Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Improve creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

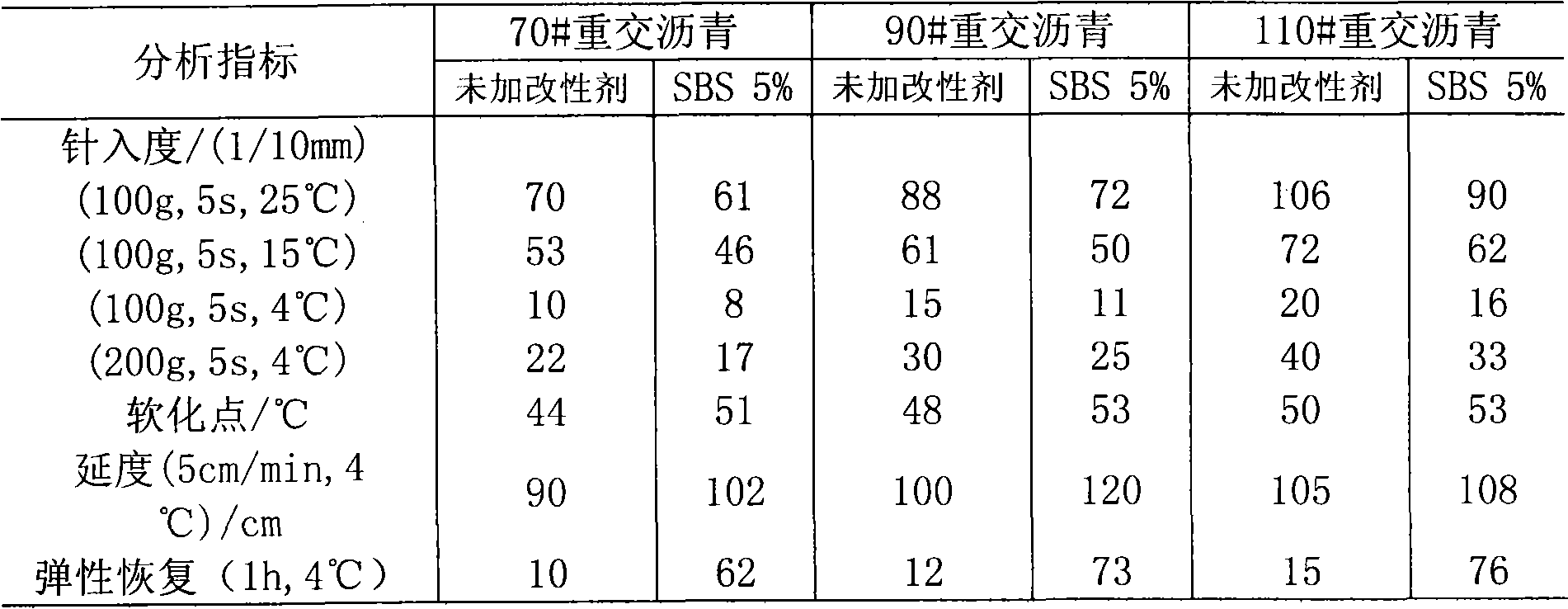

Preparation method of star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt and production method of waterproof coiled material

ActiveCN102220023AGood high and low temperature resistanceImprove stabilityBuilding insulationsBasementAdhesive

The invention provides star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt, which is a composition composed of asphalt, swelling star-shaped SBS, filler and aids and solves the problem that star-shaped SBS used as an asphalt modifier is difficult to process. The production method of the star-shaped SBS-modified asphalt involves the following steps: adding star-shaped SBS swelled by a non-polar solvent to asphalt, modifying at the temperature of 180-210 DEG C for 50-150 minutes by a colloid mill or a powerful high-speed shearing stirrer, adding the filler and aids and uniformly stirring so as to form the uniform and stable modified asphalt. The modified asphalt can be made into a waterproof coiled material with excellent performance as well as a waterproof and leak-proof adhesive used for building roofs, basements, expressways, sealants, tunnels or water conservancy facilities. The modified asphalt has the characteristics of better compatibility with asphalt and better high-temperature and low-temperature resistance, compared with existing SBS modified asphalt.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Preparation and coating method of anti-corrosive anti-scale coating material

PendingCN105199497AImprove mechanical propertiesLower surface energyPretreated surfacesAnti-corrosive paintsMechanical propertyPolytetrafluoroethylene

The invention discloses a preparation and coating method of an anti-corrosive anti-scale coating material. The method comprises the steps that polytef emulsion is mixed with same amount of absolute ethyl alcohol, and stirred liquid is added into mixed sol obtained by mixing prepared graphene dispersion liquid and titanium dioxide colloid; the coating material is obtained after high-speed stirring is conducted. A metal substrate is coated with the coating material, and a composite nano coating modified metal sheet is obtained after high-temperature sintering, cooling, temperature conservation and drying are sequentially conducted. The preparation and coating method of the anti-corrosive anti-scale coating material has the advantages that the coating material is used for corrosion and scaling prevention of the surface of metal heat exchange equipment, and the defects that a pure polytef coating is prone to creep deformation, poor in heat conductivity and poor in abrasive resistance are significantly improved. By means of introduction of graphene and titanium dioxide composite nano materials, the surface energy of polytef is decreased, the cold flow property and the heat transfer property of the polytef are significantly improved, the anti-fouling performance of the coating is improved, the abrasion resistance of the polytef is significantly improved, the mechanical properties of a composite coating are enhanced, the service life of the coating is prolonged, and the coating material is widely applied to various water-medium heat-exchange equipment.

Owner:DUNAN TIANJIN ENERGY SAVING SYST

Switch device

InactiveUS7002086B2Improve pressure resistanceAvoid probabilityEmergency actuatorsContact operating partsEngineeringSynthetic resin

A switch device includes: an operating portion made of a synthetic resin and having a conductive plating layer formed thereon, the operating portion configured to be inserted into a hole formed on a housing of an apparatus; and a shielding portion made of a synthetic resin and having no conducive plating layer formed thereon, the shielding portion formed separately from the operating portion and covers a gap between the operating portion and the hole from an inner side of the housing. The shielding portion is provided to push a tact of a switch provided at a rear side of the shielding portion when the shielding portion is displaced by a pushing operation of the operating portion. The operating portion is fixed to the shielding portion in a state in which the plating layer thereof being not exposed to the rear side of the shielding portion.

