Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

333 results about "Heat transfer model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

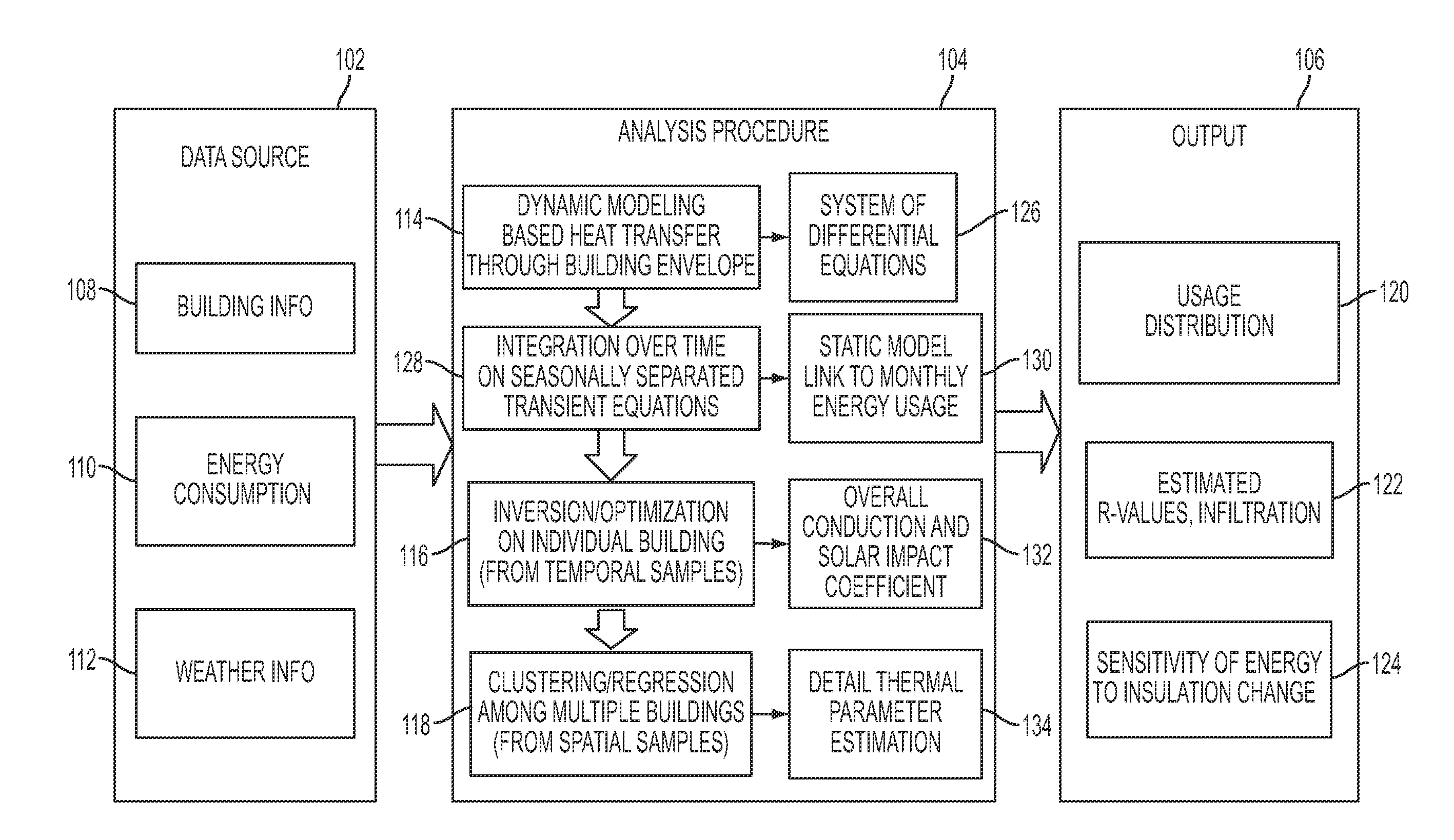

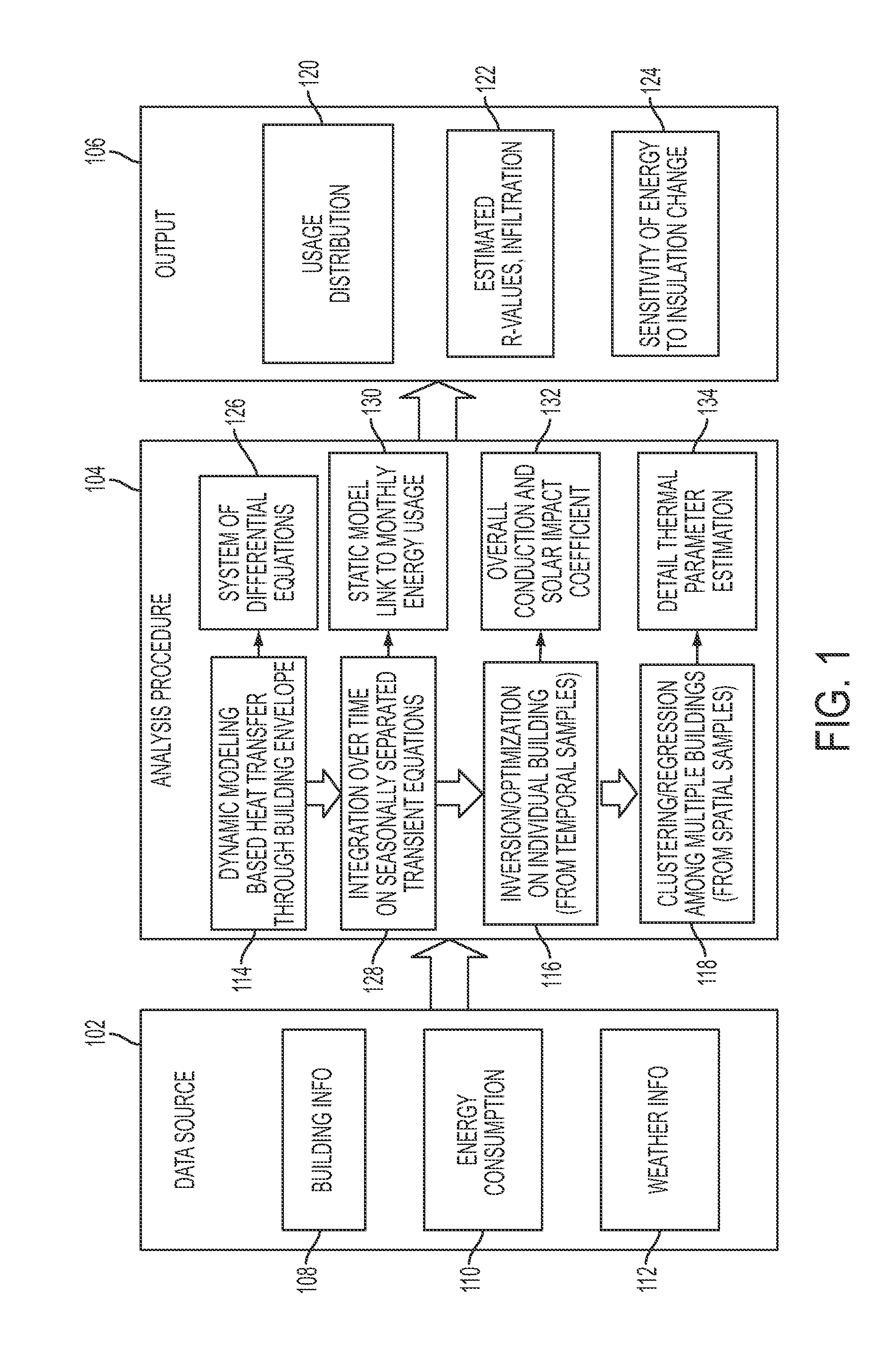

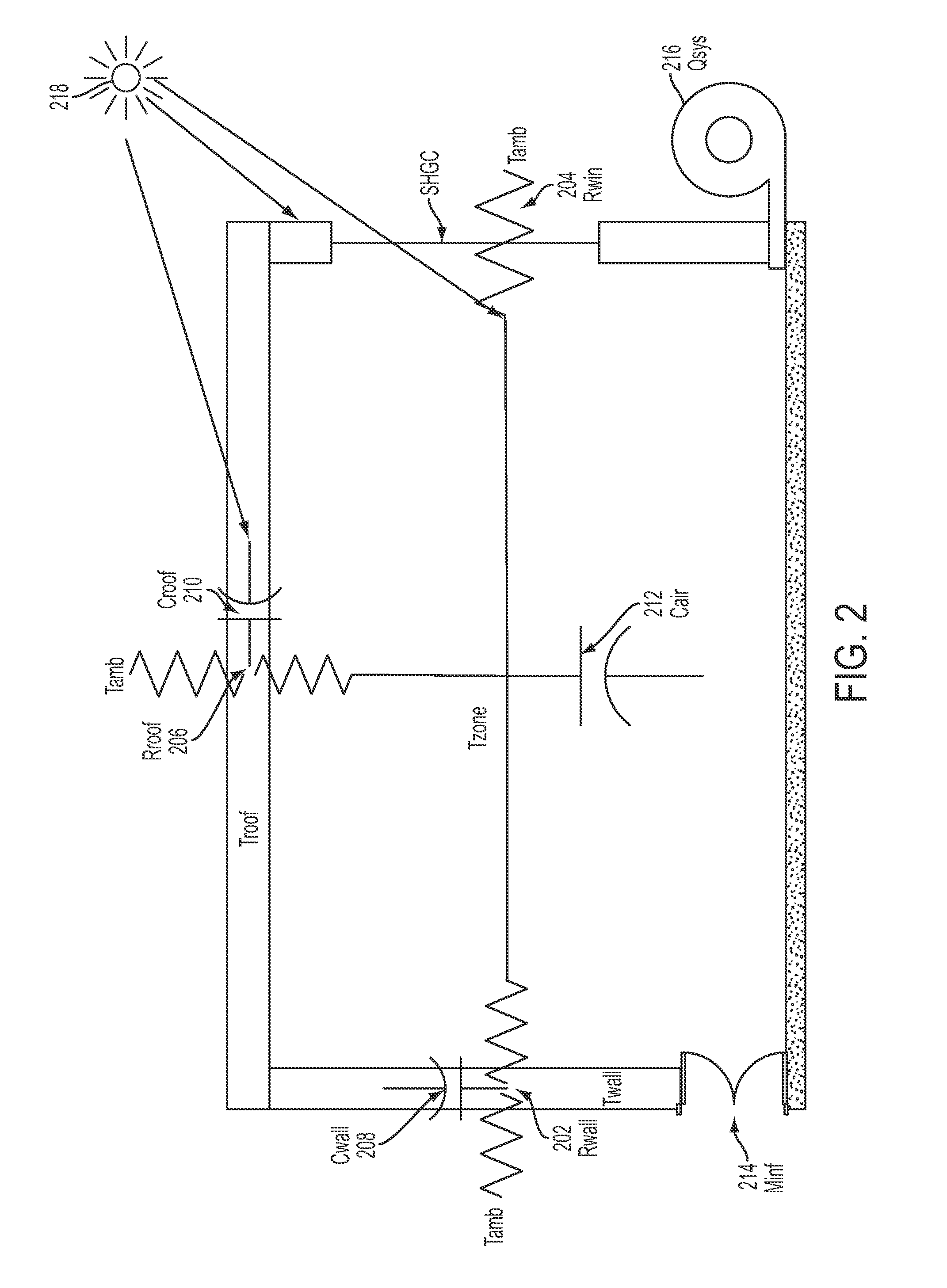

Estimating building thermal properties by integrating heat transfer inversion model with clustering and regression techniques for a portfolio of existing buildings

