Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

440results about How to "Fast temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

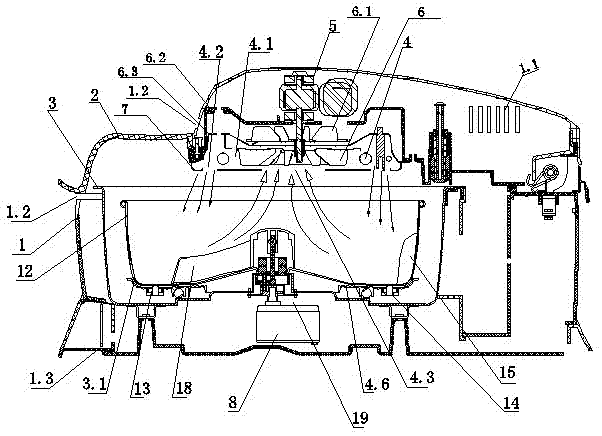

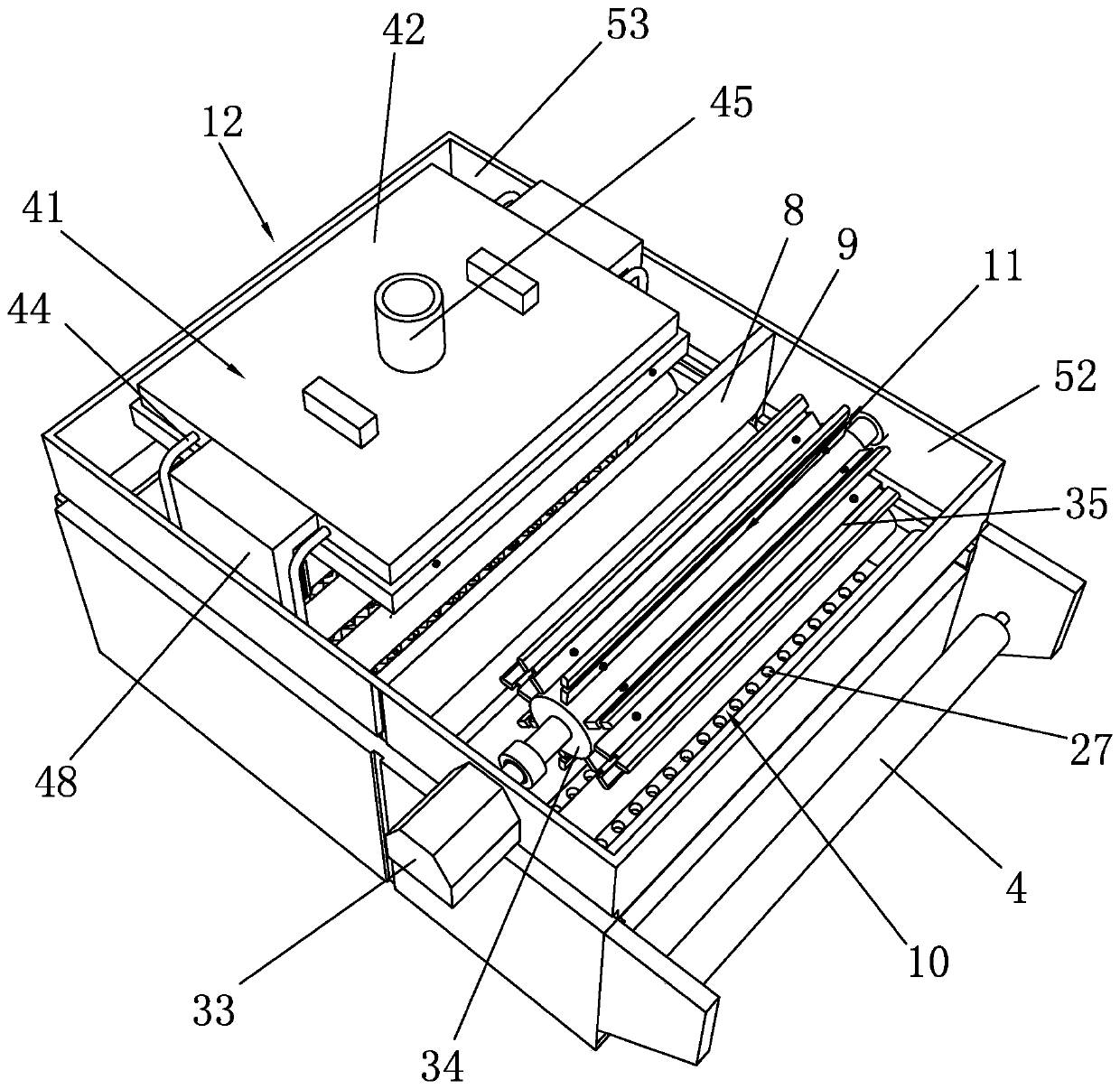

Baking pan capable of efficiently saving energy

InactiveCN106343895AEvenly heatedHard on the outside and soft on the insideRoasters/grillsEngineeringThermal radiation

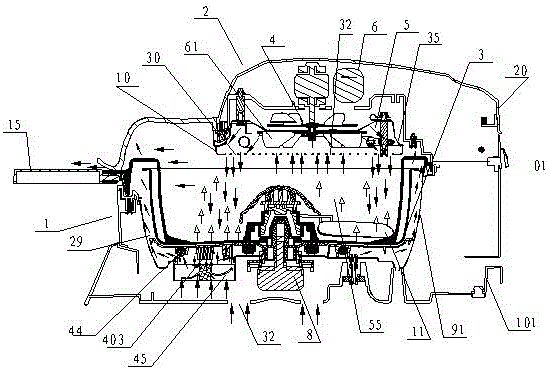

Provided is a baking pan capable of efficiently saving energy. The baking pan mainly comprises a large body, an upper cover, heaters, a pan body, a food rolling device, an air inlet hole and a cooling fan. The heaters comprise the upper heater and the lower heater, and the baking pan is characterized in that the large body is used for containing the pan body (3), the food rolling device (11) and the lower heater (44), and the large body (1) provides a conduction heating heat source for the bottom of food; the upper cover (2) provides a heat radiation or illumination radiation heat source for the upper surface of the food; the upper cover (2) and the large body (1) are closed to form a stereoscopic heating cavity (55) with the upper portion providing heat radiation or illumination radiation and the bottom providing conduction heating; the cooling fan is used for carrying out constant-temperature heating on the interior of the stereoscopic heating cavity (55) or carrying out relative cooling heating on the interior of the stereoscopic heating cavity (55), and the cooling fan is arranged outside the stereoscopic heating cavity (55); the food rolling device (11) is used for overturning the food, so that the food is evenly heated and stereoscopically heated. The baking pan has the advantages of being good in cooking effect, easy to mount and demount, easy to clean and wide in application range.

Owner:周林斌

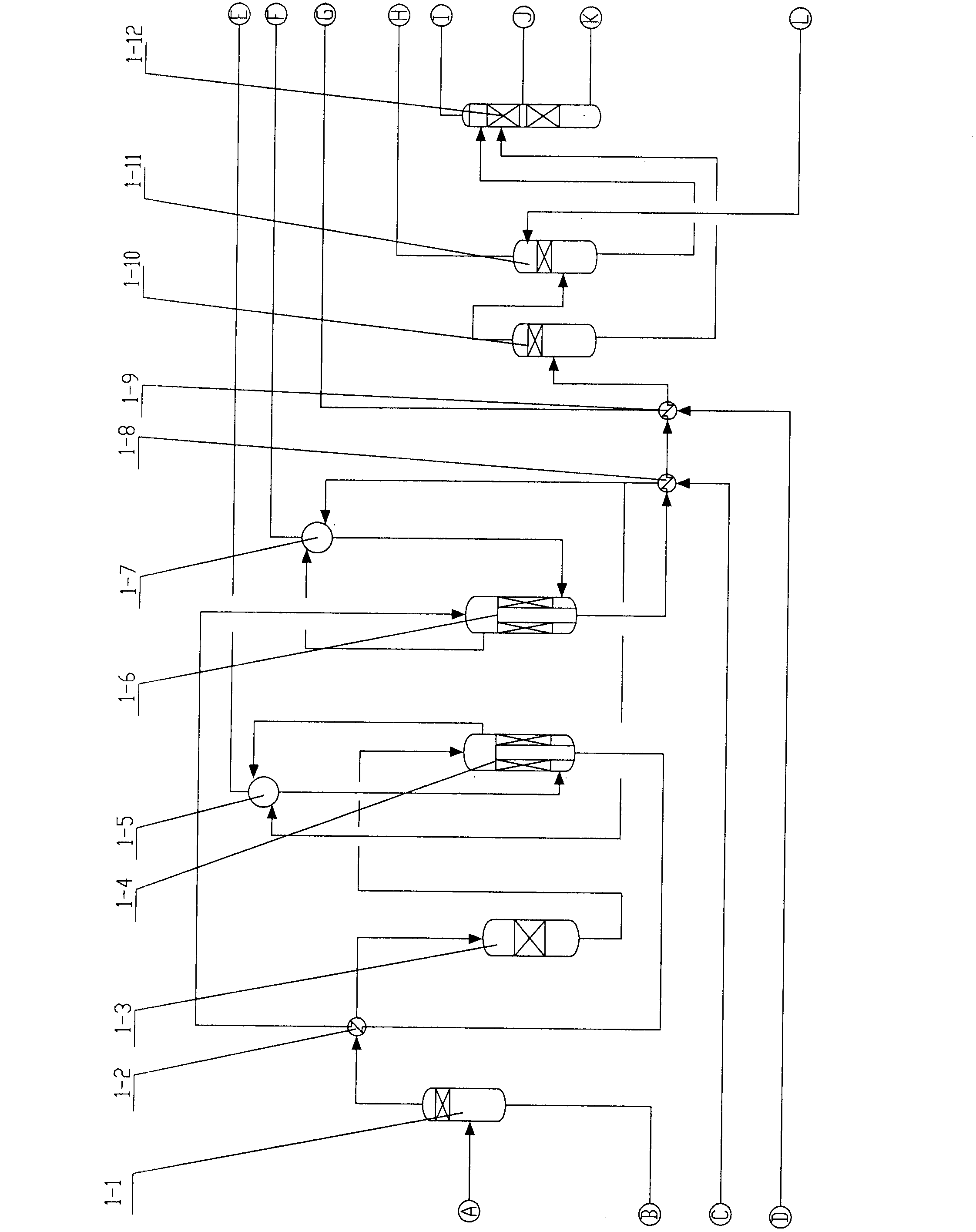

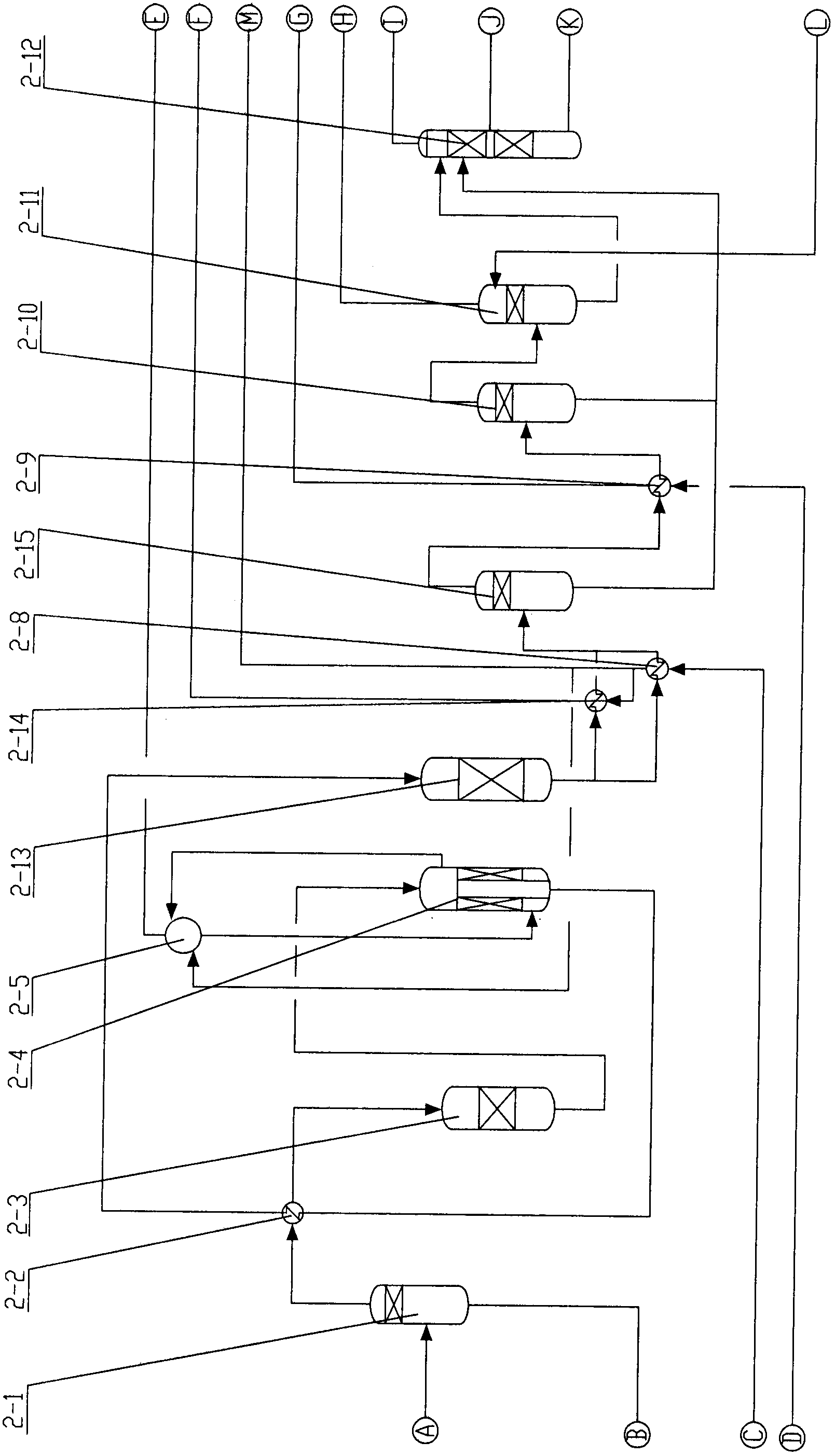

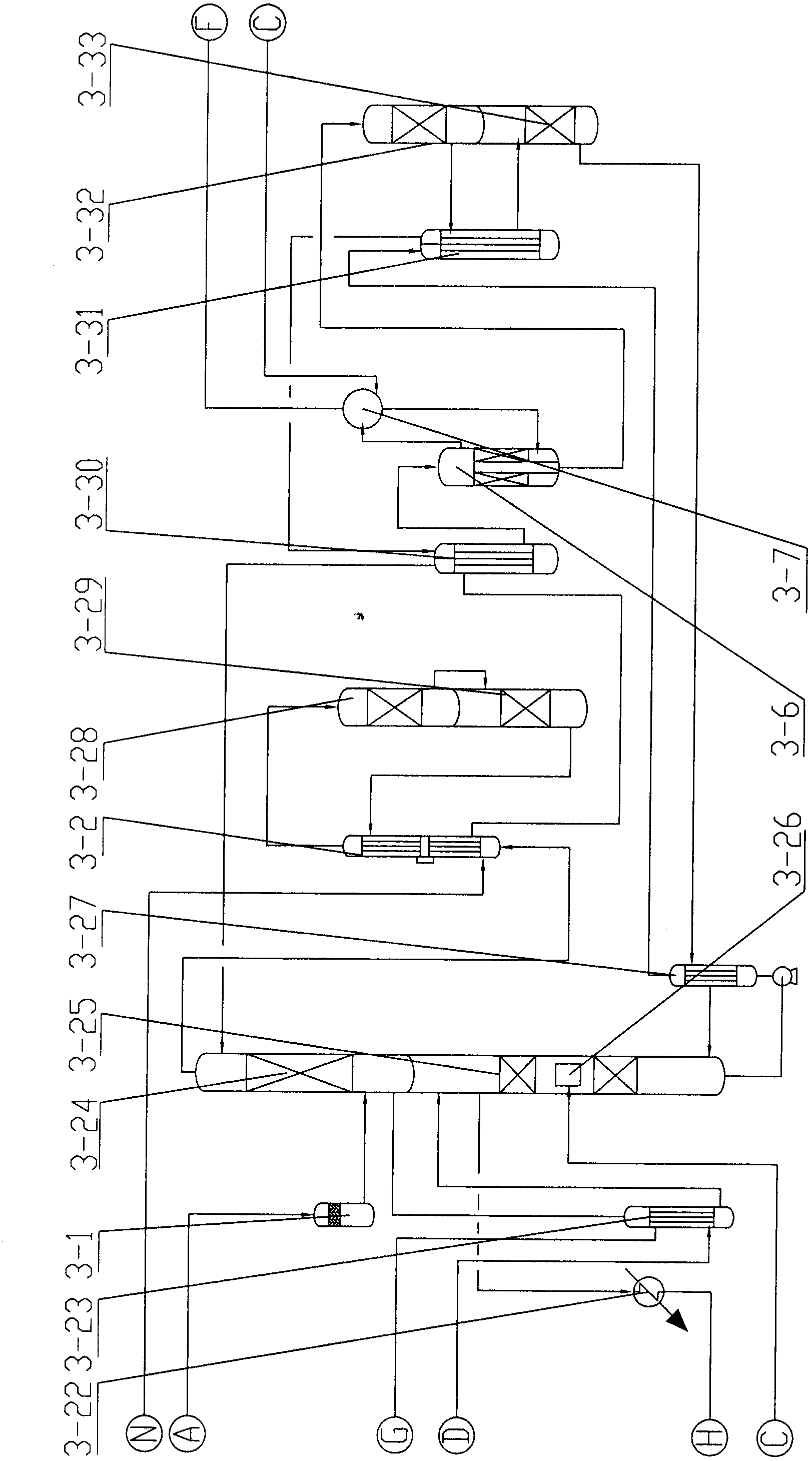

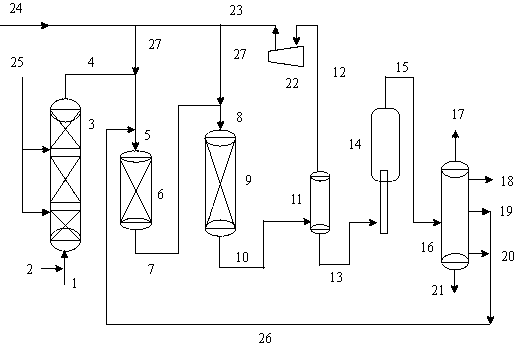

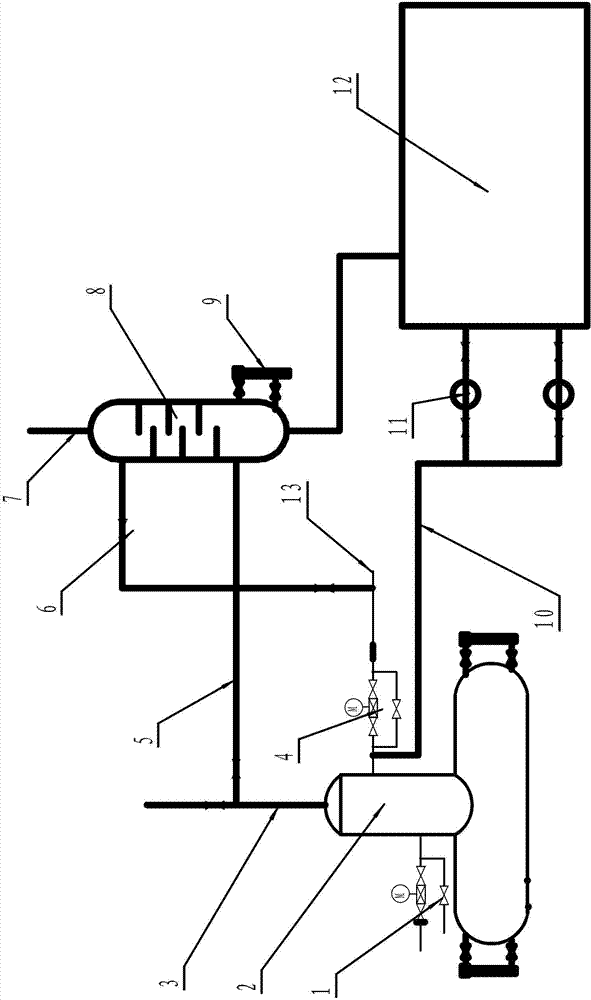

Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

ActiveCN102701149AGuaranteed service lifeEliminate "dew point corrosion"HydrogenChemical recyclingComing outThermal energy

The invention relates to a water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion. According to the process, a primary water heat-transfer shift converter and a secondary shift converter are adopted, CO in feed gas reacts with H2O to generate H2 and CO2 under the catalysis of a Co-Mo (copper-zinc) catalyst, and CO in shift gas coming out of a shift system is less than or equal to 0.1% (dry basis). In the process, CO is subject to deep conversion, the feed gas (containing water gas, semi-water gas, natural gas conversion gas or coke-oven gas conversion gas) utilization rate is high, the shift catalyst is not overheated, and the catalyst has a long service life; meanwhile, by-product saturated steam with the pressure of 0.5 to 9.0 MPa is generated, sensible heat and latent heat in the shift gas are further recovered by deoxygenated water and desalted water, low-grade heat energy is converted into high-grade heat energy, cooling water consumption is reduced, the temperature of` the shift gas coming out of a process system is lower than or equal to 40 DEG C, equipment is few, the flow is short, the investment is small, and the resistance is low (less than or equal to 0.05MPa).

