Flue gas treatment device

A technology for flue gas treatment and flue gas treatment chamber, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problem that the treatment efficiency of photochemical methods is difficult to meet the emission amount in the production process, and improve the efficiency of flue gas treatment. , Improve the quality of flue gas treatment, easy to observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

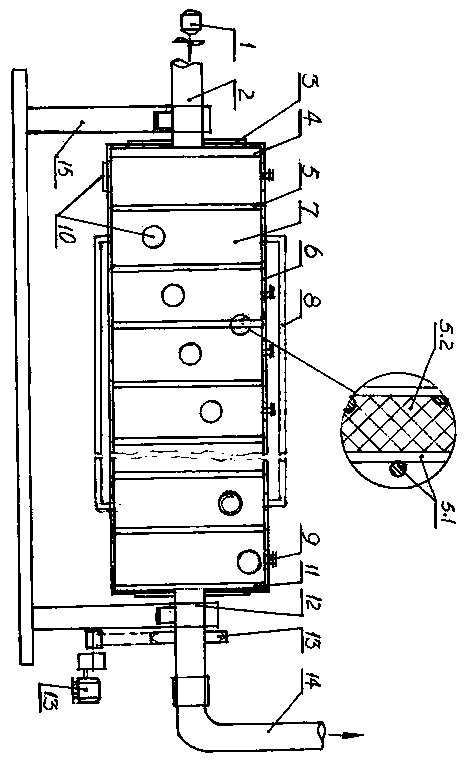

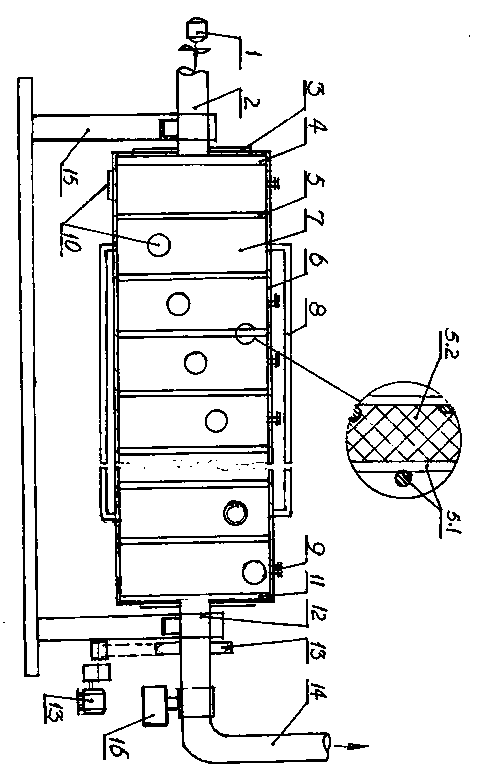

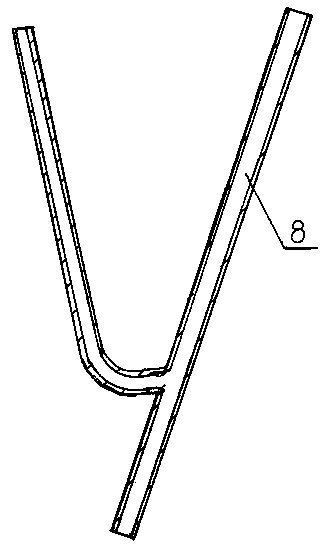

[0027] A flue gas treatment device of Example 1 of the present invention (see figure 1 ), including a frame 15, a flue gas input pipe 2, a flue gas treatment chamber 6 and a flue gas output pipe 14, wherein the flue gas input pipe 2 is arranged at the inlet end of the flue gas treatment chamber 6, and is connected with the flue gas treatment chamber 6 The inner cavities are connected, and an inlet end air distribution plate 4 is arranged at the end; 10 processing cavities 7 are evenly arranged in the inner cavities of the flue gas treatment chamber 6, and one between each two adjacent processing cavities 7 can carry The liquid catalyst can pass through the carrier interlayer 5 of the flue gas; the outer wall between the second processing chamber 7 of the flue gas processing chamber 6 and the penultimate processing chamber 7 at the end is symmetrically provided with two processing chambers respectively 7. The liquid catalyst balance conveying pipeline 8 that communicates with t...

Embodiment 2

[0039] A kind of flue gas treatment device of embodiment 2 of the present invention (see figure 2 ), including a frame 15, a flue gas input pipe 2, a flue gas treatment chamber 6 and a flue gas output pipe 14. The inner cavities of the flue gas treatment chamber 6 are connected, and an inlet end air distribution plate 4 is arranged at the end; 15 treatment cavities 7 are evenly arranged in the inner cavities of the flue gas treatment chamber 6, and between every two adjacent treatment cavities 7 A carrier interlayer 5 that can carry liquid catalyst and pass through flue gas is provided; two The liquid catalyst balance conveying pipeline 8 communicated with the inner chamber of the processing chamber 7 respectively; the outlet end of the flue gas treatment chamber 6 is provided with an outlet end air distribution plate 11, and the outlet end air distribution plate 11 is connected with the inlet end air distribution plate 4 are arranged opposite to each other, and the outside ...

Embodiment 3

[0052] A kind of flue gas treatment device of embodiment 3 of the present invention (see figure 2 ), including a frame 15, a flue gas input pipe 2, a flue gas treatment chamber 6 and a flue gas output pipe 14. The inner cavities of the flue gas treatment chamber 6 are connected, and an inlet end air distribution plate 4 is provided at the end; 19 treatment cavities 7 are evenly arranged in the inner cavities of the flue gas treatment chamber 6, and between every two adjacent treatment cavities 7 A carrier interlayer 5 that can carry liquid catalyst and pass through flue gas is provided; two The liquid catalyst balance conveying pipeline 8 communicated with the inner chamber of the processing chamber 7 respectively; the outlet end of the flue gas treatment chamber 6 is provided with an outlet end air distribution plate 11, and the outlet end air distribution plate 11 is connected with the inlet end air distribution plate 4 are arranged opposite to each other, and the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com