Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248results about How to "No sagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Assembled splicing joint sealing material for building components and application thereof

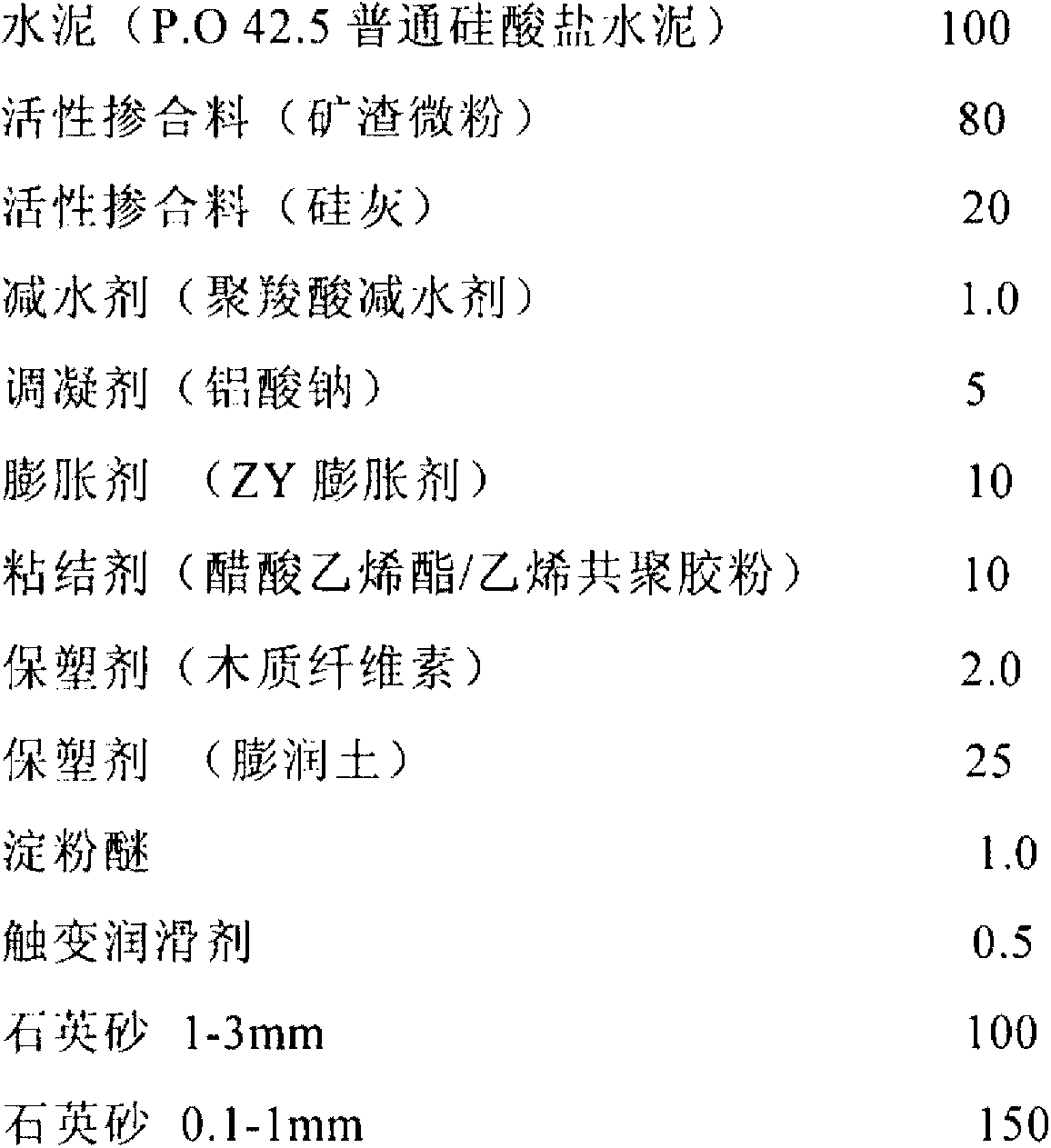

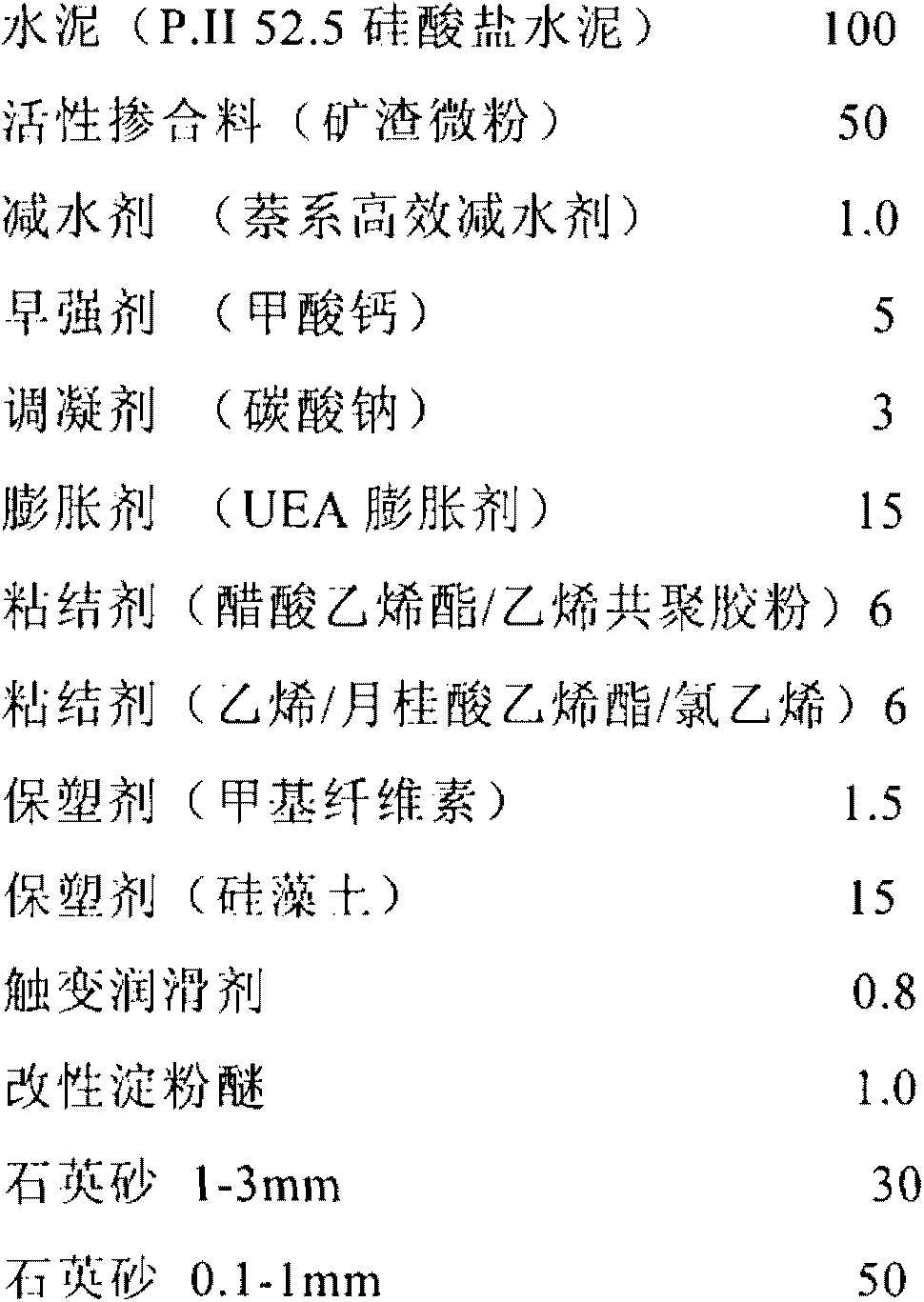

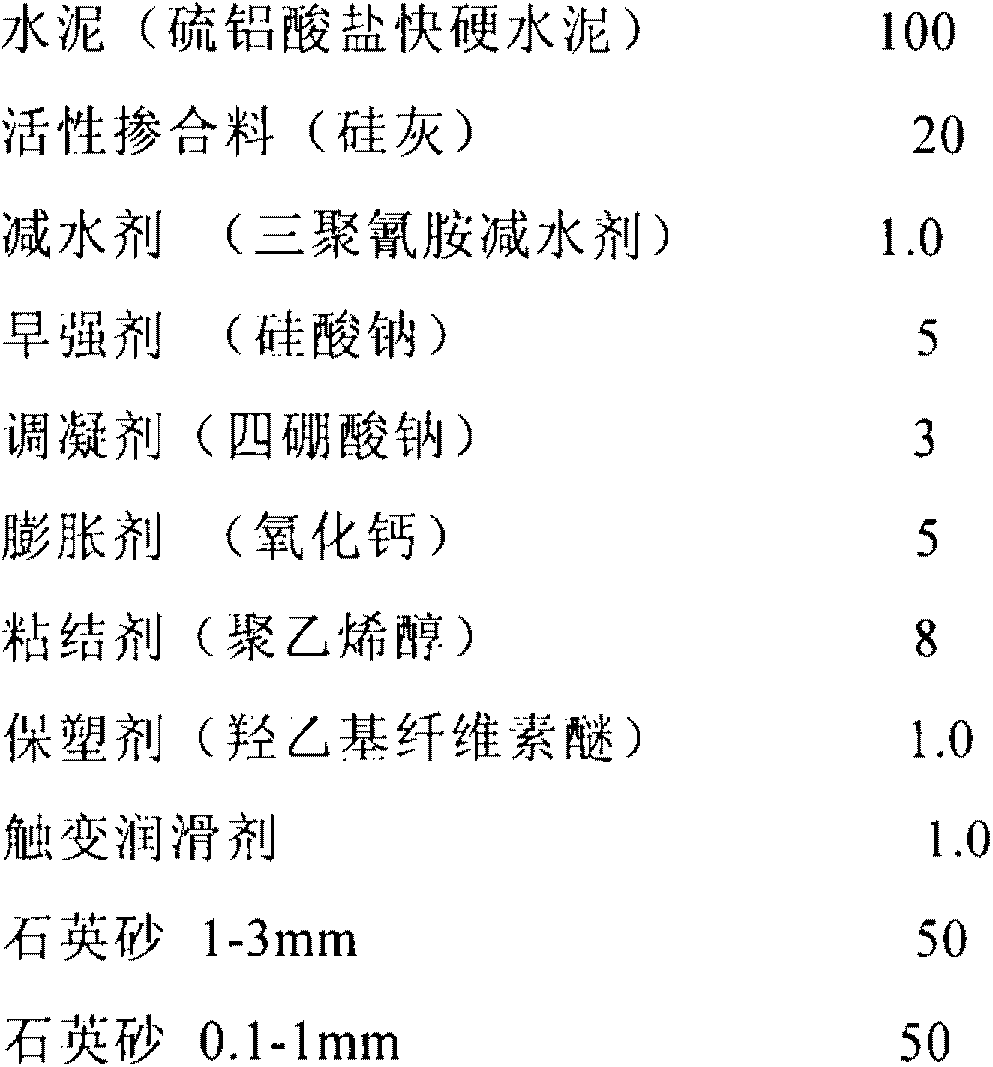

The invention relates to an assembled splicing joint sealing material for building components and an application thereof. The sealing material is prepared from raw materials in parts by weight as follows: 100 parts of cement, 0-150 parts of active admixture, 0.01-10 parts of water reducer, 0.01-10 parts of early strength agent, 0-10 parts of thickening time control agent, 0.1-30 parts of expanding agent, 0-30 parts of bonder, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of starch ether, 0-10 parts of thixotropic lubricant and 0-300 parts of quarts sand. The sealing material can be applied to sealing joint of concrete components spliced. Compared with the prior art, the sealing material is good in construction performance, and can be used by adding water to stir. The sealing material can be quickly constructed by a caulking gun or an electric caulking device, and the operating time is long. Newly mixed slurry has good plasticity, adhesive force and resistance to falling. The sagging phenomenon is further avoided when a vertical direction is spliced. The condensing time is adjusted according to the project demand, the early strength is high and the later strength is continuously increased.

