Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Guaranteed gluing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terminal front cover assembly and mobile terminal

ActiveCN105045347AGuaranteed fit tightnessAvoid damageDigital data processing detailsSmooth surfaceFront cover

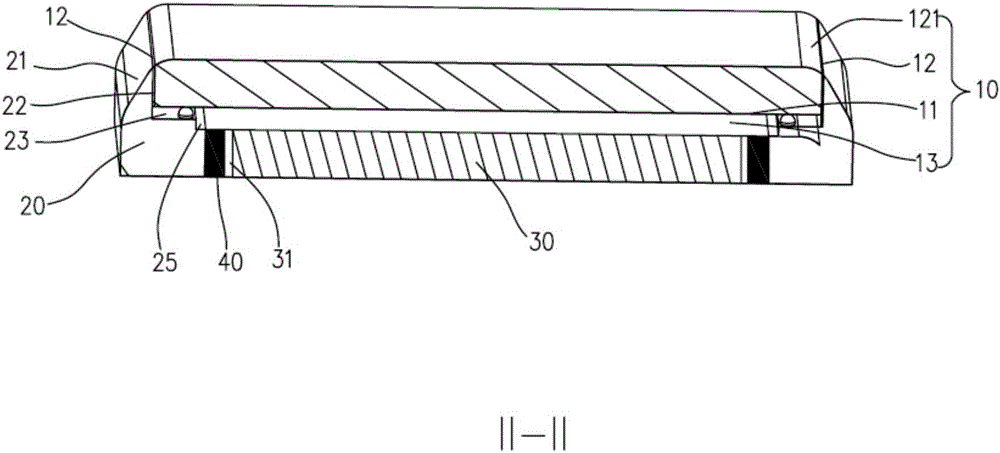

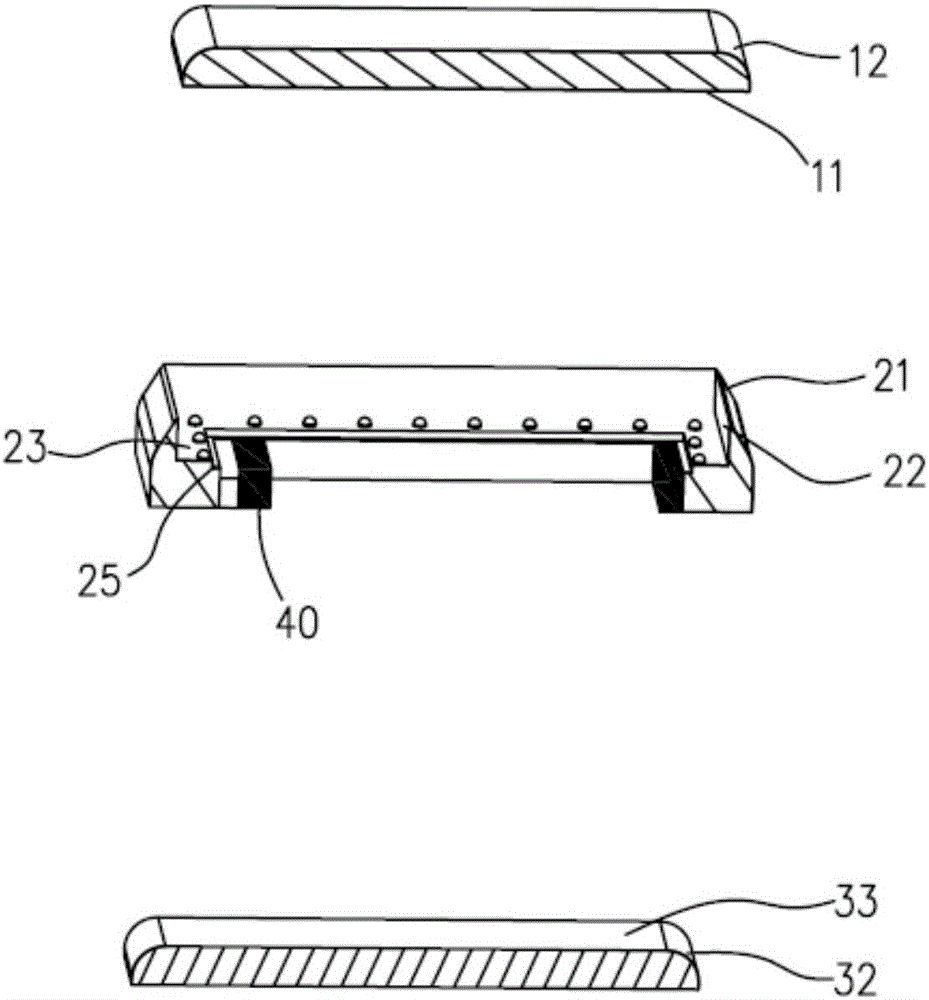

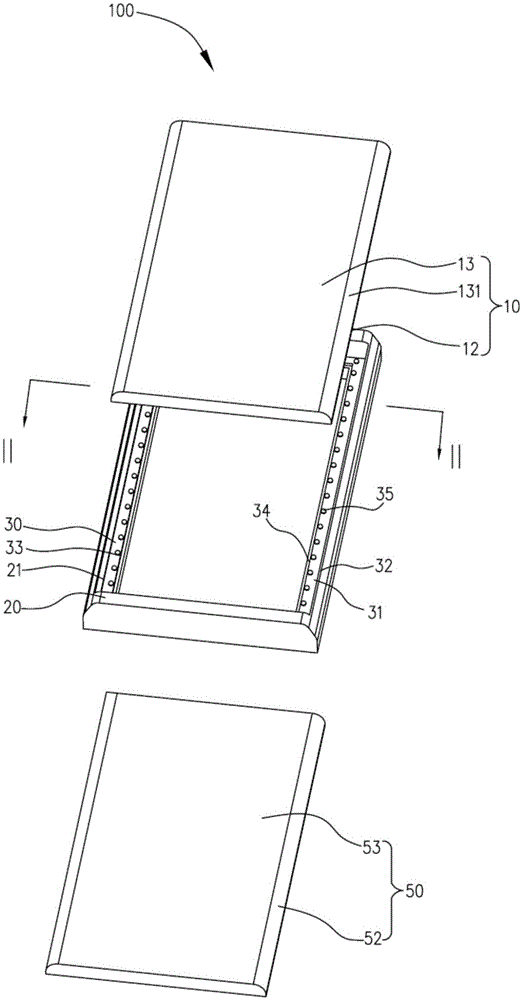

A terminal front cover assembly and a mobile terminal are disclosed. The terminal front cover assembly comprises a glass cover plate, a protective frame, a display screen, waterproof glue and an adsorption member, wherein the glass cover plate comprises a lower surface and a first side surface connected to the lower surface; the protective frame comprises an outer surface, an inner surface connected to the outer surface and a step protruding from the inner surface; the inner surface is clung to the first side surface; the outer surface is in smooth connection with the first side surface to form a seamless smooth surface; the step comprises a step top surface and a step side surface; a glue groove is formed in the step top surface; a gap is formed between a second side surface of the display screen and a step side wall; the waterproof glue is arranged in the glue groove; and the adsorption member is arranged in the gap and used for adsorbing the waterproof glue that drips into the gap. According to the terminal front cover assembly and the mobile terminal provided by the present invention, the inner surface is clung to the first side surface, and the outer surface to be in smooth connection with the first side surface to form the seamless smooth surface, so that a user cannot see internal mucilage glue; and the adsorption member is arranged in the gap between the step side wall and the second side surface of the display screen to adsorb the waterproof glue, so that the occurrence of glue overflow is prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