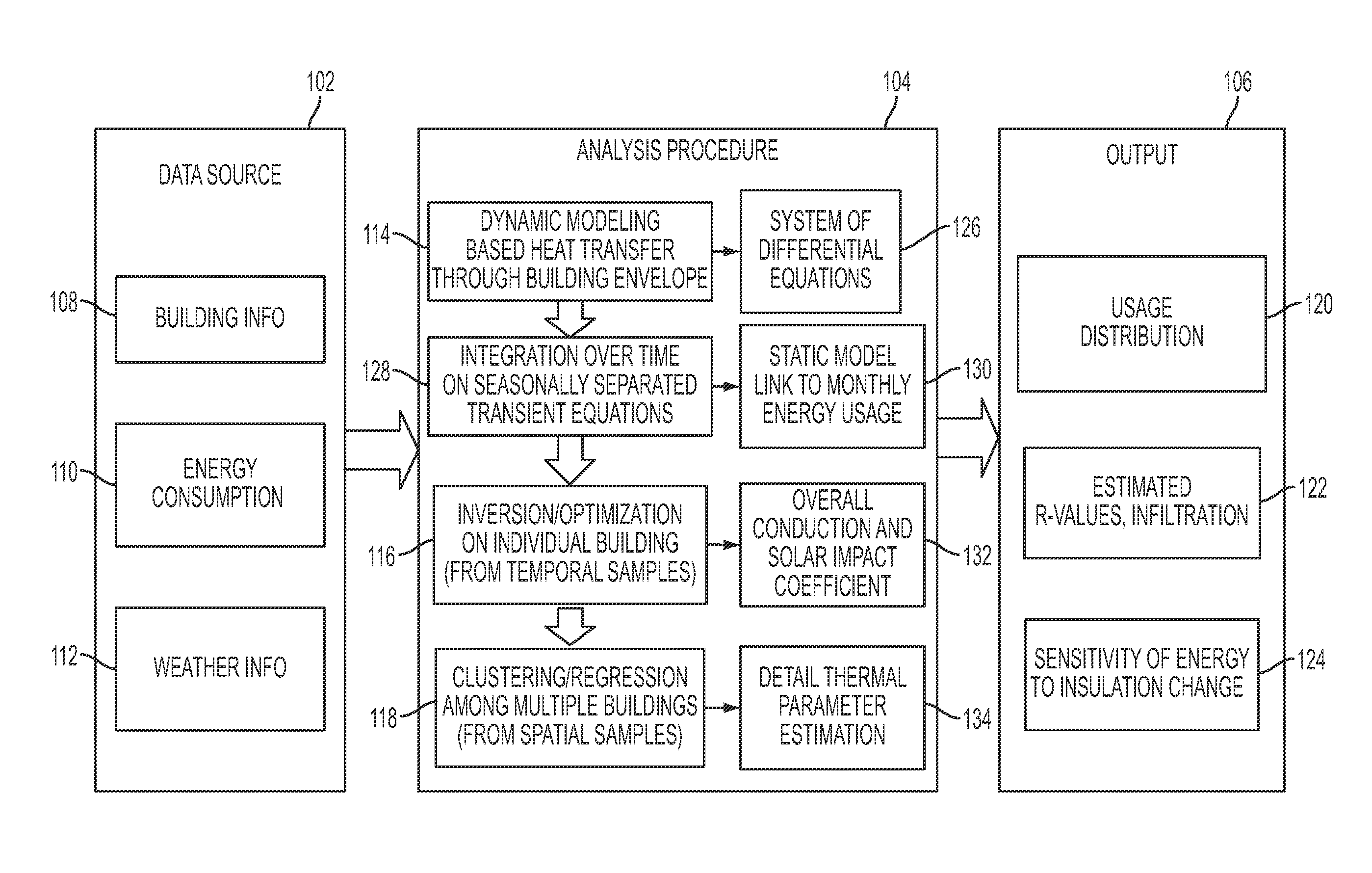

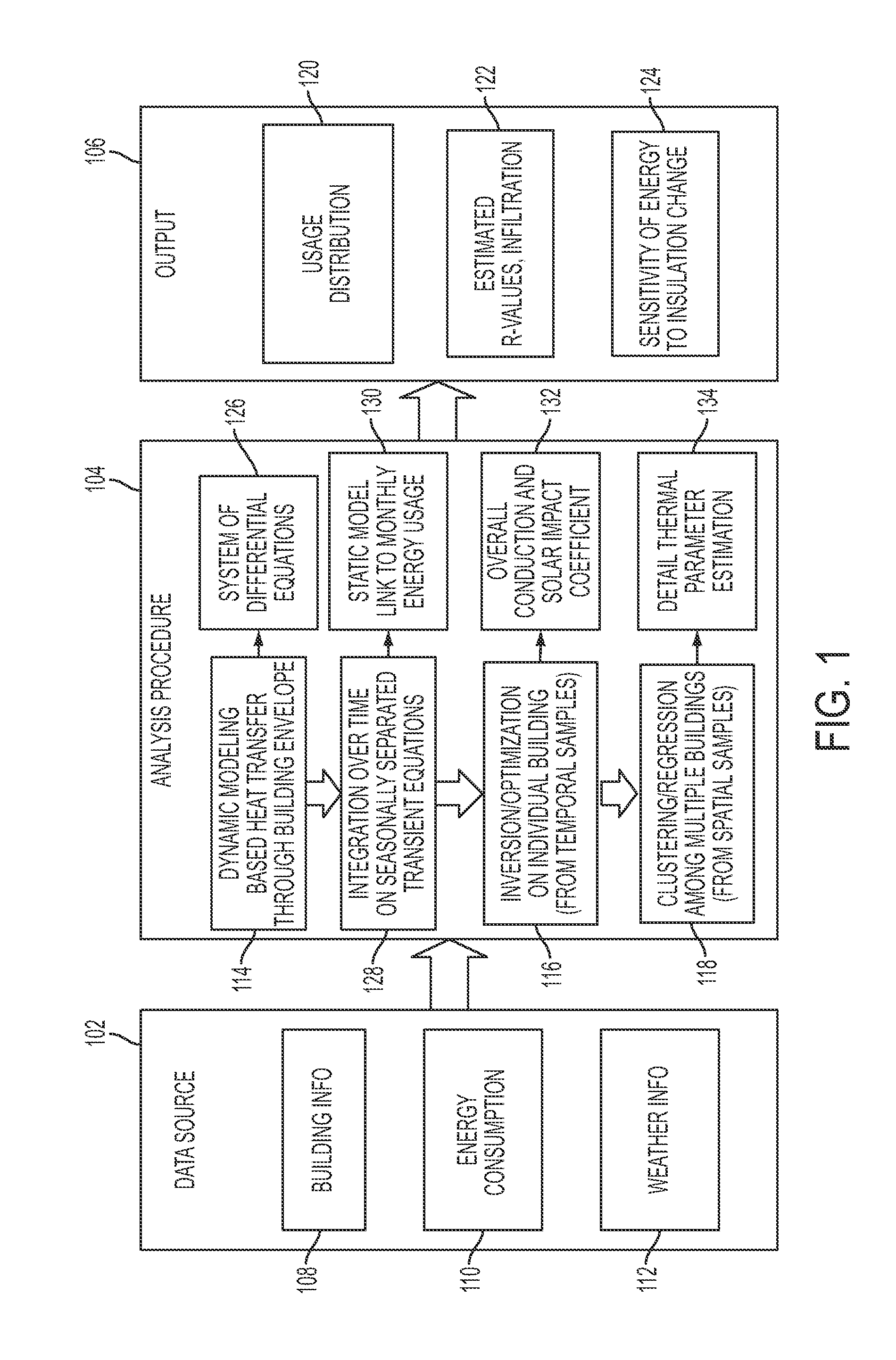

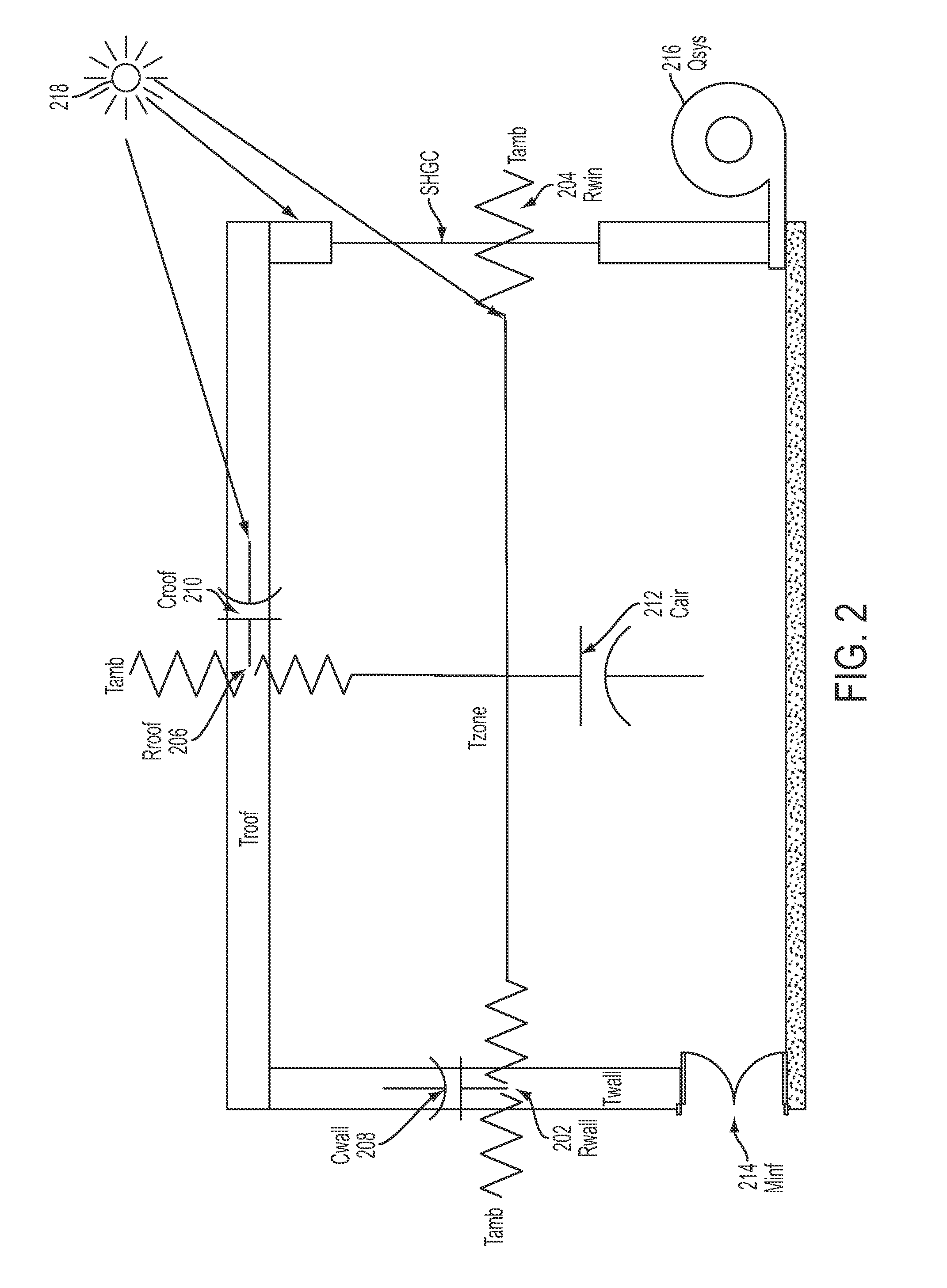

A static heat transfer model is derived from a system of dynamic equations by integrating the dynamic equations over different time periods. That static heat transfer model links periodic (e.g., monthly) energy usage with cooling and heating degree hours, humidifying and dehumidifying hours. Its coefficients of measuring correlations correspond to the thermal parameters of buildings. Temporal data from a building may be used to estimate the overall heat transfer parameters. A clustering scheme may be developed to decompose all the buildings into different clusters based on one or more similarity criteria. The overall heat transfer parameters are separated into values for the wall, roof and window using multiple buildings' data in the same cluster or group.

