Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Flat thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

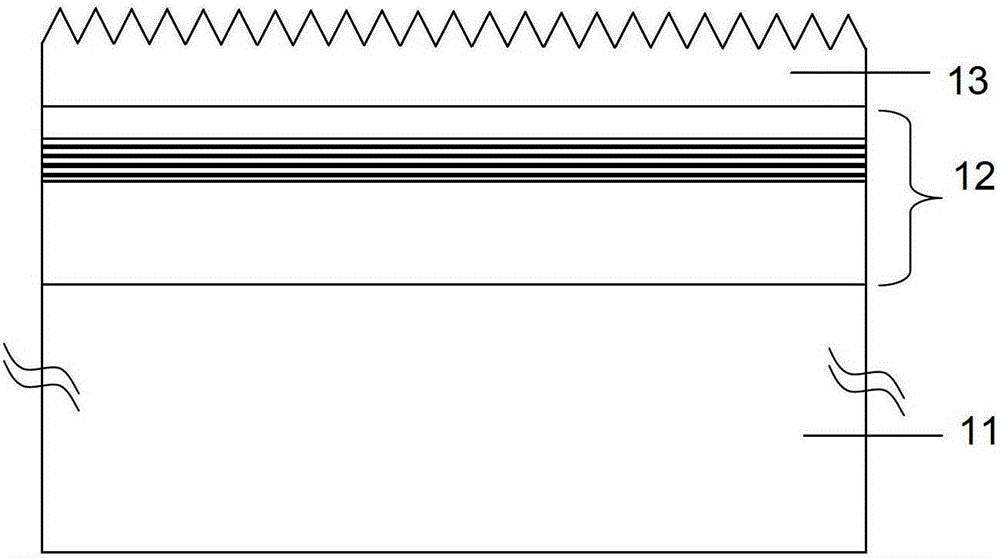

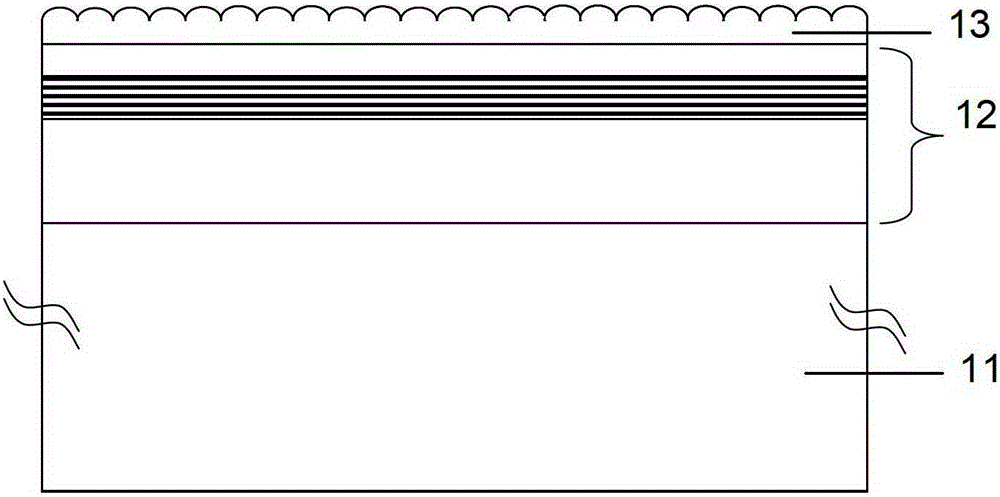

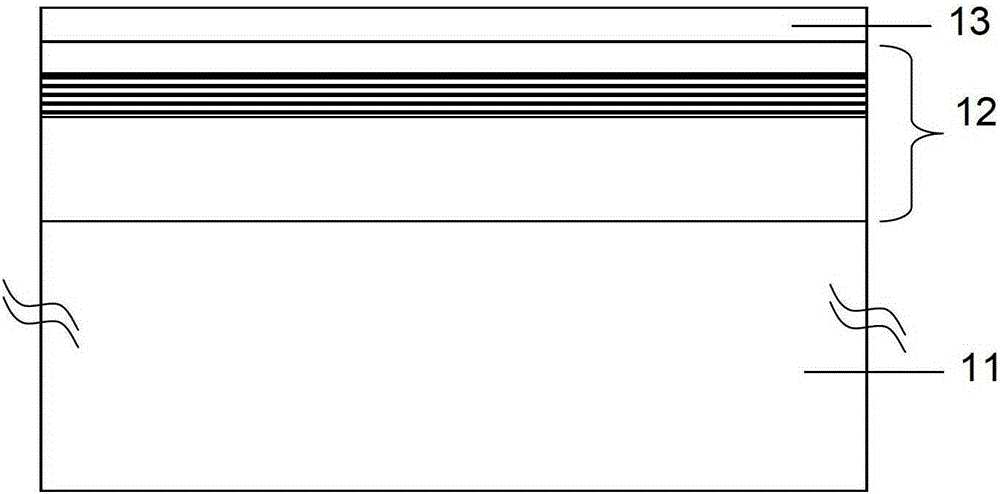

Lithium-containing negative plate and preparation method thereof

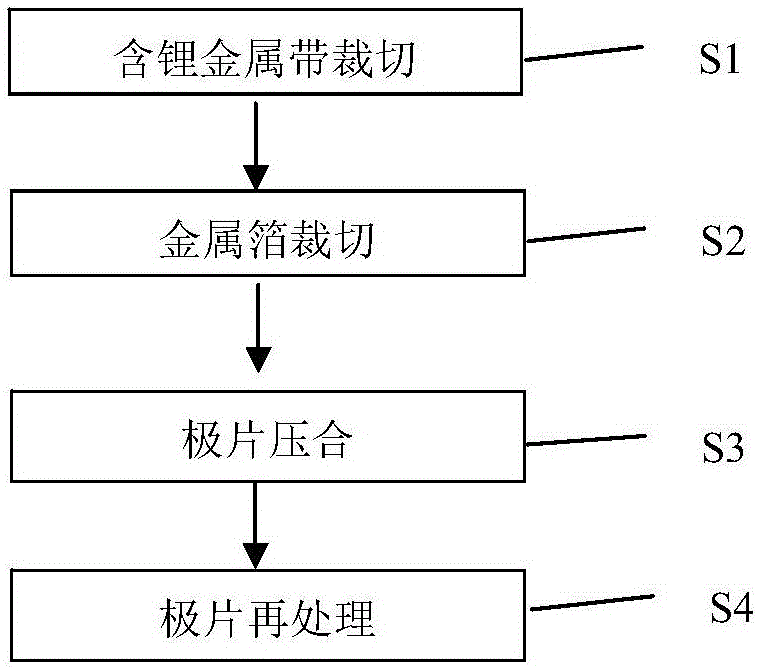

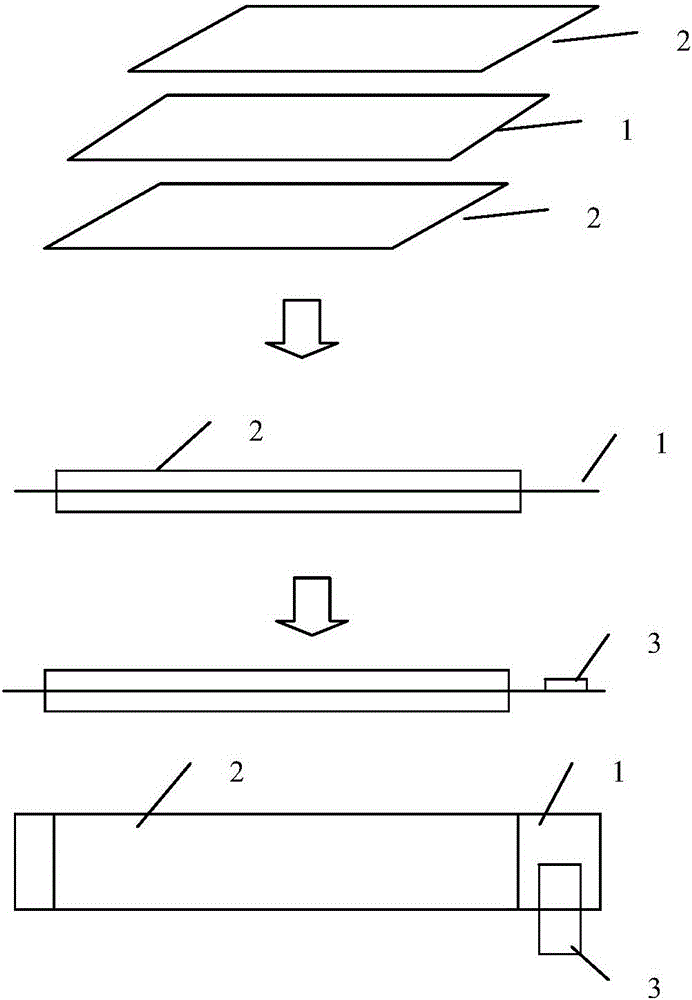

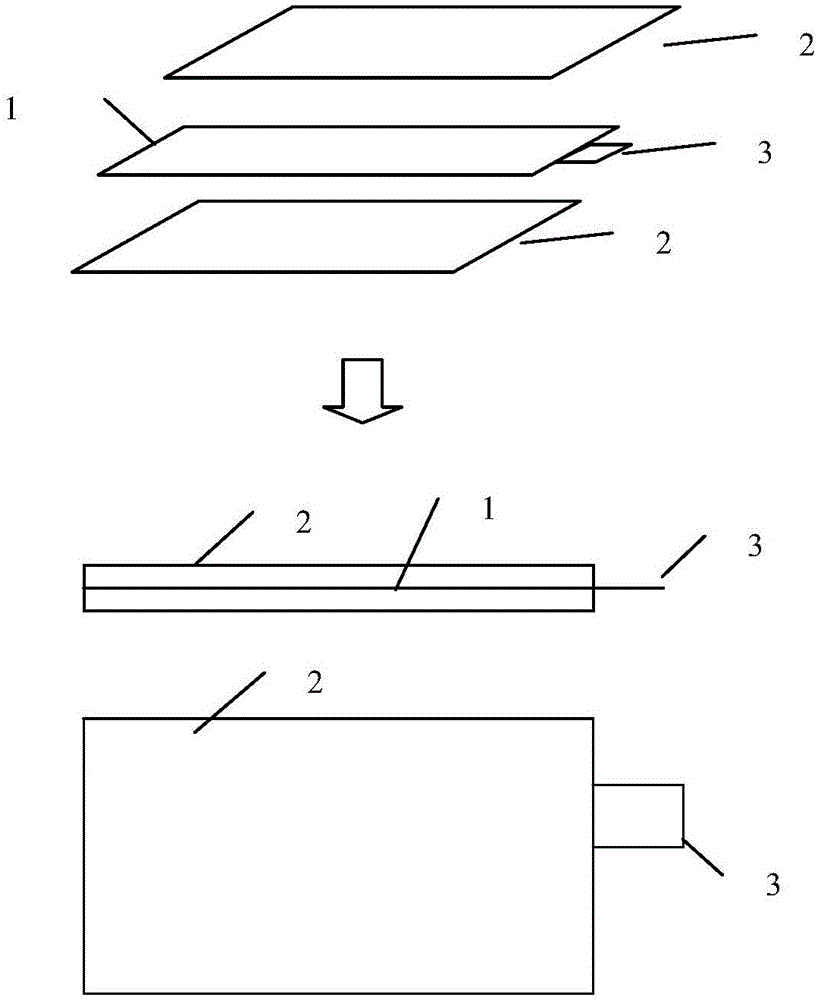

InactiveCN106784600AFlat thicknessImprove convenienceElectrode manufacturing processesElectrode carriers/collectorsMetal foilCurrent collector

The invention discloses a lithium-containing negative plate. The lithium-containing negative plate comprises a lithium-containing metal belt, a metal foil and a current collector tab, wherein the size of the metal foil is matched with the size of the lithium-containing metal belt, the lithium-containing metal belt is formed by an upper layer and a lower layer, the metal foil is clamped between the upper layer and lower layer of the lithium-containing metal belt, the lithium-containing metal belt and the metal foil are laminated together by virtue of a laminating device to form a compact combination body, and the metal foil has the characteristic of a rough surface. By adopting a particular structural design and innovative implementation method, the lithium-containing negative plate provided by the invention has the advantages of flat thickness, good current collector effect, good heat dissipation effect, high combination force of the lithium belt and a current collector, and the like, can be used for automatic mass production of batteries, and is very applicable to high-energy density battery systems such as a lithium-sulfur battery, a full-solid lithium ion battery, a different-system primary lithium battery and the like; and the provided plate preparation method is simple, high in operability and suitable for mass production.

Owner:TIANJIN LISHEN BATTERY

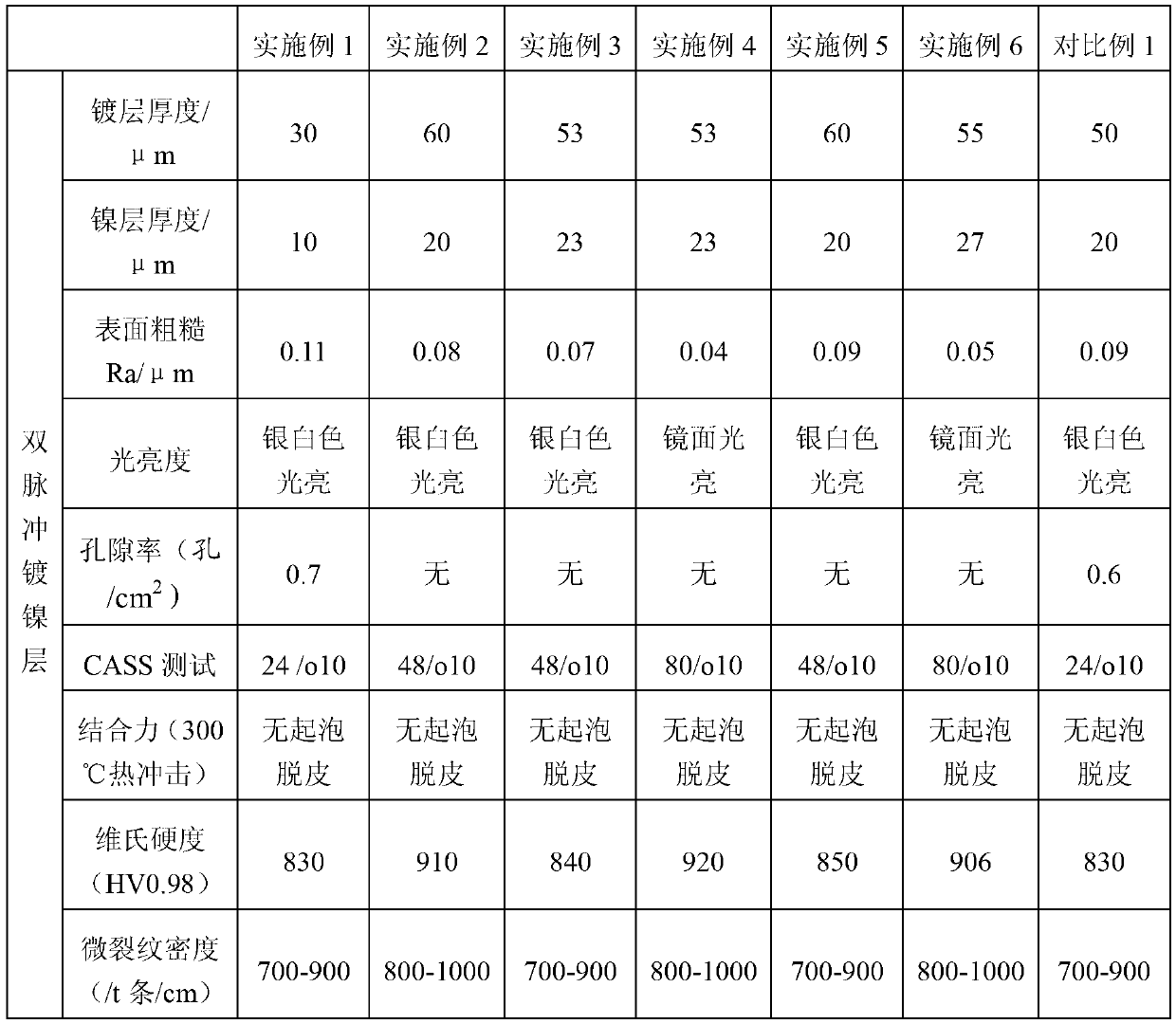

Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

The invention discloses a wear-resistant workpiece and a manufacturing method of a wear-resistant coating thereof. The preparation method of the wear-resistant coating comprises the following steps: forming a preparation piece according to the structure of a required wear-resistant workpiece; coating nickel on the surface of the preparation piece through a double-pulse method, thus forming a nickel-coated transition piece; and coating a hard chromium layer on the surface of the nickel-coated transition piece, thus forming the wear-resistant coating on the surface of the preparation piece. For the manufacturing method of the wear-resistant workpiece, a step of coating nickel on the surface of the workpiece through a double-pulse nickel coating method is added; and the double-pulse nickel coating method is characterized in that the magnitude of current or voltage is regulated by an external control means, the current is additionally controlled by controlling the pulse switch-on time, the pulse switch-off time, the pulse duty factor, the pulse current density and the like, and corresponding variables are changed to respectively achieve the effects of increasing the cathode current density, inhibiting the generation of side reaction, reducing the impurity content in the coating, improving the current distribution and the like, thus improving the quality of the coated nickel layer and prolonging the service life of the wear-resistant workpiece.