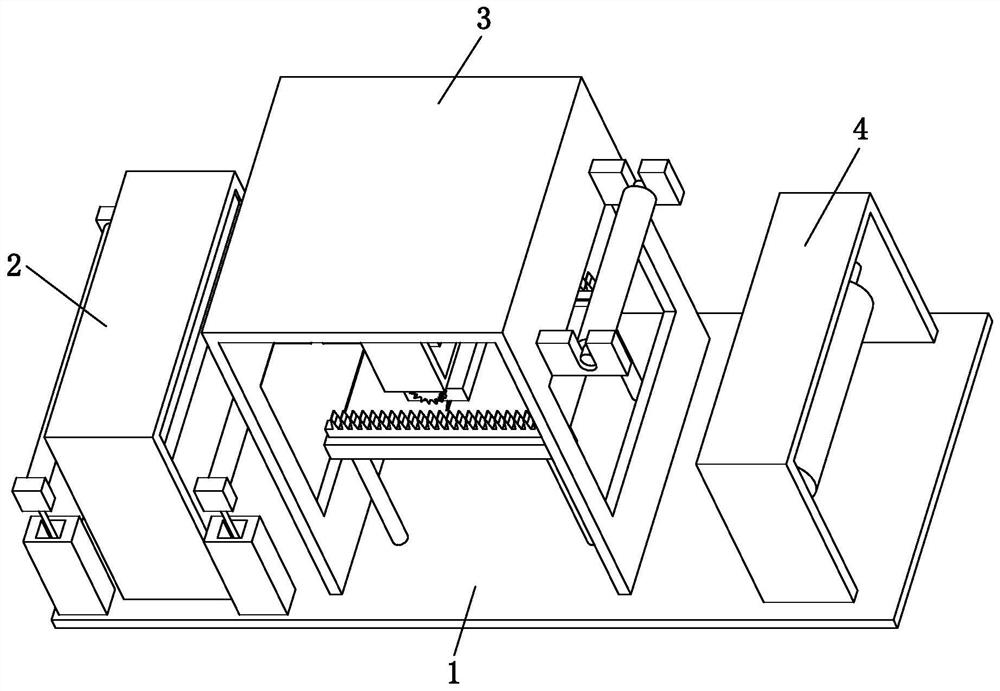

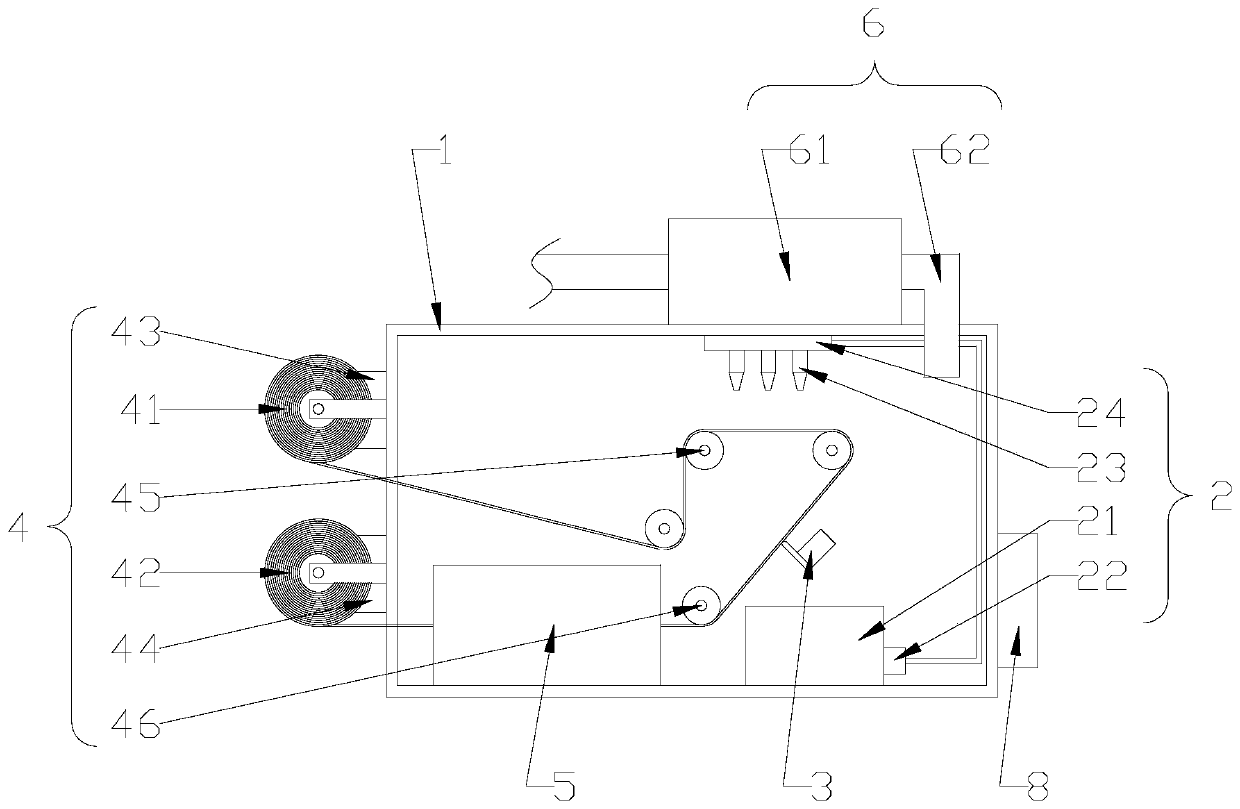

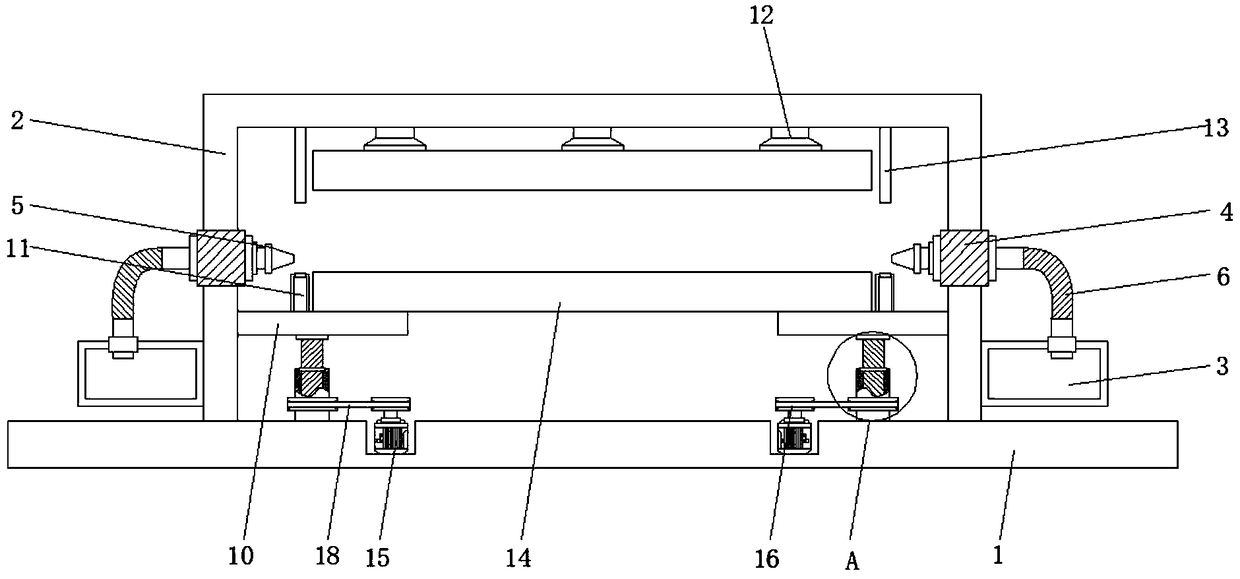

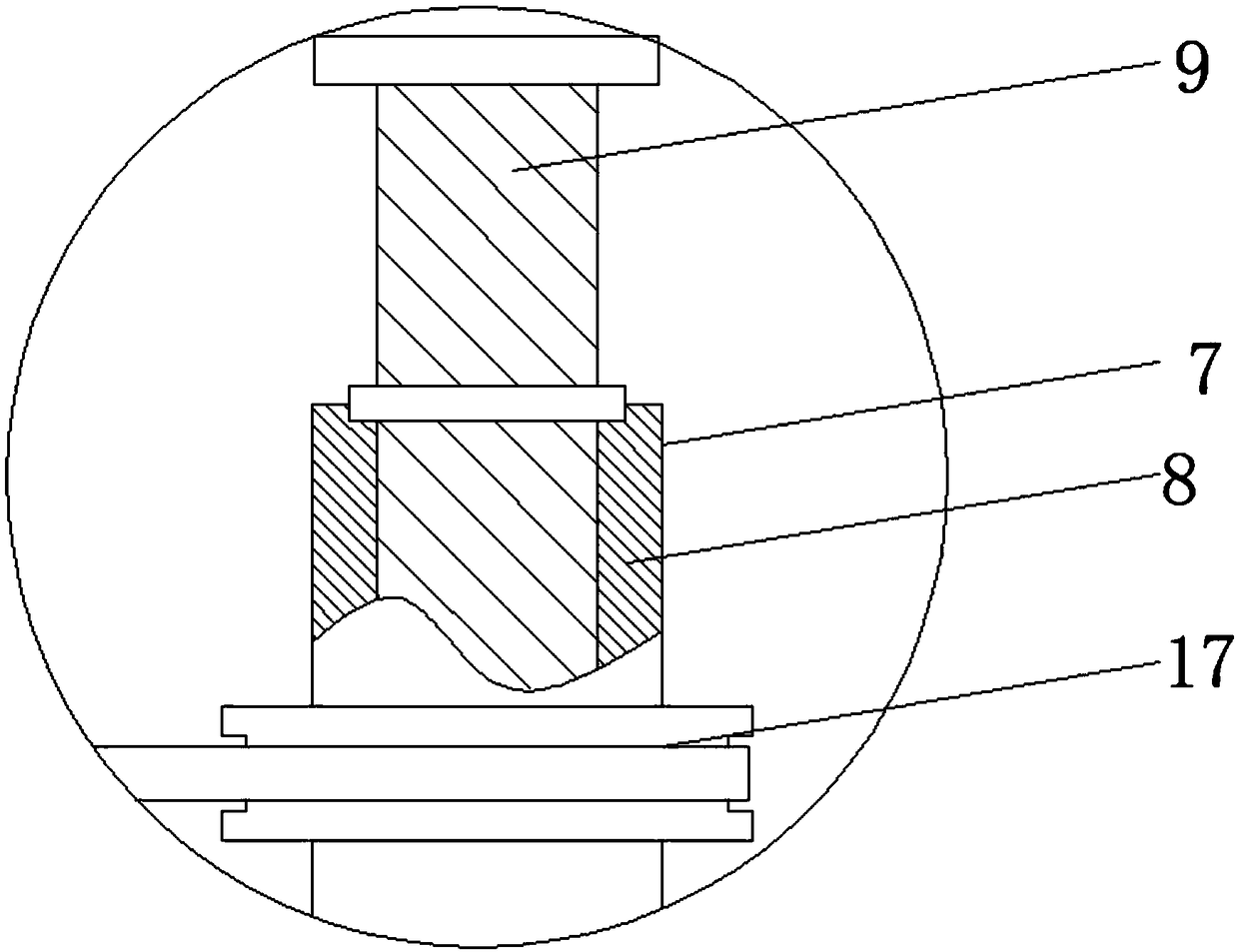

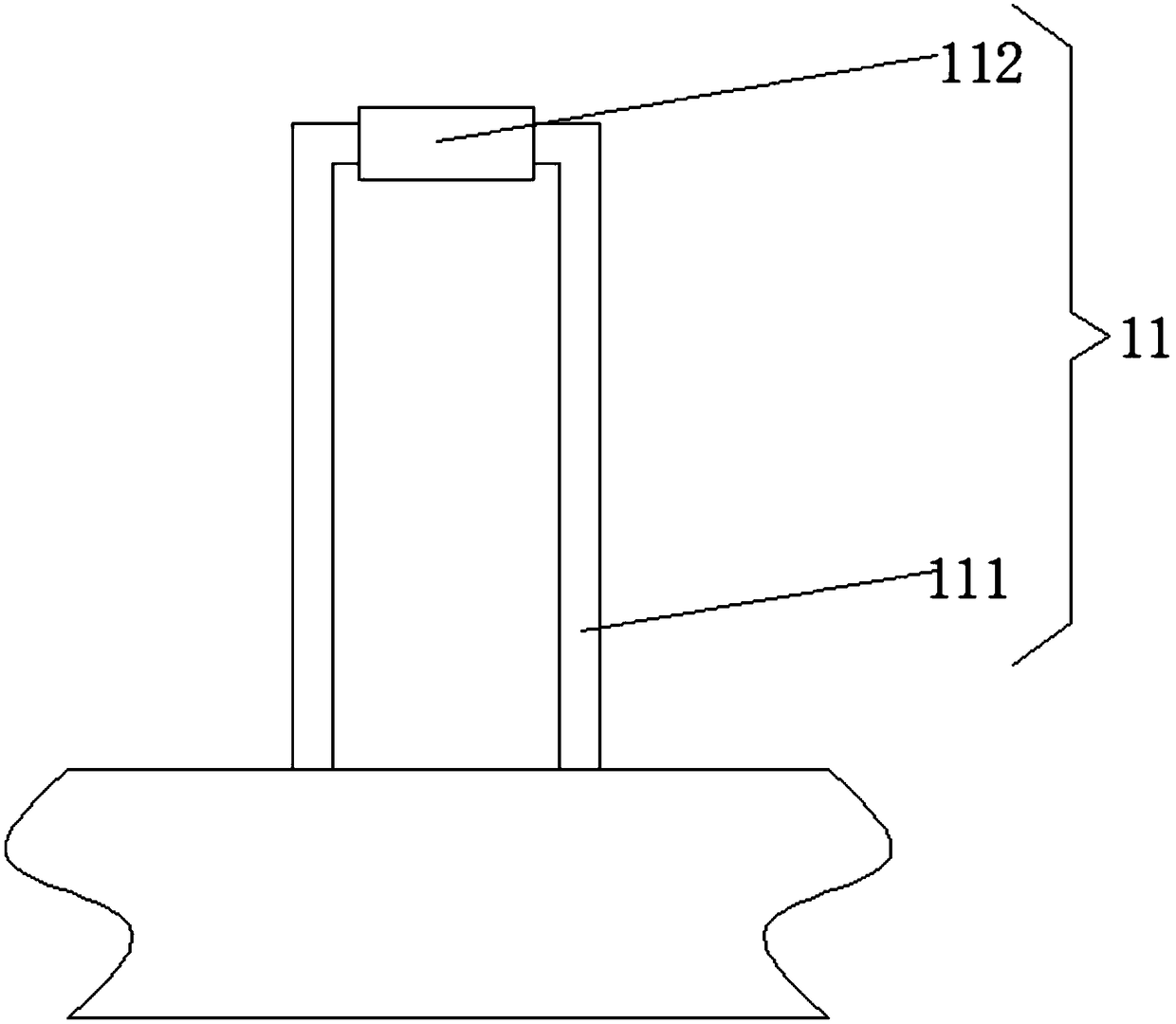

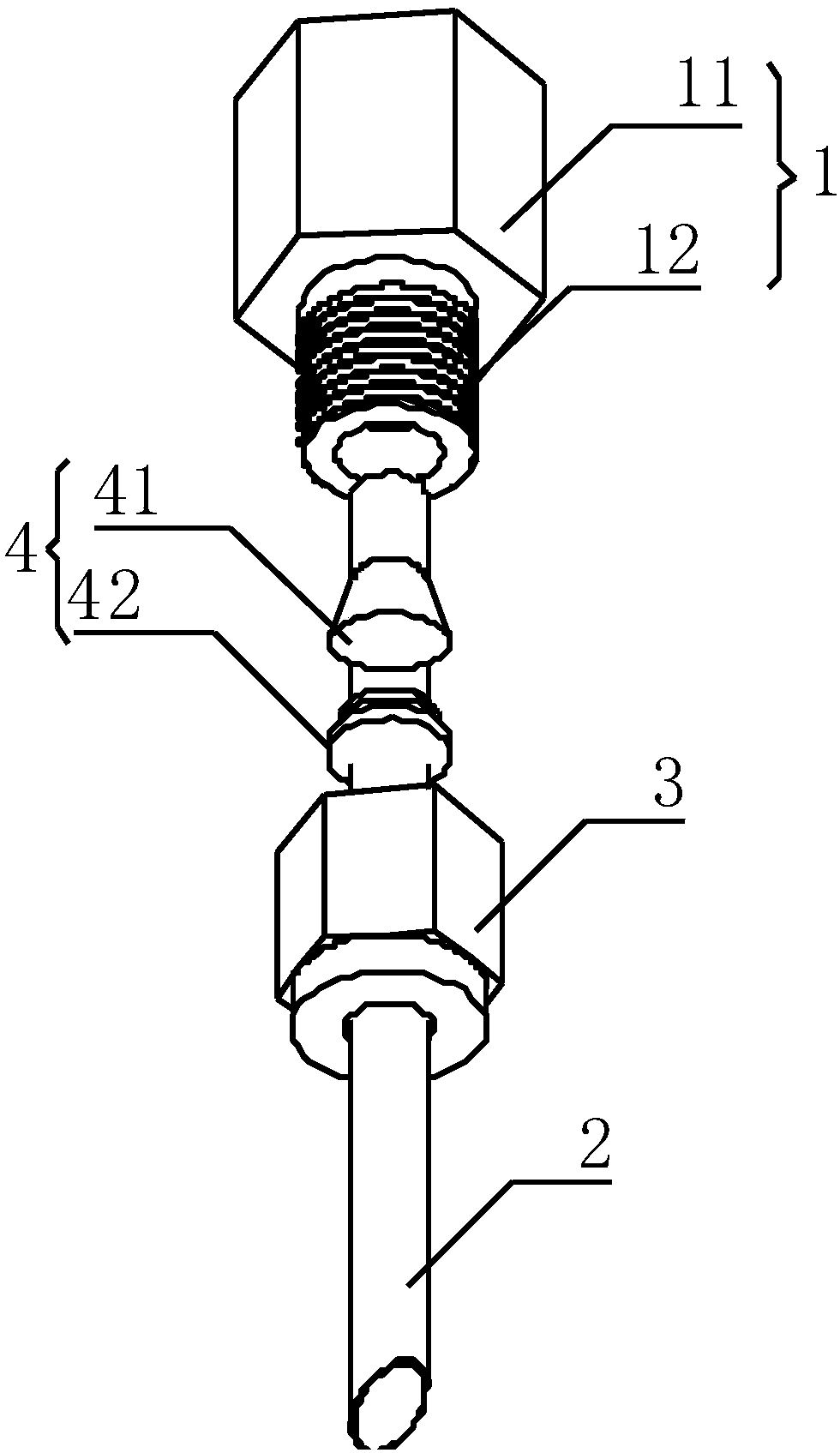

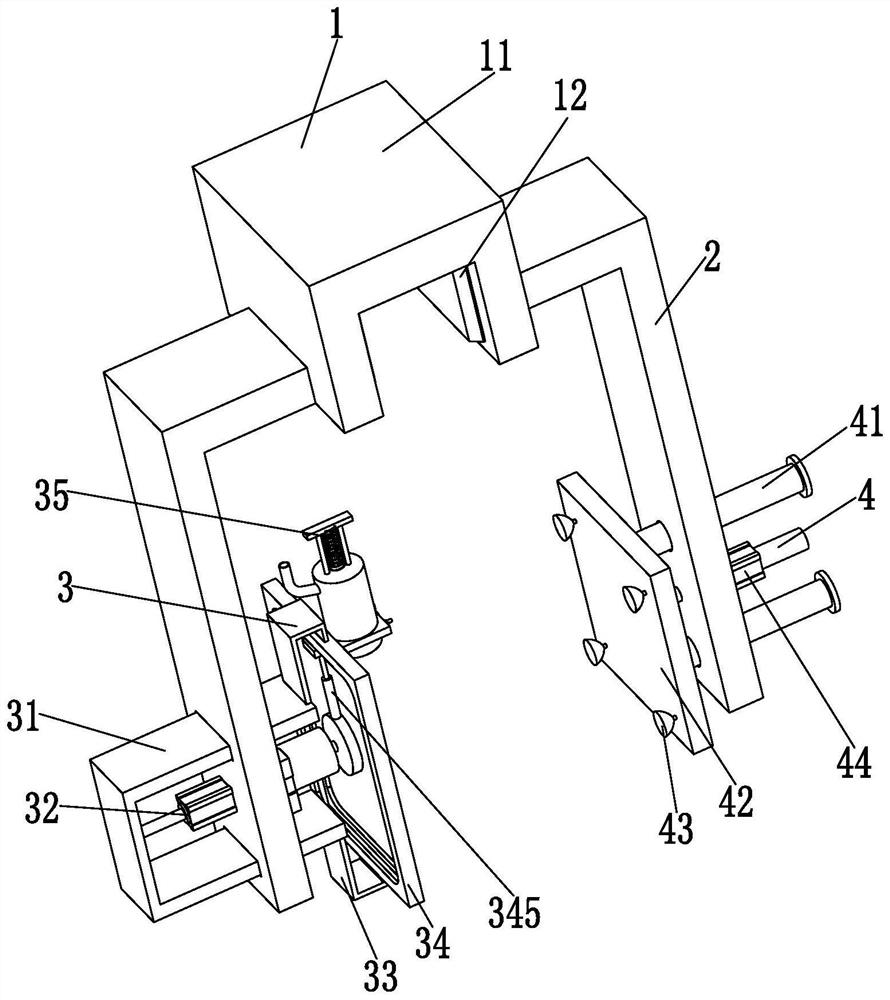

Composite board automatic gluing device

ActiveCN108656260AMeet work needsAvoid affecting work progressAdhesive application devicesEngineeringMechanical engineering

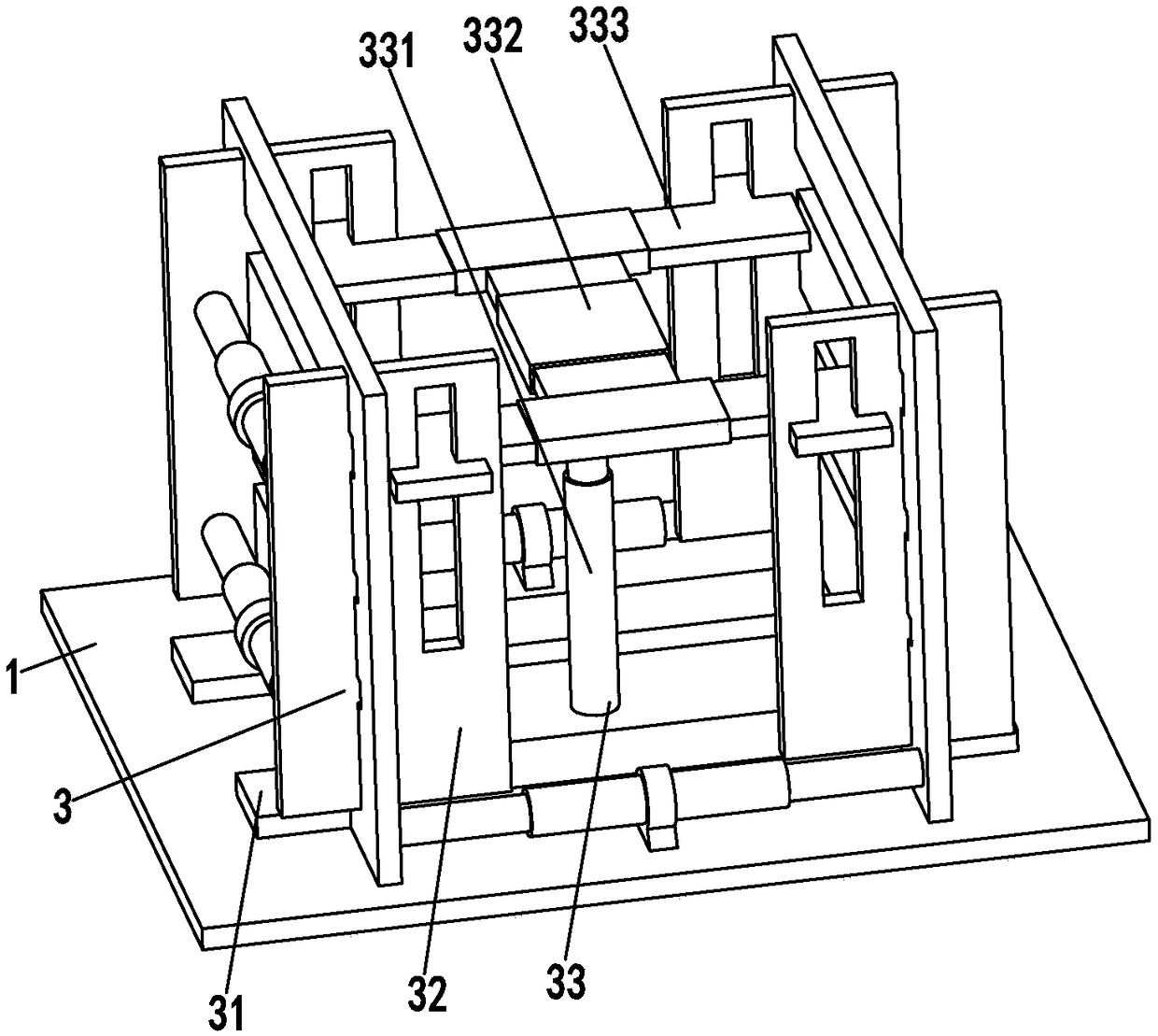

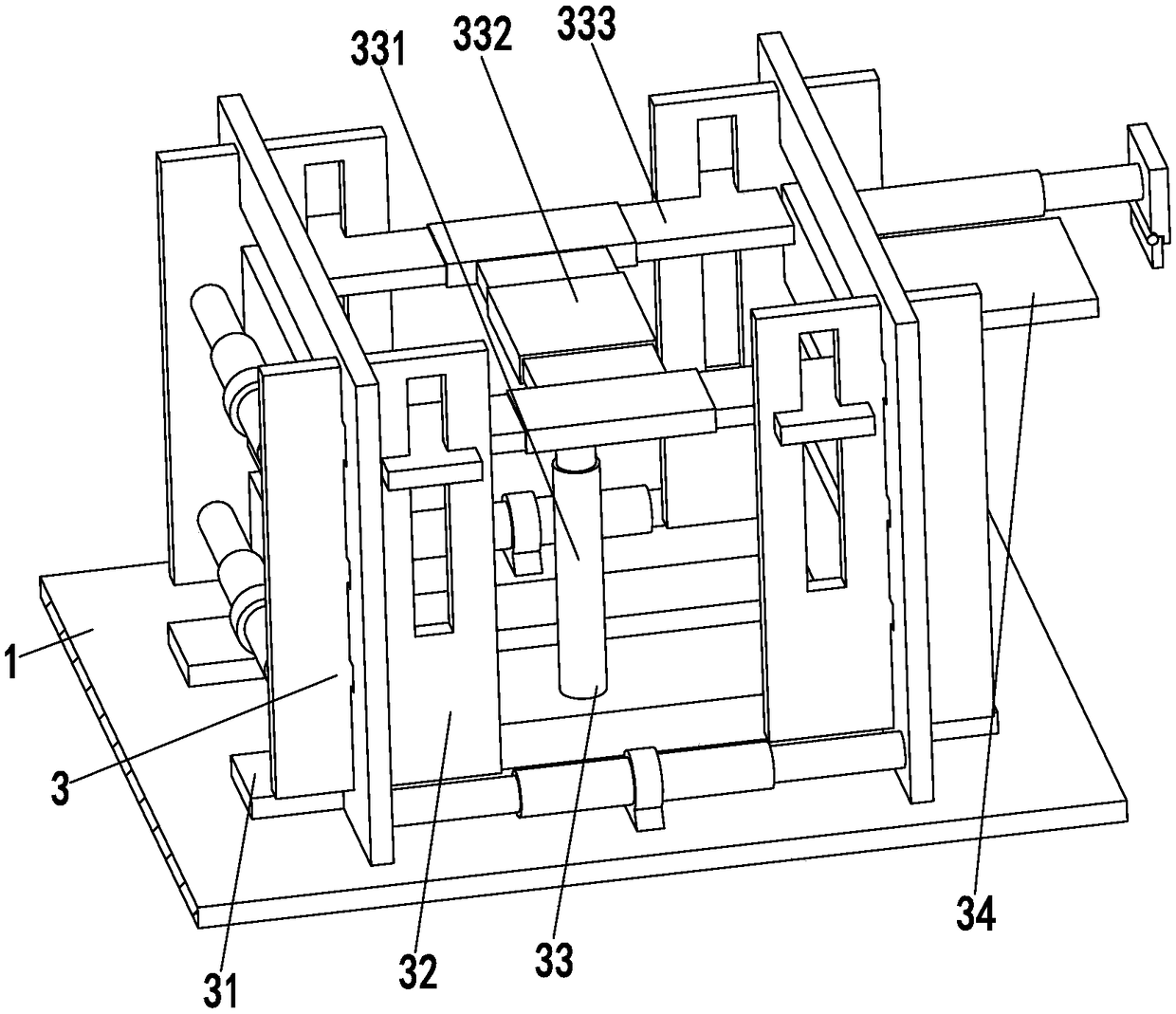

The invention relates to a composite board automatic gluing device. The device comprises a bottom plate, a mounting rack, a stacking device and a gluing device; the mounting rack is installed on the bottom plate, sliding chutes are formed in the mounting rack, the gluing device is installed in the sliding chutes, and the stacking device is installed at the lower end of the gluing device; the stacking device is installed on the bottom plate, and the stacking device comprises a linear guide rail, a limiting mechanism and a supporting mechanism; the gluing device comprises a glue discharging mechanism and a leveling mechanism; and the leveling mechanism comprises sliding blocks, sliding rods, a transverse plate, a telescopic leveling frame, a fixed supporting plate, an adjusting length air cylinder, a connecting ring and a driving branched chain. According to the composite board automatic gluing device, the problems that board codes are not even, gluing are non-uniform, glue is easy to waste, the adjustability is poor and the like in an existing composite board gluing process are solved; and the function of automatically gluing the composite board can be achieved, and the device has the advantages of being neat in stacking, uniform in gluing, not easy to waste glue, and flexible to adjust.

Owner:江苏林德曼新材料科技有限公司

Method for mixing bamboo woods and bamboo broken materials to manufacture brick machine supporting plate

ActiveCN104400870AGuaranteed gluing effectAchieve fullnessLaminationLamination apparatusAdhesive gluePulp and paper industry

The invention provides a method for mixing bamboo woods and bamboo broken materials to manufacture a brick machine supporting plate. The method comprises the following steps of (1) grinding or slicing moso bamboos to form bamboo chips, weaving to form a bamboo mat or a bamboo curtain, and then drying; (2) gumming the bamboo mat, the bamboo curtain and bamboo splints by using phenolic resin glue, and drying through a low temperature way or a temperature reducing way; (3) smashing remained bamboo materials (hereafter referred to as the 'bamboo broken materials') after other bamboo products are processing by waste bamboo woods or moso bamboos; (4) drying, cooling and then mixing the bamboo broken materials (or drying, glue mixing and then cooling) with glue, wherein the glue is the phenolic resin glue; (5) mixing and assembling a bamboo mat, a bamboo curtain or thin bamboo strips which are dried by low temperature or dehumidification with 'glue bamboo broken materials' subjected to glue mixing; (6) performing hot pressing on a pre-processed bamboo wood brick machine supporting plate blank to form a bamboo plywood semi-finished product; (7) cutting and painting the semi-finished product bamboo wood brick machine support plate to form the bamboo wood brick machine supporting plate which has the advantages of high strength and the like.