Owner:NANJING DUNXIAN CHEM TECH

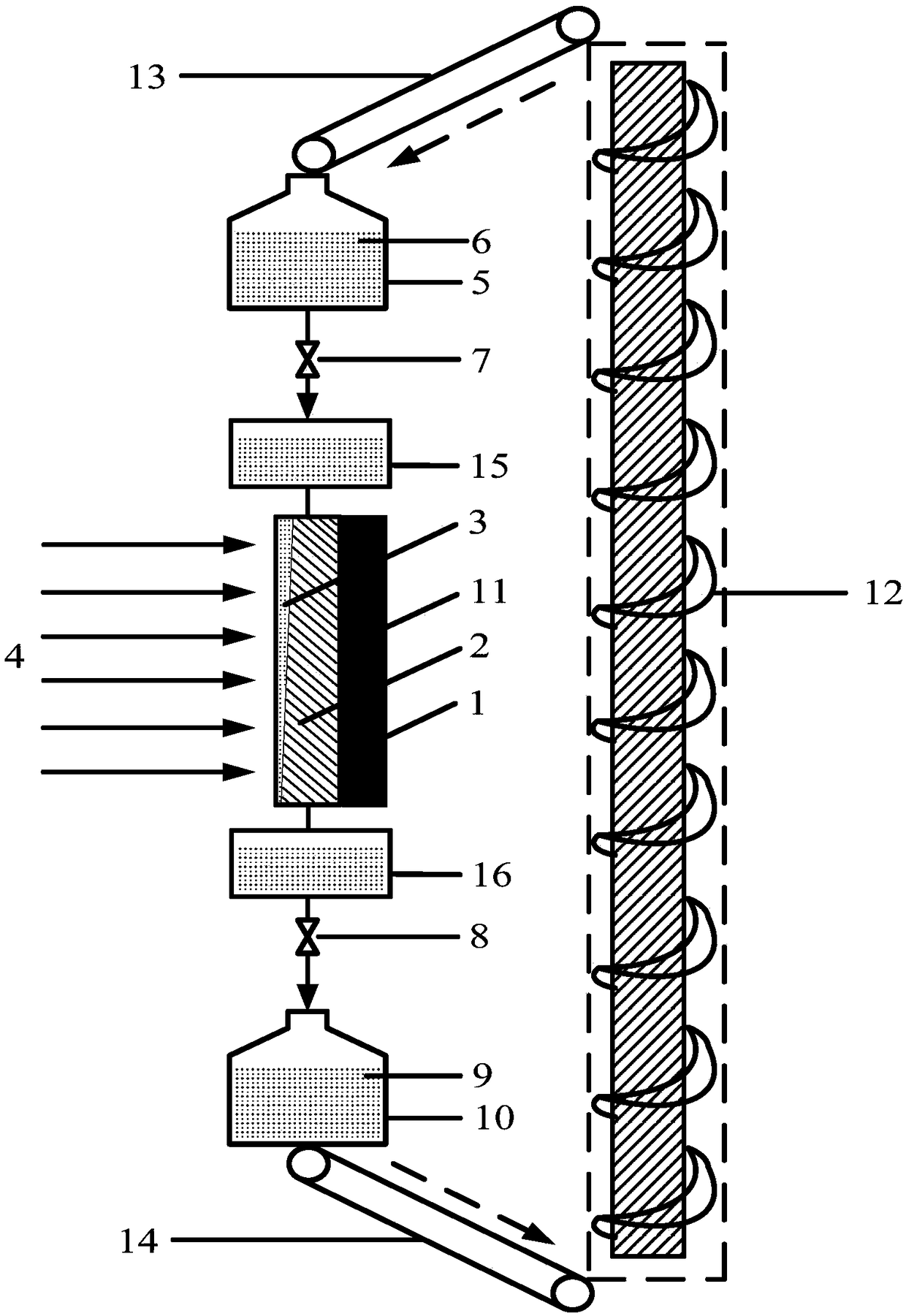

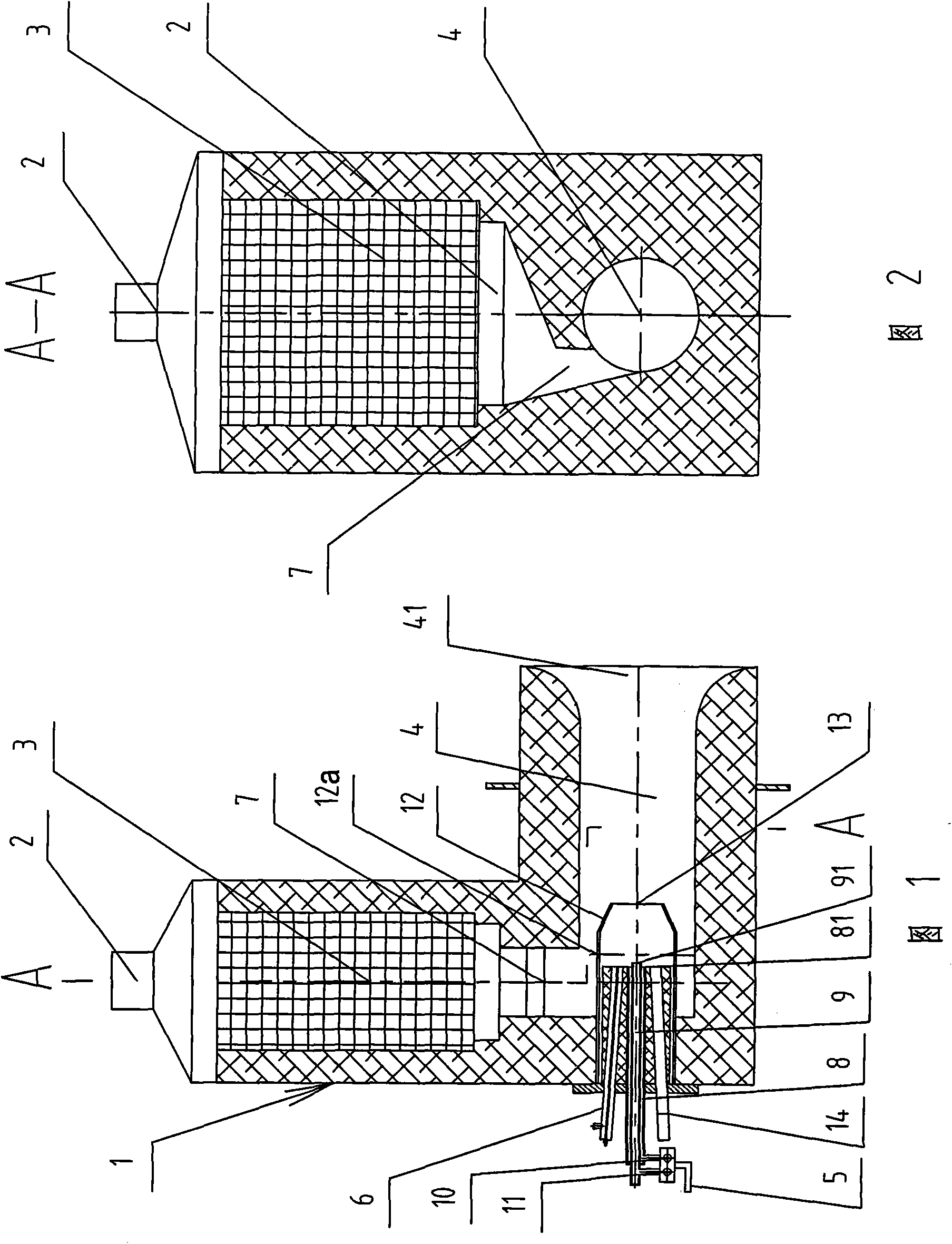

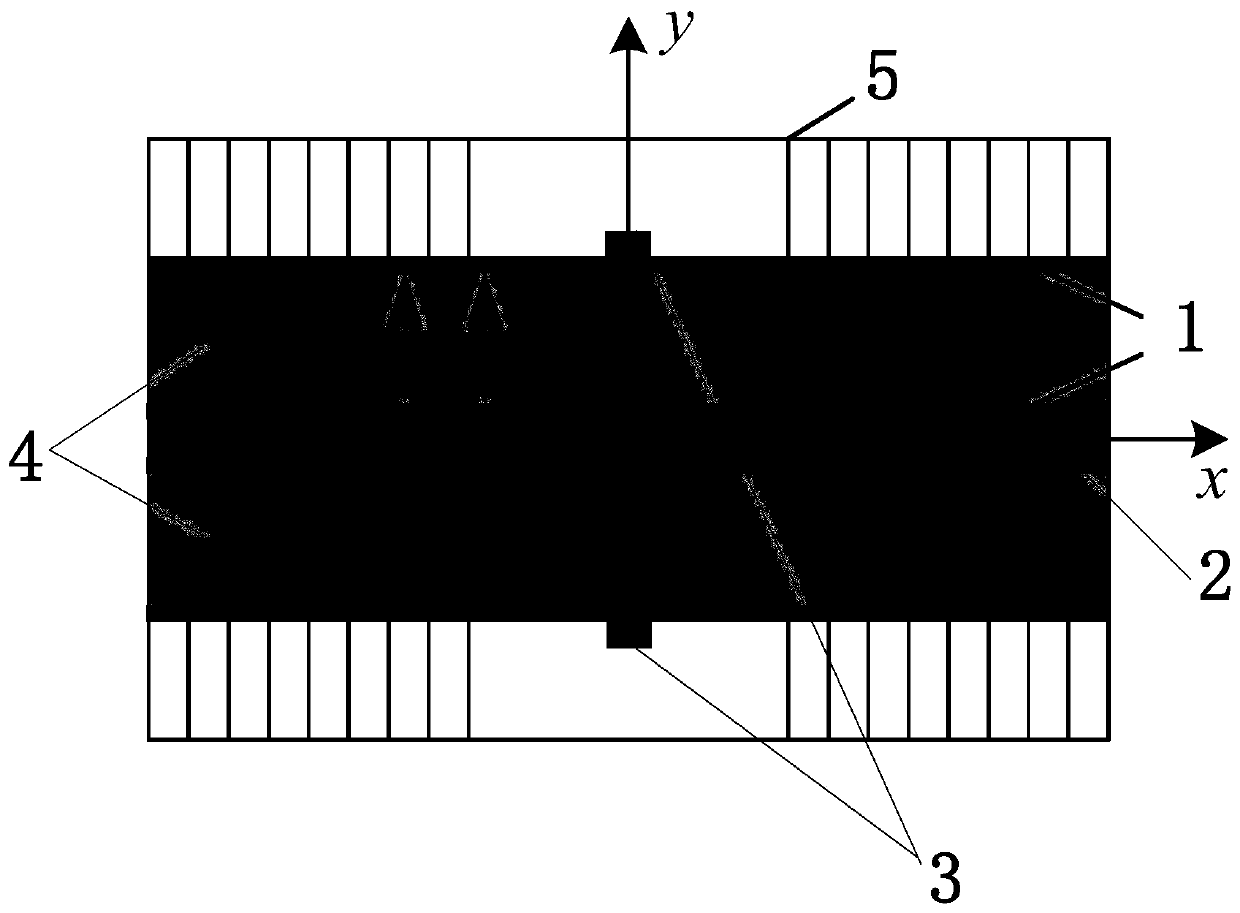

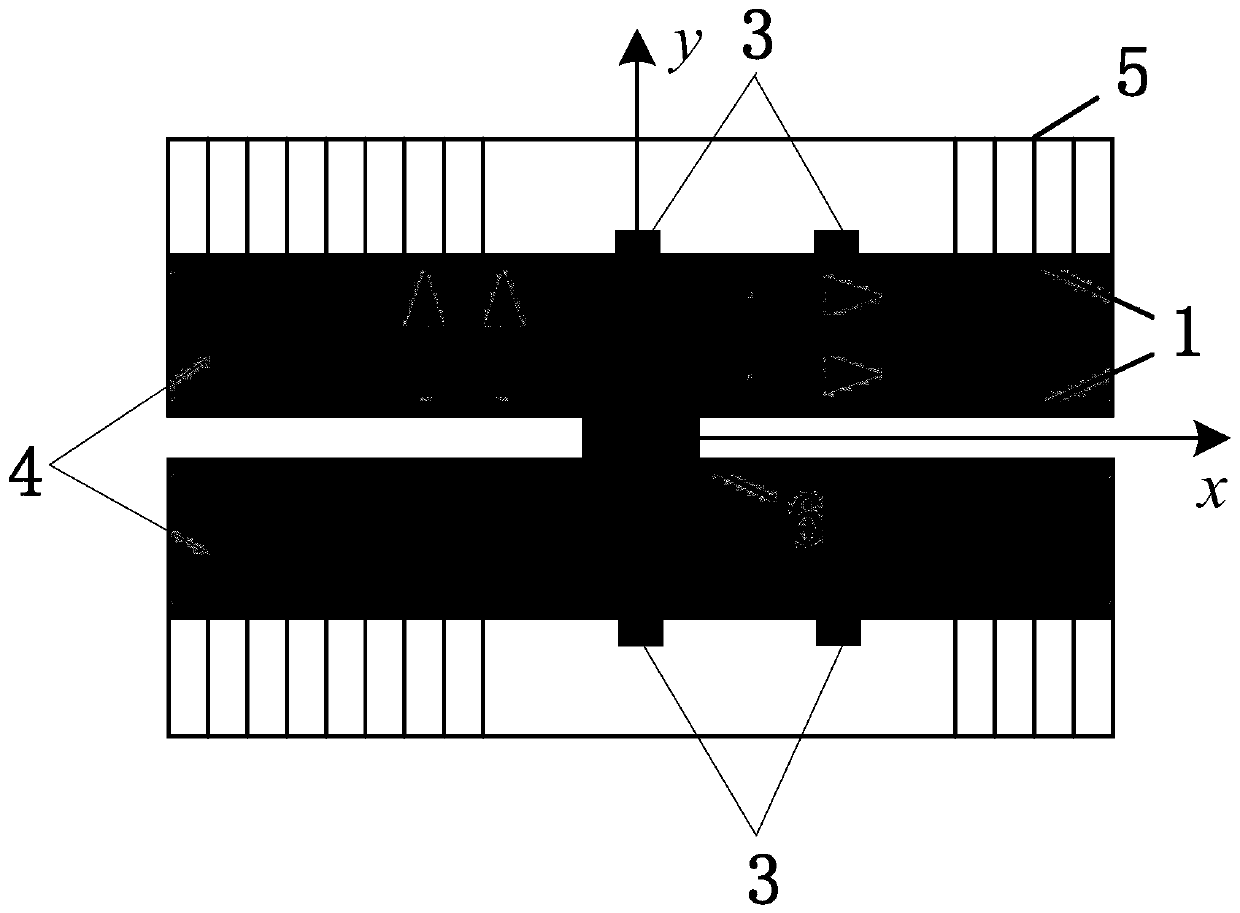

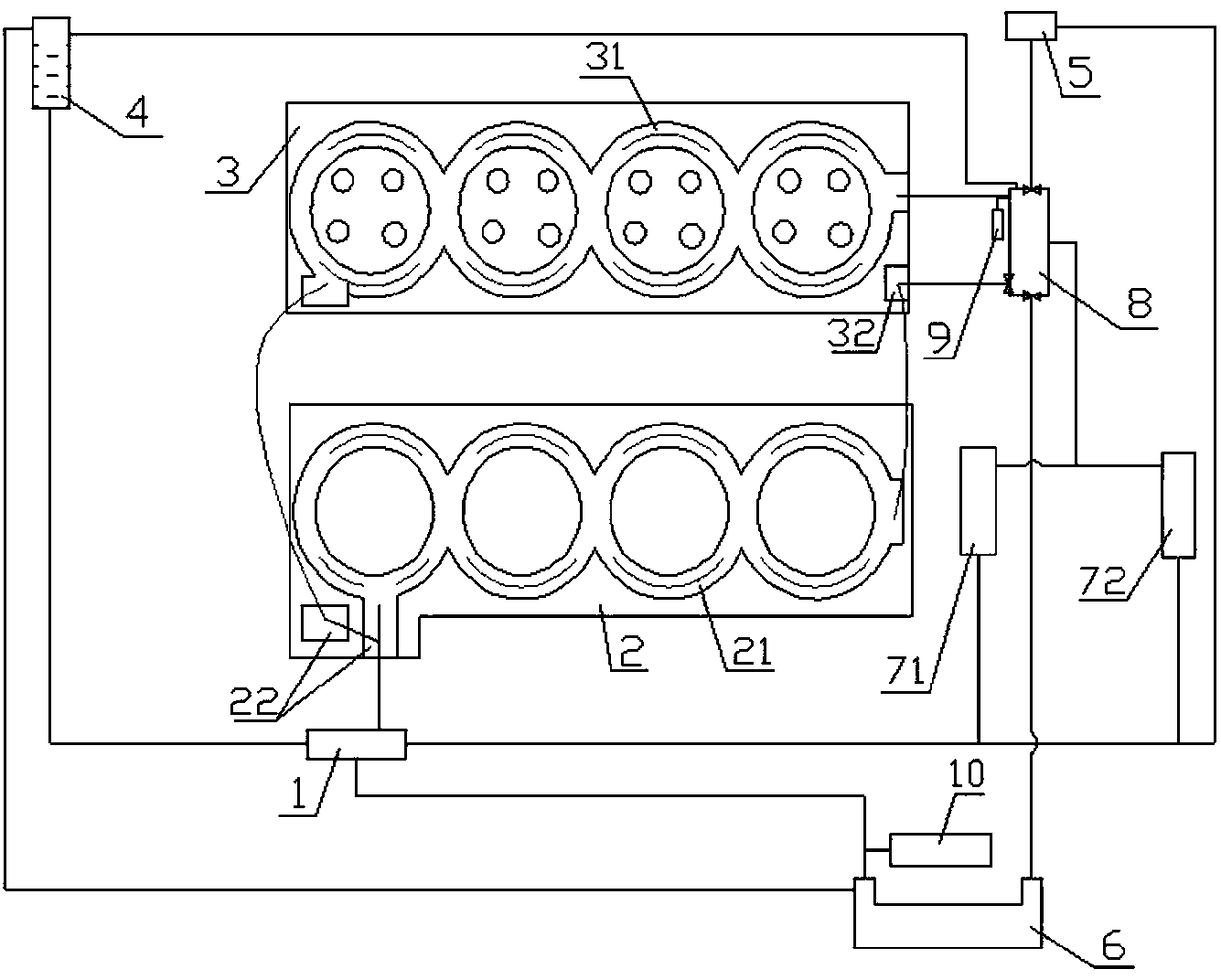

Solid particle heat absorber for solar thermal power generation

ActiveCN108458506AReduce the likelihood of cloggingControllable flow trajectorySolar heating energySolar heat storageSolid particleQuartz

The invention relates to a solid particle heat absorber for solar thermal power generation. A quartz glass tube bundle (1) filled with solid particles (3) is arranged facing a radiant flux (4). An inner heat-insulation layer (2) is located on the backlight side in a tube of the quartz glass tube bundle (1); and the change of a sectional area of a solid particle runner is realized through adjustinga geometrical shape of the inner heat-insulation layer (2). An outer heat-insulation layer (11) surrounds the periphery of the quartz glass tube bundle (1) and is located on one surface back to the radiant flux. A first solid particle valve (17) is arranged on the bottom part of a particle distributor (15) on the upper part of the quartz glass tube bundle (1). A second solid particle valve (18) is arranged on the top part of a particle collector (16) on the lower part of the quartz glass tube bundle (1). A low-temperature particle storage tank (5) is arranged above the particle distributor (15), and a high-temperature particle storage tank (10) is arranged under the particle collector (16). A valve is arranged between the low-temperature particle storage tank (5) and the particle distributor (15); and a valve is arranged between the particle collector (16) and the high-temperature particle storage tank (10).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

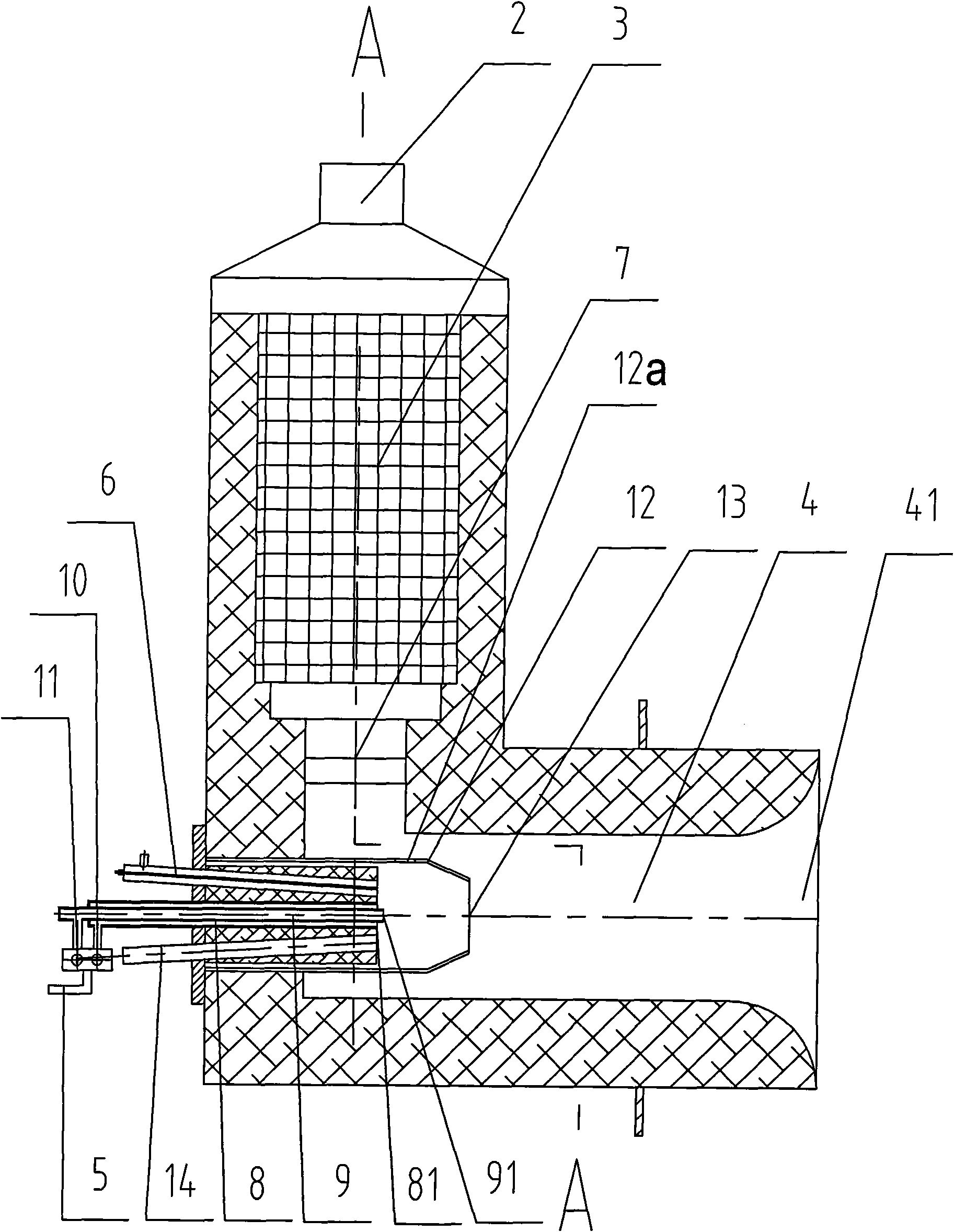

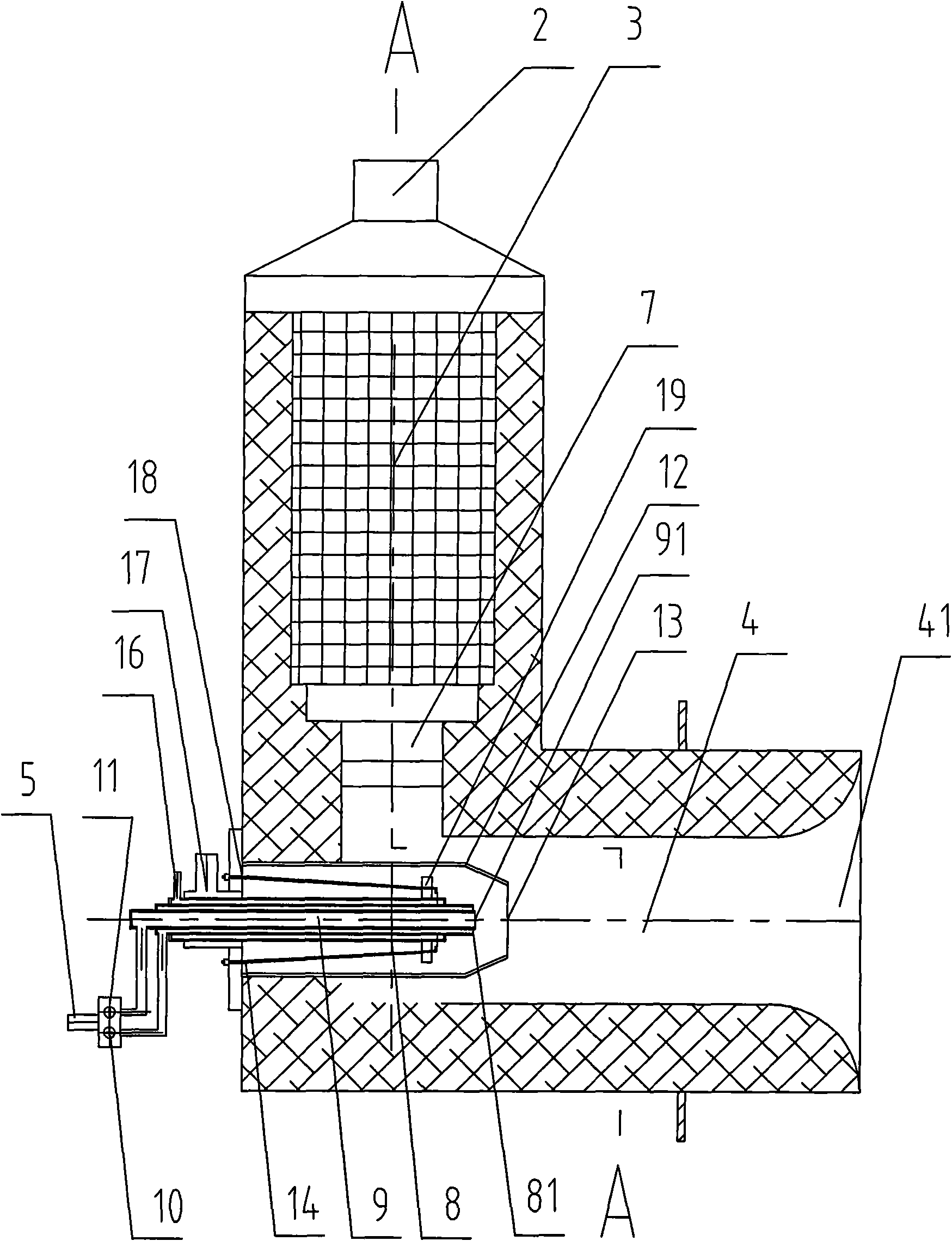

Flameless combustion heat accumulating type flat flame combustion nozzle

ActiveCN101639218AGood energy saving effectImprove energy efficiencyElectric spark ignitersIndirect carbon-dioxide mitigationGas pipelineHigh energy