Owner:TONGJI UNIV

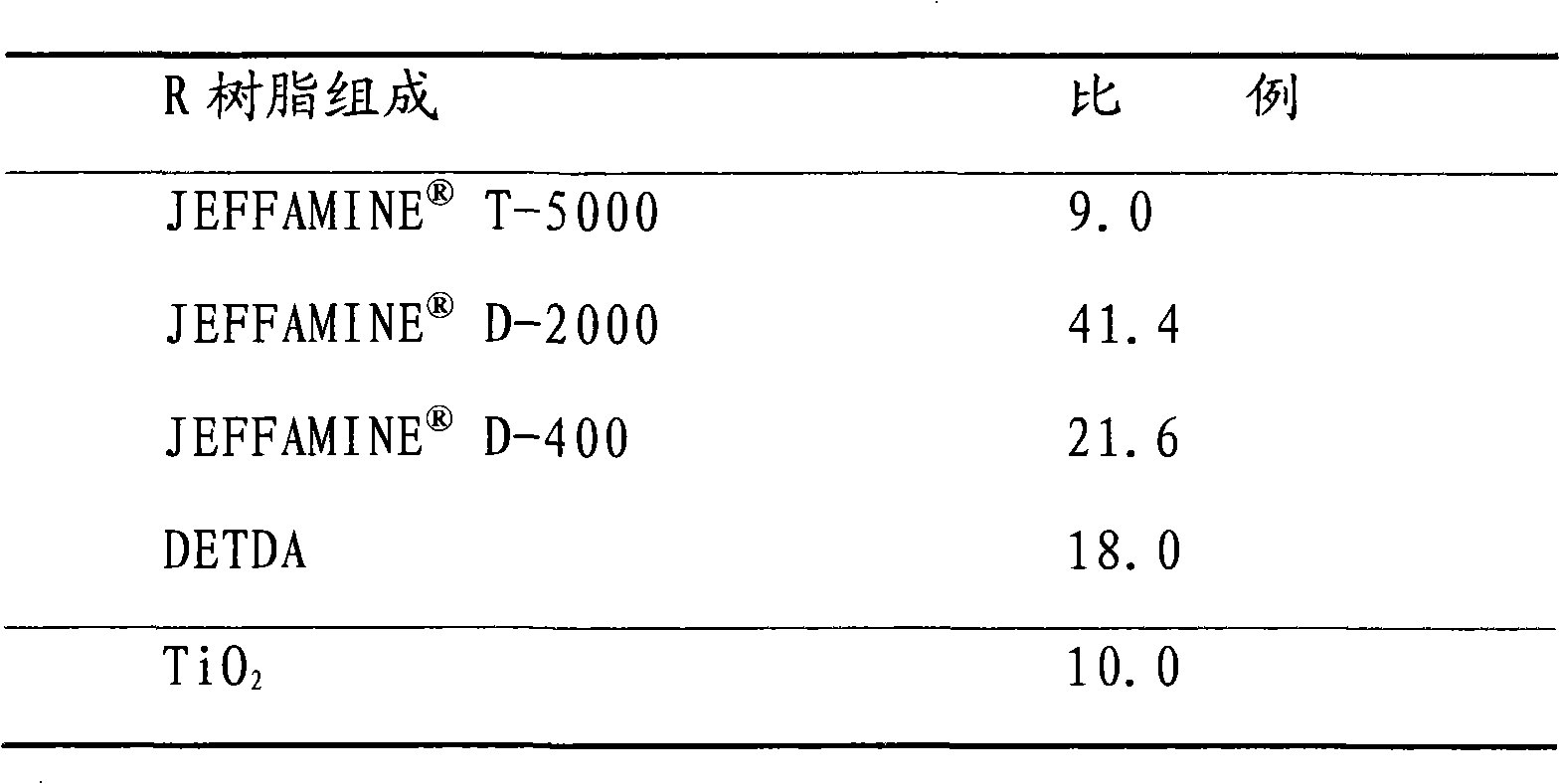

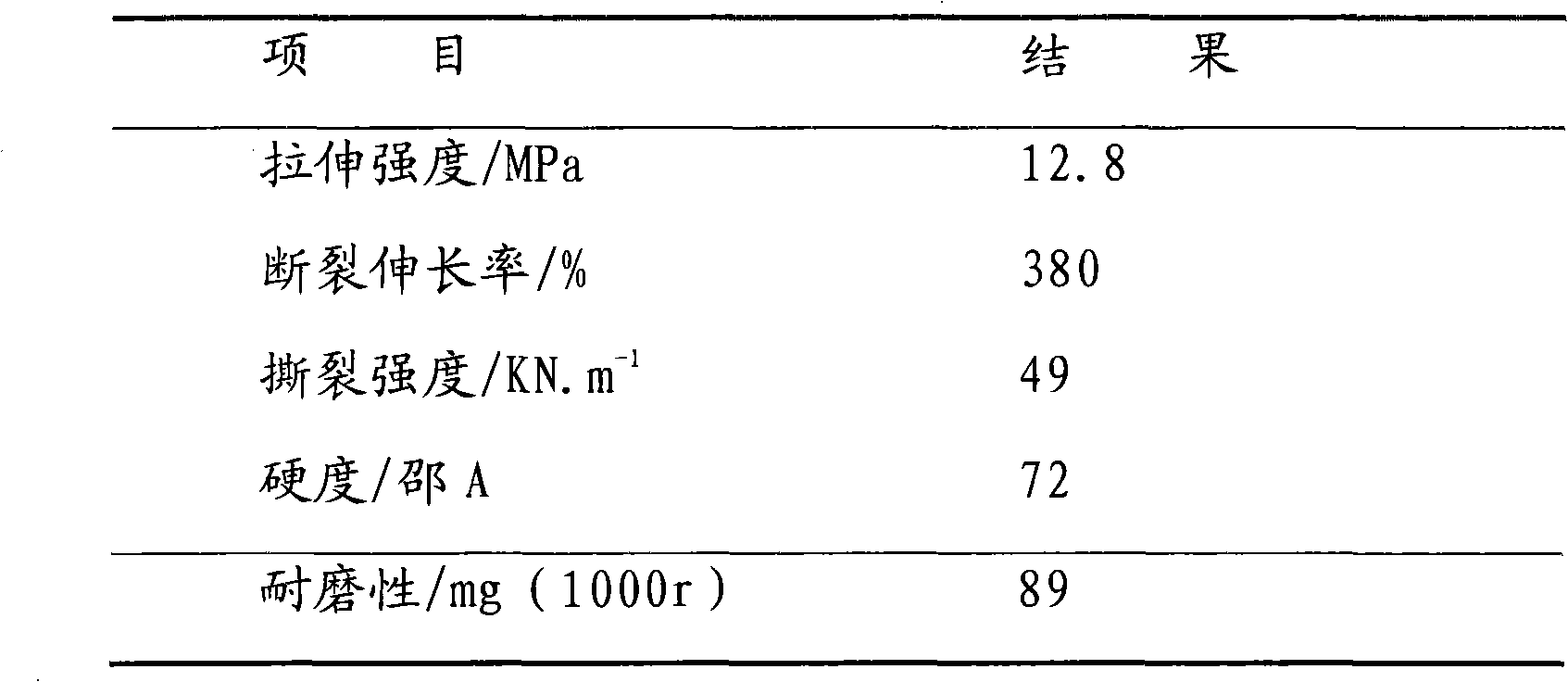

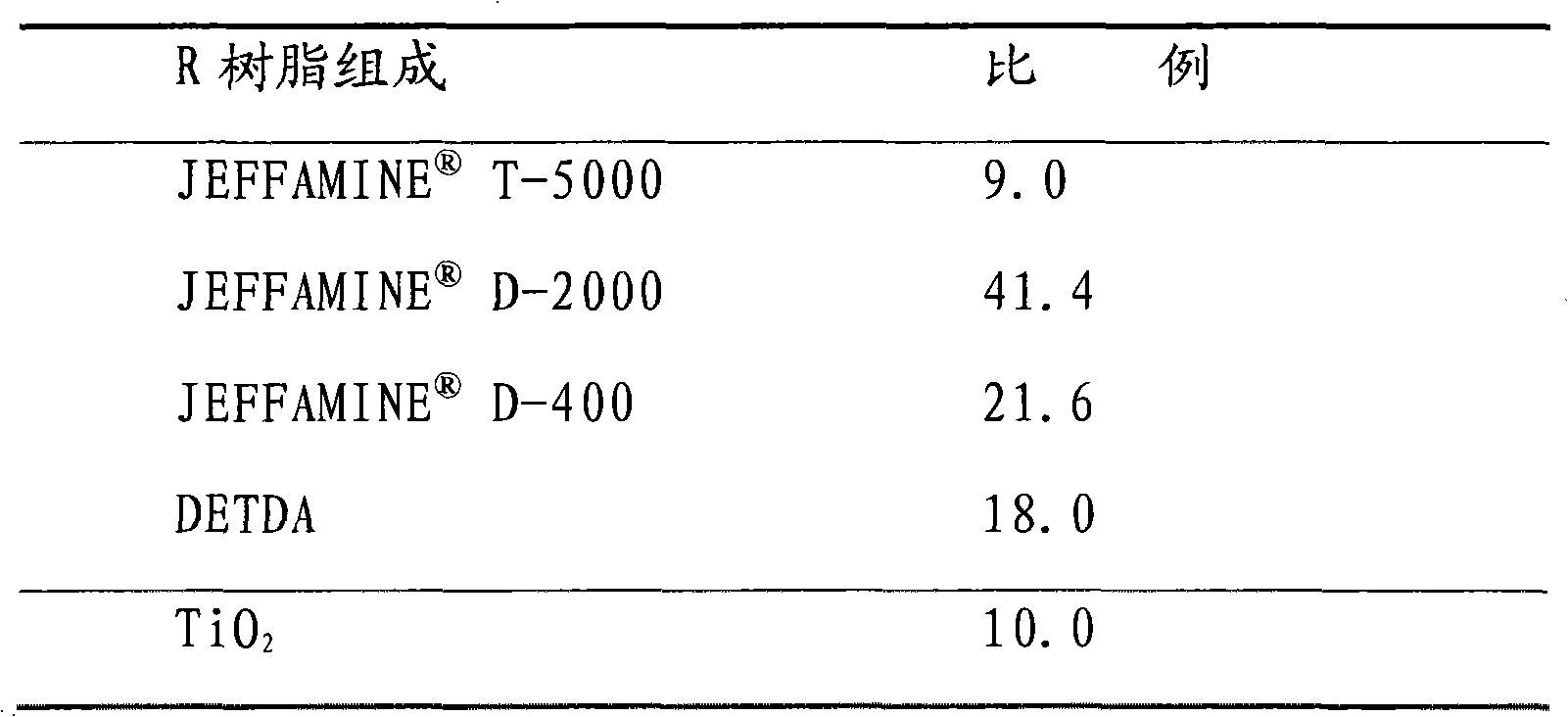

Spray polyurea elastomer for mine, preparation and construction method thereof

InactiveCN101302393ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsPolyurea/polyurethane coatingsElastomerPolyol

