Boring rod component for machining thrust surface of diesel body

A thrust surface, diesel engine technology, applied in the direction of boring bars, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure, inconvenient adjustment, etc., and achieve the effect of simple driving, convenient tool adjustment, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

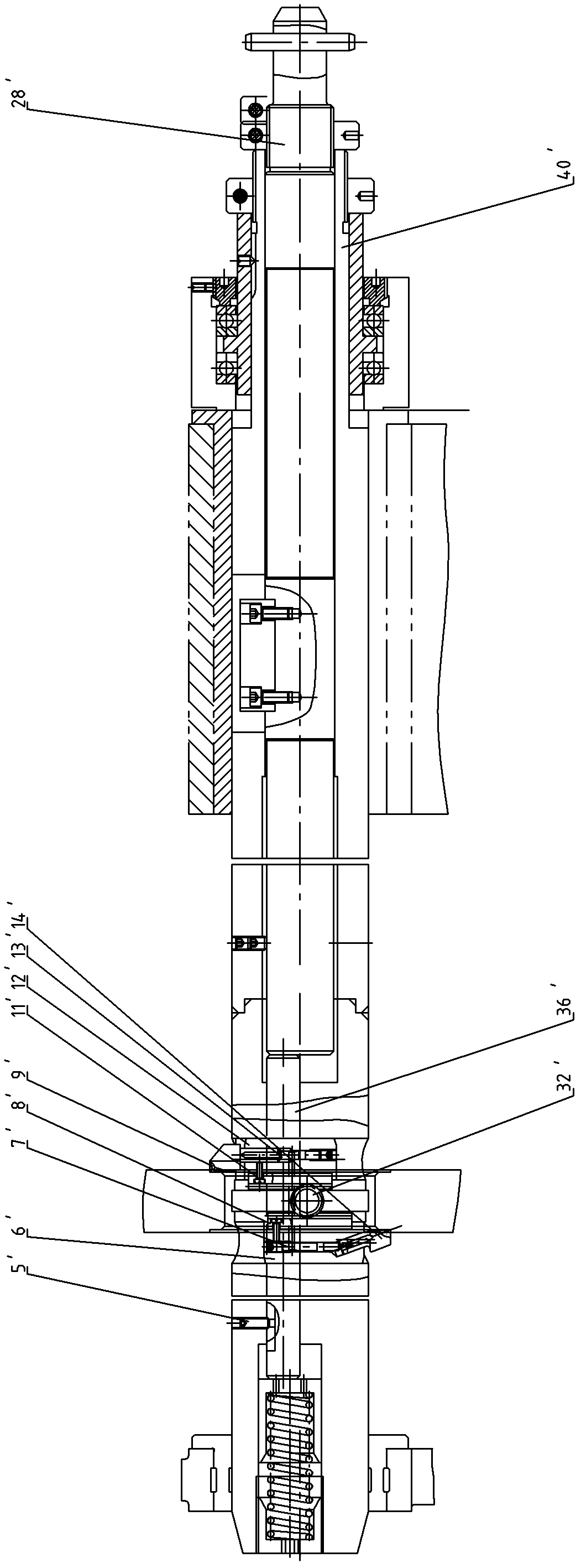

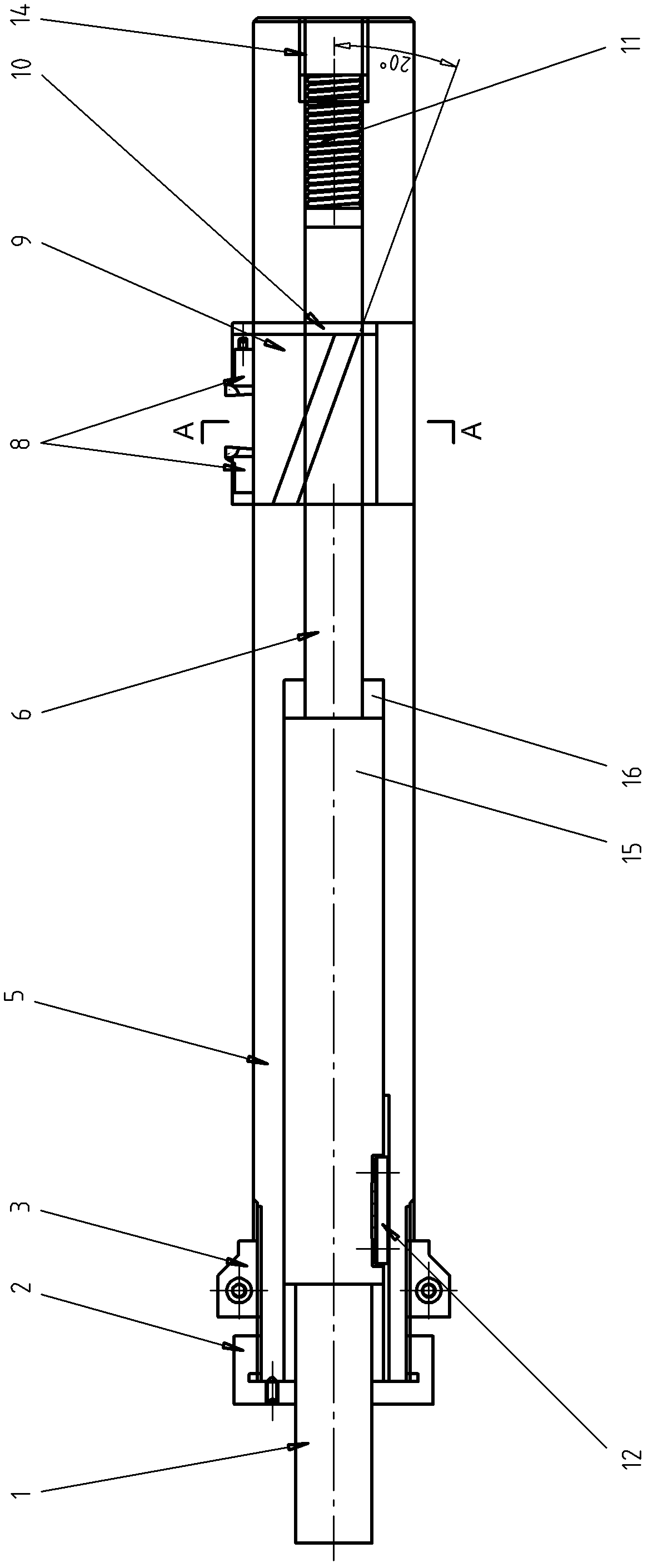

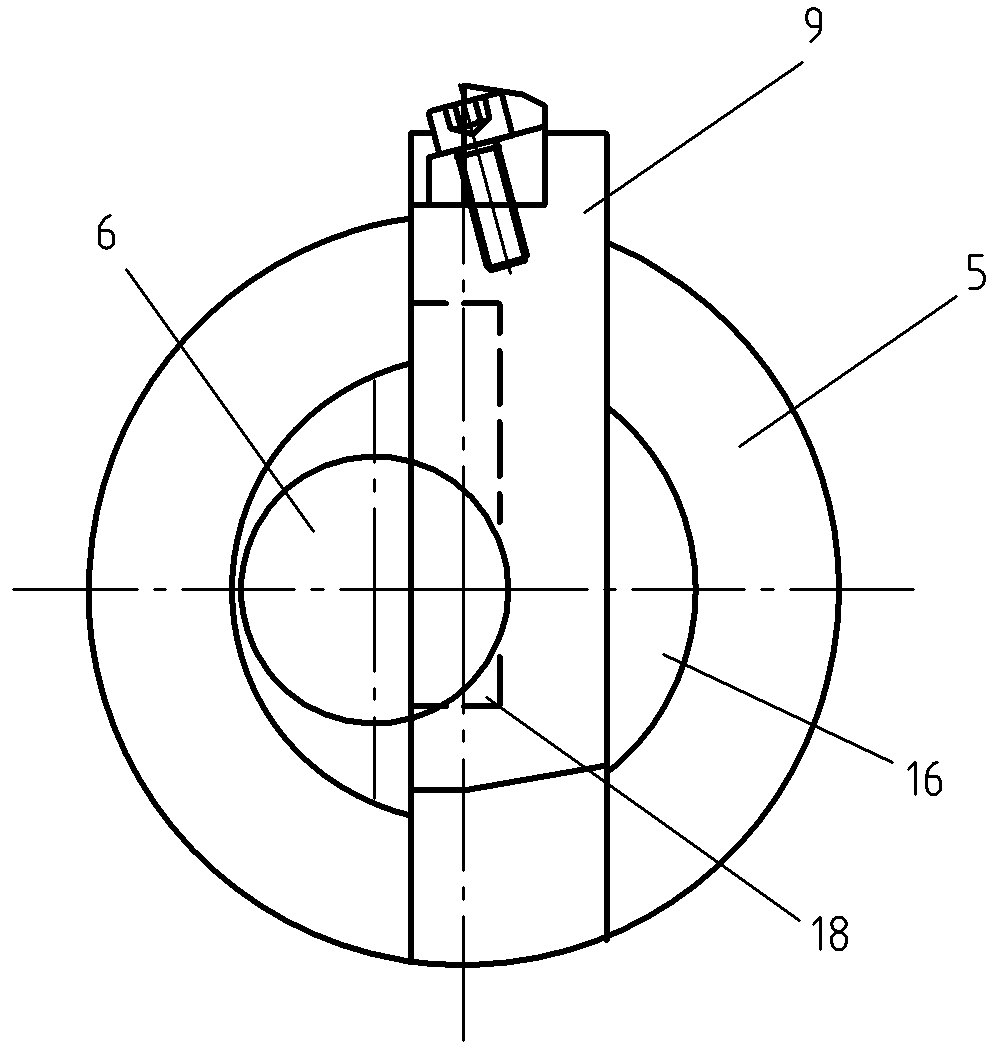

[0047] refer to Figure 2 to Figure 6 , the boring bar assembly for processing the thrust surface of the diesel engine body of the present invention includes a drive rod 1, a push rod 6, a slider 9 and a return spring 11, the boring bar 5 is a hollow structure, and its rear end is provided with a decommissioning positioning nut 2, A thrust surface axial positioning nut 3 is also provided on the circumferential surface near the rear end, and the thrust surface axial positioning nut 3 controls the axial position of the thrust surface. The drive rod 1, the push rod 6 and the return spring 11 are placed in the hollow cavity 16 of the boring bar 5 in turn, the front end of the hollow cavity 16 is provided with threads, and a fixed nut 14 is arranged on it, and the reset The front end of the spring 11 is fixed on the said fixing nut 14 . The drive rod 1 and the boring bar 5 are connected through a feather key 12, so that the two rotate synchronously, but they can move relative to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com