Owner:HUNAN TELI HYDRAULIC +1

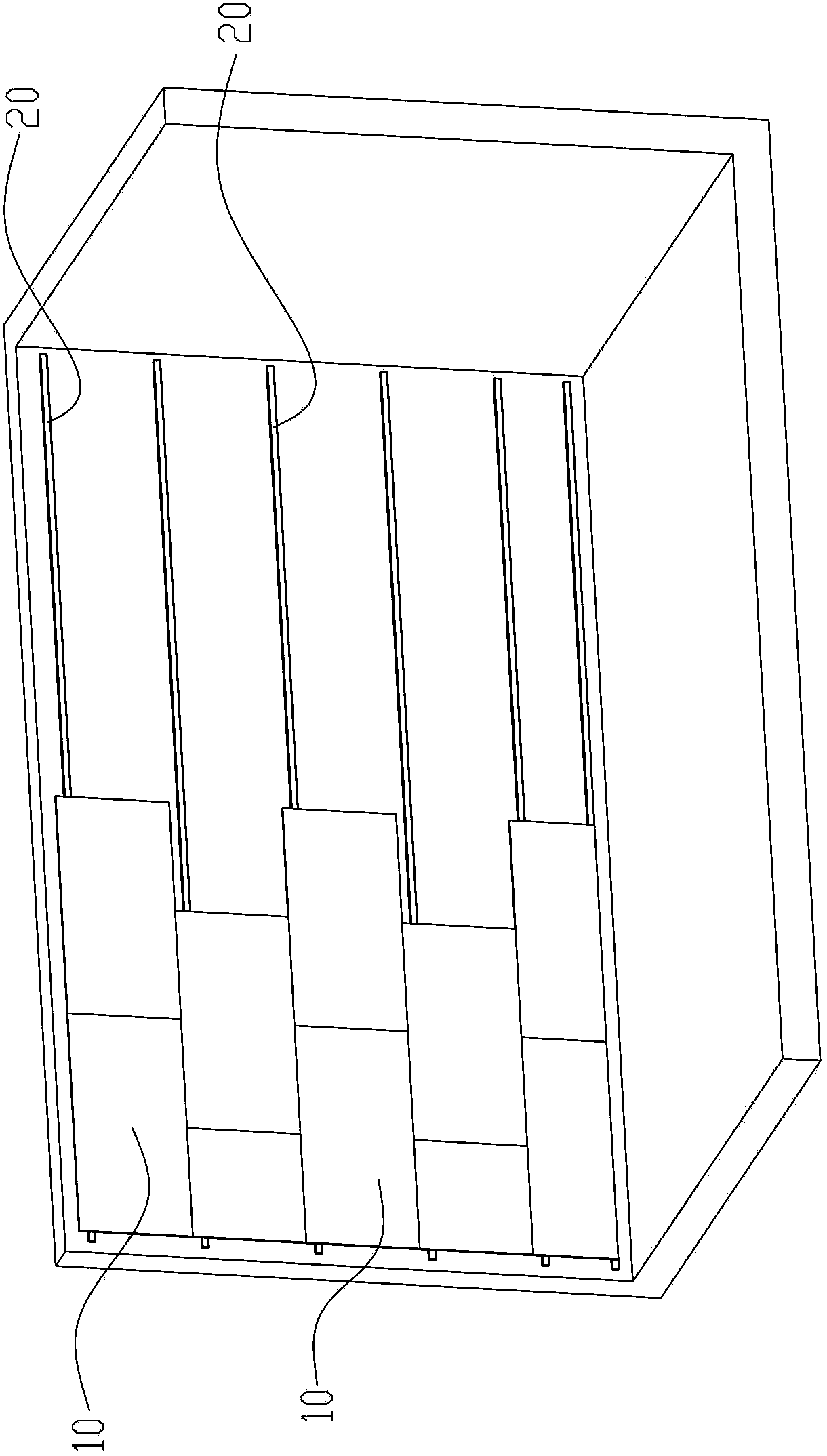

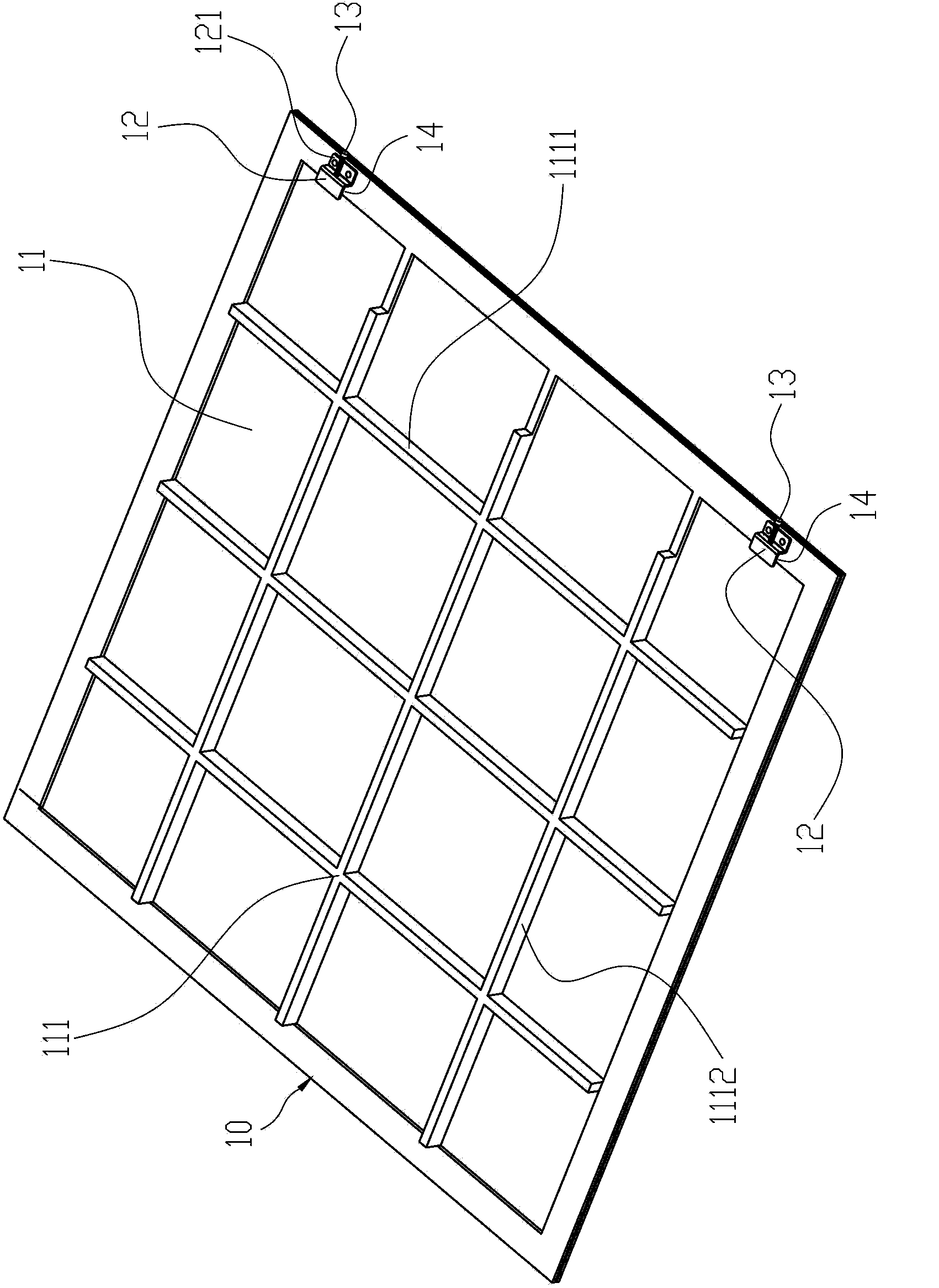

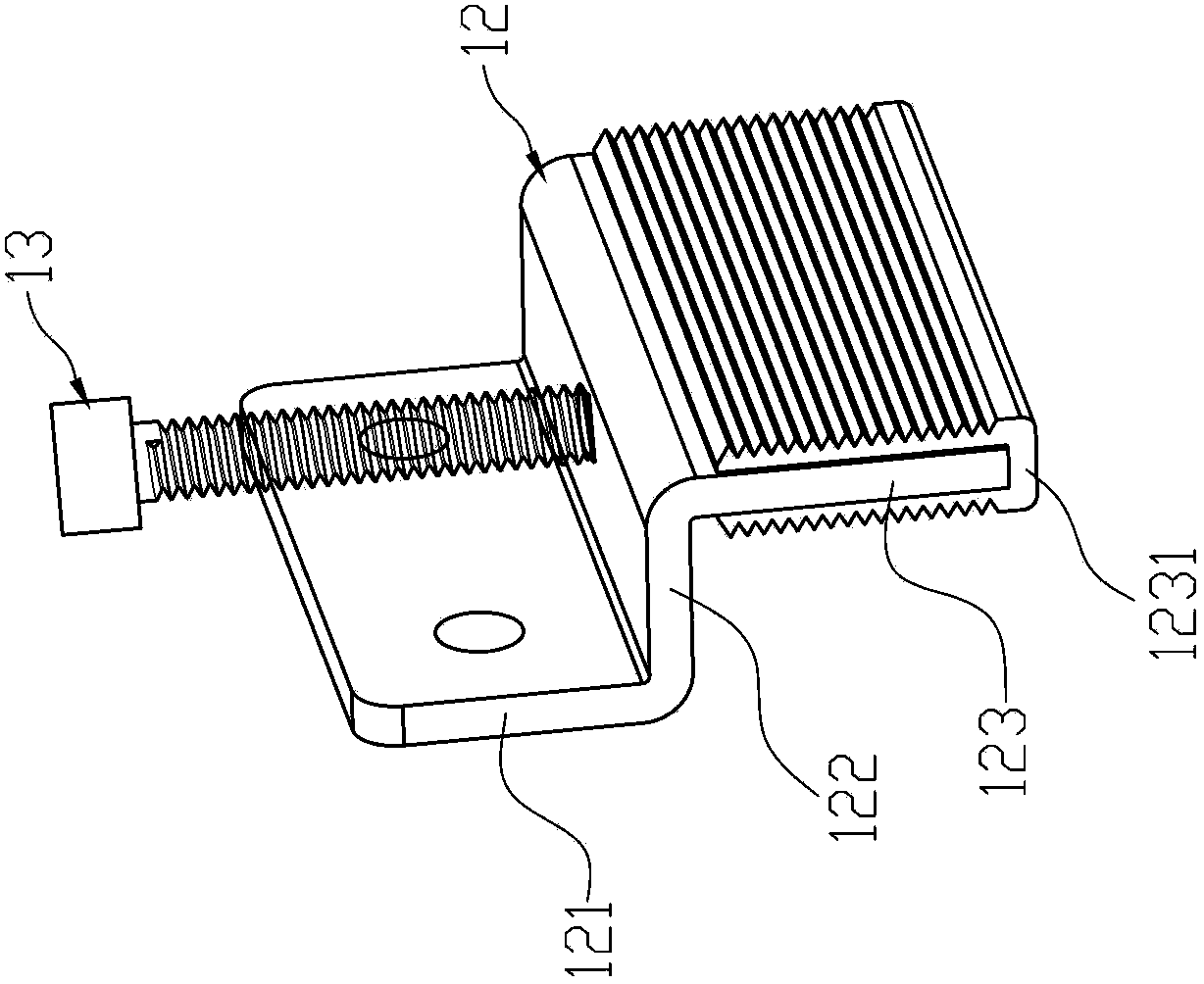

Dry-hanging wall slab structure

The invention discloses a dry-hanging wall slab structure which comprises composite panels and keel frames, wherein the composite panels comprise support slabs and fasteners; the fasteners are connected with the back surfaces of the support slabs; the keel frames comprise keels and adjustors used for adjusting the keels to move relatively closer to or far away from a wall surface; the adjustors are connected with the wall surface and the keels; and the fasteners are in hanging connection with the keels. According to the dry-hanging wall slab structure, positions of the keels are adjusted by the adjustors, and then the composite panels are arranged on the keel frames in a hanging manner to allow the fasteners to be in hanging connection with the keels, so that a construction process of a wall slab can be accomplished quickly, and the field operation time can be reduced; compared with the traditional operation mode, procedures are few, and the efficiency is increased to 2-3 times; in addition, a common worker can accomplish construction operation, and no skillful muddy water slurry and painting technicians are required; and the composite panels are uniform, even and precise in thickness, stable in quality, smooth in surface, and high in leveling precision.

