Clamping claw structure of fixing intermediate body

A technology of intermediate bodies and claws, which is applied in the field of claw structures for fixing intermediate bodies, and can solve problems that affect the processing quality of intermediate body holes and cannot guarantee the stability of intermediate bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

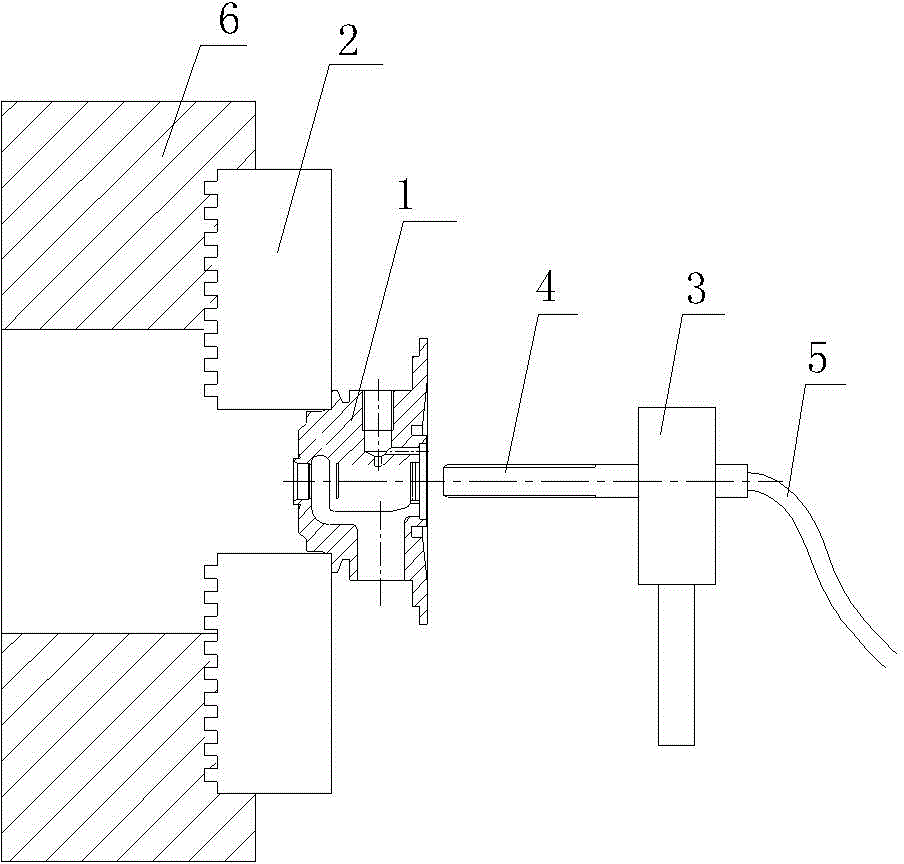

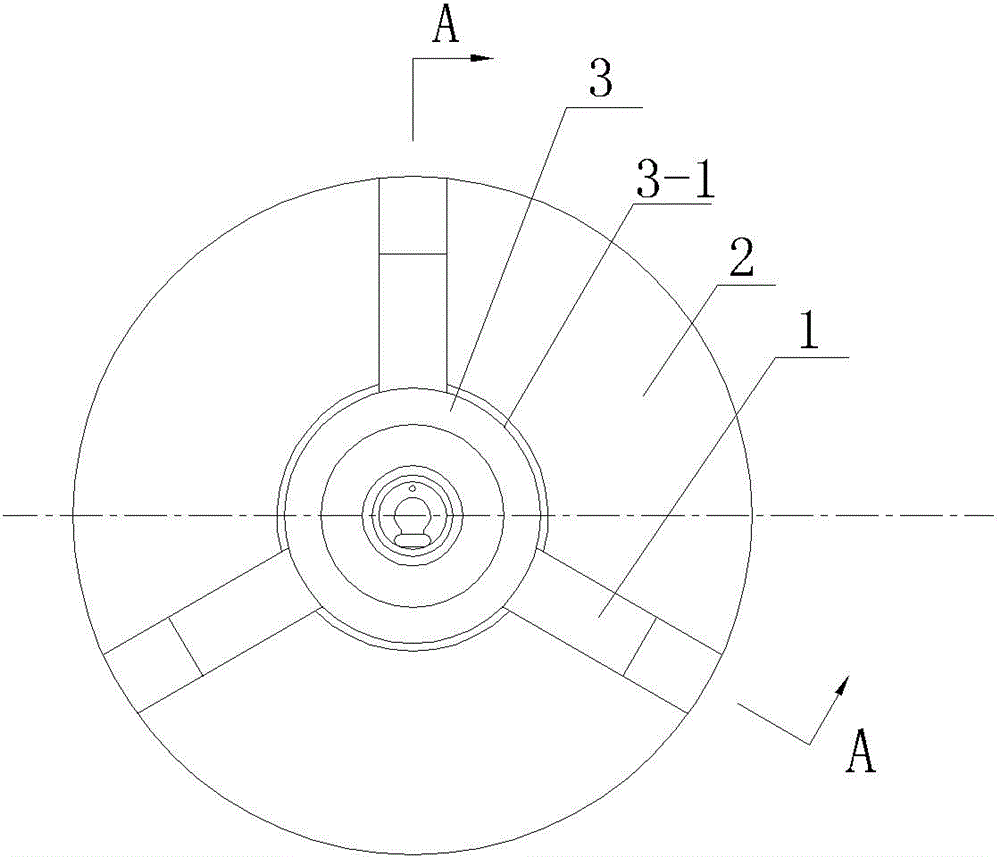

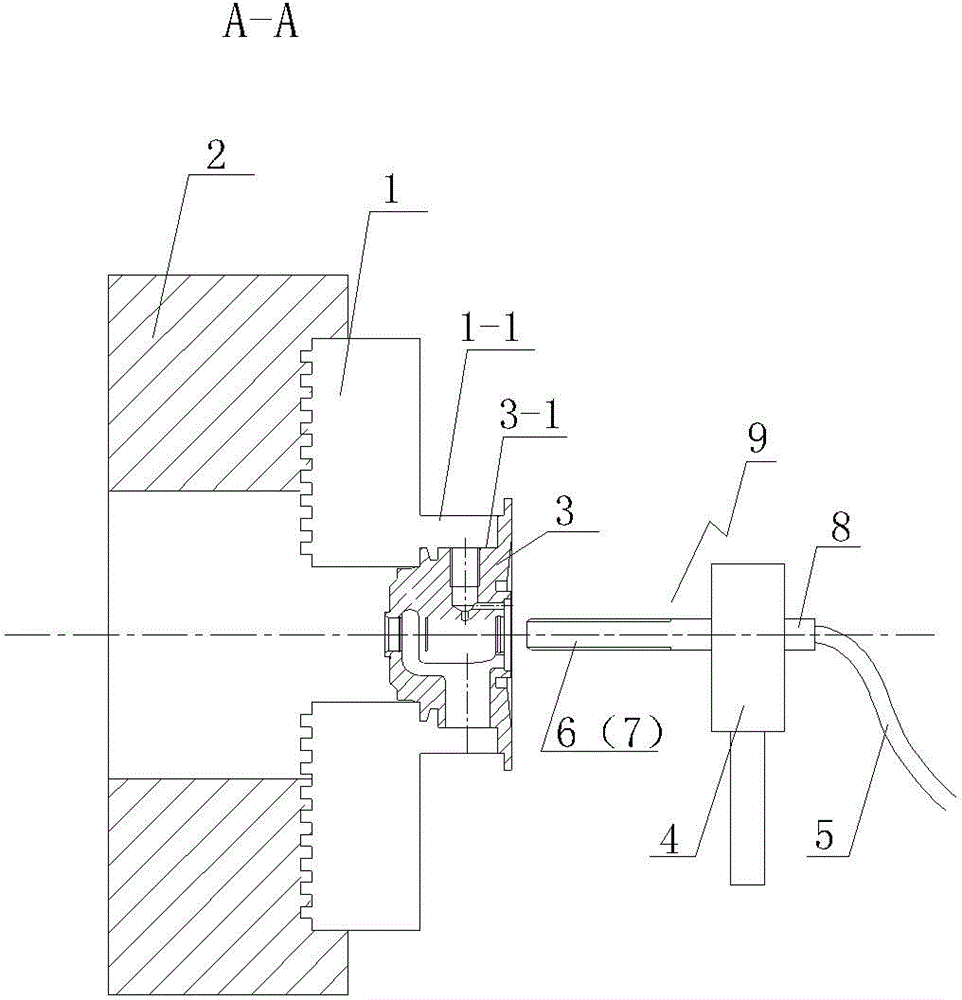

[0009] See figure 2 , image 3 , the present invention includes a claw 1, the claw end of the claw 1 is installed on the chuck 2, on the body of the claw 1, an enveloping platform 1-1 is also arranged on the inner side of the claw 1, and the enveloping platform 1 The inner wall surface of -1 wraps the outer edge surface 3-1 of the intermediate body 3, which also includes a honing tool 9, and the honing tool 9 includes a handle 4, an oil guide pipe 5, a rough reamer 6, a fine reamer 7, and a rough reamer 6 and the fine reamer 7 are provided with a lubricating oil hole 8, the handle 4 is set on the coarse reamer 6 or the fine reamer 7, the oil guide pipe 5 is connected with the lubricating oil hole 8, and the coarse reamer 6 and the fine reamer 7 are on the drill bit side Threads are provided and the head is provided with chamfers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com