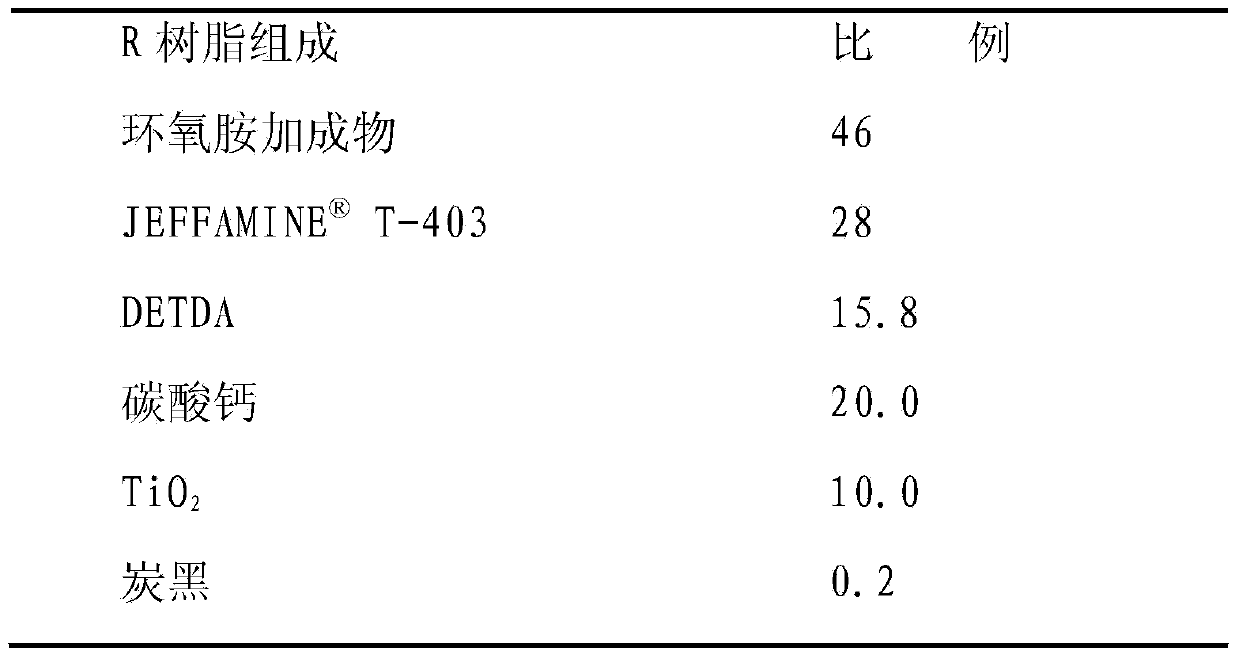

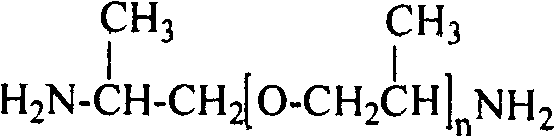

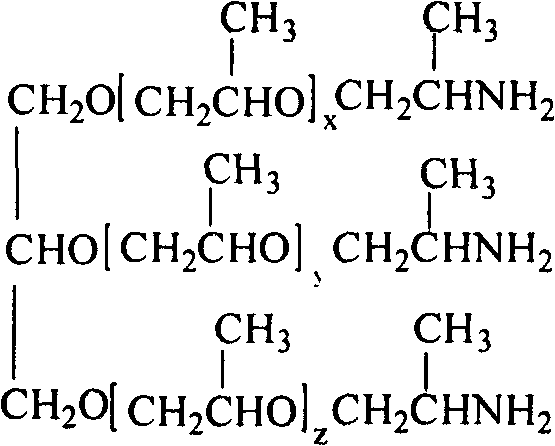

The invention provides a spraying polyurea elastomer applied to a mine, a method for making the same and a construction method. The spraying polyurea elastomer can solve the problem of poor wearing resistance in the prior art. The invention comprises the following technical proposals that: the spraying polyurea elastomer applied to the mine comprises two compositions A and R, wherein, the composition A is a semi-prepolymer synthesized by 45 to 65 portions of polyisocyanate and 35 to 55 portions of polyether polyol; the composition R comprises 55 to 80 portions of amine terminated polyether, 15 to 33 portions of chain extender and 5 to 25 portions of antiwear filler; and the compositions A and R are matched for use according to an isocyanate index of between 0.9 and 1.2. The spraying polyurea elastomer has good physical performance, high wearing resistance, good oil resistance, hydrolization resistance, bacteria resistance and aging resistance and good construction performance and can be used in a vibration sieve equipment lining, a flotation equipment lining, etc. of the mine and other application places which have high requirement on wearing resistance.

Owner:青岛佳联化工新材料有限公司

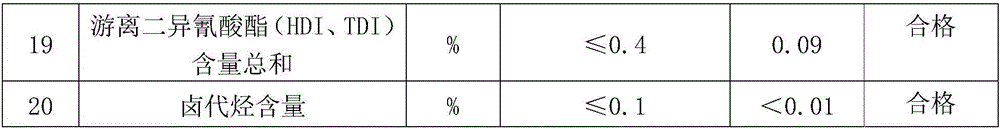

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Two-component epoxy decorating sealant and preparation method thereof

ActiveCN105802451ANo saggingWon't flowAntifouling/underwater paintsPaints with biocidesGlycidyl ethersColloid

The invention provides a two-component epoxy decorating sealant, comprising component A and component B. The component A comprises, by weight: 70-90 parts of first epoxy resin, 0-7 parts of glycidyl ether type diluent, 1-5 parts of a coupling agent, 3-7 parts of a first thixotropic agent, 0.1-0.3 part of a yellowing aid, and 0.1-0.3 part of a defoaming agent; the component B comprises 20-25 parts of an alicyclic curing agent, 20-30 parts of second epoxy resin, 25-30 parts of benzyl alcohol diluent, 3-6 parts of an accelerant, 3-7 parts of a second thixotropic agent, and 5-10 parts of a pigment. After being constructed and cured, the two-component epoxy decorating sealant attaches tightly to ceramic tiles, and water and dust never enter a gap to cause mold or leakage. In addition, colloid of the decorating sealant of the invention never flows or sags during construction, construction is facilitated, and construction efficiency is improved. The invention also provides a preparation method of the two-component epoxy decorating sealant.

Owner:HUNAN KOSEN NEW MATERIAL

Preparation method for scratch-resistant and yellowing-resistant polyurethane carpentry matte white finish

The invention relates to a preparation method for scratch-resistant and yellowing-resistant polyurethane carpentry matte white finish. The finish comprises a component A of resin paint and a component B of curing agent; the weight proportioning of the component A and the component B is 1:0.5; the component A of resin paint comprises alkyd resin, titanium dioxide, extinction powder, coarse whiting powder, dispersant, light stabilizer, flatting agent, defoaming agent, anti-settling agent and solvent; and the component B of curing agent comprises TDI-HDI mixed tripolymer or TDI / TMP addition product, HDI tripolymer and solvent. The scratch-resistant polyurethane carpentry matte white finish, produced by the method, has no precipitate during storing, takes a high-solid and low-viscosity shape, and has the advantages of good leveling property, large thickness of once formed films without generating sags, mild hand feel, fullness, fineness, smoothness, coexistence of hardness and softness, and plump decoration effect as mirror face, gives elegant and comfortable feelings to people, adapts to the modern aesthetic view, is popularized in markets, and is favored by clients. The paint is widely applied in the surface of a product, such as carpentry, metal, plastic and the like, and is used as protection decoration.

Owner:UNION FOSHAN CHEM +1

Assembly type building component joint gypsum base sealing material and application thereof

ActiveCN103496936AEasy constructionImprove plasticityBuilding constructionsResource utilizationEther

The invention relates to an assembly type building component joint gypsum base sealing material and application thereof. The assembly type building component joint gypsum base sealing material comprises, by weight, 100 parts of waste gypsum, 20-200 parts of active admixture, 0.01-10 parts of water reducer, 0.1-50 parts of excitant, 0-10 parts of thickening control agent, 0-30 parts of binder, 0-10 parts of air entraining agent, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of water repellent, 0-5 parts of starch ether, 0-10 parts of thixotropic lubricant, 0-150 parts of powder filler and 0-300 parts of aggregate, and can be applied to joint sealing after being mixed with water uniformly. Compared with the prior art, the assembly type building component joint gypsum base sealing material has the advantages of convenience in use, good filling ability, high binding power, durability, low cost and the like. In the sealing material, much industrial waste gypsum is used as gelatinization materials, so that performance of sealing mortar can be improved, material cost is reduced, pollution control and emission reduction are facilitated, and a new way for resource utilization of the industrial waste gypsum is provided.

