Planar heating film for lithium ion power battery and lithium ion power battery

A power battery and heating film technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of increasing the volume of the heating film battery module, reducing the energy density of the battery module, etc., so as to eliminate the safety problem of the battery cell. Risk, uniform thickness, and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

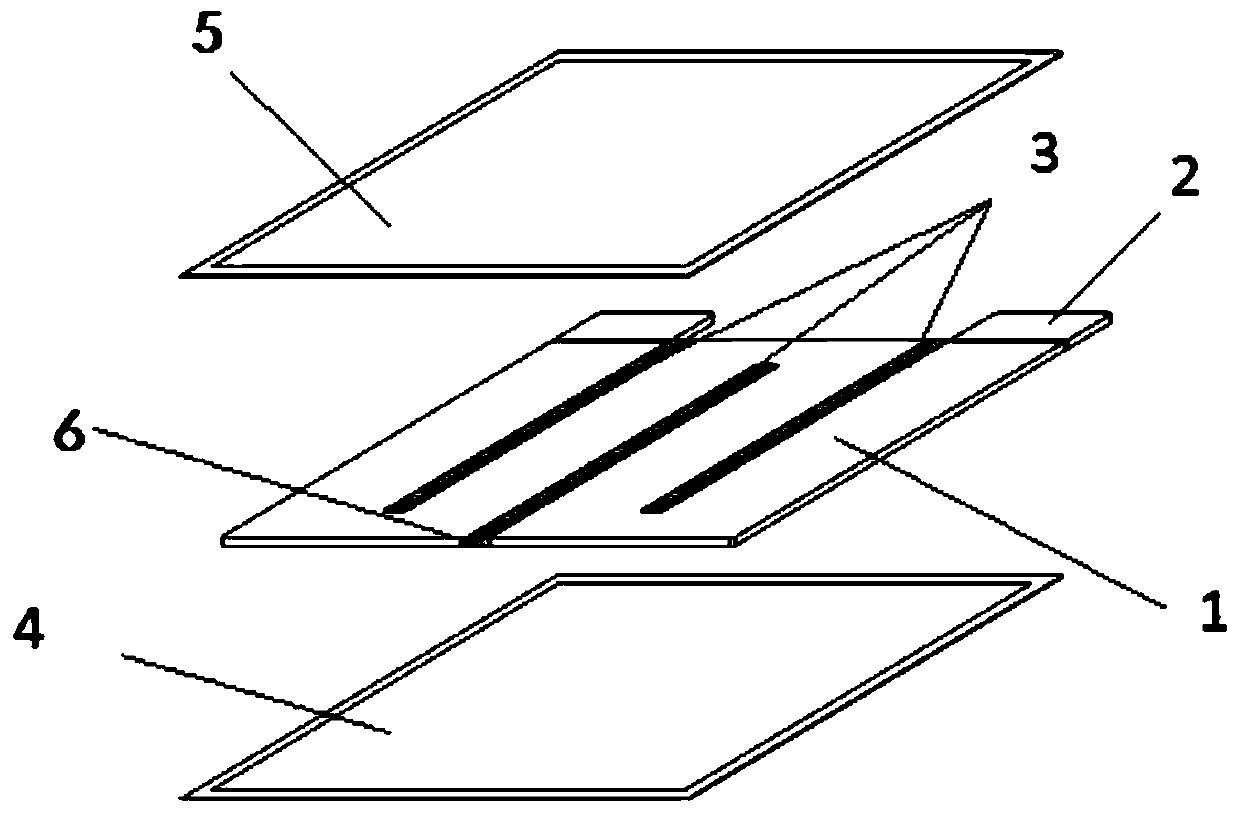

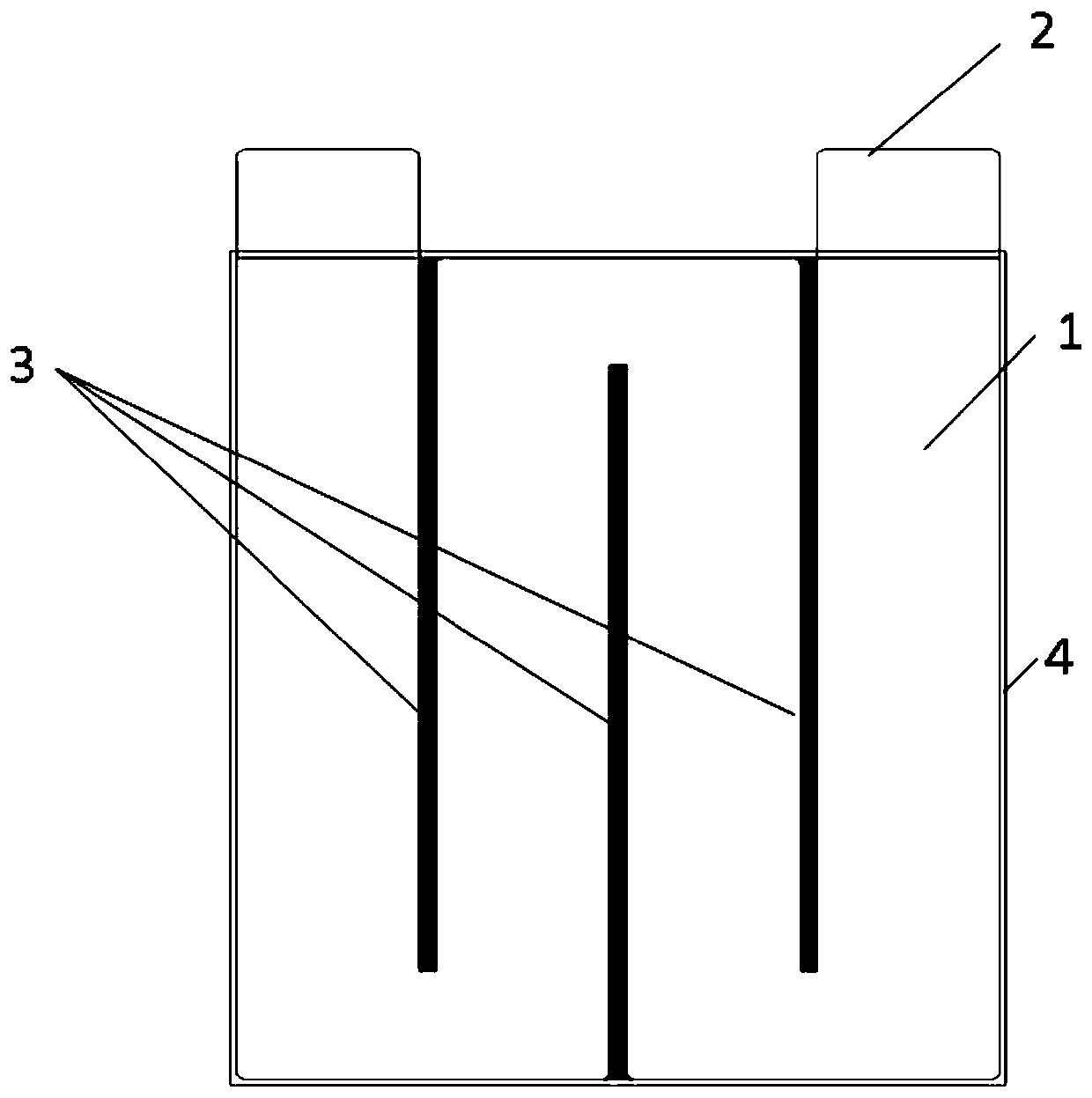

[0055] like Figure 1 to Figure 2 As shown, the invention provides a kind of planar heating film for lithium-ion power battery, comprising:

[0056] Insulation isolation film, with a space inside the insulation isolation film;

[0057] The heating body, the heating body includes a heating body 1 and a pair of heating tabs 2, the heating body 1 is set in the placement space, the pair of heating tabs 2 protrude to the outside of the placement space, and there is a gap 6 inside the heating body 1;

[0058] The insulating filling layer 3 is arranged in the gap 6 of the heating body 1 .

[0059] In this embodiment, the heating body includes a heating body 1 and a pair of heating tabs 2. The heating body 1 is a plane S-shaped or U-shaped, thereby forming a gap 6 communicating with the outside in the heating body 1. The heating tabs 2 are used For electrical connection with the outside, the insulating isolation film is wrapped on the surface of the heating body 1 to form a sheet-sh...

Embodiment 2

[0072] The difference between the planar heating film for a lithium-ion power battery according to this embodiment and that of Embodiment 1 is that

[0073] In this embodiment, both the first insulating isolation film 4 and the second insulating isolation film 5 are made of modified polypropylene film.