Owner:FUNAI ELECTRIC CO LTD

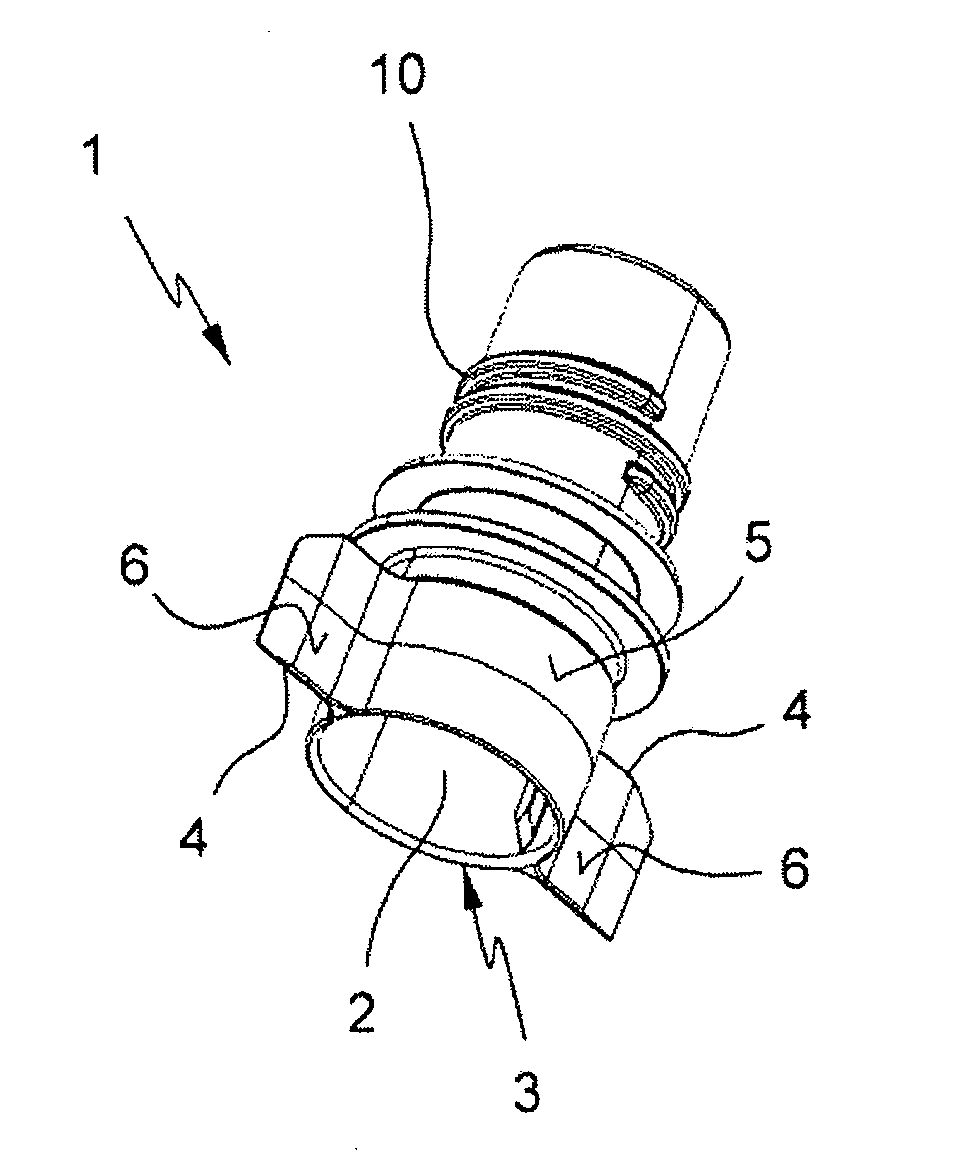

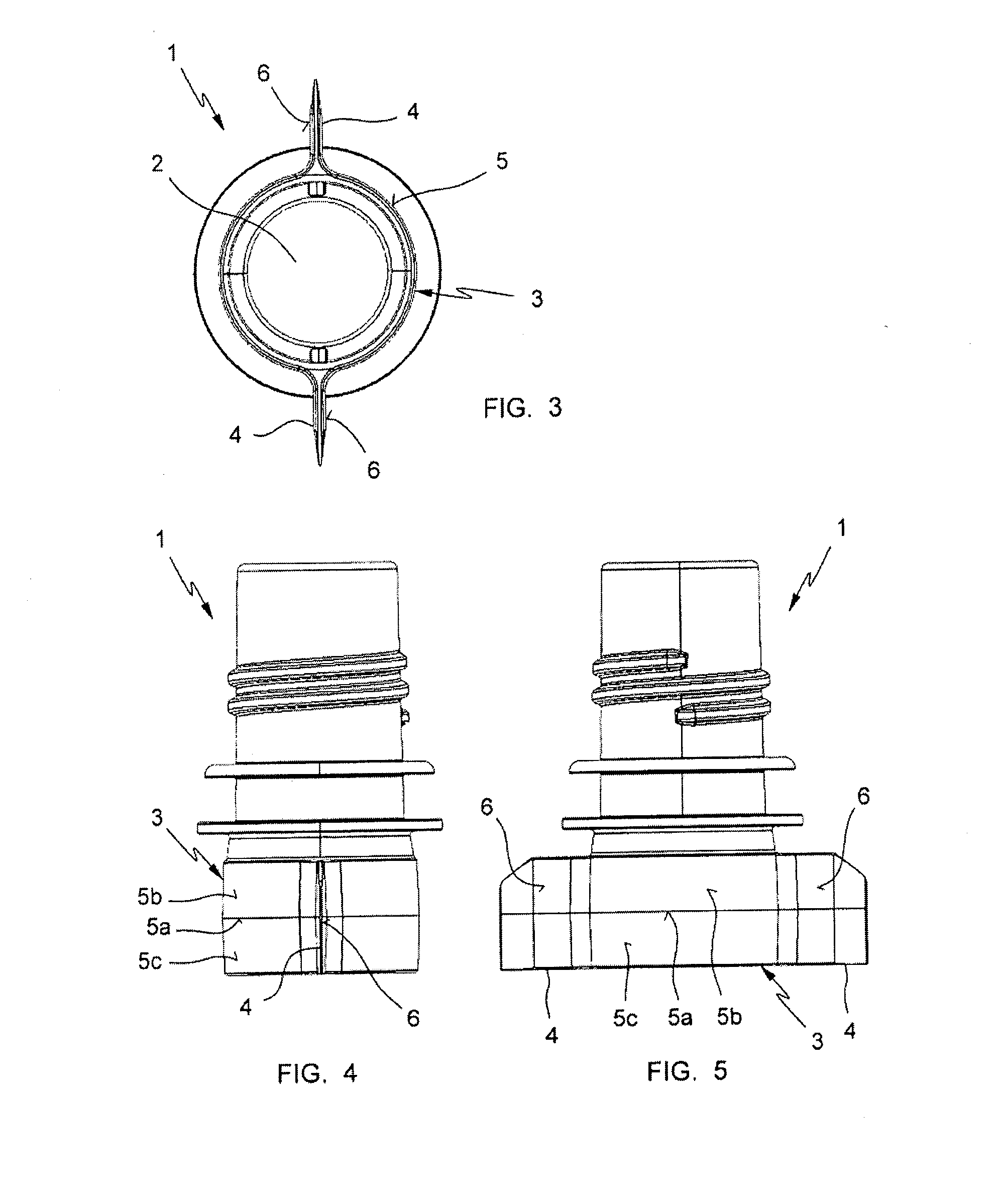

Discharge spout for flexible bags

InactiveUS20110147421A1Easy maintenanceImprove seal qualityClosuresClosure using stoppersEngineeringMechanical engineering

The invention relates to a discharge spout for flexible bags, of the type comprising a rigid plastic body forming a discharge passage and having a tube (3) intended to be inserted between two walls of a flexible bag and joined to such walls by means of sealing. The tube (3) has a smooth outer surface and two opposite flat flaps (4) extending externally in a mid-plane of said tube (3). The outer surface of the tube (3) forms, together with the surface (6) of the flat flaps (4), a sealing surface. The outer surface of the tube (3) is a dished surface in the axial direction of the tube, and it has a middle area (5a) in which the distance to the axis (7) of the tube is maximum, separating two side sections (5b, 5c) in which the distance to the axis (7) is decreasing toward the ends of the tube.