Owner:GLOBALFOUNDRIES INC

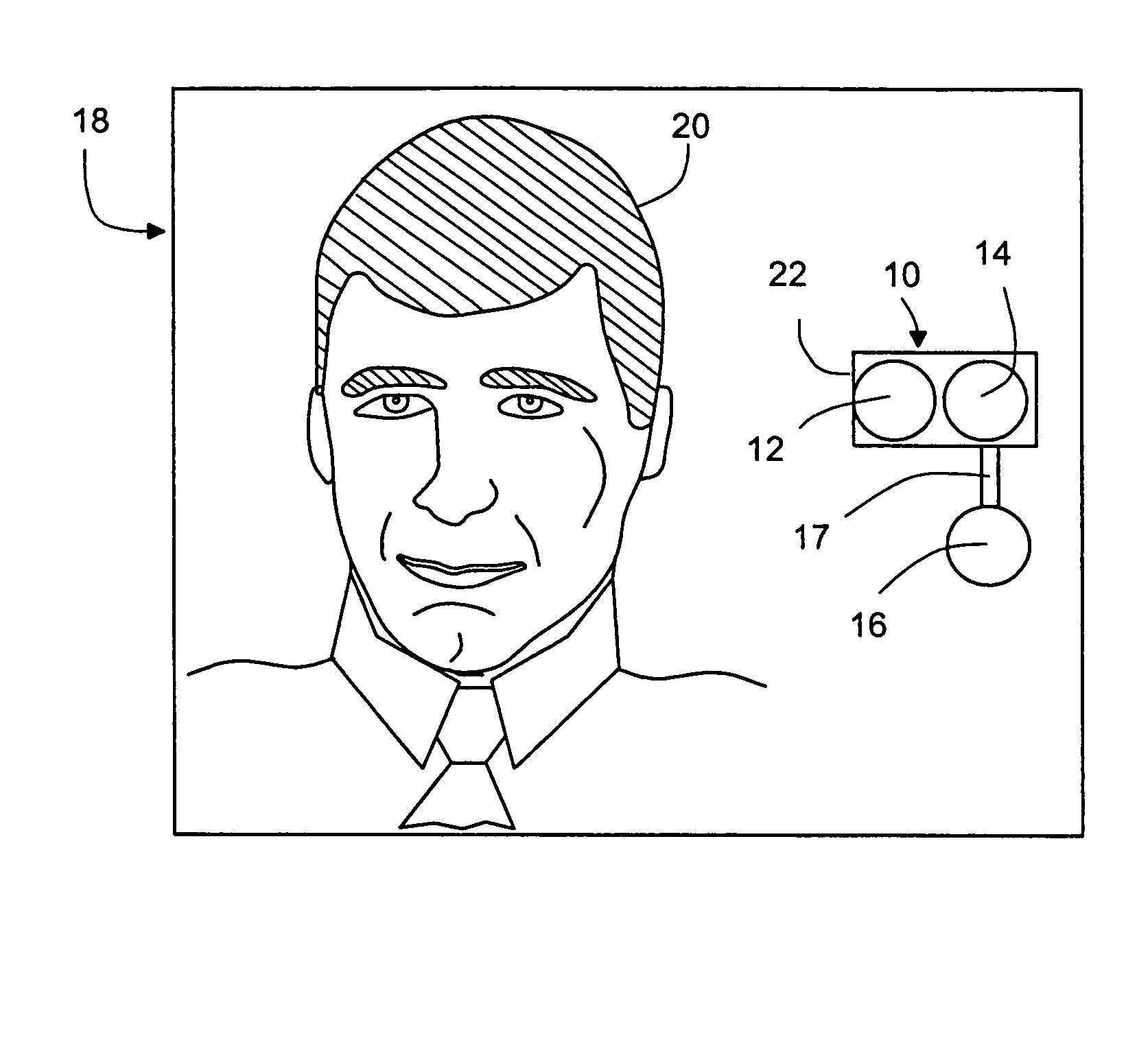

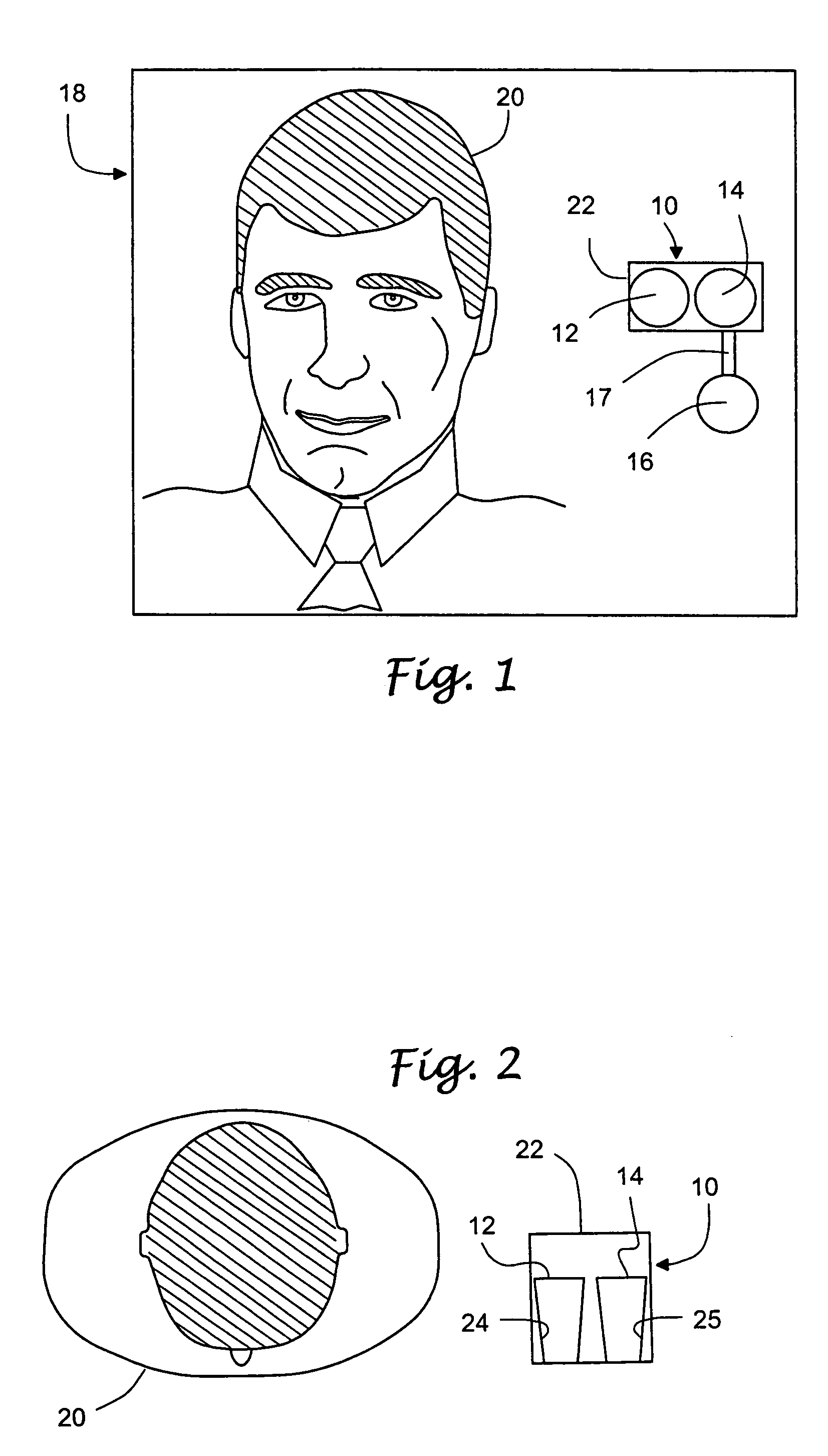

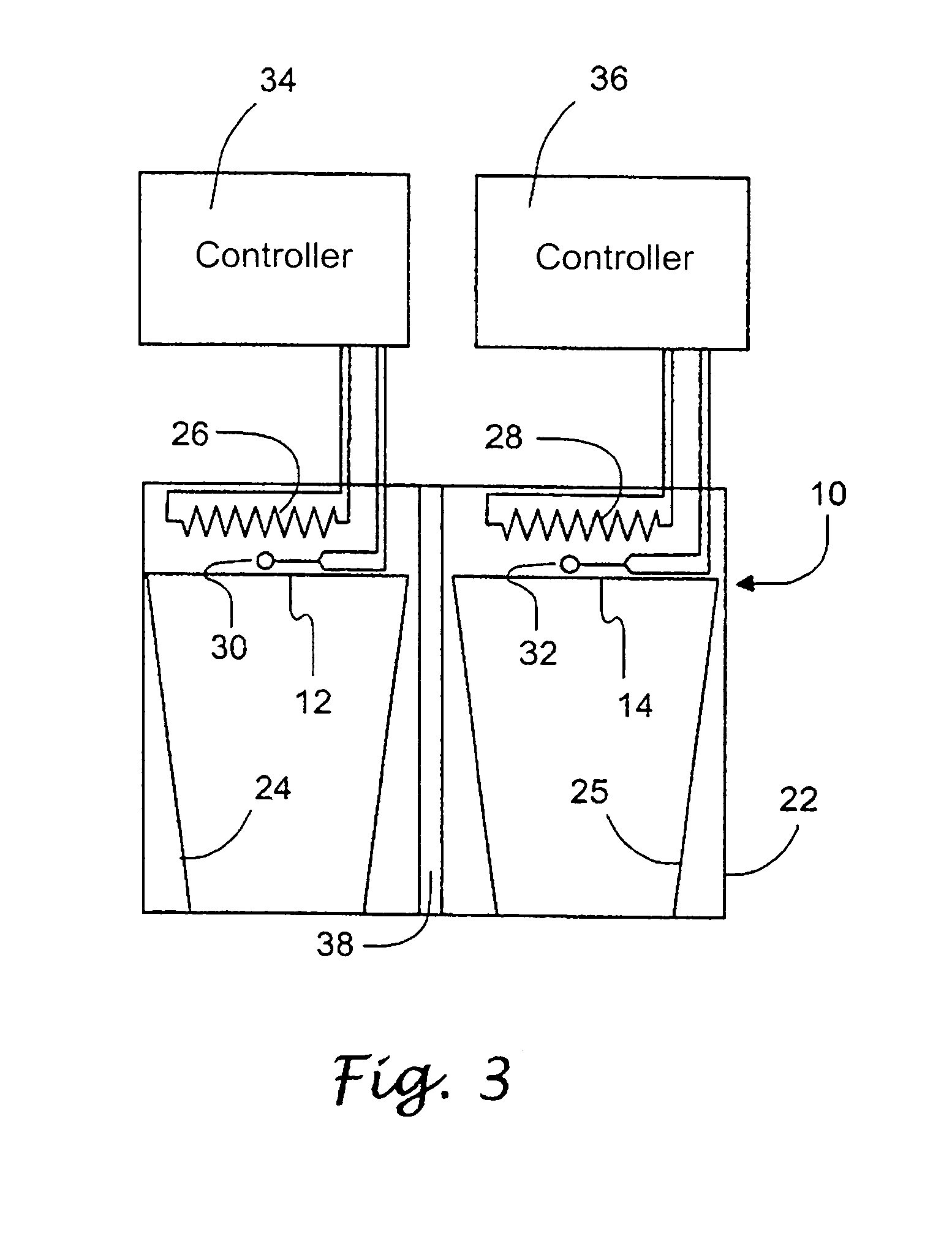

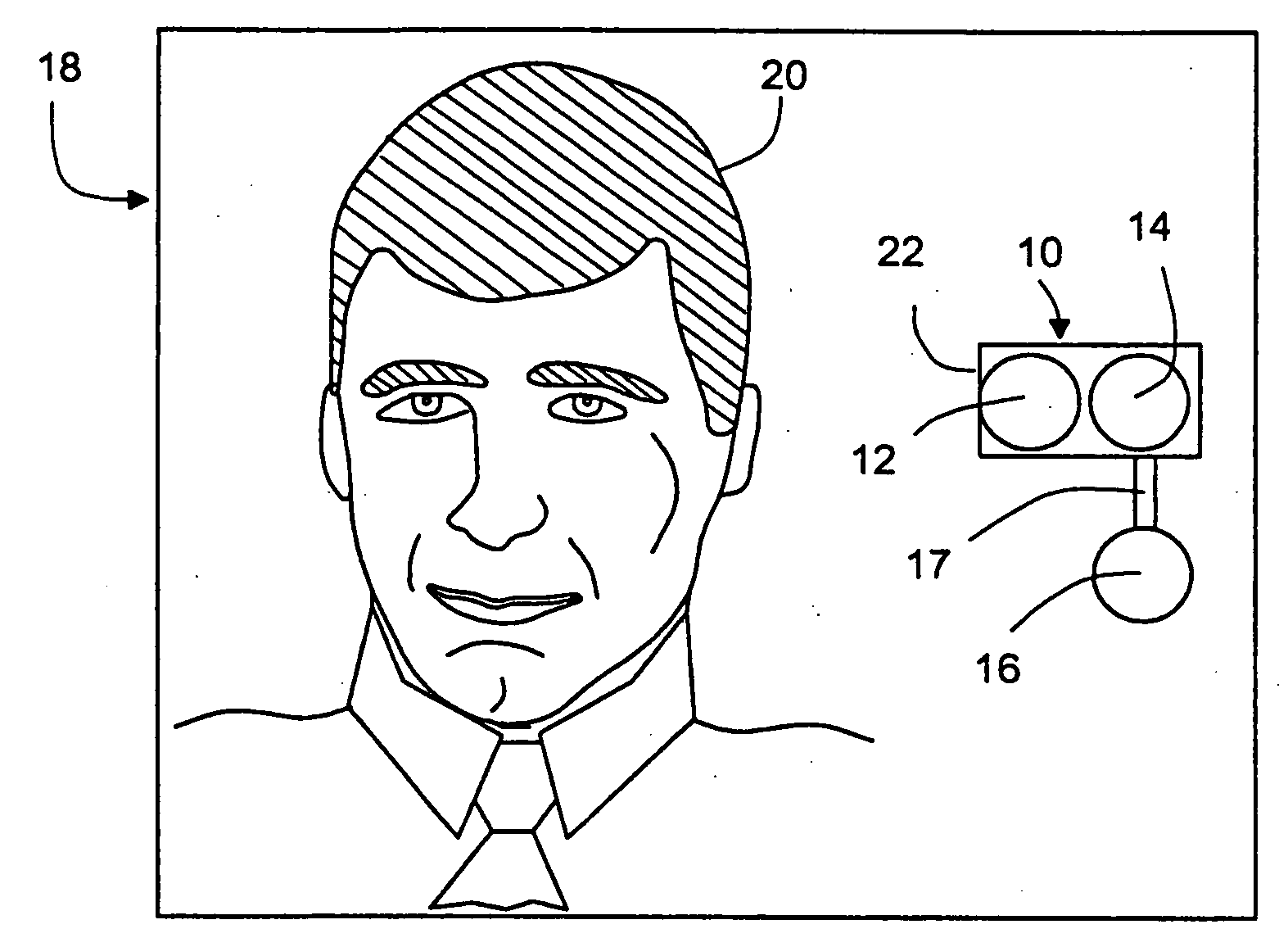

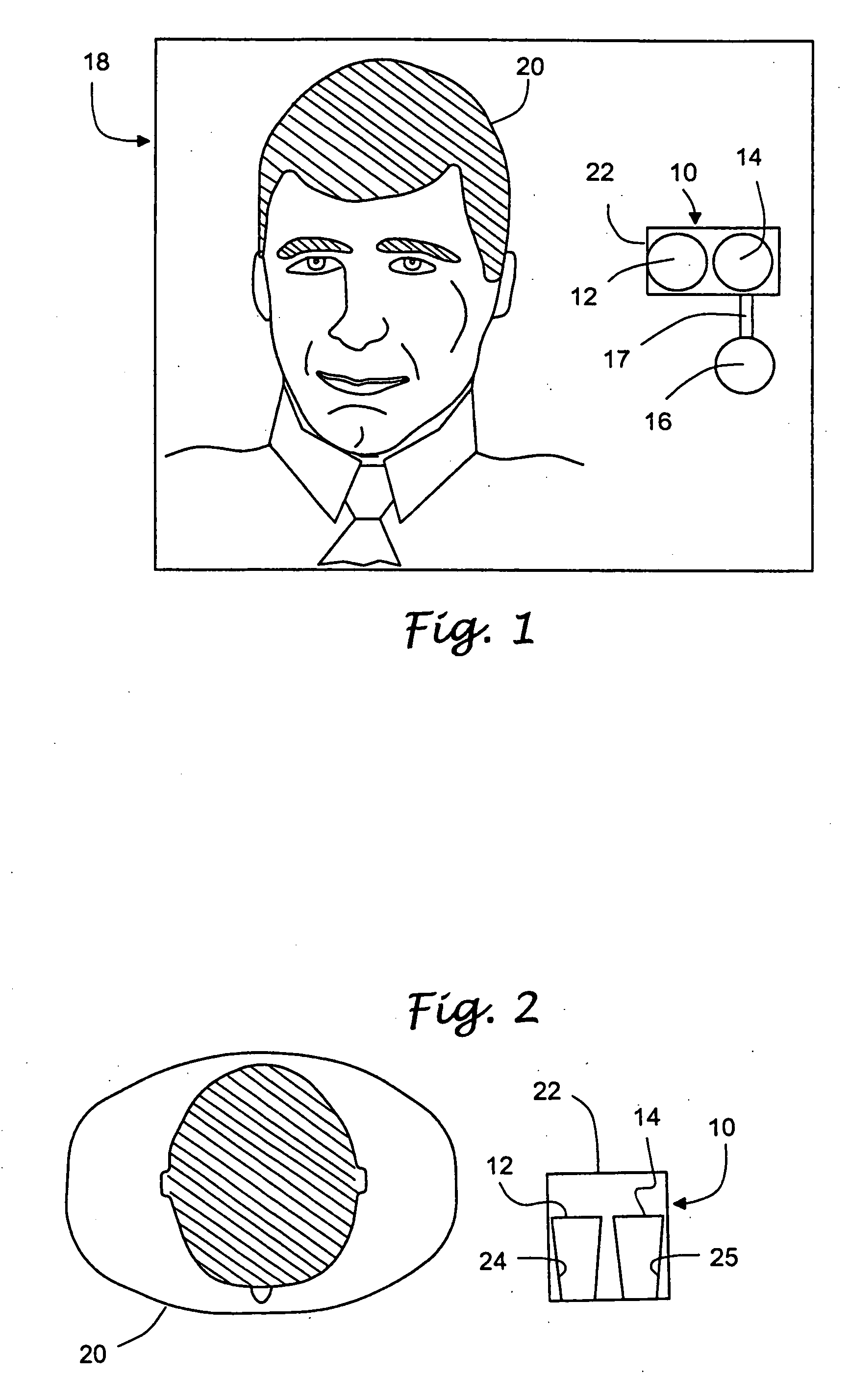

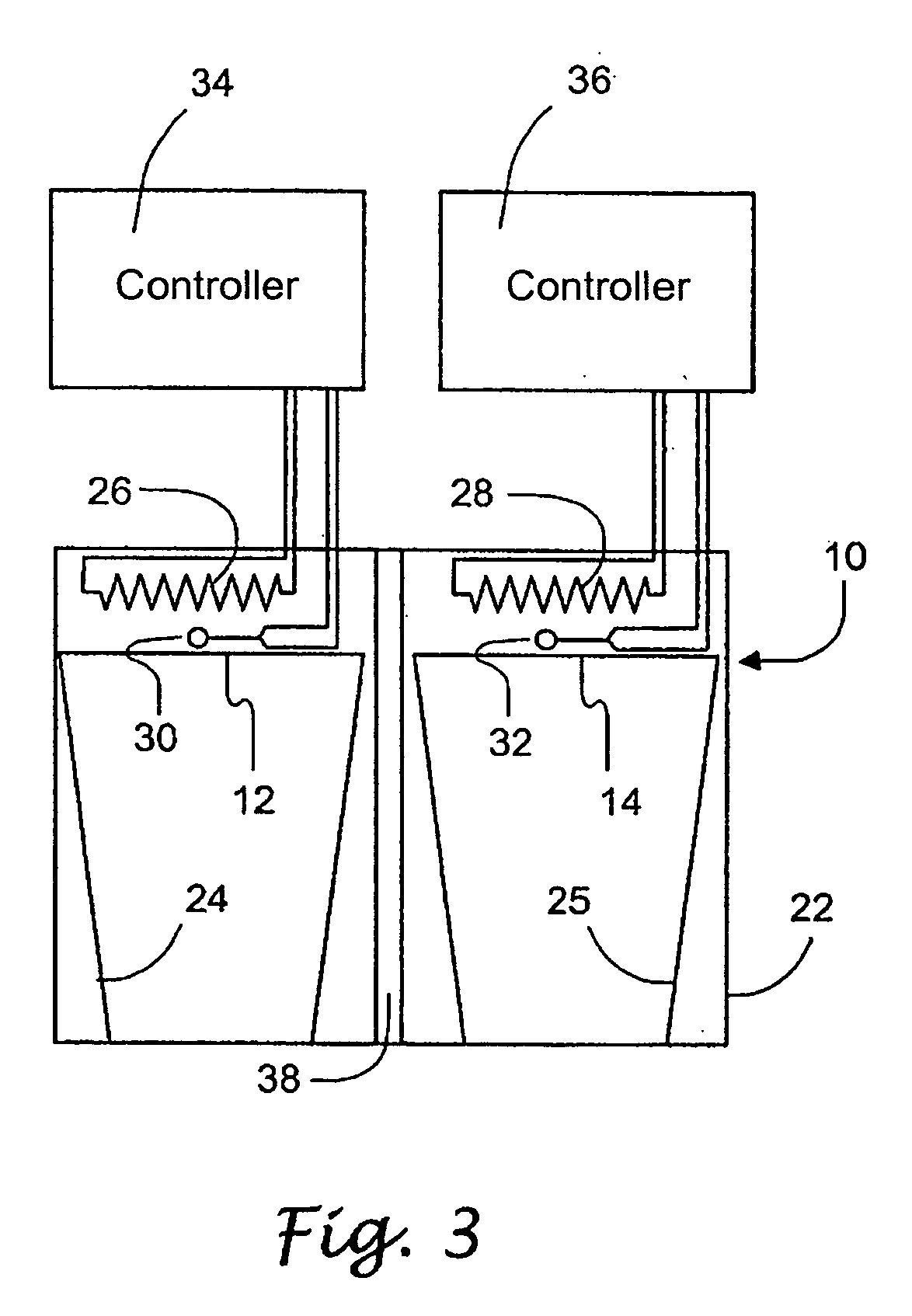

Methods and apparatus for a remote, noninvasive technique to detect core body temperature in a subject via thermal imaging

ActiveUS7340293B2Accurate of core body temperatureConvenience and securitySensing radiation from moving bodiesDiagnostic recording/measuringDiseaseEngineering

An approach to noninvasively, remotely and accurately detect core body temperature in a warm-blooded subject, human or animal, via thermal imaging. Preferred features such as the use of in-frame temperature references, specific anatomical target regions and a physiological heat transfer model help the present invention to overcome pitfalls inherent with existing thermal imaging techniques applied to physiological screening applications. This invention provides the ability to noninvasively, remotely and rapidly screen for diseases or conditions that are characterized by changes in core body temperature. One human application of this invention is the remote screening for severe acute respiratory syndrome (SARS), since fever is a common, early symptom. Other diseases and conditions that affect the core body temperature of humans or animals may also be noninvasively and remotely detected with this invention.