Owner:XIAMEN GRAND ONE IND DESIGNS

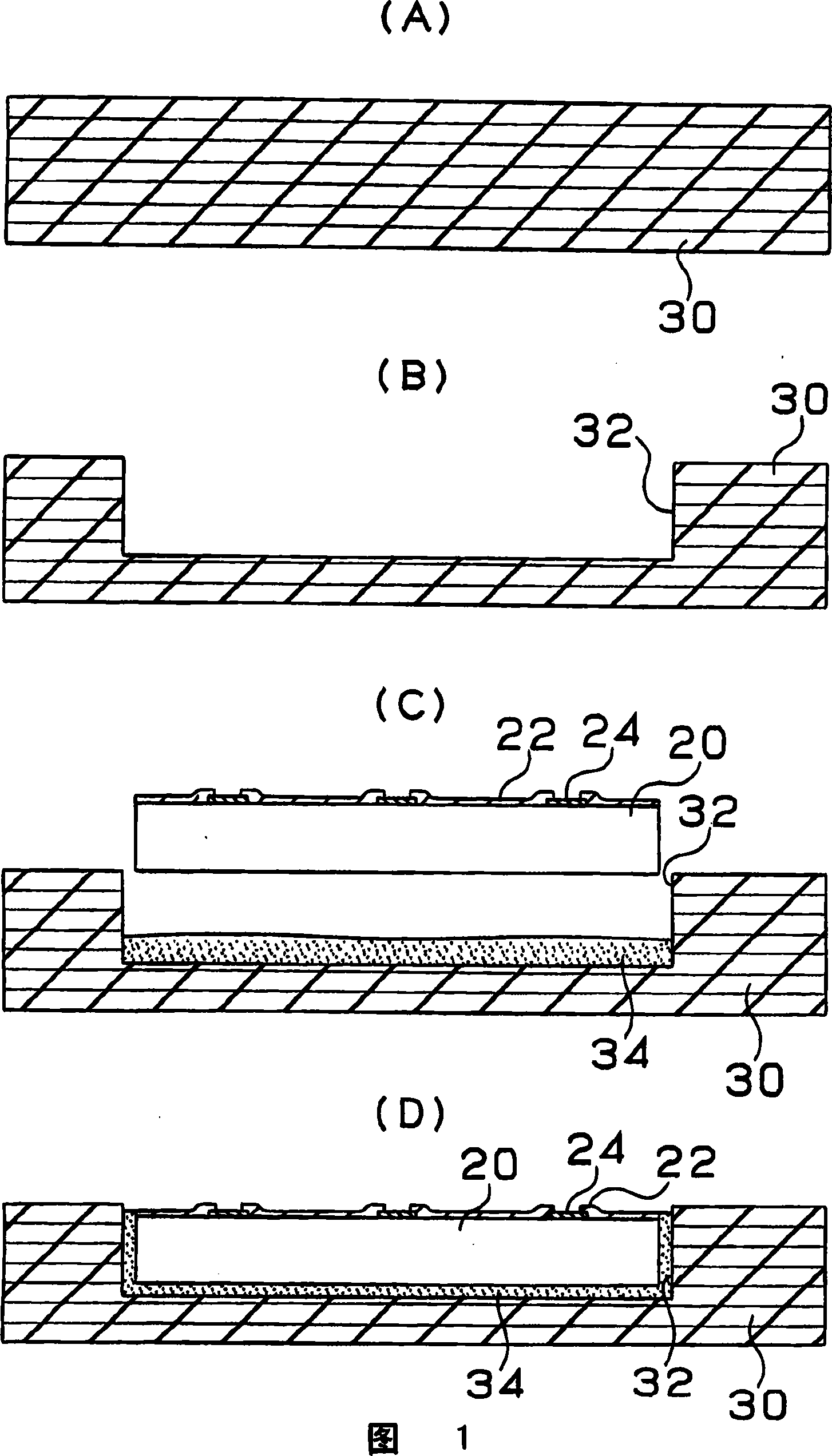

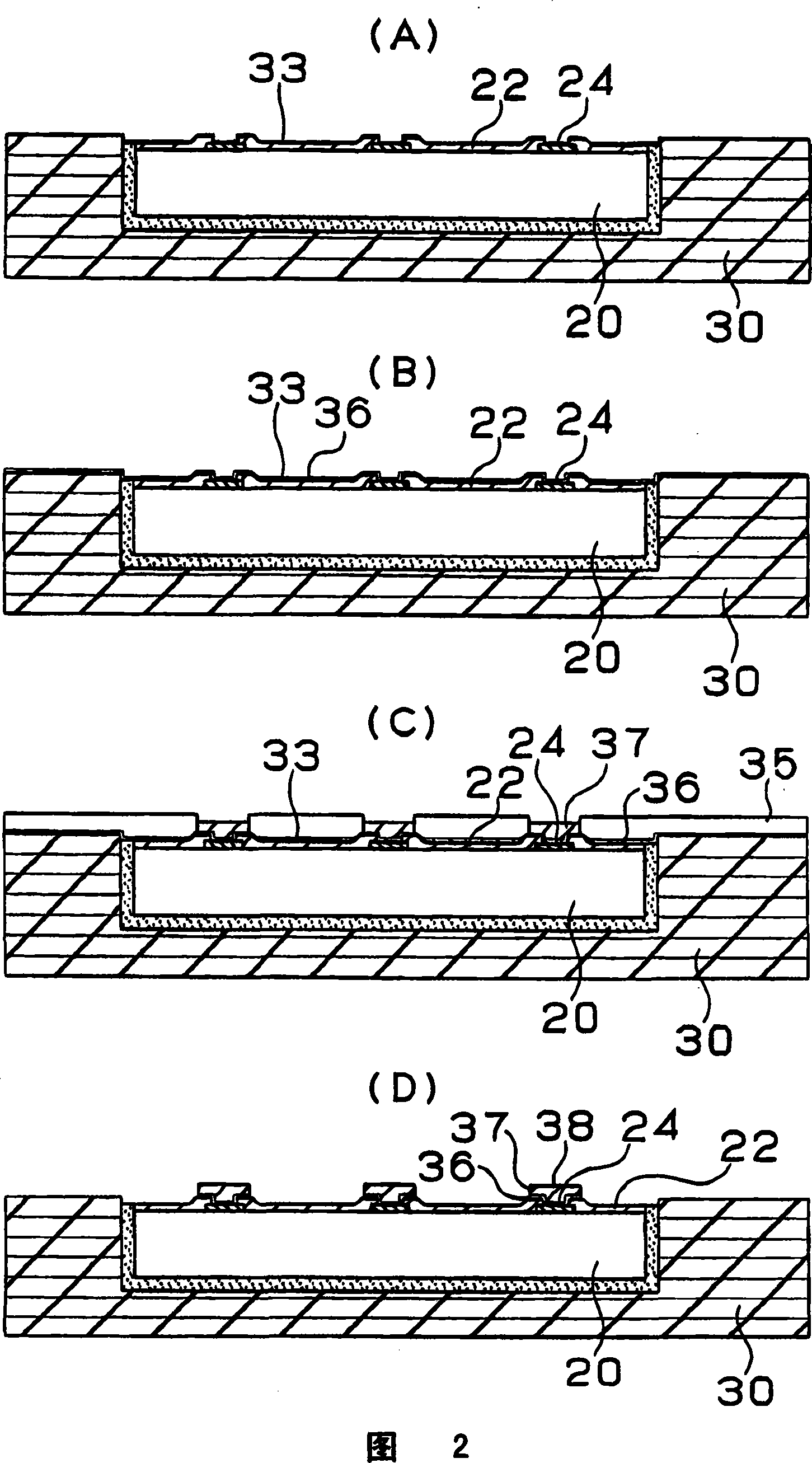

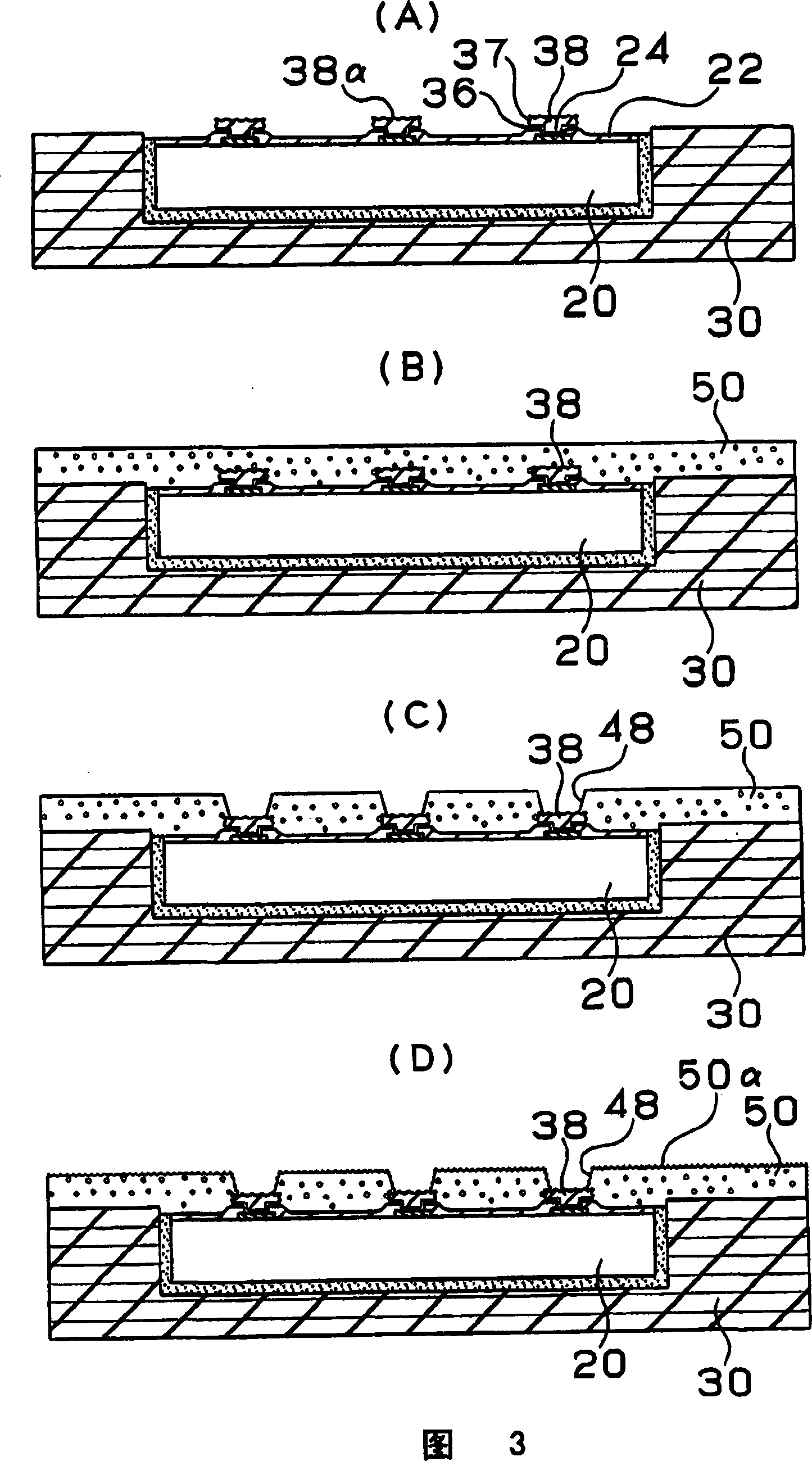

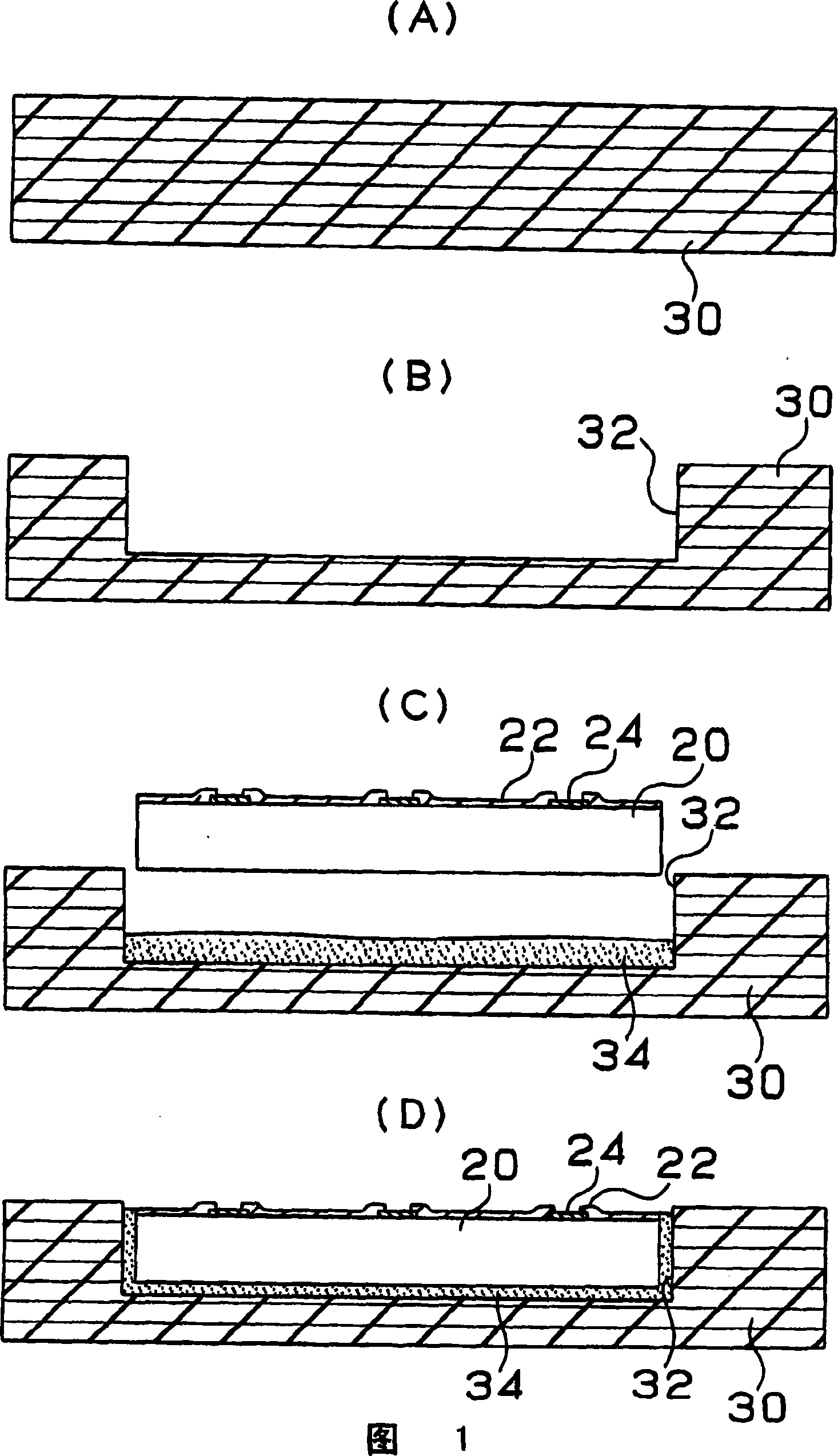

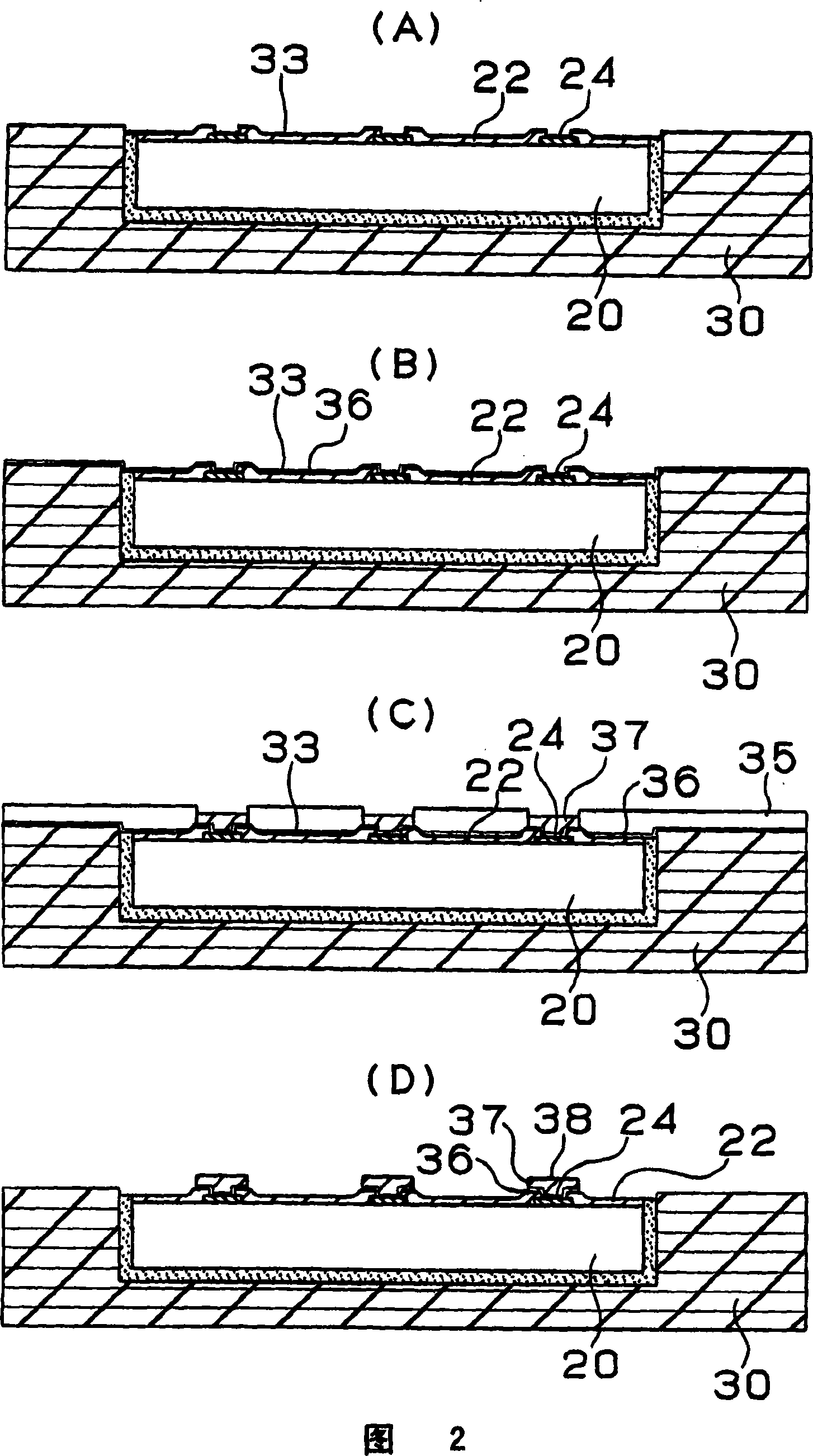

Multilayer printed circuit board

InactiveCN101098588AGood electrical conductivityExcellent adhesionPrinted circuit detailsSemiconductor/solid-state device detailsCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20 . Due to this, it is possible to electronically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24 , it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

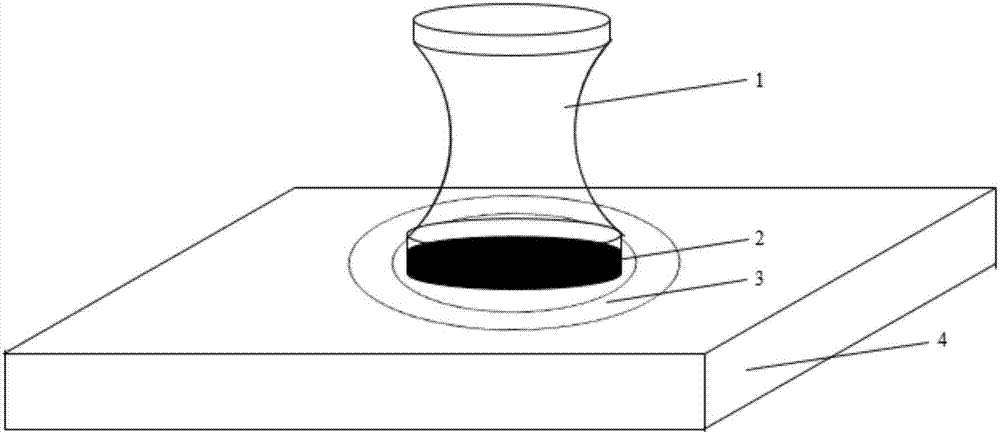

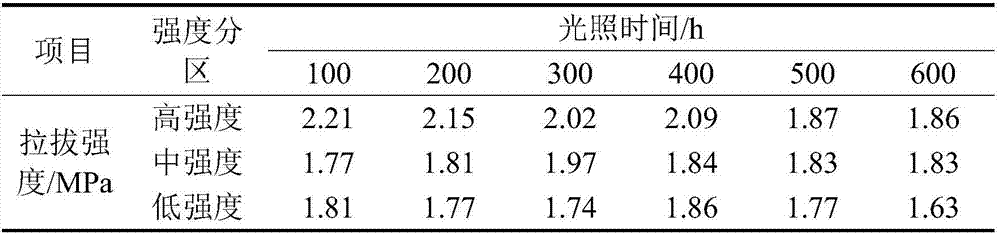

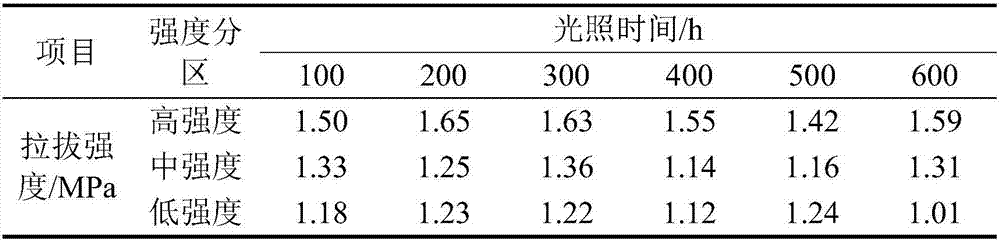

Method for performing pull-off test on ultraviolet-aged asphalt and asphalt mortar

InactiveCN106908383AMeet the requirements of less thinnessLess sample demandUsing mechanical meansMaterial analysisUltravioletRoad surface

The invention relates to a method for performing a pull-off test on ultraviolet-aged asphalt and asphalt mortar. The method comprises the following specific steps: (1) thermally aging an asphalt and asphalt mortar sample; (2) performing ultraviolet aging on the asphalt and asphalt mortar sample; (3) performing the pull-off test by using a pull-off tester: selecting a square rock block as an aggregate, pouring the asphalt and asphalt mortar sample onto the surface of the square rock block, then placing a puller, and performing the pull-off test after the puller and the asphalt and asphalt mortar are adhered while standing. Compared with the prior art, the method has the advantages as follows: before the pull-off test, thermal aging and ultraviolet aging are performed first, thermal aging simulates the thermal aging process in the mixing, transporting and paving processes of the asphalt and asphalt mortar, ultraviolet aging simulates change of an asphalt pavement after actual irradiation and is closer to the actual situation, quantitative operation is achieved in each step, and accurate calculation and analysis can be performed to ensure the testing accuracy.