Owner:VOLPAK

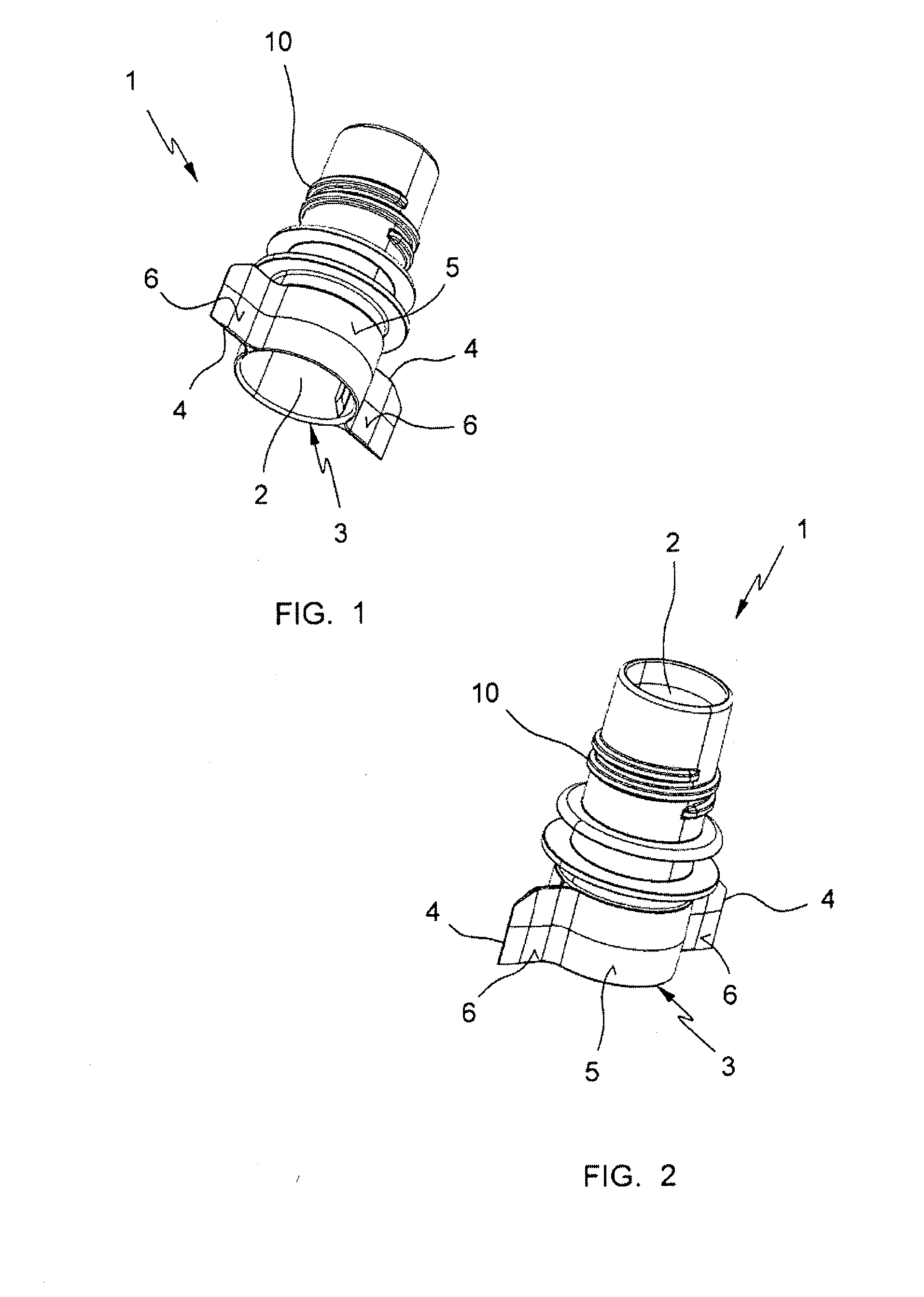

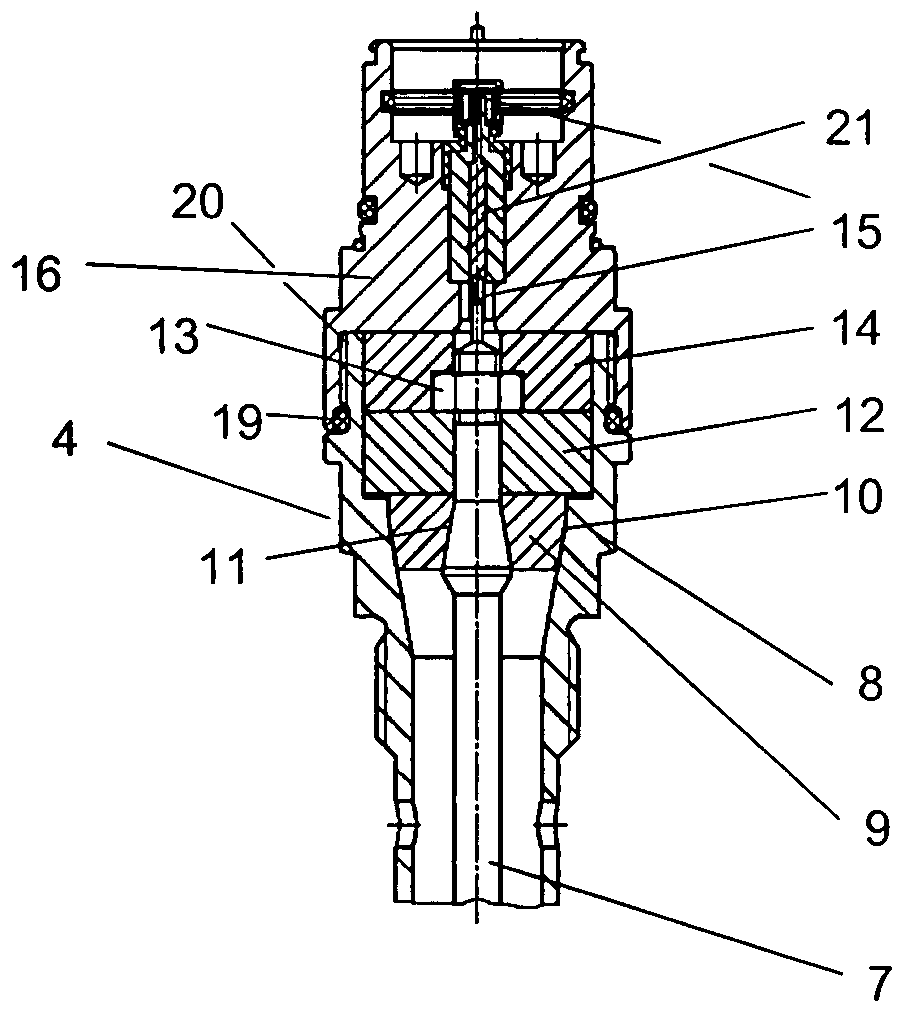

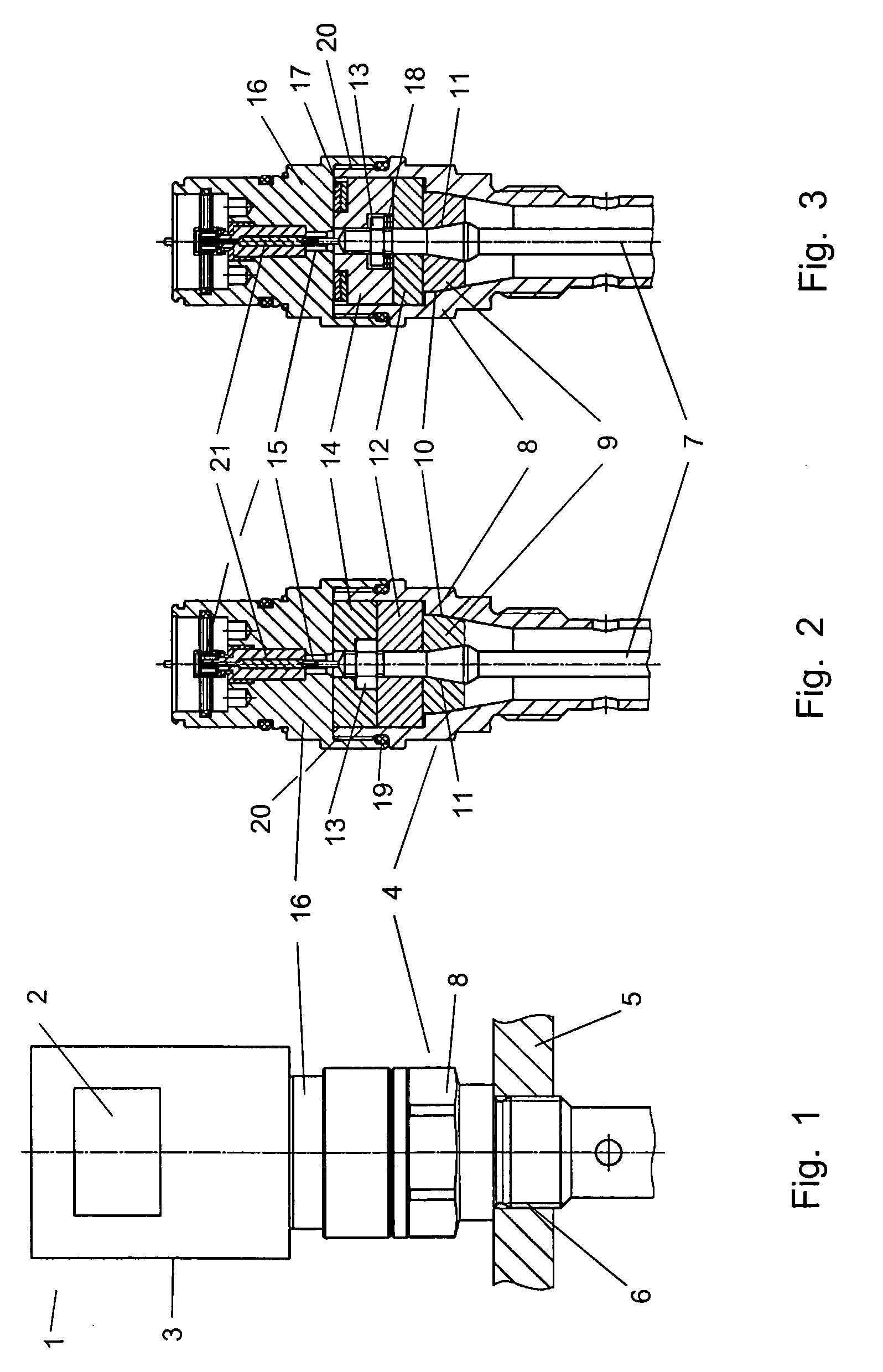

Coaxial gapless guide-through assembly for a filling level sensor

InactiveUS20050150568A1Well formedImprove stabilityLiquid fillingLiquid flow controllersElectrical conductorLevel sensor

The present invention relates to a guide-through assembly (4) for a filling level sensor working according to the principle of delay measurement of guided electromagnetic waves or for a capacitive filling level sensor, which for sealing the interior of the vessel against the interior of the sensor has no elastomeric sealing materials and in particular no elastomeric o-rings seals. This can be ensured by precisely machining the components which are essentially concentrically arranged in the guide-through assembly (4) on their circumferential surfaces (10, 11), so that in an assembled state the components arranged in the guide-through assembly (4), such as the interior conductor (7) and the dielectric materials (9, 12, 14) surrounding the interior conductor (7), contact each other at their mutually adjacent circumferential surfaces (11) in a sealing and positive engagement, so that additional sealing elements are not needed.

