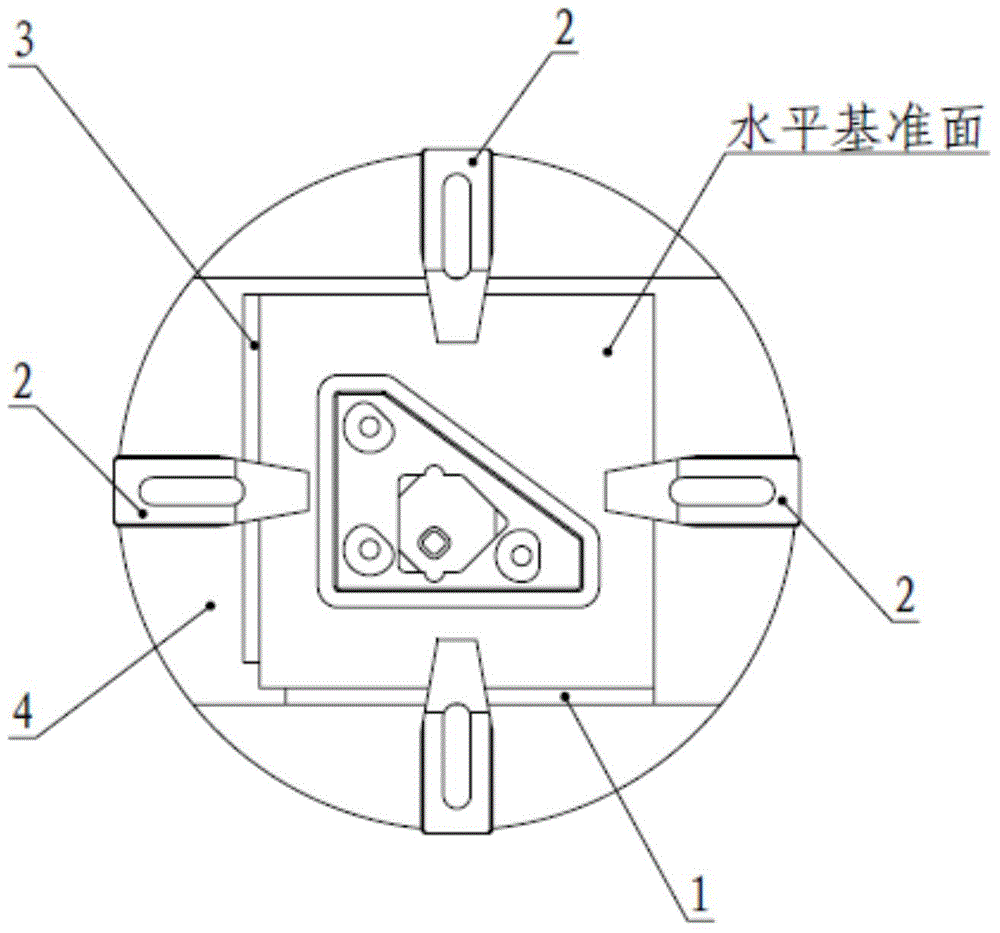

[0118] In the clean studio, the staff put on anti-static gloves, wipe the upper and lower planes of the glued detection board with anti-static optical glass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com