Low-loss alternate sander

An alternate, sanding machine technology, applied in the field of sanding machines, can solve problems such as sanding machine wear and tear, and achieve the effects of increasing service life, avoiding secondary pollution, and reducing excessive wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

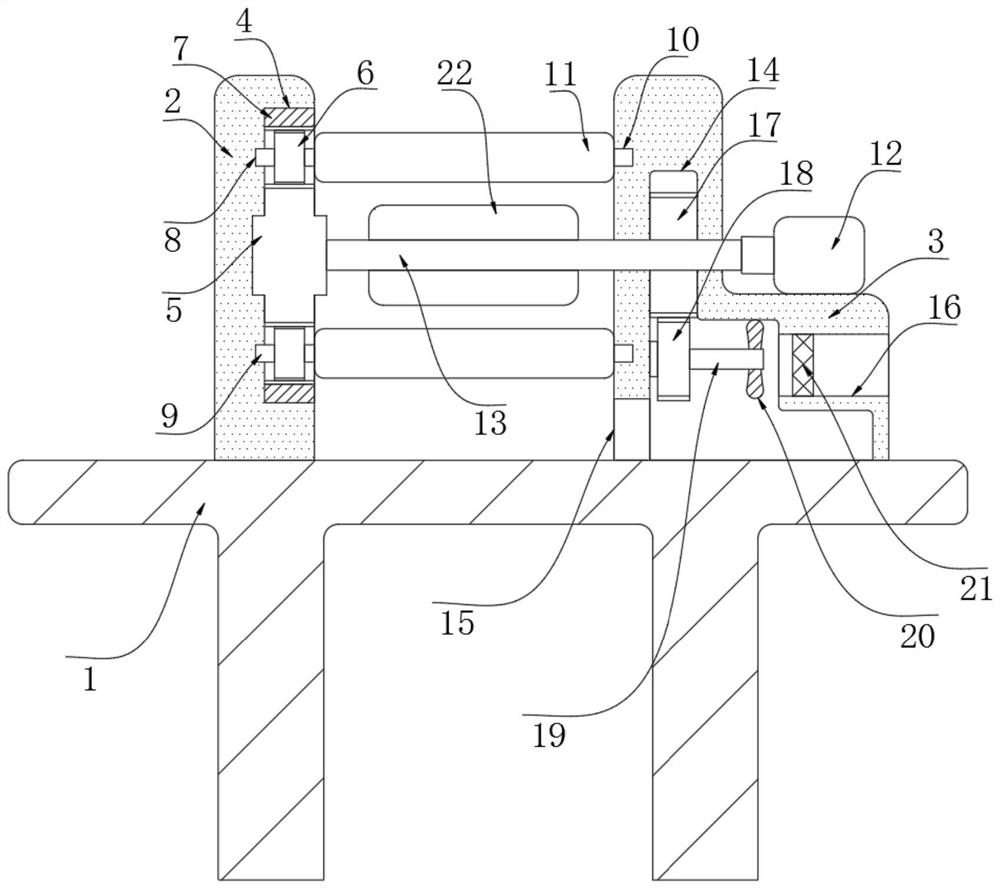

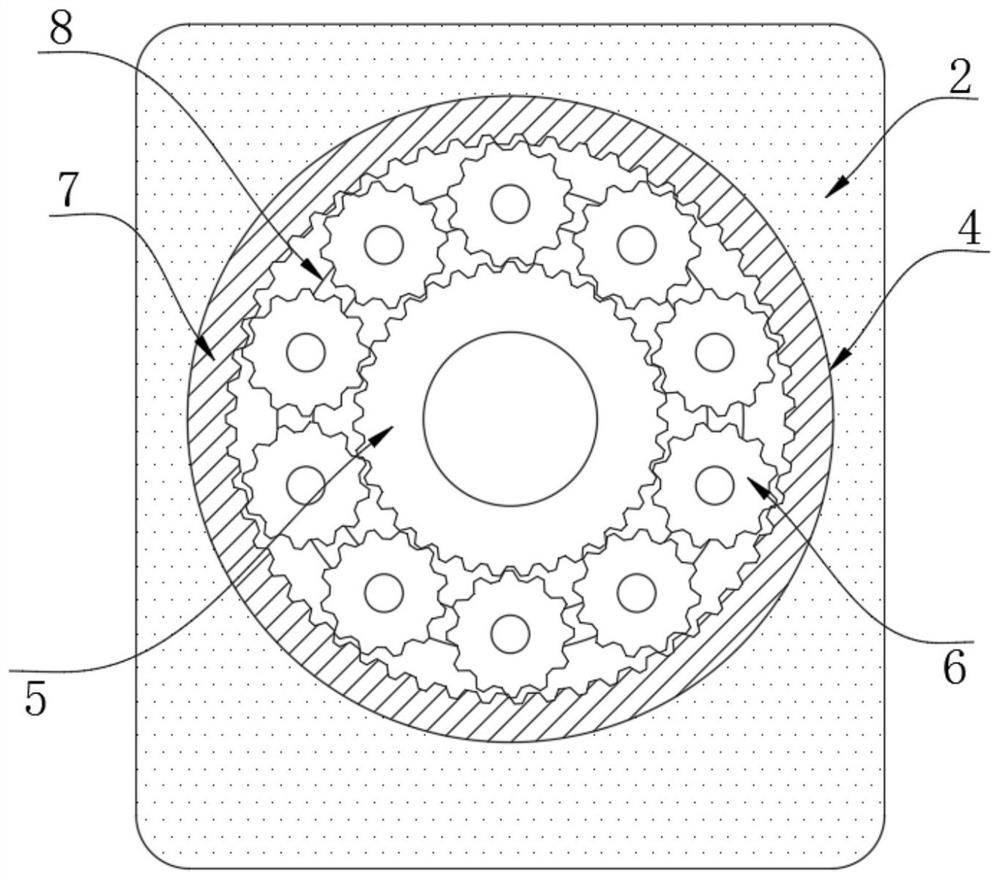

[0017] refer to Figure 1-2 , a low-loss alternating sander, including a processing table 1, the upper end of the processing table 1 is fixed with a transmission frame 2 and a power table 3, the side wall of the transmission frame 2 is provided with a mounting groove 4, and the center of the mounting groove 4 rotates A central gear 5 is connected, and a ring gear 7 is fixed on the side wall of the installation groove 4. The ring gear 7 and the central gear 5 mesh with a plurality of planetary gears 6. The inner wall of the installation groove 4 is provided with a guide groove 8. The central gear 5, the planetary gear 6 and the ring gear 7 form a planetary gear train, and the rotation and revolution of each planetary gear 6 are realized through the rotation of the central gear 5. The side wall of each planetary gear 6 is fixed with a rotating rod 9 slidingly connected to the inner wall of the guide groove 8, and the power The side wall of the table 3 is provided with a matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com