Owner:龙泉市凯森板业有限公司

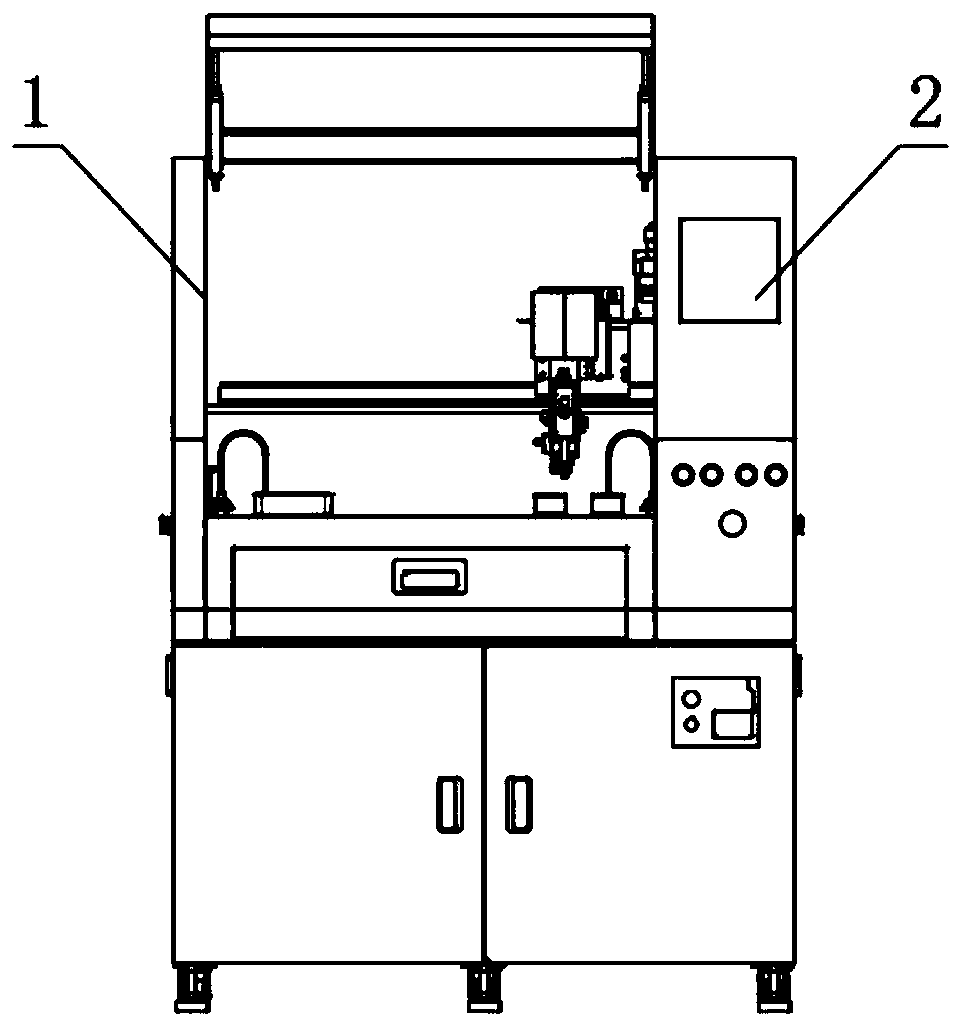

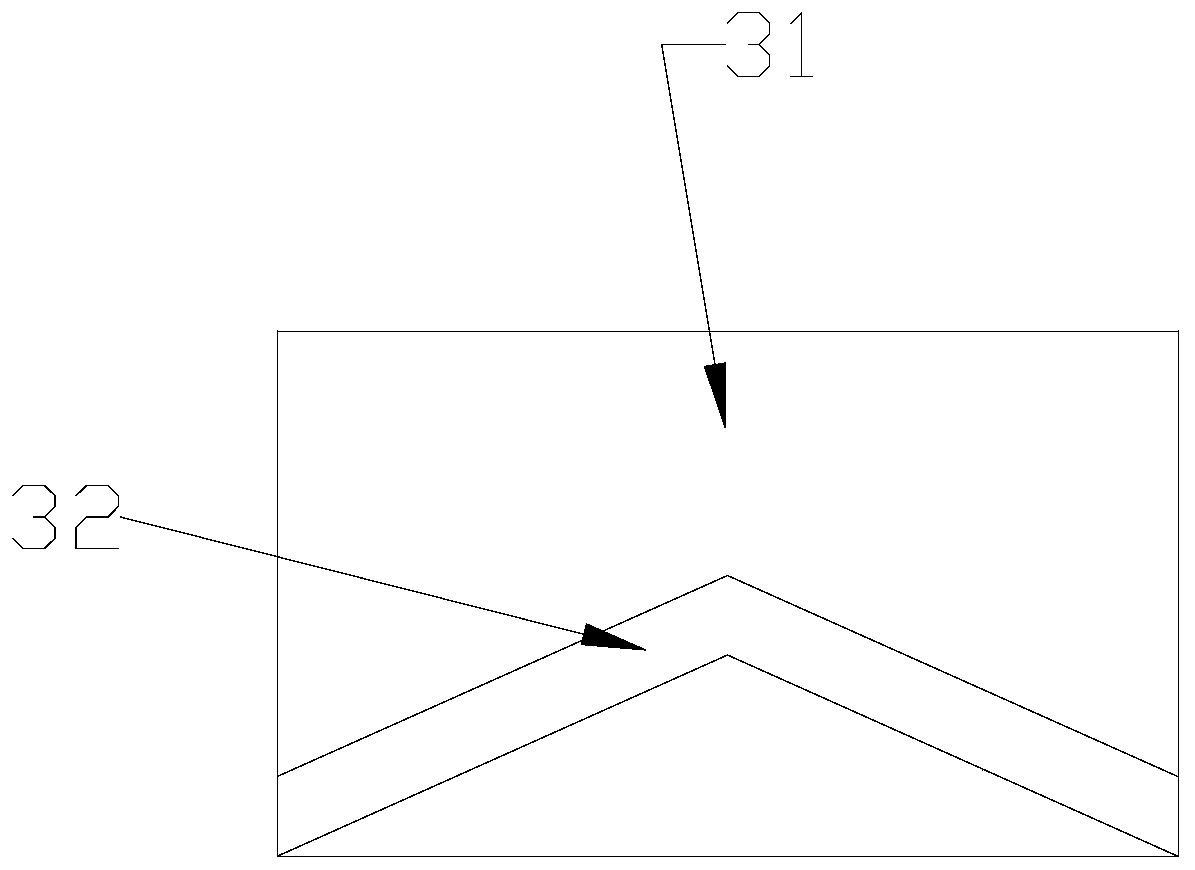

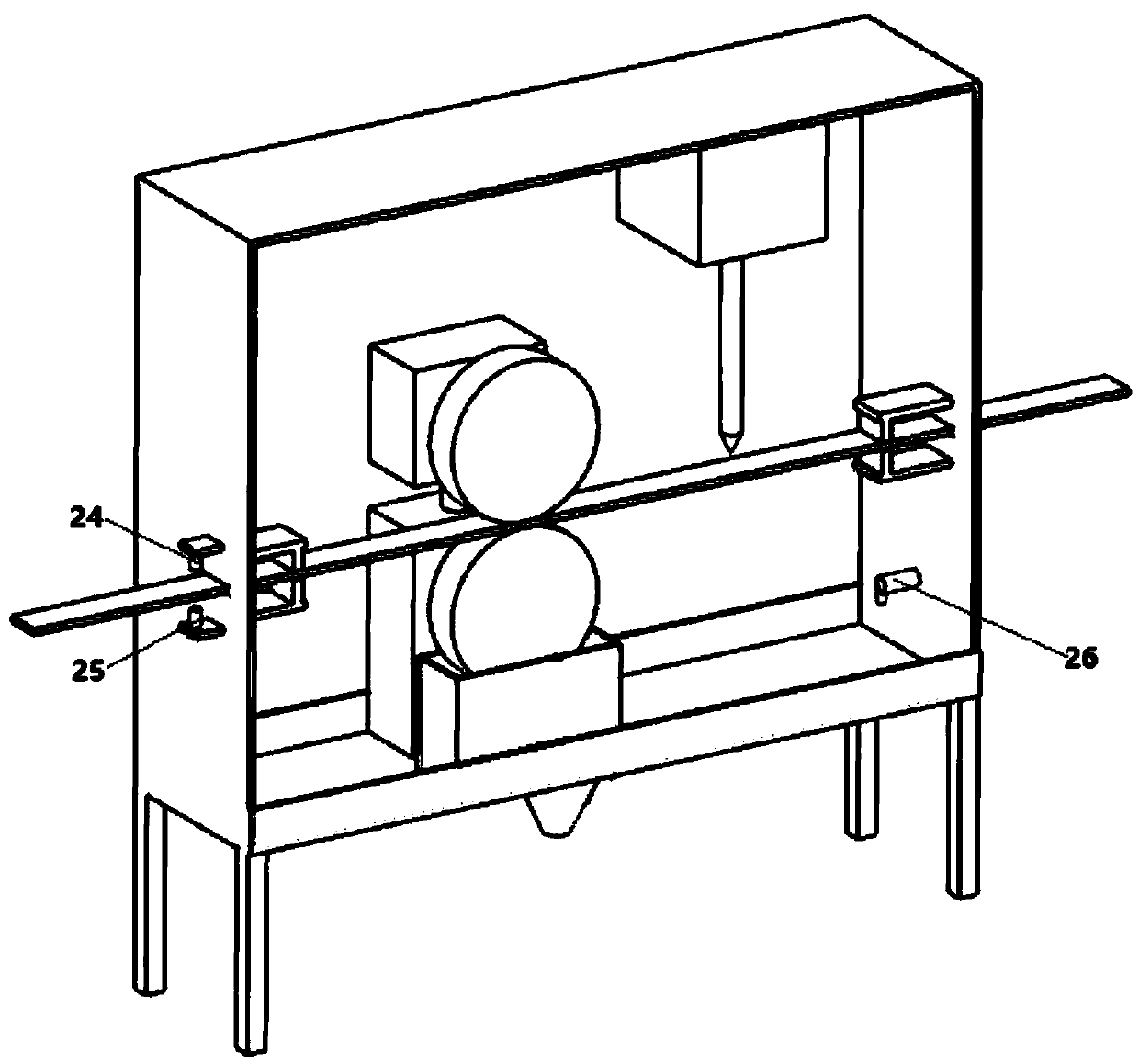

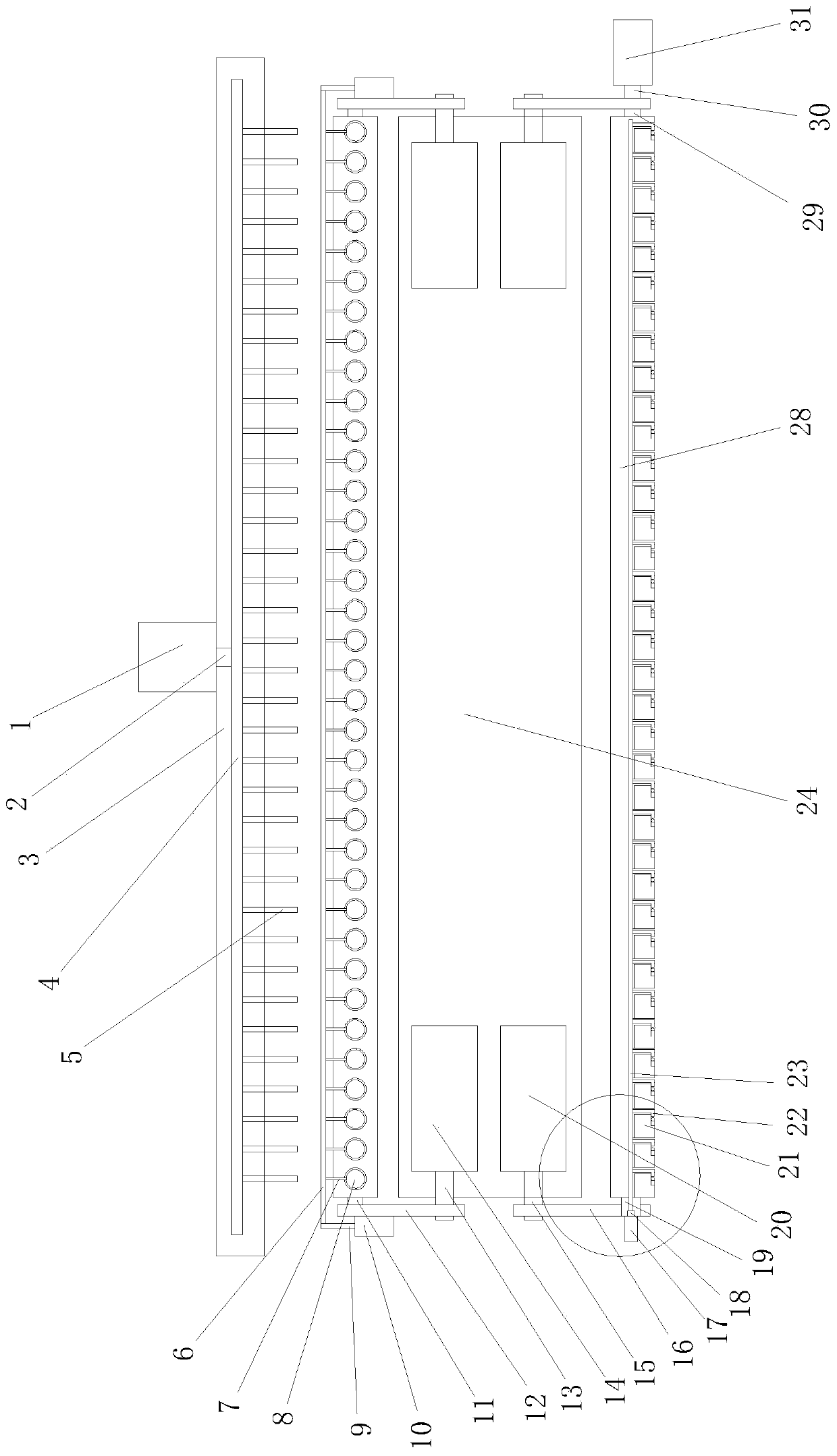

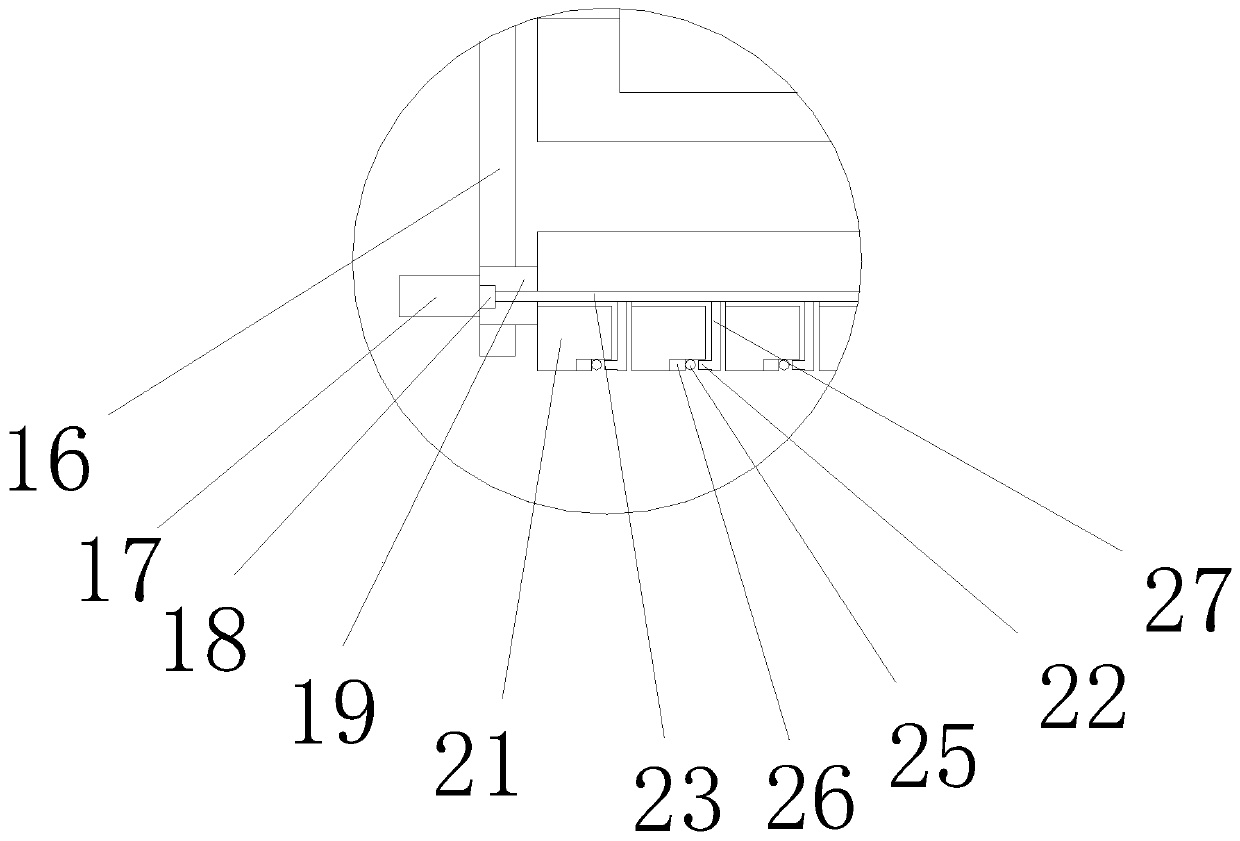

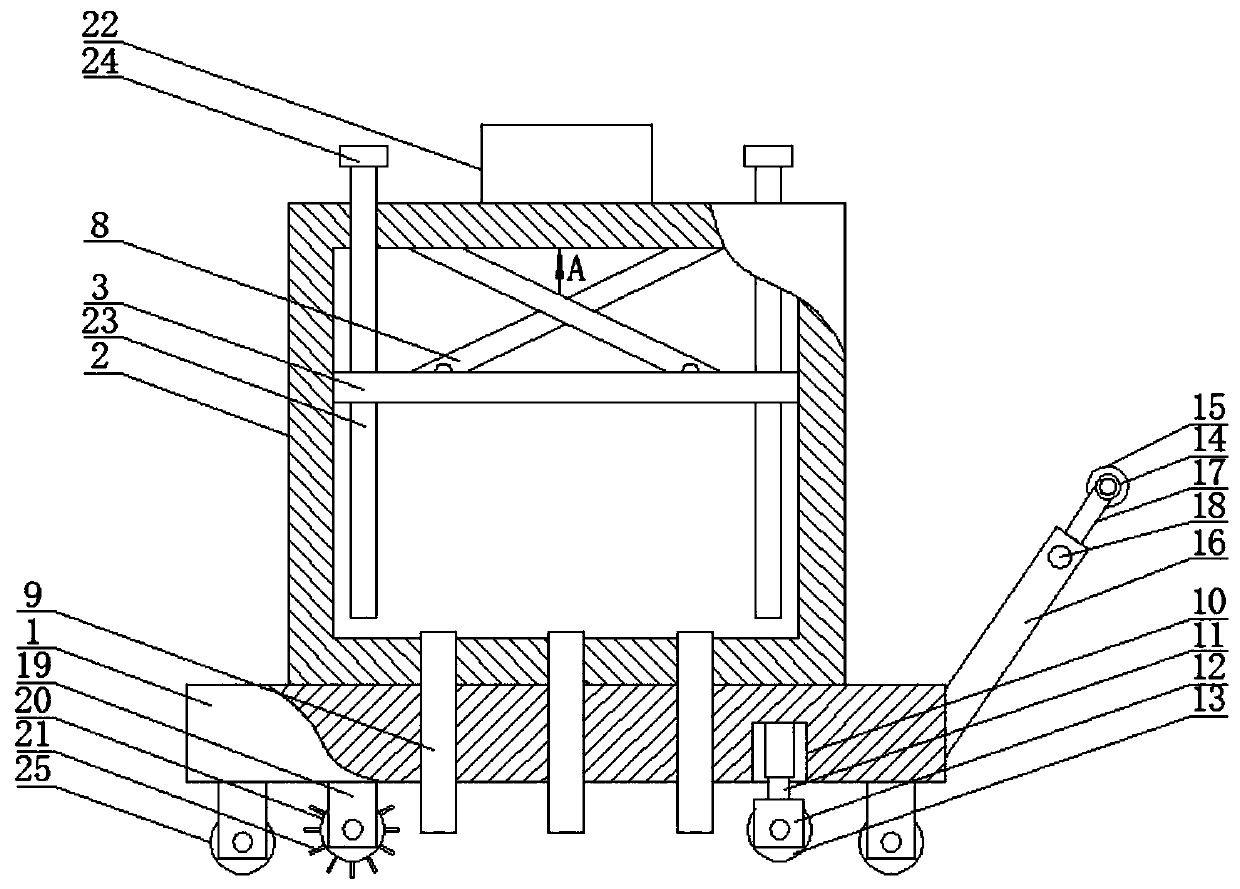

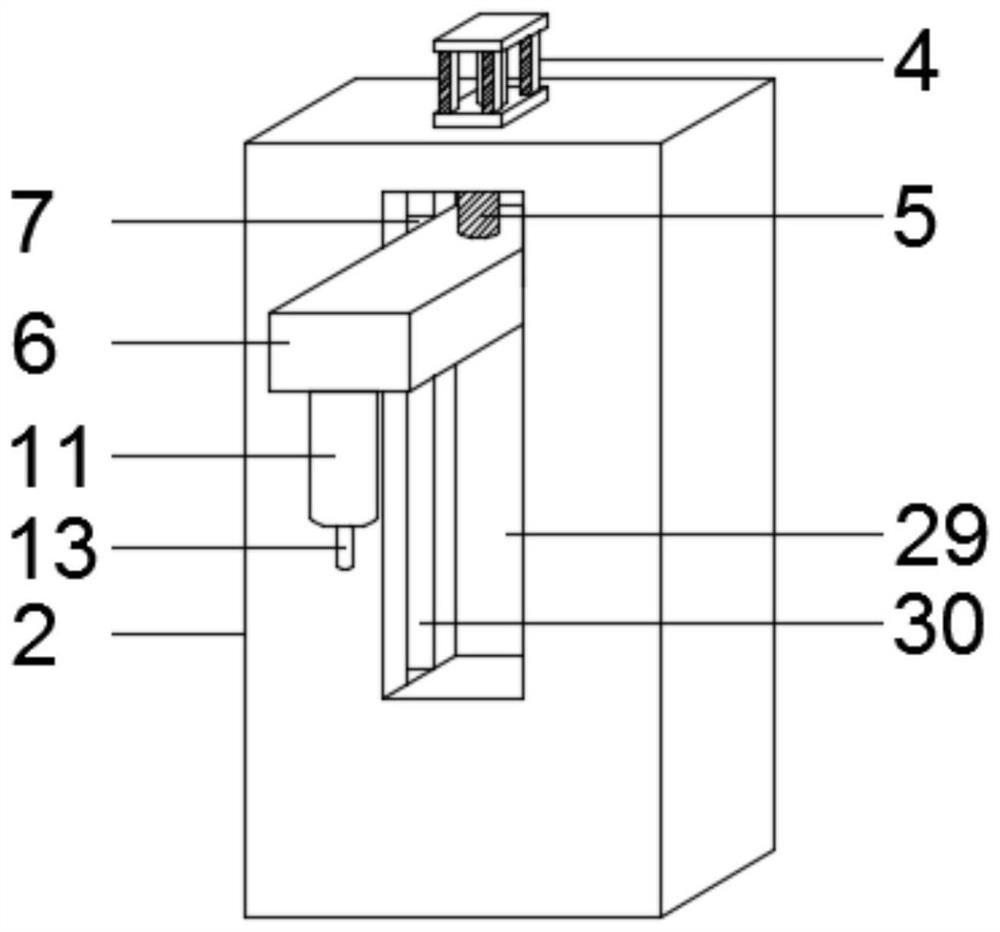

Book perfect binding device with good gluing effect

PendingCN110154576AGuaranteed gluing effectGuaranteed grinding effectCasing-inBookbinding adhesiveMilling cutterEngineering

The invention discloses a book perfect binding device with a good gluing effect and belongs to the technical field of advertising and printing. The book perfect binding device comprises a worktable arranged along a front-back direction, and a book fixing structure, a facing cutter, a primer structure and a side glue structure on the worktable. A left clamping plate and a right clamping plate are arranged on the book fixing structure, two milling cutter baffle plates capable of sliding left and right are arranged above the facing cutter on the worktable, and guide bars are arranged on the frontand back sides of the bottoms of the left and right clamping plates along the front-back direction; horizontal front eccentric distracting wheels are arranged on the milling cutter baffle plates; theside glue structure comprises a side glue pot, two sliding plates slidably arranged left and right on the worktable above the side glue pot, back eccentric distracting wheels horizontally arranged onthe sliding plates and side gluing wheels, the lower parts of which are immersed into the side glue pot, on the sliding plates. According to the device, the side gluing wheels are arranged on the sliding plates capable of sliding left and right, and the eccentric distracting wheels matched with the guide bars on the front and back sides of the clamping plate are arranged on the sliding plates andthe milling cutter baffle plates for distracting the book fixing structure in advance before the book fixing structure passes through and / or distracting the book fixing structure when the book fixingstructures passes through.