Owner:TONGJI UNIV

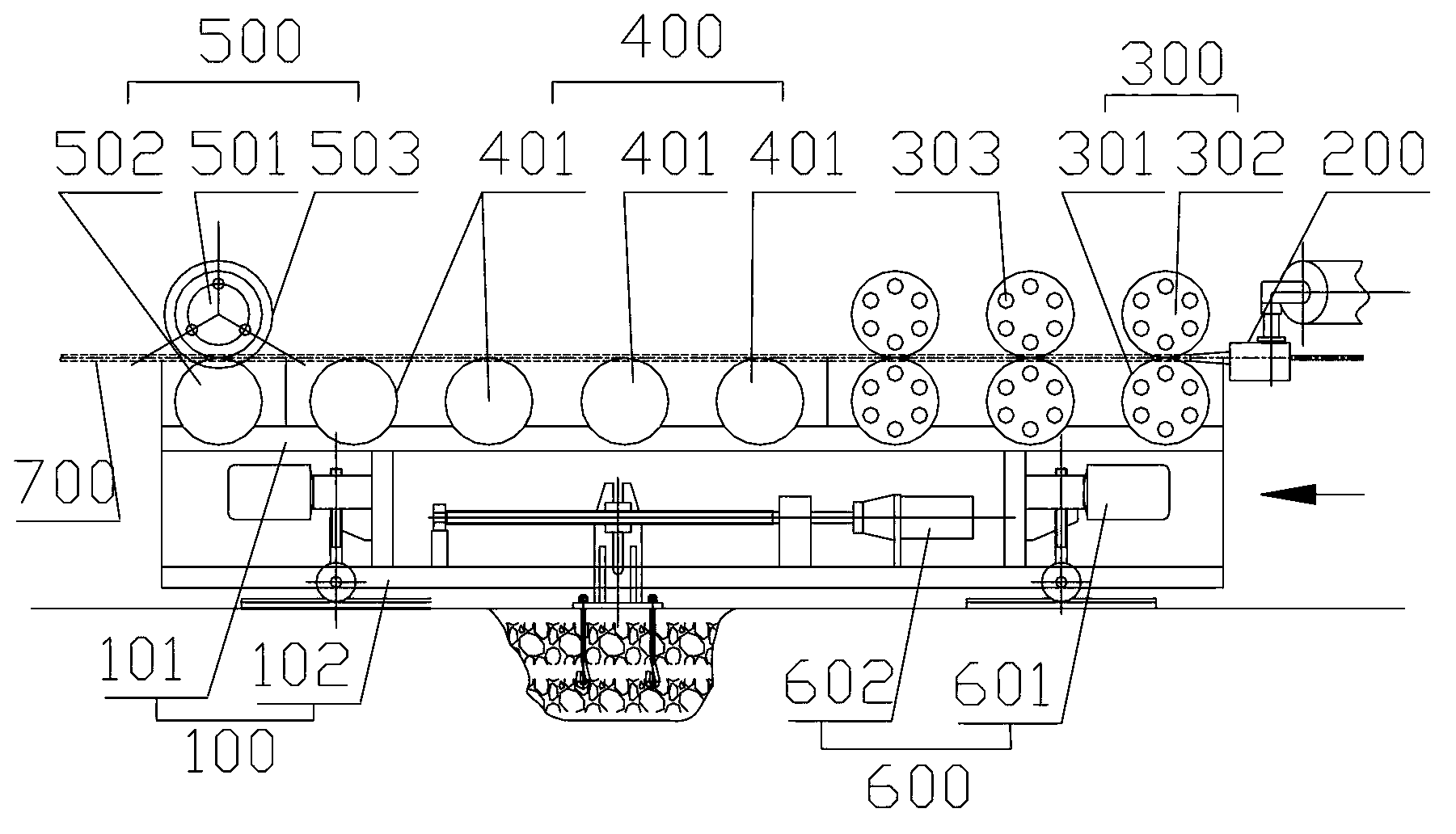

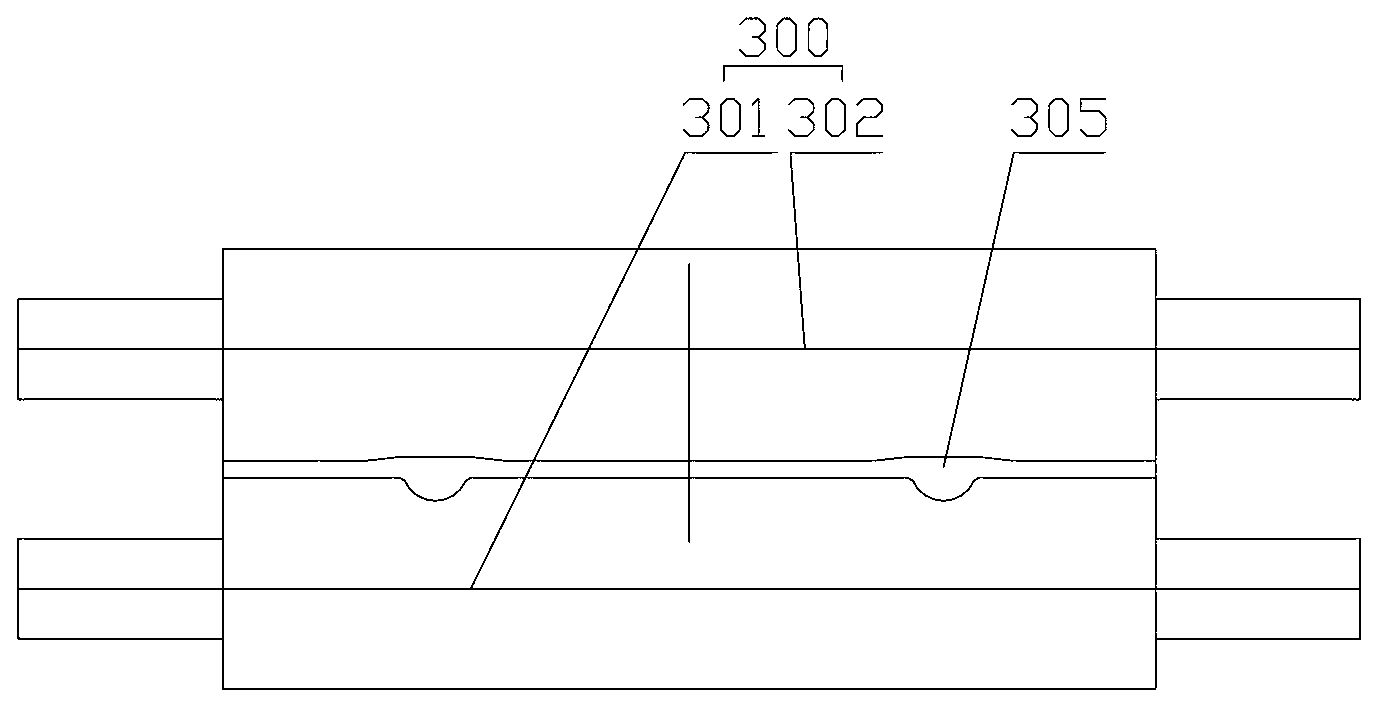

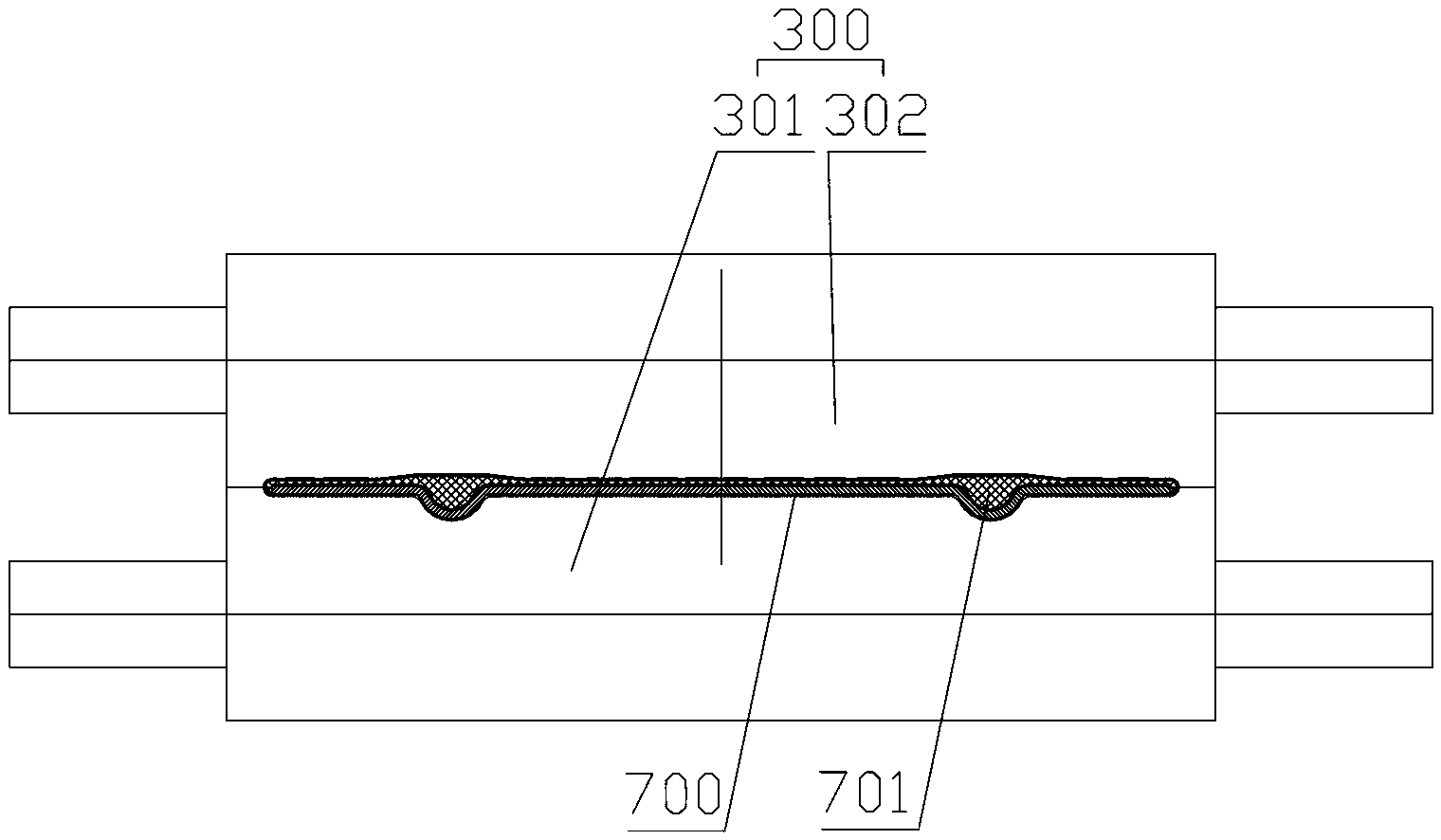

Rolling sizing device

The invention discloses a rolling sizing device comprising a frame. The following components are sequentially arranged on the frame: a rolling roller set used for carrying out drawing and progressive extrusion and sizing upon a strip-shaped thermoplastic composite material, a slow-cooling guide roller set used in further sizing, and an edge-cutting roller set used for trimming the edge of the strip-shaped thermoplastic composite material. The rolling roller set, the slow-cooling guide roller set, and the edge-cutting roller set are linearly arranged. The rolling sizing device also comprise a position adjustment mechanism used for adjusting the relative positions of the rolling roller set, the slow-cooling guide roller set, the edge-cutting roller set, and an extrusion mold. With the strip-shaped thermoplastic composite material rolling sizing device provided by the invention, strip-shaped thermoplastic composite material continuous sizing can be carried out, and the sizing is precise.

Owner:四川江瀚工业股份有限公司

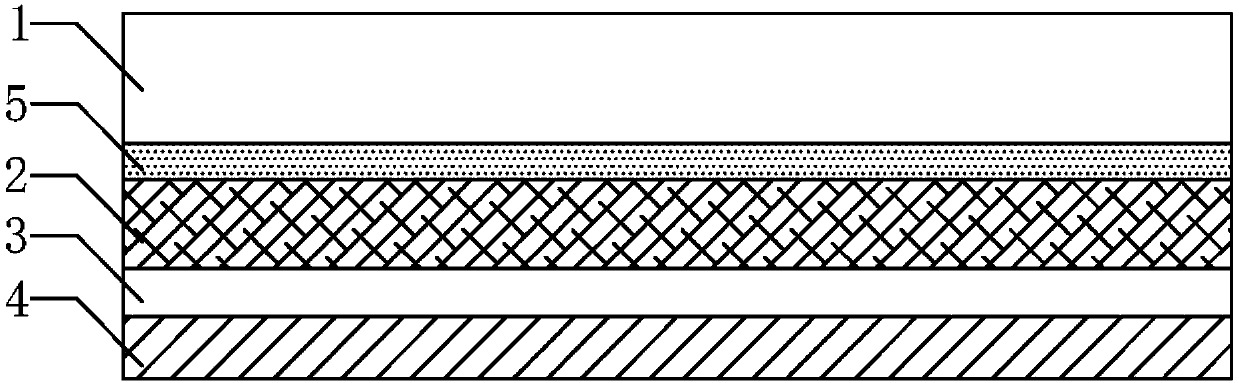

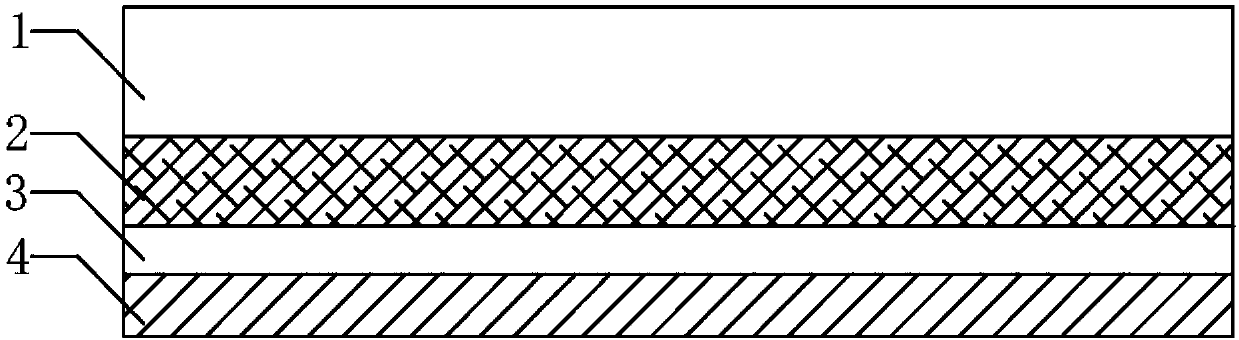

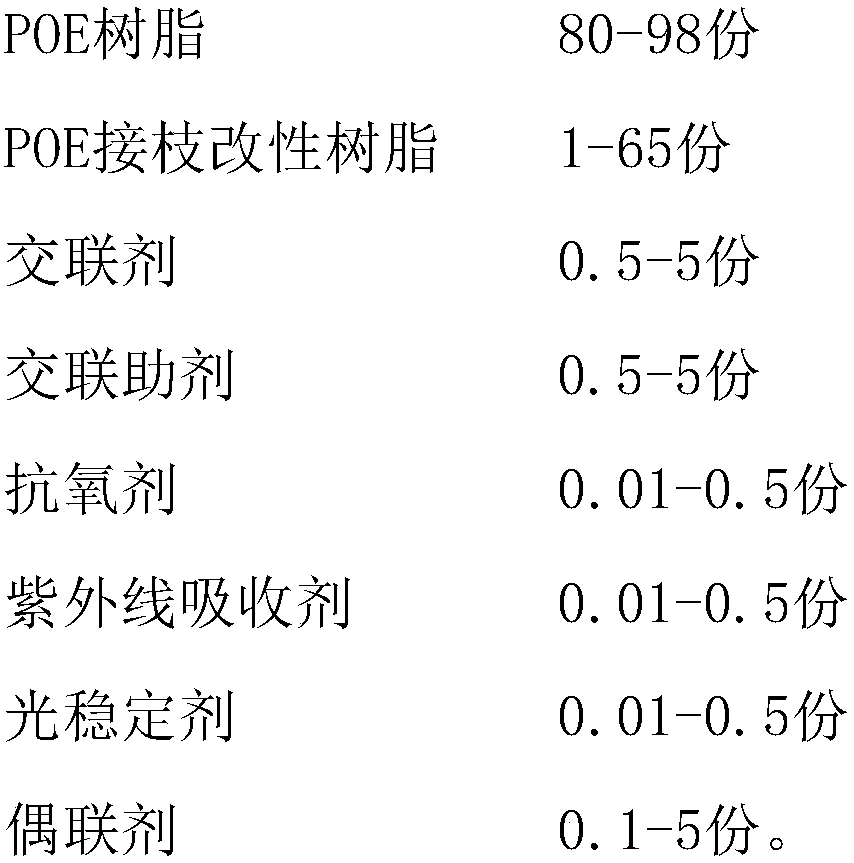

Adhesive film back plate integrated material and preparation process thereof

InactiveCN108034377AGood weather resistanceHigh light transmittanceNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerThermoplastic

The invention relates to the technical field of adhesive film back plates, in particular to an adhesive film back plate integrated material and a preparation process thereof. The adhesive film back plate integrated material comprises an adhesive film layer, a structure reinforcement layer, a bonding layer and a weather-proof layer which are sequentially connected from inside to outside, a frostedlayer is arranged between the adhesive film layer and the structure reinforcement layer, and the adhesive film layer is prepared from modified thermoplastic POE (polyolefin elastomer). The adhesive film back plate integrated material has performances such as better barrier property, heat resistance, aging resistance, toughness, light transmittance and electrical insulating property, and is strongin layer-to-layer bonding power, not easy to fall off and long in service life. The preparation process is convenient to operate and control, high in production efficiency and low in production cost,the POE adhesive film layer and the frosted layer can be firmly adhered and smoothly curled, the thicknesses of the POE adhesive film layer and the frosted layer can be controlled, the prepared adhesive film back plate integrated material is excellent in performance, the assembly procedure of a component is simplified, and the assembly cost of the component is reduced.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

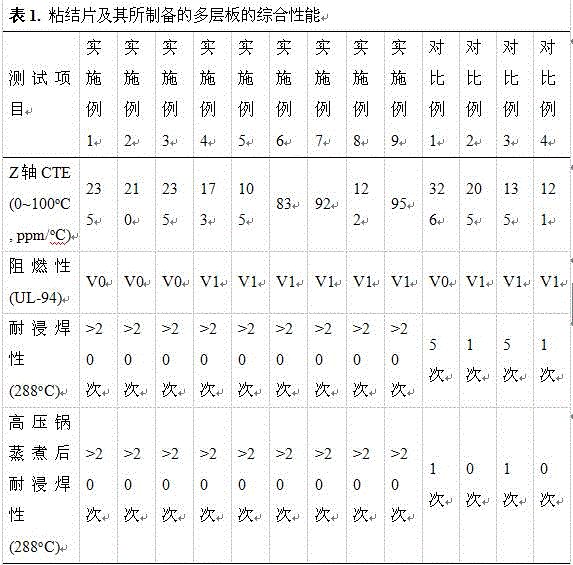

Adhesive sheet for copper-clad laminate

ActiveCN106590452AControllable areaFlat surfaceNon-macromolecular adhesive additivesFilm/foil adhesivesSmooth surfaceHot pressing

The invention belongs to the field of communication materials, and in particular relates to an adhesive sheet for a copper-clad laminate. The adhesive sheet with a controllable area, a smooth surface, a uniform easy-to-control thickness and suitable toughness and viscosity is prepared by mixing uniformly resin, an inorganic filler and an auxiliary agent, then hot pressing, sintering, turning, and the like. According to actual application scenes, various types of composite adhesive sheets are prepared by selecting of the suitable resin and inorganic filler, and prepregs with various polymer matrixes, different dielectric properties and different surface structures can be well composited. In particular, due to the use of glass fiber and other reinforcing materials, the dielectric properties of the adhesive sheet can be adjusted to a large extent, and the practicability and universality of the adhesive sheet can be effectively enhanced. In the invention, the adhesive sheets and the prepregs are well compatible and strong in adhesion, and a prepared multilayer board has good thermal and mechanical performances, high stability and low hygroscopicity, and can meet comprehensive performance requirements of different communication fields on the copper-clad laminate.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

Centrifugal coating device and coating method for prefabricated insulator

The invention belongs to the field of insulator composite anti-pollution flashover coating equipment and method, in particular to a centrifugal coating device and a coating method applied to insulatorcoating. The invention adopts the centrifugal coating method with the rotating coating reagent of the workpiece insulator stationary, the coating thickness is uniform, smooth, free of bubble, bump, hanging flow, concave mark and other defects, and the coating process is convenient to disassemble and assemble. Compared with the traditional way of spraying by manipulator, the safety is greatly improved, and the quality and efficiency of the finished product are significantly improved compared with the artificial dip coating. The device and the coating method of the invention are suitable for coating outer umbrella insulators (single umbrella, double umbrella or multiple umbrellas), column insulators and other insulators.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Construction method for paining waterproof paint before cement is finally set

The invention relates to a construction method for paining waterproof paint before cement is finally set. The construction method includes the steps of (1) wetting the base with water at first, blade coating a pure cement layer or a cement screed layer, and coating waterproof paint with a blade after the surface of the pure cement layer or the cement screed layer is dried to form a waterproof layer; (2), or coating waterproof paint with a blade directly before the pure cement layer or the cement screed layer are finally set. The construction method for paining waterproof paint before cement is finally set has reaction, solves the problems that adhesion of coating layers and bases or protective layers is insecure, drying speed of water-based paint is slow and requirement on bases is high and the like, construction is simple to operate, technical features of waterproof materials can be fully utilized, the problems that screed-coat layers are not needed to perform construction on concrete bases or cement mortar bases are solved in large-scale construction, paint can form a sealed bonding layer to solve a problem of water leakage of waterproof paint.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

