Clamp for assembling aero-engine fan-shaped block assemblies

A technology of aero-engines and sector blocks, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as inability to meet process requirements, achieve the effect of solving spot welding blind spots, not affecting processing accuracy, and reducing operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

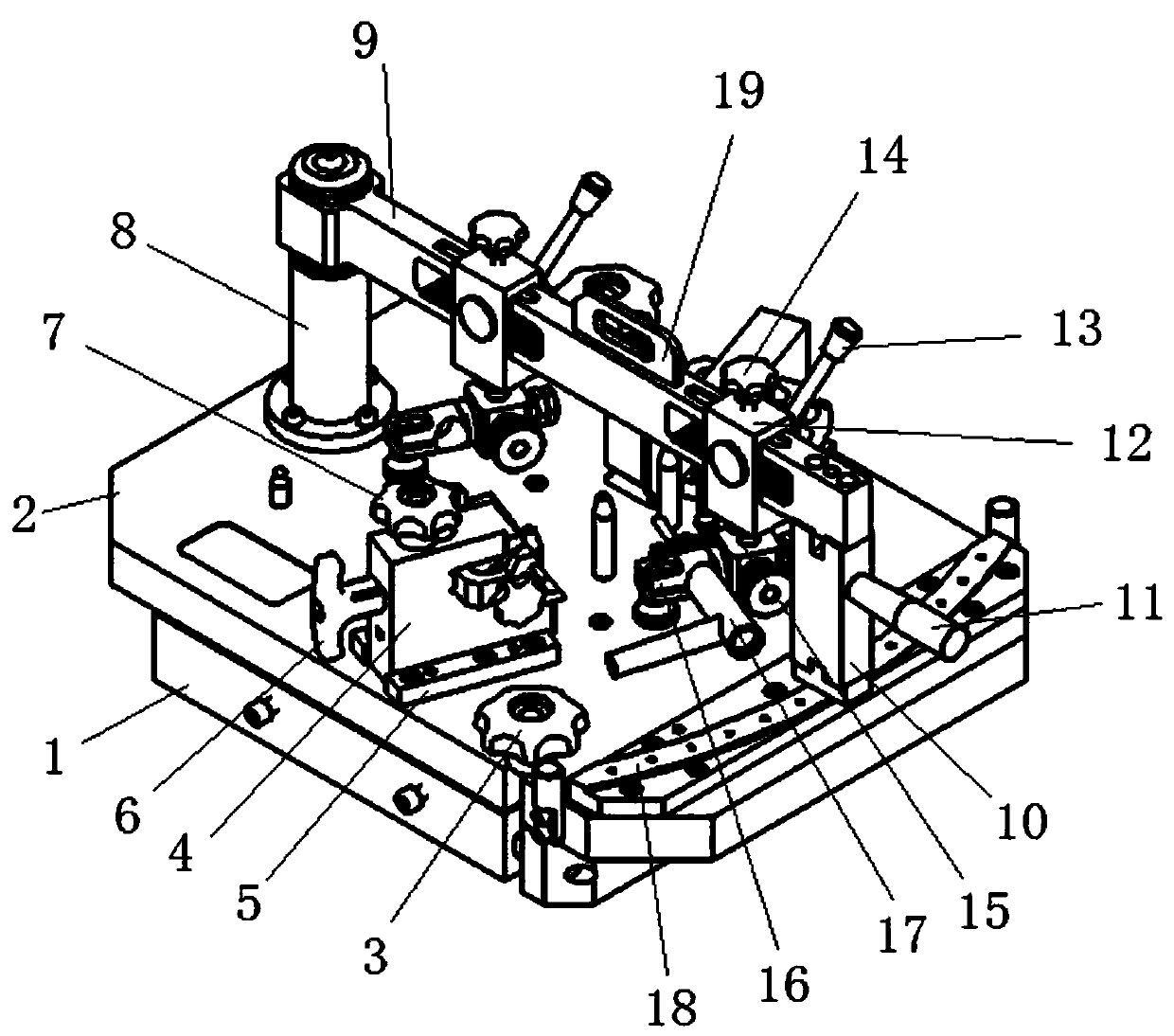

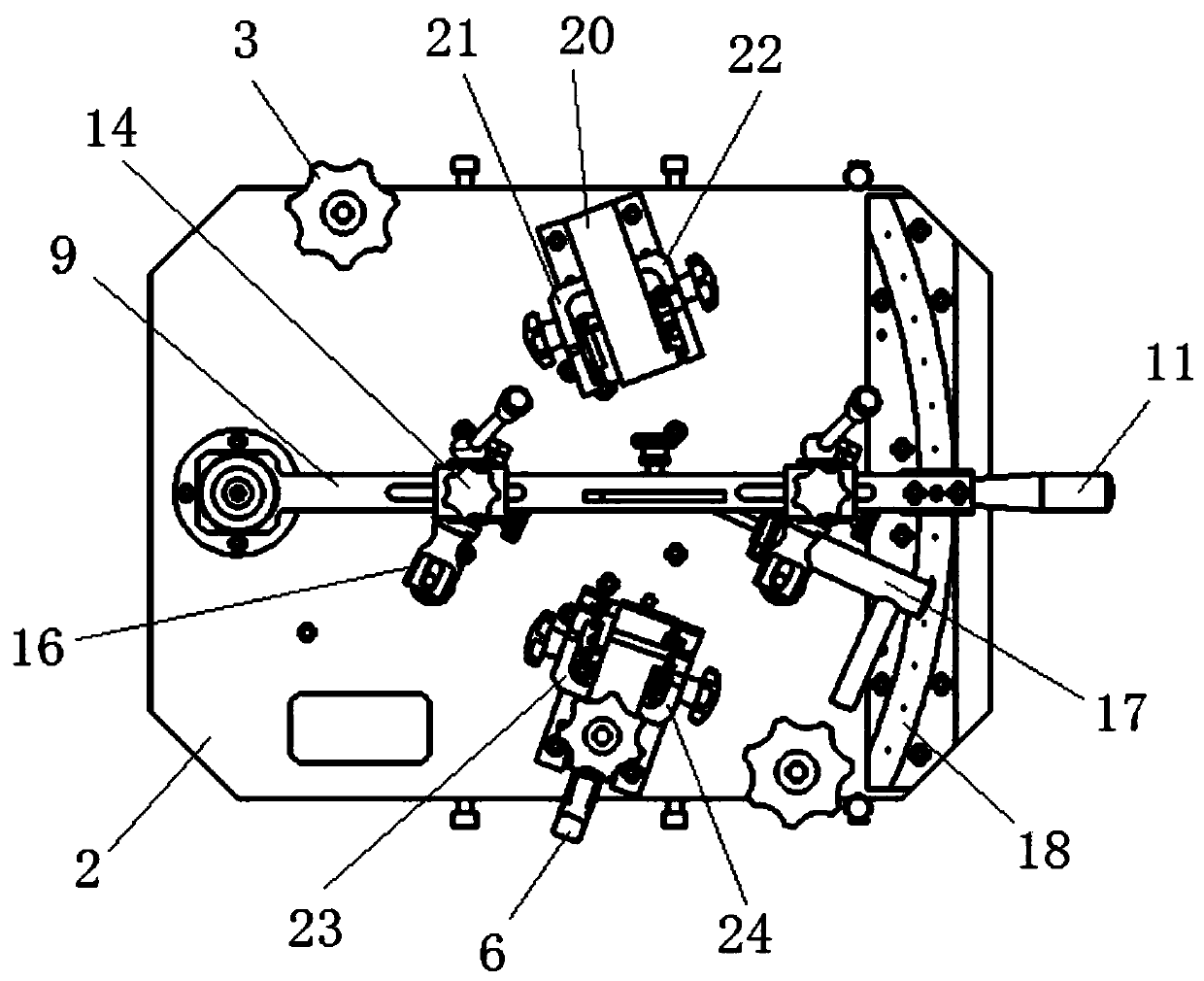

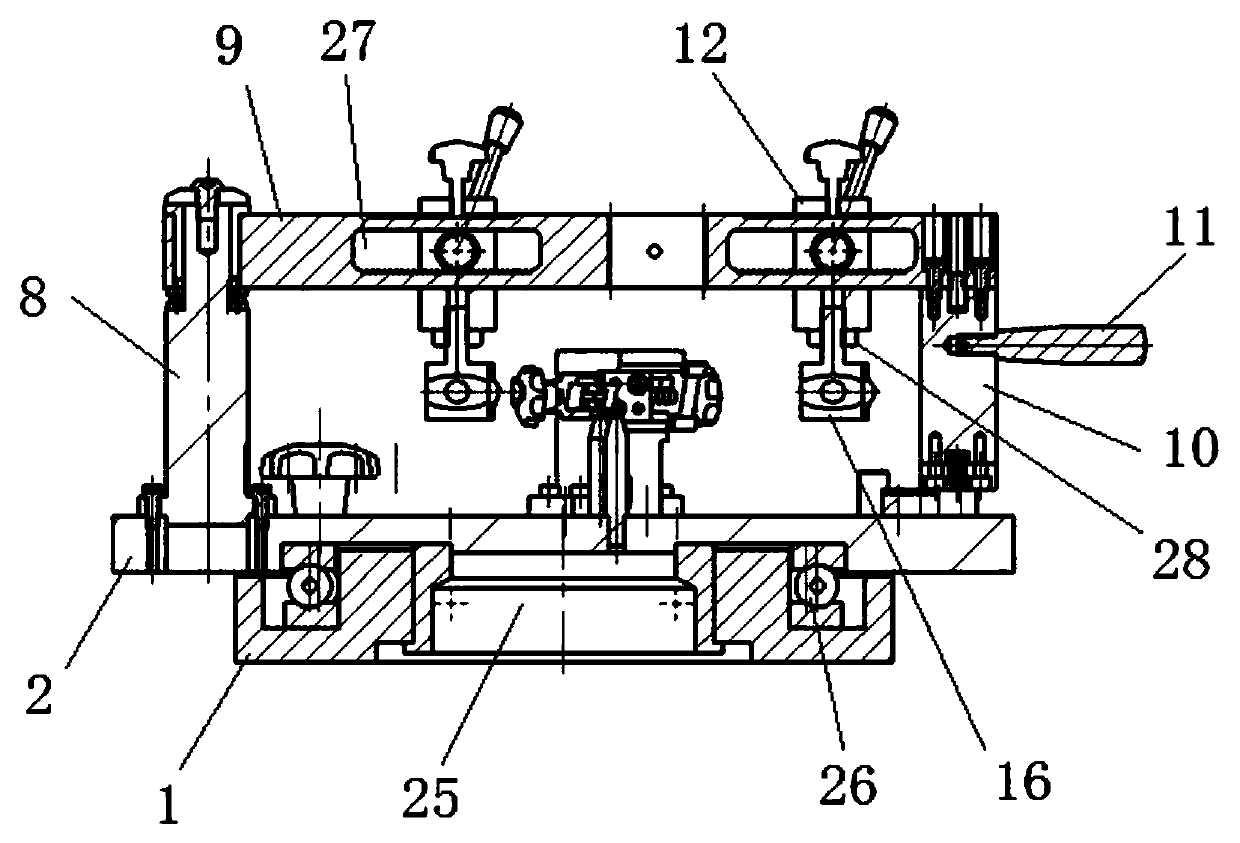

[0019] like Figure 1-3 As shown, a fixture for the assembly of aero-engine sector block components includes a chassis rotation unit, a positioning and pressing unit, a cantilever welding unit and an angular indexing plate 18, and a positioning and pressing unit, a cantilever welding unit and an angular indexing unit The units are respectively installed on the chassis rotation unit, the positioning and pressing unit is used to press and position the inner flow channel plate 31 and the outer flow channel plate 32 of the sector block assembly, and the cantilever welding unit is used to connect the blade 33 of the sector block assembly to the inner flow channel plate 31 and the outer runner plate 32 are welded together, and the angular indexing plate 18 is used for angular positioning of the cantilever welding unit.

[0020] The chassis rotation unit includes a base 1, a turntable 25, a bottom plate 2, an annular thrust bearing 26, slip bolts and star nuts 3, the turntable 25 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com