Owner:麻城市阳光传媒印务有限公司

Terminal front cover assembly and mobile terminal

ActiveCN105120623AAvoid damageGuaranteed fit tightnessCasings/cabinets/drawers detailsGlass coverComputer terminal

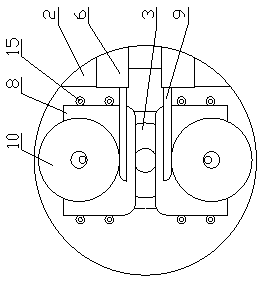

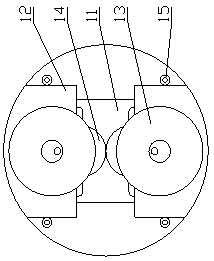

The invention relates to a terminal front cover assembly comprising a glass cover plate, a protection frame, a support frame, a first adsorption element, waterproof glue, a display screen, and a second adsorption element. The glass cover plate contains a lower surface and a first side surface. The protection frame includes an accommodation cavity in contact with the first side surface. The support frame embedded into the accommodation cavity consists of a support top surface, an outer side surface, and an inner side surface; and a first gap is formed between the outer side surface and the accommodation cavity. The first adsorption element is in contact between the outer side surface and the accommodation cavity. A second gap is formed between the display screen and the inner side surface. The waterproof glue is arranged in glue slots. And the second adsorption element is arranged in the second gap and is used for adsorbing the waterproof glue dripping into the second gap. According to the terminal front cover assembly and the mobile terminal, because the first adsorption element and the second adsorption element are respectively arranged in the gap between the support frame and the protection frame and the gap between the support frame and the display screen, the redundant waterproof glue can be adsorbed, thereby avoiding the glue overflowing phenomenon. Besides, with the first adsorption element and the second adsorption element, the buffering effect on the glass cover plate and the display screen can be realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

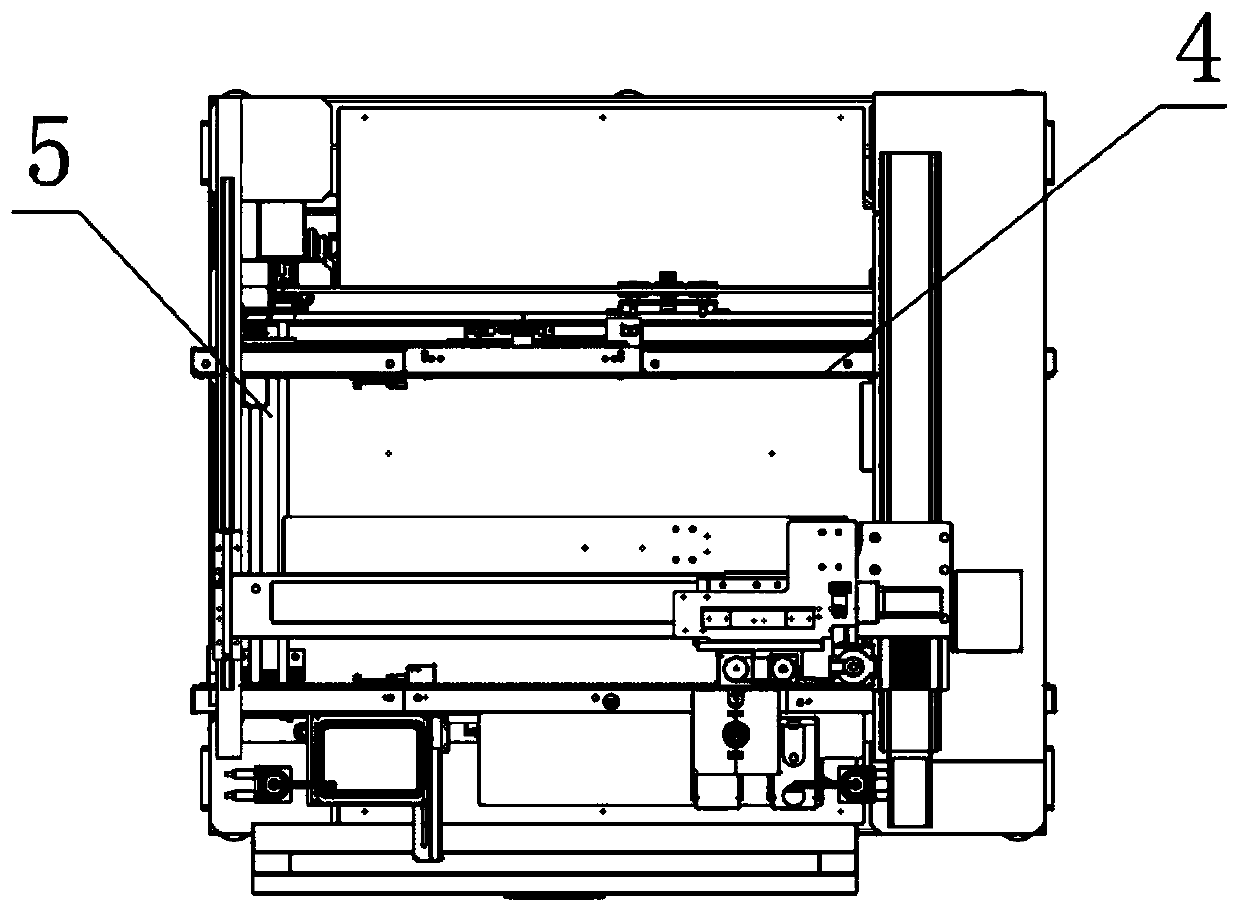

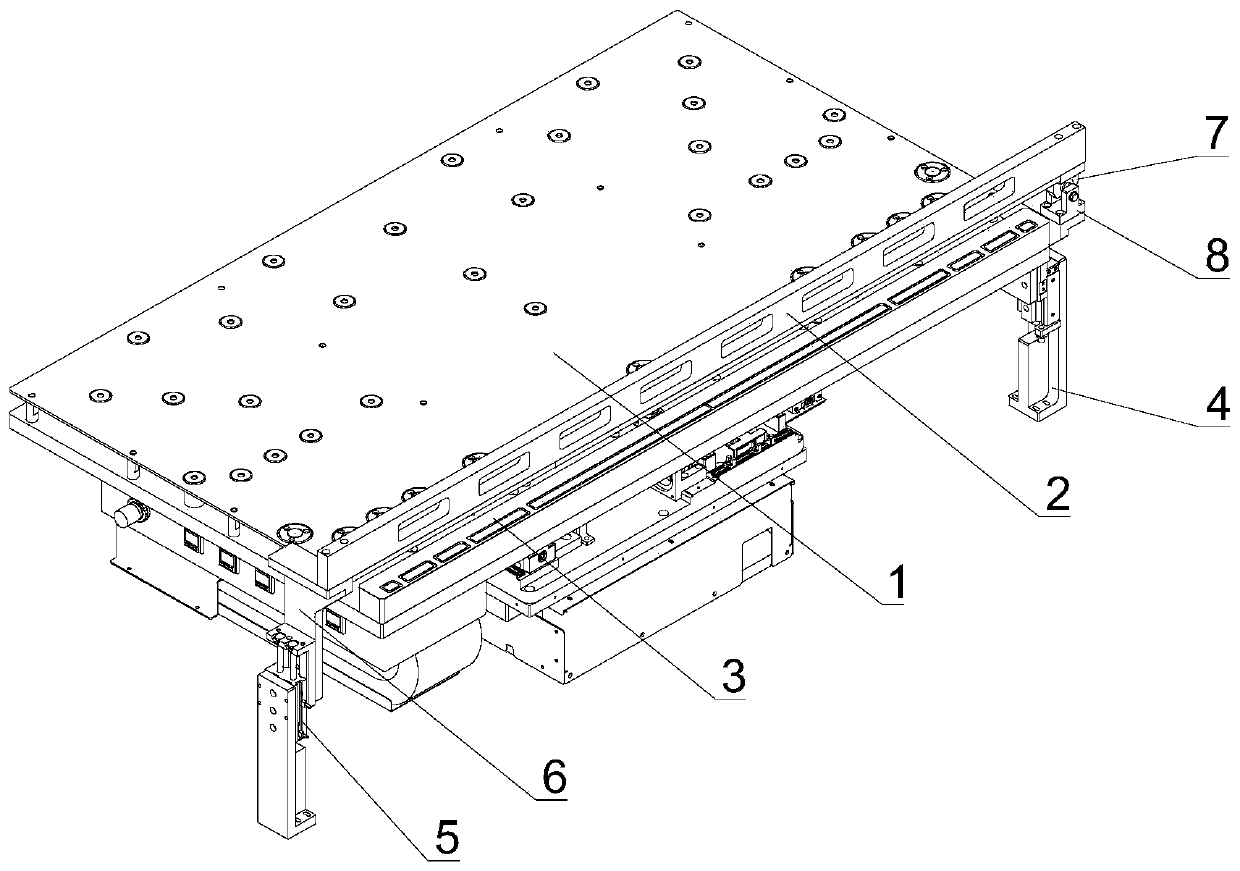

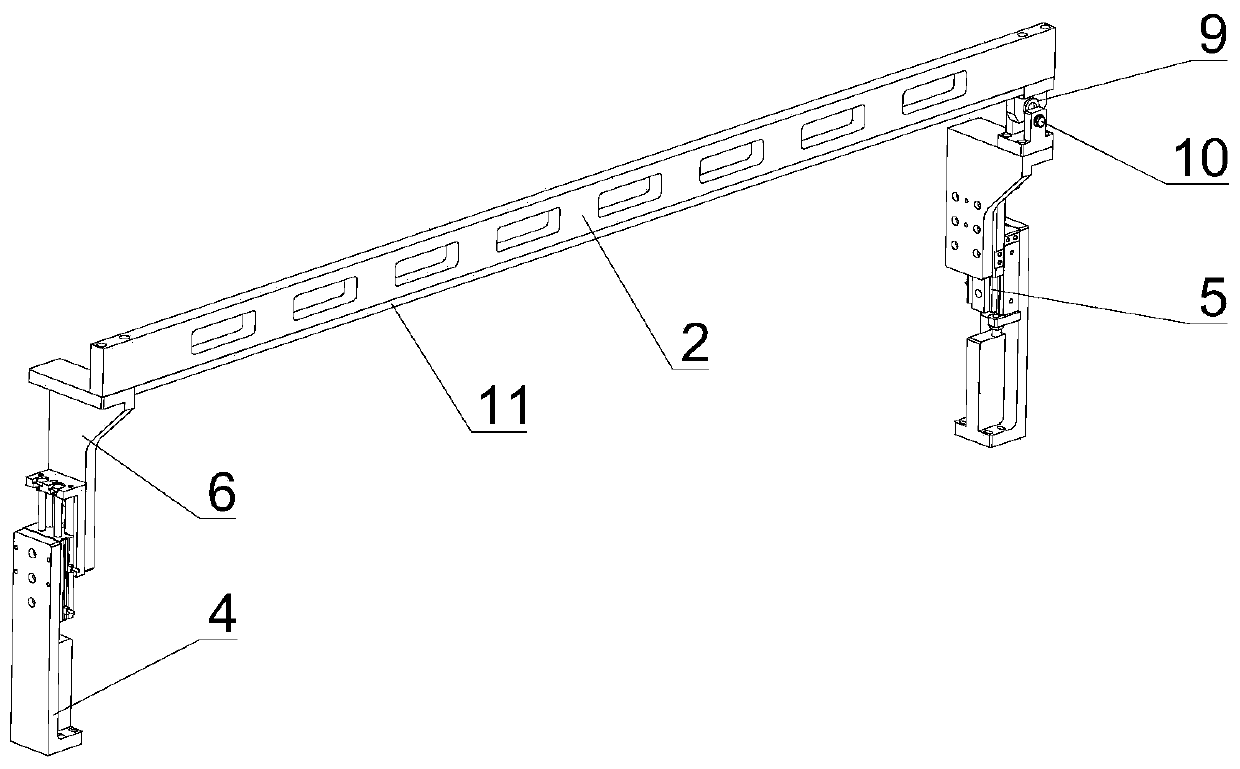

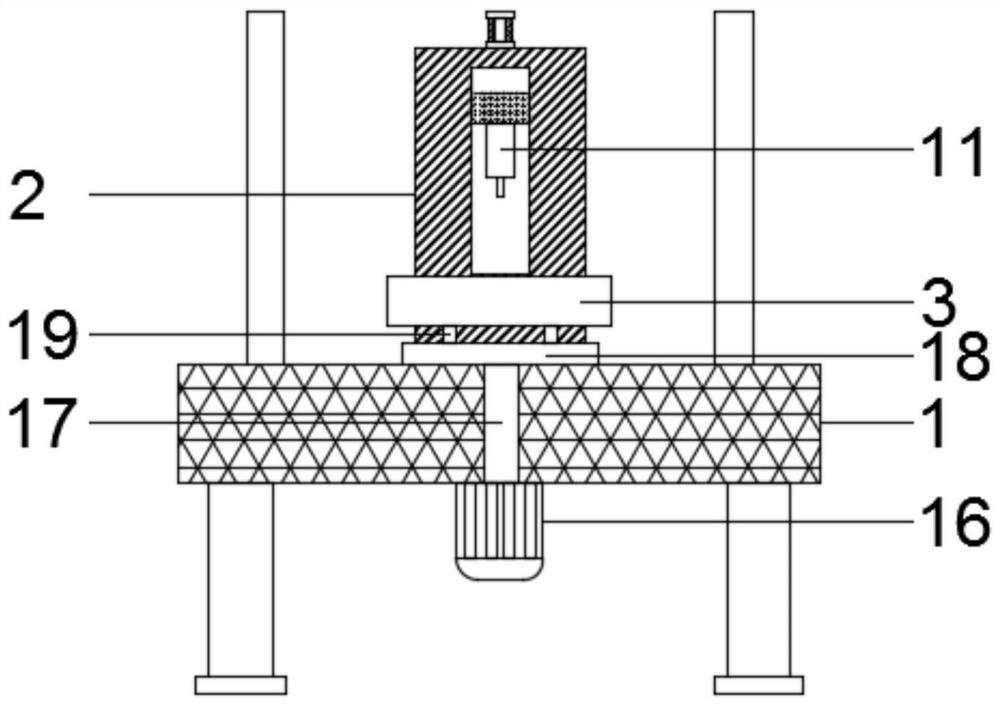

Composite wood board gluing machine

ActiveCN108687893ARealize automatic gluingWasteful realizationAdhesive application devicesPulp and paper industryWood panel

The invention relates to a composite wood board gluing machine. The composite wood board gluing machine comprises a bottom plate, an installing frame, a stacking device and a gluing device; the installing frame is installed on the bottom plate, and provided with a slide groove; the gluing device is installed in the slide groove, and the stacking device is arranged at the lower end of the gluing device, and installed on the bottom plate; the stacking device comprises a linear guide rail, a limiting mechanism, a supporting mechanism and a feeding mechanism; the gluing device comprises a glue outflow mechanism and a uniform smearing mechanism; and the uniform smearing mechanism comprises a sliding block, a sliding rod, a cross plate, a telescopic uniform smearing frame, a fixed supporting plate, a length adjusting cylinder, a connection ring and a driving branched chain. The composite wood board gluing machine can solve the problems that in the existing composite wood board gluing process, wood boards are stacked in disorder, gluing is not uniform, glue waste can be caused easily, and adjustability is poor, the function of performing automatic gluing on composite wood boards can be achieved, and the beneficial effects that stacking is in order, gluing is uniform, glue waste is not likely to be caused, and adjusting is flexible are achieved.