Owner:VEGA GRIESHABER GMBH & CO

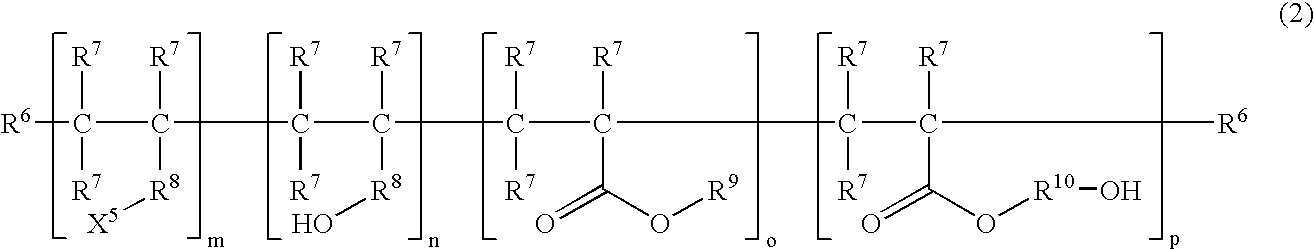

Moisture-curable, graft-modified resin composition, process for its manufacture and process for bonding substrates employing the resin composition

ActiveUS20080311419A1High modulusHigh strengthAdhesive processesFilm/foil adhesivesSilylenePolymer bonding

A moisture-curable, graft-modified resin composition includes at least one thermoplastic polymer (i) and at least one silyl group containing polymer (ii) possessing at least one hydrolyzable silyl group that is bonded to the polymer through a linking group containing at least one heteroatom selected from the group consisting of oxygen and nitrogen, each of polymers (i) and (ii) having grafted thereto at least one same or different silane (iii) which, prior to being grafted, possesses at least one reactive carbon-carbon unsaturated bond.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Use of ziegler-natta catalyst to make a polypropylene homopolymer or random copolymer having a high melt flow rate

The present invention relates to a method for producing propylene homopolymer or random copolymer which has the characteristics of faint odor, low volatile content and high flux fluidity. The propylene homopolymer or random copolymer is suitable for the application of thin-wall injection molding. The method comprises a step of polymerizing propylene and one or a plurality of random comonomer in the presence of Ziegler-Natta catalyst, organic aluminium component and random external object, wherein the Ziegler-Natta catalyst comprises a titanium compound having at least one titanium-halogen bond and a succinate compound as internal electron donor. The titanium compound and succinate are loaded on magnesium halide with an active form.

Owner:TOTAL RES & TECH FELUY

Sports bottle cap

A fluid container is disclosed with a cap body made of rigid or semi rigid material and a valve body disposed within the cap body and movable between and open and closed position. The valve body is made of a semi flexible semi rigid material that has a coefficient of thermal linear expansion that is smaller than that of the cap body. The cap body and nozzle valve are configured with three different hermetic seals to counteract the effects of exposure to heat and cold over time and thereby extend the useful life of the cap and valve.

Owner:HYDRAPAK LLC

Pencil comprising a stack of oxide nuclear fuel pellets

InactiveUS9053830B2Reduce hoop stressImprove creepFuel elementsNuclear energy generationUranium oxideEnriched uranium

The rod contains substantially cylindrical oxide nuclear fuel pellets based on enriched uranium oxide. The H / D ratio of the height over the diameter of the pellets lies in the range 0.4 to 0.6. The initial diametral clearance between the pellets and the cladding does not exceed 200 μm.

