Polyolefin treatment process for uniform crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

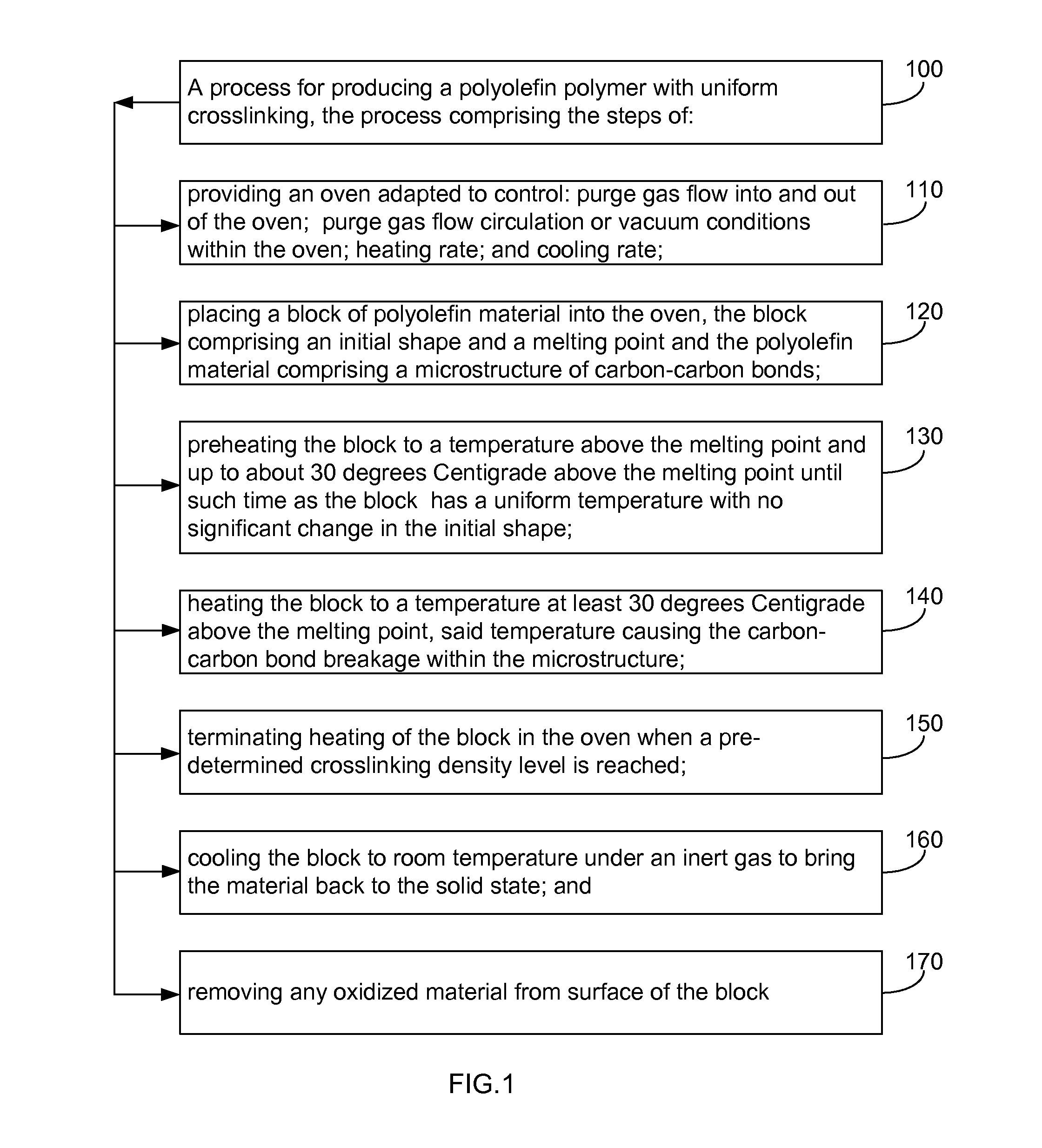

Image

Examples

example 1

[0044]For producing a polymer with enhanced and uniform physical crosslinking, steps include:

[0045](1) Using solid UHMWPE block as the starting material;

[0046](2) Placing the UHMWPE block in an oven with controlled purge gas flow (m, out, and internal circulation), heating, and cooling capabilities;

[0047](3) Pre-heating the UHMWPE block at a temperature which is about 0-30 C above the melting point (such as 170 C; UHMWPE's melting point is about 130-140 C) until the block is completely melted (due to the abundant chain entanglement, the molten UHMWPE block maintains its shape with no significant flow);

[0048](4) Heating the UHMWPE block at a temperature at least 30 C above its melting point to cause the carbon-carbon bond breakage along the polyethylene backbone. The gas environment in the oven can be air or inert gas (such as vacuum, nitrogen, argon, or helium). The oven chamber temperature must be uniform by a convective gas flow. Gases in the oven should be removed on continuous o...

example 2

[0087]For producing a polymer with uniform chemical crosslinking and enhanced physical crosslinking, steps include:[0088](1) Using solid UHMWPE block as the starting material;[0089](2) Subjecting the UHMWPE block to radiation;[0090](3) Placing the irradiated UHMWPE block in an oven with controlled purge gas flow (in, out, and internal circulation), heating, and cooling capabilities;[0091](4) Pre-heating the UHMWPE block at a temperature which is about 0-30 C above the melting point (such as 170 C; UHMWPE's melting point is about 130-140 C) until the block is completely melted (due to the abundant chain entanglement, the molten UHMWPE block maintains its shape with no significant flow);

[0092](5) Heating the UHMWPE block at a temperature at least 30 C above its melting point to cause the carbon-carbon bond breakage between existing crosslinks and along the polyethylene backbone. The gas environment in the oven can be air or inert gas (such as vacuum, nitrogen, argon, or helium). The o...

example 3

[0097]For producing a polymer with uniform chemical crosslinking, the steps are:[0098](1) Using solid UHMWPE block as the starting material;[0099](2) Subjecting the UHMWPE block to radiation;[0100](3) Placing the irradiated UHMWPE block in an oven with controlled purge gas flow (in, out, and internal circulation), heating, and cooling capabilities;[0101](4) Pre-heating the UHMWPE block at a temperature which is about 0-30 C above the melting point (such as 170 C; UHMWPE's melting point is about 130-140 C) until the block is completely melted (due to the abundant chain entanglement, the molten UHMWPE block maintains its shape with no significant flow);[0102](5) Heating the UHMWPE block at a temperature at least 30 C above its melting point (such as 250 C) to cause the carbon-carbon bond breakage along the polyethylene backbone. The gas environment in the oven can be air or inert gas (such as vacuum, nitrogen, argon, or helium). The oven chamber temperature must be uniform by a convec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com