Owner:SHANGHAI LIVABLE BUILDING SCI & TECH CO LTD

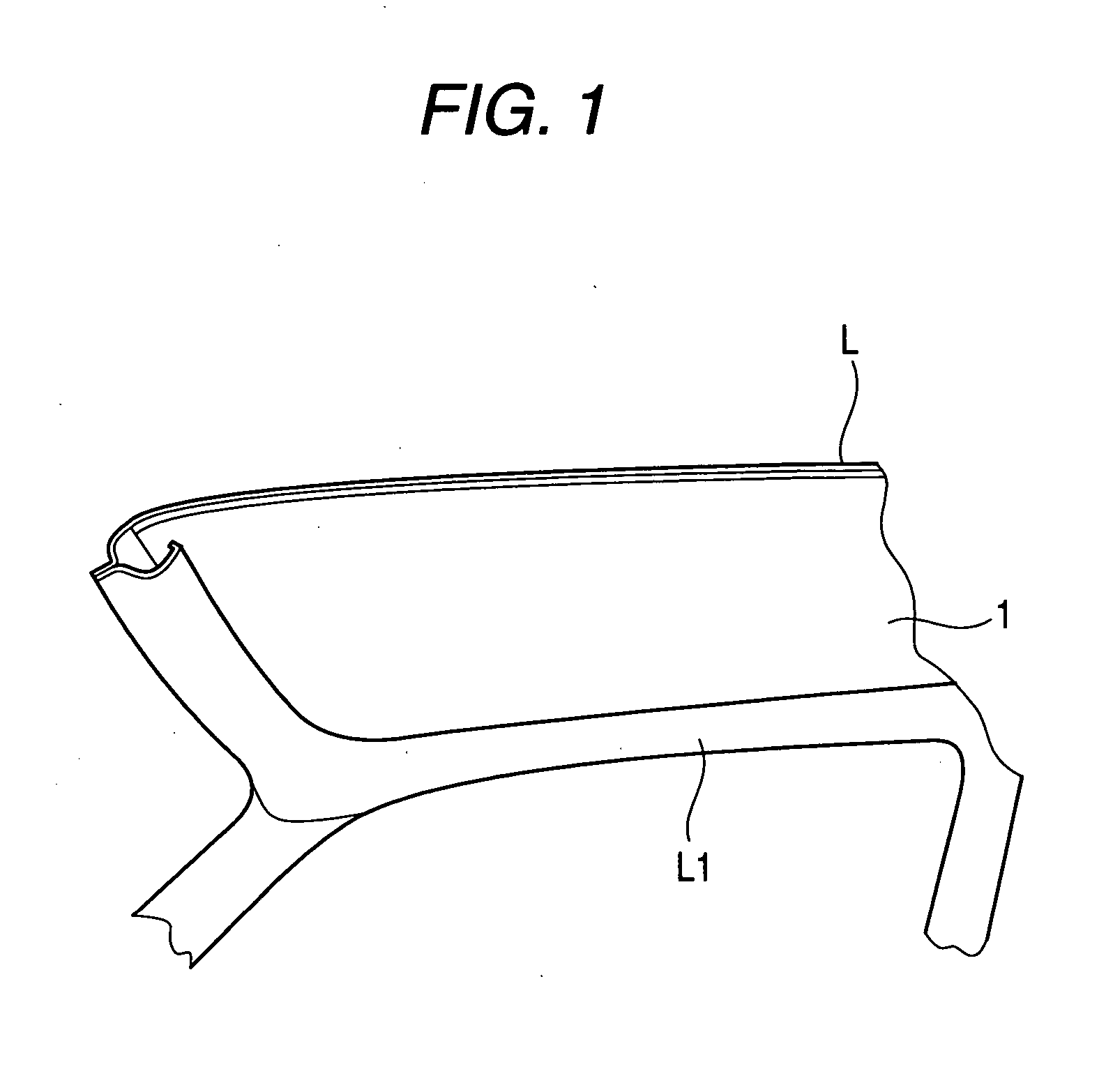

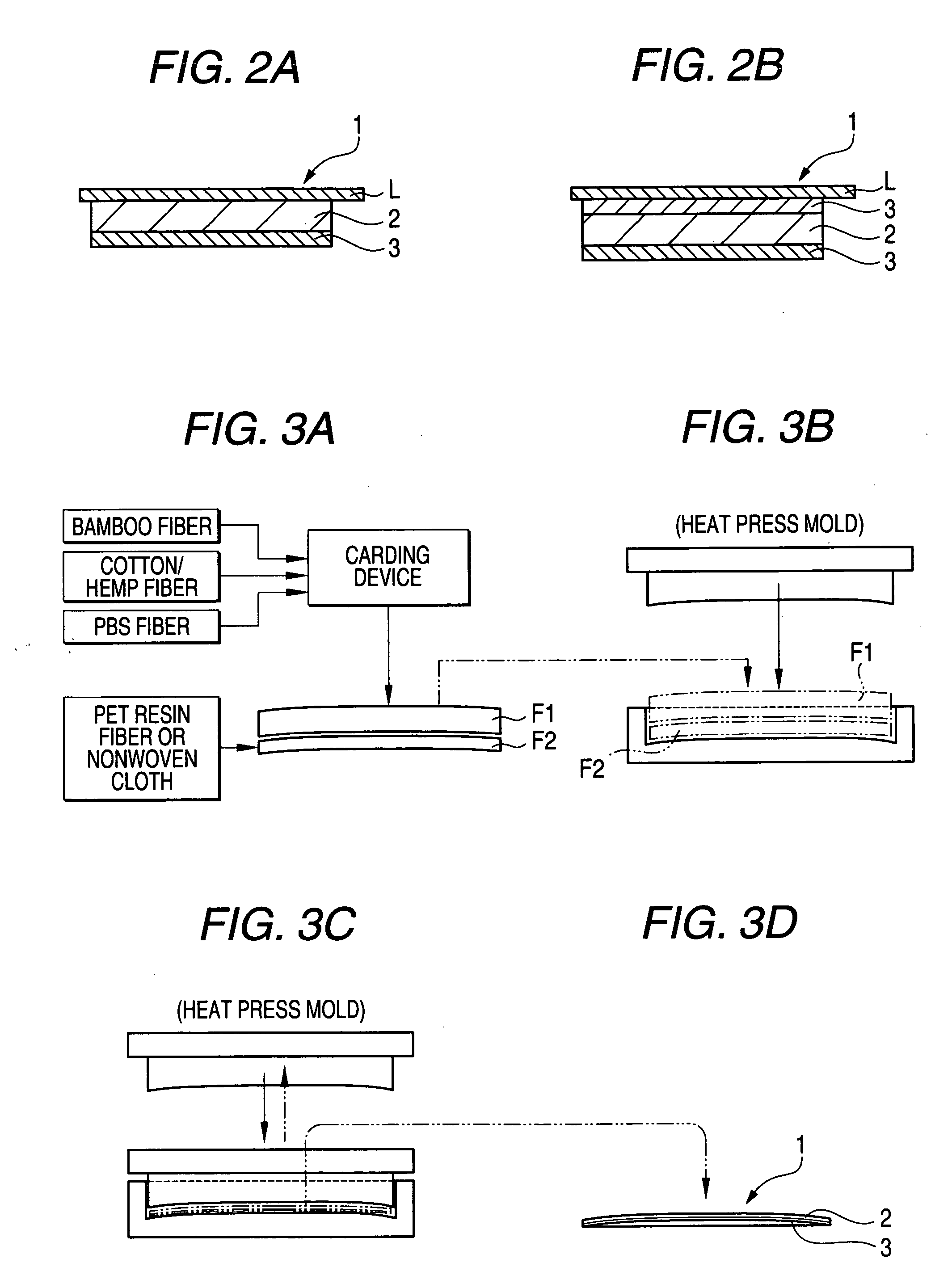

Automobile interior board and method of producing automobile interior board

InactiveUS20070149081A1Easy to produceNo feeling of physical disorderSynthetic resin layered productsLaminationFiberSurface layer

An automobile interior board includes a base layer; and a nonwoven or woven surface layer, laminated on at least one surface of the base layer. The base layer is comprised of a composite material of: a first fiber, comprised of a bamboo fiber; a second fiber, comprised of one of cotton, hemp and mixture of cotton and hemp; and a biodegradable resin. Weight percentage of the first fiber, the second fiber and the biodegradable resin satisfies a following equation, the first fiber:the second fiber:the biodegradable resin=30 to 70:10 to 60:20 to 60. The surface layer is comprised of one of a PET resin fiber and a natural material-derived fiber.

Owner:MITSUBISHI MOTORS CORP

Sound proofing and noise reducing damping coating and production process thereof

The invention relates to a sound proofing and noise reducing damping coating and a production process thereof, and belongs to the technical field of chemical industry. The damping coating comprises the following raw materials in part by weight: 22 to 25 parts of acrylic emulsion, 15 to 20 parts of deionized water, 44.5 to 54.5 parts of silicate packing, 0.1 to 0.2 part of polysiloxane assistant, 0.5 to 0.8 part of sodium mercaptide assistant, 4.5 to 5 parts of antimonous oxide assistant, and 3 to 3.5 parts of chlorinated paraffin assistant. The damping coating has the advantages that: the sound proofing and noise reducing damping coating belongs to an environmental protection product without any solvent, and has good physical properties and chemical stability, good sound proofing damping performance, corrosion resistance, abrasion resistance, waterproofing, impact resistance, good adhesive force to steel, concrete and the like, quick curing and adjustable curing time; and the sound proofing and noise reducing damping coating can meet the requirements after once spraying, can be sprayed on any curved surfaces, inclined planes and special parts and cannot generate a phenomenon of sagging.

Owner:CHANGCHUN HUARI PAINT

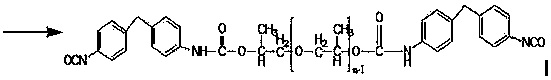

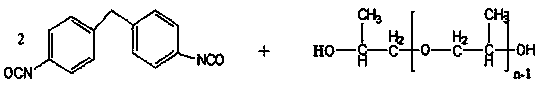

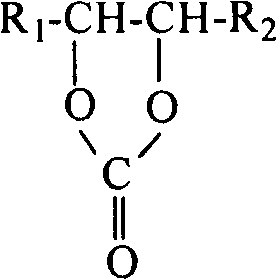

A preparation method of a polyurethane/epoxy resin composite material

ActiveCN103524703AImprove rigidity and comprehensive mechanical propertiesImprove bonding performancePolyureas/polyurethane adhesivesIsocyanateChemistry

A preparation method of a polyurethane / epoxy resin composite material comprises a step of adding a polyether polyol into a reactor to be treated, adding a diisocyanate and heating, controlling the mass content of free -NCO, and obtaining an A component after vacuum deaeration; a step of heating a binary aromatic amine, adding dropwise the liquid epoxy resin and heating again, and reacting to obtain a B component; and a step of stirring and mixing uniformly the A component and the B component stoichiometrically, and reacting and curing to obtain the polyurethane / epoxy resin composite material. When being used as an adhesive, the composite material has good bonding strength, high-temperature resistance, low-temperature resistance, impact resistance and flexibility. The composite material has a wide application scope, and can be prepared into a high-hardness polyurethane elastomer composite material to be applied.

Owner:太原英可奥笔墨科技有限公司

Sealing corrosion proof protection method of rope-suspension bridge cable system

ActiveCN101457364AGood weather resistanceIncrease elasticityHot-dipping/immersion processesLiquid surface applicatorsShock mountEngineering

The invention discloses a sealing and anti-corrosion protection method of a suspension bridge cable system, and belongs to an anti-corrosion protection method of a bridge cable. The method helps divide the whole cable system into 7 types of surfaces: an outer surface of a main cable of a wire wrapping section; the outer surface of the main cable of a non-wire wrapping section; the outer surface of a main cable saddle exposing a strand; the outer surfaces of a cable strand inside an anchor chamber, a sling wire rope, as well as a railing rope and a side rope of a maintaining roadway; the outer surfaces of a cable clamp, a cable saddle (sleeve) and a saddle, and exposed surfaces of bolts and nuts; the outer surfaces of an anchor cup, a sling clamp, a sling shock mount, and columns and brackets of the maintaining roadway; and gap sealing surfaces of the cable clamp, a cable jacket girth seam, an abutted seam and a top saddle opening. The 7 types of the surfaces are treated by different methods, and the sealing and anti-corrosion method is complete. In the method, novel sealing materials and anti-corrosion paints are used, which has good sealing performance, long anti-corrosion service life and high strength, and ensures the durability of the suspension bridge cable system.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Spray polyurea elastomer applied to marine drilling platform corrosion prevention as well as preparation method and construction method thereof

ActiveCN103740247ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsAnti-corrosive paintsElastomerSalt resistance

The invention provides a spray polyurea elastomer applied to marine drilling platforms as well as a preparation method and construction method thereof. The problems of poor adhesion and poor corrosion resistance in the marine environments in the prior art can be solved. The spray polyurea elastomer comprises components A and R and is characterized in that the component A is a semi-prepolymer synthesized by 10-40 parts of polyisocyanates, 20-90 parts of epoxy modified polyether polyol and 0-50 parts of polyether polyol by weight; the component R comprises 15-60 parts of epoxy amine adduct, 0-30 parts of amine-terminated polyether resin, 15-40 parts of chain extender and 5-25 parts of filler by weight. The spray polyurea elastomer material has good physical properties and high adhesion, simultaneously has excellent oil resistance, salt mist resistance, bacterium resistance, aging resistance and construction properties, can be shaped randomly, and can be widely applied to the parts with relatively high corrosion prevention requirements, such as platform decks, pile legs and the like of the marine drilling platforms.

Owner:MARINE CHEM RES INST

Novel shape memory spraying polyurethaneurea elastomer resin bathroom product and preparation method thereof

ActiveCN102504173ALow viscosityShort reaction timePretreated surfacesPolyurea/polyurethane coatingsPolyesterElastomer

The invention discloses a spraying elastomer raw material composition. The composition comprises an A component raw material and a B component raw material, wherein the A component raw material comprises one or more of polyester polyol having a number-average molecular weight of 400-3000, polyether polyol having a number-average molecular weight of 400-3000, vegetable oil polyol having a number-average molecular weight of 400-2000, amino-terminated polyether having a number-average molecular weight of 200-4000 and polyisocyanate; and the B component raw material comprises polyoxypropylene diamine having a number-average molecular weight of 200-4000, polyoxypropylene triamine having a number-average molecular weight of 400-5000, active aromatic diamine and aromatic diamine. The invention also discloses a prepolymer of a spraying elastomer, a raw material composition and a preparation method of the prepolymer as well as a bathroom product. The spraying elastomer disclosed by the invention is good in various comprehensive properties; and after pressed, the product can memory the original shape, thereby improving the whole comfortable sensation and broadening the use range of the spraying elastomer.