The invention discloses a flameless combustion heat accumulating type flat flame combustion nozzle. A combustion nozzle body is internally provided with an air or smoke gas passage, a porous heat accumulator, a combustion cavity, a gas pipeline and an ignition device, wherein the tail end of the air or smoke gas passage is provided with a tangential air inlet duct positioned along the tangential direction of the circumferential combustion cavity, and the air or smoke gas passage is connected with the combustion cavity through the tangential air inlet duct; the tail end of the gas pipeline is provided with a flame combustion gas pipe and a flameless combustion gas pipe which are parallel and respectively controlled by a flame combustion control valve and a flameless combustion control valve, and the aperture of a flameless combustion gas spray orifice positioned on the tail end of the flameless combustion gas pipe is smaller than that of a flame combustion gas spray orifice positioned on the tail end of the flame combustion gas pipe. The flameless combustion heat accumulating type flat flame combustion nozzle has high energy utilization efficiency and good furnace temperature uniformity and can greatly reduce the discharge amount of NOX; fuel is sprayed at high speed through the necking spray orifice, thereby effectively controlling the flame temperature and being beneficial tothe sufficient combustion of the fuel; and in addition, the flame sprays into a furnace cavity with a very short spraying distance so as not to spray to parts inside the furnace cavity.

Owner:CHONGQING AOKEQI TECH

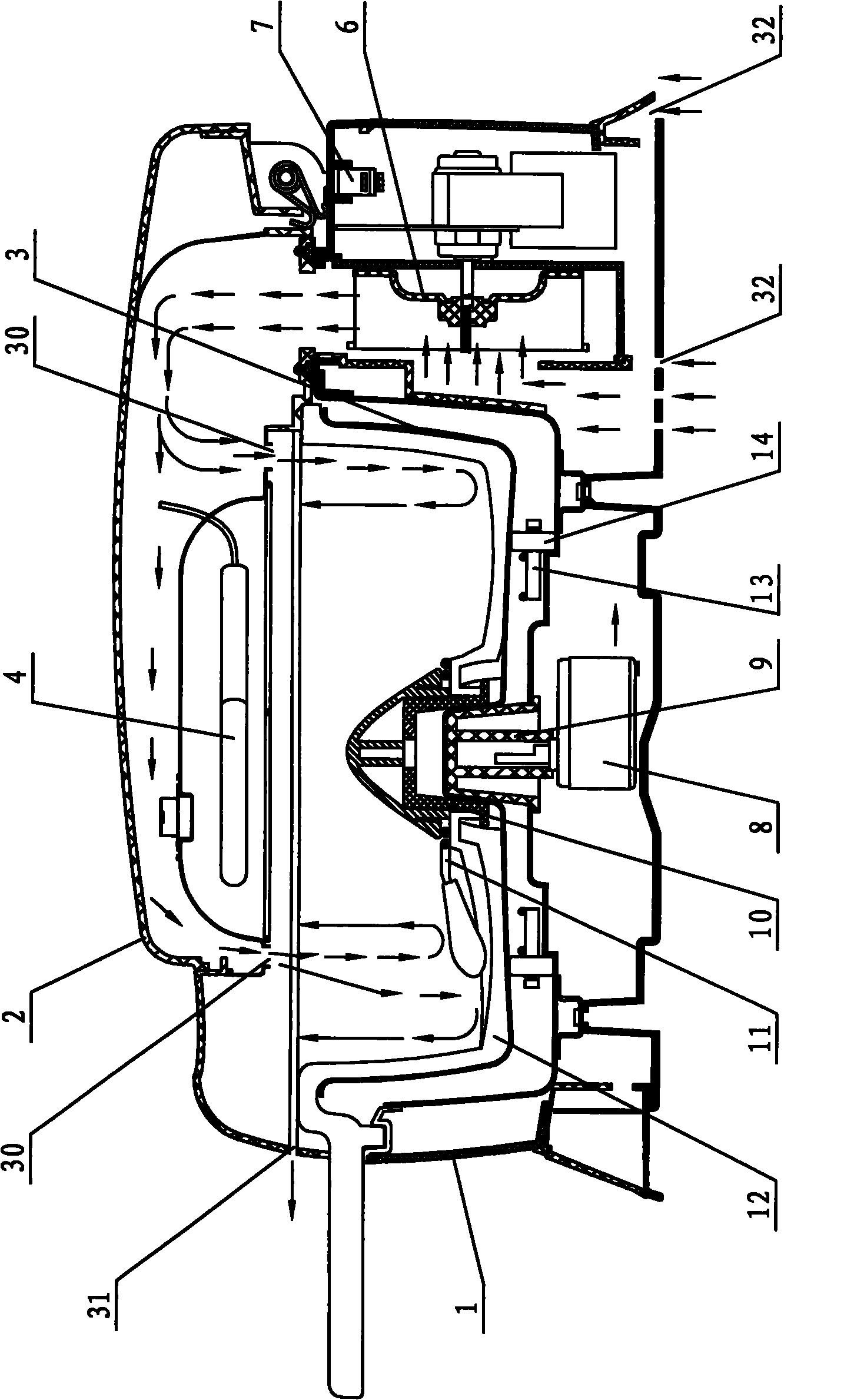

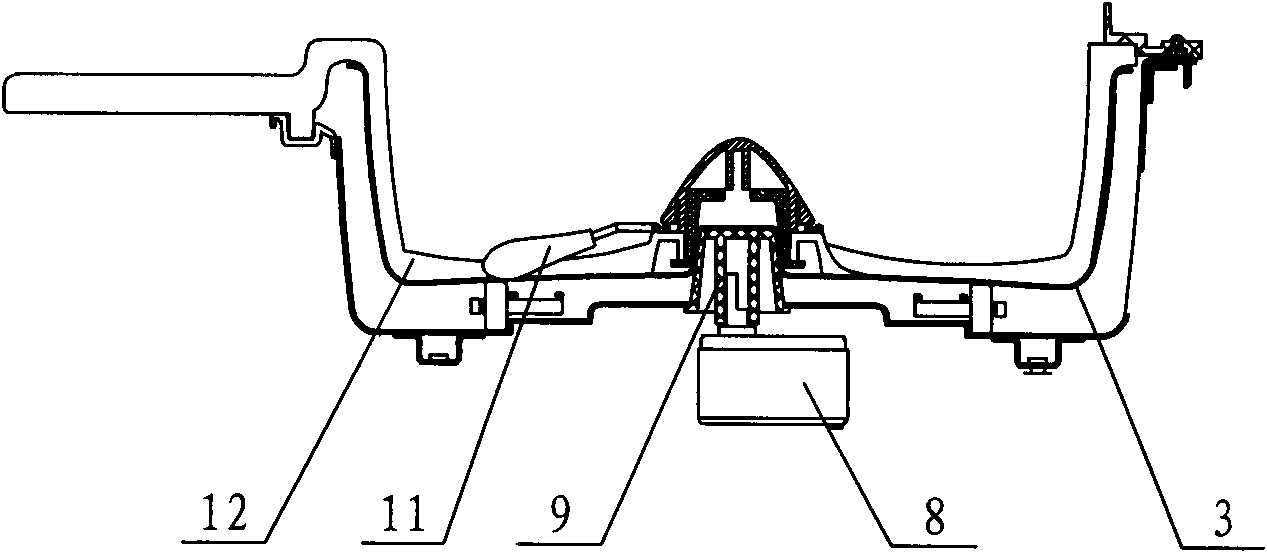

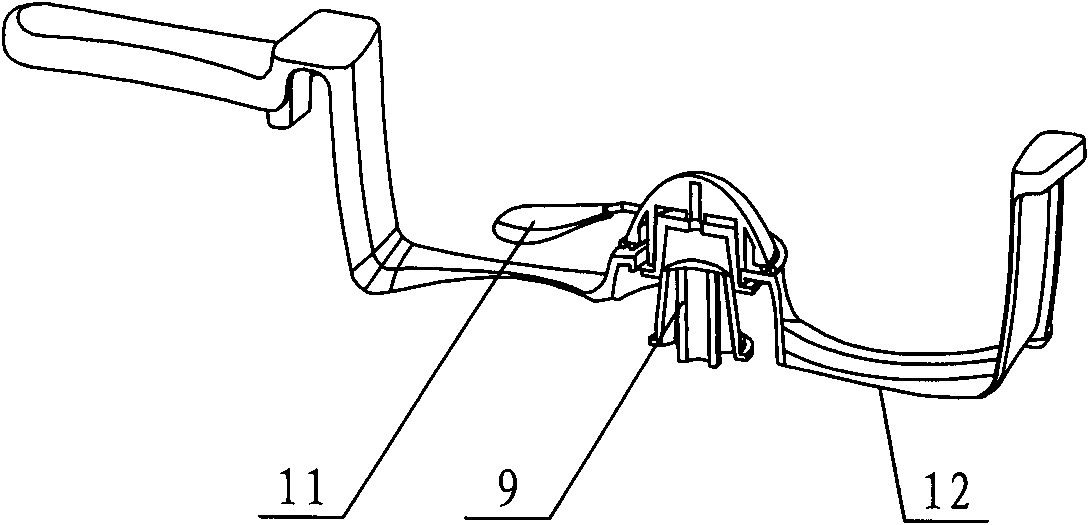

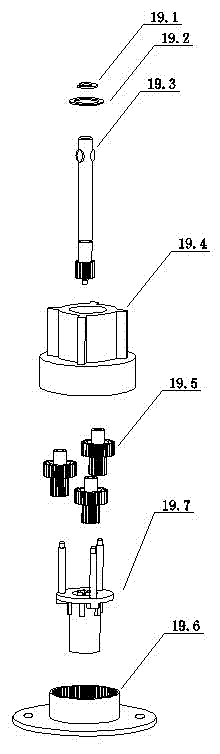

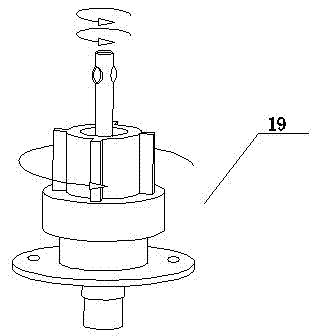

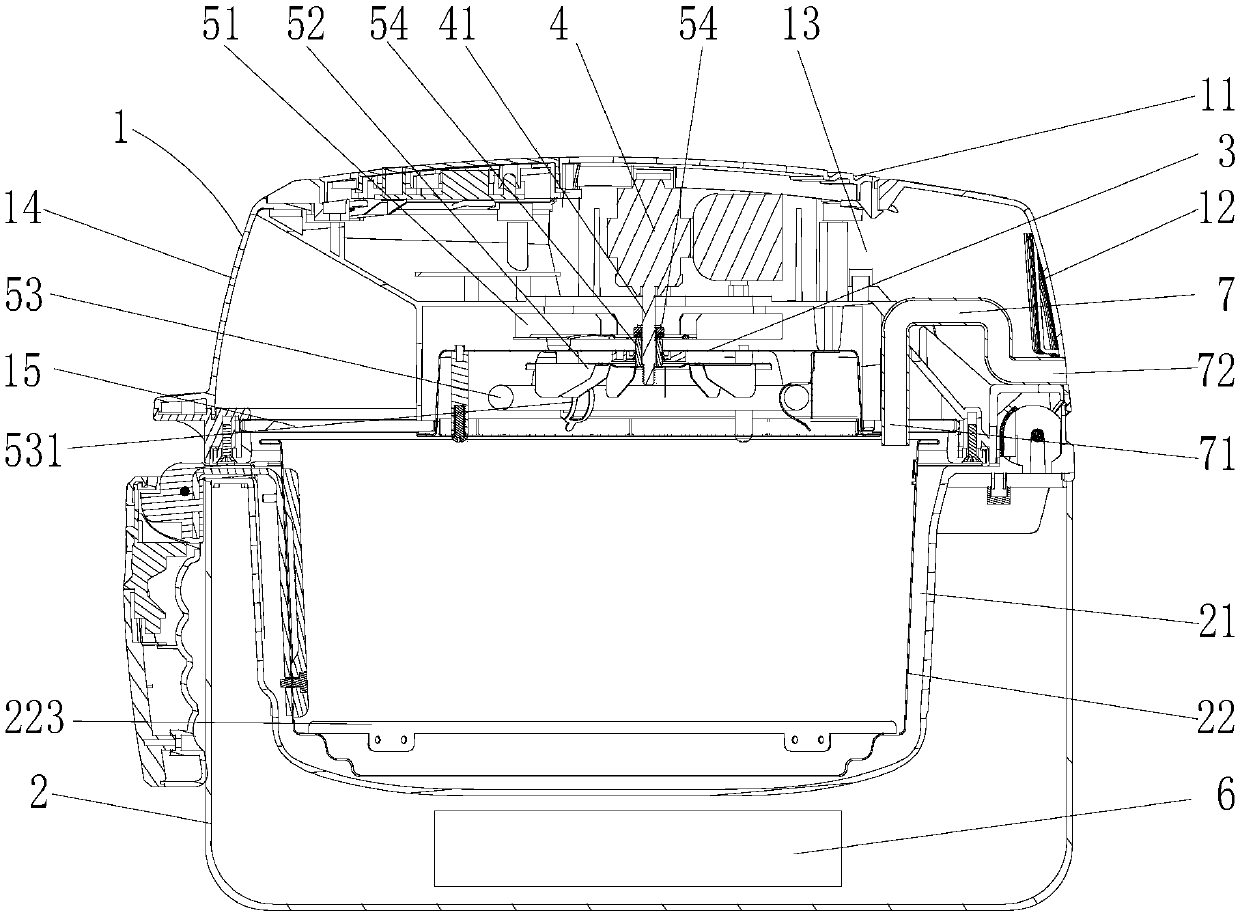

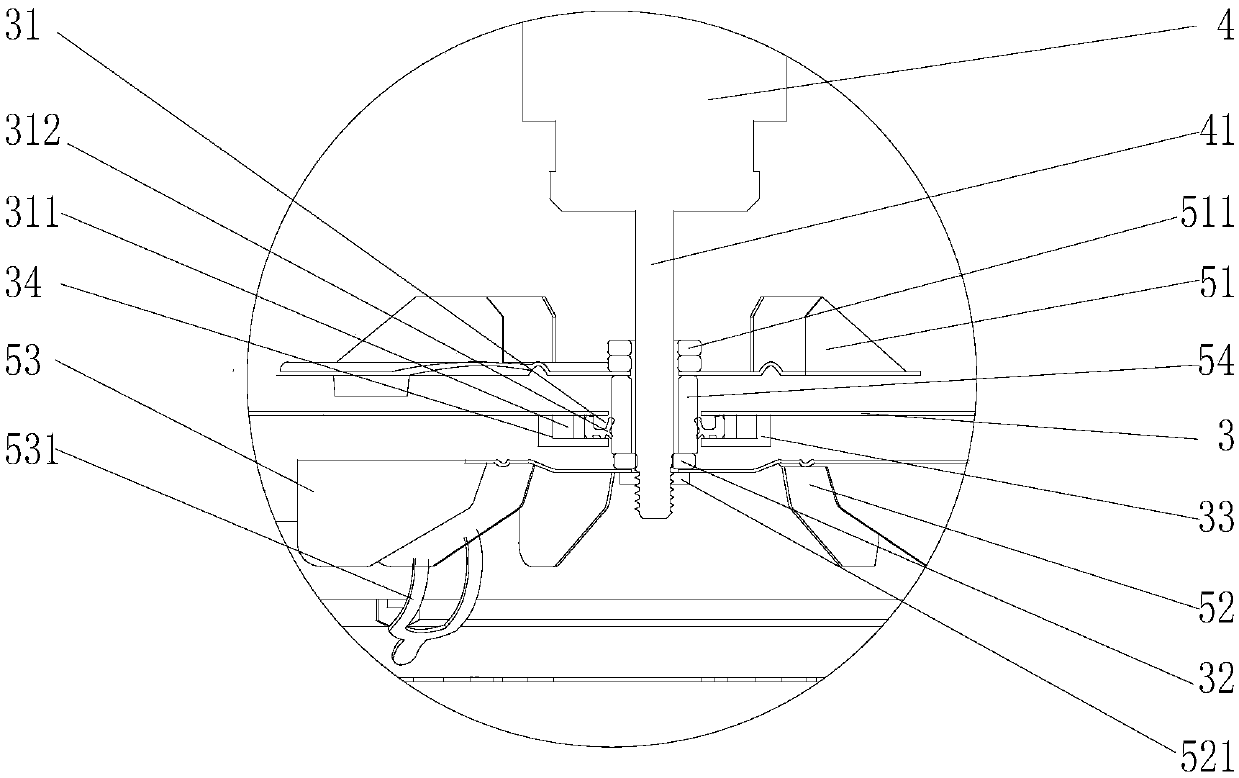

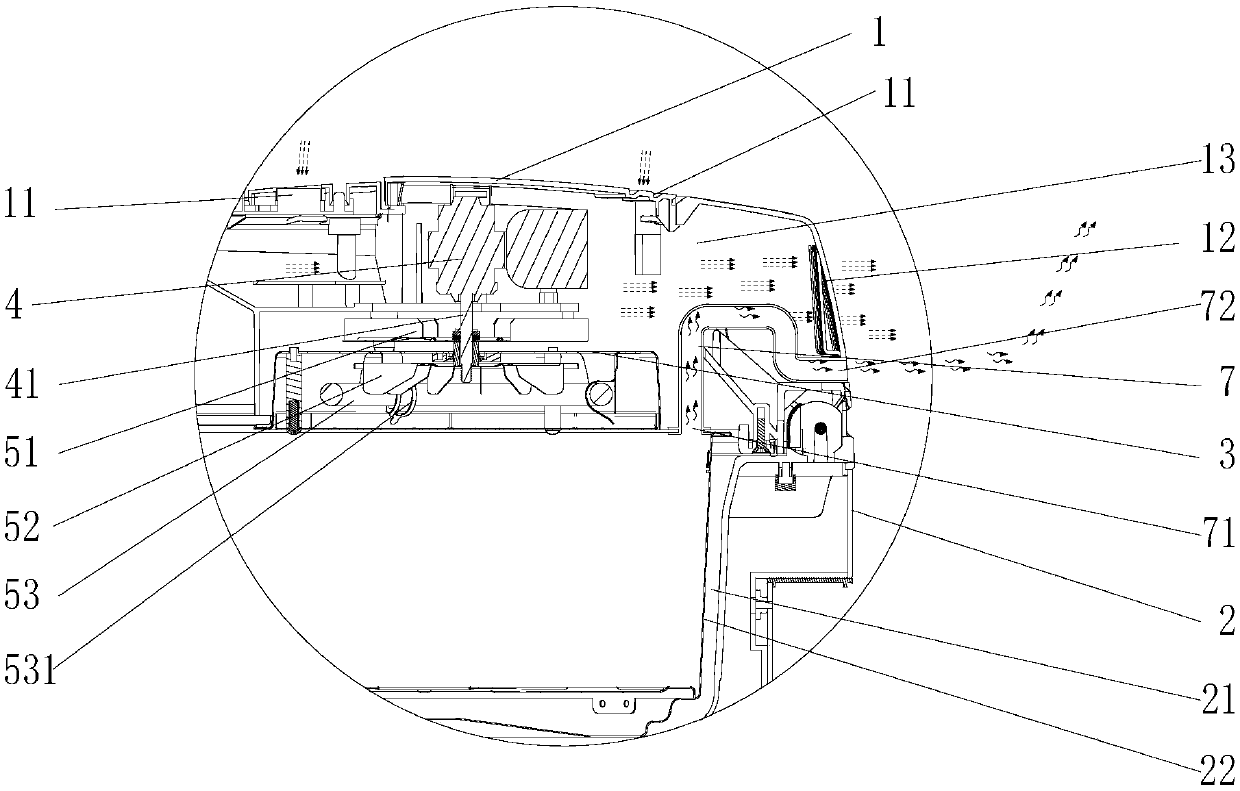

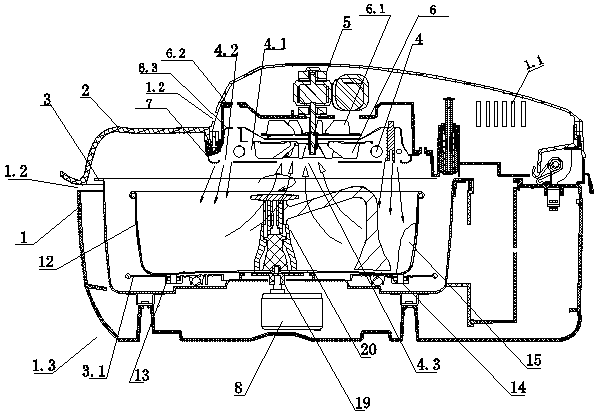

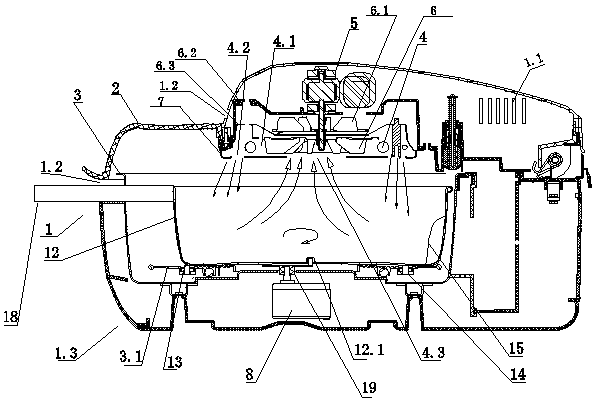

Multi-functional cooking pan

InactiveCN102151094AEvenly heatedHard on the outside and soft on the insideRoasters/grillsWaste managementAir drying

The invention discloses a multi-functional cooling pan, which comprises a body, a cover and a heater. A cooking pan container is arranged in the body; a food rolling device is arranged in the cooking pan container; the body and the cover enclose a relatively sealed cavity together; a cooling and air drying airduct is arranged in the cavity; a cooling and air drying fan is arranged in the cooling and air drying airduct; the cavity is provided with an air outlet and an air inlet; one end of the cooling and air drying airduct is communicated with the air outlet, while the other end is communicated with the air inlet which is communicated with the outside; the air outlet faces the food rolling device. The cooling and air drying airduct comprises a first cooling and air drying airduct and a second cooling and air drying airduct; the first cooling and air drying airduct is arranged in the cover; and the cooling and air drying fan and the second cooling and air drying airduct are arranged in the body and outside the cooking pan container. The multi-functional cooling pan has the characteristics of good cooking effect, simple disassembly and cleaning, and wide application range.