Owner:CARDIOWAVE

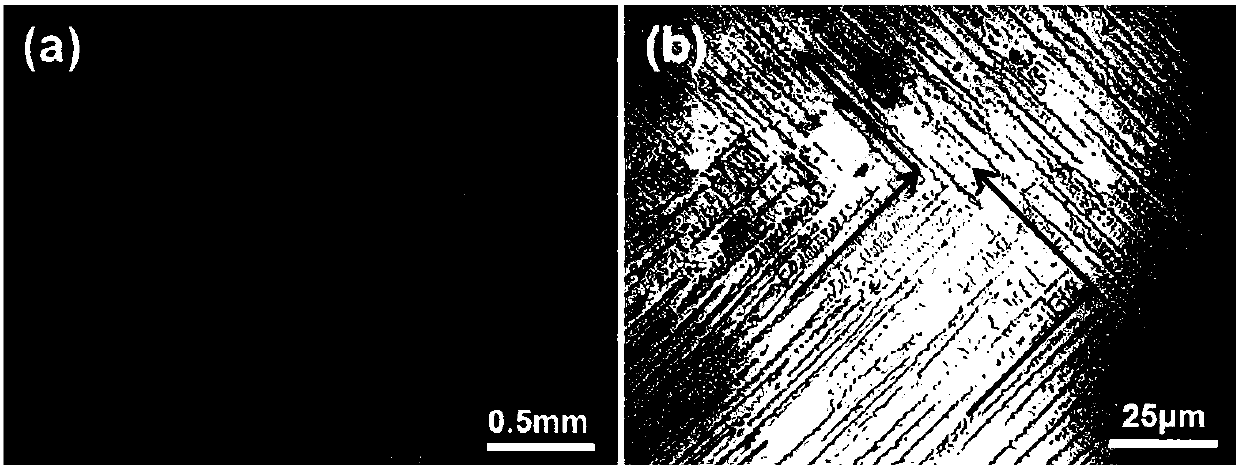

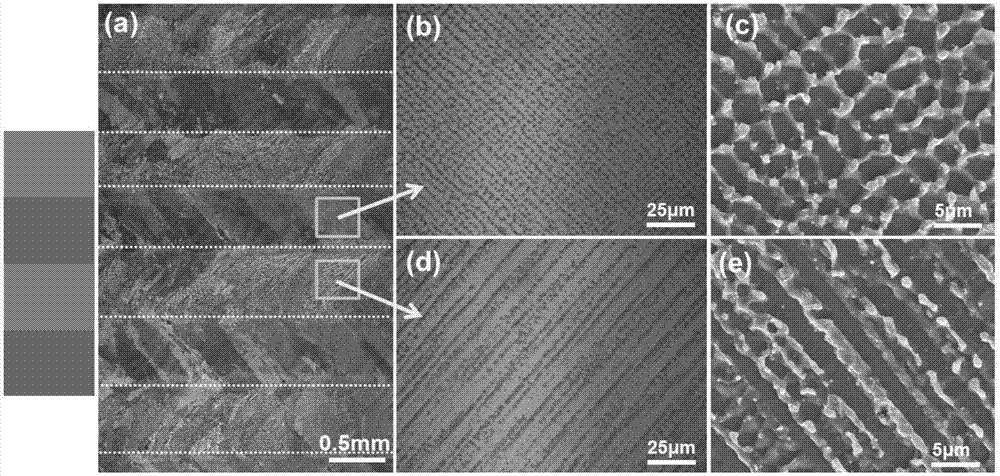

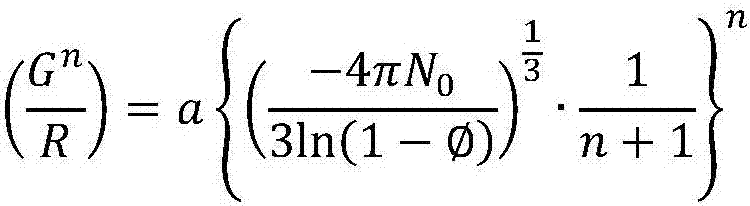

Quasi-continuous laser metal 3D printing method capable of realizing regulation of nickel base alloy crystallographic texture

ActiveCN107790717AImprove consistencyImprove microstructureAdditive manufacturing apparatusIncreasing energy efficiencyMolten bathMatch rule

The invention discloses a quasi-continuous laser metal 3D printing method capable of realizing regulation of nickel base alloy crystallographic texture. Laser output is set as a quasi-continuous lasermode, and then a laser metal 3D printing technical window is preliminarily optimized. The temperature field of a molten bath under the preliminarily optimized parameter is calculated by using a finite element heat transfer model; the temperature gradient G and the cooling rate xi of the moving boundary of the molten bath during closing of laser in a single pulse period are extracted, and the growth length L of a single pulse internal columnar dendrite is worked out according to a structure growth theoretical model; the laser parameter is optimized according to the matching rule that the ratioof the scanning speed V to pulse frequency f is 0.5-0.8L, and finally 3D printing forming is conducted according to the optimized parameter, so that a formed part with the consistent crystallographicorientation height is obtained. By regulating the heat source output mode, an effective remelting mechanism for mixed crystal or isometric crystal is introduced in the scanning direction, all columnar dendrite growth is obtained, and the consistency of grain orientation is remarkably improved.

Owner:HUNAN UNIV

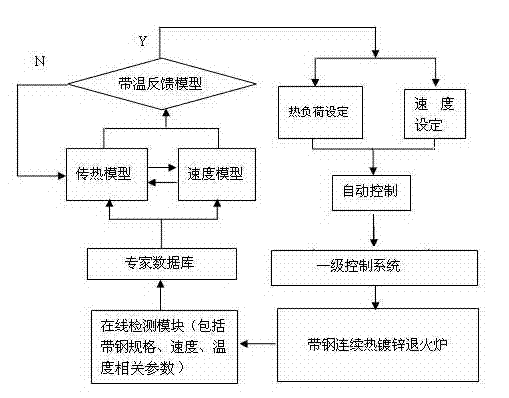

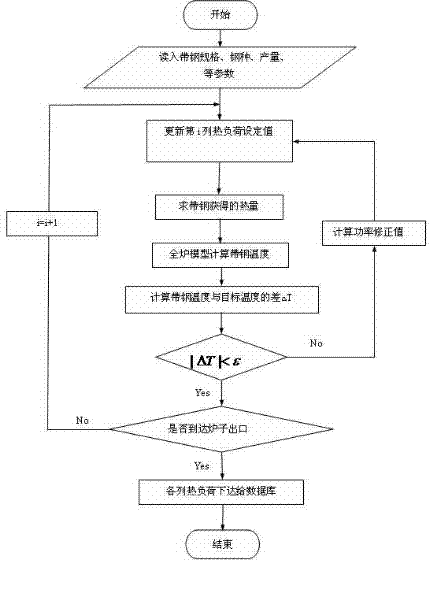

Online comprehensive control method for hot-galvanized continuous annealing furnace

ActiveCN102392119ASimple structureRealize online production controlFurnace typesAdaptive controlAutomatic controlControl system

The present invention discloses an online comprehensive control method for a hot-galvanized continuous annealing furnace. The method collects the operating information, including band steel speed, processing technique, steel coil codes and band steel specifications, of band steel through an online detection module. According to the collected operating information of band steel, the method calls main parameters through an expert database, so as to complete thermal load setting and speed setting by the co-operation of a speed model, a heat transfer model and a band temperature feedback model. Therefore, according to the set parameters, the method automatically controls a primary control system, so as to achieve the online production control of an annealing furnace. Based on heat transfer mechanism analysis, the method achieves the online production control of an annealing furnace by building a one-dimensional math model and the expert database with two cross-control methods: coarse tuning and fining tuning. In addition, the method also provides an additional series of complete control strategies such as a transition control method, so as to form a relative perfect control method. The models can be built conveniently and operate fast. Therefore, the method is suitable for the online production computation and control of an annealing furnace.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Methods and apparatus for a remote, noninvasive technique to detect core body temperature in a subject via thermal imaging

InactiveUS20080154138A1Convenience and securityGuarantee economic securitySensing radiation from moving bodiesDiagnostic recording/measuringDiseaseEngineering