Owner:SHANGHAI MOERSHU CORP DEVING +1

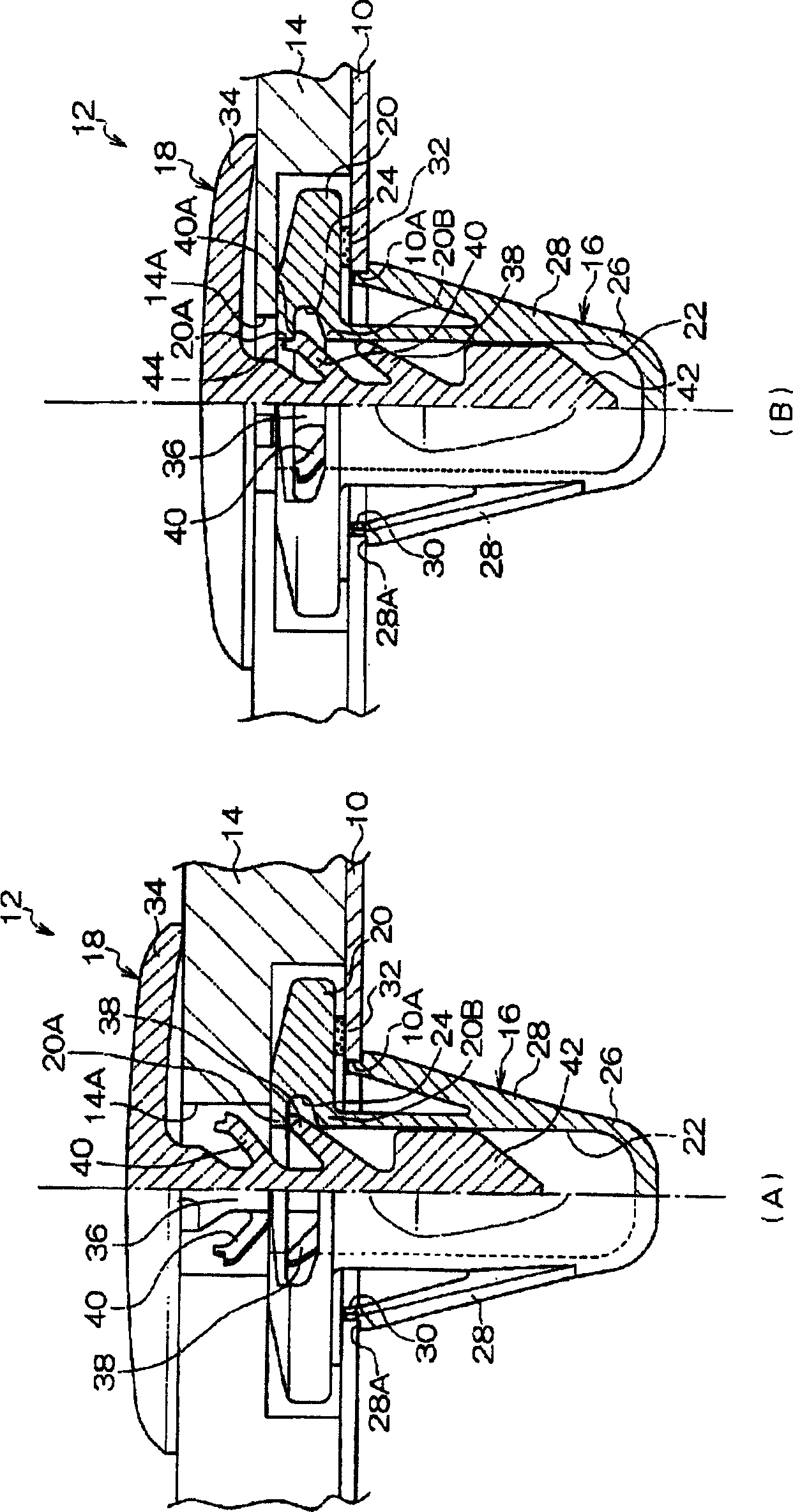

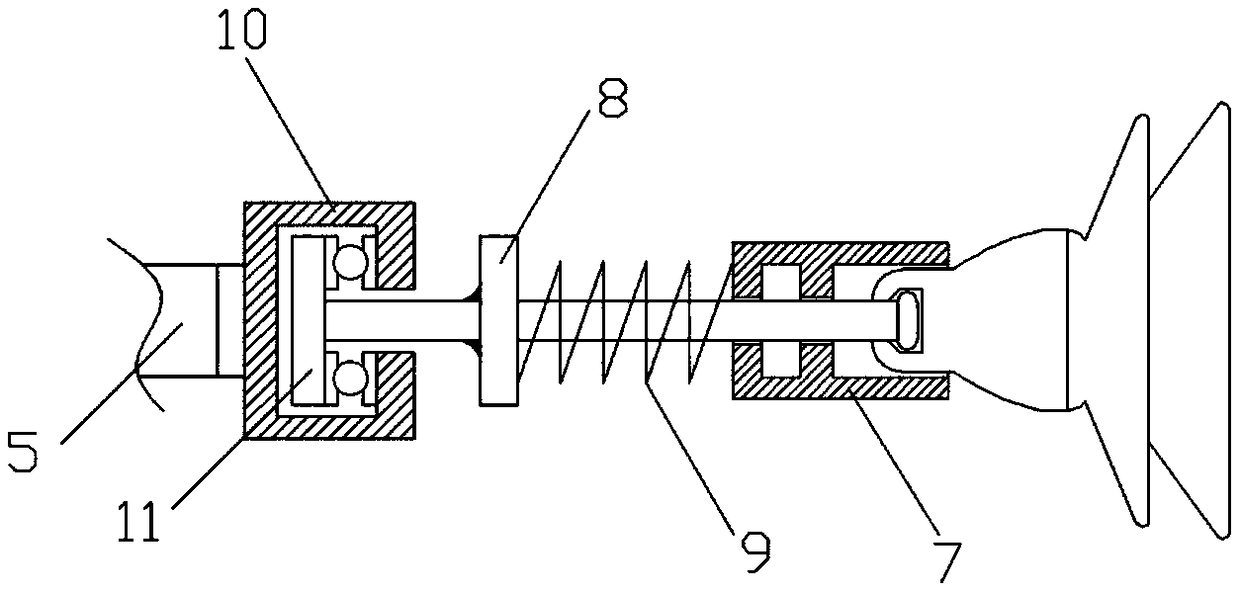

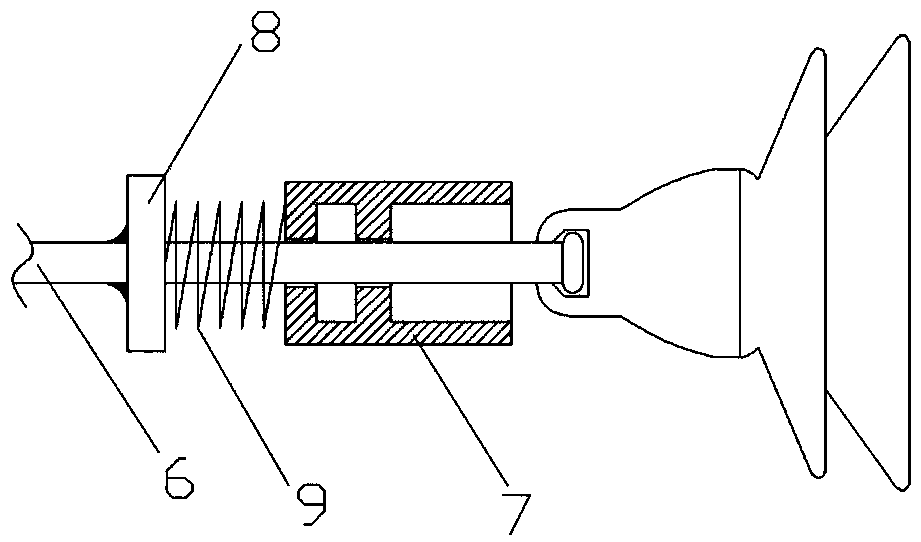

Fixing device

The present invention provides a fastener capable of preventing refuse and moisture from entering, raising an extraction force for a pin, and reducing insertion resistance in inserting the pin. Since a base 26 of a grommet 16 is formed in a bag shape, refuse and moisture do not enter into the base 26. Accordingly, water content does not ooze from the base 26 to a floor carpet 14 through an insertion hole 22 of the grommet 16. Also, a through hole 24 is formed in a flange 20 along a direction crossingly perpendicular to the axial direction of the grommet 16, and the flange 20 is divided into an upper part 20A and a lower part 20B. Accordingly, a locking claw 38 or a locking claw 40 can be locked to the upper part 20A. Since the upper part 20A of the flange 20 is recessed along a direction perpendicularly crossing the axial direction of the grommet 16, an extraction force can be increased more than in the case that the upper part 20A is formed in a tilted state relative to the axial direction of the grommet 16 despite the fact that the insertion resistance for the pin 18 is approximately the same.