Owner:周林斌 +1

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377AReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

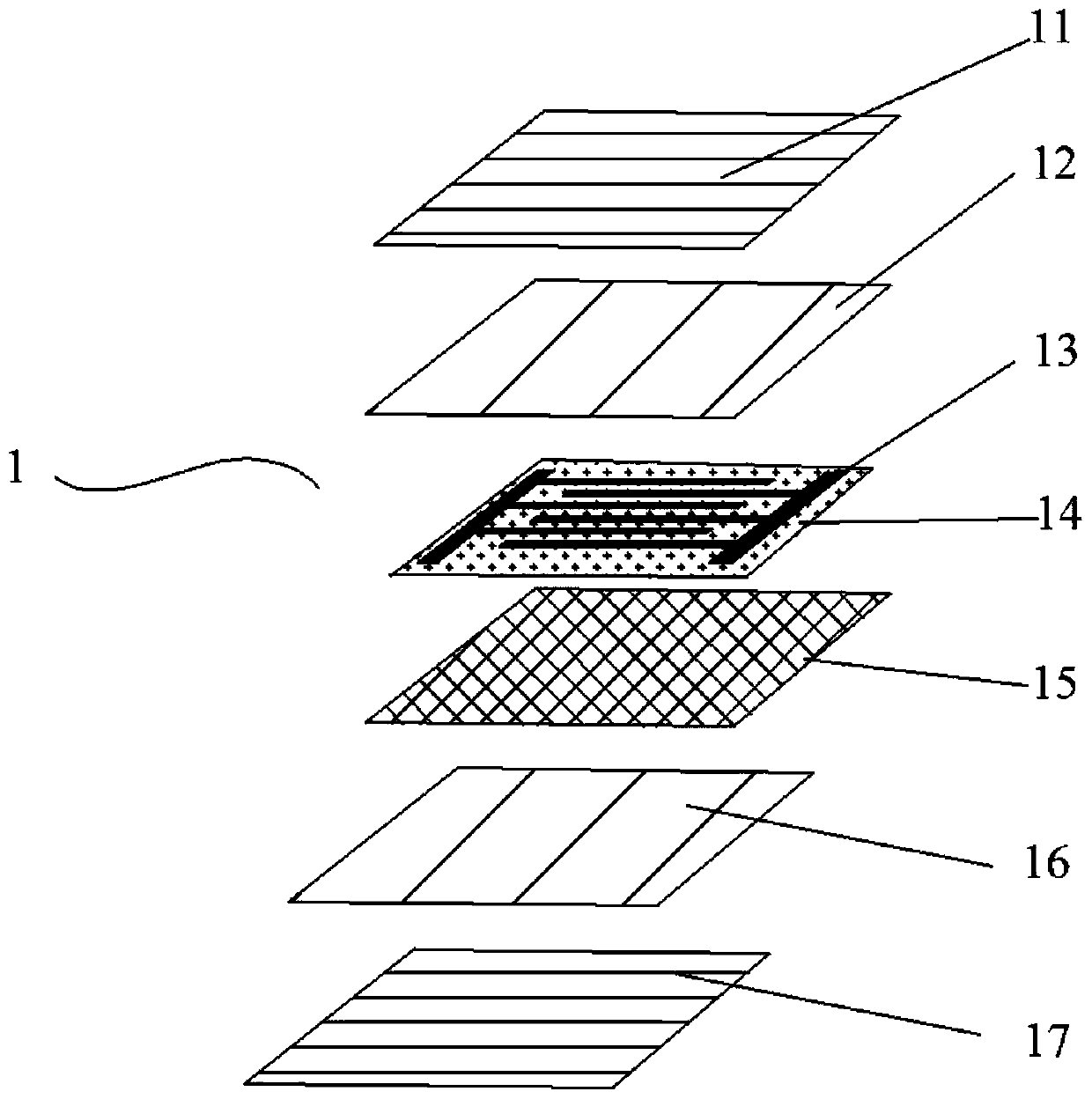

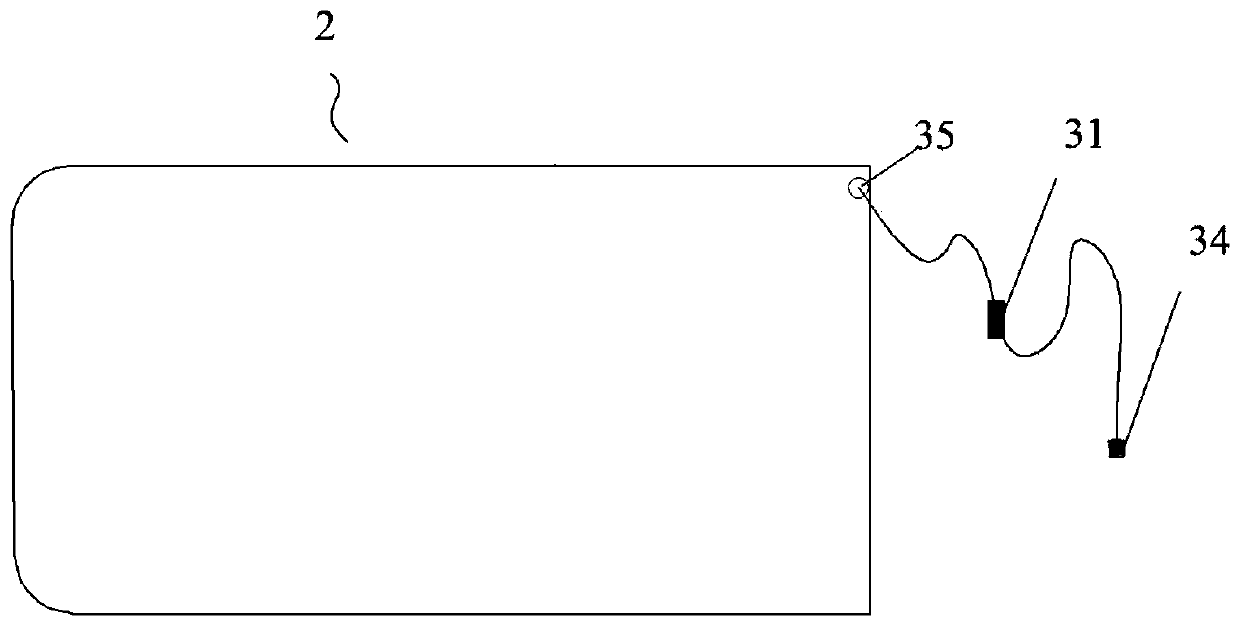

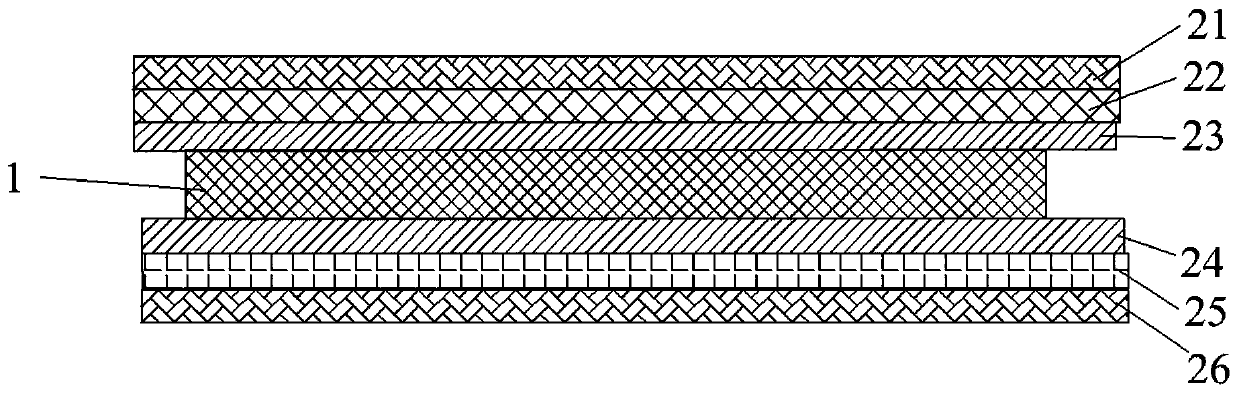

Graphene heat-emitting film assembly with single-side far infrared radiation function and bed warmer based on graphene heat-emitting membrane assembly

PendingCN110475396AUniform and stable heatingImprove the effect of physical therapyOhmic-resistance electrodesChemical industryBlood circulationFar infrared

The invention discloses a graphene heat-emitting film assembly with a single-side far infrared radiation function and a bed warmer based on the graphene heat-emitting film assembly. According to the graphene heat-emitting film assembly of the invention, one surface of a graphene heat-emitting film layer, which is far away an electrode layer, is provided with a far infrared reflecting layer. The graphene heat-emitting film assembly disclosed by the invention has an excellent infrared reflection effect and is more energy-saving; the bed warmer based on the graphene heat-emitting film assembly has the advantages of good heat-emitting stability, high temperature rise speed, uniform heat emission and soft material, and can realize the physical therapy functions of promoting blood circulation, repairing cells, preventing diseases and the like..

Owner:合肥微晶材料科技有限公司

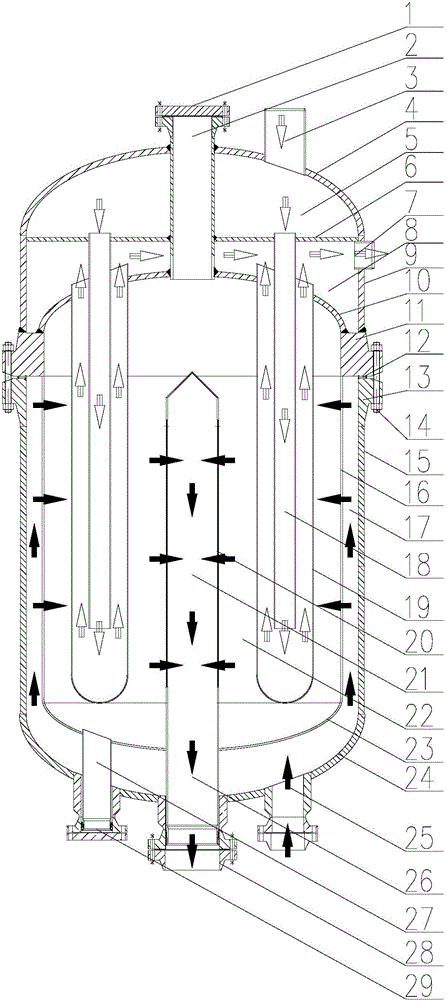

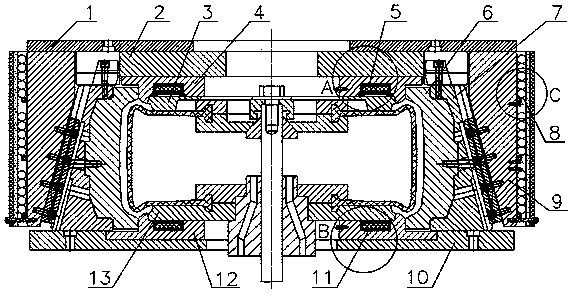

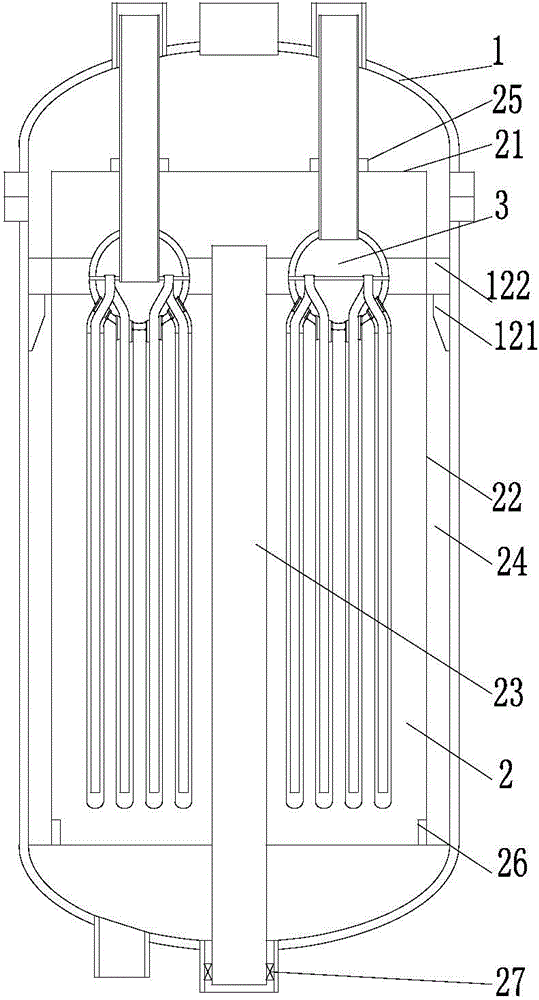

Dual-seal-head controllable water heat removing reactor

ActiveCN104645897AEasy to unloadPromote repairHydrogenHydrocarbon from carbon oxidesTemperature controlProduct gas

The invention discloses a dual-seal-head controllable water heat removing reactor. The top of a main cylinder body is connected with a lower flange; the bottom of the main cylinder body is connected with a lower outer seal head; the upper flange is connected with the lower flange; one end of a catalyst filling pipe is connected between an upper inner seal head and a gas distribution cylinder, and the other end of the catalyst filling pipe sequentially penetrates through a baffle and an upper external seal head; one end of a water guide pipe is communicated between the baffle and the upper outer seal head, and the other end of the water guide pipe sleeves a heat exchange pipe internally; a pipe body of the heat exchange pipe is positioned in a gas distribution cylinder; an outlet of the heat exchange pipe is formed between the baffle and the upper inner seal head; a cylinder body of a gas collecting cylinder is positioned in the gas distribution cylinder; an outlet of the gas collecting cylinder is connected with a gas outlet. The heat exchange pipe is buried in a catalyst bed layer so as to remove reaction heat in the catalyst bed layer timely, and the defects of short service life, easiness in overtemperature, multiple auxiliary reactants, difficulty in bed layer temperature control, long driving time, difficulty of scaling up, high running energy consumption, high project investment and the like in the prior art can be solved.

Owner:NANJING DUNXIAN CHEM TECH

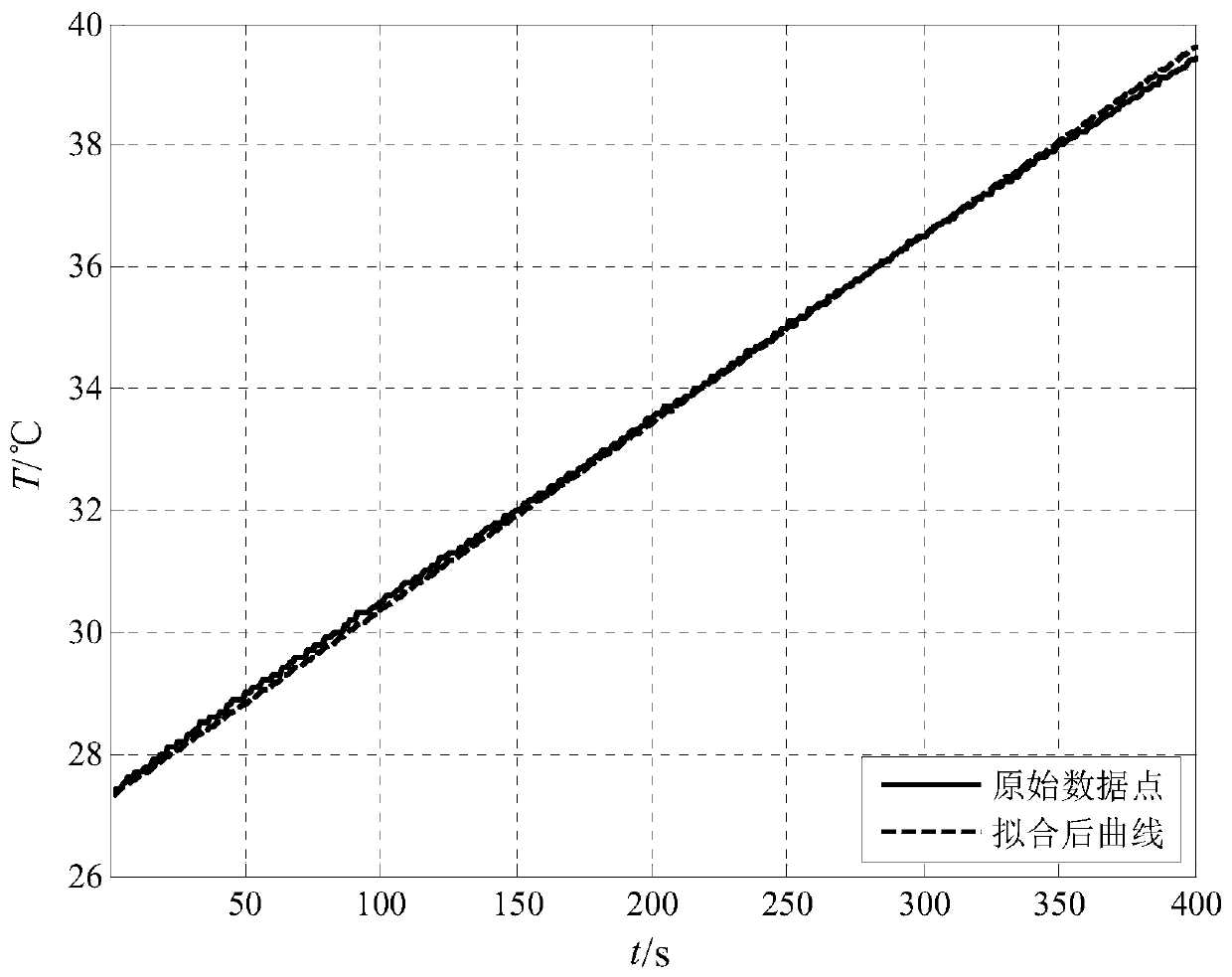

Square lithium ion battery internal thermophysical parameter identification method

ActiveCN109900734ARealize the establishmentAvoid errorsMaterial heat developmentSecondary cellsTwo temperatureEngineering

The invention relates to a square lithium ion battery internal thermophysical parameter identification method and belongs to the field of lithium ion batteries. According to methods for directly obtaining the analytical solutions of heat transfer model equations in existing battery thermophysical parameter identification methods, the overall parameters of batteries are identified, and the internalthermophysical properties of the batteries cannot be identified, while, with the square lithium ion battery internal thermophysical parameter identification method of the invention adopted, the problems in the existing methods can be solved. According to the square lithium ion battery internal thermophysical parameter identification method of the invention, the internal specific heat at constantpressure of a battery is obtained according to battery shell and internal mass, the specific heat at constant pressure of battery shells, heating power and the relation of the temperature of the battery varying with heating time; and the internal longitudinal thermal conductivity coefficient of the battery is obtained according to a heat transfer process, specific heat capacity and boundary conditions; two thermocouples on each battery shell are adopted to obtain two temperatures, and the temperatures of two temperature points at the inner sides of an equal thickness of the lithium ion batteryshells are obtained according to the longitudinal thermal conductivity coefficient and a heat transfer model; and on the basis of the two temperature points and the boundary conditions, the transverse thermal conductivity coefficient of the internal material of the battery is obtained according to the heat transfer model. The method is used to identify the internal thermophysical parameters of the battery.