Owner:桃江县万众木业股份有限公司

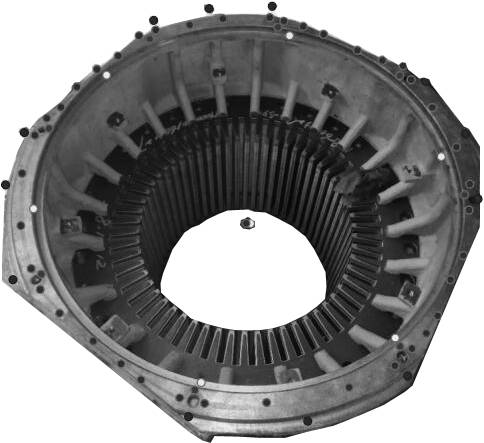

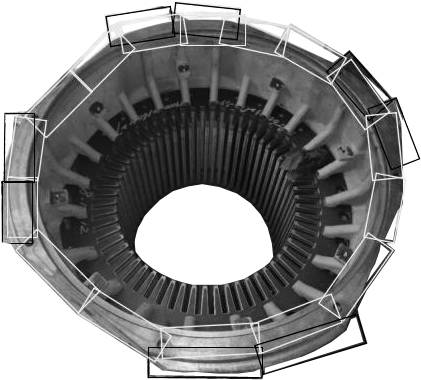

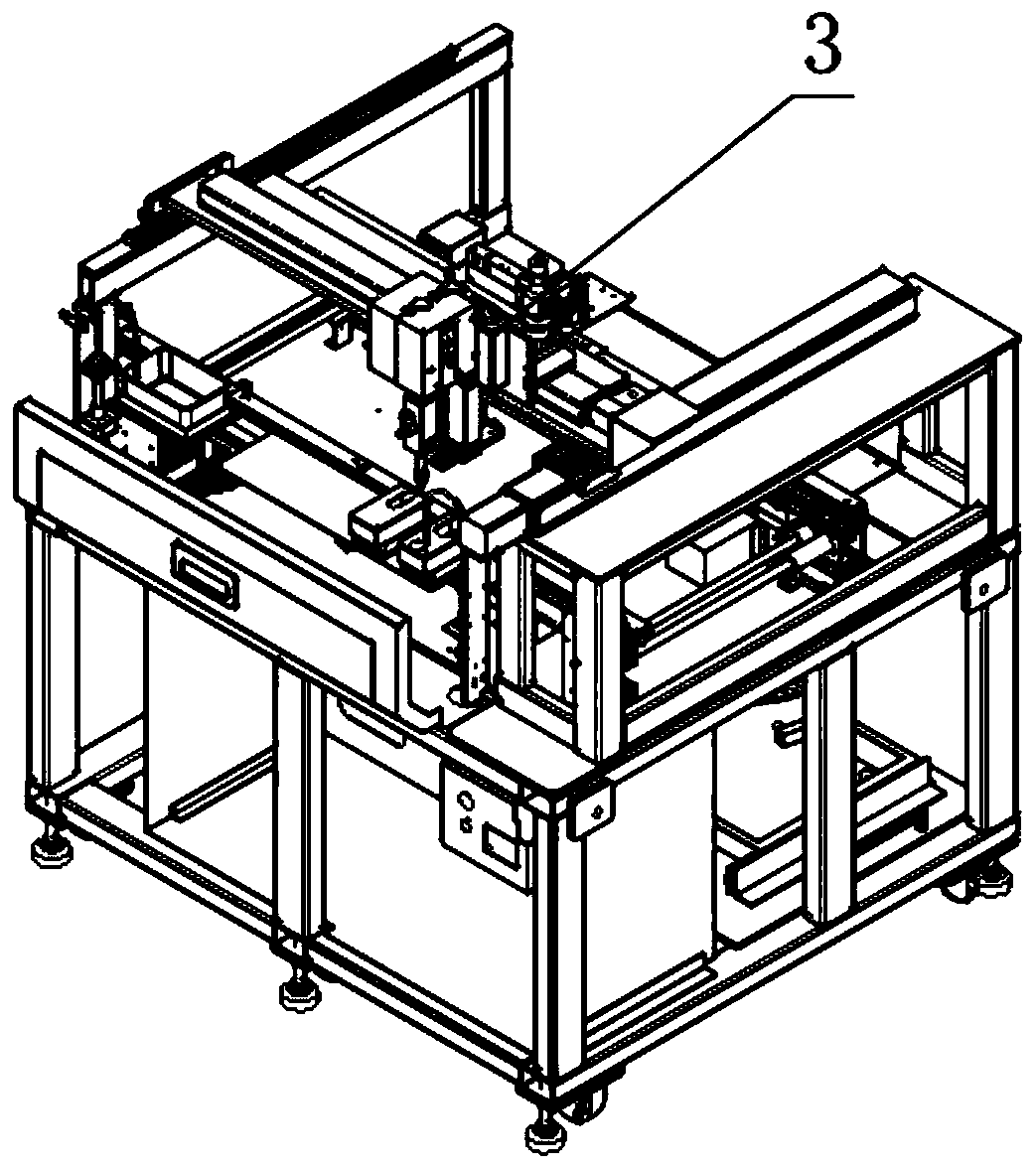

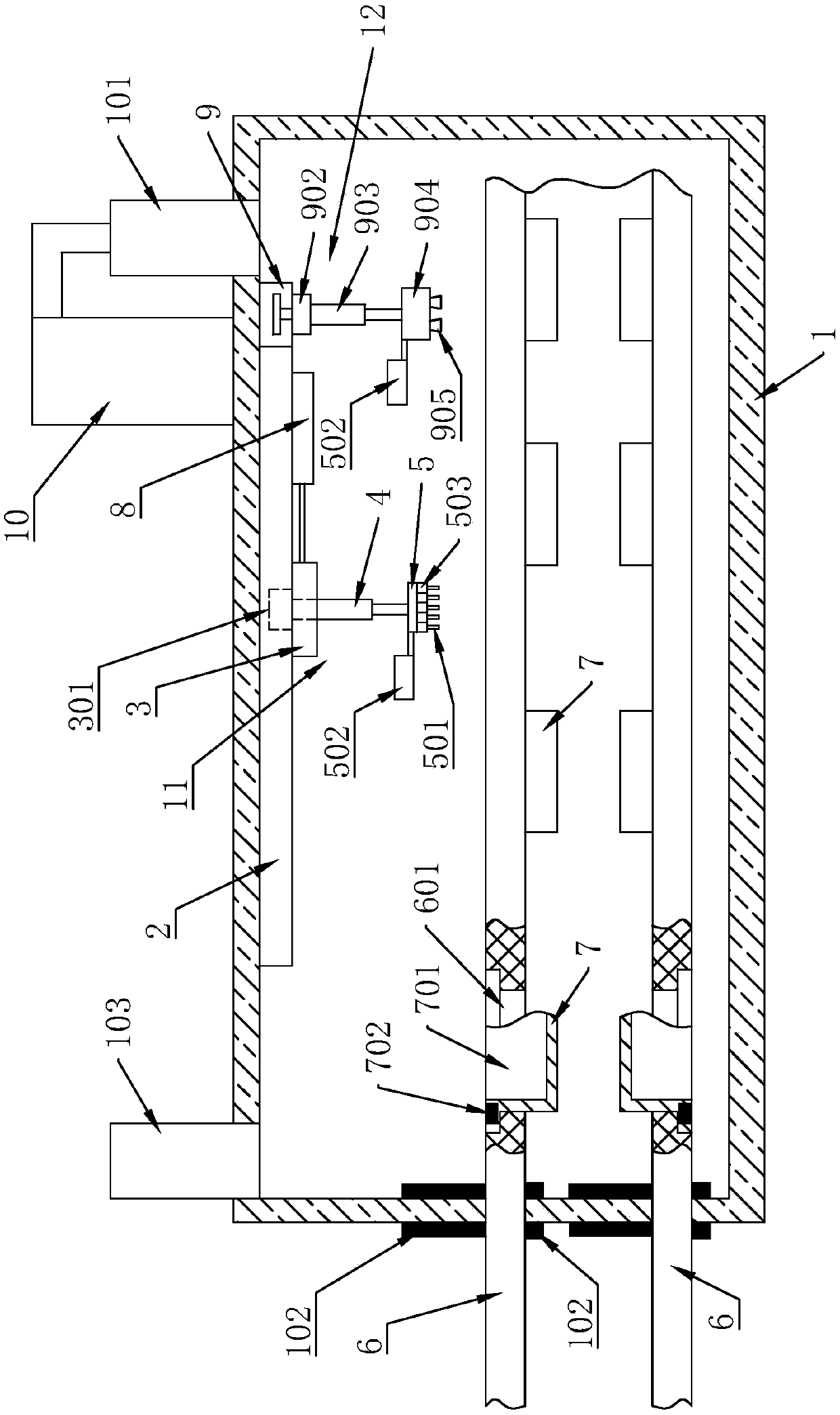

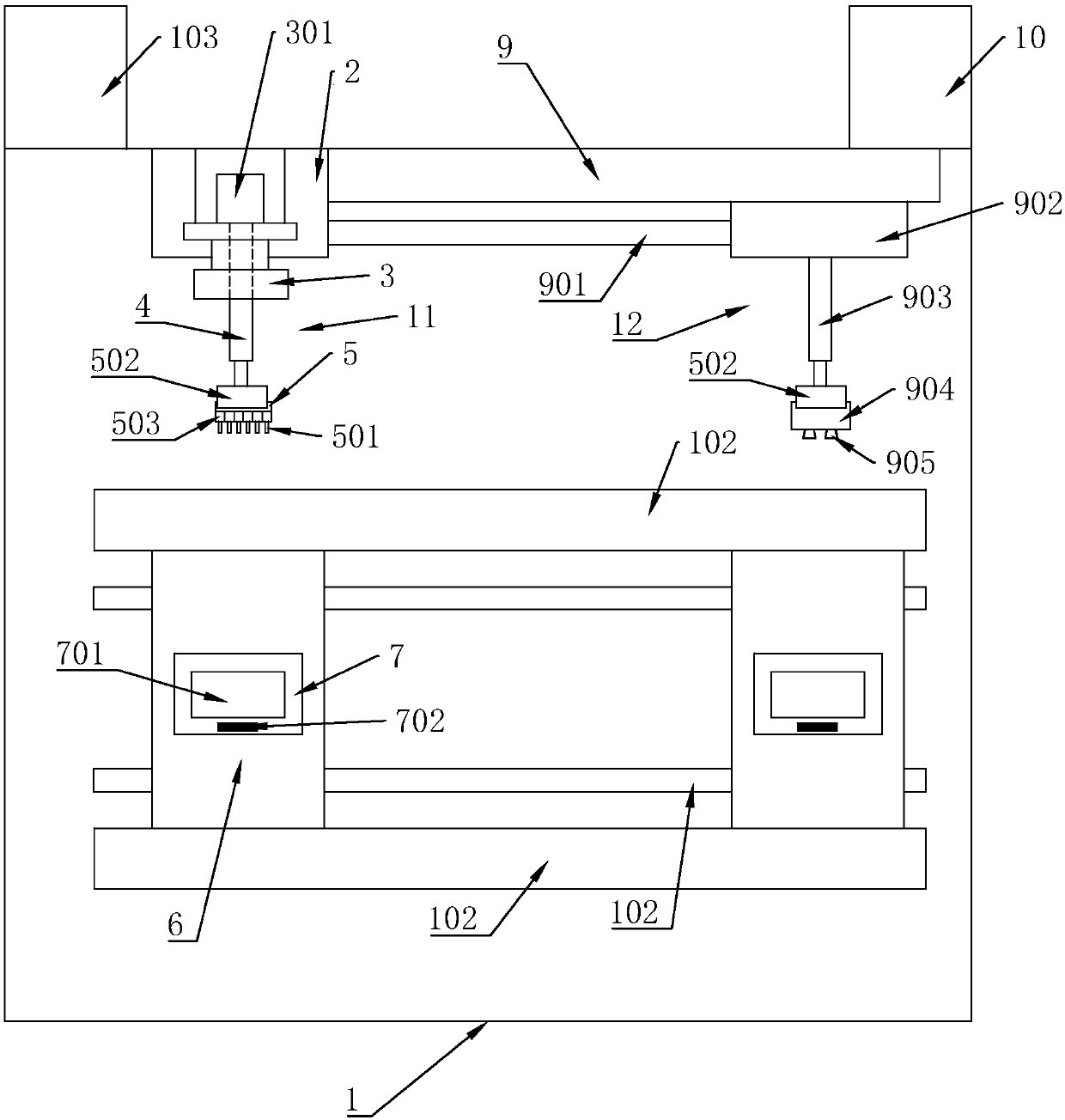

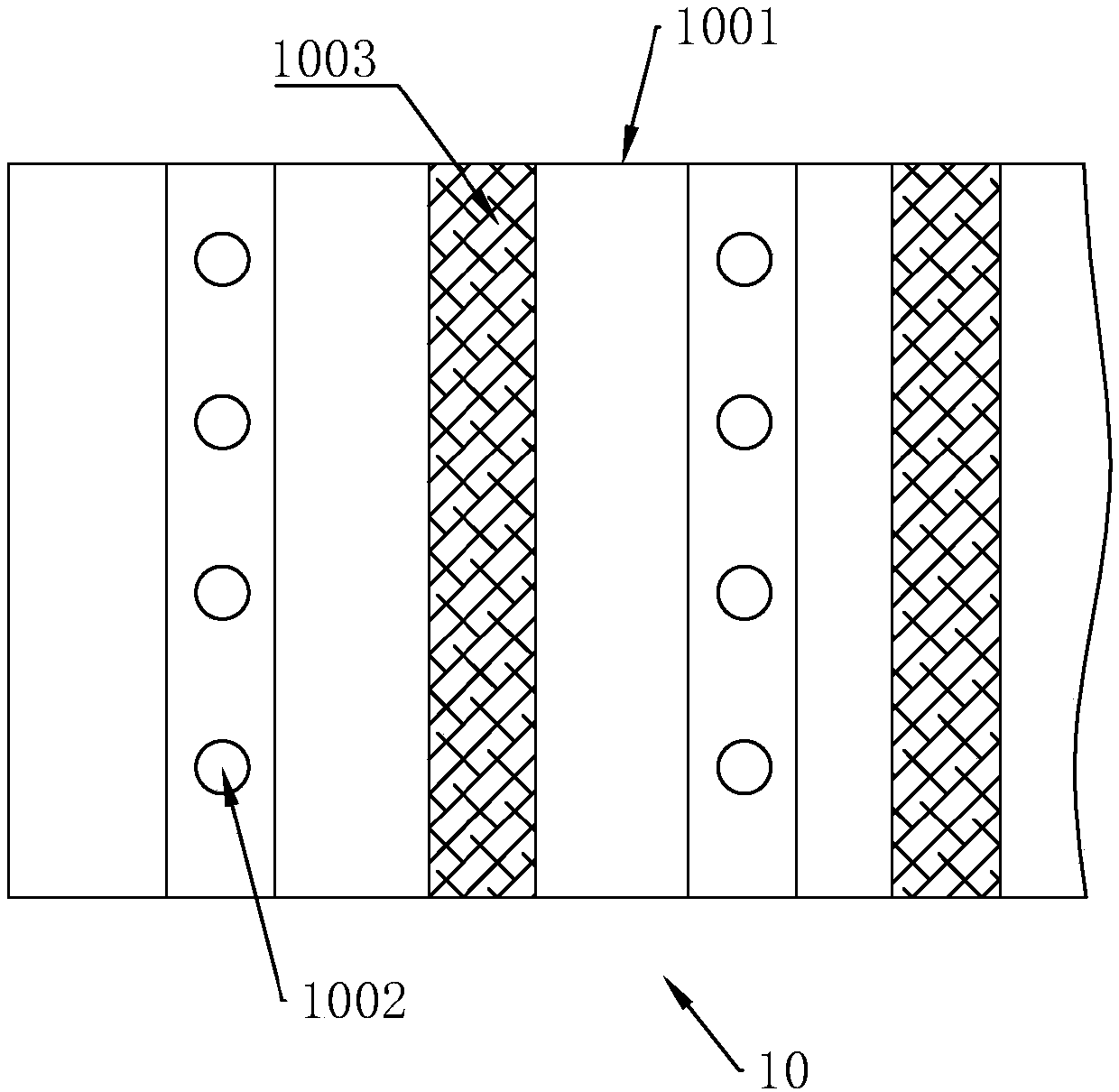

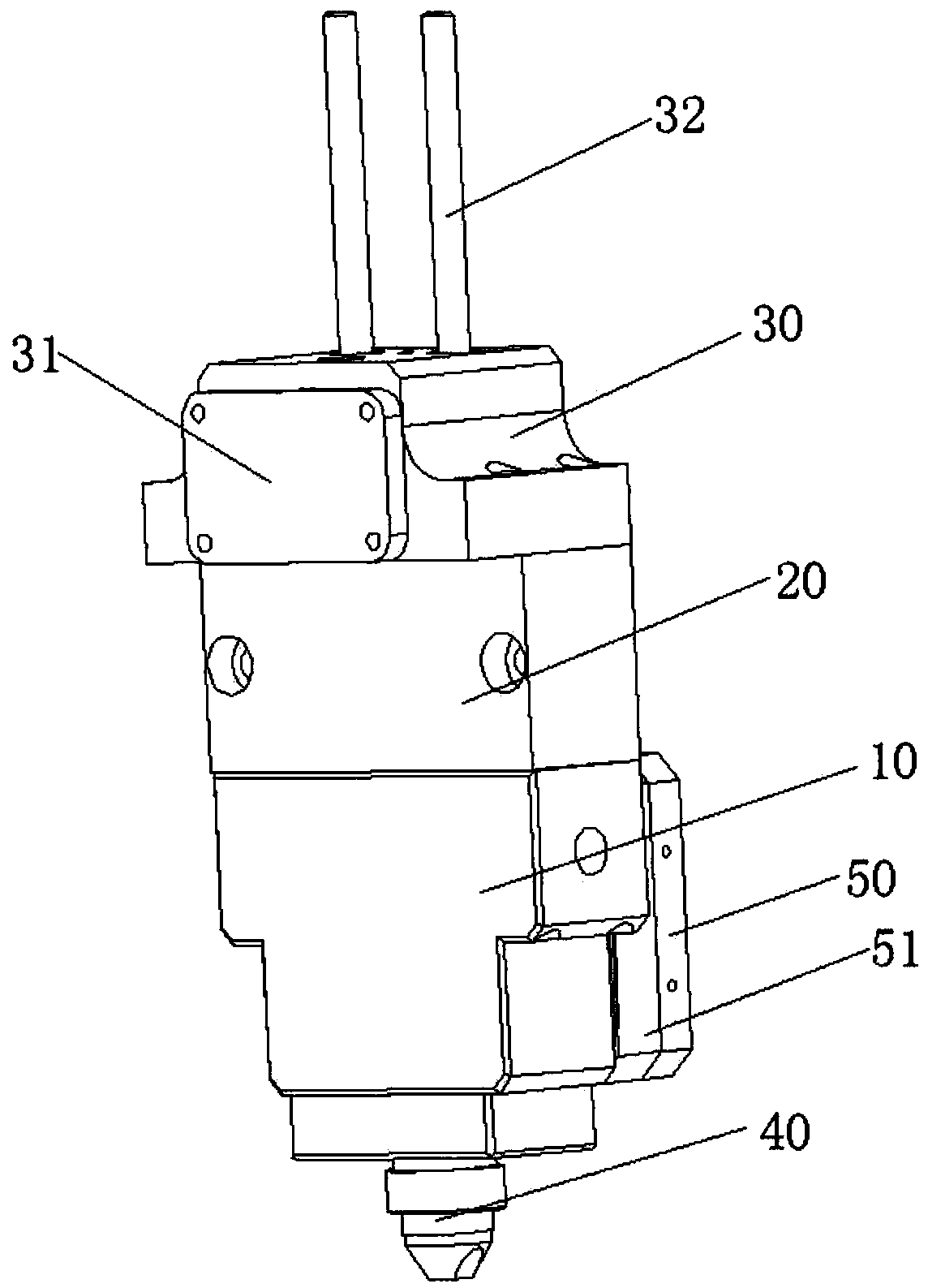

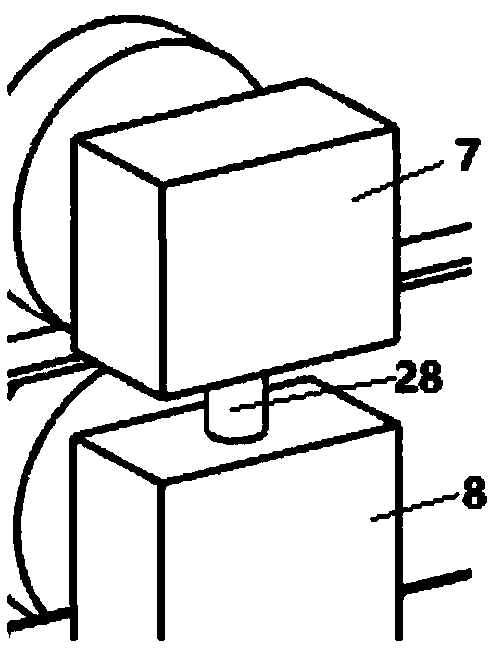

Gluing equipment of motor stator of urban rail and standard traction motor and a gluing method thereof

ActiveCN111729811AGuaranteed gluing effectThe gluing and testing process is neat and orderlyLiquid surface applicatorsCoatingsTraction motorManipulator

The invention relates to the technical field of gluing equipment, and discloses gluing equipment of a motor stator of an urban rail and standard traction motor and a gluing method thereof. The gluingequipment comprises a first station and a second station, the first station glues the end face of a stator, and the second station glues a non-transmission end bolt, a non-transmission end side face,a transmission end bolt and a transmission end side face; the first station comprises a first six-axis manipulator and a gluing device mounted at the tail end of the first six-axis manipulator, a gluing device comprises two or three glue supply mechanisms, and each glue supply mechanism comprises a glue supply head and a sliding table cylinder for controlling the glue supply head to move; the second station comprises a second six-axis manipulator and a waterproof sealant coating device mounted at the tail end of the second six-axis manipulator; the first work station and the second work station are each provided with a 2D color area-array camera and a 3D line-scan laser camera which provide process reference for gluing. The gluing equipment is suitable for gluing motors of different typesand sizes, and the gluing process and the gluing effect detection can be automatically and efficiently completed.

Owner:湖南天桥嘉成智能科技有限公司

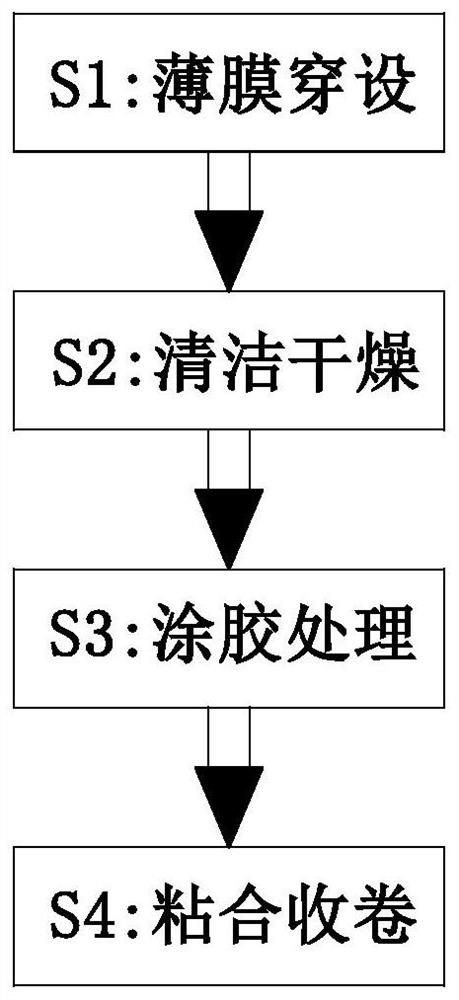

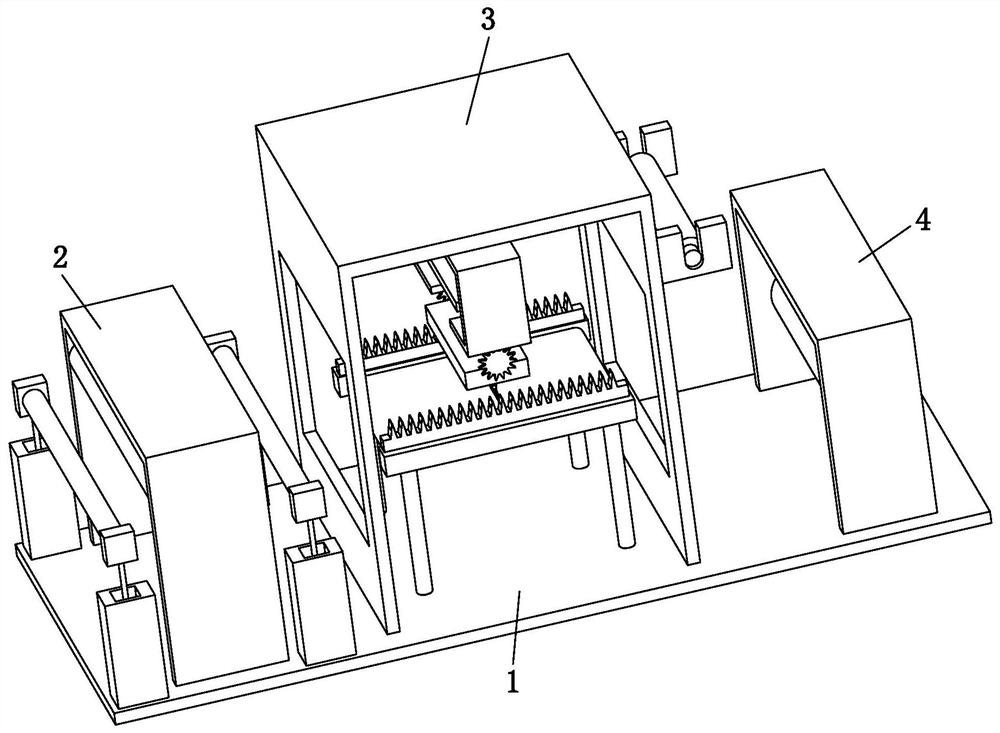

Printing method for composite plastic flexible package

InactiveCN113145382AImprove gluing effectGuaranteed cleanlinessLiquid surface applicatorsLamination ancillary operationsBonding processPlastic film

The invention relates to a printing method for a composite plastic flexible package. The method involves a bottom plate, a cleaning device, a gluing device and a bonding and winding device. The method can solve the following problems possibly occurring in the plastic film gluing and bonding process of existing equipment that a, when the existing equipment glues plastic film, the plastic film cannot be effectively sucked and fixed generally, so that the plastic film is liable to slip in the gluing process, the gluing effect is poor, and then subsequent processing of the plastic film is influenced; and b, when the existing equipment performs gluing, the phenomenon of non-uniform gluing often occurs, so that the thickness of the glued plastic film is not uniform, the bonding effect is poor, the production quality of the plastic film is reduced, and then the quality of the composite plastic flexible package is influenced.

Owner:徐楠楠

Coating method based on coating machine

InactiveCN111167667ANo saggingQuality improvementLiquid surface applicatorsCoatingsMachineIndustrial engineering

The invention relates to the field of melt glue coating, and particularly discloses a coating method based on a coating machine. The technical problem that in the prior art, in the equipment gluing process, due to the unreasonable arrangement of a spray head / nozzle, sagging and other phenomena can be generated, and the product quality is directly influenced is mainly solved. According to the coating method based on the coating machine, an XY horizontal moving system is additionally arranged in the coating machine and comprises an X moving mechanical arm and a Y moving mechanical arm, so that the spray head reaches any position of a plane, gluing treatment on a product to be coated is carried out according to a pattern or a route preset by the system, the sagging phenomenon is avoided and the product quality is improved.