Owner:NIFCO INC

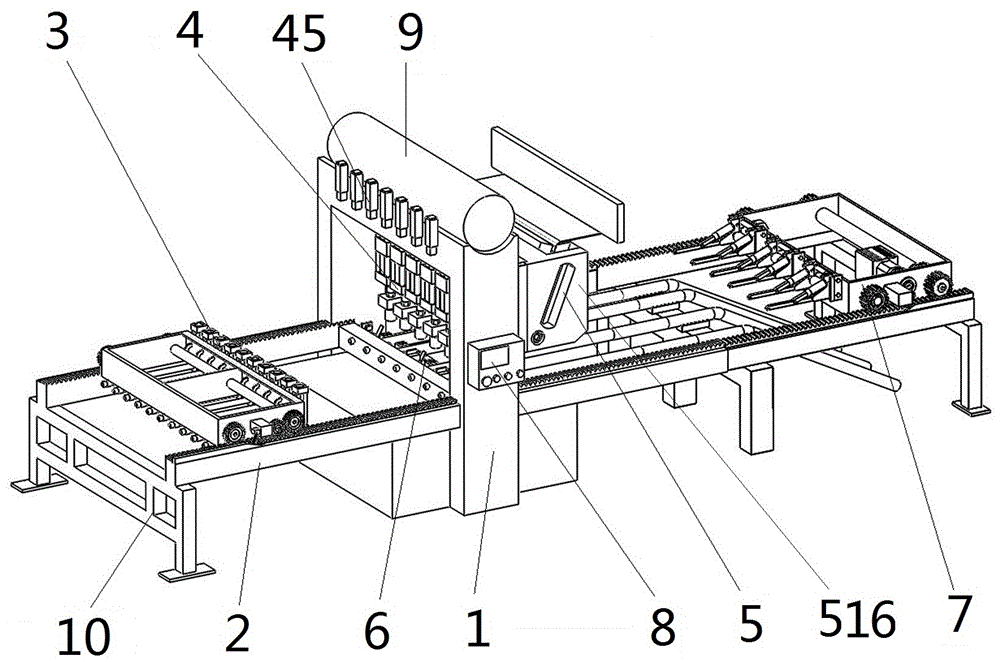

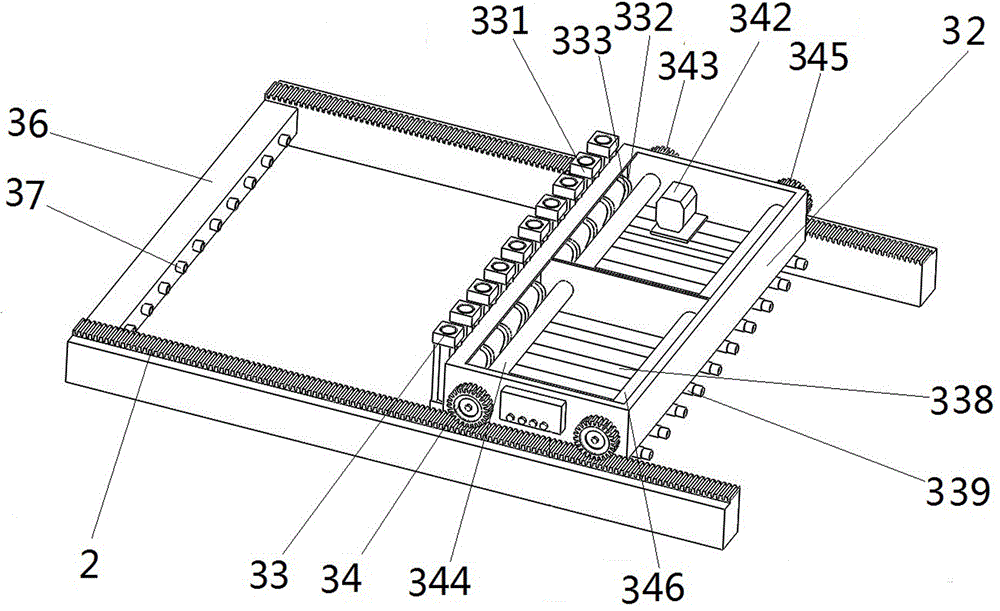

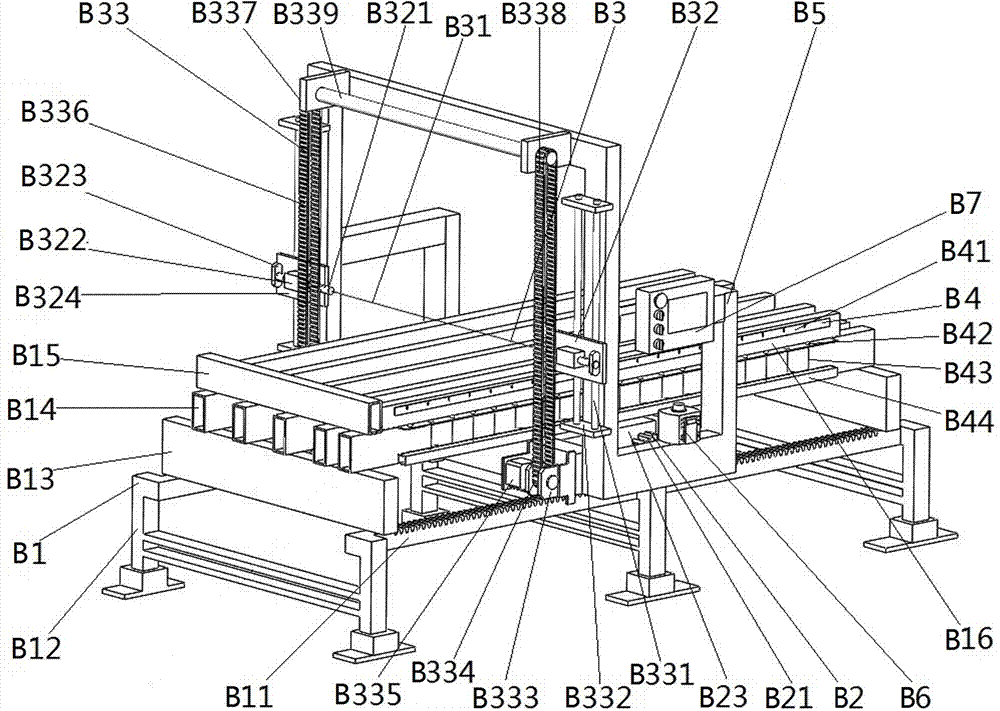

Plain net welding machine

The invention discloses a plain net welding machine. The plain net welding machine comprises a plain net welding machine frame; a longitudinal rib wire feeding device, a welding device, a transverse rib blanking device and a net pulling device are arranged on the plain net welding machine frame in sequence from back to front; a transverse rib absorbing and detecting device for precisely positioning transverse ribs, dropping out from the transverse rib blanking device, into the welding device is arranged on one side of the welding device at the bottom end of the transverse rib blanking device; and the plain net welding machine frame is provided with a main controller for controlling coordinative operations of the longitudinal rib wire feeding device, the welding device, the transverse rib blanking device, the net pulling device and the transverse rib absorbing and detecting device. The plain net welding machine solves such problems as conveying position deviation of longitudinal ribs in the conveying process, influence on the production quality due to no aligned correction of transverse ribs dropping on the longitudinal ribs, deviation from the welding position of the transverse ribs dropping on the longitudinal ribs, incapability of full-automatically pulling nets by the net pulling device and inconvenience to pull the transverse ribs by net pulling hooks in actual production, and improves the production efficiency and the product quality.

Owner:河北森阳建筑设备科技有限公司

Healant for chemical pipes and preparation method thereof

ActiveCN102311715AGood chemical resistanceWide range of chemical mediaNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a healant for chemical pipes and a preparation method thereof. The healant comprises the components in parts by weight as follows: modified epoxy resin 40-60, a coupling agent 1-8, a thixotropic agent 1-5, nano chemical resistant powder 10-40, an anti-aging agent 0.5-10 and pigment cream 0-5. The preparation method comprises the steps of: adding the modified epoxy resin obtained through synthesizing into a reaction kettle; adding the coupling agent; heating and gradually adding the nano chemical resistant powder; keeping the temperature in vacuum and dispersedly mixing at a high speed for 2-4 h; re-adding the anti-aging agent, the pigment cream and the thixotropic agent; and continuously sealing the reaction kettle and dispersedly mixing at a high speed in vacuum for 1-2 h to obtain the product. Compared with the prior art, the healant for chemical pipes is added with adhesive capacity of adhesives and greatly improved in tensile strength and impact resistance, can be applied to more chemical mediums, specifically aims at the repairing of the chemical pipes, and is attractive in appearance.

Owner:上海海鹰粘接科技有限公司

Epoxy micaceous iron ash primer

The invention relates to the technical field of oil paints, in particular to an epoxy micaceous iron ash primer. The epoxy micaceous iron ash primer comprises the following components in parts by weight: 20-30 parts of epoxy resin, 20-25 parts of acrylic resin, 10-15 parts of mica iron oxide, 2-5 parts of curing agent, 2-4 parts of acrylic acid, 0.2-0.8 part of dispersing agent, 0.2-0.5 part of wetting agent, 20-25 parts of diluent and 0.08-0.12 part of anti-settling agent. The technical scheme provided by the invention has the following beneficial effects: organic modified bentonite is added in the epoxy micaceous iron ash primer so that the leveling property of a coating is good without sagging, and the settling time of the pigments is prolonged; furthermore, the epoxy micaceous iron ash primer provided by the invention hardly falls off, can be quickly dried, has strong impact force resistance, excellent adhesive force, flexibility, water resistance and excellent anti-rust performance, is environment-friendly, and has no harm to a human body in construction.

Owner:DANYANG YONGSHENG PAINT

Interior wall plastering mortar and construction method thereof

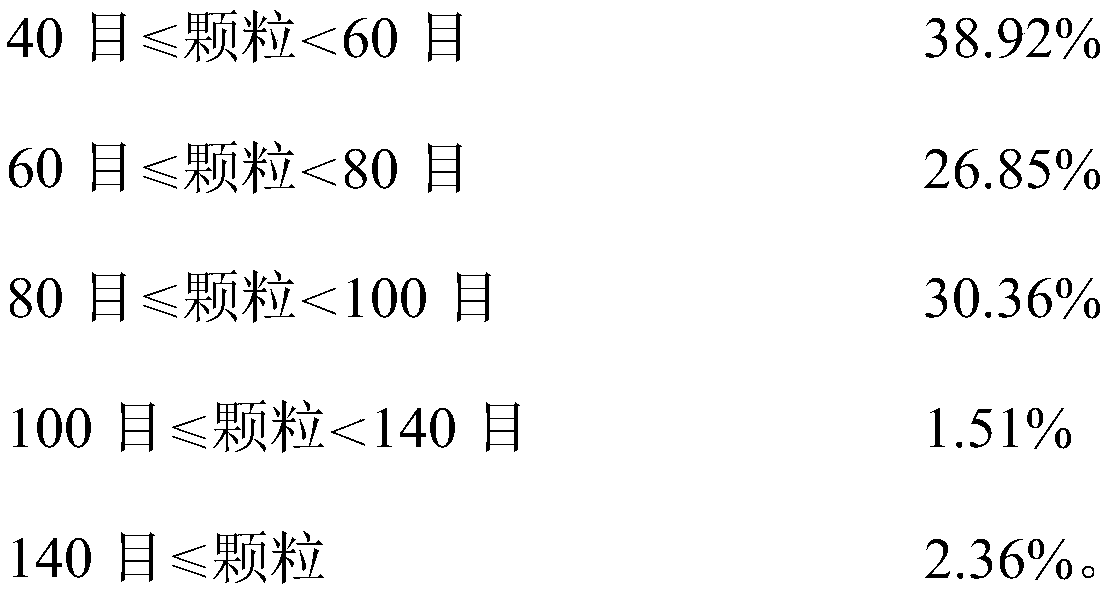

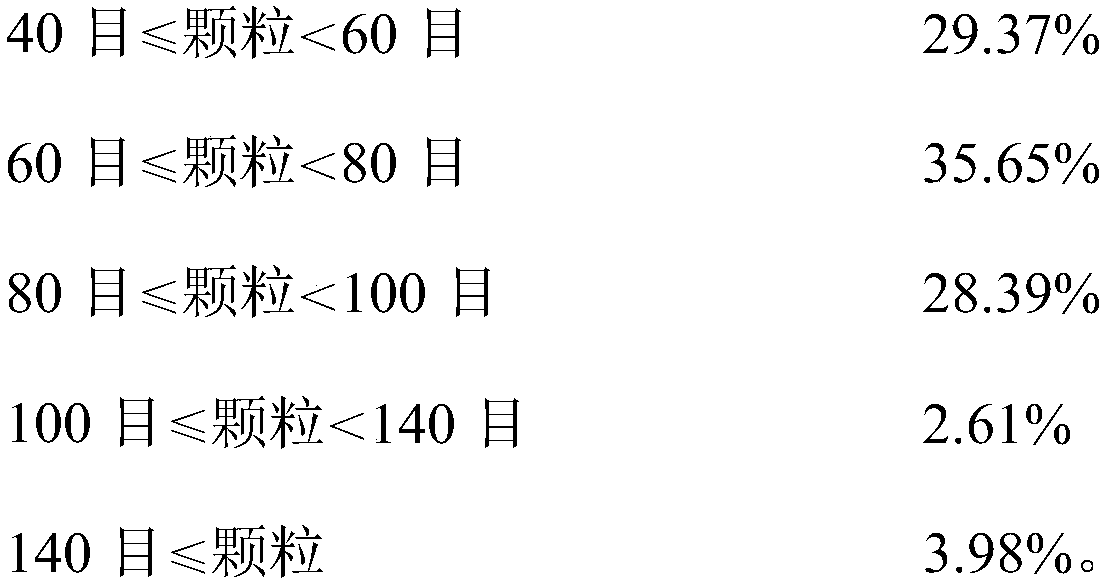

InactiveCN101712545AHigh tensile strengthReduce stretchCovering/liningsSolid waste managementRiver sandFineness

