Water pressure nozzle-converging chuck

A technology of shrinking nozzles and chucks, applied in the field of EDM perforation, can solve the problems of improper clamping action, affecting processing quality, complicated installation and use, etc., and achieves the effect of convenient use and good clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

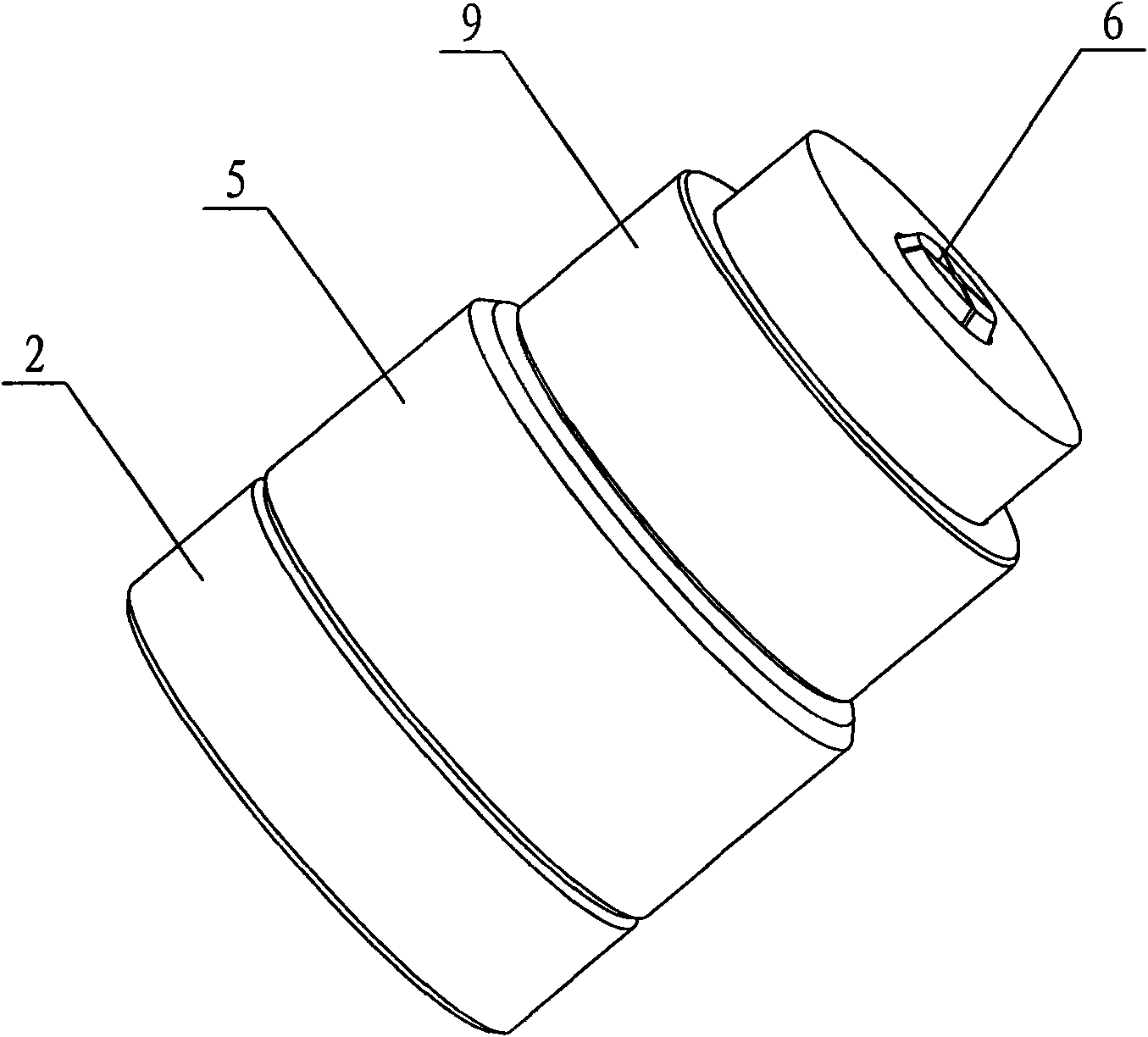

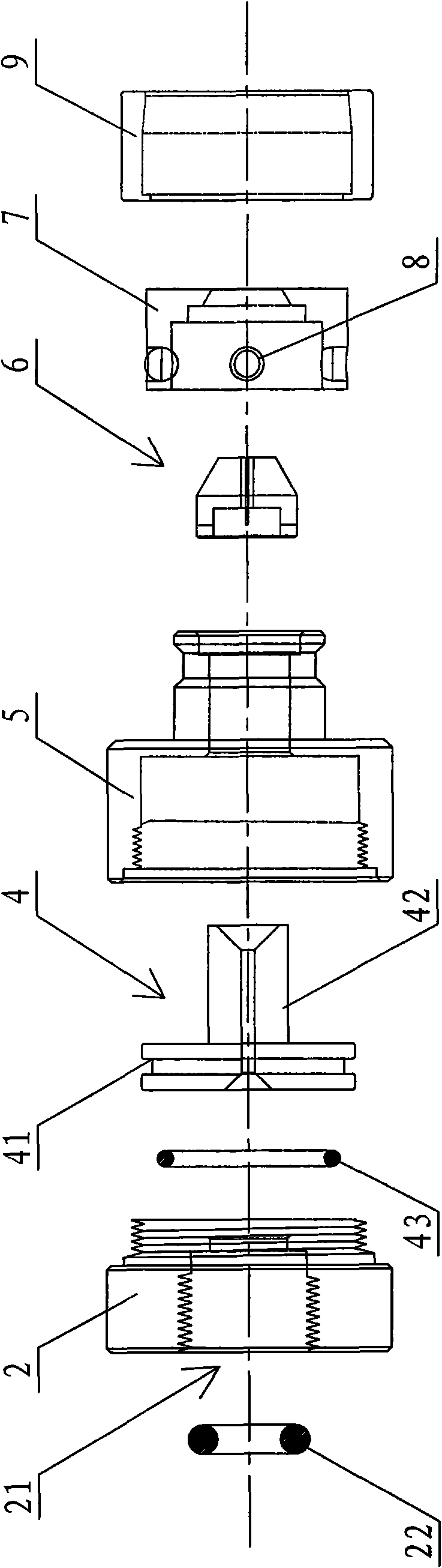

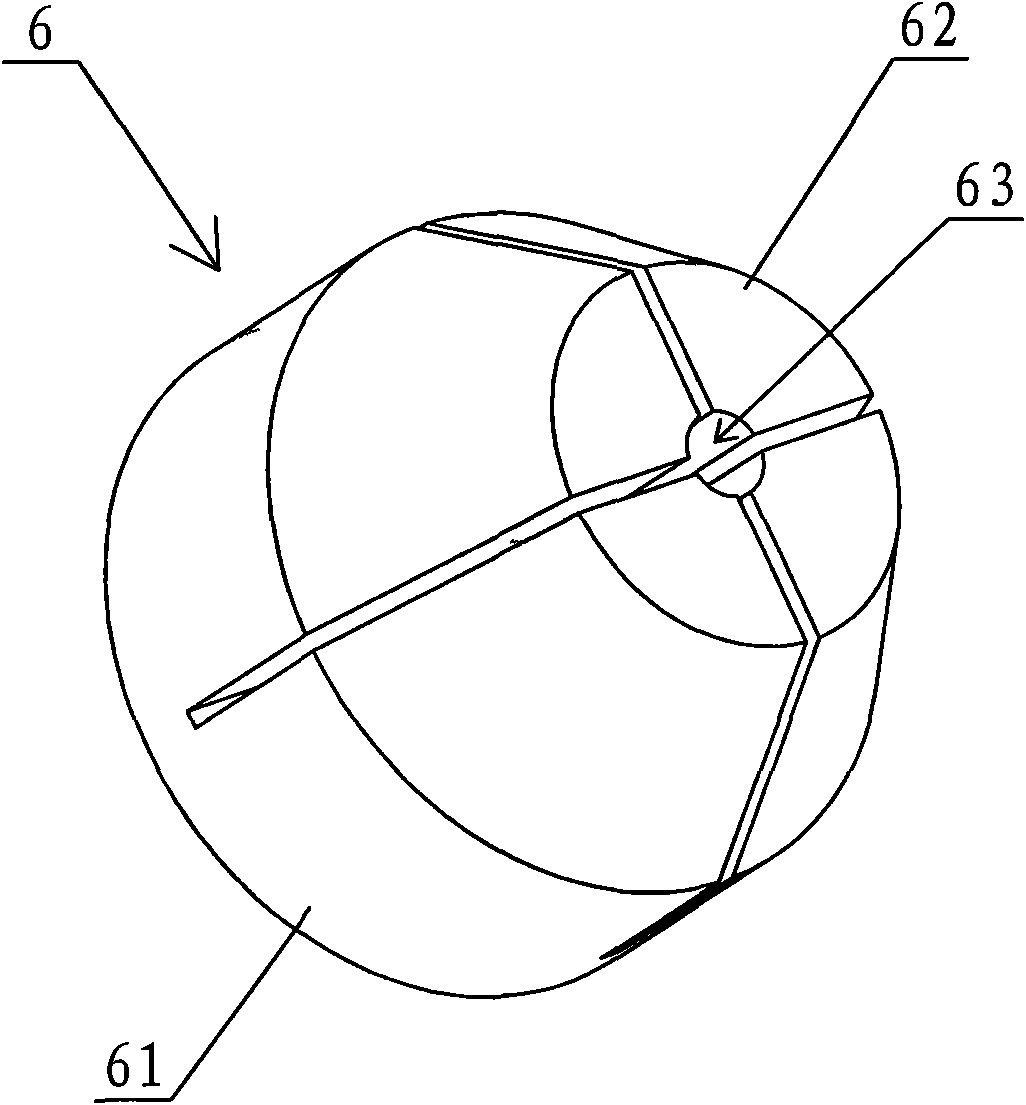

[0020] Such as Figure 1 to Figure 3 Shown is an embodiment of a water compression nozzle chuck according to the present invention, including a piston 4 and a piston cylinder liner 5, and the piston cylinder liner 5 is tightly sleeved on the outer edge of the piston 4. This embodiment also includes a Water connector 2, elastic neck 6, neck sleeve 7, piston seat 41 of piston 4 is connected with connector 2, connector 2, piston 4 and piston liner 5 form an oil cylinder structure, elastic neck 6 includes a Shrinking seat 61, elastic shrinking mouth 6 is connected to the head of the piston rod 42 of piston 4 through its shrinking mouth seat 61, is provided with some elastic shrinking mouth pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com