Owner:MCQUILKIN GARY L

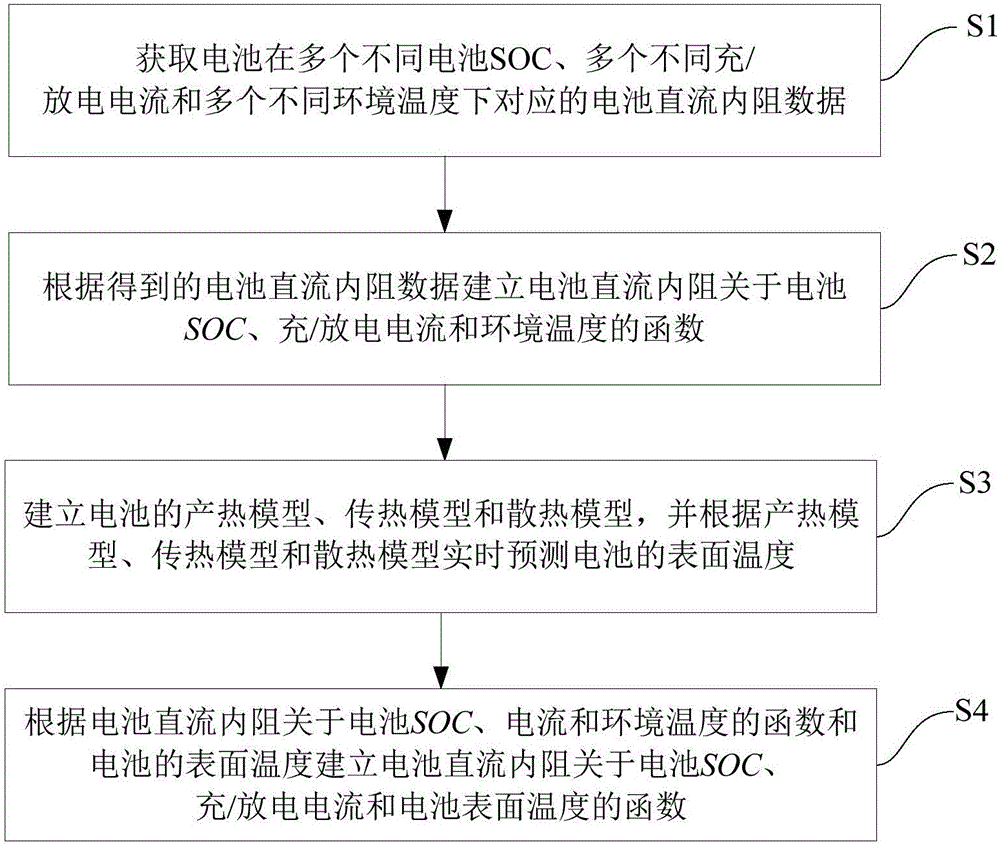

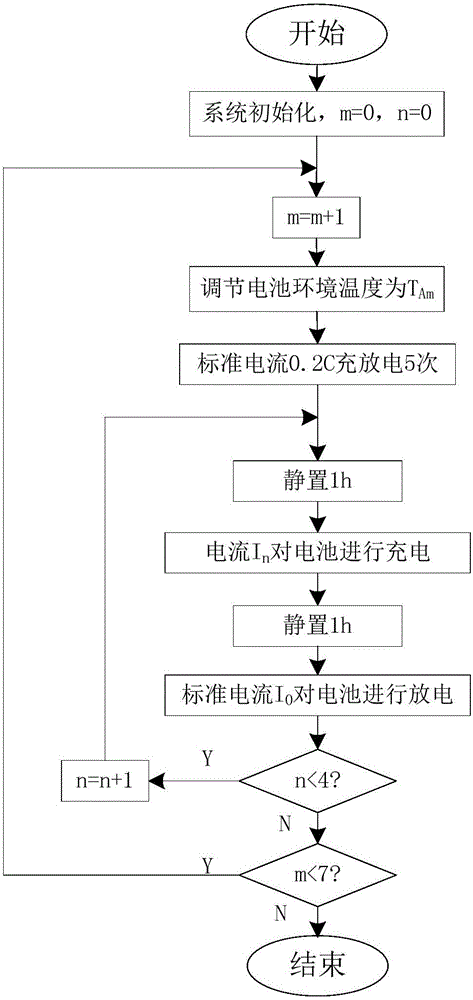

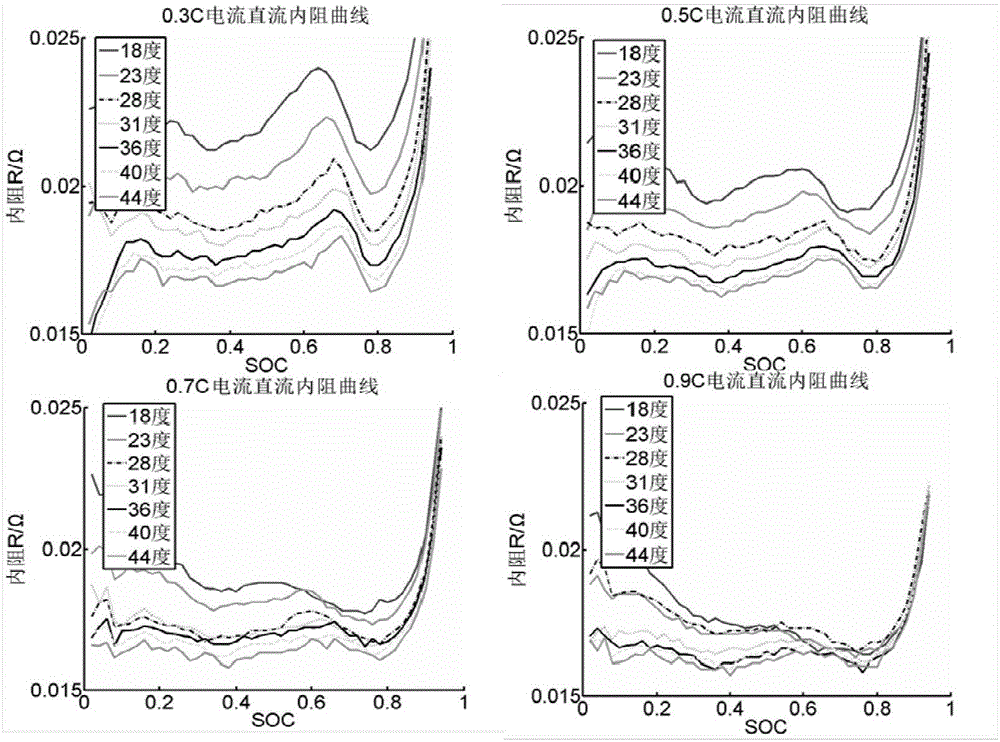

Method of building battery DC inner resistance function

The invention provides a method of building a battery DC inner resistance function. The method comprises the following steps: corresponding battery DC inner resistance data of a battery under different battery SOCs (State of Charge), multiple different charging / discharging currents and multiple different ambient temperatures are acquired; according to the acquired battery DC inner resistance data, a function of the battery DC inner resistance relative to the battery SOCs, the charging / discharging currents and the ambient temperatures is built; a heat production model, a heat transfer model and a heat dissipation model for the battery are built, and according to the heat production model, the heat transfer model and the heat dissipation model, the surface temperature of the battery is predicted in real time; and according to the function of the battery DC inner resistance relative to the battery SOCs, the currents and the ambient temperatures and the surface temperature of the battery, a function of the battery DC inner resistance relative to the battery SOCs, the charging / discharging currents and the surface temperature of the battery is built. The function relationship between the battery SOCs, the current and the surface temperature of the battery and the battery DC inner resistance can be described simply, comprehensively, accurately and in real time, realization is easy, and engineering applications are facilitated.

Owner:TSINGHUA UNIV

Intelligent monitoring method for cooling wall of blast furnace

InactiveCN101319256AAvoid damageProduces results quickly and accuratelyChecking devicesData acquisitionEngineering

The invention discloses an intelligent monitoring method for a blast furnace cooling wall, which comprises the following steps that: a cooling wall heat transfer model is established, a heat transfer core model is extracted through a non-linear regression mode, the core model and an artificial neural network are combined to produce a monitoring model for a highest temperature value of a hot surface of the cooling wall and form monitoring software, and the running state and local high-temperature positions of the cooling wall as well as the safety of the cooling wall are evaluated by combining the heat transfer model with temperature values of test points of an in-situ sensor. The method has the advantages of simple data acquisition for theoretical analysis, quick and accurate result generation, and less damage to shells of blast furnaces.

