Extrusion casting manufacture method of piston with reinforced pseudo-alloy circular groove

A manufacturing method, squeeze casting technology, applied to pistons, piston rings, cylindrical pistons, etc., can solve the problems of poor microstructure density, short service life of pistons, heavy weight of pistons, etc., and achieve dense internal structure of materials and reliable use Enhanced performance and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

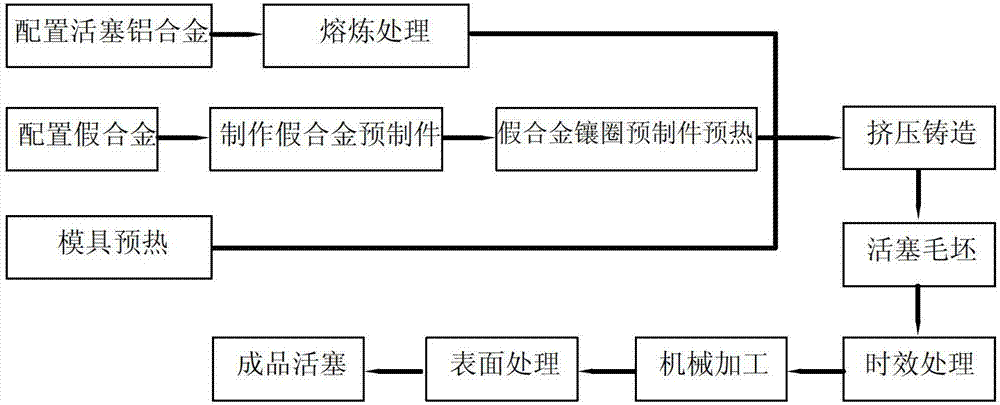

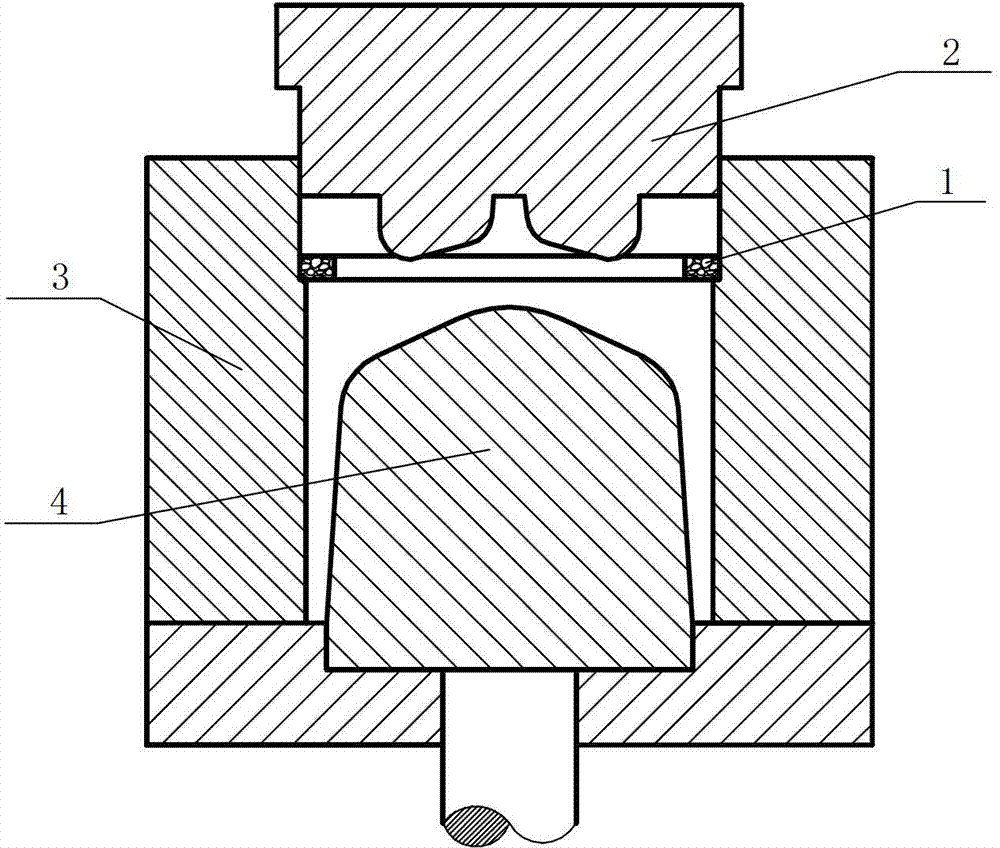

[0051] The preparation process of the squeeze casting manufacturing method of the pseudo-alloy reinforced ring groove piston is as follows:

[0052] ①Preparation of aluminum alloy for piston, the composition and mass percentage of the alloy are: Si: 11.0%; Mg: 0.6%; Cu: 2.6%; Ni: 1.8%; Fe: 0.1%; Ti: 0.1%; Mn: 0.01% ; Zn: 0.01%; the total amount of Cr, Pb, Ca and Sn impurity elements does not exceed 0.5%, and the rest is Al;

[0053] ②Configure pseudo-alloy composition, the composition and mass percentage of pseudo-alloy powder particles are: Cr: 15%; Ni: 11%; Si: 1%; Mn: 1%; the total amount of C, O, S and P impurity elements is not More than 1.0%, the rest is Fe;

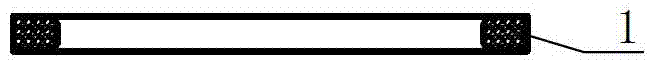

[0054] ③ To make the pseudo-alloy prefabricated part, the average size of the pseudo-alloy powder particles will be less than 80 μm, and after the particles are evenly mixed, the porosity of the pseudo-alloy inlay prefabricated part 1 is controlled to 40%, and the pseudo-alloy inlaid prefabricated part is formed a...

Embodiment 2

[0063] ①Preparation of aluminum alloy for piston, the composition and mass percentage of the alloy are: Si: 12.0%; Mg: 1.0%; Cu: 3.2%; Ni: 2.2%; Fe: 0.2%; Ti: 0.15%; Mn: 0.1% ; Zn: 0.1%; the total amount of Cr, Pb, Ca and Sn impurity elements does not exceed 0.5%, and the rest is Al;

[0064] ②Configure pseudo-alloy composition, the composition and mass percentage of pseudo-alloy powder particles are: Cr: 20%; Ni: 15%; Si: 3%; Mn: 1.5%; the total amount of C, O, S and P impurity elements is not More than 1.0%, the rest is Fe;

[0065] ③ To make the pseudo-alloy prefabricated part, the average size of the pseudo-alloy powder particles will be less than 80 μm. After the particles are evenly mixed, the porosity of the pseudo-alloy insert preform 1 is controlled to 45%. After mold pressing and sintering, the pseudo-alloy insert preform is formed. 1.

[0066] ④Smelting treatment, put the prepared aluminum alloy for piston into the melting furnace for melting, after melting, refin...

Embodiment 3

[0074] ①Preparation of aluminum alloy for piston, the composition and mass percentage of the alloy are: Si: 13.0%; Mg: 1.2; Cu: 4.0%; Ni: 2.8%; Fe: 0.3%; Ti: 0.2%; Mn: 0.2%; Zn: 0.2%; the total amount of Cr, Pb, Ca and Sn impurity elements does not exceed 0.5%, and the rest is Al;

[0075] ②Configure pseudo-alloy composition, the composition and mass percentage of pseudo-alloy powder particles are: Cr: 30%; Ni: 18%; Si: 5%; Mn: 2%; the total amount of C, O, S and P impurity elements is not More than 1.0%, the rest is Fe;

[0076] ③ To make the pseudo-alloy prefabricated part, the average size of the pseudo-alloy powder particles will be less than 80 μm. After the particles are evenly mixed, the porosity of the pseudo-alloy insert preform 1 is controlled to 50%. After mold pressing and sintering, the pseudo-alloy insert preform is formed. 1.

[0077] ④Smelting treatment, put the prepared aluminum alloy for piston into the melting furnace for melting, after melting, refine, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com