Owner:张家港市欧微自动化研发有限公司

Gluing device for performing processing production on carpets

PendingCN108787314AGuaranteed smoothGuarantee the quality of gluingPretreated surfacesCoatingsPulp and paper industryProduction quality

The invention discloses a gluing device for performing processing production on carpets. The gluing device comprises a box body, a flattening device, a carpet grey fabric, and a gluing roller, whereinthe carpet grey fabric transversely passes through the inner side of the box body; the flattening device is arranged at the left end, positioned on the inner side of the box body, of the carpet greyfabric; the gluing roller is arranged at the lower end of the middle part of the carpet grey fabric; a glue pool is arranged under the gluing roller; and the gluing roller is arranged on the upper port part of the glue pool. According to the gluing device disclosed by the invention, the carpet grey fabric is flattened by using the arranged flattening device before gluing, so that flatness of the gluing surface of a carpet is ensured, uniform gluing is realized, and the gluing equality is ensured; electric heating tubes are arranged on the inner sides of an upper flattening block and a lower flattening block; the carpet grey fabric is pre-heated before being glued while the carpet grey fabric is flattened by using the flattening blocks at the same time, so that the gluing effect of the carpet is ensured, and the production quality of the carpet is improved.

Owner:ZHEJIANG MEINUO CARPET MFG CO LTD

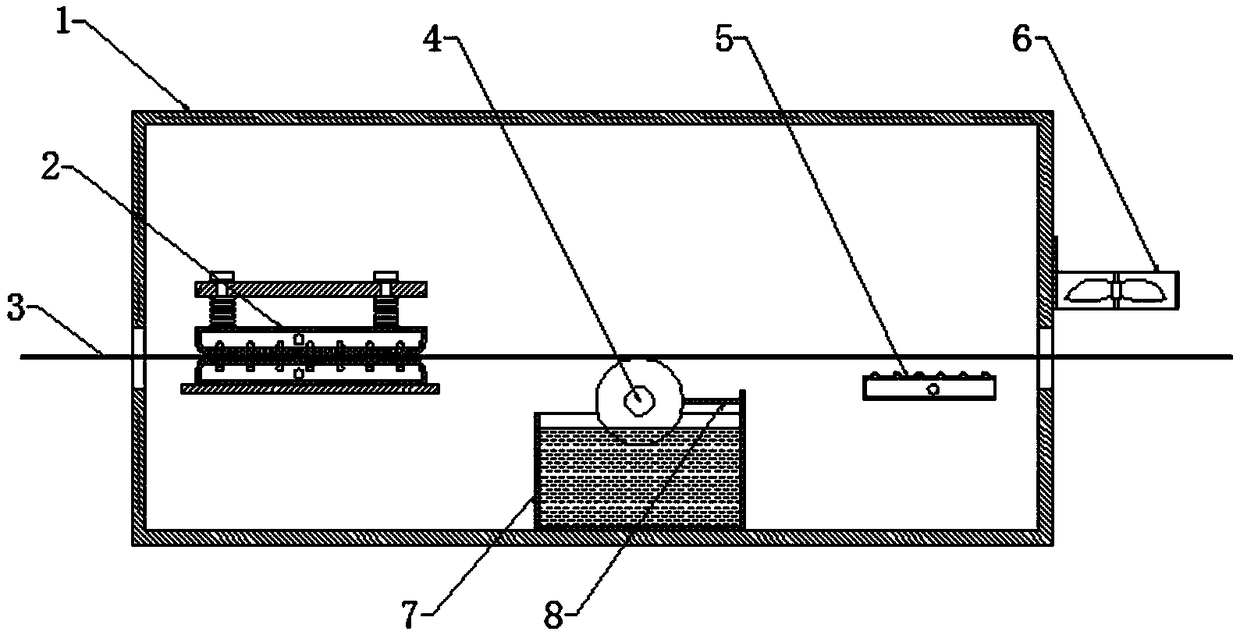

Automatic elastic gluing and transferring device

The invention discloses an automatic elastic gluing and a transferring device. The device comprise a sealed gluing chamber, wherein the top of the sealed gluing chamber is provided with a gluing mechanism and a transferring mechanism; a plurality of spray heads are arranged on the gluing mechanism in an elastic mode; the device further comprises two conveying belts which are arranged in parallel and are opposite in running direction, and the same ends of the two conveying belts extend to the outside of the sealed gluing chamber, and the other ends of the two conveying belts are located in thesealed gluing chamber; each conveying belt is provided with a plurality of mounting holes; templates are arranged on the portions, located in the mounting holes, of the conveying belts; grooves are formed in the templates; and the sealed gluing chamber is further communicated with an air inlet pipe and an exhaust pipe, and the exhaust pipe is communicated with a peculiar smell treatment device. According to the automatic elastic gluing and the transferring device, mechanical glue spraying work is realized, the labor intensity of workers is reduced, the labor amount and the labor cost are reduced, the working efficiency is improved, the working environment is improved, and the problem that the peculiar smell pollutes the environment and harms the health of the body is solved.

Owner:青岛创高世纪信息科技有限公司

Fully-automatic bookbinding machine

ActiveCN109177576AImprove protectionAvoid scratchesBook making processesBookbinding adhesivePulp and paper industryFully automatic

The invention discloses a fully-automatic bookbinding machine. The fully-automatic bookbinding machine comprises a glue application mechanism and a cover paper conveying mechanism. The cover paper conveying mechanism comprises a suction mechanism, a conveying assembly and a mark pressing mechanism. Cover paper is sucked by the suction mechanism and conveyed to the conveying assembly. The conveyingassembly receives the cover paper conveyed by the suction mechanism and conveys the cover paper to the mark pressing mechanism. After mark pressing of the cover paper is completed through the mark pressing mechanism, the cover paper is output. The glue application mechanism comprises a preliminary glue application assembly, a supplementary glue application assembly and a glue scraping assembly. The preliminary glue application assembly comprises a first rotating shaft, a first scraping plate and a first glue application roller, wherein the first rotating shaft is connected to an assembling seat in a rotary manner; the first scraping plate is fixedly connected to the first rotating shaft; and the first glue application roller is immersed in a glue solution in a glue solution containing tank and connected to the assembling seat in a rotary manner. By means of the fully-automatic bookbinding machine, the cover paper can be conveyed automatically, and hands of workers are liberated; and meanwhile, the glue application quality can be guaranteed.

Owner:WENZHOU RUIGUANG MACHINERY

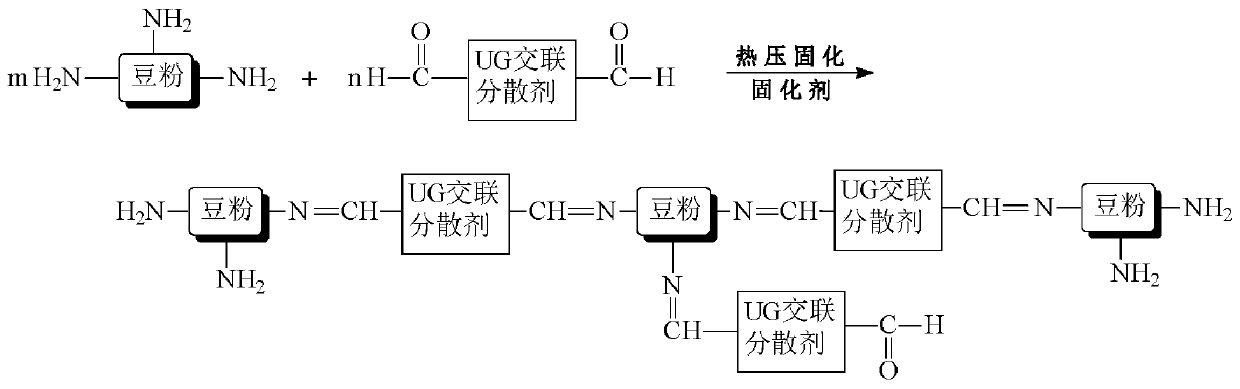

Preparation method of low-cost formaldehyde-free cross-linking dispersing agent and soybean adhesive prepared by using same

ActiveCN110713581AModerate viscosityImproved coating propertiesProtein adhesivesMacromolecular adhesive additivesPolymer scienceFirming agent

The invention discloses a preparation method of a low-cost formaldehyde-free cross-linking dispersing agent and a soybean adhesive prepared by using the same, and relates to a preparation method of across-linking dispersing agent and an adhesive prepared by using the cross-linking dispersing agent. The invention aims to solve the problems that an artificial board prepared from an existing urea-formaldehyde resin adhesive is difficult to meet the requirement on formaldehyde release amount, and a formaldehyde-free PAE type soybean adhesive is high in cost. The preparation method comprises the following steps: 1, uniformly mixing a glyoxal solution with water, adjusting the pH value, heating the mixture, adding urea, heating the mixture, and carrying out a thermal insulation reaction to obtain a cross-linking dispersant; 2, cooling the mixture and adding water to obtain a low-cost formaldehyde-free cross-linking dispersing agent; the soybean adhesive prepared by utilizing the cross-linking dispersing agent is prepared by stirring the cross-linking dispersing agent which is low in cost and free of formaldehyde, bean flour and a curing agent at room temperature. The invention relates to the preparation method of the low-cost formaldehyde-free cross-linking dispersing agent and the soybean adhesive prepared by using the same.

Owner:浙江蓝歌新材料科技有限公司

Manufacturing device based on broken bridge aluminum doors and windows

ActiveCN113369092AScientific and reasonable structureEasy to useLiquid surface applicatorsCleaning using gasesSlide plateScrew thread

The invention discloses a manufacturing device based on broken bridge aluminum doors and windows. A gluing assembly is arranged on one side of a back plate, a mounting plate is connected to the middle of a lead screw through threads, an electric glue gun is mounted in the middle of the mounting plate, an auxiliary sealing assembly is mounted at one end of the mounting plate, a sealing plate is bonded to one end of a connecting spring, and a triangular soft plate is mounted at the end, close to a storage groove, of a smoothing plate; a supporting adjusting assembly is mounted on one side of the back plate, a sliding plate is slidably mounted in the back plate, and a feeding cleaning assembly is arranged at one end of the back plate. Manual gluing is changed into automatic gluing through the gluing assembly, so that the labor intensity is relieved while the gluing effect is better; the auxiliary sealing assembly assists the gluing assembly in use, so that the gluing effect at the smoothing plate is further improved, and the gluing efficiency is improved. The filling effect is better, and a supporting and adjusting assembly adapts to the space size to be adjusted, so that normal use of the device is guaranteed; the feeding and cleaning assembly cleans sundries at a gluing position while facilitating feeding, and the multiple assemblies work together to guarantee the gluing efficiency.

Owner:安徽住方智能制造有限公司

Transfer printing film adhesive layer coating device

ActiveCN110252568ATackle splashGuarantee air qualityLiquid spraying apparatusSpray boothsAdhesiveEngineering

The invention discloses a transfer printing film adhesive layer coating device. The transfer printing film adhesive layer coating device comprises an outer shell, a glue spraying unit, a scraper, a conveying unit, a drying oven, a deodorization unit and a control unit, wherein the conveying unit comprises a feeding roller and a discharging roller which are fixed on the outer side of the outer shell through a supporting frame, and the feeding roller and the discharging roller are wound around the two ends of the base material to be coated and are driven by a first motor and a second motor to rotate respectively; the central section of the base material to be coated extends into the interior of the outer shell and is guided by a plurality of first guide rollers to form a coating plane, a second guide roller is arranged on the lower side of the first guide roller, the rear section of the base material to be coated is guided to form a material scraping inclined surface through the second guide roller, and then passes through the drying oven to finally guide back to the discharging roller; the scraper is fixed at the lower side of the material scraping inclined surface and is in contact with the material scraping inclined surface, a spray head and a glue solution tank of the glue spraying unit are arranged on the upper side of the coating plane and the lower side of the scraper respectively, and the surface sizing speed can be adjusted through the spraying speed of the spray head.

Owner:海盐三湾塑业有限公司

Glue outlet mechanism of mixed glue valve

PendingCN107755191AWon't stayHigh precisionLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention relates to a glue outlet mechanism, and particularly relates to a glue outlet mechanism of a mixed glue valve. According to the glue outlet mechanism, a quantitative cylinder is matchedwith a valve body, so that quantitative dispensing can be controlled, glue is shut off smoothly and cleanly, accurate dispensing can be realized, in addition, the processing and manufacturing are easy, so that glue leakage cannot occur under high pressure, and an air gap does not exist, so that air cannot remain, and the glue outlet accuracy is increased; the mixed glue is pushed and extruded to aglue outlet head by the quantitative cylinder and the valve body, so that the problem of pollution caused by dripping or flowing of the glue in other positions due to the flowability of the glue whenthe mixed glue is extruded is solved, the dispensing efficiency is improved, and the glue outlet effect of the mixed glue is guaranteed.

Owner:嘉孚朗机器人设备(苏州)有限公司

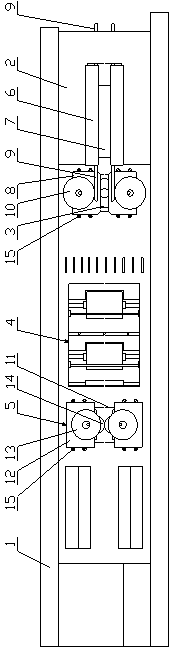

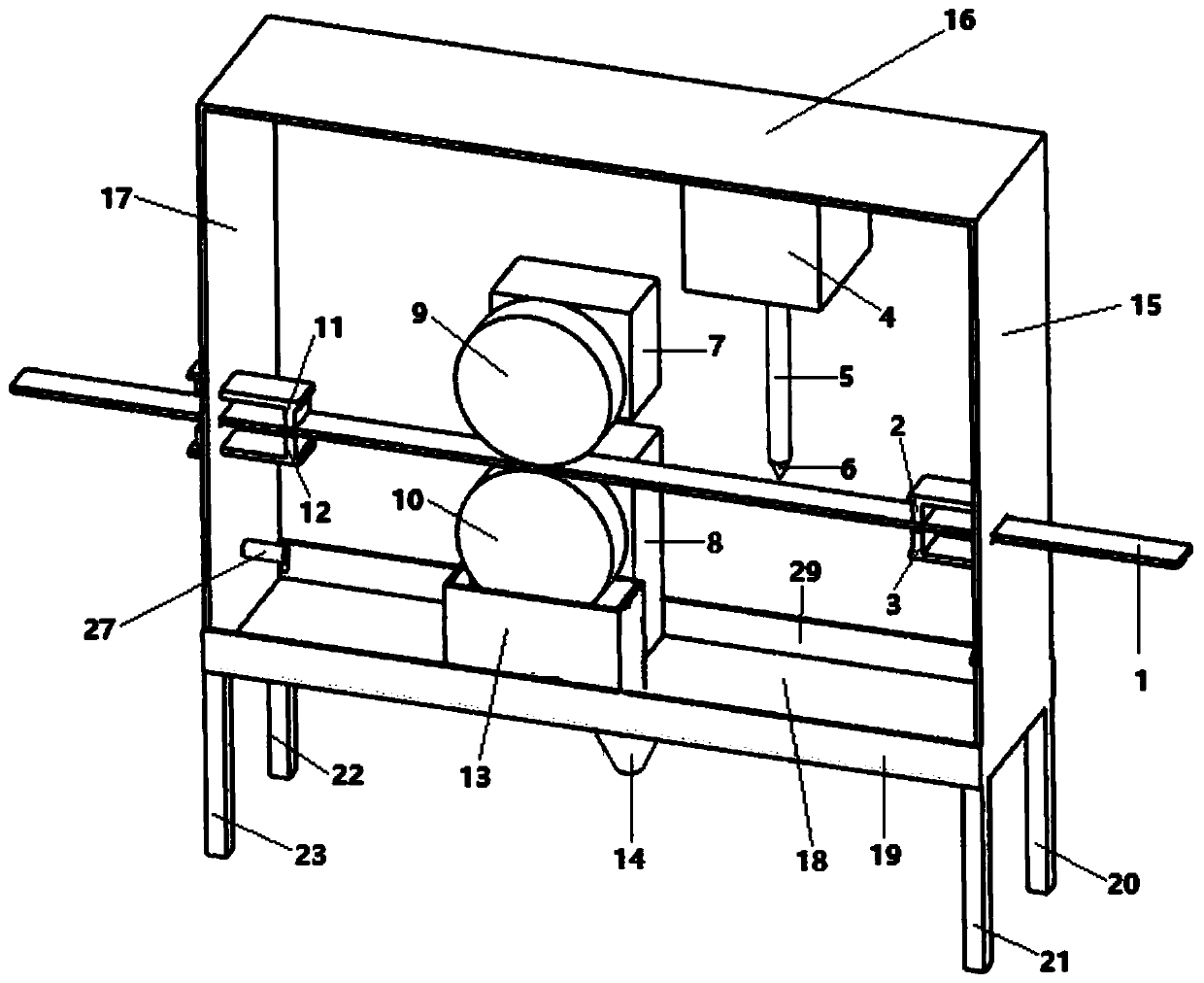

Automatic glue-coating device for steel sheet in automotive waist-line sealing strips

The invention discloses an automatic glue-coating device for a steel sheet in automotive waist-line sealing strips. The automatic glue-coating device comprises a glue-coating and detection system, a framework and a cleaning system, wherein the glue-coating and detection system comprises a steel sheet, a cleaning plate, a glue box, a glue conveying pipe, a glue spraying head, a first power chamber,a second power chamber, a push rod, an upper roller, a lower roller, a lower roller glue box, a brush head and a camera; the framework comprises a top plate, side plates, a bottom plate, bottom platecoamings and support legs; and the cleaning system comprises a water gun and a water drainage hole. The automatic internal steel sheet glue-coating device for the automotive waist-line sealing stripsdisclosed by the invention has the advantages that through cooperation of a mechanical structure and an electric control and detection system, double-sided uniform glue coating of the internal steelsheet of the automotive waist-line sealing strips can be realized, the glue coating effect is ensured, and the quality of a product is improved; and meanwhile, the automatic glue-coating device has anautomatic cleaning function, and moreover, glue scraps can be quickly and effectively cleared up, and the cleanliness of the equipment is improved and the service life of the equipment is prolonged.

Owner:长沙越联精密成型制品有限公司

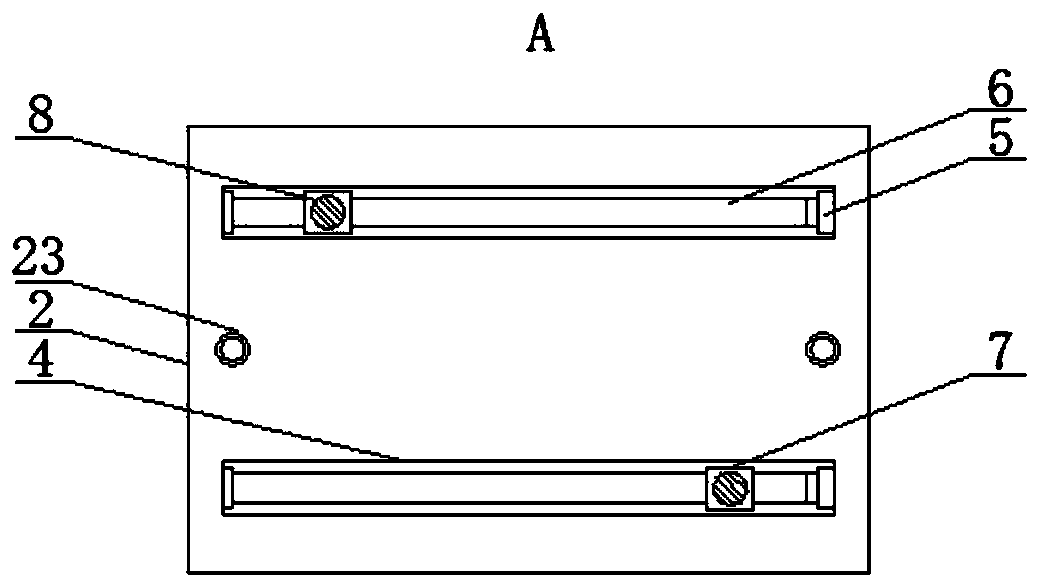

Edge pressing mechanism for overcoming glass warpage

PendingCN110252613AAvoid warpingGuaranteed flatnessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:KUNSHAN SAMON AUTOMATION TECH

Production process for drawing and twisting aluminum wire

InactiveCN106448944AAvoid darkeningGuaranteed gluing effectCable/conductor manufactureSocial benefitsHeating furnace

The invention discloses a production process for drawing and twisting an aluminum wire. The production process comprises the following steps: S1, selecting materials: selecting an aluminum rod and a mold, which meet drawing and twisting requirements; S2, heating: putting the selected aluminum rod and mold into a heating furnace; S3, drawing: matching with the mold and stretching to form the aluminum wire; S4, cooling: rapidly putting the aluminum wire formed by stretching into a cold water groove; S5, drying by blowing: putting the cooled aluminum wire onto a blow drying machine and carrying out blow drying treatment; S6, coating oil: coating one layer of anti-oxidization oil on the surface of the aluminum wire; S7, turning: putting the aluminum wire on a special twisting disc and turning the aluminum wire; S8, adjusting: uniformly adjusting payoff tension as much as possible; and S9, twisting: carrying out inching operation to finish aluminum wire twisting. By adopting the production process for drawing and twisting the aluminum wire, problems that the aluminum wire becomes black due to an annealing process and the appearance is damaged are effectively avoided; and a lead wire gluing effect is guaranteed, and economic and social benefits are improved.