Owner:TONGJI UNIV

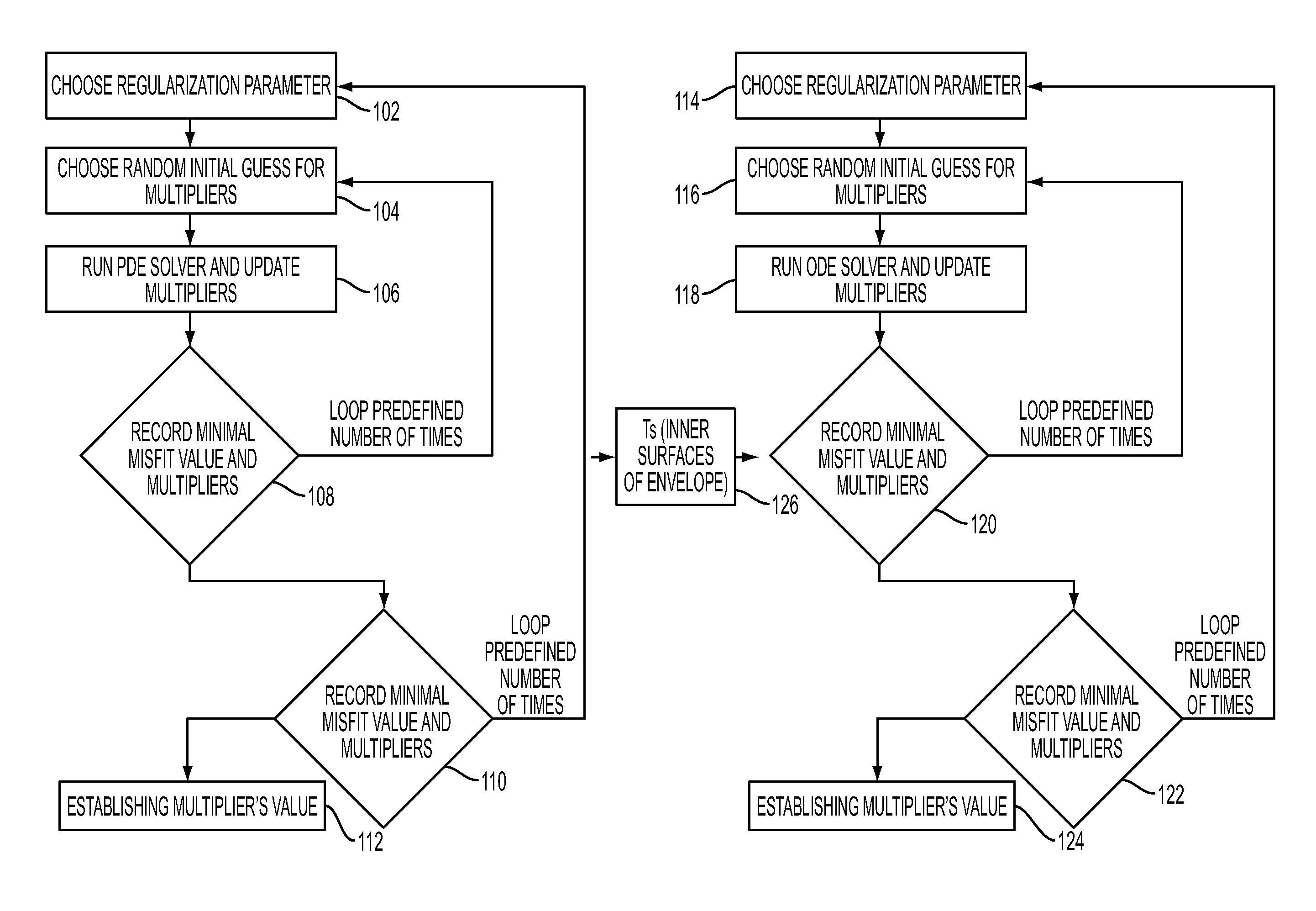

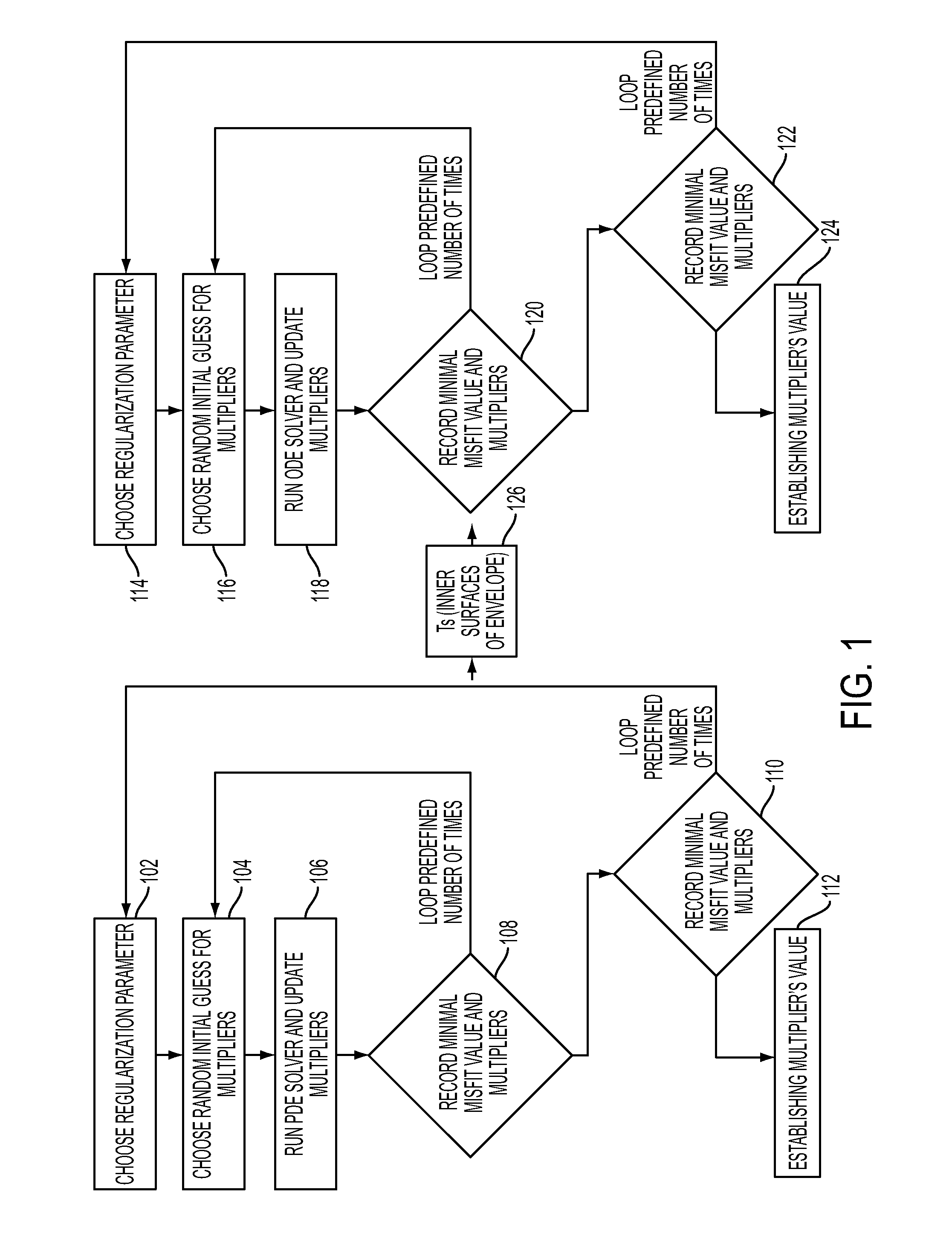

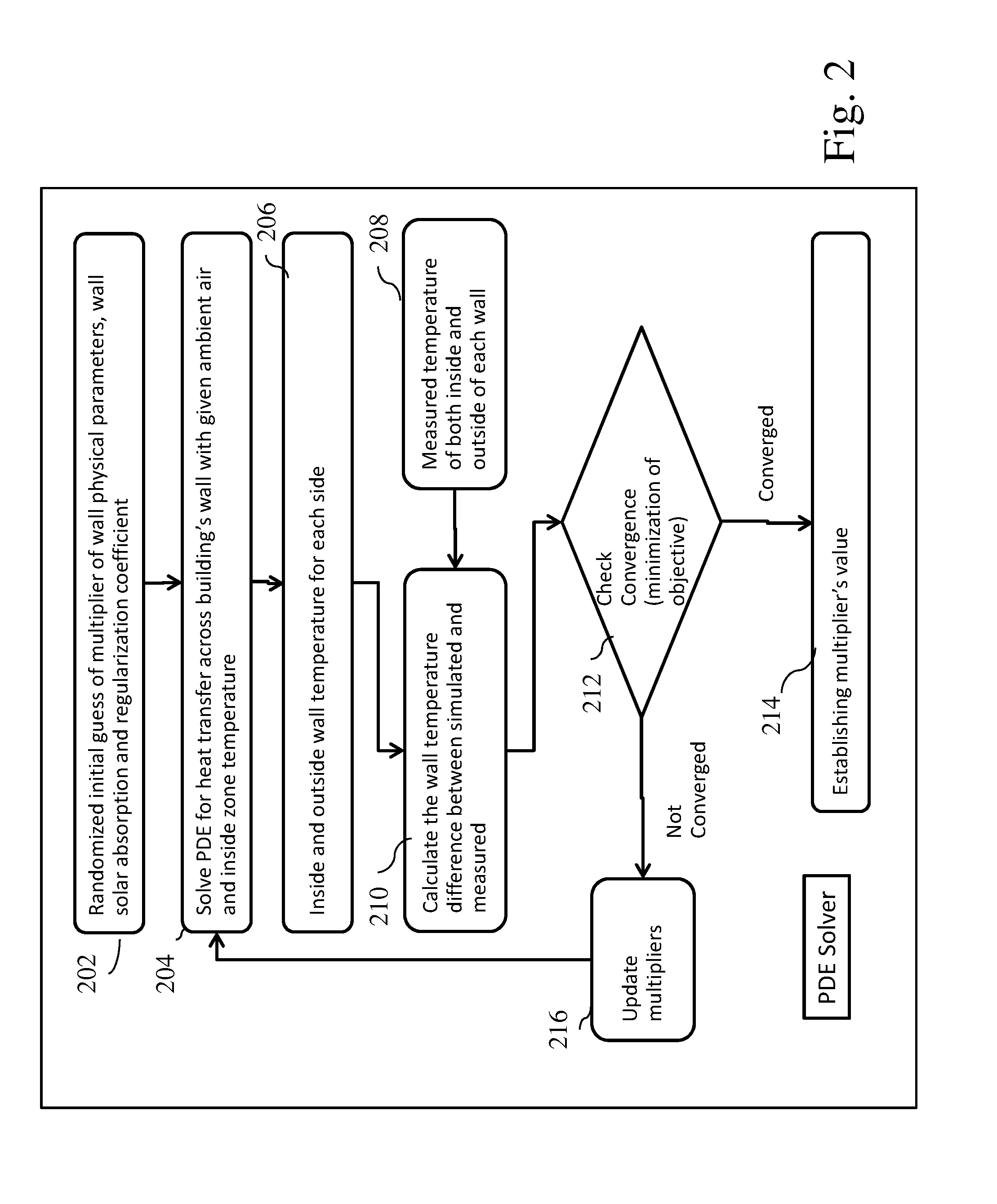

Inverse modeling procedure for building energy using integrated pde-ode models and stepwise parameter estimation

Generating a heat transfer model for building energy may comprise developing a PDE model that describes heat transfer through building envelope of a building, and developing an ODE model that describes the heat transfer and thermal balance in a space inside the building. Stepwise parameter estimation integrates the PDE model and the ODE model in generating the heat transfer model.