[0074] Both the first insulating isolation film 4 and the second insulating isolation film 5 are made of a layer of film material.

[0075] The second insulating and isolating film 5 is made of a modified polypropylene film that can transmit ultraviolet rays.

[0076] A kind of manufacturing method of using UV glue as the plane heating film of insulating filling layer 3 is as follows:

[0077] Attach the first layer of insulating isolation film to the bottom of the heating body 1, inject the liquid insulating filling layer 3 material into the gap of the heating body 1 in a horizontal state, and ensure that the liquid level of the insulating filling layer 3 material is not low...

Embodiment 3

[0079] The difference between the planar heating film for a lithium-ion power battery according to this embodiment and that of Embodiment 1 is that

[0080] In this embodiment, the insulating filling layer 3 is made of polypropylene.

[0081] The manufacture method of the planar heating film using polypropylene material as the insulating filling layer 3 is as follows:

[0082] Fix the heating body 1 in the injection mold, keep the same distance between the two side panels of the mold and the front and back sides of the heating body 1, inject the insulating filling layer 3 material into the mold, fill the gap 6 of the heating body 1, and solidify and demould ; The first insulating isolation film 4 and the second insulating isolation film 5 are attached and placed on both sides of the heating body 1, and packaged by hot pressing, so that the first insulating isolation film 4 and the second insulating isolation film 5 are hermetically connected to form Flat heating film as a who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com