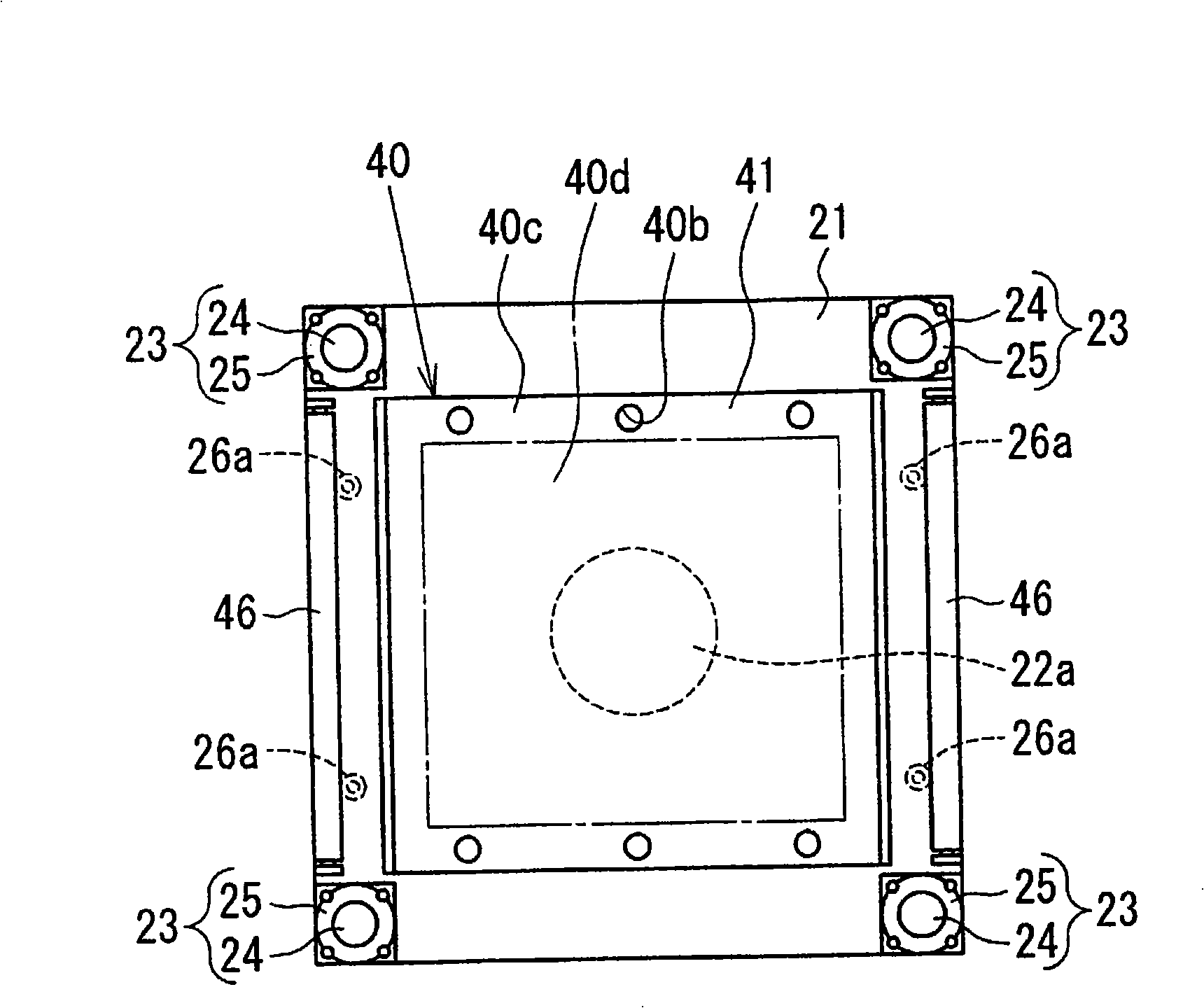

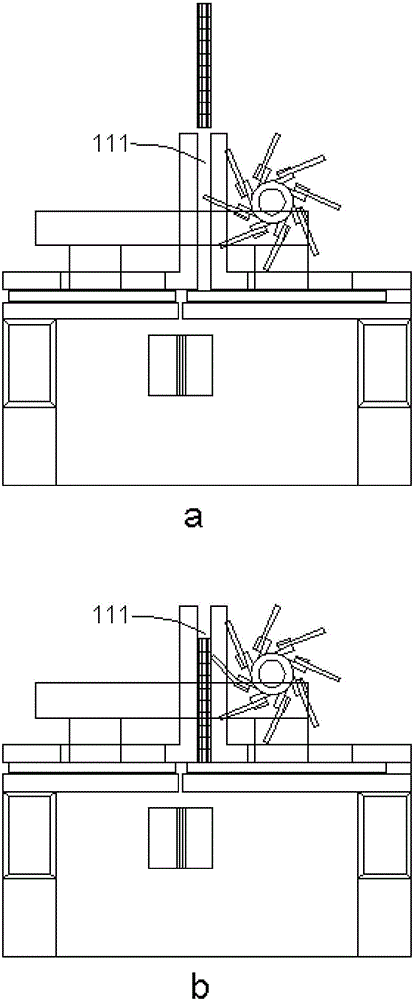

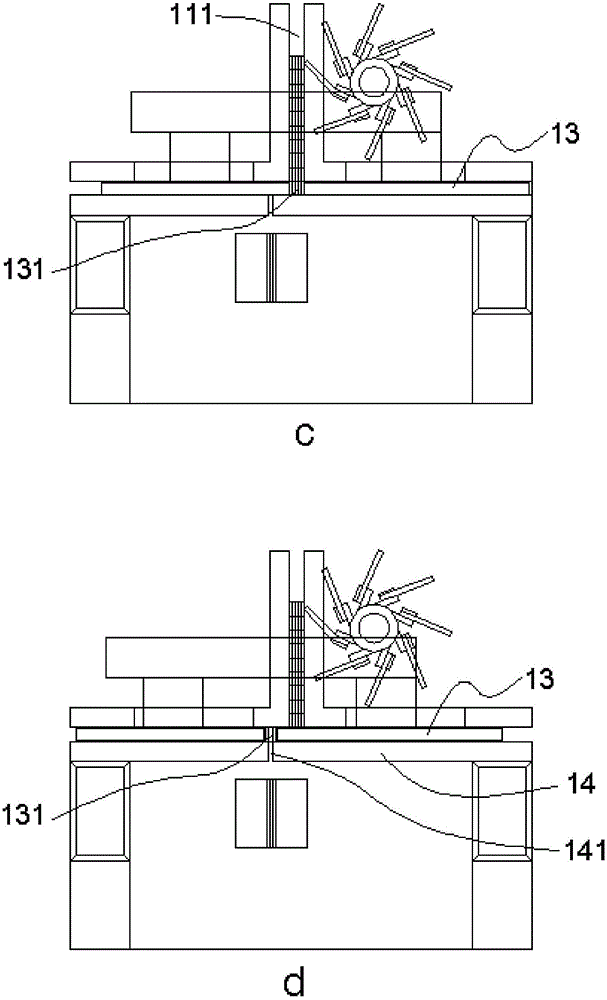

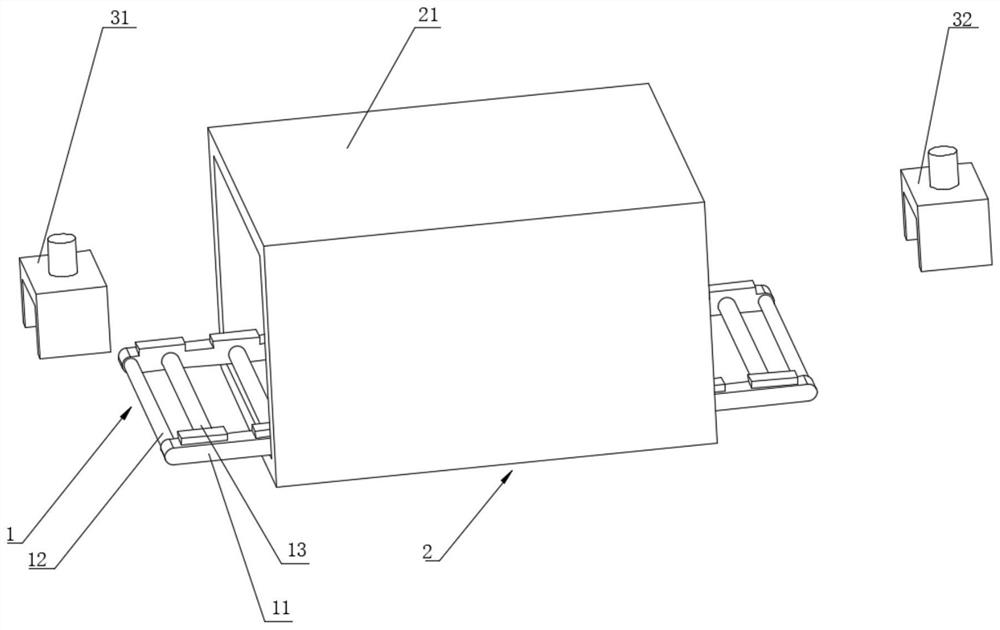

Laminated moulding device and laminated moulding method

InactiveCN101332696AGuaranteed parallelismReliable and uniform formingLamination plant layoutLamination ancillary operationsMechanical engineeringBall spline

The invention provides a lamination forming device and a lamination forming method for forming intermediate lamination products into lamination forming products with even thickness. The invention comprises a laminating apparatus (1) for laminating the lamination part(A1) and the laminated part(A2) to form the intermediate lamination product(A3), a plane press (2) for flat forming the surface by pressing the intermediate lamination product(A3) at the predetermined temperature, and a conveying unit (3). The plane press (2) comprises a fixed template (20), a movable template (21) and a translation unit (23) with a guiding movable template (32) making the movable template (21) move straightly in the vertical direction of the opposite surface. The translation unit (23) comprises multiple ball spline shafts (24), a corner part equipped on the movable template (21) and ball spline cylinders (25) respectively inserted by ball spline shafts (24).

Owner:MEIKI

Multilayer printed circuit board

InactiveCN101102642ALower resistanceGood electrical conductivityPrinted circuit detailsSemiconductor/solid-state device detailsEngineeringCopper

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20 . Due to this, it is possible to electronically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24 , it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

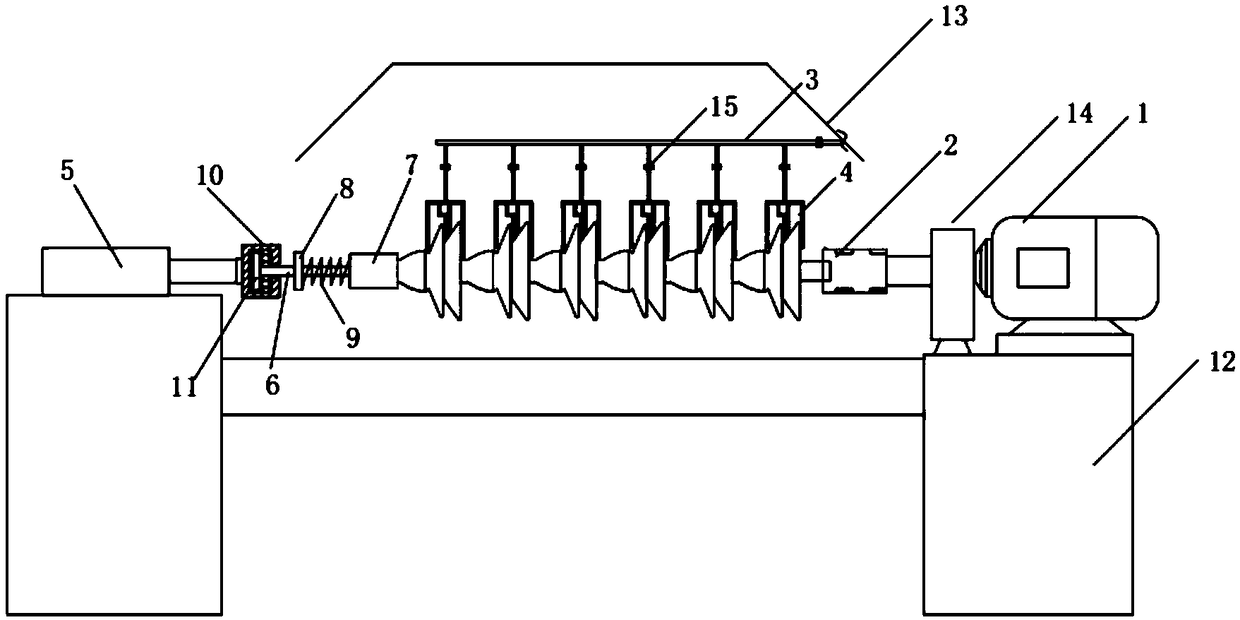

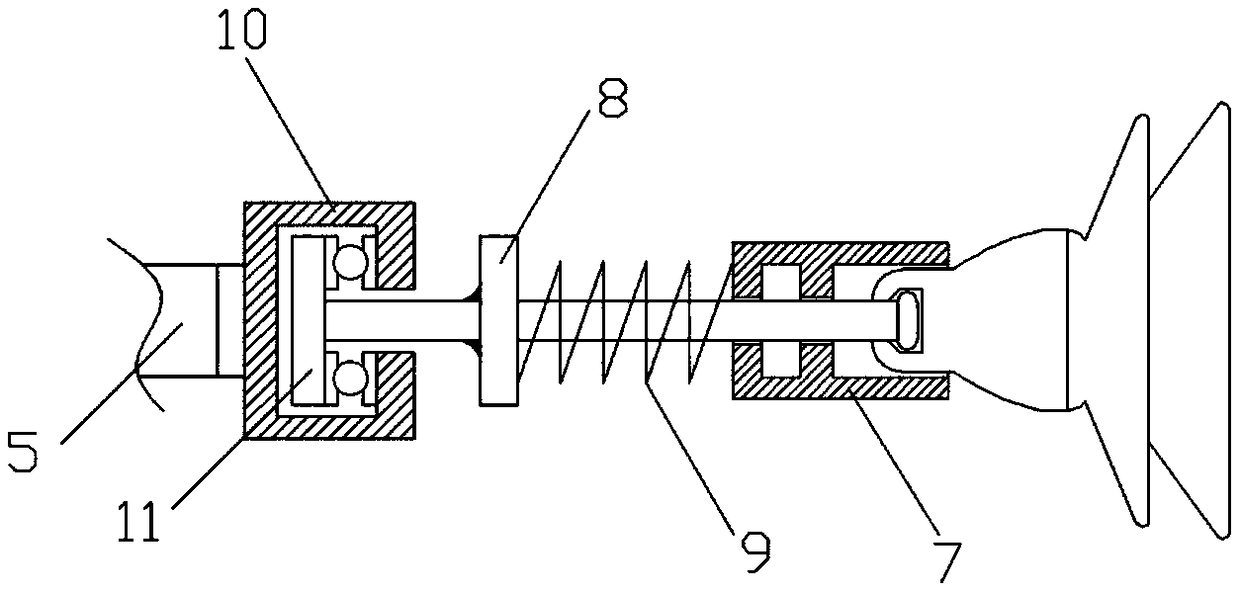

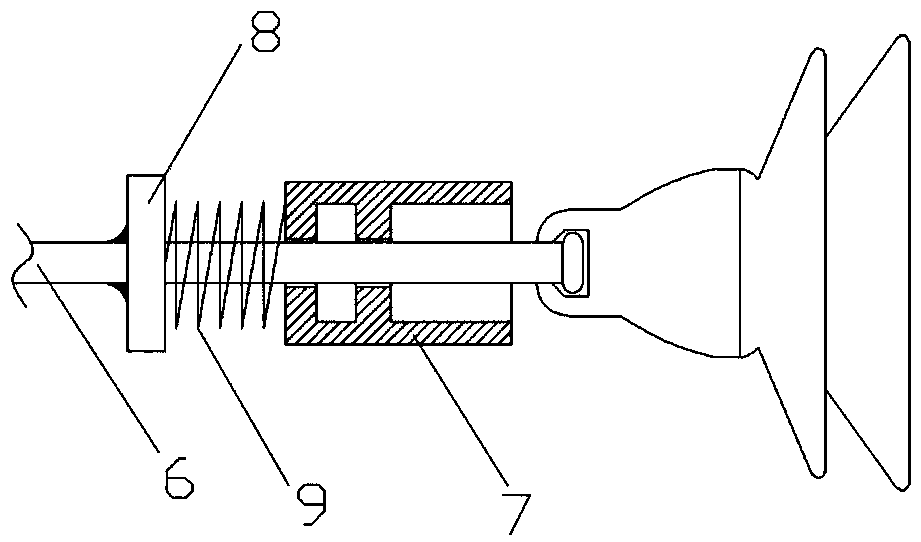

Board splicing machine

ActiveCN105109993APrevent rollingFlat thicknessWood veneer joiningConveyor partsEngineeringMechanical engineering

A board splicing machine comprises an alignment device which comprises an alignment platform, an alignment press plate and push plates, wherein the alignment press plate is disposed above and is parallel to the alignment platform, a gap is left between the alignment press plate and the alignment platform so as to form an alignment space, the height of the alignment space can be configured according to the thickness of strips, and the push plates can horizontally move inside the alignment space, thus to push the strips into the alignment space. According to the board splicing machine provided by the present invention, the height of the alignment space where the strips are aligned is limited, rolling of the strips during alignment is prevented, thickness smoothness of board materials after alignment is ensured, and the quality is stable.

