Multi-contact-point floatable electromagnetic centerless fixture support

An electromagnetic centerless, multi-contact technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of ferrule scrapping, affecting processing quality, and easy wear of hard alloy blocks, so as to reduce the number of supports, improve grinding quality, and The effect of processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

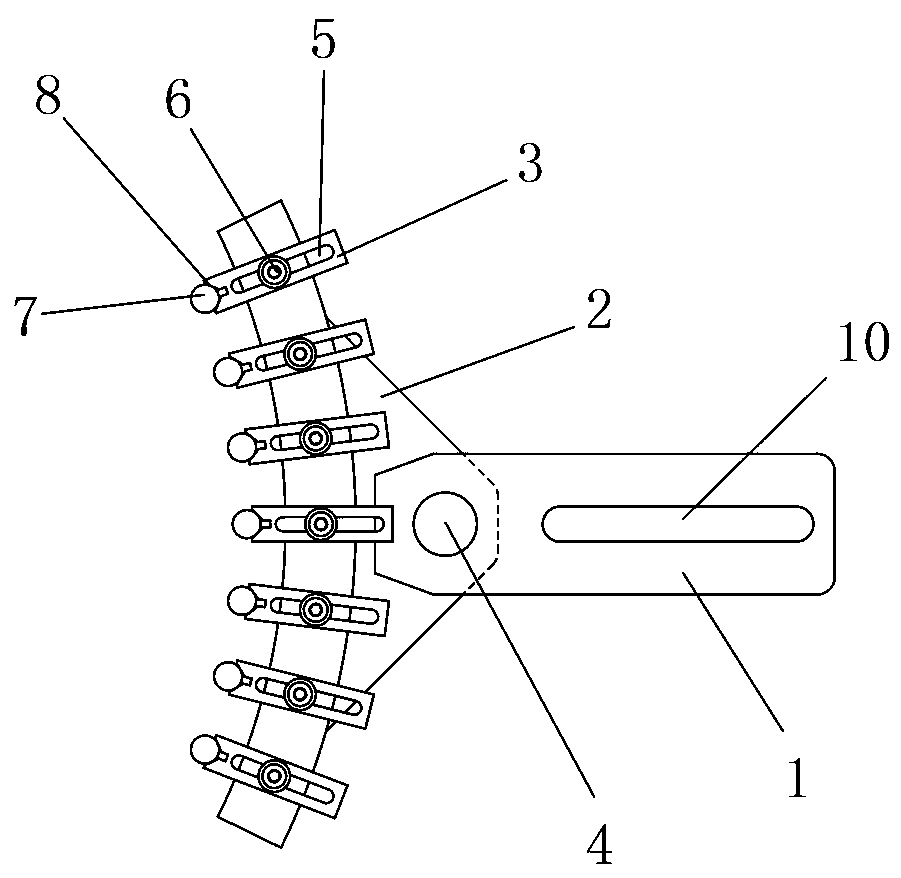

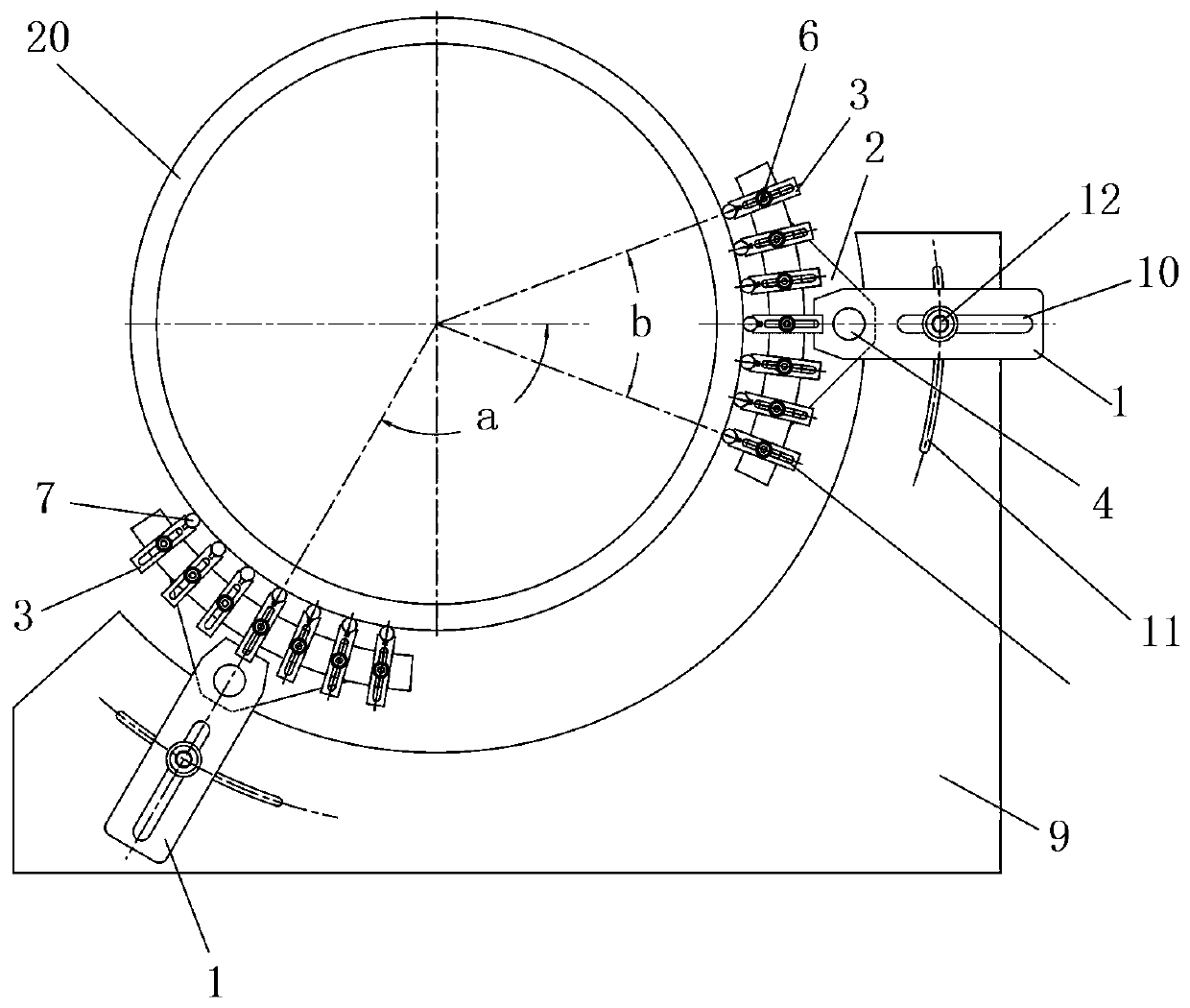

[0033] Embodiment 1: The difference from the above is that the support head 3 and the support frame 2 are slidably connected in the radial direction of the circular arc. The sliding connection structure: the support frame 2 is provided with several The sliding groove corresponding to the supporting head 3, the axis of the sliding groove is located in the radial direction of the arc shape, the supporting head 3 is connected to the sliding groove to form the slidable connection, and the rest of the structure is as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com