Owner:HARBIN INST OF TECH

Codirectional stirring oven and related method thereof

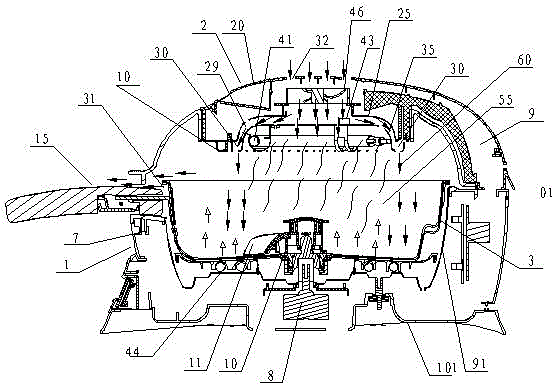

ActiveCN102961055AReduce distanceFor culinary needsRoasting apparatusRoasters/grillsHeat flowEngineering

The invention relates to a codirectional stirring oven which comprises a pot body, a pot cover, fan blades, a motor and a heater. The pot body is provided with a rotating basin for containing foods and a stirring device; a relatively sealed cavity is formed by the pot body and the pot cover in a surrounding manner; and the heater, a heat flow passage, the fan blades and the motor which are communicated with and correspond to the rotating basin are arranged in the cavity. The codirectional stirring oven is characterized in that heat flow generated by the fan blades, the motor and the heater is blown into the rotating basin so as to heat the foods, the rotating basin and the stirring device rotate in the same direction so as to generate speed difference, and when the stirring device rotates, the foods are pushed to be rolled over and uniformly heated; and the opening of the rotating basin faces up, so that when the rotating basin rotates, the foods are driven to be uniformly heated in a multidirectional manner. The codirectional stirring oven has the characteristics of simple and reasonable structure, flexibility in operation, uniformity in heating foods, good cooking effect, easiness in assembly, disassembly and cleanliness and wide application range.

Owner:ZHONGSHAN CITY GOLDLABO ELECTRIC CO LTD

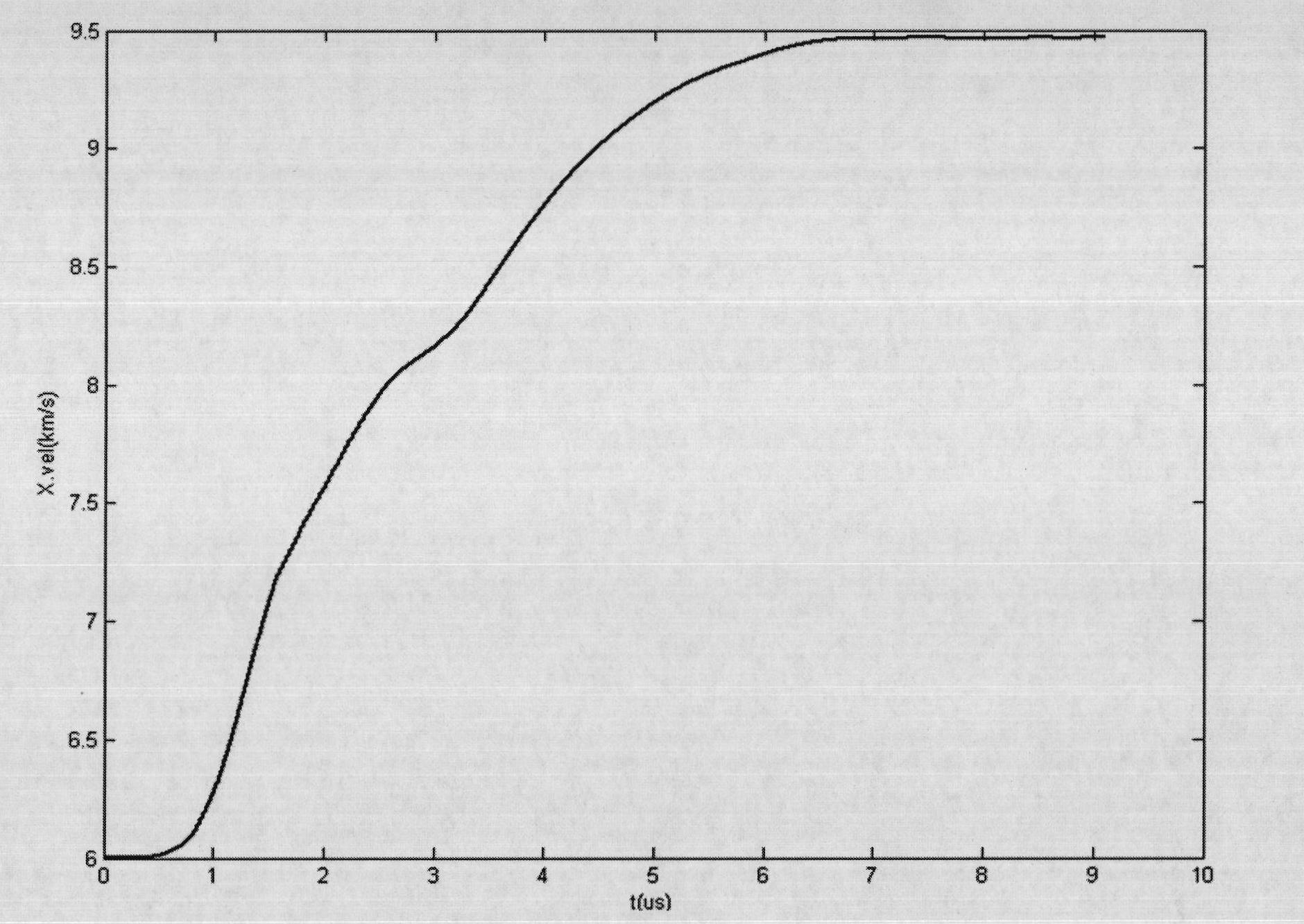

Ultra-high-speed gram-magnitude spherical projectile transmitting device

The invention discloses an ultra-high-speed gram-magnitude spherical projectile transmitting device comprising a two-stage light gas-gun, an extension section and a three-stage accelerating cavity, wherein one end of the extension section is fixedly connected with an outlet of the two-stage light gas-gun, the other end of the extension section is fixedly connected with the connection end of the three-stage accelerating cavity, the three-stage accelerating cavity is designed with a two-section inner diameter, an annular PC resin sleeve is arranged on an annular boss in the cavity towards the extension section, and a high explosive is embedded into the PC resin sleeve; an accelerating unit transmitted by the two-stage light gas-gun comprises a projectile holder, spherical projectiles and annular steel sheets, wherein the projectile holder is in a cylindrical structure, the top of the cylindrical structure is provided with a cylindrical projective end, the annular steel sheets are in sleeve joint with the projective end and are bonded on the front end surface of the projectile holder, and the spherical projectiles are bonded at the projective end of the projectile holder. The ultra-high-speed gram-magnitude spherical projectile transmitting device not only can accelerate gram-magnitude spherical projectiles to 10km / s, but also can ensure that the spherical projectiles are not overheated, has the last length to diameter ratio L / d near 1 and has no primary flyer fragments to follow in order to ensure the effects of space fragment protective structure optimization design and performance evaluation impact test.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

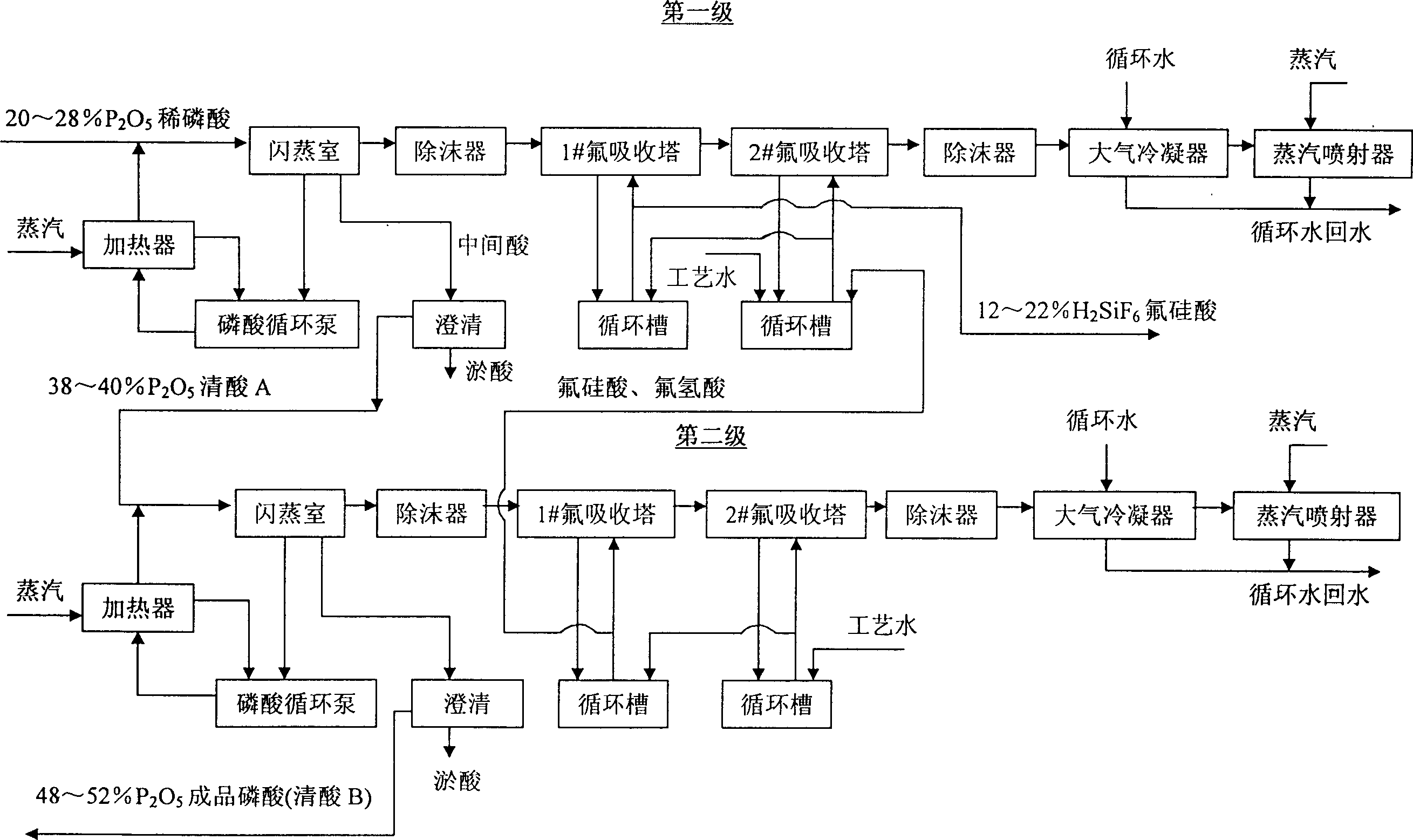

Wet-process two-stage phosphoric acid concentration method

ActiveCN1843901AReduce concentrationReduce power consumptionPhosphorus compoundsWater circulationFertilizer

The invention discloses aprocess of two-stage condensing phosphoric acid with wet method. It comprises condensing phosphoric acid, clarifying, adsorbing with fluorine and water circulation system; and it employs a two-stage condensing course in series: adding diluted phosphoric acid into the first stage condensing closed circuit, heating with steam, steaming out of water in a short time invacuum condition to condense phosphoric acid into mediate acid, clarifying to remove part of suspending soild and getting clean acid A; putting acid A to the second condensing system to be condensed into diluted phosphoric acid, clarifying and getting clean acid B, that is the finished product. The left acid by clarifying in the two stages is used for preparing compound fertilizer or is recoveried after press filtration; the SiF4 and HF in steam is adsorbed through two-stage adverse current and is prepared into side product of fluosilicic acid. The invention smploys a two-stage condensing process, which improvese heat and mass transferring process, saves investment at the same production capability; reduces phosphoric acid circulation amount and circulating water consumption; reduces phosphoric acid viscosity and improves concentration and quality of finished product.

Owner:SINOPEC NANJING ENG & CONSTR

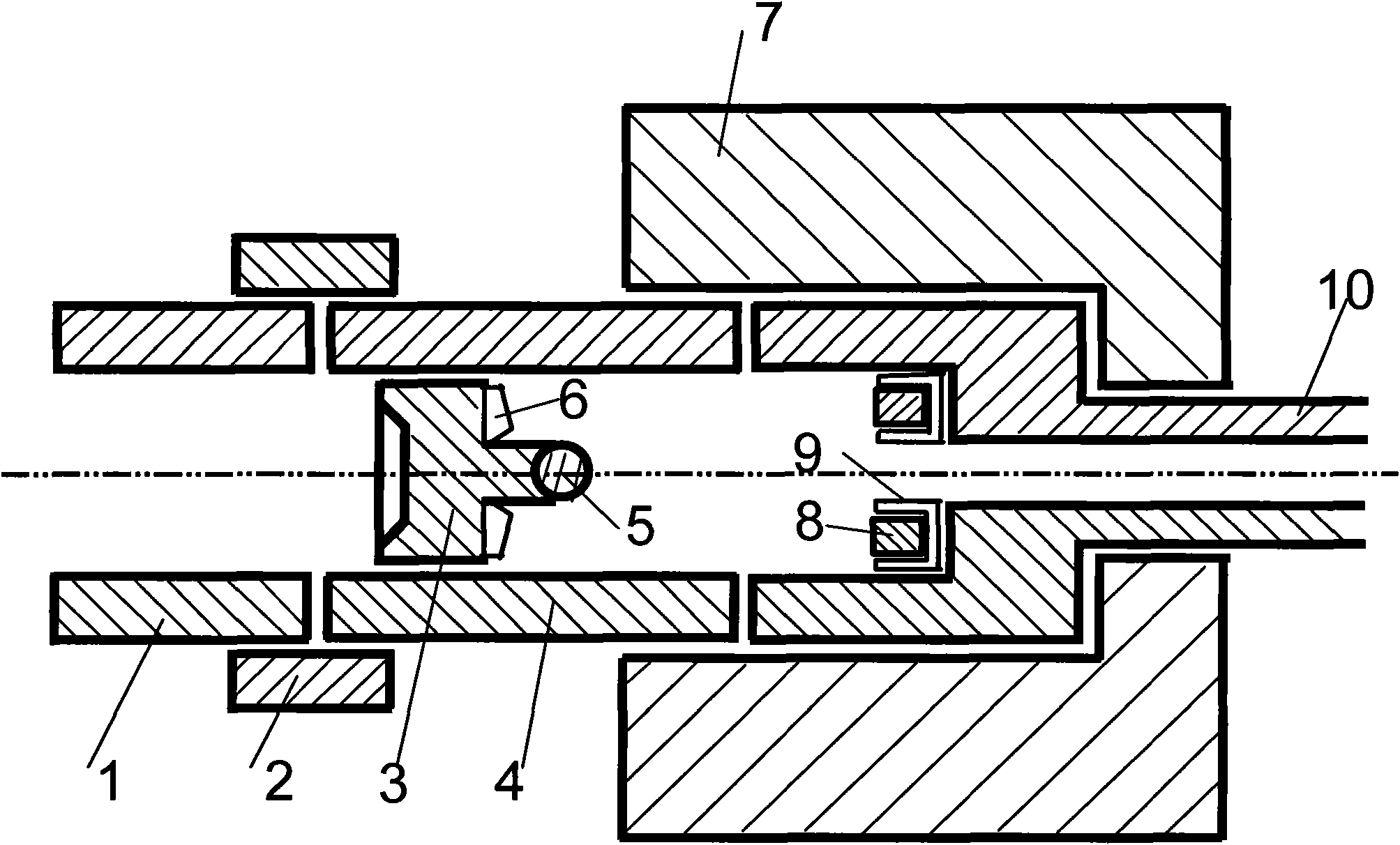

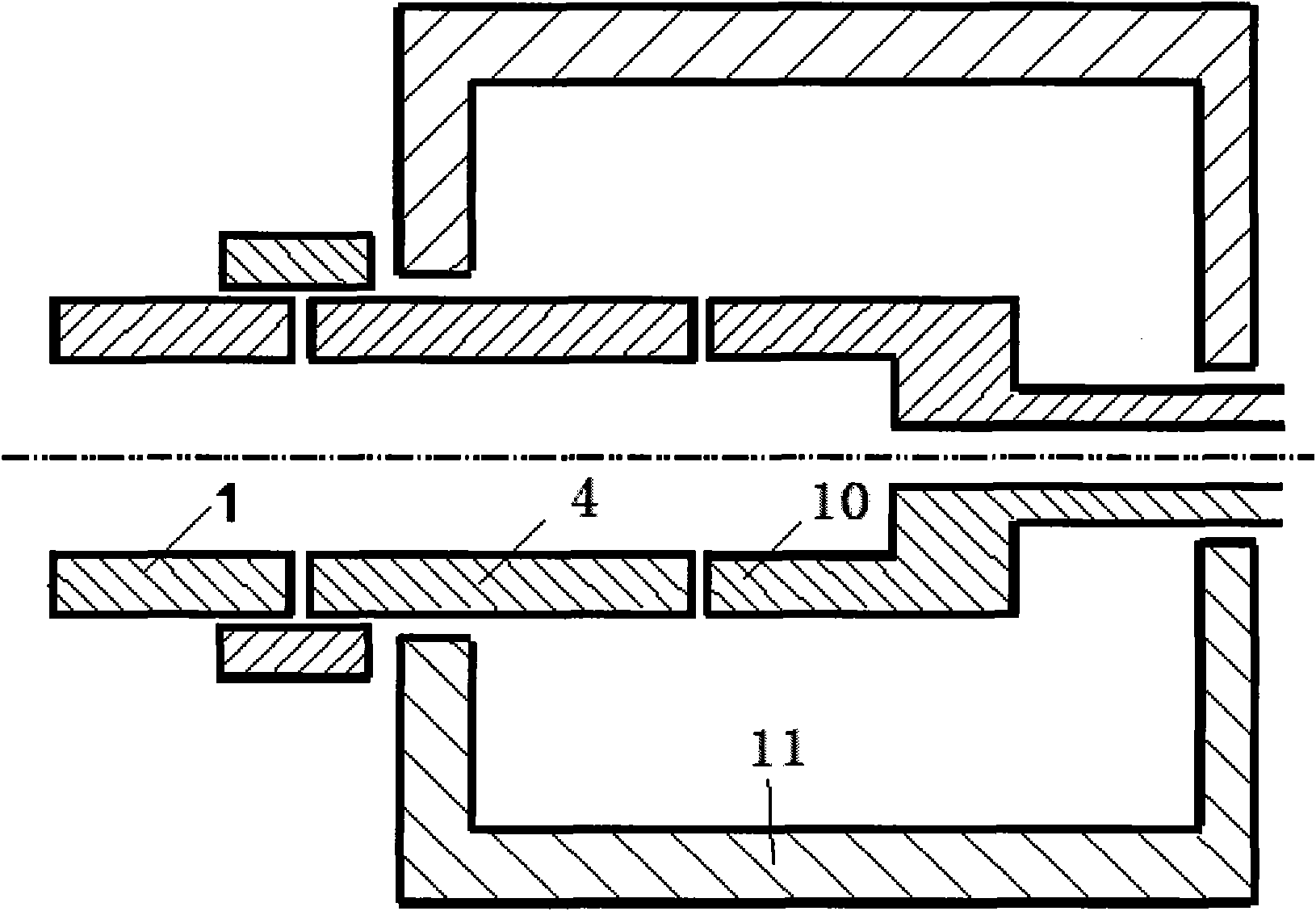

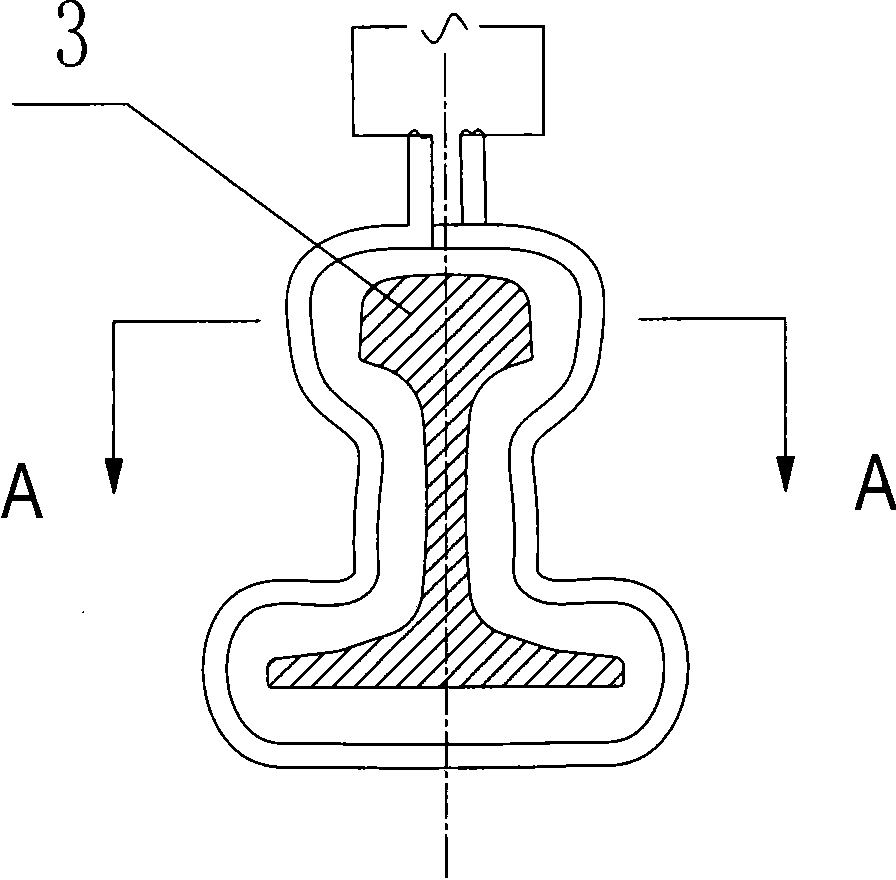

Superconductive heat pipe electric heater

ActiveCN103363571ASimple structureReasonable structureElectric heating systemIndirect heat exchangersHeat conductingEngineering

The invention provides a superconductive heat pipe electric heater, belongs to the field of electrical heating equipment, and particularly relates to an electric heater using a heat pipe as a heat transfer element to dissipate heat. A heat-conducting medium absorbs heat released by a heating element. The heat is dissipated to the air through fins (4). The superconductive heat pipe electric heater is characterized in that a circulation chamber (5) and a heating chamber (1) are installed in a heater shell body (9); the circulation chamber (5) and the heating chamber (1) are communicated through the heat pipe (3) which is used as a heat conduction element; the circulation chamber (5), the heating chamber (1) and the heat pipe (3) form an airtight vacuum space; the circulation chamber (5), the heating chamber (1) and the heat pipe (3) are filled with heat-conducting media respectively; an electrical heating rod (2) is installed in the heating chamber (1). According to the superconductive heat pipe electric heater, the heating method and heat conduction method of a traditional electric heater are changed, superconductive liquid is used as the heat-conducting media, therefore, the temperature rise speed is increased, energy sources are saved, and heat exchange efficiency is improved at the same time.