Owner:JIANGSU PROVINCE WEINENGDA WIRE & CABLE

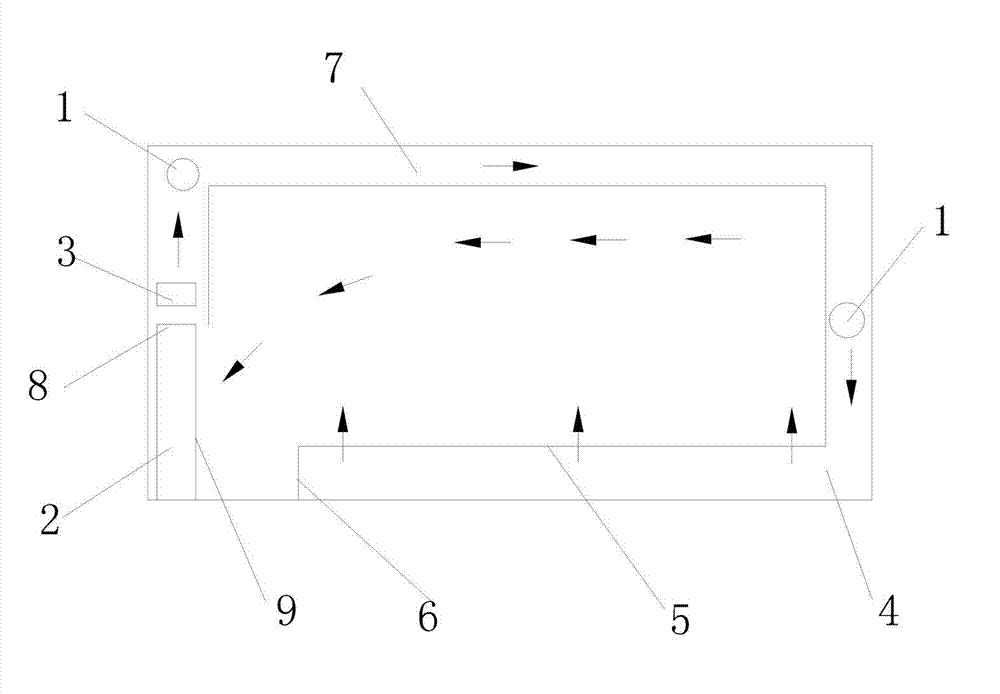

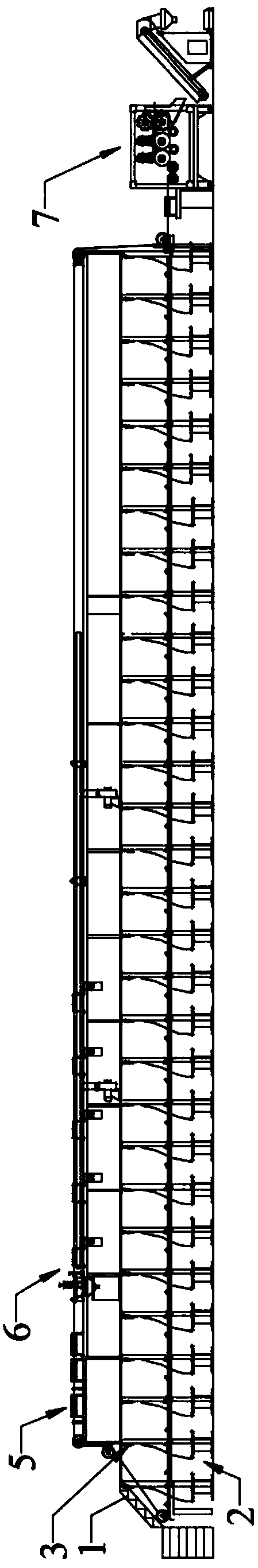

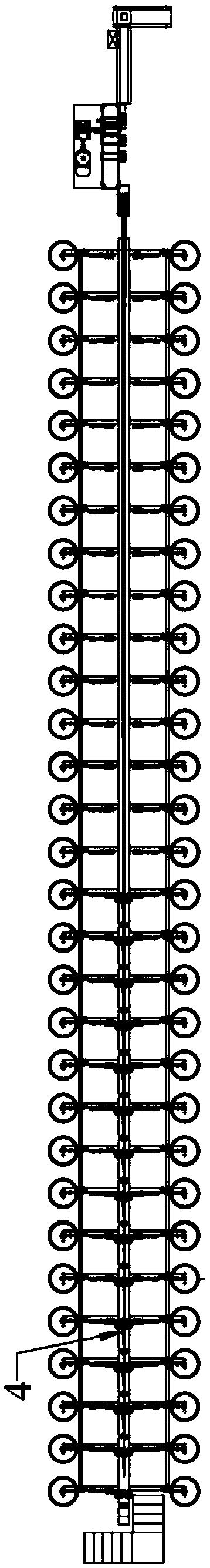

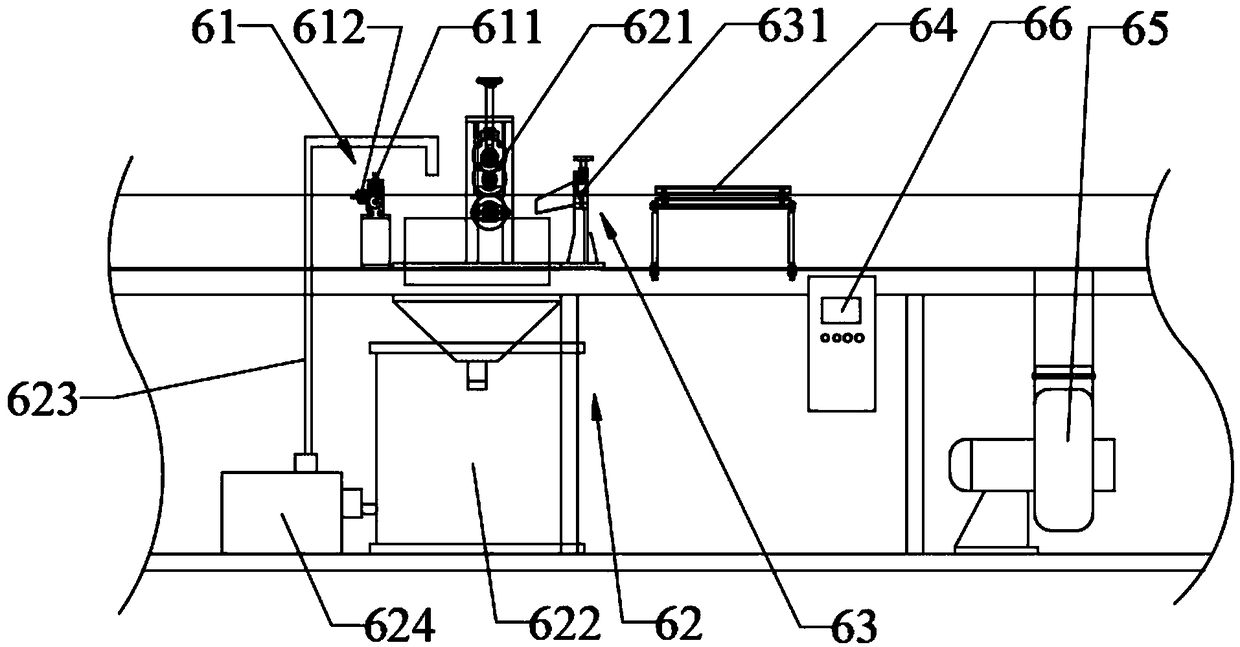

Dehumidifying room for drying glue impregnated bamboo curtain

ActiveCN102967123AImprove ventilationDry completelyDrying gas arrangementsDrying machines with local agitationProduction rateEngineering

The invention discloses a dehumidifying room for drying a glue impregnated bamboo curtain. The dehumidifying room is characterized in that a dehumidifying machine, an air tube and a material platform are arranged in a sealed dehumidifying room; the dehumidifying machine is arranged at one end of the dehumidifying room; a set distance is kept between the material platform and the dehumidifying machine; two sides of the material platform are close to the inner walls of the two sides of the dehumidifying room; a set distance is kept between the material platform and the bottom of the dehumidifying room and ventilating holes are intensively formed in the material platform and the bottom of the dehumidifying room; a wind shielding device is arranged at one end of the material platform close to the dehumidifying machine; an opening is formed at the other end of the material platform; one end of the air tube is arranged at the air outlet of the dehumidifying machine and the other end of the air tube is connected with the opening; and a driving fan is arranged in the air tube. The dehumidifying room for drying the glue impregnated bamboo curtain, disclosed by the invention, has the advantages as follows: (1) the dehumidifying room is suitable for vertically drying bamboo curtain materials so as to ensure that the materials are uniformly ventilated and completely dried; (2) as a low temperature dehumidifying method is adopted, the activity of thermosetting dehydration is completely kept, so that the bonding strength of bamboo plywoods can be guaranteed; and (3) the labor intensities of workers are reduced and the production rate is increased.

Owner:浙江凯森板业有限责任公司

Annealing method of exterior aluminum wire of composite-core soft aluminum stranded wire

InactiveCN106328309AImprove plasticityEasy to processApparatus for heat treatmentSocial benefitsOxidation resistant

The invention discloses an annealing method of an exterior aluminum wire of a composite-core soft aluminum stranded wire, comprising the following steps of S1, material selection: selecting an aluminum wire meeting specifications; S2, heating: heating the demanded aluminum wire and a heating furnace; S3, insulation treatment: standing the demanded aluminum wire in the heating furnace; S4, decreasing temperature treatment: decreasing the internal temperature of the heating furnace; S5, cooling: quickly placing the aluminum wire in a cold water basin; S6, drying: placing the cooled aluminum wire on a blow drying machine; S7, oil coating: coating the aluminum wire surface with oxidation-resistant oil. By the annealing method, the aluminum wire is relatively strong in plasticity to facilitate cutting and cold deformation and the aluminum wire stranding process can be completed, and thus the annealing method can be widely used and popularized, and economic and social benefits are increased.

Owner:JIANGSU PROVINCE WEINENGDA WIRE & CABLE

Manufacturing equipment for rows of steel fibers

ActiveCN109395983AGuaranteed adhesive performanceGood coagulationLiquid surface applicatorsCoatingsFiberIntermediate frequency

The invention relates to the technical field of building materials, in particular to manufacturing equipment for rows of steel fibers. The equipment comprises a gluing heating device which is providedwith a cleaning and shaping mechanism, a gluing mechanism, an evenly gluing mechanism, a heating device, an air blower and a controller. According to the manufacturing equipment for the rows of the steel fibers, before gluing is conducted, steel wires are subjected to cleaning and purification, after gluing is conducted, glue is applied evenly, the gluing effect of the rows of the steel wires isguaranteed, and meanwhile by means of recycling and reuse of the glue, the cost is greatly lowered; the glue is dried through intermediate frequency induction, warming is rapid, the heat efficiency ishigh, pollution discharge is less, the rows of the steel wires can be heated uniformly, by means of repeated heating and cooling operation, the solidification effect of the glue is better, and the steel fiber adhesive performance is fully guaranteed; manufacturing of the steel fibers is completed on an entire assembly line, no manual operation is needed, the process is simple, and the productionefficiency is high.

Owner:福建蓝美新材料有限公司

Decoration panel gluing assisting device

InactiveCN108979092AAvoid large density deviationsReduce wasteBuilding constructionsConstant forceEngineering

The invention discloses a decoration panel gluing assisting device, and relates to the technical field of decoration building materials. The device comprises a supporting base plate, movable slide grooves are fixedly connected to the left and right sides of a fixed shelf, a glue spraying head is slidably connected into each movable slide groove, and a corrugated bending pipe is communicated with the top of a mucilage glue storage groove; rotary inner thread rods are rotatably connected to the portion, located at the two sides inside the fixed shelf, of the top of the supporting base pate, inner threads are in threaded connection with threaded lifting top rods, and limiting sleeve mechanisms are fixedly connected to the tops of lower supporting top plates. The decoration panel gluing assisting device has the advantages that the situation in the prior art that distribution is not uniform when the mucilage glue is smeared manually is avoided, and the phenomenon that the density deviationof glued panels is large is avoided; meanwhile, the waste of viscose is reduced, the displacement of the panels during gluing is avoided, and the overlapping degree among the panels is improved; meanwhile, mechanical and constant-force squeezing is conducted, the gluing effect of the decoration panels is guaranteed, and the labor force for processing is reduced.

Owner:安吉吉来雅装饰材料有限公司

Silica gel applying machine gel head and silica gel applying machine

InactiveCN107716214AFast glueAvoid spilling glue on the frontLiquid surface applicatorsCoatingsBiomedical engineeringEconomic benefits

The invention discloses a silica gel applying machine gel head and a silica gel applying machine. The silica gel applying machine gel head comprises a fixing part and a gel outlet pipe, wherein one end of the gel outlet pipe is fixedly connected with the fixing part, and the gel outlet pipe is a cylindrical body. The silica gel applying machine comprises the silica gel applying machine gel head, and the fixing part is fixedly arranged at a gel outlet of the silica gel applying machine. The silica gel applying machine gel head is provided with the cylindrical gel outlet pipe, compared with a traditional silica gel applying machine gel head with a cuboid gel outlet pipe, in the gel applying process to frames of photovoltaic assemblies, gel is output more quickly and more evenly, the gel consumption of each photovoltaic assembly can be remarkably lowered, and meanwhile, the phenomena of front surface gel overflowing and back surface gel rolling of the photovoltaic assemblies can be avoided; and accordingly, the silica gel applying machine gel head is remarkable in economic benefit and greatly guarantees the appearance and performance of the photovoltaic assemblies.

Owner:SERAPHIM SOLAR SYST

Needle head feeding and fixing device for needle matched with disposable insulin pen

PendingCN110711673AReasonable designPracticalLiquid surface applicatorsMedical devicesInsulin syringesInjections needle

The invention discloses a needle head feeding and fixing device for a needle matched with a disposable insulin pen. The needle head feeding and fixing device comprises a gluing base and an assemblingbase which are mounted on an insulin injection needle production line, wherein a gluing support is arranged on the gluing base; a gluing driving device is mounted on the gluing support; the gluing driving device is in transmission connection with a gluing plate; the gluing plate slides in the gluing support; a plurality of rows of gluing heads are arranged on the gluing plate; each gluing head iscommunicated with a gluing pipeline; and all the gluing pipelines are jointly communicated with a gluing container mechanism. The device is reasonable in design, is used in cooperation with an insulininjector production line, achieves feeding of the needle tube, glues the needle tube, combines the needle tube with the needle head after gluing, achieves preliminary combination of the needle head and the needle tube, and is high in practicability and suitable for popularization.