Owner:FRAMATOME ANP

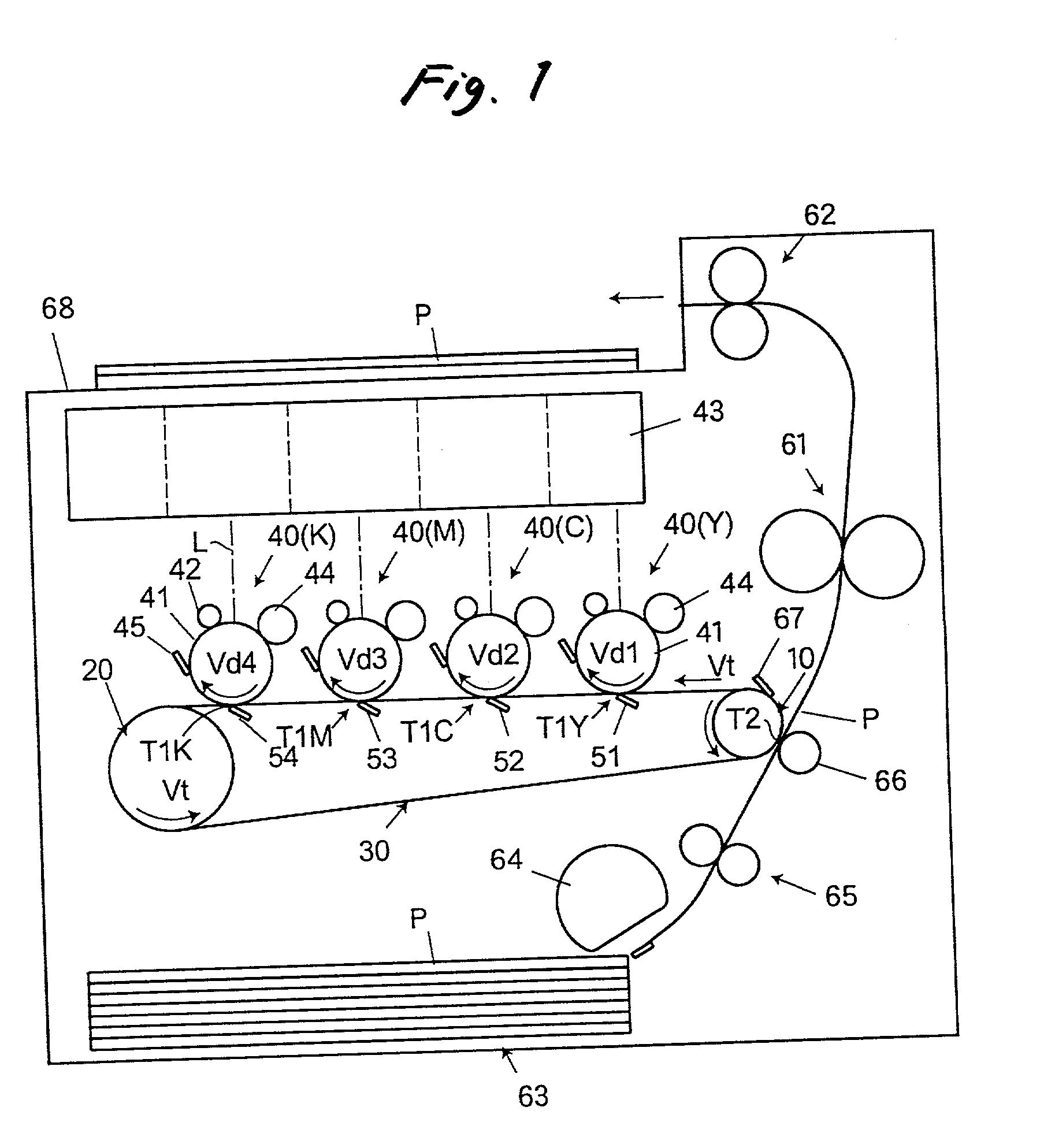

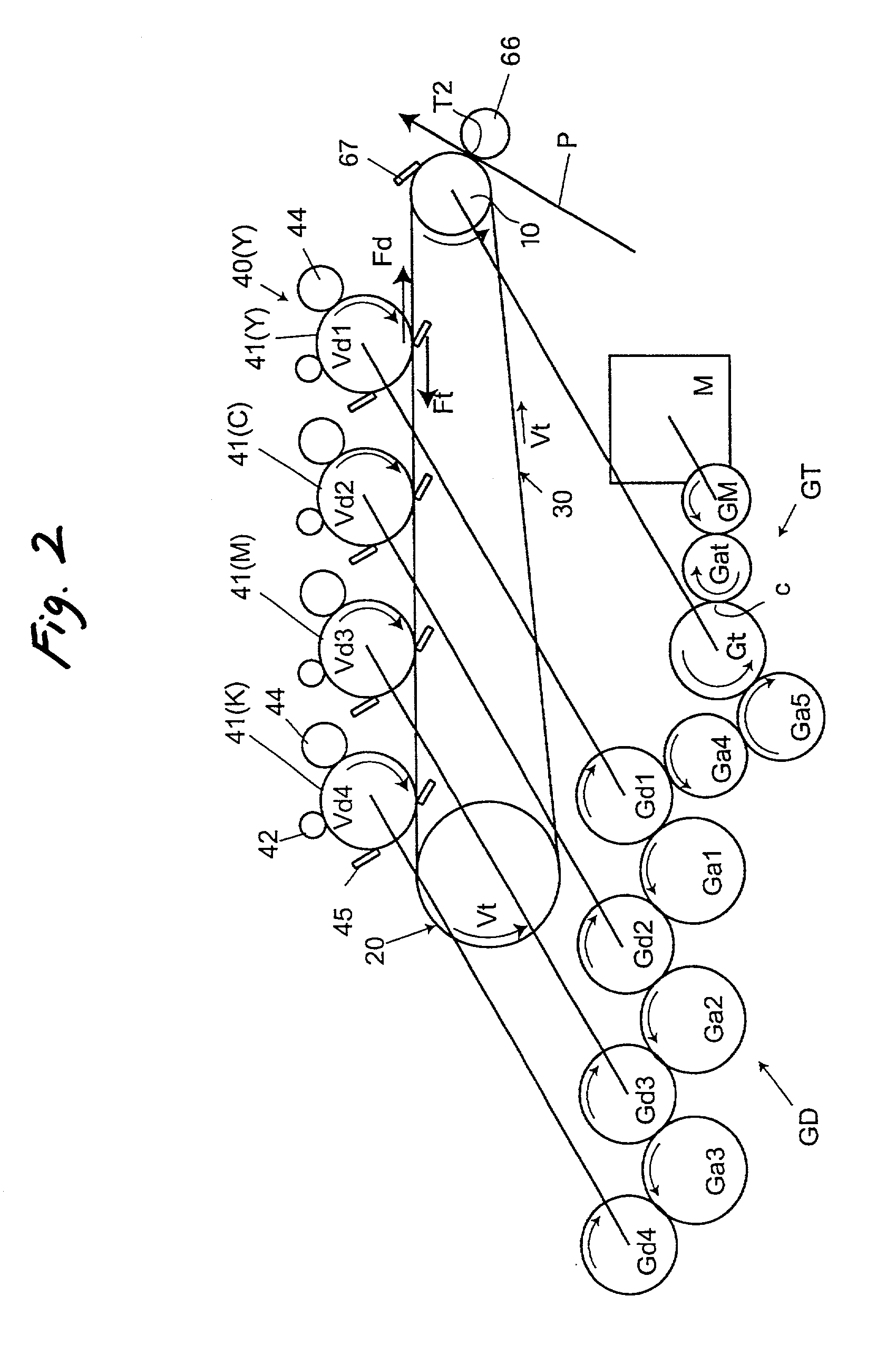

Color image forming apparatus

InactiveUS20020127030A1Not promote creepImprove creepElectrographic process apparatusColor imageMonochromatic color

In a color image forming apparatus, a looped belt member is stretched and circulated by at least a drive roller and a driven roller so as to have a tensed side and a slack side. Each of plural image supporting members supports a single color toner image thereon, and abuts onto the slack side of the belt member to define a transferring position at which the toner image is transferred onto either the belt member or a recording medium held by the belt member, while being rotated. A circumferential velocity of each image supporting member is determined so as to be higher than a circulation velocity of the belt member.

Owner:SEIKO EPSON CORP

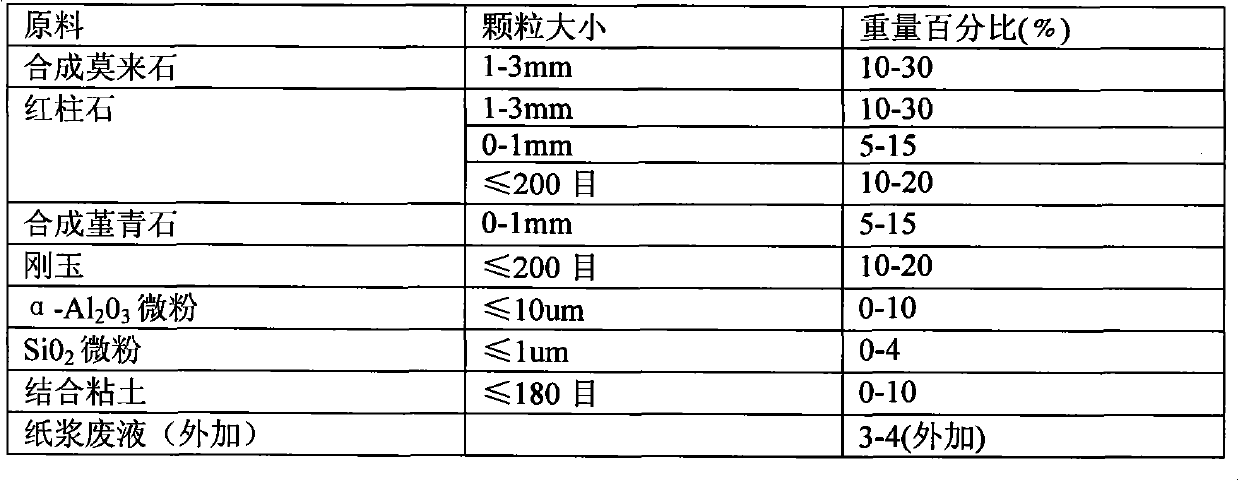

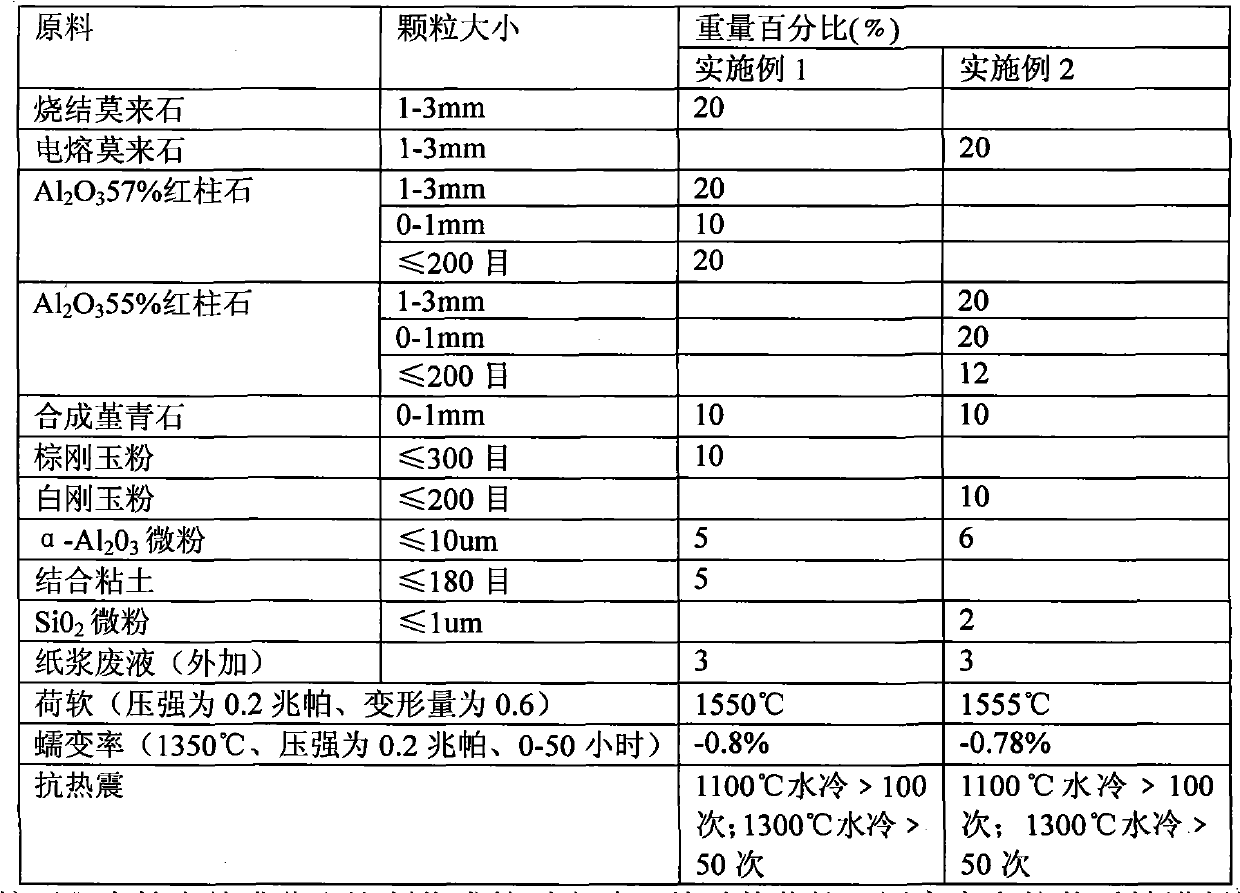

High-stress-strain low-creepage high-thermal-shock-resistance refractory brick and manufacturing method thereof

The invention discloses a manufacturing method of a refractory brick. According to the manufacturing method, low-and-medium-grade andalusite (the contents of Al2O3 are 53%, 55% and 57%) are used as main raw materials, large and intermediate andalusite particles are replaced with large mullite particles and intermediate cordierite particles, and corundum, alpha-Al2O3 micropowder and SiO2 micropowder and combining clay and waste paper pulp are added. The preparation method comprises the following steps of: mixing the ingredients in a wet pan mill evenly and then discharging out of the mill; forming by a frictional brick press; drying the formed green blanks in a dryer; calcining the dried blanks in a calcining kiln, wherein the highest calcining temperature ranges from 1370DEG C to 1400DEG C. The refractory brick obtained by adopting the method can effectively solve the problems of the conventional refractory brick, such as high manufacturing cost, low load softness, large creepage, poor anti-seismic property and short service life; the appearance defects of the refractory brick are fewer, and the refractory brick can be widely applied in a ceramic burner of an ironmaking blast-furnace hot blast stove.