The invention provides interior wall plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 35 parts of ordinary Portland cement, 4 to 5 parts of hydrated lime, 5 to 10 parts of light aggregate, 50 to 60 parts of heavy aggregate, and 1.0 part of C-type composite auxiliary, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; the heavy aggregate is ordinary river sand; and the C-type composite auxiliary is sold by Guangzhou Hecheng Trading Company. The construction method for the interior wall plastering mortar comprises the following steps: diluting the light energy-saving interior wall plastering mortar with water accounting for 30 to 50 percent of the weight of the mortar; and mechanically or manually stirring the diluted mortar until the mortar is mixed uniformly to achieve the viscosity suitable for mechanical spraying or manual construction. Therefore, the mortar can be sprayed mechanically or constructed manually. The interior wall plastering mortar has light weight and energy conservation, can prevent hollowness, cracking and falling off by being matched with a light wall body, can effectively reduce cracking of the mortar, ensures the quality of construction work, has the advantages of heat insulation and noise reduction, low cost of unit area, good grain composition, good peaceability, mechanical construction contribution and simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Process for producing novel material with high functional capability from waste diatomaceous earth, and novel material with high functional capability from waste diatomaceous earth, and diatomaceous e

ActiveCN1968901ADurableNoise-absorbingSludge treatment by de-watering/drying/thickeningCovering/liningsAtmospheric airFiltration

There is provided a process for disposal of waste diatomaceous earth discharged from a filtration operation, etc. of various production plants, which process excels in handling easiness and in fuel cost for drying and realizes obtaining of high functional capability at low cost through, for example, holding and controlling of organic components, such as enzymes and yeasts, contained in waste diatomaceous earth and utilization of the functional capability thereof. Further, there is provided a diatomaceous earth composition for building containing a porous inorganic material such as fired diatomaceous earth and a cement for use as a coating material applied to panels, walls, etc. The composition is capable of preventing dew condensation, and is applicable without compulsory pressurization on a wood sheathing by means of coating roller, brush, spray coating, etc. Furthermore, the composition for building without exception is substantially from any color fade-out phenomenon due to coloring by natural soil grains. Still further, a certain effect of powerful photocatalyst redox reaction impact by titanium dioxide exposed to air on the decomposition of harmful pollutants of the atmospheric air is promising by causing the composition to contain a powdery porous inorganic mineral as a main component and titanium oxide as a pigment.

Owner:ISSI CORP +1

Preparation method of scratch resistant double-component polyurethane woodenware glossy vanish

The invention relates to a preparation method of a scratch resistant double-component polyurethane woodenware glossy vanish. The vanish is composed of a resin paint component A and a curing agent component B, wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic acid resin, aldehyde-ketone resin, a chelating leveling agent, an antifoaming agent, and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The prepared vanish has the advantages of high hardness, low viscosity, and good leveling property. The paint membrane has high gloss and an appearance like a crystal or a jade, is transparent, thick, and smooth, can give people a high class feeling, can create a mirror-liked decoration effect, is capable of forming a refreshing, grace, concise and tranquil space, brings a relaxed and happy sense to people, is accord with the modern aesthetics, is welcomed by the market and customers, and is widely used to protect and decorate surfaces of woodenware, metal products, and plastic products.

Owner:美家化工(惠州)有限公司

Scratch resistant polyurethane woodenware glossy black finish paint

ActiveCN103937402AStrong molecular structureGood flexibilityPolyurea/polyurethane coatingsLacquerAcrylic resin

The invention relates to a preparation method of a scratch resistant polyurethane woodenware glossy black finish paint. The finish paint is composed of a resin paint component A and a curing agent component B; wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic resin, aldehyde-ketone resin, carbon black color paste, a chelating leveling agent, an antifoaming agent, an anti-settling agent, and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The prepared finish paint has the advantages of high hardness, low viscosity, and good leveling property. The finish paint can form a membrane at a time, the membrane is thick, and no sag is generated. The paint has high gloss and a transparent crystal appearance like a black jade. The paint membrane is like a crystal, is thick and smooth, gives people a high quality sense, has a decoration effect like a mirror, and creates a fresh, grace, concise, and tranquil space. A refreshing unique feeling is created by the finished paint which is accord with the modern aesthetics, so the finish paint is welcomed by market and customers. The finish paint can be used to decorate and protect the surfaces of woodenware, metal products, and plastic products.

Owner:UNION FOSHAN CHEM +1

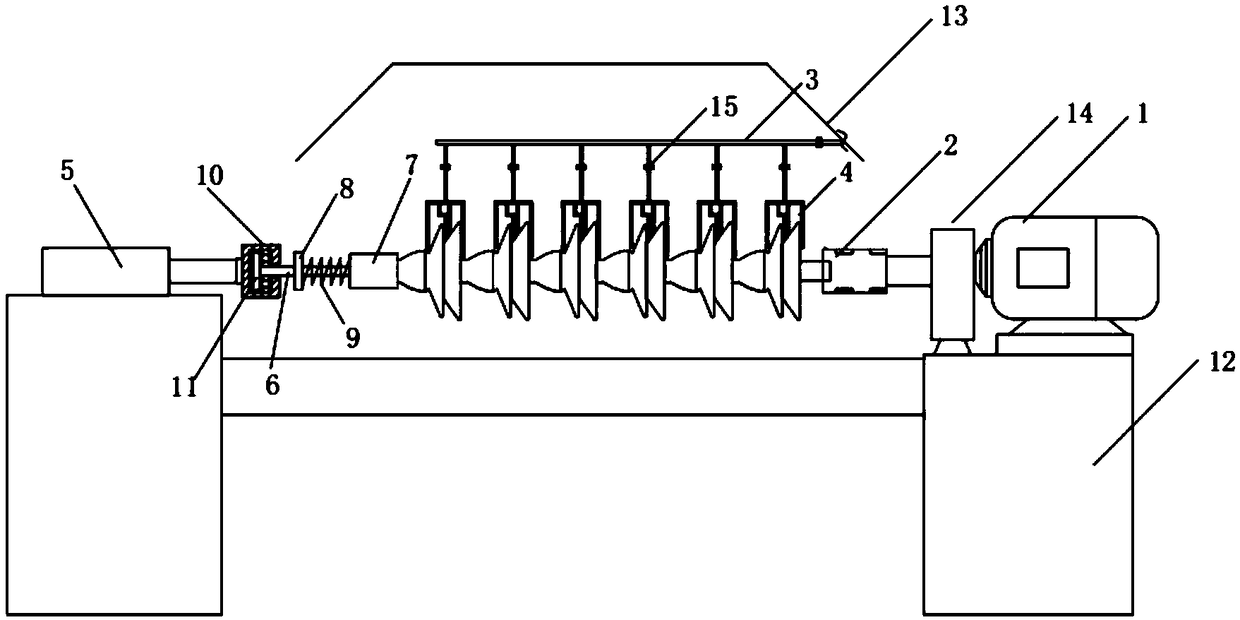

Centrifugal coating device and coating method for prefabricated insulator

The invention belongs to the field of insulator composite anti-pollution flashover coating equipment and method, in particular to a centrifugal coating device and a coating method applied to insulatorcoating. The invention adopts the centrifugal coating method with the rotating coating reagent of the workpiece insulator stationary, the coating thickness is uniform, smooth, free of bubble, bump, hanging flow, concave mark and other defects, and the coating process is convenient to disassemble and assemble. Compared with the traditional way of spraying by manipulator, the safety is greatly improved, and the quality and efficiency of the finished product are significantly improved compared with the artificial dip coating. The device and the coating method of the invention are suitable for coating outer umbrella insulators (single umbrella, double umbrella or multiple umbrellas), column insulators and other insulators.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

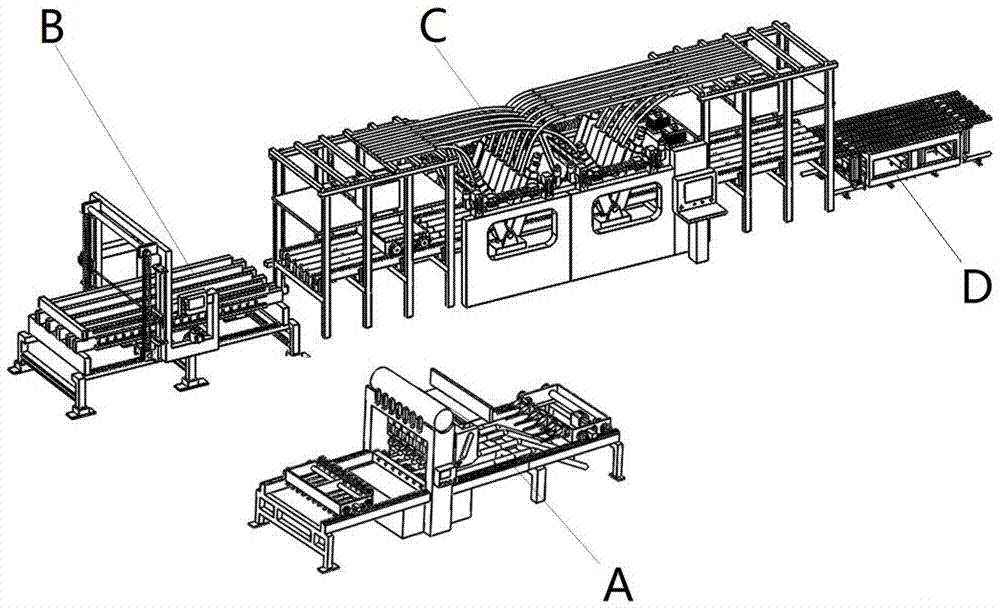

Net rack production line for producing heat insulation board wall

PendingCN107537959AEfficient productionMeeting urgent needsWire networkMetal working apparatusProduction lineEngineering

The invention discloses a net rack production line for producing a heat insulation board wall. The net rack production line comprises a flat net welding machine for welding already straightened longitudinal bars and transverse bars into flat net layers, a heat insulation board cutting machine for carrying out heat insulation board cutting in the thickness, length and width directions of an heat insulation board and forming the heat insulation boards meeting the specification requirements by cutting, an oblique inserting rib welding machine for inserting oblique inserting ribs into the heat insulation board and welding the oblique inserting ribs to the two flat net layers up and down, and a net rack heat insulation board conveyer for conveying an already produced net rack heat insulation board; the feed end of the oblique inserting rib welding machine corresponds to the discharge end of the flat net welding machine and the discharge end of the heat insulation board cutting machine; thedischarge end of the oblique inserting rib welding machine corresponds to the feed end of the net rack heat insulation board conveyer; and the flat net welding machine, the heat insulation board cutting machine, the oblique inserting rib welding machine and the net rack heat insulation board conveyer are each provided with control equipment for controlling various mechanisms in the flat net welding machine, the heat insulation board cutting machine, the oblique inserting rib welding machine and the net rack heat insulation board conveyer to carry out coordinative operation. Welding productionof the flat nets, efficient cutting of the heat insulation board, accurate insertion and welding of the oblique inserting ribs, conveying and transportation of the net rack heat insulation board are integrated in the net rack production line, so that the effect of efficiently producing the net rack heat insulation board throughout is realized.

Owner:河北森阳建筑设备科技有限公司

Plastering-free mechanically-sprayed putty powder, plastering-free mechanically-sprayed putty slurry as well as preparation method and application thereof

ActiveCN109439054AInhibition of ubiquitinationQuality assuranceFilling pastesBuilding constructionsFiberCrack resistance

The invention provides plastering-free mechanically-sprayed putty powder, plastering-free mechanically-sprayed putty slurry as well as a preparation method and application thereof. The plastering-freemechanically-sprayed putty powder is prepared from the following components in percentage by weight: 25.0-35.0% of an inorganic cementing material, 35.0-50.0% of aggregate, 10.0-30.0% of a filler, 1.0-3.0% of alkali-resistant additives, 3.0-5.0% of redispersible latex powder, 0.2-0.4% of hydroxypropyl methyl cellulose ether, 0.2-0.3% of anti-cracking fiber, 0.1-0.3% of a thixotropic agent, 0.05-0.15% of a water reducer and 0.01-0.05% of a water-repellent agent. The prepared plastering-free mechanically-sprayed putty has excellent bonding strength, cracking resistance, flexibility, water resistance, alkali resistance, efflorescence resistance and droop resistance, spraying constructability and scraping constructability, so that the construction efficiency is greatly improved, the construction period is shortened, and the labor cost is reduced.