Owner:山东伟瑞制冷科技有限公司

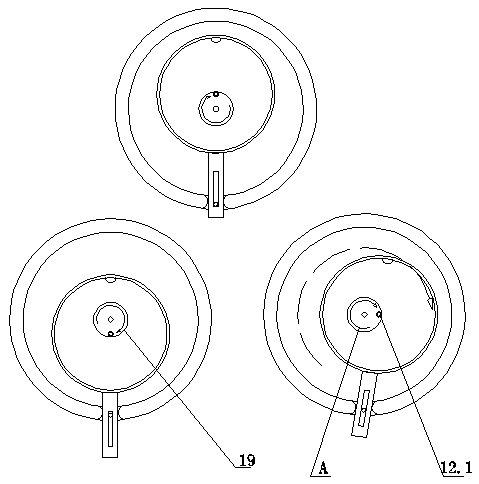

Electromagnetic induction heating device for tire vulcanization outer mould

The invention relates to an electromagnetic induction heating device for a tire vulcanization outer mould, belonging to the field of tire production equipment. The electromagnetic induction heating device consists of an upper side plate heating unit, a lower side plate heating unit and a middle mould sleeve heating unit. The upper side plate heating unit comprises a base plate, a disc-shaped electromagnetic coil and a coil cover plate, wherein an upper side plate is provided with a ring-shaped groove; the base plate is laid in the ring-shaped groove; the disc-shaped electromagnetic coil is arranged on the base plate; the coil cover plate is arranged at the upper part of the disc-shaped electromagnetic coil. The lower side plate heating unit comprises a base plate, a disc-shaped electromagnetic coil and a coil cover plate, wherein a lower side plate is provided with a ring-shaped groove; the base plate is arranged at the bottom of the ring-shaped groove; the disc-shaped electromagnetic coil is arranged on the base plate; the coil cover plate is arranged in the ring-shaped groove. The middle mould sleeve heating unit comprises an internal spacer bush, a column-shaped electromagnetic coil, a heat insulation layer and a shell, wherein the internal spacer bush is arranged at the periphery of a middle mould sleeve and is wound with the column-shaped electromagnetic coil; the heat insulation layer and the shell are sequentially arranged at the periphery of the column-shaped electromagnetic coil. The electromagnetic induction heating device is high in thermal efficiency, low in energy consumption and low in processing and manufacturing cost.

Owner:三角(威海)华盛轮胎有限公司 +2

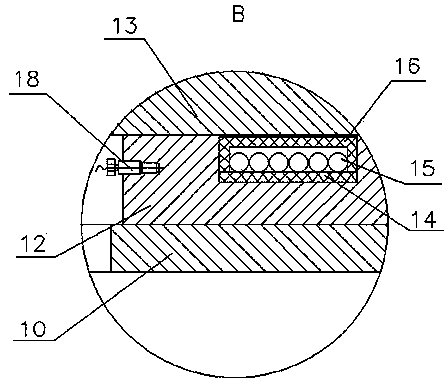

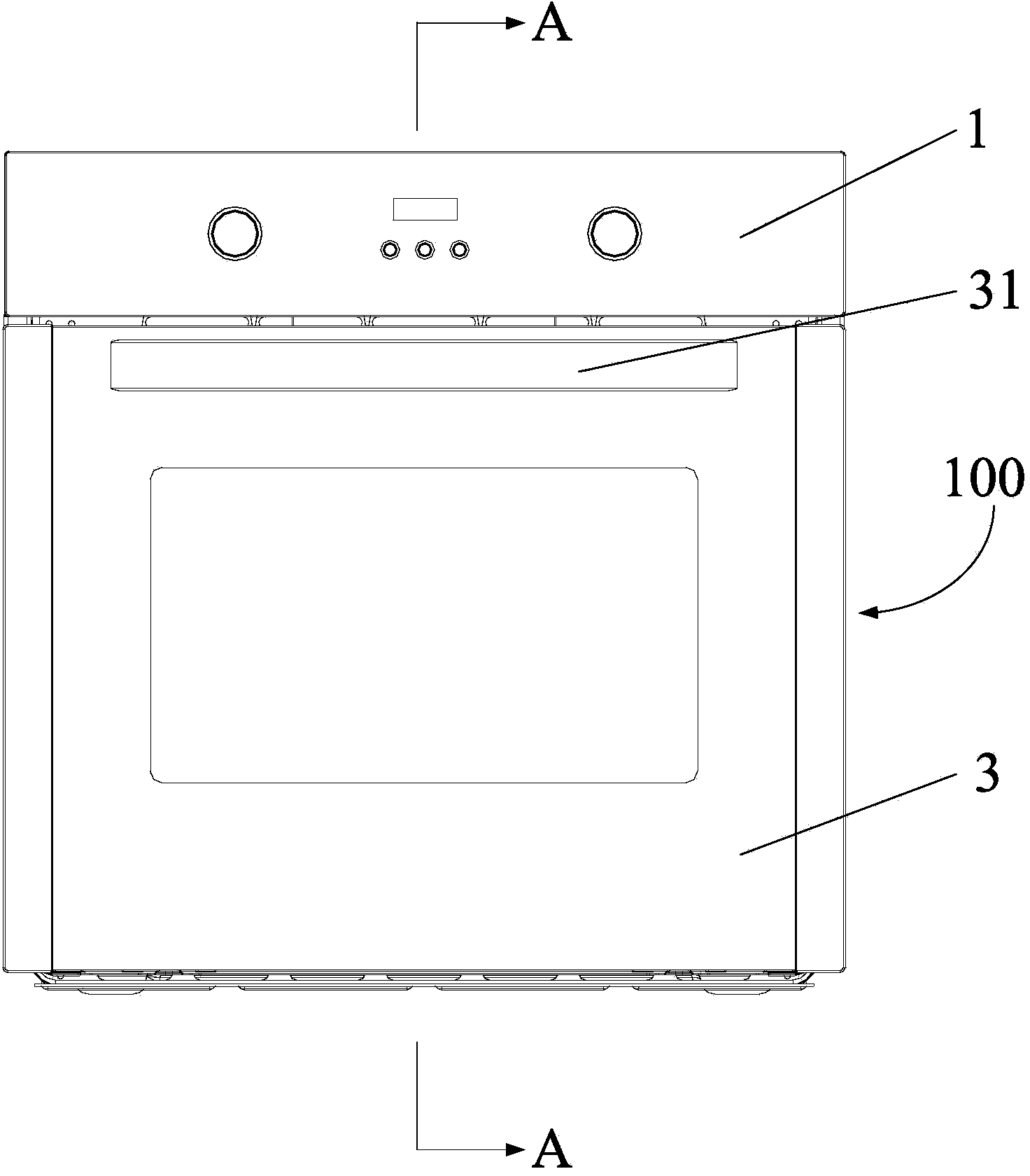

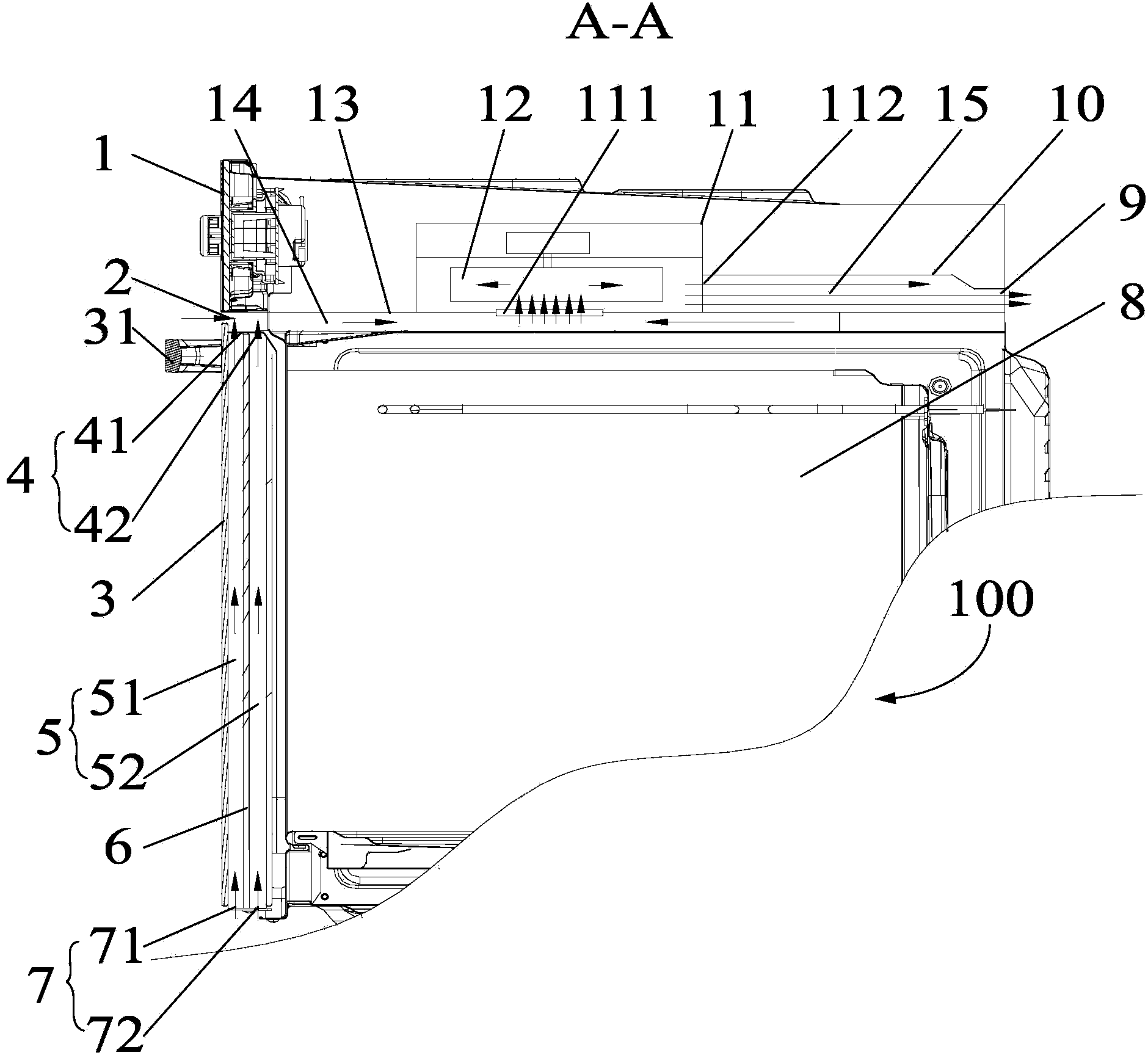

Heat dissipation system for oven and electric oven

The invention provides a heat dissipation system for an oven and the electric oven. The heat dissipation system for the oven comprises an air inlet, an air channel, an air outlet and a fan. The air inlet comprises an oven body air inlet and a door body air inlet, the oven body air inlet is formed in the front portion of the oven, and the door body air inlet is formed in the bottom of an oven door body. The air channel comprises a door body air channel, a first air channel and a second air channel, the door body air channel is communicated with the door body air inlet, and the first air channel is communicated with the oven body air inlet and the door body air channel. The air outlet is formed in the rear portion of the oven and is communicated with the second air channel. A fan exhausts air inside the first air channel into the second air channel. According to the technical scheme, users are effectively prevented from being scalded by the hot air exhausted from the air outlet, and the safety of the oven is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

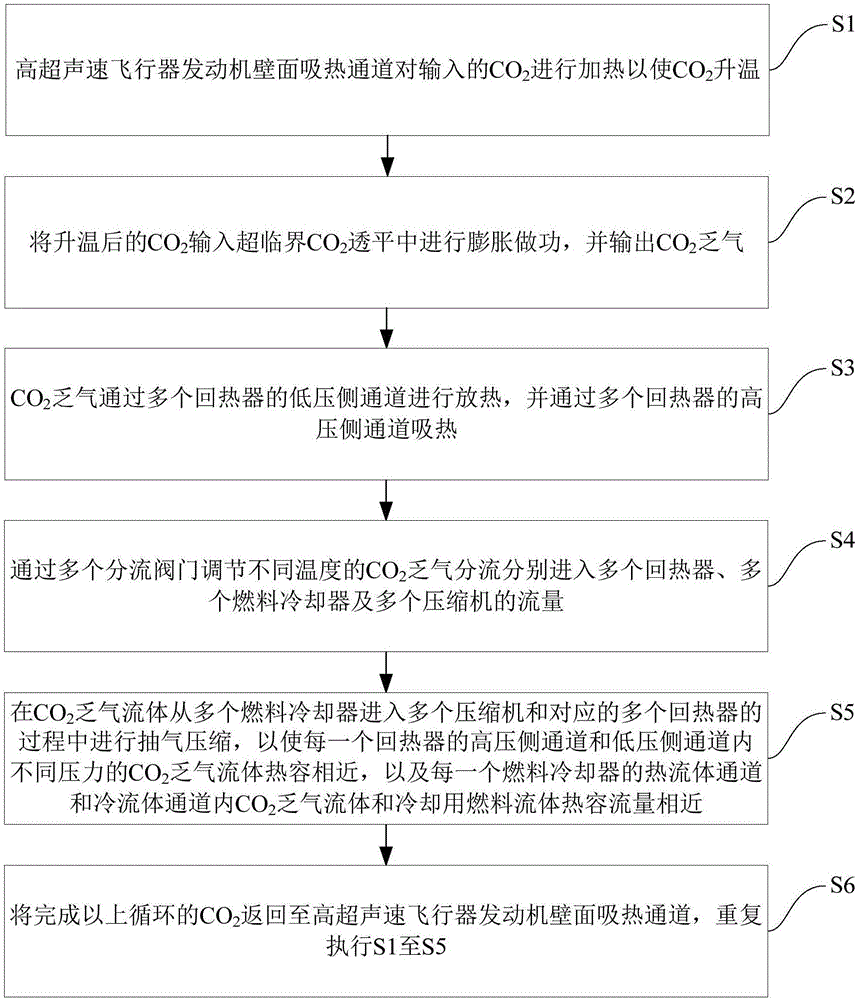

Hypersonic flight vehicle engine heat recovery power generation system and control method thereof

ActiveCN106640242AEfficient conversionFully recycleEngine fuctionsTurbine/propulsion engine coolingEngineeringHigh pressure

The invention provides a hypersonic flight vehicle engine heat recovery power generation system and a control method thereof. CO2 is heated in a hypersonic flight vehicle engine wall face heat absorption channel to enter a supercritical CO2 turbine to swell to act, output CO2 exhaust air releases heat through low-pressure side channels of multiple heat regenerators and absorbs heat through high-pressure side channels, air exhaust compression is carried out in the process that CO2 exhaust air fluid enters multiple compressors and the corresponding heat regenerators from multiple fuel coolers, the heat capacities of different-pressure CO2 exhaust air fluid in the high-pressure side channel and the low-pressure side channel of each heat regenerator are close, and the heat capacity of the CO2 exhaust air fluid in a heat fluid channel and a cold fluid channel of each fuel cooler and the heat capacity of fuel fluid for cooling are close. By means of the hypersonic flight vehicle engine heat recovery power generation system and the control method, the heat of the engine wall face can be efficiently converted into electric energy and compressor power; and meanwhile, the heat recovery rate is improved, the amount of fuel for cooling is reduced, and cost is saved.

Owner:TSINGHUA UNIV

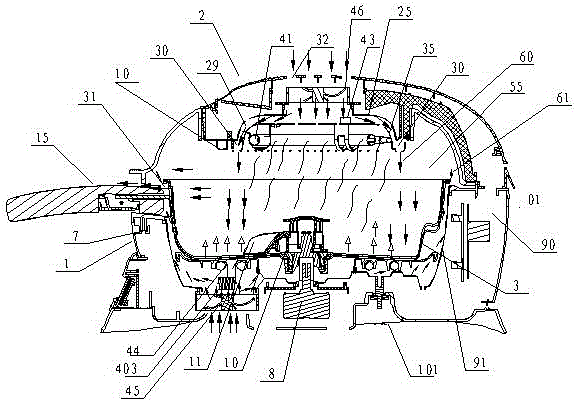

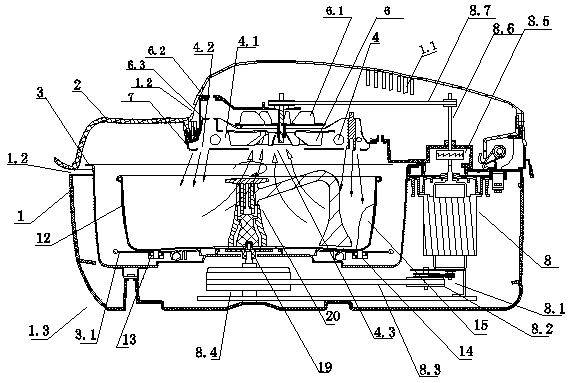

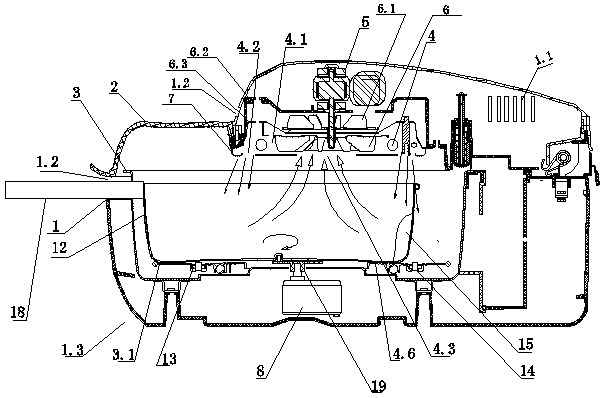

Multifunctional cooking utensil

InactiveCN110876559AExtended service lifeAvoid damageSteam cooking vesselsRoasters/grillsCold airElectric machinery

The invention discloses a multifunctional cooking utensil. The multifunctional cooking utensil comprises an upper shell and a lower shell, an air inlet and an air outlet are formed in the upper shell;a air guide cover r is arranged below the upper shell; a cold air cavity is defined between the upper shell and the air guide cover; the air inlet and the air outlet are communicated with the cold air cavity; a motor and a cold air fan are arranged in the cold air cavity; the cold air fan is fixedly connected with a motor shaft of the motor; a hot air fan and a heating element are arranged belowthe air guide cover; a motor shaft penetrates through the air guide cover and then is fixedly connected with the hot air fan; a containing cavity is formed in the lower shell body, a container is arranged in the containing cavity, the multifunctional cooking utensil further comprises a steam generation device for providing steam for the container. The cold air cavity is hermetically separated fromthe containing cavity; and a steam exhaust channel is formed in the upper shell, a first communicating opening of the steam exhaust channel communicates with the containing cavity, a second communicating opening of the steam exhaust channel communicates with the outside, and the second communicating opening is located in the upper shell and is formed in the side different from the side provided with the air inlet.

Owner:JOYOUNG CO LTD

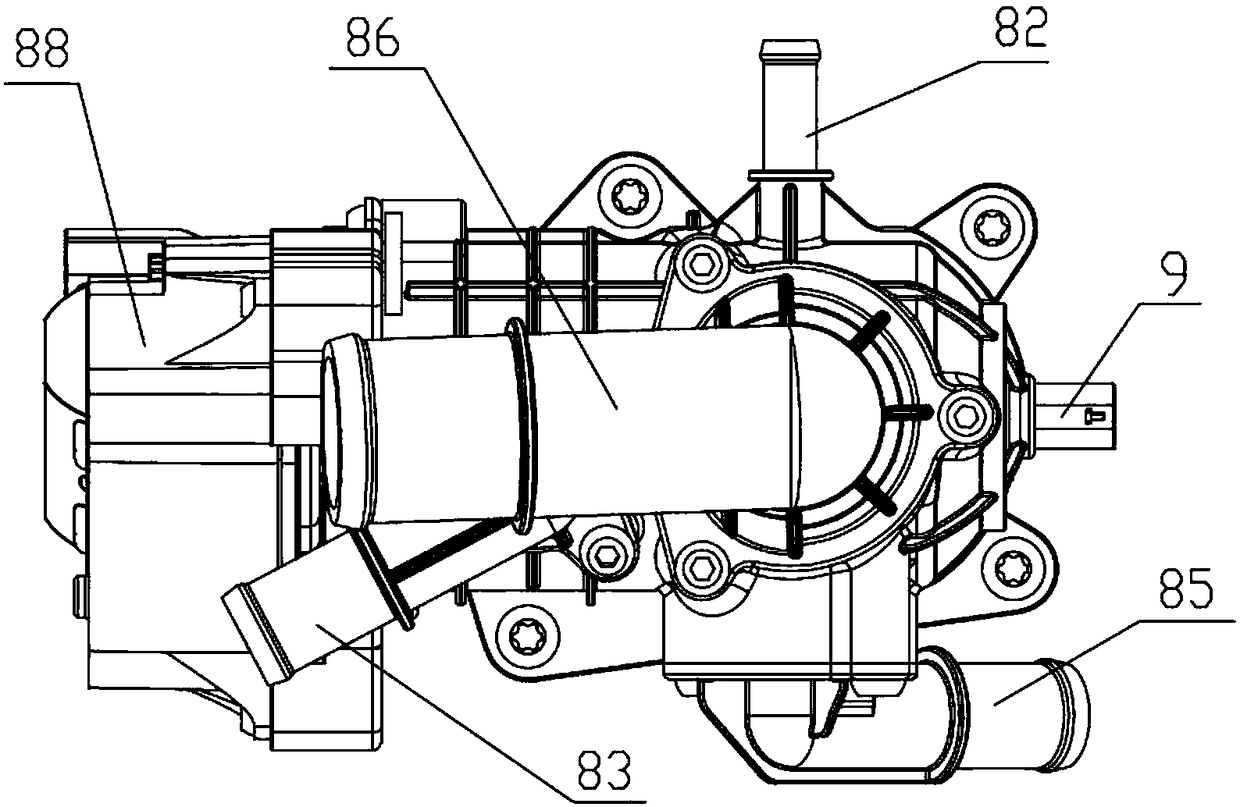

Cooling system and cooling method for automobile engine

ActiveCN108278172AControl allocationHeating up fastLiquid coolingCoolant flow controlHeat managementControl valves

The invention discloses a cooling system and a cooling method for an automobile engine. The automobile engine cooling system comprises a cylinder body, a cylinder cover, a water storage pot, a heat exchanging part, a radiator, engine oil coolers and a heat management module, wherein the heat management module is provided with a control valve, a normally-communicated cylinder cover water jacket connector, a water storage pot connector, an engine oil cooler connector, a cylinder cover water passing channel connector capable of adjusting a connecting area through the control valve, a heat exchanging part connector and a radiator connector. During a cold start, a connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connectoris enabled to be zero; when the engine is heated, the connecting area of the cylinder cover water passing channel connector and the radiator connector is enabled to be zero, and the connecting area of the heat exchanging part connector is enabled to be 100 percent; and when temperature of the engine is in a high working state, the connecting area of the cylinder cover water passing channel connector, the heat exchanging part connector and the radiator connector is enabled to be 100 percent. According to the cooling system and the cooling method for the automobile engine, the heating speed ofthe engine and the engine oil heating speed can be increased, and the oil consumption can be reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Rotary multifunctional oven and method thereof

InactiveCN103006087AEvenly heatedHard on the outside and soft on the insideRoasting apparatusRoasters/grillsRolloverHeat flow

The invention relates to a rotary multifunctional oven and a method thereof. The rotary multifunctional oven comprises a pot body, a pot cover, a blower assembly and a heater, wherein the pot body is provided with a rotary basin for food rollover, a relatively-sealed cavity is formed by the pot body and the pot cover together through enclosing, and the heater and a hot flow air passage which are communicated with the rotary basin are arranged in the cavity corresponding to the rotary basin. The rotary multifunctional oven is characterized in that the rotary basin is set to be in intermittent rotation, an inertial pushing device is arranged in the rotary basin, foods and the inertial pushing device are pushed during the rotation of the rotary basin and move or roll inertially along the advancing direction when the rotary basin is stopped, the inertial pushing device accelerates the movement or rollover of the foods, an opening of the rotary basin is upward, and the blower assembly and the heater generate hot flow and blow the hot flow into the rotary basin, so that part of the foods is heated. The rotary multifunctional oven has the characteristics of simple and reasonable structure, flexibility in operation, uniformity in food heating, good cooking effect, easiness in assembly / disassembly, easiness in cleaning, and wide range of application.