Owner:ZHENGZHOU ANNEC IND

Nickel-base superalloys and components formed thereof

InactiveCN101935781AImproved high-temperature load-holding propertiesImprove creepTurbinesBlade accessoriesNiobiumHafnium

Owner:GENERAL ELECTRIC CO

Construction method for paining waterproof paint before cement is finally set

The invention relates to a construction method for paining waterproof paint before cement is finally set. The construction method includes the steps of (1) wetting the base with water at first, blade coating a pure cement layer or a cement screed layer, and coating waterproof paint with a blade after the surface of the pure cement layer or the cement screed layer is dried to form a waterproof layer; (2), or coating waterproof paint with a blade directly before the pure cement layer or the cement screed layer are finally set. The construction method for paining waterproof paint before cement is finally set has reaction, solves the problems that adhesion of coating layers and bases or protective layers is insecure, drying speed of water-based paint is slow and requirement on bases is high and the like, construction is simple to operate, technical features of waterproof materials can be fully utilized, the problems that screed-coat layers are not needed to perform construction on concrete bases or cement mortar bases are solved in large-scale construction, paint can form a sealed bonding layer to solve a problem of water leakage of waterproof paint.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

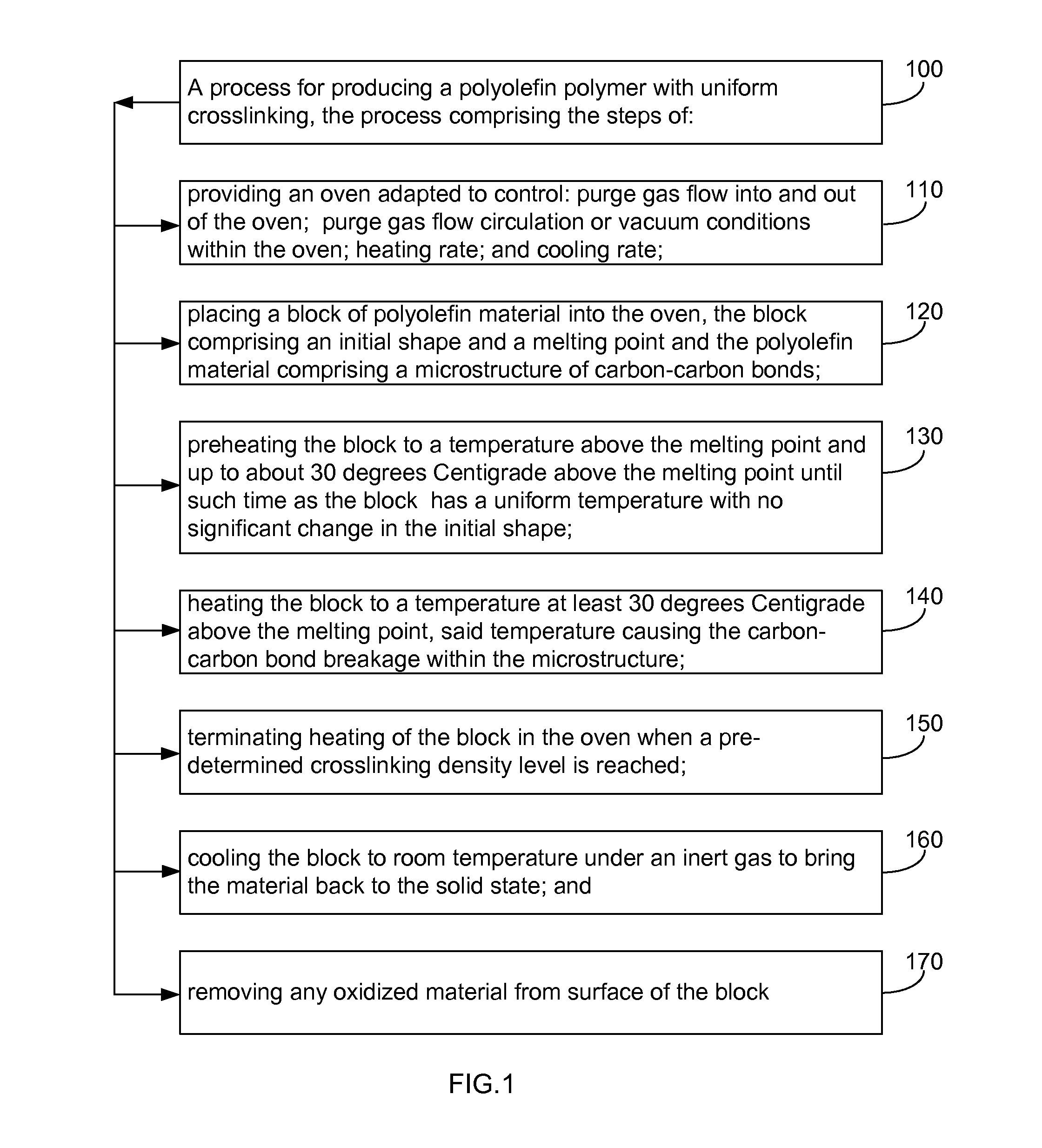

Polyolefin treatment process for uniform crosslinking

A process produces a block of polyolefin material with uniform crosslinking, which may be uniform between and within polymer chains in the polyolefin material. Steps include: providing an oven; placing the block into the oven; preheating the block to a uniform temperature above the melting point; further heating the block to a temperature at least 30 degrees Centigrade above the melting point; cooling the block to room temperature under an inert gas; and removing oxidized material from surface of the block. Optional steps include: subjecting the block to radiation before placing the block into the oven; removing the gases from the oven on a continuous or stepwise basis; controlling the purge gas flow out of the oven; and determining a heating time period for the block by subjecting control blocks to the same process and analyzing them after various heating times.

Owner:SUN DEHCHUAN

Spandex with improved backing-off property and creep property for paper diaper and production method thereof

ActiveCN107502978AImprove unwindingImprove creepMonocomponent synthetic polymer artificial filamentArtifical filament manufactureUreaMagnesium stearate

The invention discloses a spandex with improved backing-off property and creep property for a paper diaper and a production method thereof. Thermoplastic polyurethane which accounts for 3-35% of the spandex by weight percent and cellulose acetate butyrate or cellulose acetate propionate which accounts for 0.5-2.0% of the spandex by weight percent or a mixture of the two, as well as an internal lubricant and external lubricant composition which accounts for 0.3-5.0% of the spandex by weight percent, are added into a polyurethane-urea stock solution, and drying spinning is performed to prepare a polyurethane elastic fiber, wherein an internal lubricant is one or more of n-butyl stearate, oleamide, ethylene bis stearamide and amino silicon oil; and an external lubricant is one or more of talcum powder, carbon monofluoride and magnesium stearate. The prepared spandex has favorable backing-off property and creep property, can be effectively applied to the field of elastic materials of paper diapers, and meanwhile, is suitable for two modes of rotary backing off and axial backing-off.

Owner:ZHEJIANG HUAFENG SPANDEX

High-precision ceramic pressure sensor

ActiveCN105424231AEliminate the effects ofHigh precisionForce measurementFluid pressure measurement using capacitance variationCapacitanceCapacitor

The invention discloses a high-precision ceramic pressure sensor which comprises a ceramic baseplate containing a concave hole and a plurality of electric-conductive through holes as well as a ceramic thin plate combined on the side of the ceramic baseplate where the concave hole is located, a measuring electrode and a first annular electrode winding the measuring electrode are disposed on a concave face of the concave hole, a moving electrode and a second annular electrode winding the moving electrode are disposed on the face of the ceramic thin plate which is opposite to the concave face, leading-out ends of the measuring electrode, the first annular electrode, the moving electrode and the second annular electrode are respectively led out from the other side opposite of the ceramic baseplate which is opposite to the concave hole via the corresponding electric-conductive through holes, the moving electrode and the measuring electrode constitute a measuring capacitor, the moving electrode and the first annular electrode constitute a reference capacitor, and the first annular electrode and the second annular electrode also constitute an isoelectric face through short circuits of the electric-conductive through holes. The high-precision ceramic pressure sensor disclosed by the invention can control an electrode spacing within a very high precision scope without introducing any second material, and has high sensitivity and good sealing effects.

Owner:SHENZHEN SUNLORD ELECTRONICS

Method for making blank of retainer of bearing from high molecular composite material

The invention relates to a method for making the blank of a retainer of a bearing from a high molecular composite material. The high molecular composite material comprises an aramid pulp fiber, a thermosetting polyimide and polytetrafluoroethylene. The aramid pulp fiber is subjected to reflux cleaning, the cleaned aramid pulp fiber and the thermosetting polyimide are subjected to vacuum drying ina vacuum drying box, the dried thermosetting polyimide is sieved by a 1000 mesh sieve to remove oversize materials, the high molecular composite material is formed by mixing above three processed components by a high speed mixer, the high molecular composite material which is ground is filled into a retainer die, is subjected to pressure preformation and is removed out of the die to obtain a tubular retainer blank, and the tubular retainer blank is sintered in a sintering furnace to form the blank of the retainer of the bearing. The high molecular composite material which has the advantages of excellent thermal stability and chemical corrosion resistance, good thermal conductivity and compression creep resistance, high strength, excellent friction and wear resistance, small density and light mass is in favor of the reduction of the self weight of the retainer and the improvement of the high speed running stability of the bearing.