Owner:ASIA PAINT SHANGHAI

Paint for high-class woodenware artwork and preparation thereof

InactiveCN101343498AGood weather resistanceImprove anti-corrosion performanceLiquid surface applicatorsEpoxy resin coatingsPolyesterChemistry

The invention relates to high-grade wooden artwork coating, which is composed of host crystal and solidifying agent, wherein according to the weight parts: the host crystal and solidifying agent are 100:20 to 100:40. The high-grade wooden artwork coating of the invention is characterized in that the coating is made through utilizing that polyester modified epoxy resin is mixed with materials such as high color pigment, dispersing agent, leveling agent, anti-sagging auxiliary agent, anti-scratching auxiliary agent, filler and the like, and additionally matched with polyamide and aliphatic amine solidifying agent. Under the high temperature and high humidity conditions the coating can be coated on the surfaces of various wooden artworks, when the thickness of one-time coating paint film is within 120 um to 150 um, the high-grade wooden artwork coating can not generate sagging phenomenon, and the paint film is bright and flat and has good physical chemical properties. The coating has the protecting and decorating effects to the wooden artwork, which can be widely used for the coating of the wood sculpture, the long high table, the noble furniture and the wooden artwork products.

Owner:TIANJIN COLOROAD COATING & CHEM

Polyurea elastomer construction engineering waterproof material

InactiveCN101037587ANot affected by ambient temperatureNot affected by ambient humidityOther chemical processesBuilding insulationsAlkaneElastomer

The invention relates to a polyurea elastic body architectural engineering water-proofing material, which is constituted of component A and component B of equal weight ratio. The component A is isocyanate, component B includes raw materials (by weight ratio of component B) of: amido end-sealing epoxy alkane compound of 55-70%, diethyl toluenediamine of 8-10%, 3,3'-diethyl-4,4'-diaminodiphenylmethane of 3-5%, phosphite triester of 5-7%, dihexandiol ester of 3-5%, N,N'-dialkyldiamine of 5-8%, N,N'-dialkylmethanediamine of 2-4%, and titanium dioxide of 4-6%. Advantages of the invention are: high strength, plant puncture resistant, aging resistant, energy-saving, environmental protection, long using lifetime of more than 30 years, and changeable colors.

Owner:山东斯泰普力高新建材有限公司

Preparation method of scratch and yellowing resistant polyurethane woodenware glossy white finish paint

ActiveCN103937400AStrong molecular structureGood flexibilityPolyurea/polyurethane coatingsKetoneSolvent

The invention relates to a preparation method of a scratch and yellowing resistant polyurethane woodenware glossy white finish paint. The finish paint is composed of a resin paint component A and a curing agent component B, wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic acid resin, aldehyde-ketone resin, titanium dioxide, a dispersant, a yellowing resistant agent, a chelating leveling agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The finish paint has the advantages of high paint membrane gloss, beautiful and refreshing appearance like a white jade, crystal-liked, transparent, thick and high quality paint membrane, and smooth and mirror-liked decoration effect; can create a refreshing, grace, concise and tranquil space, brings people a relaxed and happy feeling, is accord with the modern aesthetics, is welcomed by the market and customers, and is widely used to protect and decorate surfaces of woodenware, metal products, and plastic products.

Owner:UNION FOSHAN CHEM +1

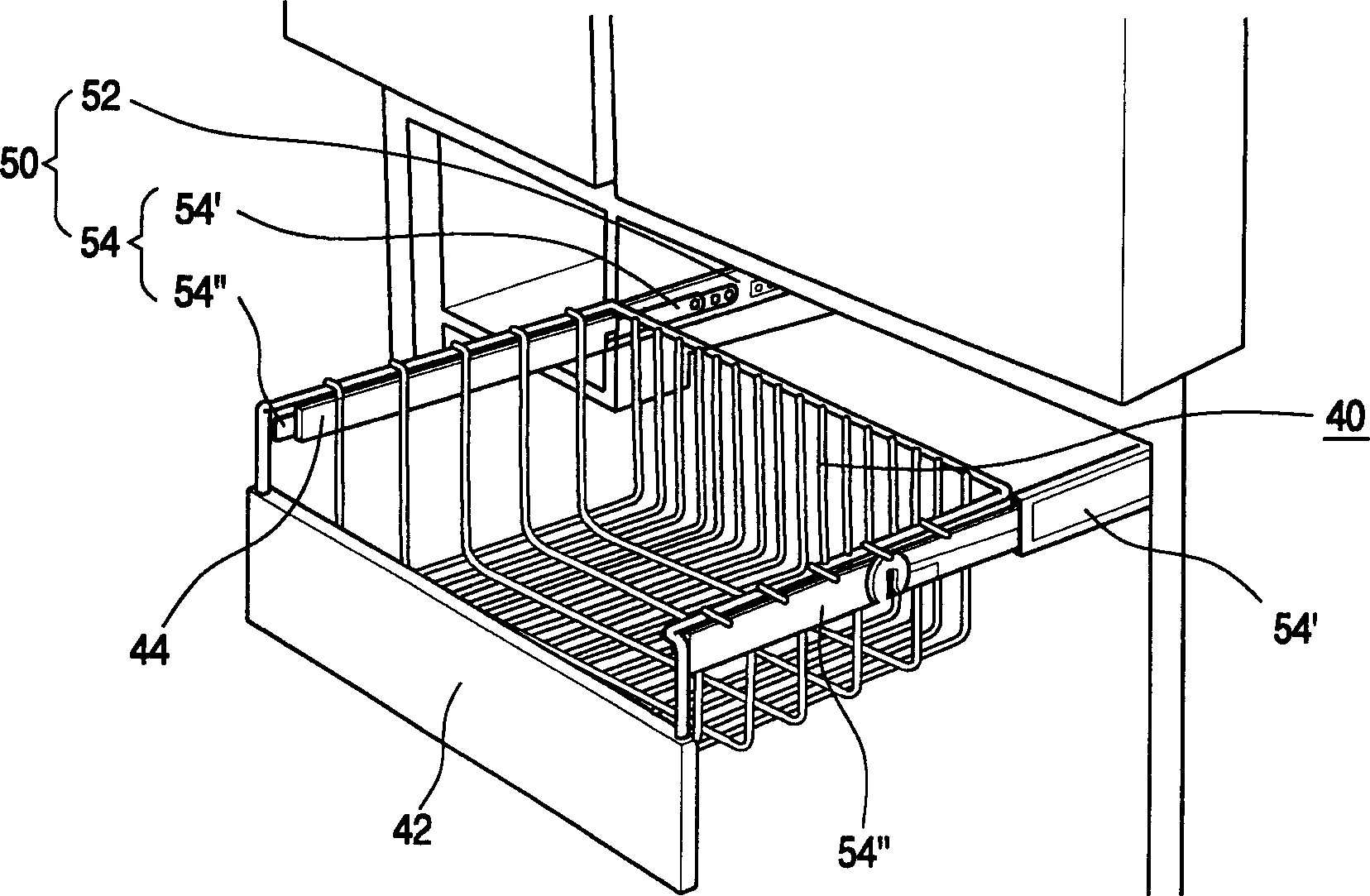

Double drawer for refrigerator

InactiveCN1896664AIncrease capacity capacityImproved capacityLighting and heating apparatusSupportInterior spaceEngineering

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

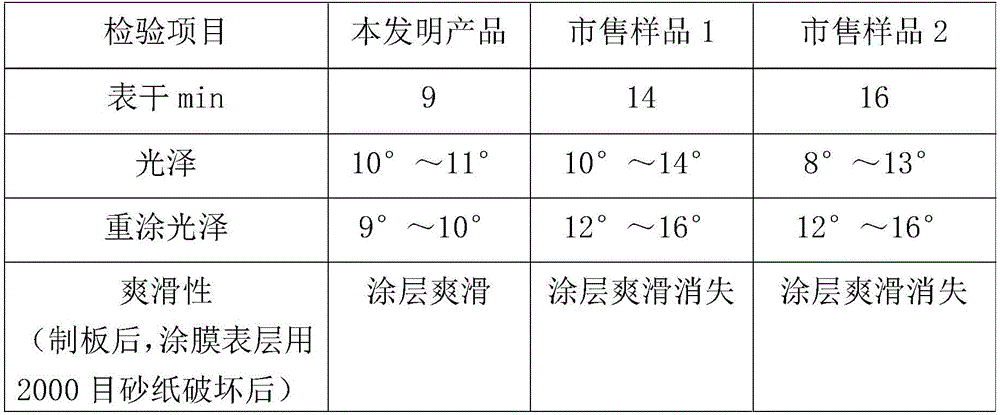

PU matte white finish stable in gloss and permanently smooth and preparation method thereof

The invention provides PU matte white finish stable in gloss and permanently smooth and a preparation method thereof. The PU matte white finish is prepared in the steps that white paste with the solid content being 60%, short oil alkyd resin, PE matting wax slurry, 6900-20X anti-sediment wax, anti-sediment slurry, wetting dispersant, a flatting agent, a defoaming agent, MIBK, vinyl chloride-vinyl acetate resin solution with the solid content being 20%, ED-30 matt powder, polytetrafluoroethylene wax powder and the like are prepared from a first component; a 1451 light trimer curing agent, a TDI additive product curing agent, an HDI trimer curing agent, MIBK, MEK and n-butyl acetate are prepared into a second component; methylbenzene, n-butyl acetate, acetic ether, MEK and propylene glycol methyl ether acetate are prepared into a third component; the first component, the second component and the third component are evenly mixed according to the proportion. Detection and trial prove that a paint film obtained after the PU matte white finish is sprayed is good in leveling property and high in sagging resistance, dazzled does not happen if the white finish is coated thin, the white finish can be kept permanently smooth, gloss is stable, and the PU matte white finish is suitable for coating of high-furniture and other wood products.

Owner:GUANGDONG BADESE CHEM

Preparation method of benzene-free odor-free scratch-resistant polyurethane matt gloss white topcoat for woodware

The invention relates to a preparation method of a benzene-free odor-free scratch-resistant polyurethane matt gloss white topcoat for woodware. The benzene-free odor-free scratch-resistant polyurethane matt gloss white topcoat is composed of a component A and a component B which are in the weight ratio of 1:0.5, wherein the component A is composed of odor-free alkyd resin, titanium dioxide, matting powder, calcium carbonate powder, a dispersing agent, an anti-yellowing agent, a flatting agent, a hand feeling agent, a defoaming agent, an anti-settling agent and a solvent; and the component B is a benzene-free curing agent with TDI, an HDI tripolymer or an addition product as a main component. The matt gloss white topcoat prepared by using the preparation method does not contain arene, aldehyde ketone or heavy metals, and no residual odor is left on a paint film after 48 hours; the matt gloss white topcoat can not be settled when being stored, is good in flatting performance, capable of forming a thick film at one step without sagging, soft in hand feeling, full and exquisite, slippery, good in scratch resistance and capable of generating a mirror-surface-like full decorative effect and bringing elegance and comfort for people, and conforms to the modern aesthetic view so as to be popular to the market and consumers; and the matt gloss white topcoat is widely applied to the surfaces of woodware, metals, plastics and other products to take protective and decorative effects.

Owner:靖江市浩鑫电气机械配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com