Owner:廖述新

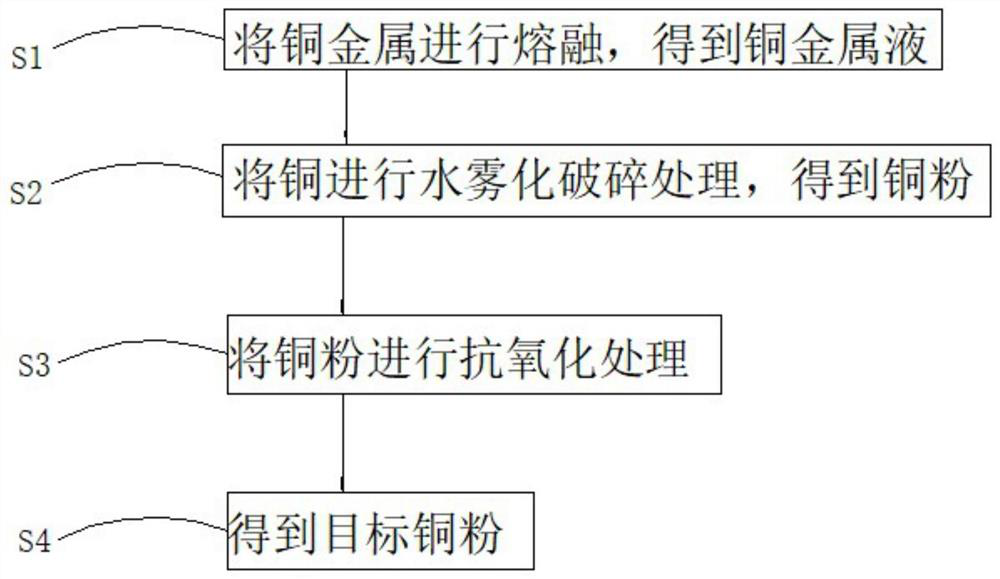

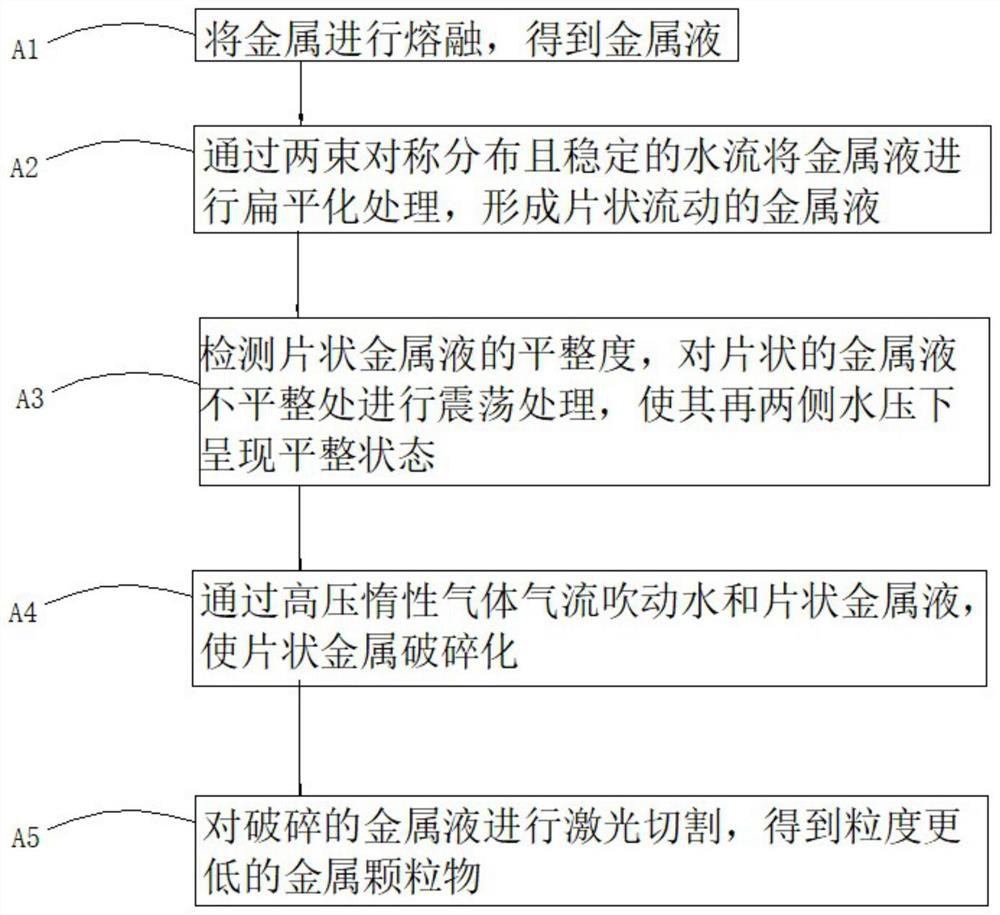

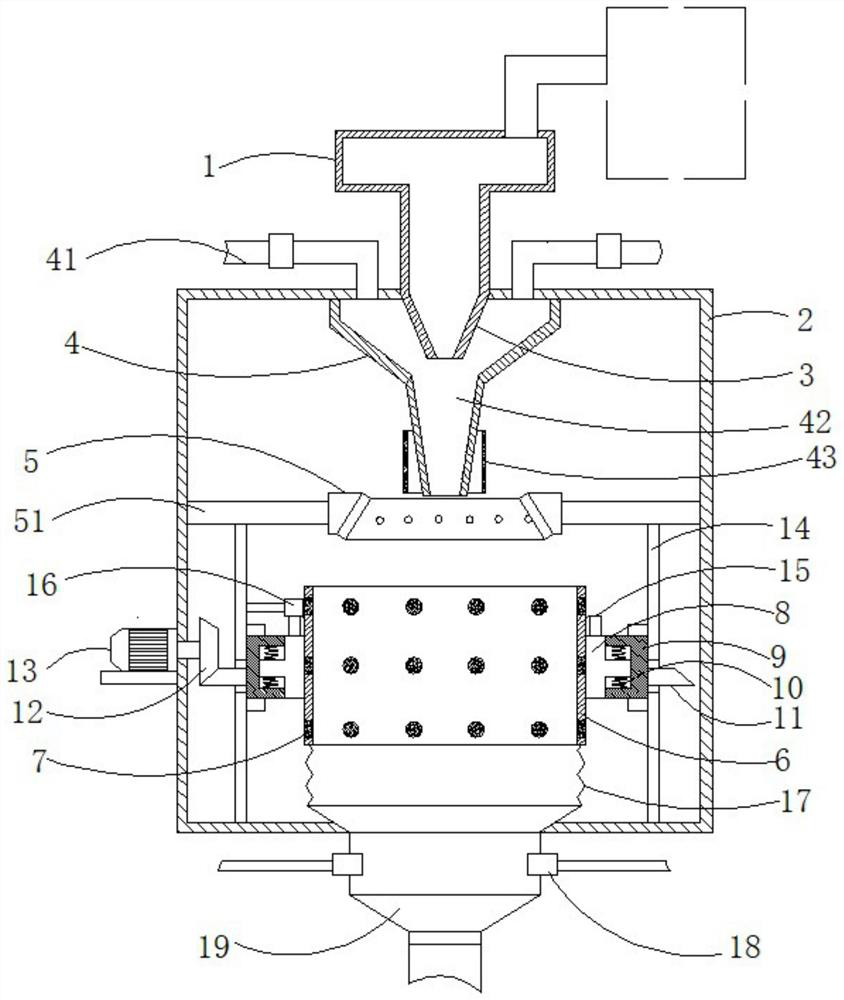

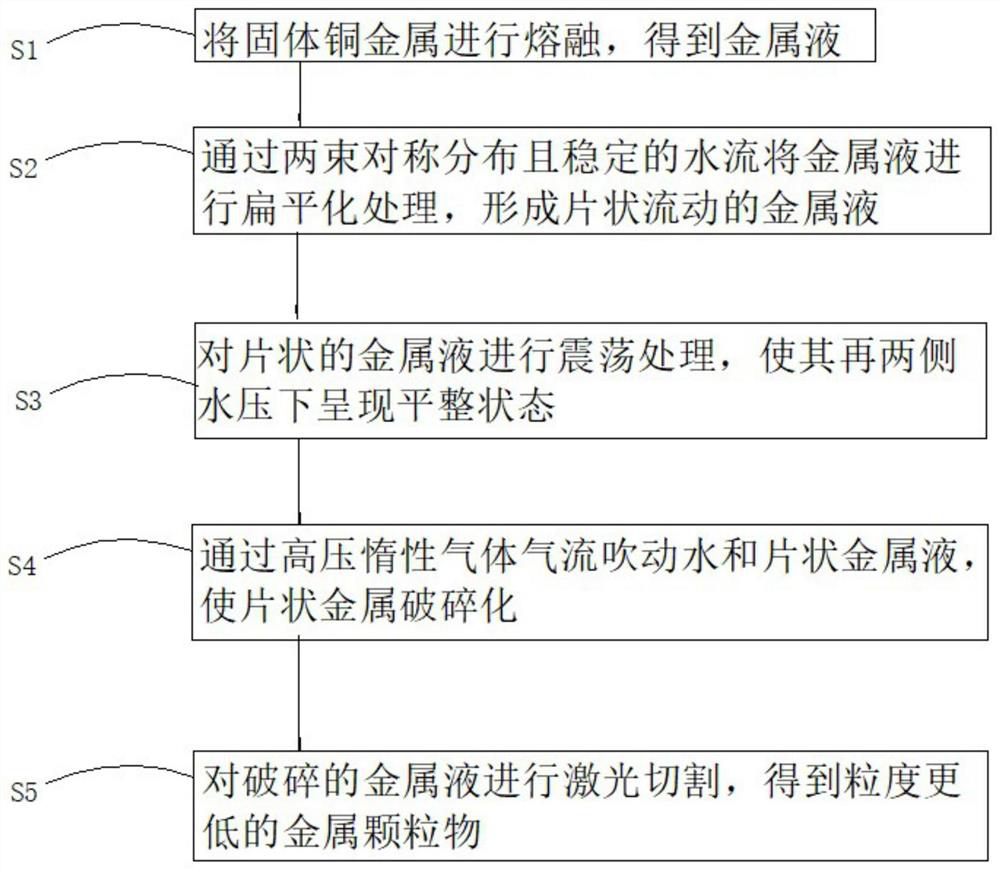

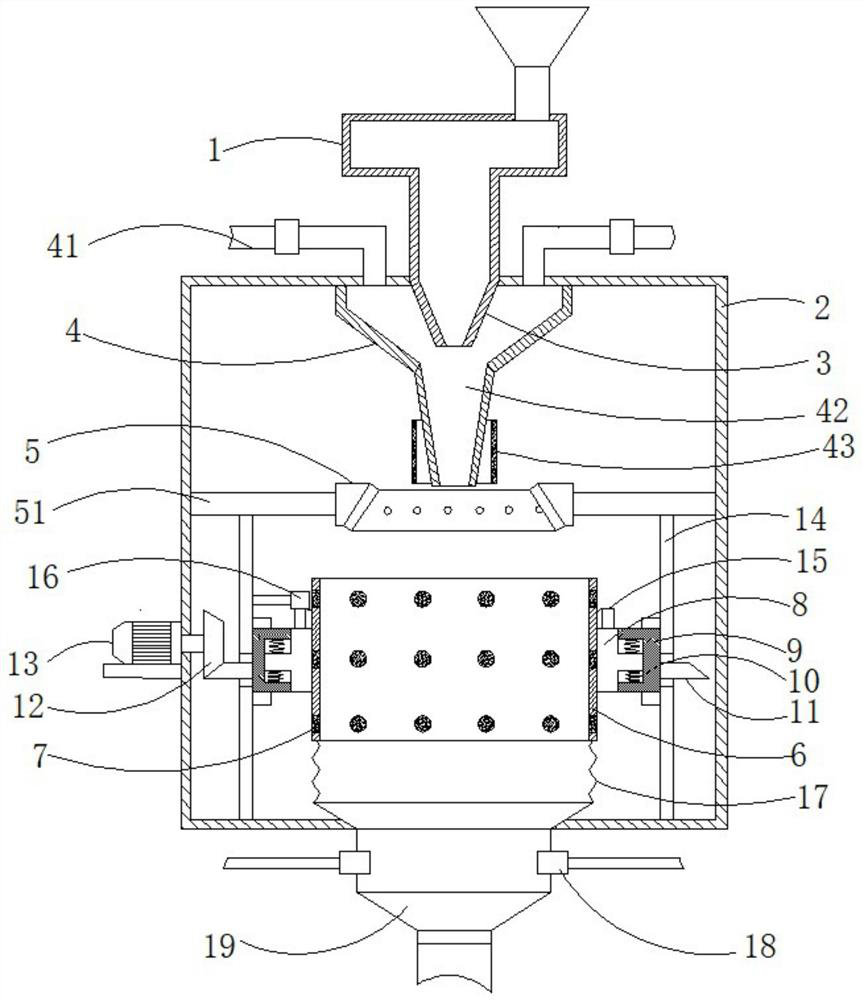

Preparation process for high-purity low-oxygen copper powder and water atomizing device thereof

The invention discloses a preparation process for high-purity low-oxygen copper powder and a water atomizing device thereof. The preparation process for copper powder comprises the following steps: melting solid copper metal to obtain copper molten metal; performing water atomizing crushing treatment on the copper to obtain copper powder; performing anti-oxidant treatment on the copper powder to obtain target copper powder, wherein the copper powder is subjected to water atomizing treatment through a water atomizing step: performing flattening treatment on the molten metal through two bunchesof symmetrical and stable water flow to form sheet-shaped flowing molten metal; performing oscillation treatment on the sheet-shaped flowing molten metal, and enabling the sheet-shaped molten metal tobe in a flat state under water pressure at the two sides, wherein the thickness is uniform; blowing water and the sheet-shaped molten metal through high-pressure inert-gas gas flow, and crushing sheet-shaped metal; and performing laser cutting on the crushed molten metal to obtain metal particles with smaller particle sizes. The water atomizing device is combined with gas atomizing advantage forcrushing and cutting after sheeting the molten metal, so that spherical powder with small adhesion, a smooth surface, high purity and low oxygen content is obtained.

Owner:湖南省天心博力科技有限公司

Composite flame-retardant paperboard and preparation method thereof

ActiveCN106848862AImprove safety warning effectLow costLayered product treatmentSynthetic resin layered productsSurface layerPaperboard

The invention discloses a composite flame-retardant paperboard and a preparation method thereof. The composite flame-retardant paperboard is characterized in that the structure sequentially comprises surface layers, secondary surface layers and a core part from exterior to center; the surface layers are 1-2 MP layers, the secondary surface layers are at least one CEM1 layer, the core part is at least one core layer, wherein each core layer is composed of 1-3 PP layers and 1-2 CEM1 layers. The composite flame-retardant paperboard has the very good tensile strength (133-140 MPa), vertical layer bending strength (257-267 MPa), relative electric mark index (larger than or equal to 400), arc resistance (124-128) and vertical layer electric strength (in normal oil, the pressure is quickly increased, and a 25-75-mm cylinder electrode is adopted), the combustibility is in a V-0 grade, and the property is good.

Owner:厦门弘诚复合材料有限公司

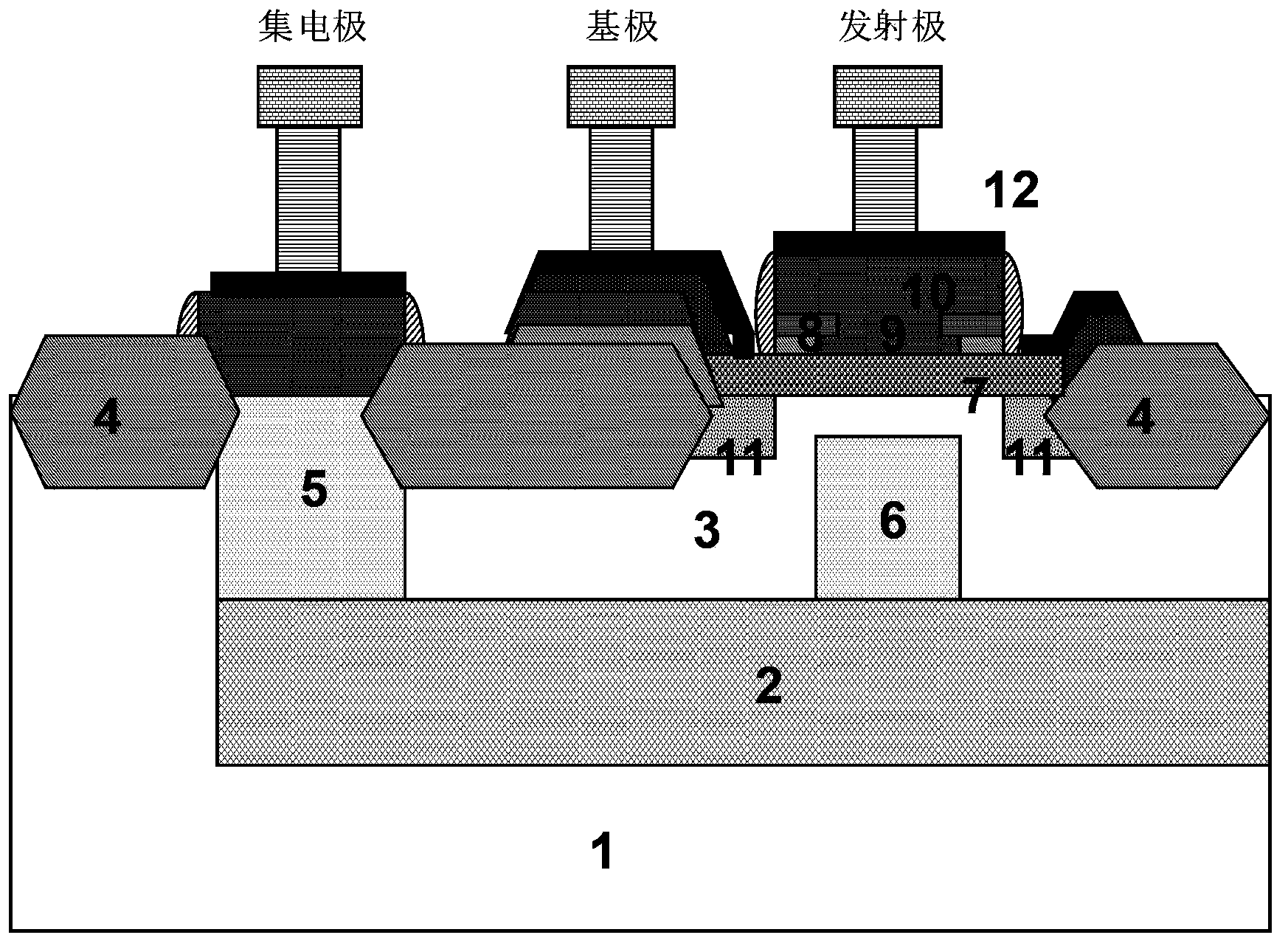

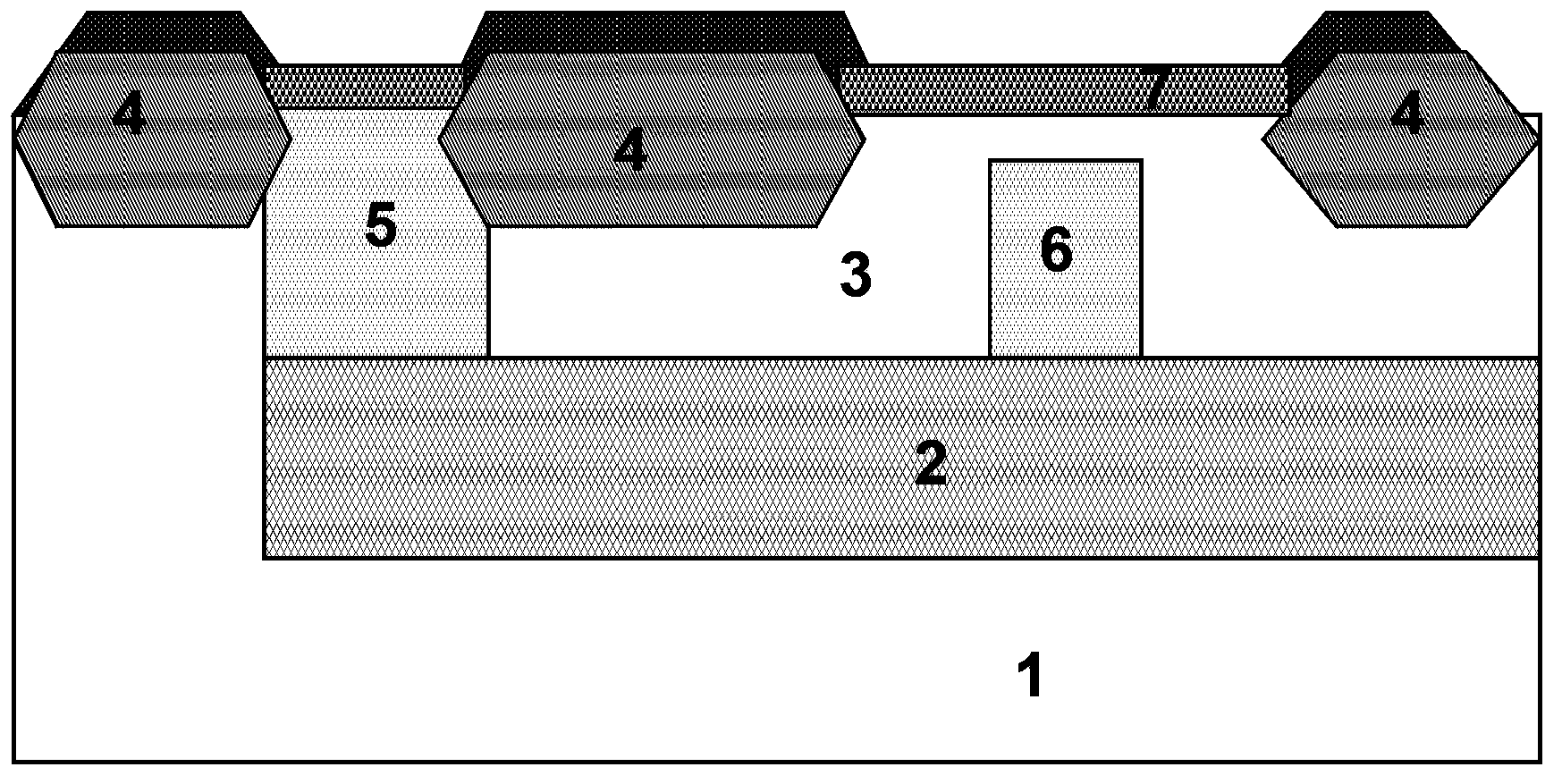

Manufacturing method of germanium-silicon heterojunction bipolar triode device

ActiveCN103456628AFlat thicknessLower resistanceSemiconductor/solid-state device manufacturingSurface cleaningHigh doses

The invention discloses a manufacturing method of a germanium-silicon heterojunction bipolar triode device. The method includes that a current collecting area is prepared by a low-doping N-type epitaxial process, a heavy N-type doped low-resistance buried layer passage is arranged at the bottom, and high-dose middle-energy N-type ions are injected in a current collecting electrode active area to form a current collecting electrode leading-out end; after an isolation area is formed, surface cleaning and growing of a germanium-silicon epitaxial layer of a thick buffering layer are performed, the germanium-silicon epitaxial layer outside a base area and an outer base area is defined by photoetching and removed by dry-etching; an emitting electrode window medium is deposited, an emitting electrode window and the whole current collecting electrode active area are opened by photoetching, dry-etching and wet-etching, N-type heavily-doped emitting electrode polysilicon is deposited, and an N-type emitting electrode-base electrode junction and a lower-resistance passage are formed. Polysilicon thickness of the outer base area is increased by adjusting thickness of the germanium-silicon buffering layer, so that resistance performance of the base area is guaranteed, process cost is lowered, and more stable technological process and higher product yield are acquired.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Double-side Z-shaped folding handle, carton/paper box including same, and preparation method thereof

The invention discloses a double-side Z-shaped folding handle comprising a handle belt and a substrate; two ends of the handle belt are folded in a Z-shape; bottom surfaces of two ends of the handle belt are fixed with the substrate; the invention also discloses a carton / paper box including the folding handle, and a preparation method thereof; the handle employs a double-side Z-shaped folding mode, and two sides of the folded handle belt are consistent in thickness and flat, thus preventing partial over pressuring; the handle belt is bonded with the substrate to form a whole structure, and the whole structure is bonded with the carton / paper box bonding with a liner, thus increasing force bearing area of the handle belt, and simplifying handle processing steps; in application, the high intensity substrate is bonded around the inner side of the position to which the handle of the carton / paper box is mounted, then die cutting is carried out; the handle and the carton / paper box are bonded through glue in liner positions, thus increasing force bearing area of the handle belt in a pulling process.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