Owner:张毅蔚

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

Exhaust steam recycling heating device for waste heat power generation deaerator

InactiveCN103499089AReduce volumeOvercome expensiveLiquid degasificationEconomic benefitsInlet valve

The invention discloses an exhaust steam recycling heating device for a waste heat power generation deaerator, belongs to a waste heat recycling device, and particularly relates to a device for recycling waste heat of a boiler deaerator. The device comprises the deaerator, the deaerator is connected with a steam pipeline through a deaerator air inlet valve with a steam flow meter, and a deaerating exhaust pipe with a valve is arranged on the top of the deaerator. The device is characterized in that a deaerator exhaust pipeline which is connected with the lower portion of a disc steam-water mixing heater is arranged below the valve of the deaerating exhaust pipe, the upper portion of the disc steam-water mixing heater is connected with a desalted water pipeline provided with a desalted water inlet valve for the heater, a non-condensable gas exhaust pipe is arranged on the top of the disc steam-water mixing heater, a pipeline connected with a drainage tank is arranged at the bottom of the disc steam-water mixing heater, and a drainage pipe provided with a drainage pump is arranged on the drainage tank and connected with the deaerator. A water level gauge is arranged on the deaerator. The exhaust steam recycling heating device is simple in structure, after exhaust steam is recycled, hot water enters the deaerator without affecting the deaerating effect, and the exhaust steam recycling heating device is easy to operate and remarkable in economic benefits.

Owner:JINAN AOHAI CARBON PROD

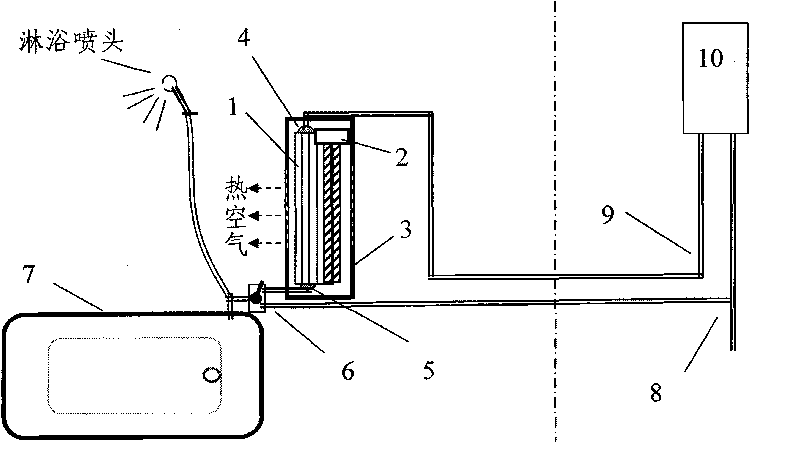

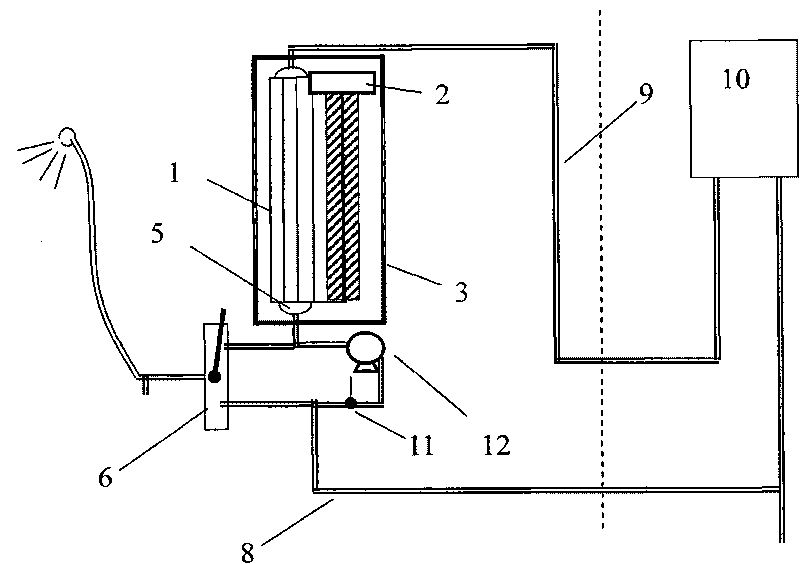

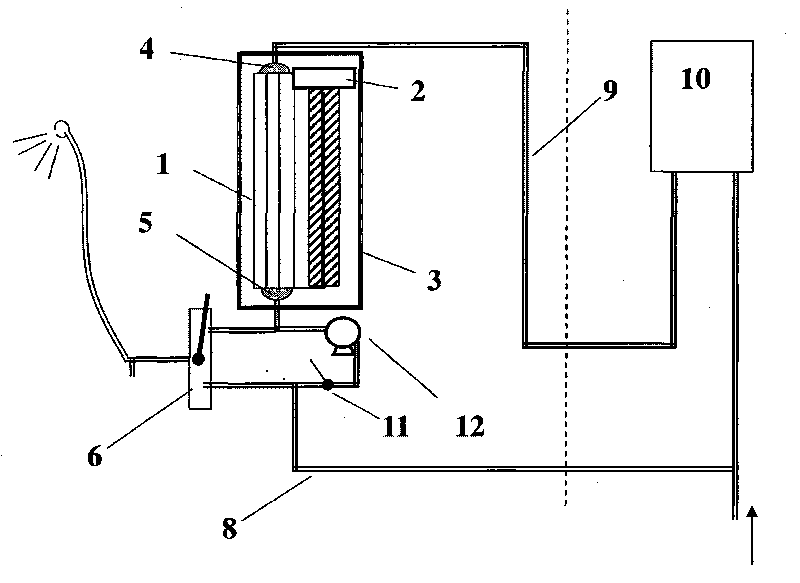

Novel hot-water-type bathroom heater

InactiveCN101699172ADoes not require high power consumptionComfortable bathingLighting and heating apparatusEnergy efficient heating/coolingEngineeringThermal water

The invention relates to a novel hot-water-type bathroom heater. The traditional bathroom heater generally uses a high-power heating lamp and an electrothermal air heater, which emits heat mainly by electric heating elements, as heat sources for heating. Heating with electric heating elements has the defects of low efficiency, high electric power consumption and great potential safety hazard, and the heating lamp can produce many harmful light rays. The invention overcomes the defects and is characterized by using hot water output by the water heater as the heat source for heating, the hot water exchanges heat in a heat exchanger of a water-cooling heater, the air heater is used for quickly rising the air temperature of the bathroom, and the discharged hot water after heat exchanging can still be used for bath. The hot-water-type bathroom heater has the advantages of high bathroom heating speed, no harmful light rays, high safety, energy saving, comfort, economy and practicality.

Owner:胡志超

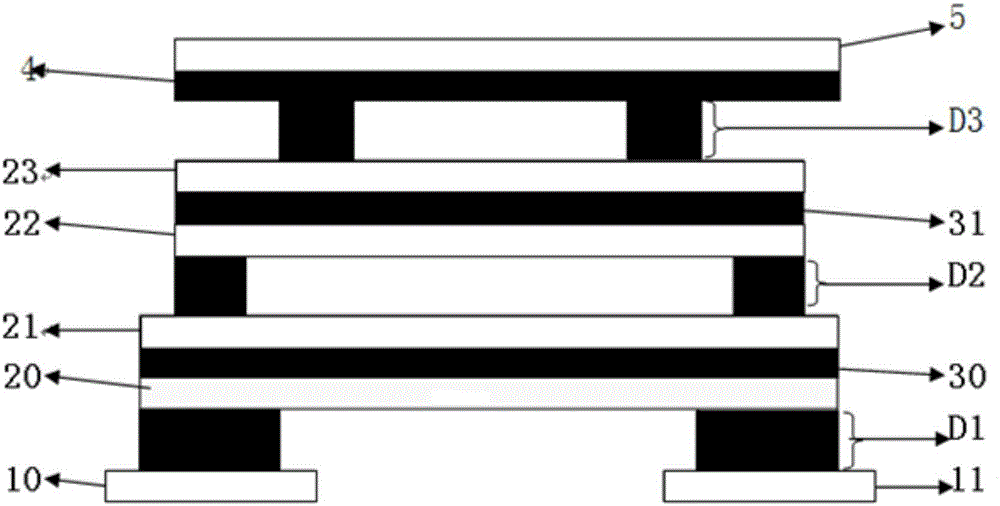

Three-layer micro-bridge structure, three-layer uncooled micro-bolometer and preparation method thereof

InactiveCN106052883AEasily brokenFast temperature risePyrometry using electric radation detectorsResonant cavityStress conditions

A three-layer micro-bridge structure provided by the present invention comprises a bridge surface, a second-layer micro bridge, a first-layer micro bridge and left and right aluminum electrodes, and a light absorption material, a thermistor thin film and a passivation layer are laid on the uppermost bridge surface of the micro-bridge structure. An upper-layer optical resonant cavity is formed between the bridge surface and the second-layer micro bridge, an intermediate-layer optical resonant cavity is formed between the two layers of micro bridge, and a lower-layer optical resonant cavity is formed between the first-layer micro bridge and a bottom-layer silicon substrate. The present invention also provides a three-layer uncooled micro-bolometer containing the micro-bridge structure and a preparation method of the three-layer uncooled micro-bolometer. The micro-bridge structure of the present invention has three resonant cavities, so that the optical absorption efficiency is improved greatly. Secondly, during a simulation process, on a same stress condition, the deformation amount of a three-layer S-shaped micro-bridge structure is smaller than the deformation amounts of a single-layer S-shaped micro-bridge structure and a double-layer S-shaped micro-bridge structure, thereby guaranteeing the good mechanical stability of the micro-bridge structure. Meanwhile, the increase in the lengths of the bridge legs also enables the overall temperature rise of a device to be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Controllable heat-removing reactor

ActiveCN104399413AEasy to unloadEasy to fillHydrogenHydrogen/synthetic gas productionPtru catalystProcess engineering

The invention discloses a controllable heat-removing reactor. A heat-removing pipe bundle comprises a water outlet main pipe, a water inlet main pipe, a ring pipe, a partition board, a cecum-type heat exchange tube and a water guide pipe; the partition board is arranged in the middle part of the ring pipe, and is used for partitioning the upper part and the lower part of the ring pipe into a water distribution box and a water collection box; the water inlet main pipe is communicated with the water distribution box at the upper part of the ring pipe; the water outlet main pipe is communicated with the water collection box at the lower part of the ring pipe; the water guide pipe is arranged inside the cecum-type heat exchange tube in a sleeving mode; one end of the cecum-type heat exchanger is open, and the other end of the cecum-type heat exchanger is closed; the open end of the cecum-type heat exchanger is communicated with the water collection box at the lower part of the ring pipe; openings are formed in the two ends of the water guide pipe; the top of the water guide pipe is communicated with the water distribution box at the upper part of the ring pipe; the bottom of the water guide pipe is positioned above the closed end of the cecum-type heat exchanger. A catalyst frame and the heat-removing pipe bundle of the controllable heat-removing reactor are separated from a pressure-bearing shell, so that maintenance, catalyst self-discharging and catalyst filling are facilitated; a heat-removing water pipe is buried inside a catalyst bed, so that the heat of reaction inside the catalyst bed can be removed in time.

Owner:NANJING DUNXIAN CHEM TECH

Rotary swinging oven and method thereof

ActiveCN102934948AEvenly heatedHard on the outside and soft on the insideRoasting apparatusEngineering

The invention relates to a rotary swinging oven and a method thereof. A rotary swinging oven main body comprises an upper cover, a base, a motor, a hot flow fan component, a heating piece and a basin. The rotary swinging oven is characterized in that the basin is a swinging basin with an upward opening; and the swinging basin moves in an annular or a planet track, and food collides or turns over in the swinging basin or displaces to be smeared with fat automatically. The rotary swinging oven has the characteristics of being simple and reasonable in structure, flexible to operate, uniform in heating food, good in cooking effect, easy to be mantled and dismantled, easy to clean and wide in application range.