Owner:LUOYANG BEARING RES INST CO LTD

Hybrid fabric by employing ultrahigh molecular weight polyethylene fiber and aramid fiber

InactiveCN106113813ALow densityHigh specific strengthFibre typesSynthetic resin layered productsOptical radiationResin-Based Composite

The invention relates to hybrid fabric by employing ultrahigh molecular weight polyethylene fiber and aramid fiber, wherein UHMWPE fiber has the advantages of small density, high specific strength, high specific modulus, good chemical corrosion-resistant and optical radiation-resistant performances, impact resistance, wear resistance, cutting resistance, low temperature deflection resistance, high electromagnetic transmissivity, and good biological compatibility. The UHMWPE fiber is polyethylene essentially, the melting point and the vicat softening point are low, so that the fiber heat resistance performance is poor, and creep deformation is obvious. The produced hybrid fabric improves the problems of interface compatibility and obvious creep deformation of the UHMWPE fiber, can be used for a resin-based composite material, solves the problems that diameters of the UHMWPE fiber and the aramid fiber are different, a gap is easily generated between the layers of the fiber cloth when the layers are overmuch, pore quantity of the composite material is large, glue amount of the resin after filling is inuniform, and intensity is decreased. The fiber can be used for enhanced fiber of the resin-based composite material.

Owner:TONGJI UNIV

Sports bottle cap

ActiveUS10322855B2Facilitates up and down travelReduce impactCapsClosure capsHermetic sealBottle cap

A fluid container is disclosed with a cap body made of rigid or semi rigid material and a valve body disposed within the cap body and movable between and open and closed position. The valve body is made of a semi flexible semi rigid material that has a coefficient of thermal linear expansion that is smaller than that of the cap body. The cap body and nozzle valve are configured with three different hermetic seals to counteract the effects of exposure to heat and cold over time and thereby extend the useful life of the cap and valve.

Owner:HYDRAPAK LLC

Preparation method of graphene oxide composite natural latex sponge

The invention relates to a preparation method of a graphene oxide composite natural latex sponge, and belongs to the technical field of composite sponges. According to the method provided by the invention, a modified natural latex sponge is added by adding graphene oxide, groups such as hydroxyl, carboxyl and epoxy groups among the graphene oxide can be linked by covalent bonds in the reaction process, so that resilience performance of the sponge is effectively improved; the high specific surface area of the graphene oxide can effectively improve adsorption capacity of the composite sponge; the graphene oxide composite natural latex sponge is prepared by adding casein, the casein has very good thermal stability and can be used for sterilization at a high temperature without destroying thestability and functionality, the casein can form a tough hydrophilic protein film on the surface of rubber particles of natural latex, and the film does not degenerate or shrink to destroy an emulsionsystem, so that the mechanical properties and resilience performance of the graphene oxide composite natural latex sponge can be effectively and steadily improved.

Owner:陈松

Fiber composite core rod with improved performances for overhead wire and preparation method thereof

ActiveCN102426884AHigh temperature resistantImprove mechanical propertiesPower cablesCable/conductor manufactureEpoxyOptoelectronics

The invention relates to a fiber composite core rod with improved performances for an overhead wire, comprising continuous basalt fiber twistless roving and an epoxy resin part, wherein the epoxy resin part is formed at the periphery of the continuous basalt fiber twistless roving by uniform dipping;The composite core rod is prepared by the following steps of: (1) using a coupling agent to carry out surface treatment on nano SiO2; (2) preparing infiltrate of the nano SiO2, and using the infiltrate of the nano SiO2 to carry out surface roughening and lipophilicity modification and treatment onthe continuous basalt fiber twistless roving; (3) using the coupling agent to carry out surface treatment on calcium carbonate whiskers and square zinc oxide whiskers; (4) preparing epoxy resin dipping solution and conveying the continuous basalt fiber twistless roving into the epoxy resin dipping solution for full dipping; and (5) treating the continuous basalt fiber twistless roving by adoptinga pulling-extruding process. The fiber composite core rod has the advantages of low manufacturing cost, higher cost performance, and excellent mechanization, heating and heat ageing resistance and creepage performances.

Owner:SHENZHEN YONGGUI TECH CO LTD

Adhesive film and display member using same

ActiveUS10240068B2Easy to processIncrease productivityNon-macromolecular adhesive additivesPolarising elementsCross-linkMeth-

An adhesive film of the present invention comprises a (meth)acrylate-based copolymer and a cross-linking agent, and a gel fraction thereof is approximately 50-95%, and a ratio of change G′ in storage modulus thereof, represented by the following formula 1, is 20% or less.G′=(G7−G1) / G1×100 [Formula 1](In formula 1, G1 is a storage modulus at 25° C. when the adhesive film is matured at 23° C. and a relative humidity (RH) of 55% for one day, and G7 represents a storage modulus at 25° C. when the adhesive film is matured at 23° C. and an RH of 55% for seven days.)

Owner:SAMSUNG SDI CO LTD

Integrated packaging structure and packaging method of surface acoustic wave sensor

ActiveCN111121843ASmall sizeImprove hysteresisFluid pressure measurementConverting sensor output electrically/magneticallyBusbarEngineering

The invention provides an integrated packaging structure of a surface acoustic wave sensor. An insulating protective layer covers a busbar and a wire on the upper surface of a sensor substrate; a bonding pad plating layer covers the upper surface of an external bonding pad port of the sensor; the metal support frame has a certain height and grows on the sensor substrate and the insulating protective layer; a metal cover plate grows on the metal support frame to form a metal protective layer; and a gold crystal bonding layer grows on the back surface of the sensor substrate to form an elastic metal layer. Meanwhile, the invention provides a packaging method of the packaging structure. According to the invention, the sensitive substrate and the package of the sensor are integrally manufactured and glue does not need to be spin-coated on the structure for bonding, so that the reliability of the surface acoustic wave sensor packaging structure is improved, the defects of large clutter andlarge characteristic change after packaging in traditional packaging are overcome; meanwhile, the integrated packaging structure can be applied to detection of various information such as temperature,pressure and stress / strain.

Owner:SHANGHAI JIAO TONG UNIV

Skull traction device used for cervical vertebra dislocation

InactiveCN111407489AEasy to relaxImprove creepFractureMuscle relaxationPhysical medicine and rehabilitation

The invention discloses a skull traction device used for cervical vertebra dislocation. The skull traction device comprises a cabinet body, wherein one side of the top end of the cabinet body is rotatably provided with connecting components; the connecting components are used for detachably connecting the cabinet body to a hospital bed; the top end of the cabinet body is vertically provided with atelescopic element; the top end of the telescopic element is provided with a guide component used for guiding a traction rope; a traction element is arranged in the cabinet body; the top end of the cabinet body is provided with a through hole; and in addition, the bottom end of the traction rope penetrates through the through hole and is wound to the output end of the traction element. The skulltraction device disclosed by the invention can be flexibly suitable for the height of the hospital bed and is convenient to transport a patient along with the hospital bed, linear transition is increased for traction force, weight can be continuously increased so as to be favorable for muscle relaxation and cervical vertebra creepage and also favorable for restoration, and manpower loss is reduced.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