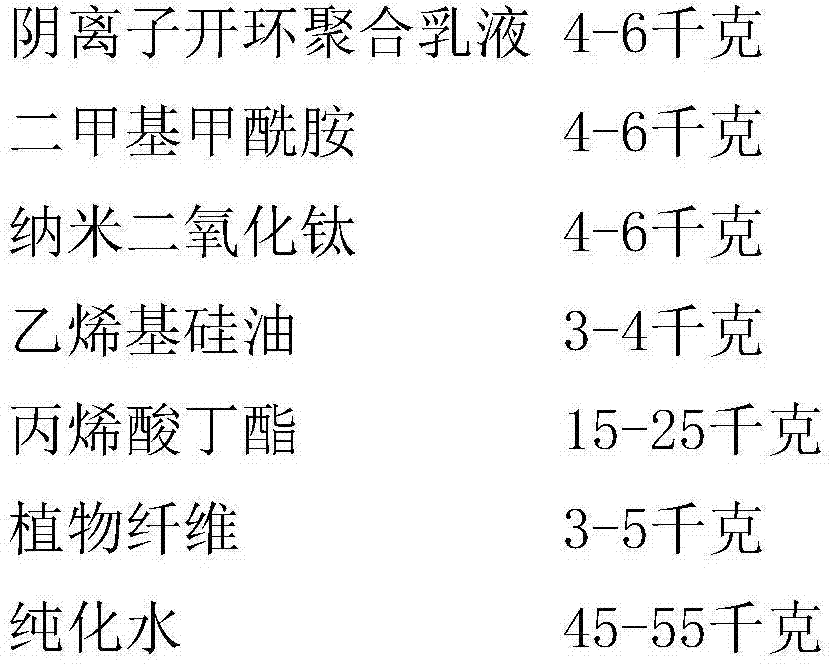

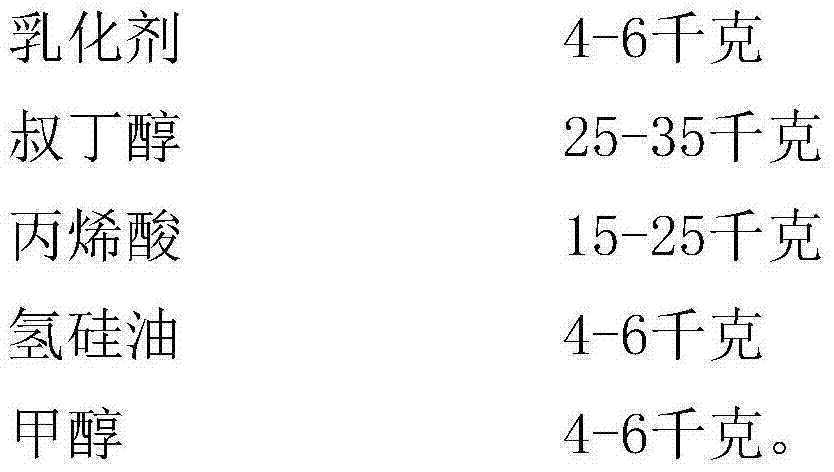

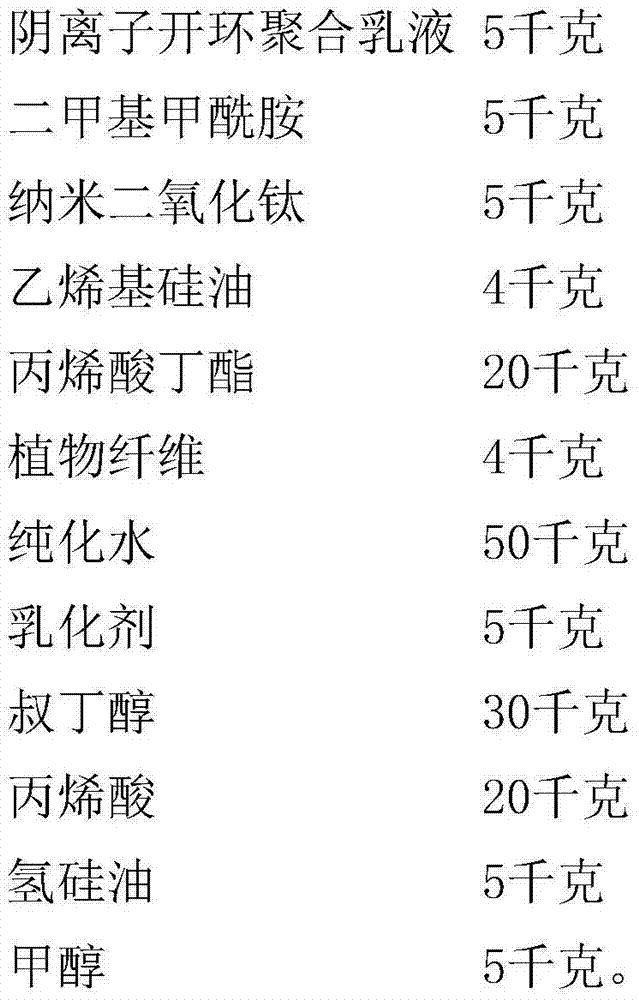

Silicon acrylic emulsion printing adhesive

The invention discloses a silicon acrylic emulsion printing adhesive, relating to the technical field of chemical engineering. The silicon acrylic emulsion printing adhesive is prepared by the following steps: (1) firstly, feeding purified water, tert-butyl alcohol and methanol into a reaction kettle for evenly stirring and mixing, heating to 50-60 DEG C to obtain a solution a for later use; (2) dissolving nano titanium dioxide, butyl acrylate, plant fibers, acrylic acid and anionic ring-opening polymerization emulsion into the solution a, fully stirring evenly, heating while stirring until the temperature achieves 80-90DEG C, and preserving heat for 2 hours to obtain a solution b for later use; (3) adding hydrogen silicon oil, an emulsifying agent and ethylene silicon oil into the solution b, and evenly stirring for 30minutes at the stirring speed being 3500r / min to obtain a solution c for later use; (4) controlling the temperature of the solution c to be 40-45DEG C, then dropwise adding dimethylformamide within 0.5 hour, and cooling to room temperature to obtain the solution d for later use; and (5) regulating the pH value of the solution d to be neutral through ammonium water, and discharging to obtain an adhesive. The silicon acrylic emulsion printing adhesive has multiple advantages of no environmental pollution, no hazard, complete chromatography, easy color matching, fresh color and the like, and can be widely applied in the printing and dyeing industry.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

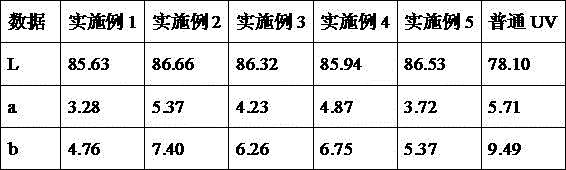

Transparent non-yellowing UV gloss oil and preparation method and application method thereof

ActiveCN106833108ASolve yellowingIncrease brightnessInksPrinting after-treatmentOligomerReactive diluent

The invention discloses transparent non-yellowing UV gloss oil and a preparation method and an application method thereof. The transparent non-yellowing UV gloss oil is prepared from the following components: a photoinitiator, a reactive diluent, a surfactant, ultramarine printing ink, titanium dioxide and an oligomer according to the ratios in parts by weight of (2-3):(35-40):(1-2):(0.1-0.2):(5-8):(47-55). From the structure of the transparent non-yellowing UV gloss oil of the present invention, the problem of yellowing of the UV gloss oil is solved from a physical standpoint through the actions of the ultramarine printing ink and the titanium dioxide in the UV gloss oil.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

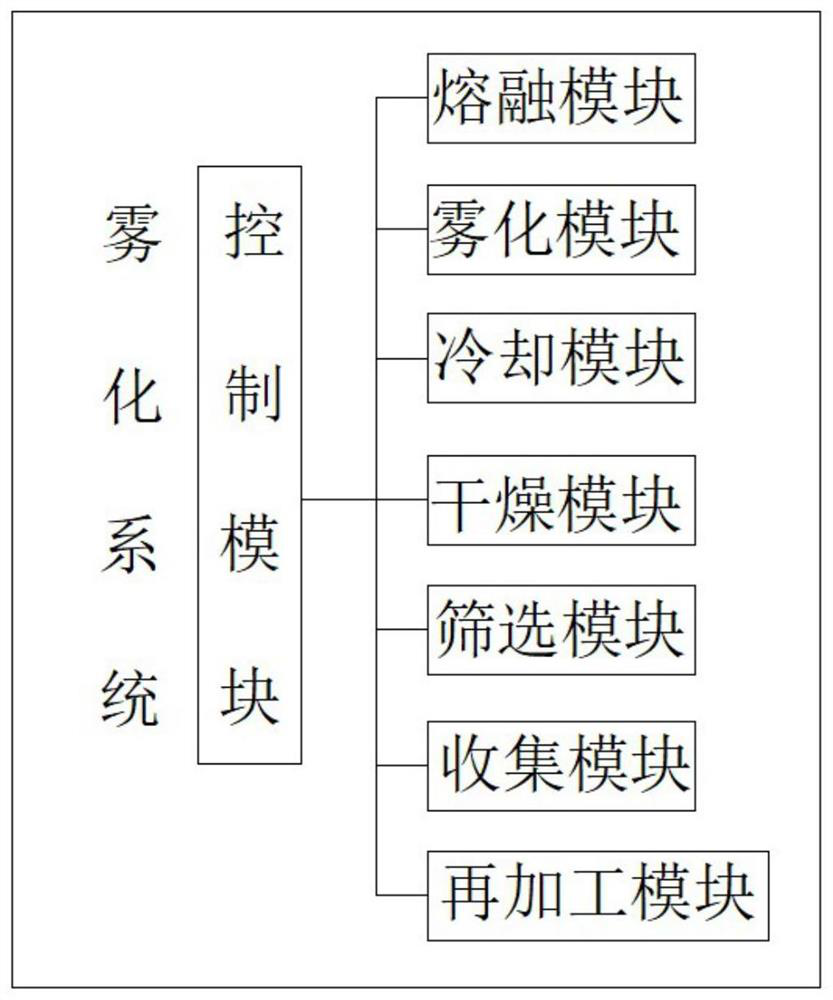

Copper powder water atomization system and atomization structure thereof

The invention discloses a copper powder water atomization system and an atomization structure thereof. The copper powder water atomization system comprises a molten module, a water atomization module,a cooling module, a drying module, a screening module, a collecting module and a reprocessing module. The atomization structure of the water atomization module carries out following water atomizationtreatment on copper powder, two beams of symmetrically-distributed stable water flows carry out flattening treatment on molten metal, molten metal flowing a piece shape is formed, the piece-shaped molten metal is subjected to shock treatment, the piece-shaped molten metal is in a flat state under the water pressure of the two sides, the thickness is uniform, through high-pressure inert gas flow,water and the piece-shaped molten metal are blown to enable the piece-shaped metal to be broken, the broken molten metal is subjected to laser cutting, metal particles with the lower granularity is obtained, the copper powder water atomization system is combined with gas atomization advantages, the molten metal is subjected to breaking cutting after laminarization, and spherical powder with the small conglutination and the smooth surface can be obtained.

Owner:湖南省天心博力科技有限公司

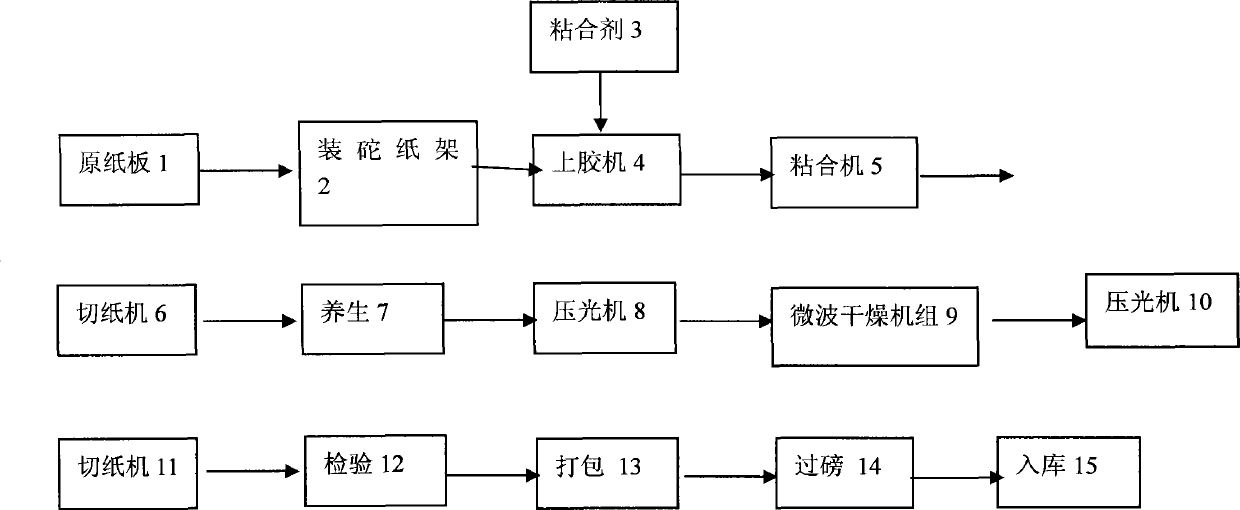

Production process of elastic paperboard

InactiveCN104179061AIncrease elastic strengthFlat thicknessMechanical working/deformationCalendersCardboardMicrowave

The invention relates to a production process of an elastic paperboard. Raw paperboards are selected and used, the water content thereof is controlled to be 8-9 percent, the raw paperboards are placed on a paper stacking rack, the layers of the raw paperboards are calculated according to the required thickness of the elastic paperboard, industrial adhesive is selected and used, the raw paperboards are uniformly coated with the adhesive on a gluing machine, the glued raw paperboards are laminated through a bonding machine and then are transversely cut into single paper in a paper cutting machine, the cut paperboards are manually stacked and sealed for curing and then are delivered to a calendering machine for calendering, the working pressure of the calendering machine is 40-50Mpa, the calendered products enter a microwave drying unit for drying, the running speed for drying is determined according to the thickness of the elastic paperboards, the drying temperature is 70-80 DEG C, the water content of the dried elastic paperboards is controlled to be 6-8 percent, then the dried elastic paperboards enter the calendering machine for calendering, the density is controlled to be 1.19-1.24g / cm<3>, the elastic paperboards are cut through the cutting machine according to required size of customers and then are inspected, and the products which are inspected as acceptable are packaged, weighted and then warehoused. The elastic paperboard produced by adopting the production process has the advantages that the surface is flat, the thickness is uniform, the thickness deviation of the same board is extremely small, the density is high, the elastic strength is high and the use effect is good.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

A kind of fabrication method of electric injection gan-based resonator

ActiveCN103325894BHigh Q valueGood electrical and optical propertiesLaser optical resonator constructionSemiconductor devicesCurrent limitingResonant cavity

The invention discloses a manufacturing method of an electrically injected GaN-based resonant cavity, which relates to a GaN-based resonant cavity luminescent device. The method comprises the steps of growing a p type current expanding layer ITO on a GaN-based epitaxial wafer with a sapphire substrate, sequentially carrying out etching, polishing and ICP (Inductively Coupled Plasma) etching on the surface of the p type current expanding layer ITO to form a n type table facet, manufacturing a current limiting layer, a n type metal contact layer, a p type metal contact layer and a top dielectric film DBR (Distributed Bragg Reflector), bonding the components with a temporary substrate, removing the sapphire substrate by a laser lift-off technology, grinding and polishing the GaN surface subjected to laser lift-off, growing a bottom dielectric film DBR on the polished GaN surface, bonding the obtained component with a permanent substrate, and removing the temporary substrate, thus completing the manufacturing of the electrically injected GaN-based resonant cavity. The high-performance GaN-based resonant cavity is realized by adopting the two high-quality dielectric film DBRs and the low-loss p type current expanding layer ITO.

Owner:XIAMEN UNIV

Metal chromium waterborne mirror-like silver pigment and manufacturing method thereof

InactiveCN109234693AOvercoming corrosion resistanceParameters are stable and easy to controlVacuum evaporation coatingSputtering coatingSolventNanometre

The invention relates to a metal chromium waterborne mirror-like silver pigment and a manufacturing method thereof. The pigment contains the following components in percentage by weight: 10%-30% of metal chromium slice particles, 70%-88% of a dispersing agent and 0-2% of an aid. The manufacturing method comprises the following steps: (1) coating a plastic film base material with a resin layer witha thickness of 1-1.2 microns; (2) depositing metal chromium on the surface of the resin layer by virtue of a continuous winding type magnetron sputtering method, so as to form a nano-chromium film; and (3) crushing a mixed solution containing a solvent, resin and a fine chromium slice, filtering, adding the aid, adjusting the sold content, so as to obtain the metal chromium waterborne mirror-likesilver pigment containing the metal chromium slice particles, the dispersing agent and the aid. According to the pigment, chromium is taken as metal chromium mirror-like silver of the material, the same mirror surface effect is preserved, and meanwhile, the problems that existing mirror surface aluminum cannot resist water and corrosion are solved, so that the application field of the mirror-likesilver pigment is extended from a waterborne system to a UV system, and the pigment is accordant with the environment-friendly demands.

Owner:深圳市崯彩特殊金属颜料有限公司

Compression mold with overflow holes and fitting and preparation scheme thereof

PendingCN108973164AReduce movementReduce the problem of tensile strength dropFibrous compositesLiquid based

The invention discloses a compression mold with overflow holes and a fitting and a preparation scheme thereof. The compression mold comprises an upper mold, a lower mold and a fitting part, wherein aplurality of uniformly distributed overflow holes are formed in the inner walls of the upper mold and the lower mold to the outside of the mold, and a fixed fitting is laid on the inner wall of the mold; the fitting comprises a metal wire layer and a mixed fabric layer. The compression mold is used for compressing a fiber composite material, so that the fiber density ratio is improved; a laminateof a fiber cloth applied or pre-impregnated with a liquid base material is compressed, so that the excess liquid is reduced in the laminate, and thus the compressed object liquid uniformly overflows from the compression surface, and the fiber hardly moves during the compressing process, thereby solving the problems of tensile strength drop, fiber damage, uneven thickness, and structural change caused by the movement of fiber in the prior art.

Owner:HANGZHOU YOUKAI BOAT CO LTD

Production technology of hot-melt waterproof roll

InactiveCN109735124AHigh tensile strengthImprove aging resistanceBuilding insulationsAging resistanceHot melt

The invention discloses a production technology of a hot-melt waterproof roll. The production technology includes the steps of raw material preparation, mixing, discharging, dip-coating, attaching, cooling and rolling. The production technology has the advantages that tensile strength and aging resistance are improved, foam generation is inhibited, and the produced waterproof roll is smoother in thickness.

