Quick blanking die

A mold and fast technology, applied in the field of blanking molds, can solve the problems of increased risk, increased production cost, increased labor burden of personnel, etc., and achieves the effect of good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

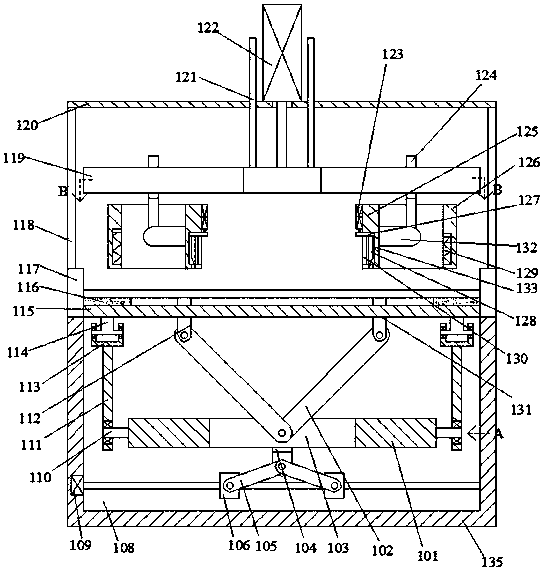

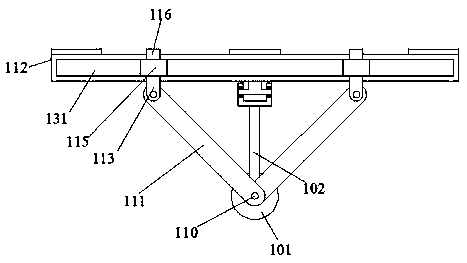

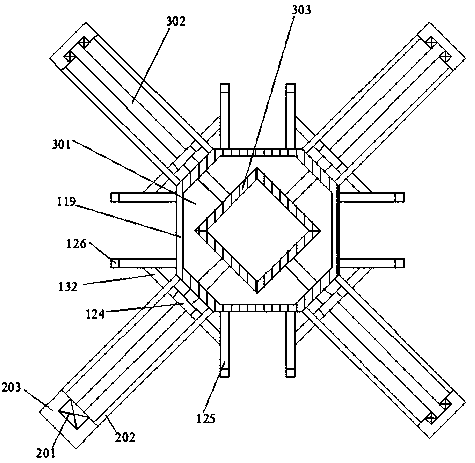

[0020] Such as Figure 1-Figure 4 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. A rapid blanking die of the present invention includes a bottom box 135, and an inner cavity 108 with an opening is fixed in the bottom box 135. A cavity 108 is provided in the inner cavity 108 for use as As for the support device supported by the lower side during the punching process, the upper end surface of the bottom box 135 is provided with a fast punching device for punching, so that the above-mentioned device can be used to realize the fast punching process.

[0021] Beneficially, wherein, the support device includes a drive motor 109 fixed in the left end surface of the inner cavity 108, the output shaft of the drive motor 109 is connected with the end wall of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com