Owner:邳州辉腾经发建设有限公司

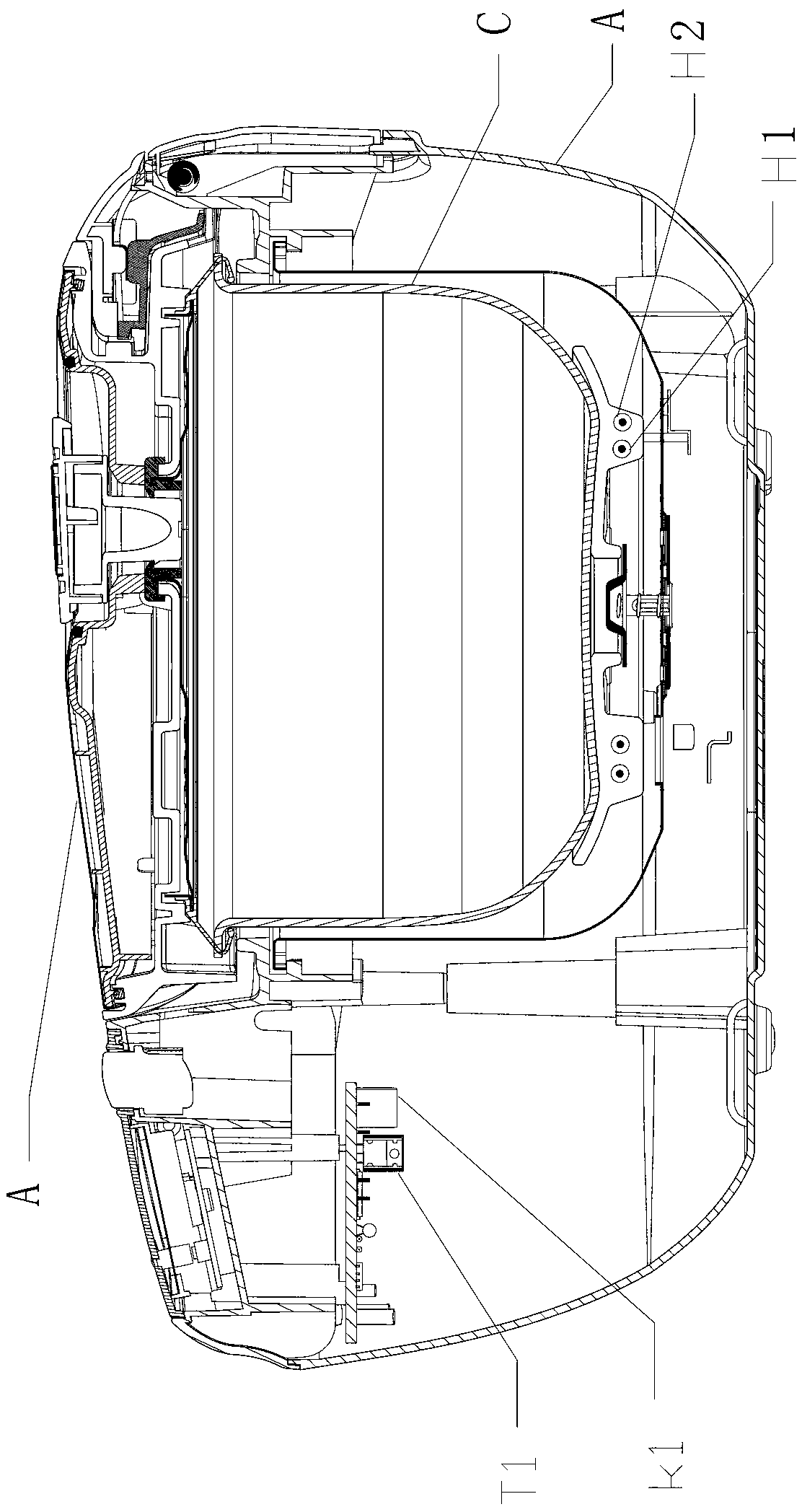

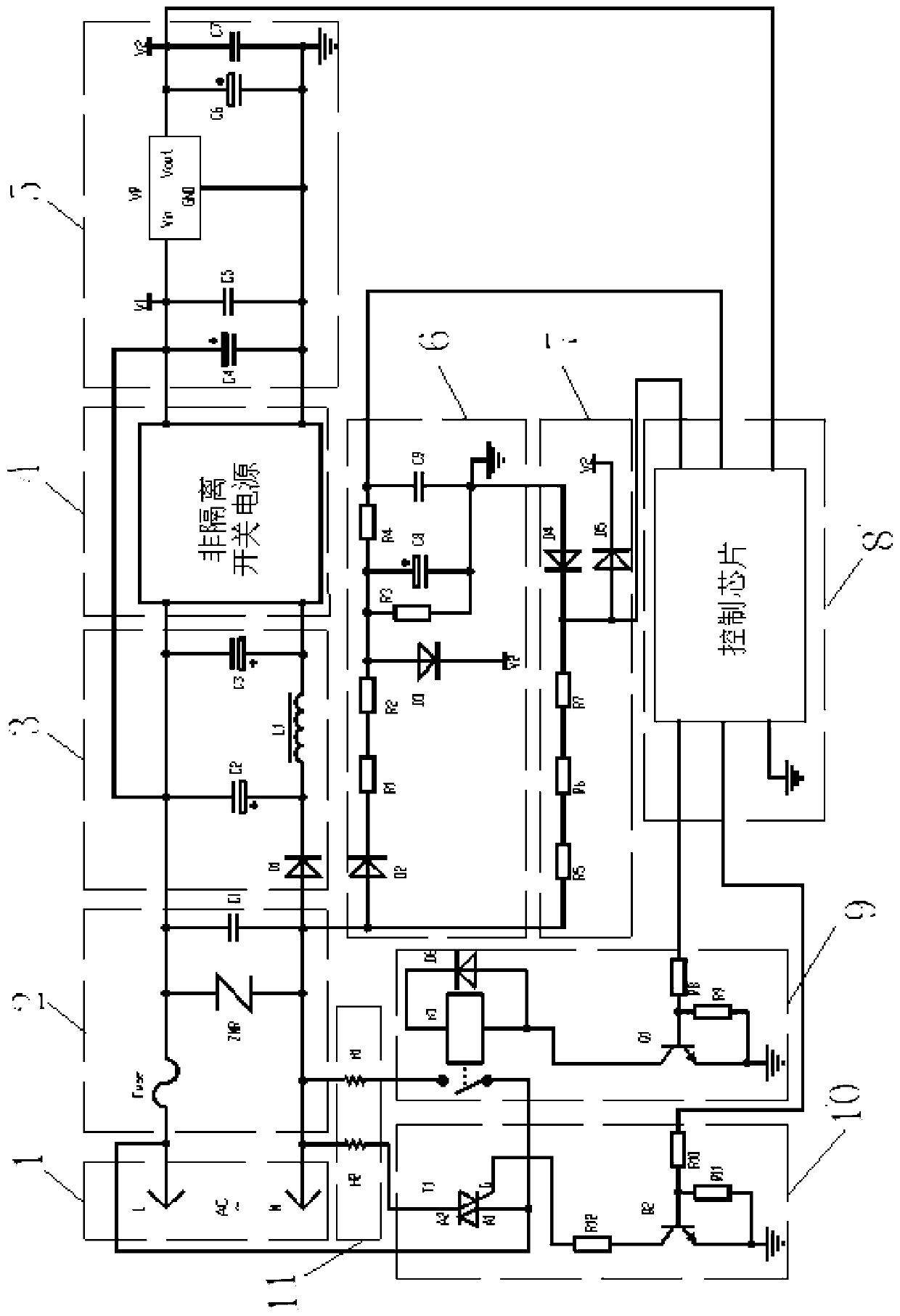

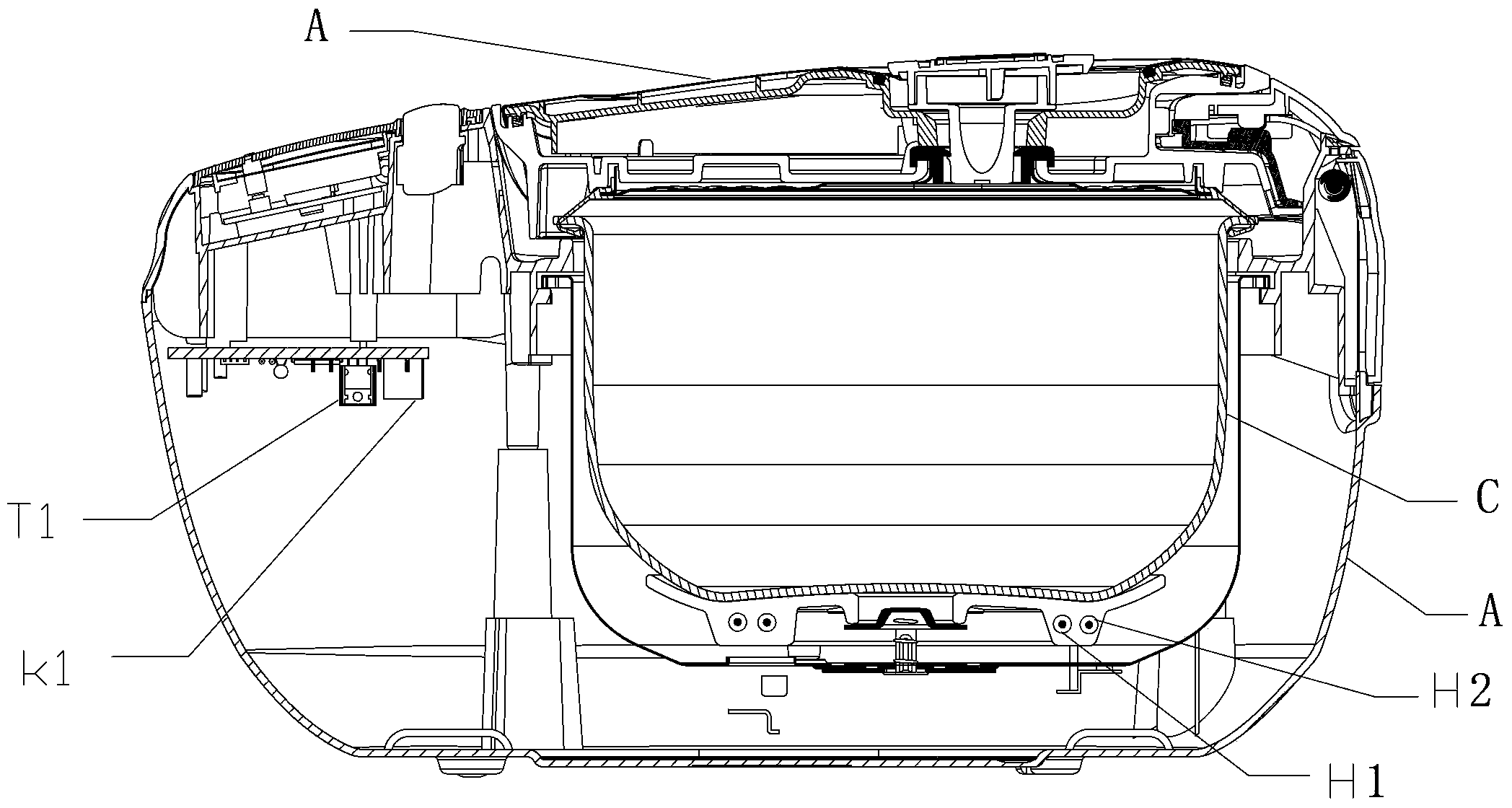

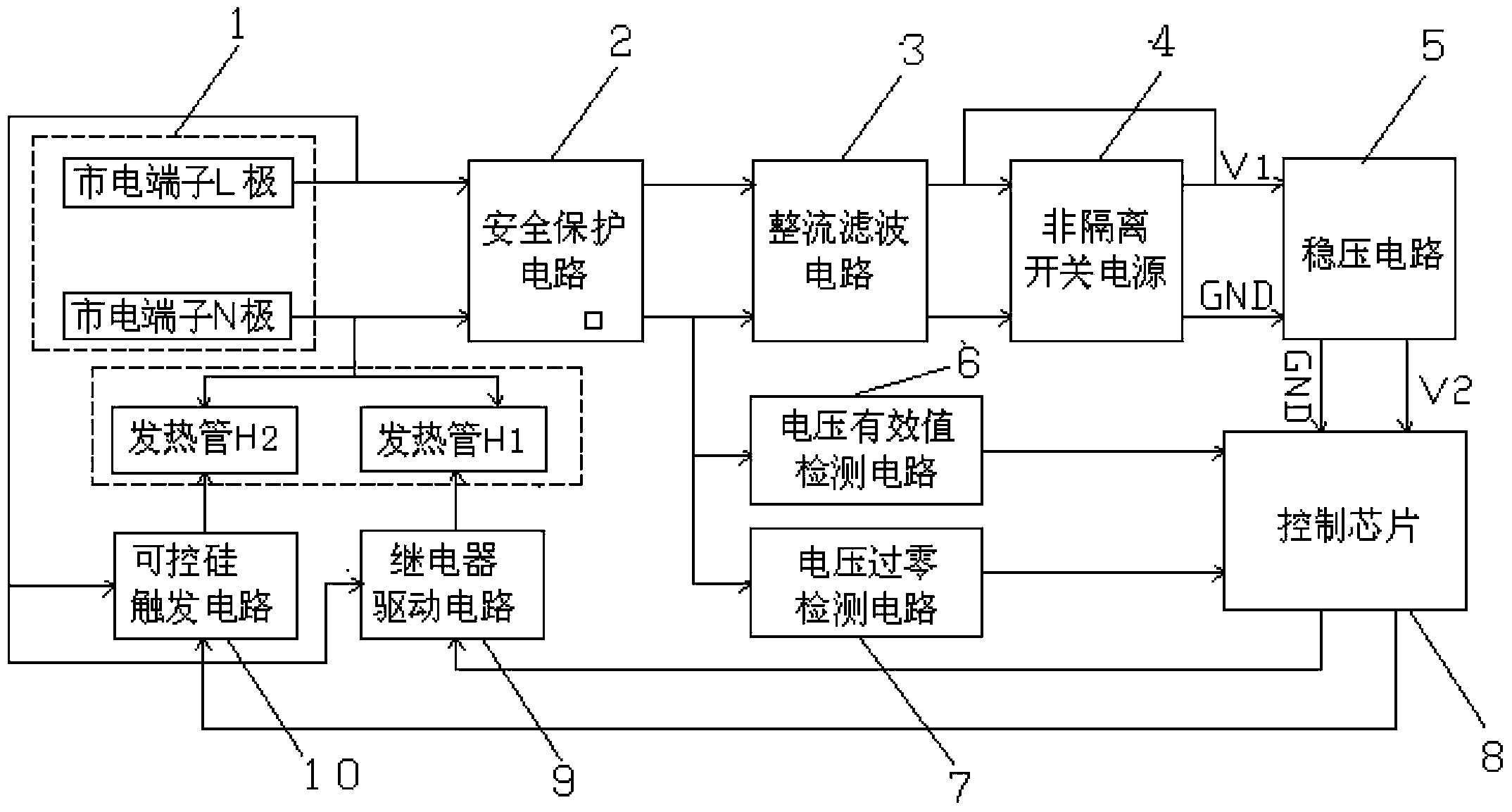

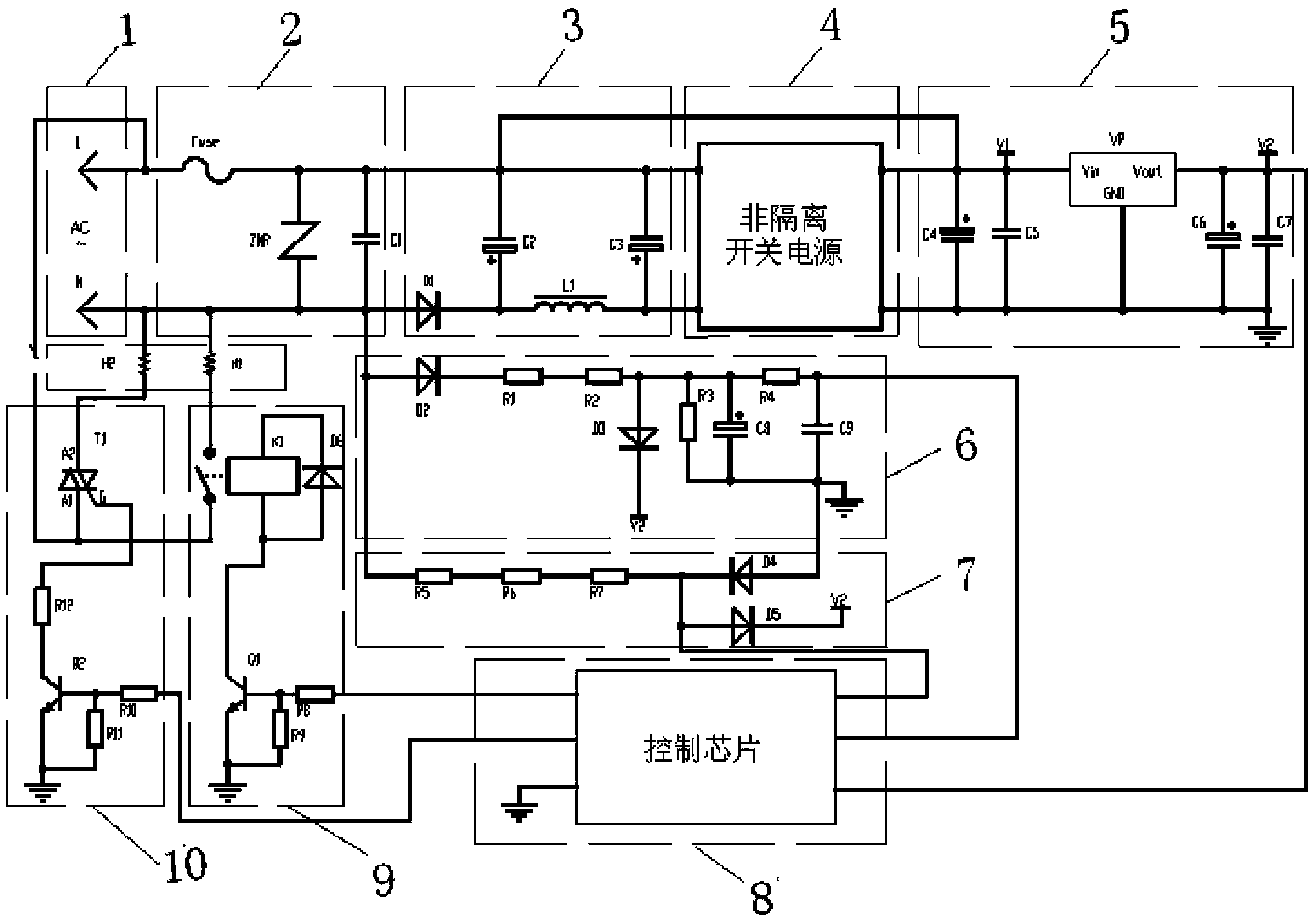

Electric cooker and heating control method thereof

InactiveCN102846182AFast temperature riseConstant output powerWarming devicesElectricityTemperature control

An electric cooker comprises a pot, a pot cover, an inner pot, a heating device, a control device and a switching power supply. The heating device comprises a relay temperature control mechanism and a thyristor temperature control mechanism. The relay temperature control mechanism comprises a relay and a first heating tube connected with the relay. The thyristor temperature control mechanism comprises a thyristor and a second heating tube controlled by the thyristor. The relay and the thyristor are controlled by the control device. A heating control method includes: setting output power P0; calculating power Pr of the first heating tube under current voltage; calculating difference between P0 and Pr, and converting ratio of the difference to Pt into thyristor-triggered semiwave number; counting the thyristor-triggered semiwave number; and acquiring current required output power. Excessive temperature rising of the thyristor can be avoided.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

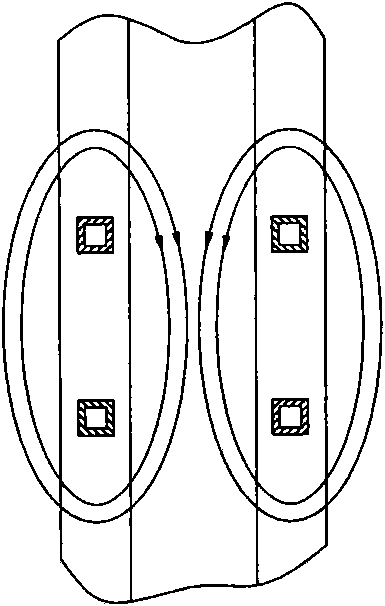

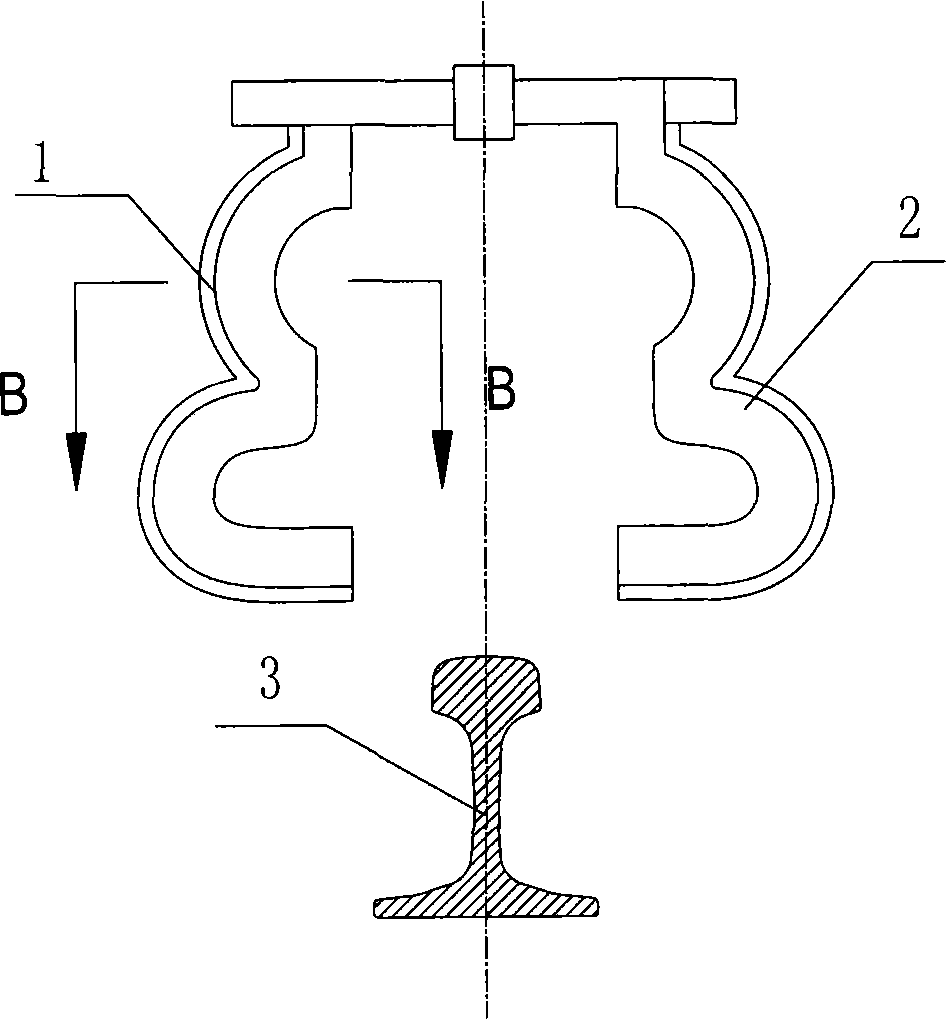

Synthetic magnetic field type on-line steel rail welding seam normalizing treatment method and normalizing middle-frequency inductor

ActiveCN101792991AEasy to buckleRealize on-line intermediate frequency normalizing treatment of weld seamRailway track constructionIntermediate frequencyWeld seam

The invention belongs to a synthetic magnetic field type on-line steel rail welding seam normalizing treatment method and a normalizing middle-frequency inductor, which relate to the field of middle-frequency induction heating and are used for overcoming the defects of roaring flame normalizing treatment. The method adopts two separate and identical sub-inductors to coat the external surface of an on-line steel rail welding seam, and the inner form of the two buckled sub-inductors fits into the external form of the section of a steel rail; the contact surfaces of the two sub-inductors are mutually insulated, a middle-frequency alternating current is introduced into the two sub-inductors so that a vortex is produced at the on-line steel rail welding seam for heating, and thus, the normalizing treatment process is completed. The normalizing middle-frequency inductor comprises a pair of identical and symmetrical sub-inductors of which the inner forms respectively correspond to the external form of the half section of the steel rail, and the two buckled sub-inductors are used for coating the on-line steel rail; and the contact surfaces between the two sub-inductors after coating are mutually insulated. The inductor can be conveniently buckled and coated to the steel rail welded into a line, and the on-line middle-frequency normalizing treatment of the steel rail welding seam is realized.

Owner:WUHAN LEADDO MEASURING & CONTROL CO LTD

Electric cooking appliance and heating control method thereof

ActiveCN103405161AConstant output powerFlexible output powerTemperature control using electric meansWarming devicesElectricityTemperature control

An electric cooker comprises a pot, a pot cover, an inner pot, a heating device, a control device and a switching power supply. The heating device comprises a relay temperature control mechanism and a thyristor temperature control mechanism. The relay temperature control mechanism comprises a relay and a first heating tube connected with the relay. The thyristor temperature control mechanism comprises a thyristor and a second heating tube controlled by the thyristor. The relay and the thyristor are controlled by the control device. A heating control method includes: setting output power P0; calculating power Pr of the first heating tube under current voltage; calculating difference between P0 and Pr, and converting ratio of the difference to Pt into thyristor-triggered semiwave number; counting the thyristor-triggered semiwave number; and acquiring current required output power. Excessive temperature rising of the thyristor can be avoided.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

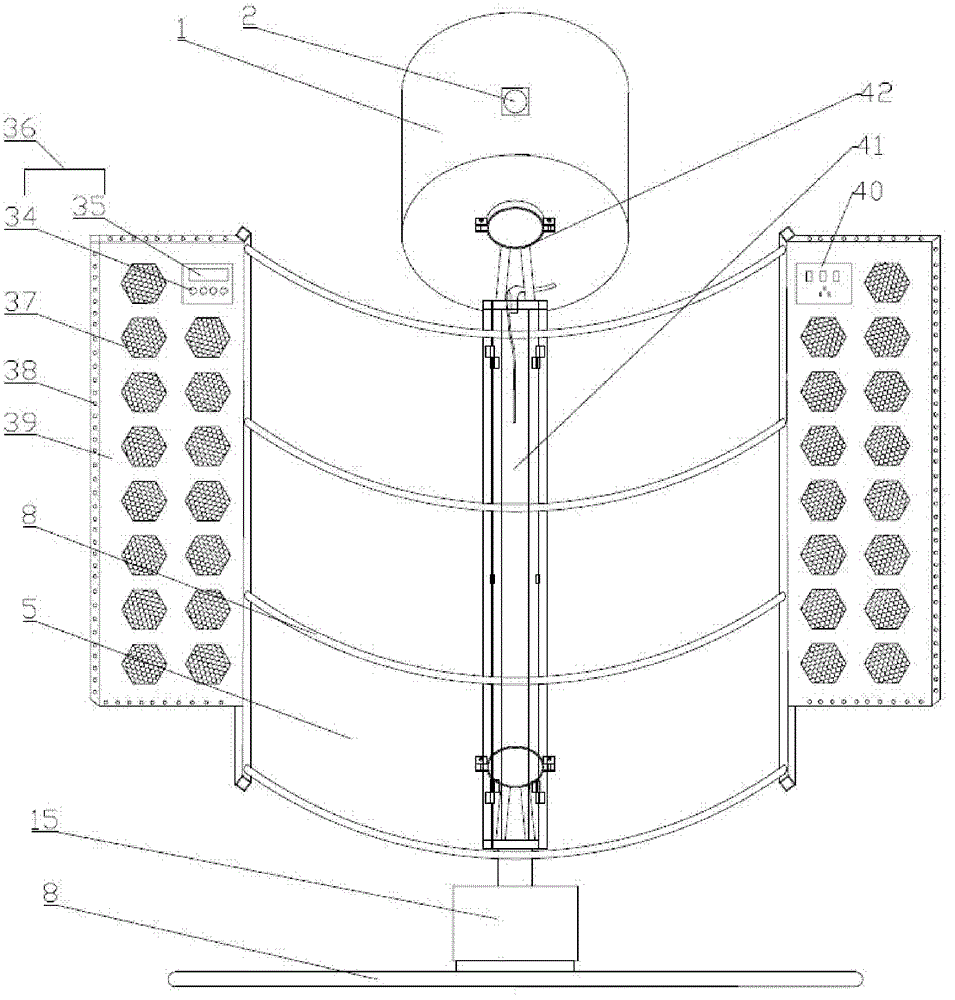

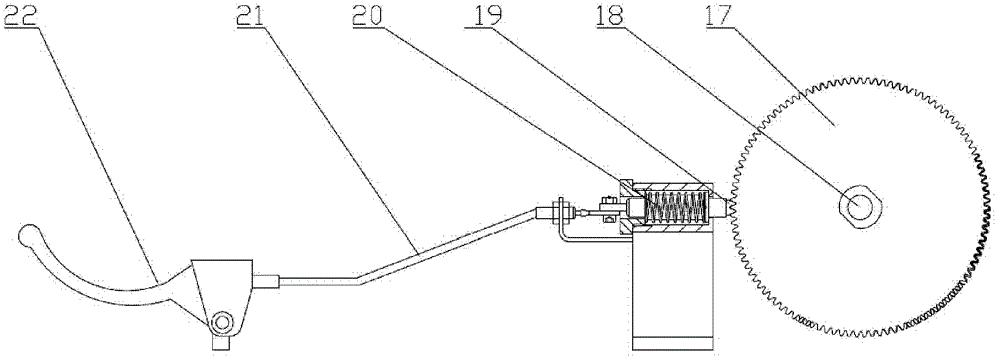

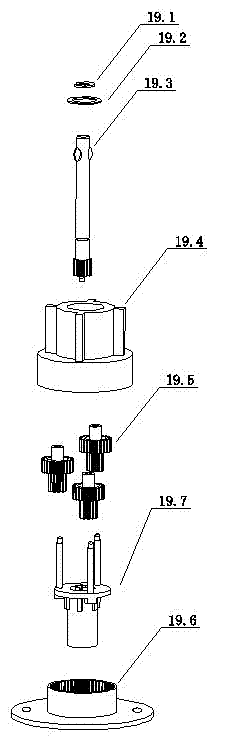

Spotlight type multifunctional solar cooking device

InactiveCN102743109AFast temperature riseImprove efficiencyBatteries circuit arrangementsClimate change adaptationCell systemCells panel

The invention discloses a spotlight type multifunctional solar cooking device. The device comprises a spotlight reflecting mirror, a barbecue vacuum tube and a photovoltaic cell system, wherein the spotlight reflecting mirror is fixed on a reflecting mirror support, the reflecting mirror support is capable of being adjusted at the pitching and horizontal positions through a double-shaft adjustable tracking system, the double-shaft adjustable tracking system is fixed on a tracking base disk, the barbecue vacuum tube is fixed at the focusing position of the spotlight reflecting mirror through a barbecue vacuum tube support, the photovoltaic cell system is installed on photovoltaic cell panel supports which are located on two sides of the spotlight reflecting mirror, the photovoltaic cell panel supports are fixed on the reflecting mirror support, the photovoltaic cell system is used for supplying power for the double-shaft adjustable tracking system, and the spotlight reflecting mirror is a parabolic spotlight reflecting mirror or a compound parabolic concentrator (CPC) composite spotlight reflecting mirror. The spotlight type multifunctional solar cooking device has the advantages that high concentration spotlight is achieved, temperature rising is rapid and efficiency is high, required time for cooking food can be reduced, and multistage differentiation food processing is achieved.

Owner:HIMIN SOLAR

Equal-directional agitating frying pan capable of automatically coating ingredients or grease and related method thereof

The invention provides an equal-directional agitating frying pan capable of automatically coating ingredients or grease, comprising a pan body, a pan cover and a heater, wherein the pan body is provided with a rotary basin for containing foods and an agitating device; and a relatively-sealed cavity is formed by surrounding of the pan body and the pan cover. The equal-directional agitating frying pan is characterized in that a speed difference is generated by equal-directional rotation of the rotary basin and the agitating device; and when the agitating device rotates in the rotary basin, the foods are pushed to be overturned to be mixed with the grease to automatically coat the ingredients or the grease on the foods. The equal-directional agitating frying pan disclosed by the invention has the characteristics of simple and reasonable structure, flexibility in operation, capability of uniformly heating the foods, good cooking effect, easiness for detaching, easiness for cleaning, wide applicable range and the like.

Owner:ZHONGSHAN CITY GOLDLABO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com