Owner:临沂市临河防水材料有限公司

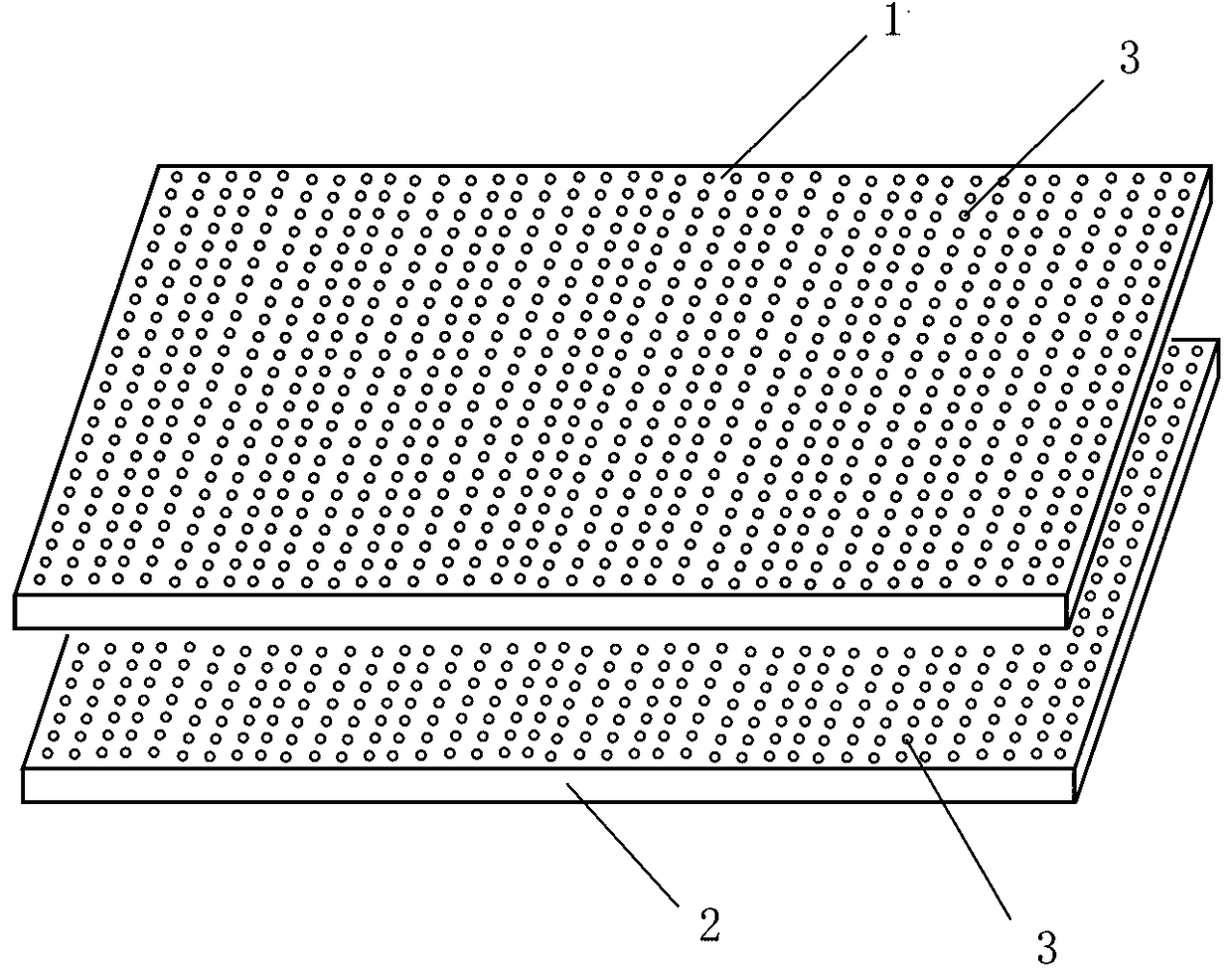

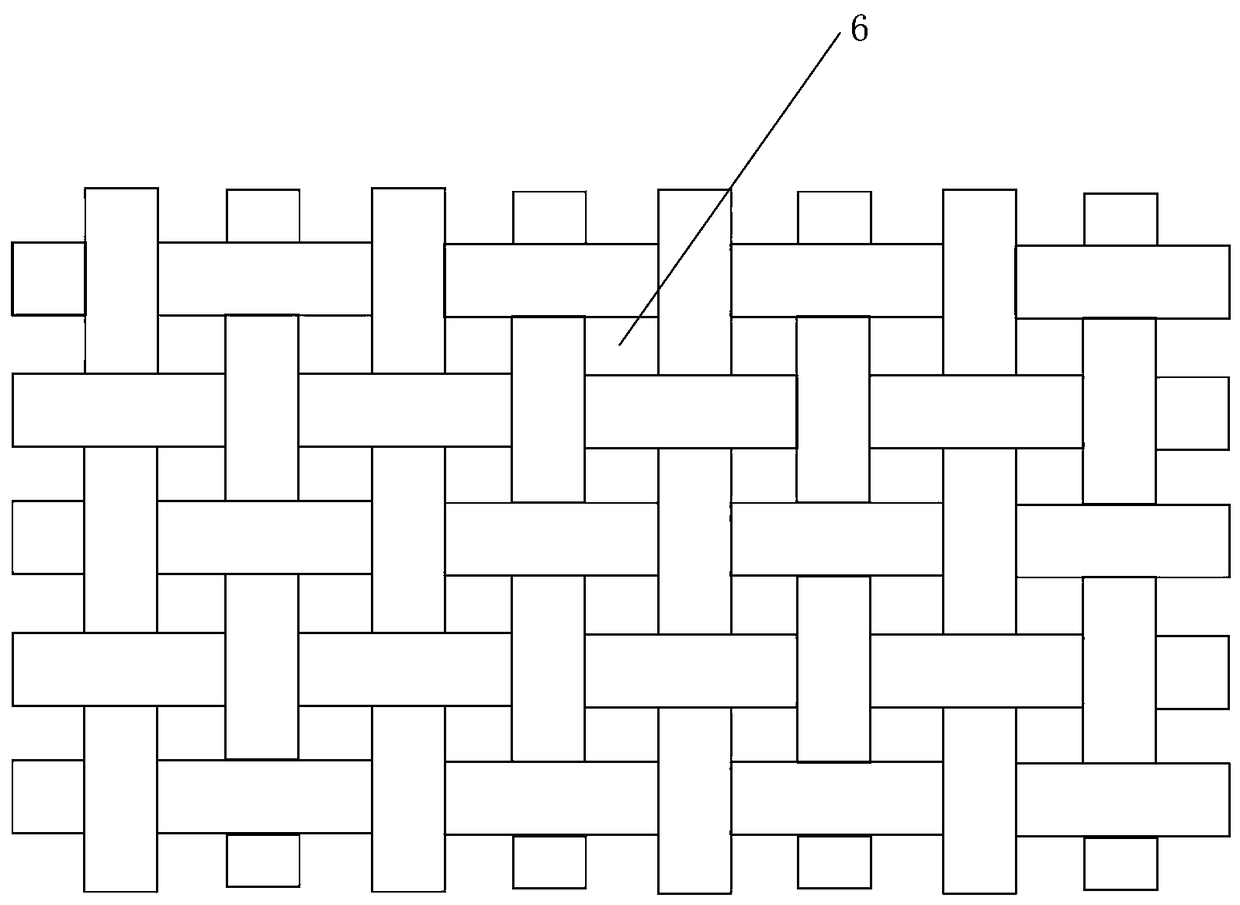

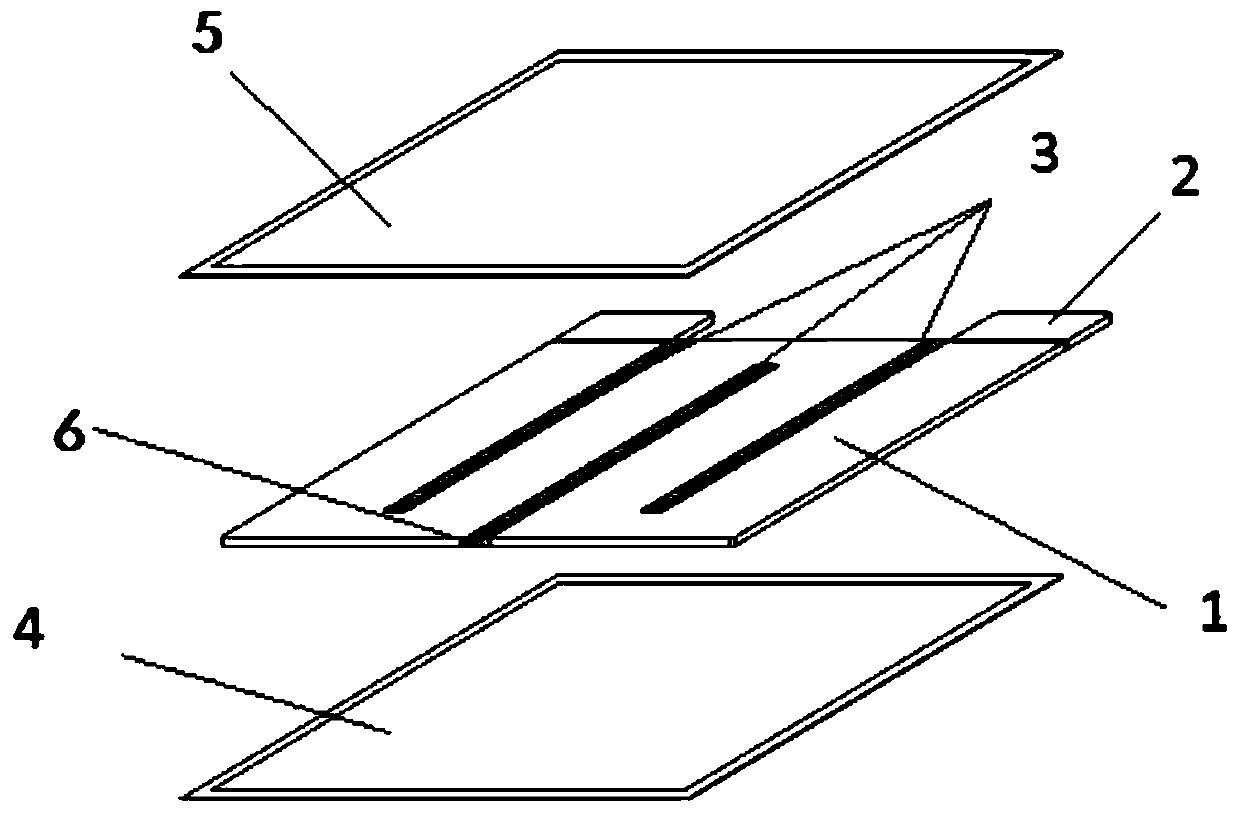

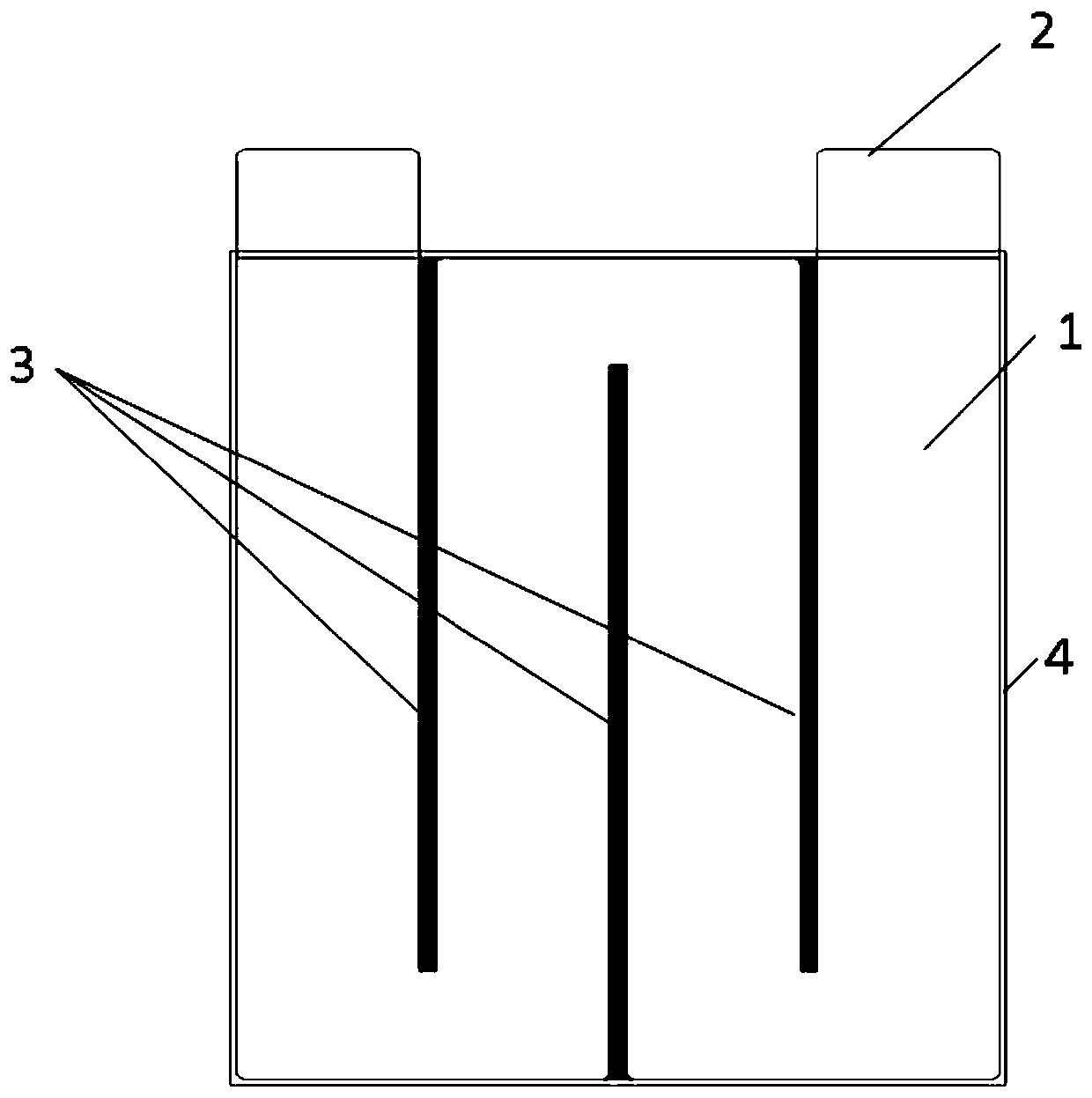

Planar heating film for lithium ion power battery and lithium ion power battery

A planar heating film for a lithium ion power battery and the lithium ion power battery are provided. The planar heating film comprises an insulating isolation film which is internally provided with aplacing space, a heating element which comprises a heating element body arranged in the placing space and provided with a gap inside and a pair of heating tabs extending out of the placing space, andan insulating filling layer which is arranged in the gap of the heating element body. According to the planar heating film for a lithium ion power battery, the gap of the heating element body is filled with the insulating filling layer, so that the heating film is consistent in thickness and smooth, the heating film can be integrally compounded with a first layer of insulating isolation film anda second layer of insulating isolation film, the risk of battery cell safety problem caused by concave-convex parts of a heating sheet can be eliminated, the bonding strength of the insulating film isimproved, and the mechanical strength of the heating sheet is improved.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

The construction method of applying waterproof paint before the final setting of cement

A construction method of applying waterproof coatings before the cement finally condensates. This method includes the following steps: wetting with water on the base surface, then scrape a cement plasma layer or cement mortar layer, wait for the cement plasma layer or the layer of the cement plasma layer or orAfter the surface of the cement mortar layer is dry, scrape the waterproof coating to form a waterproof layer; or it can directly scrape the waterproof coating before the cement plasma layer or the cement mortar layer is finally condensed.The waterproof coating construction method described by the present invention has a reaction effect, solving problems such as the adhesion of the coating layer and the grassroots or protective layer, the slow drying speed of the water -based coating, and the high requirements of the base surface.The technical characteristics of the concrete basis or cement mortar base surface can be solved during large -scale construction. The problem that can also be constructed or construction can be constructed. The coatings can form a sealing adhesive layer to solve the problem of waterproof coating.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

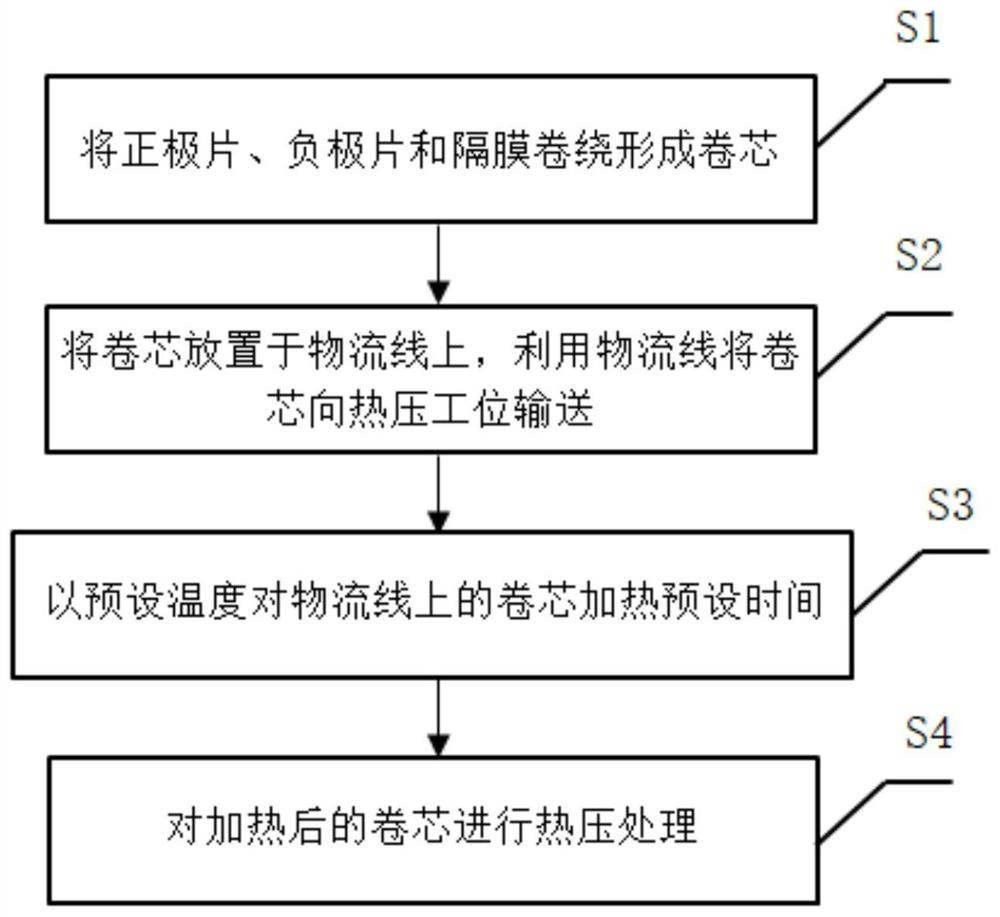

Hot-pressing process and hot-pressing device

InactiveCN111769335AFlat thicknessIncrease internal temperatureAssembling battery machinesFinal product manufactureCell fabricationHot press

The invention relates to the technical field of battery manufacturing, and discloses a hot-pressing process and a hot-pressing device. The hot-pressing process comprises the following steps of: winding a positive plate, a negative plate and a diaphragm to form a roll core; placing the roll core on a logistics line, and conveying the roll core to a hot-pressing station through the logistics line; heating the roll core on the logistics line for a preset time at a preset temperature; and carrying out hot pressing treatment on the heated roll core. By means of the technical schemes of the invention, the hot pressing process can shorten the hot pressing time, promote uniform stress distribution in the roll core and reduce wrinkles in the roll core.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD +1

Painting method of solid wood door and window

PendingCN111299111AImprove protectionUniform thicknessPretreated surfacesCoatingsSolid woodPolishing

The invention discloses a painting method of a solid wood door and window. The method comprises the following steps of S1, solid wood door and window pretreatment; S2, solid wood door and window grinding and cleaning; S3, primer coating of the solid wood door and window; S4, primary painting and airing; S5, secondary painting and airing; S6, third-time painting and airing; and S7, polishing of thesolid wood door and window. Through a paint layer brushed by the method, a paint film can be effectively prevented from rolling up and cracking, the paint protection effect is ensured, the paint layer is uniform in thickness, and flat, the thickness can be ensured, the damage by worms can be avoided, the paint layer can well isolate contact of the wood door and window and air, wood oxidization can be avoided, and the door and window can be protected for a long time.

Owner:重庆市豪迈家具有限公司

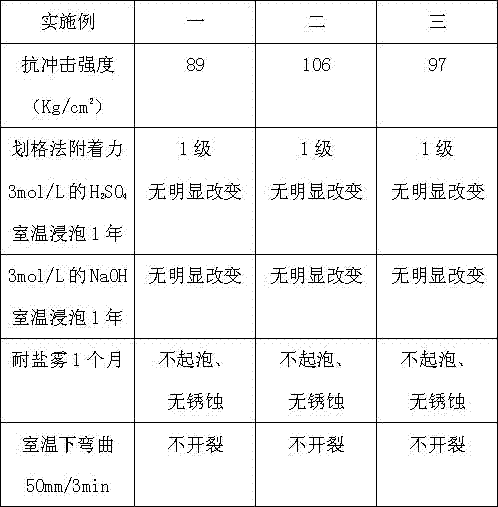

Process method for automobile bottom plate powder coating

InactiveCN107418386AEasy to operateImprove protectionPretreated surfacesAnti-corrosive paintsMelt extrusionElectric field

The invention discloses a process method for automobile bottom plate powder coating. The process method comprises the following steps: preparing raw materials, uniformly mixing the raw materials, performing melting extrusion by using a double-screw extruder, and finally crushing and grinding so as to obtain a powder coating; performing sand blasting roughening on an automobile bottom plate, performing ejection degreasing cleaning, performing hot water cleaning treatment, and performing drying treatment; preheating the pretreated automobile bottom plate, and performing powder coating operation on the surface of the preheated automobile bottom plate by using an electrostatic spray gun in an electric field environment; and performing high-temperature curing on the coated automobile bottom plate, cooling, performing quality inspection, and packaging after qualification, thereby obtaining a coated automobile bottom plate. The process method disclosed by the invention is simple to operate, mild in curing condition and short in curing time, and an obtained coating film has good properties of corrosion resistance, rusting resistance, collision prevention, noise prevention, wearing resistance, impact resistance and the like, is high in strength, good in dispersibility and good in adhesion property, plays a good protection role on an automobile bottom plate, is capable of effectively prolonging the service life of the automobile bottom plate, and is worthy of popularization.

Owner:ANHUI TIANYU AUTO PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com