Owner:JIANGSU JICHUN MEDICAL DEVICES

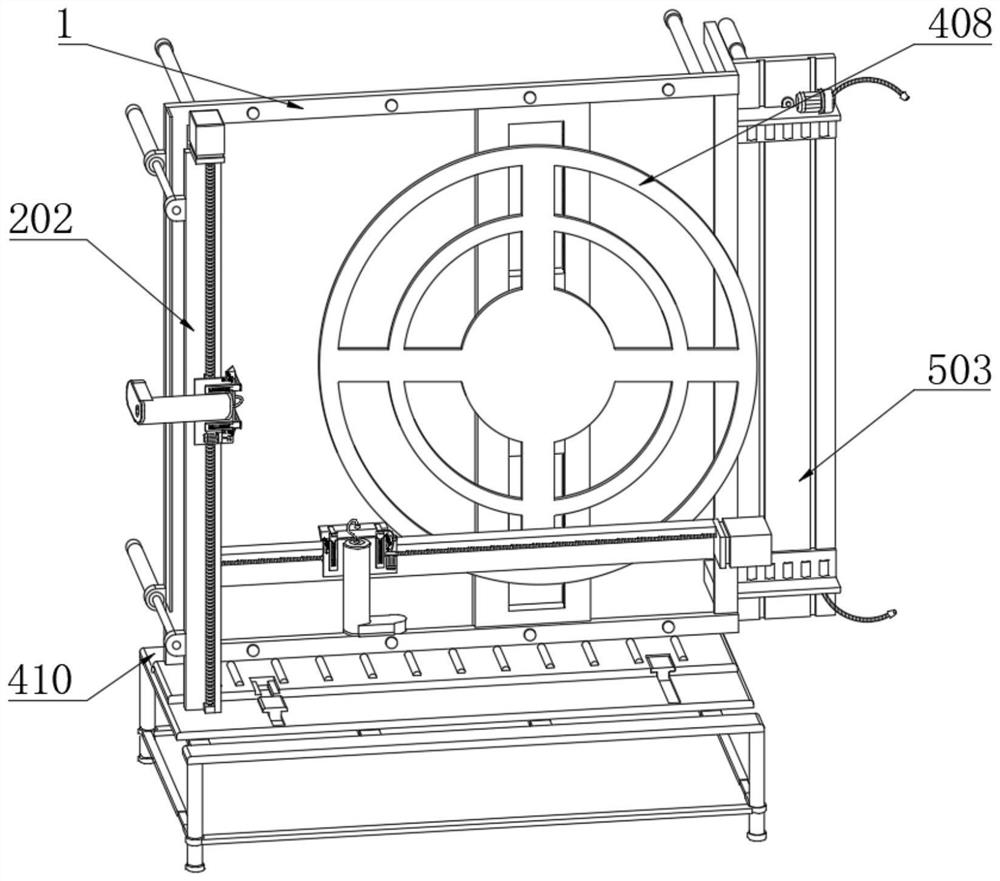

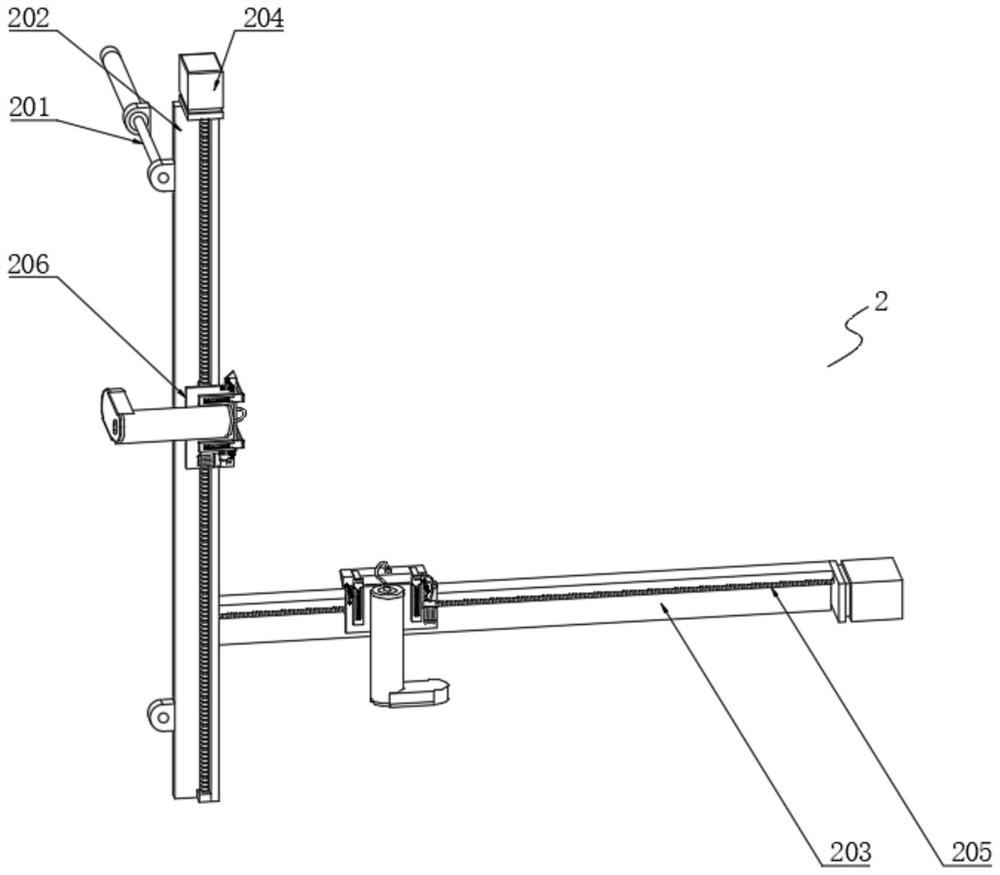

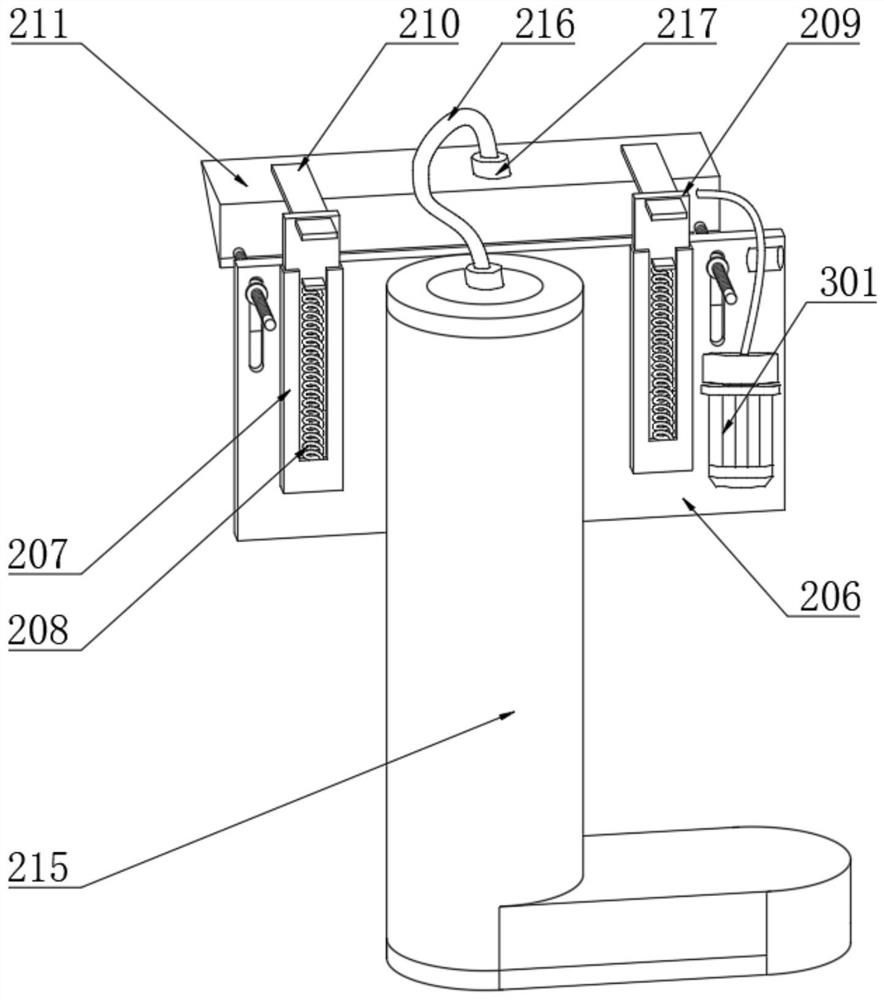

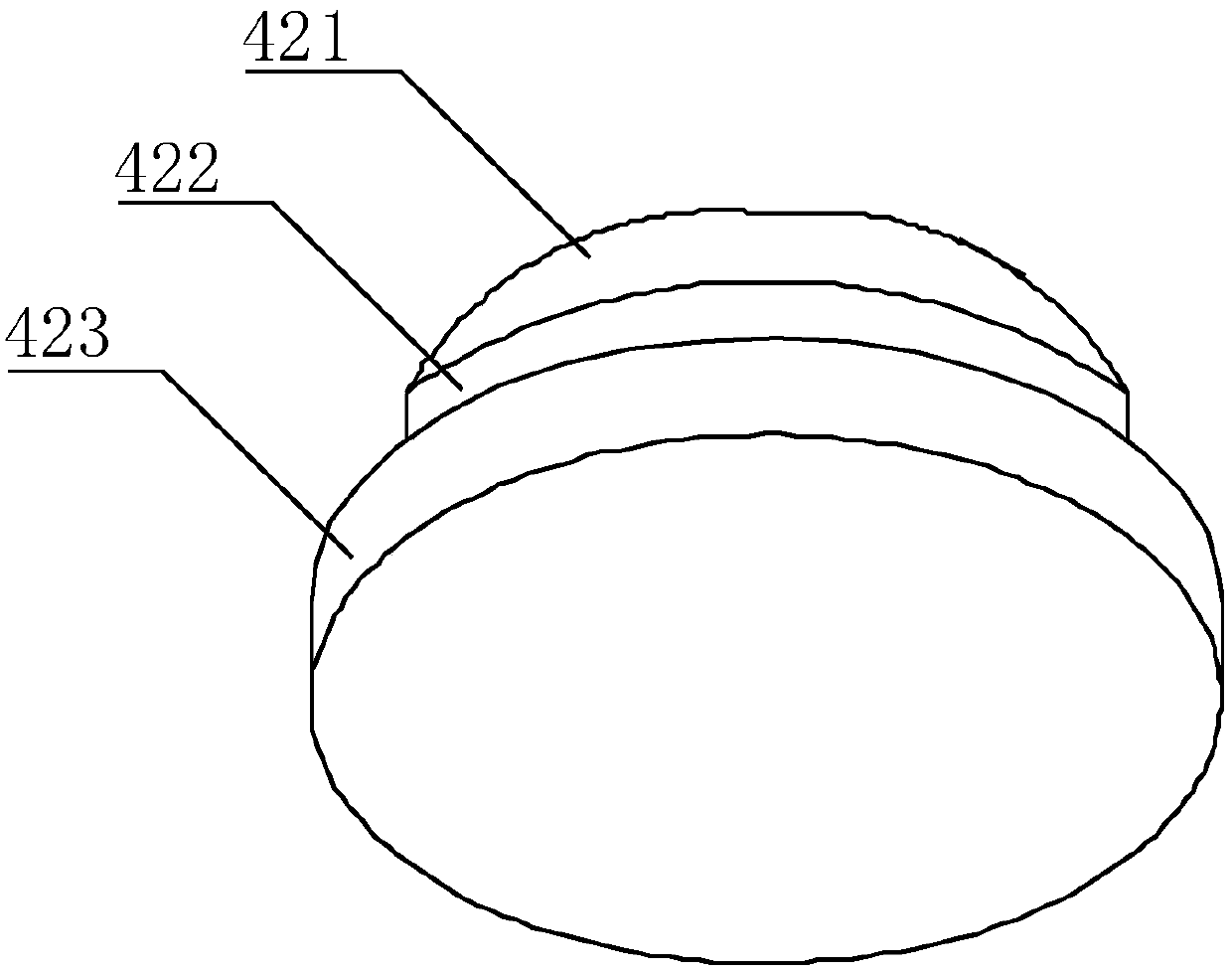

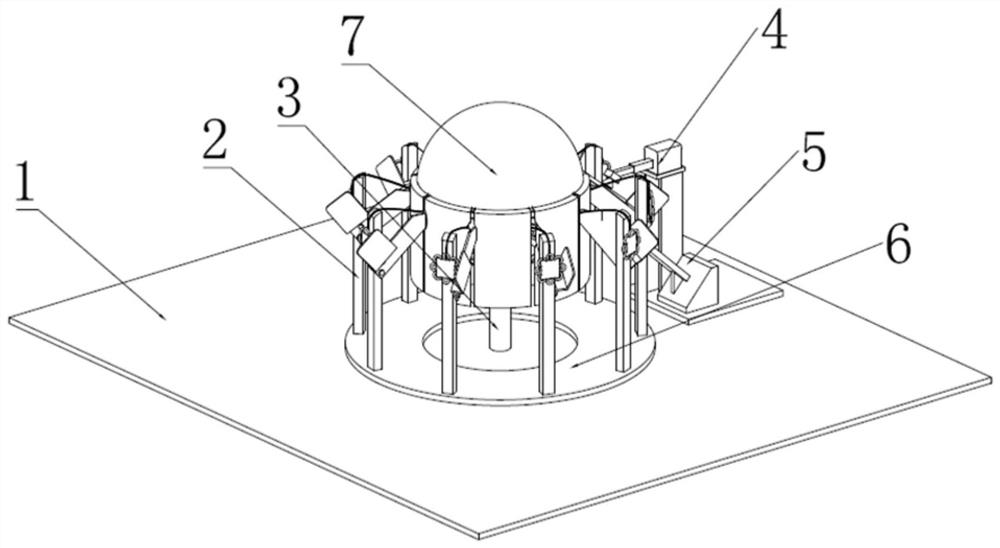

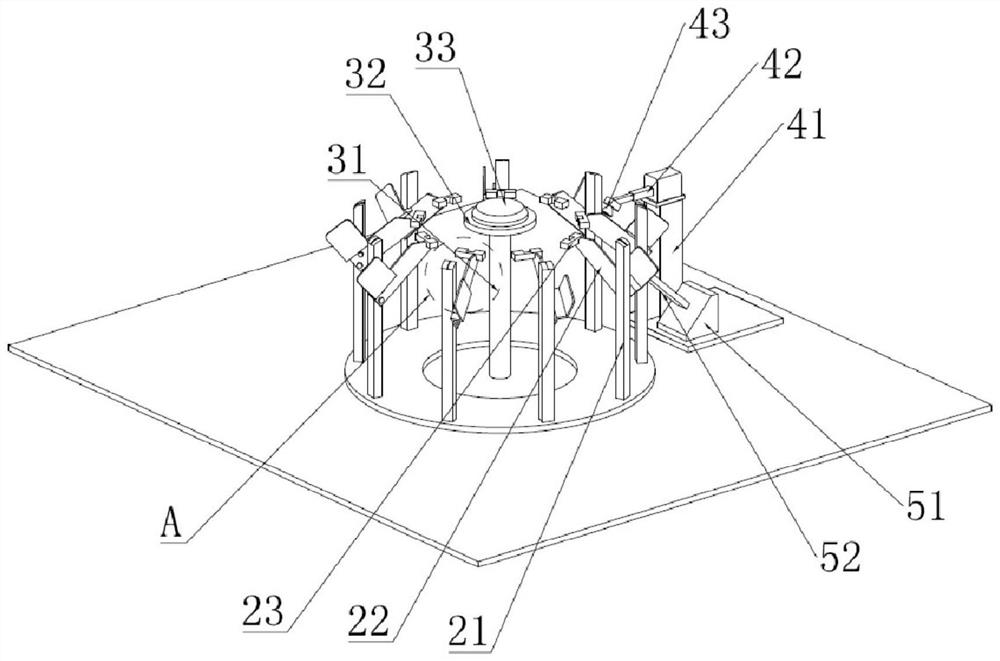

Equipment and method for processing yangko dance lamp

ActiveCN113601448AEasy to adjust the positionEasy to adjustLiquid surface applicatorsWork holdersEngineeringMechanical engineering

The invention discloses equipment and a method for processing a yangko dance lamp. The equipment comprises a rack, a gluing device and a rotating structure which are arranged on the rack, and further comprises a first supporting structure for arranging an upper lamp body and a second supporting structure for arranging an ornament assembly. The first supporting structure and the second supporting structure are both installed on a same rotatable part of the rotating structure, the first supporting structure is installed in the center of the rotating structure, and the second supporting structure comprises a plurality of positioning supporting assemblies which are evenly arranged in the annular direction with the first supporting structure as the center. The positioning and supporting assemblies are in one-to-one correspondence with ornaments, and at least one side of each positioning and supporting assembly is fixedly provided with a protection plate for separating the ornaments and connecting ropes thereof from adjacent light-clothes paper strips. According to the invention, the ornaments can be conveniently connected to a lamp bracket of the upper lamp body and attached to the lamp clothes, and a processing device and personnel are prevented from being influenced by the ornaments in the process.

Owner:CHUZHOU UNIV

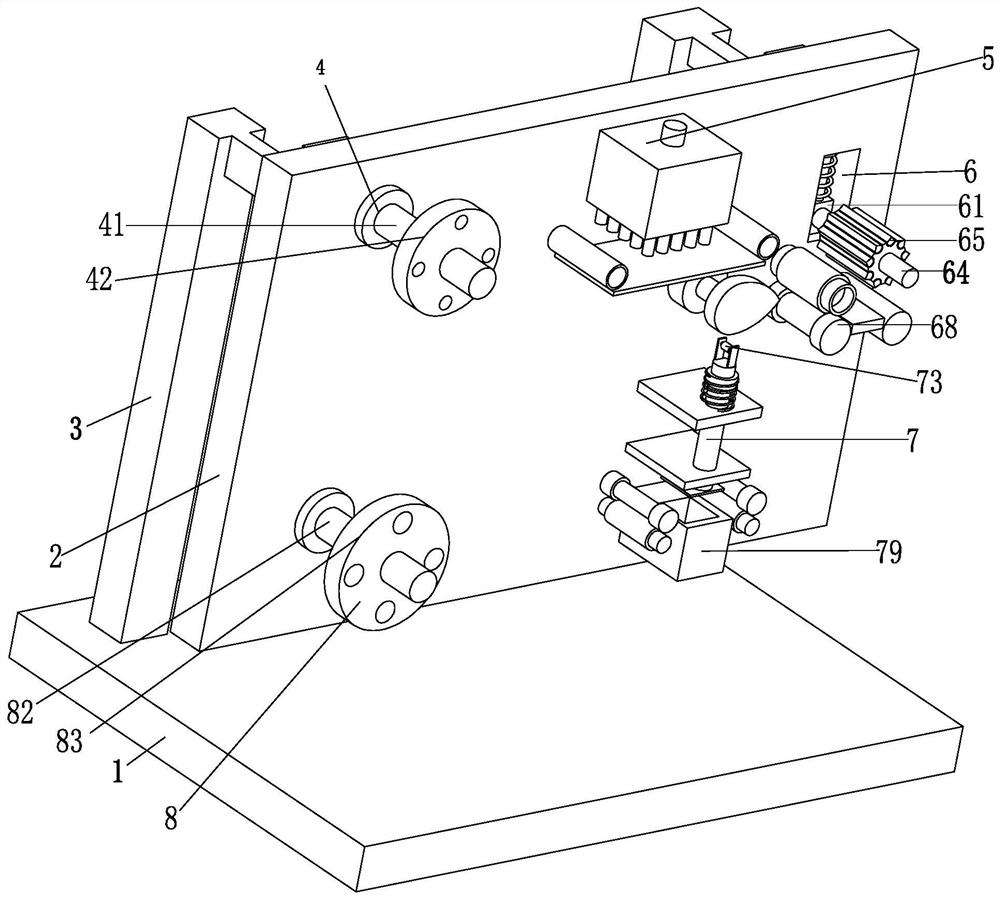

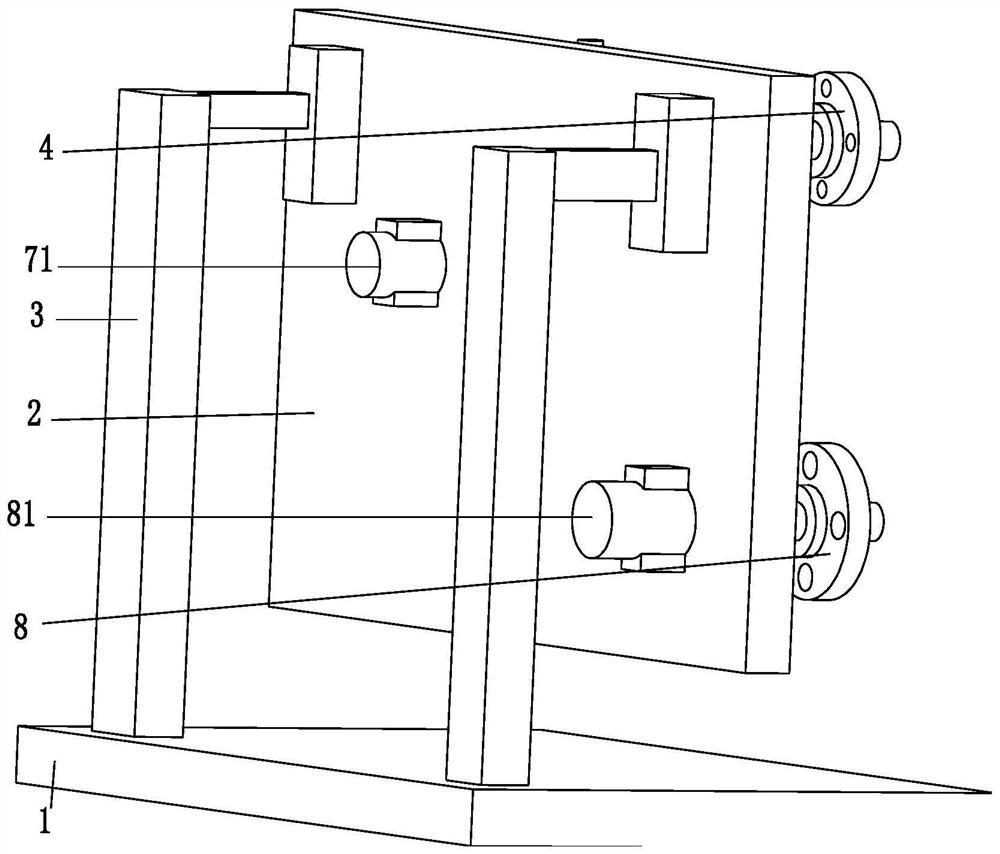

A self-adhesive label preparation and processing system

ActiveCN111495677BEasy outflowGuaranteed gluing effectLiquid surface applicatorsCoatingsAdhesiveProcess engineering

The invention relates to a self-adhesive label preparation and processing system, which includes a bottom plate, a side plate, a bracket, an unwinding unit, a gluing unit, a squeegee unit, a labeling unit and a winding unit. The problems encountered in the process of label preparation and processing are: a. The thickness of the self-adhesive label is not uniform in the production process of the existing self-adhesive label, and the produced label has poor stickiness; b. The preparation of the existing self-adhesive label Bubbles are likely to exist during pressing during the process, and the sizes of the produced labels are different; c. The existing self-adhesive labels have slow preparation speed, low degree of automation, complicated procedures, and high production costs.

Owner:临沂市金阳纸业有限公司

Glue application device for building decoration engineering construction

ActiveCN111330812AUniform forceOutflow smoothlyLiquid surface applicatorsCoatingsArchitectural engineeringElectric machinery

The invention provides a glue application device for building decoration engineering construction, and mainly relates to the field of building engineering construction. The glue application device forbuilding decoration engineering construction comprises a bottom plate, a liquid storage barrel is installed on the top surface of the bottom plate, a horizontal press plate is arranged in the liquidstorage barrel, and a plurality of liquid outlet pipes are installed on the bottom surface of the liquid storage barrel and penetrate through the liquid storage barrel and the bottom plate. The glue application device has the advantages that transmission motors provide power to drive the press plate to move downwards, then the press plate can apply force uniformly, glue can flow out from the liquid outlet pipes uniformly, glue application is more uniform, and the physical strength of an operator is saved; meanwhile, the distance between a press roller and the ground can be adjusted by controlling the expansion and contraction of electric telescopic rods, then the glue application thickness can be adjusted, the use requirement for different glue application thicknesses can be met, and thenthe glue application effect is guaranteed; and meanwhile, the waste of the glue is avoided, the glue is saved, the cost is reduced, and use is facilitated.

Owner:泰山职业技术学院

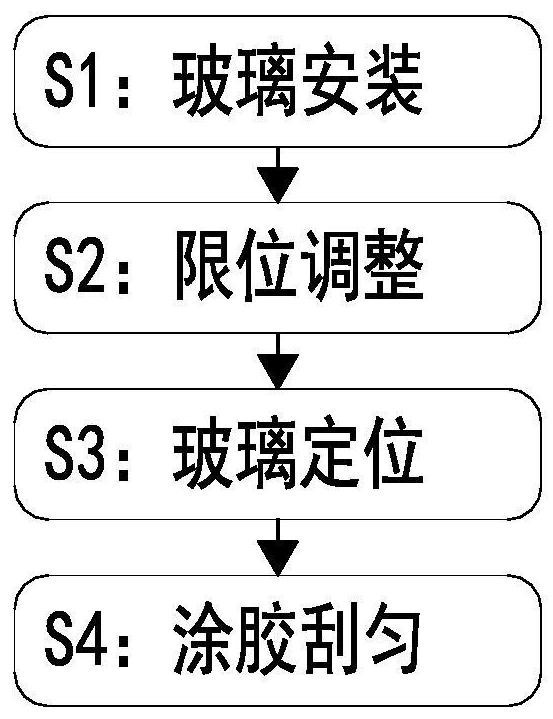

Fireproof door production and assembling method

InactiveCN113171937AReduce wasted manpowerImprove assembly efficiencyLiquid surface applicatorsMaterial gluingMaterial resourcesManufacturing engineering

The invention relates to a fireproof door production and assembling method. A fireproof door production and assembling machine is used in the method. The machine comprises a limiting moving frame, L-shaped mounting rods, a gluing device and a mounting device, wherein the L-shaped mounting rods are symmetrically fixed to the lower sides of the left end and the right end of the limiting moving frame, the gluing device is mounted on the lower side of the L-shaped mounting rod on the left side, and the mounting device is arranged on the lower side of the L-shaped mounting rod on the right side. The method can solve the problems that when fireproof glass on a fireproof door is mounted, multiple persons are required to jointly complete assembling of the fireproof glass in a traditional gluing method, manpower and material resources are wasted, and the assembling efficiency of the fireproof door is low; and when the fireproof glass and the mounting position are connected in a gluing mode, the mounting effect of the fireproof glass is poor due to the fact that glue always floats at the joint of the fireproof glass and the mounting position and is difficult to enter a gap, and meanwhile the connection strength is unstable as a result of uneven glue distribution in the gluing process.

Owner:苏永碧

Automatic high-efficiency gluing equipment for electronic components

PendingCN113814118ATo stabilizeAct as a limitLiquid surface applicatorsCoatingsMaterial resourcesElectronic component

The invention discloses automatic high-efficiency gluing equipment for electronic components, and relates to the technical field of electronic component gluing equipment. The automatic high-efficiency gluing equipment comprises a machining table, a control box and a containing plate arranged on the machining table, wherein a first air cylinder is arranged at the top of the control box; the control box is connected with a lifting mechanism through the first air cylinder; the bottom of the lifting mechanism is connected with a fine adjustment mechanism; a gluing mechanism is arranged above the containing plate; a fixing mechanism is arranged in the containing plate; the lifting mechanism comprises a connecting rod, a moving block and a sliding block; the fine adjustment mechanism comprises an electric sliding rail, a vehicle body and a fixing frame; and the fixing mechanism comprises a second air cylinder, a damping frame, a movable column, a limiting plate, a damping spring and a clamping plate. According to the automatic high-efficiency gluing equipment for the electronic components, the height of a spraying mechanism can be adjusted, the electronic components can be firmly fixed, the spraying range is widened, the spraying effect is improved, the spraying efficiency is improved, full-automatic spraying is achieved, manual operation is not needed, convenience and rapidness are achieved, and manpower and material resources are saved.

Owner:湖南芷江正向科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com