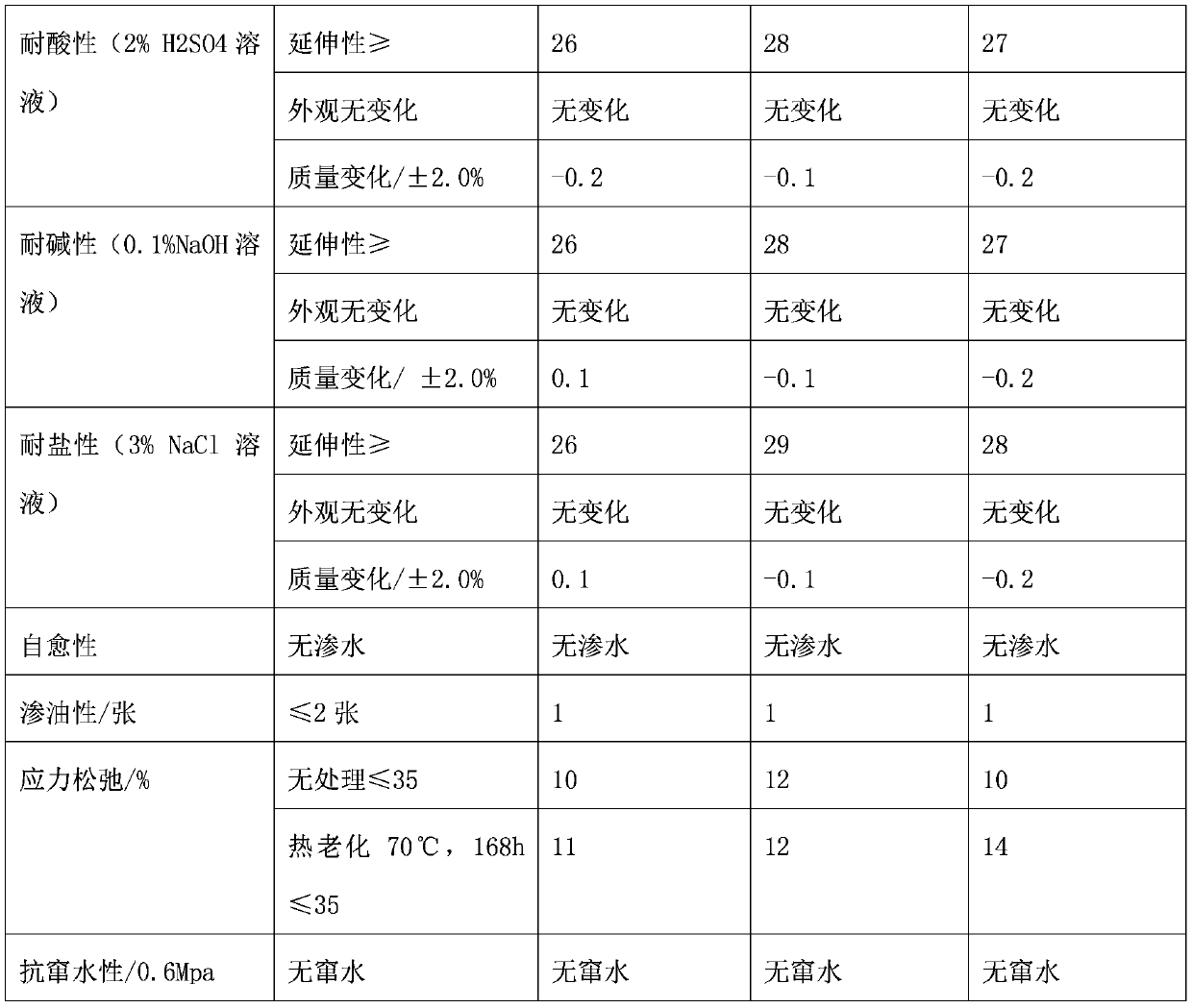

Creep type viscoelastic rubber waterproof coating and production method thereof

ActiveCN110373110AFacilitate creepIncrease the areaConjugated diene hydrocarbon coatingsBituminous coatingsChemistryCoupling reagent

The invention provides a creep type viscoelastic rubber waterproof coating and a production method thereof, and belongs to the technical field of waterproof materials. The creep type viscoelastic rubber waterproof coating is prepared by the follow raw materials in percentage by weight: 30-40% of 90#pitch, 15-20% of thermoplastic styrene-butadiene rubber, 10-16% of butyl rubber, 8-12% of activatedviscosified resin, 7-12% of softened oil, 3-5% of a coupling reagent, and 8-10% of filler; and the activated viscosified resin is formed through mixture of viscosified resin JT-260, alkylphenol acetylene viscosified resin, and C5 petroleum resin in the quality ratio of 1 to 2 to 3-5. According to the waterproof material, adhesive property is excellent, adhesion immediately occurs when the waterproof material is touched, stripping is difficult, the adhesion can occur on the wet substrate, and the adhesion can occur with wood, metal and other base materials; and construction is convenient and efficient, knife coating and spraying can be conducted according to requirements, film formation is quick without the need of maintenance, overlap joint is not needed, and efficiency is high.

Owner:广西禹杰防水防腐材料有限公司

Formula and preparation of train wheel tread friction control agent based on inorganic adhesive

ActiveCN107760067AGood mechanical propertiesIncrease coefficient of frictionCoatingsAdhesiveAgricultural engineering

The invention discloses a formula and preparation of a train wheel tread friction control agent based on an inorganic adhesive. The friction control agent is prepared from the following ingredients byweight percentage: 34%-45% of a composite adhesive, 25%-35% of a lubricating agent, 3.2%-11% of a friction adding agent and 20% of other fillers. According to the train wheel tread friction control agent based on the inorganic adhesive and a preparation method thereof, the friction control agent has the characteristics of being good in high temperature resistance, high in hardness, high in mechanical strength and good in abrasion resistance and has the advantages of effectively controlling a friction coefficient, being good in film-forming property, lowering traveling noise, effectively reducing friction of steel rails and wheels and ensuring traffic safety; in addition, the related preparation method is simple and is used conveniently, therefore, the preparation method is suitable for promotion and application.

Owner:ZHEJIANG BAOSHENG RAILWAYNEW MATERIALS TECH

Protection device for vehicle-mounted weighing sensor

InactiveCN104568097AEliminate the effects ofAchieve conversionSpecial purpose weighing apparatusHorizontal forceVehicle frame

The invention discloses a protection device for a vehicle-mounted weighing sensor. The protection device comprises a limiting rack, a base, a metal cushion plate and at least one roller, wherein the limiting rack comprises a limiting frame at the top and supporting plates on two sides, the limiting frame is used for horizontally limiting the rollers, and the supporting plates on the two sides are fixedly connected with two ends of the base respectively; the vehicle-mounted weighing sensor is arranged between the limiting rack and the base and fixedly connected with the base; a boss is arranged at the top of the vehicle-mounted weighing sensor, the metal cushion plate is fixedly arranged on the upper surface of the boss, the bottom of each roller is in contact with the upper surface of the metal cushion plate, and the top of the roller protrudes out of the limiting frame of the limiting rack. According to the protection device, the rollers are adopted for converting relatively small horizontal sliding displacement between a compartment and a vehicle frame into rolling displacement to eliminate the influence of horizontal force on the weighing sensor.

Owner:PLA UNIV OF SCI & TECH

Coherent nanophase-reinforced medium-entropy alloy with excellent thermal stability and preparation method of coherent nanophase-reinforced medium-entropy alloy

The invention discloses a coherent nanophase reinforced medium-entropy alloy with excellent thermal stability and a preparation method, the coherent nanophase reinforced medium-entropy alloy comprises 30 at.%-33 at.% of Ni, 30 at.%-33 at.% of Co, 30 at.%-33 at.% of Cr, 5 at.%-7 at.% of Al and 1.0 at.%-3.0 at.% of Ta, gamma'phase is added into the NiCoCr medium-entropy alloy with excellent mechanical properties to form elements Al and Ta, and then a nanophase is introduced into a NiCoCr alloy matrix through an aging process, so that the thermal stability of the alloy is improved. A gamma + gamma'structure similar to a high-temperature alloy is constructed, and meanwhile, the strength of the NiCoCr alloy is also greatly improved through the nano precipitation strengthening effect; the alloy not only has the characteristic of high toughness, but also has excellent structure thermal stability, so that the alloy has great competitive advantages in alloys with similar structures, has great engineering application prospects in the high-temperature field, and is expected to become a next-generation high-temperature structural material.

Owner:XI AN JIAOTONG UNIV

Phosphorus and magnesium anchoring glue and preparation method thereof

The invention relates to the technical field of building materials, and especially relates to a phosphorus and magnesium anchoring glue and a preparation method thereof. The glue comprises, by weight,80-120 parts of dead-burned magnesia, 80-120 parts of ammonium dihydrogen phosphate and 10-20 parts of water. The preparation method includes the following steps: S1, taking 80-120 parts of the dead-burned magnesia and 40-60 parts of ammonium dihydrogen phosphate, and performing dry mixing until uniformity in order to obtain a dry material mixture; S2, adding 10-20 parts of the water to the dry material mixture, and performing stirring and mixing until uniformity in order to obtain a wet material mixture; and S3, adding 40-60 parts of the ammonium dihydrogen phosphate to the wet material mixture, and performing stirring and mixing until uniformity in order to obtain the phosphorus and magnesium anchoring glue. The phosphorus and magnesium anchoring glue has can firmly bond to steel and other metals, has an excellent reinforcement performance, no special requirements for anchoring or fixing parts, very low creep and shrinkage and good resistance to acid and groundwater corrosion, is suitable for rapidly anchoring post-anchor bolts (reinforcements) and anchor poles of concrete structures, and has excellent application prospects in the fields of rapid repairing, first-aid repairing and reinforcement.

Owner:广州市泰宇科技发展有限公司

New-energy power battery relay ceramic material and preparation method thereof

InactiveCN110330266AImprove insulation performanceFast temperature riseContact materialsNew energyPolymer insulation

The invention provides a new-energy power battery relay ceramic material and a preparation method thereof. The new-energy power battery relay ceramic material comprises the following components in parts by weight: 15-20 parts of Co, 20-30 parts of Nb, 20-30 parts of TiB2, 30-40 parts of AlN, 40-50 parts of a filling high-molecular polymer, 5-8 parts of a crosslinking adhering agent, 3-4 parts of acoupling agent, 3-6 parts of chitosan acetic acid-polyethyleneimine, 9-12 parts of hydroxyapatite, 2-3 parts of sodium tartrate, and 0.5-1.5 parts of benzene sulfonic acid. The ceramic material has ametal conductive phase and a high-molecular polymer insulation phase and has the characteristics of being high in current breaking capacity, high in voltage resistance, high in flame welding resistance, high in electricity conductivity, high in thermal conductivity, low in electric arc burn out rate, low in chopping current, high in mechanical intensity, high in deformation resistance and high inabrasion resistance.

Owner:HUNAN MEICHENG CERAMIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com