Owner:GLOBALFOUNDRIES INC

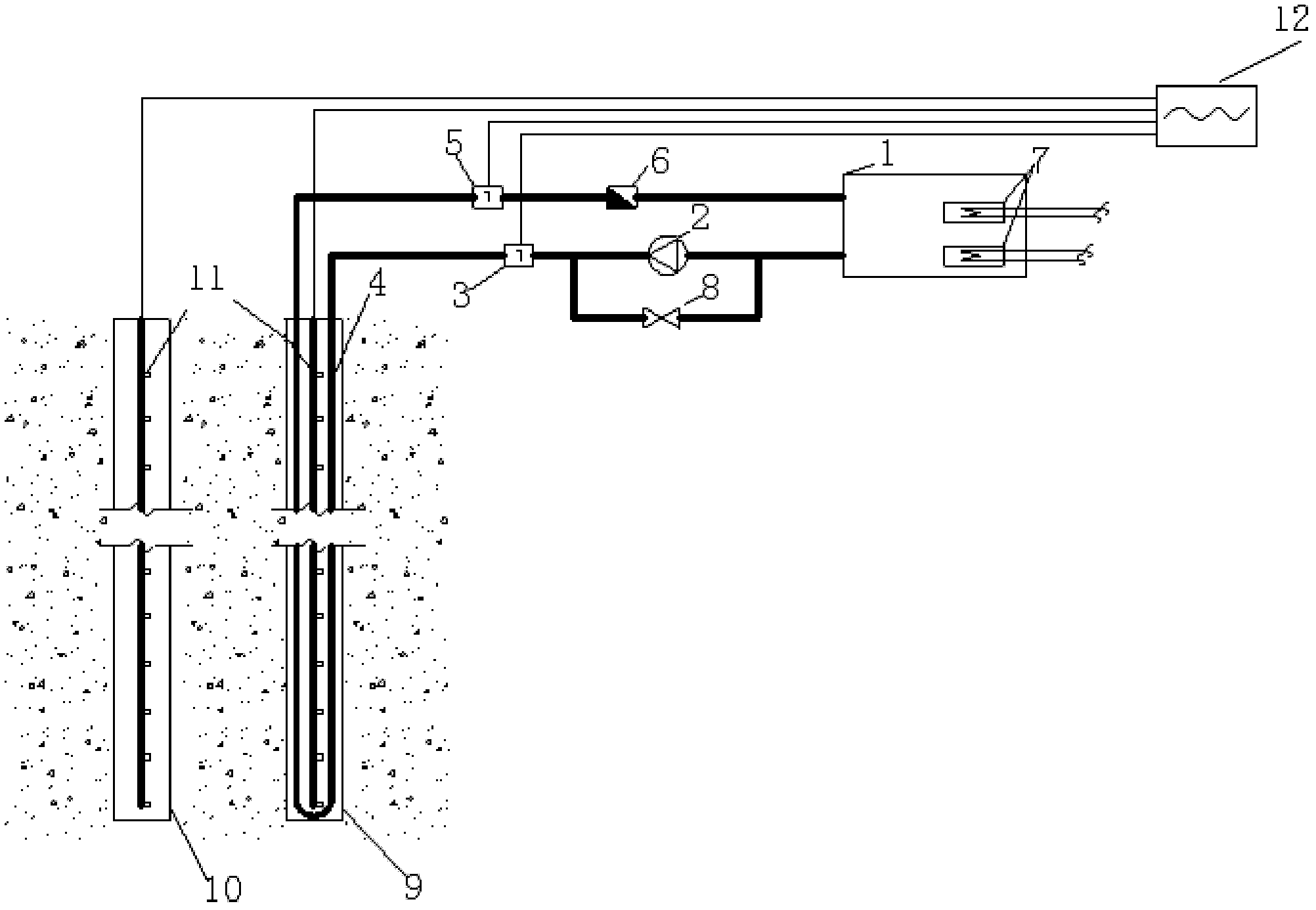

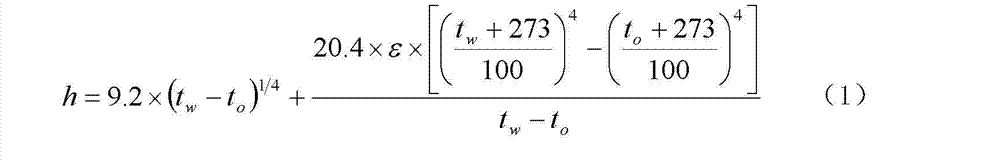

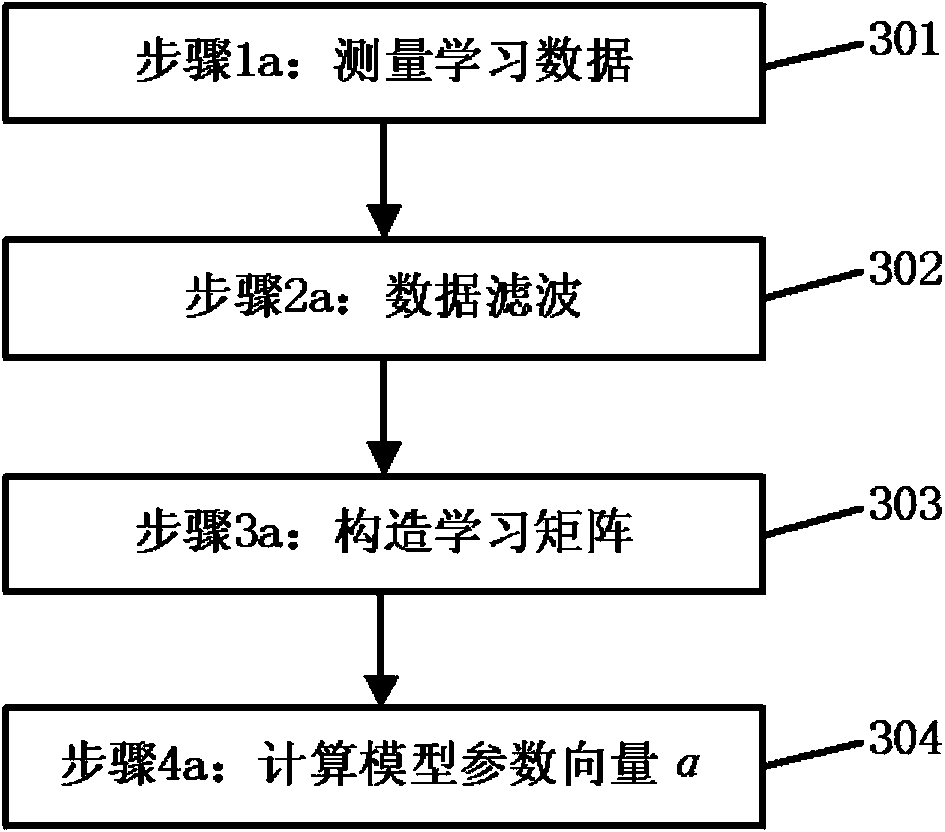

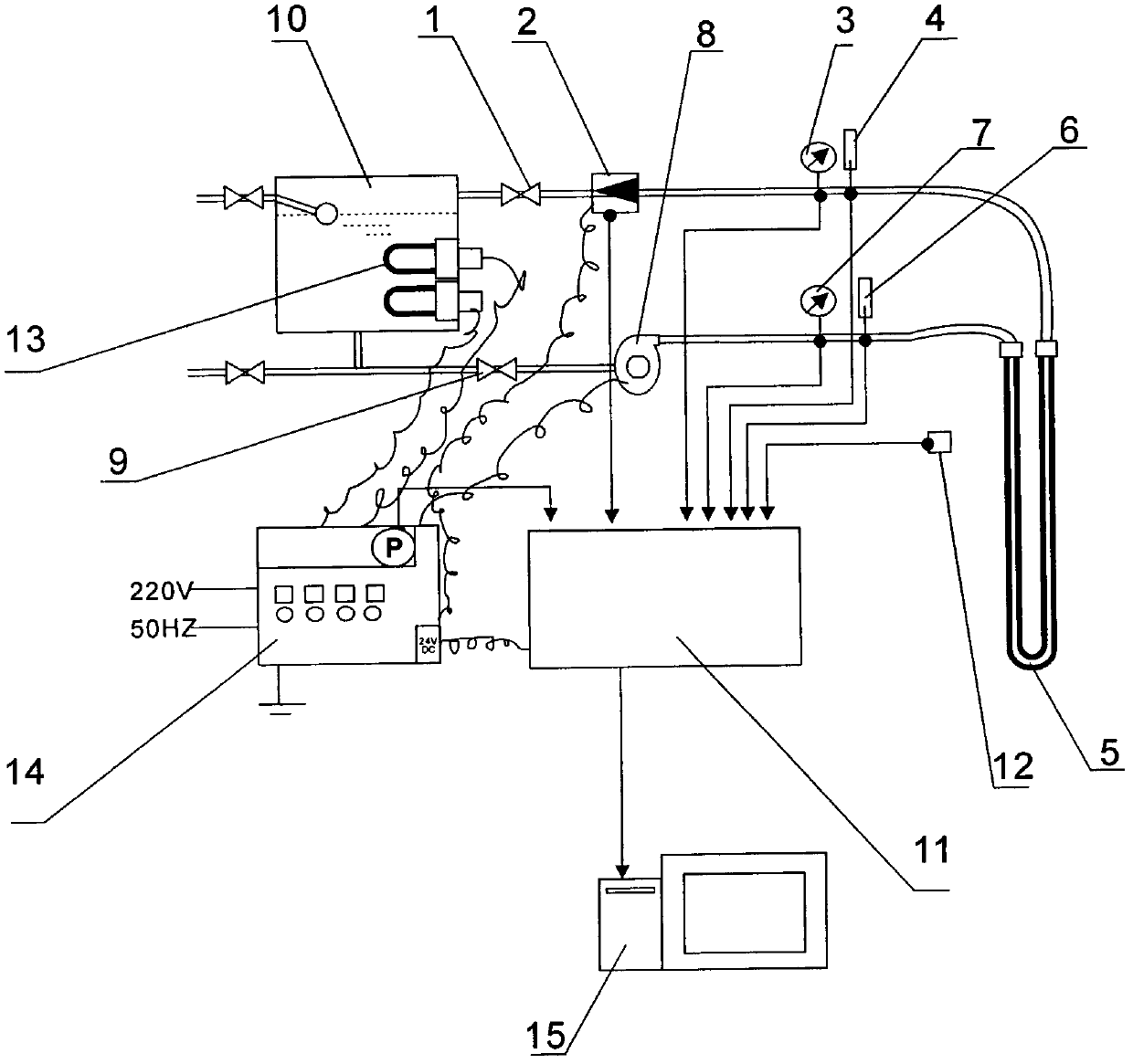

Ground source heat pump rock-soil heat response dynamic testing system and testing method

InactiveCN102590271ALearn more about heat transferRealize measurementMaterial heat developmentData acquisitionEngineering

The invention relates to a ground source heat pump rock-soil heat response dynamic testing system, which consists of a heating water tank, a circulating pump, a bypass-valve, a heating well, a U-shape pipe, a temperature monitoring well, a data acquisition analyzer, temperature sensors, flow sensors and a heater, and is characterized in that the temperature monitoring well is arranged in the position 0.3-1.2 m away from the heating well, a temperature sensor group identical to temperature sensors group on the heating well is arranged in the temperature monitoring well, and all the temperature sensors and flow sensors are connected with the data acquisition analyzer through signal lines. In testing, a rock-soil original temperature value data test, a basic heating process data test, a strengthened heating process data test and after heating stop data test are respectively carried out on the heating well and the temperature monitoring well. By the comparison of a calculation value and a measured value of a heat transfer model and the revision of rock-soil thermal conductivity, the actual rock-soil thermal productivity is ultimately approximated. The rock-soil temperatures in the heating well and the temperature monitoring well are monitored synchronously to shorten the test time; and the heat transfer conditions of rock-soil at different depths and the mutual influence of wells are accurately mastered to provide data for designing.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

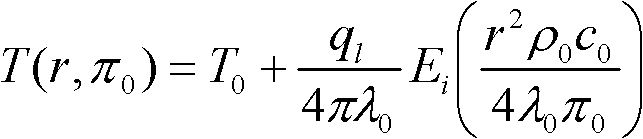

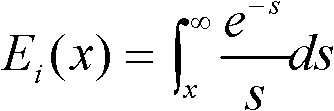

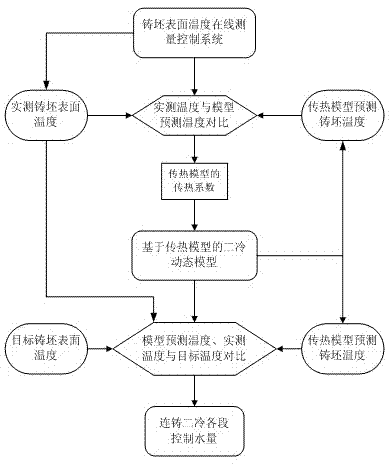

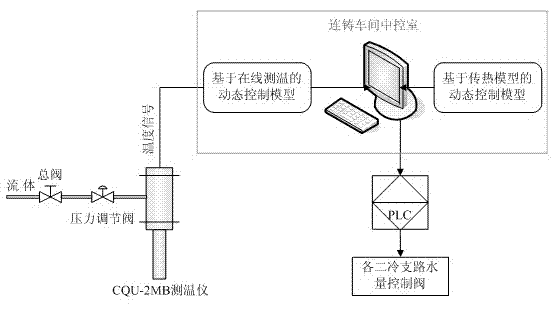

Continuous casting secondary cooling dynamic control method based on online temperature measuring and heat transferring model

The invention provides a continuous casting secondary cooling dynamic control method based on an online temperature measuring and heat transferring model. The continuous casting secondary cooling dynamic control method includes constructing a new continuous casting secondary cooling dynamic model, planting the new continuous casting secondary cooling dynamic model into a computer system, embedding the new continuous casting secondary cooling dynamic model into a water distribution system of a continuous casting machine and enabling the new continuous casting secondary cooling dynamic model to be in communication connection with a PLC (programmable logic controller); mounting a non-contact type temperature measuring instrument CQU-2MB in a continuous casting straightening area and enabling the non-contact type temperature measuring instrument CQU-2MB to be in communication connection with the PLC and to form a feedback circuit with the new continuous casting secondary cooling dynamic model; acquiring various technological operation parameters by the new continuous casting secondary cooling dynamic model in an online manner during continuous casting; carrying out simulation computation of parameters in real time; measuring the temperature of the surface of a casting blank in the continuous casting straightening area in an online manner; and controlling and adjusting the quantity of water for continuous casting secondary cooling by comparison and computation for the temperature measured in real time in the online manner, the temperature which is predicted by a heat transferring model and is corrected in real time and the temperature of the surface of a target casting blank. By the continuous casting secondary cooling dynamic control method, accuracy and reliability of continuous casting secondary cooling dynamic control and stability of running of continuous casting secondary cooling are greatly improved, and the method is simple and feasible in implementation and obvious in effect.

Owner:CHONGQING UNIV

Estimating building thermal properties by integrating heat transfer inversion model with clustering and regression techniques for a portfolio of existing buildings

A static heat transfer model is derived from a system of dynamic equations by integrating the dynamic equations over different time periods. That static heat transfer model links periodic (e.g., monthly) energy usage with cooling and heating degree hours, humidifying and dehumidifying hours. Its coefficients of measuring correlations correspond to the thermal parameters of buildings. Temporal data from a building may be used to estimate the overall heat transfer parameters. A clustering scheme may be developed to decompose all the buildings into different clusters based on one or more similarity criteria. The overall heat transfer parameters are separated into values for the wall, roof and window using multiple buildings' data in the same cluster or group.

Owner:GLOBALFOUNDRIES INC

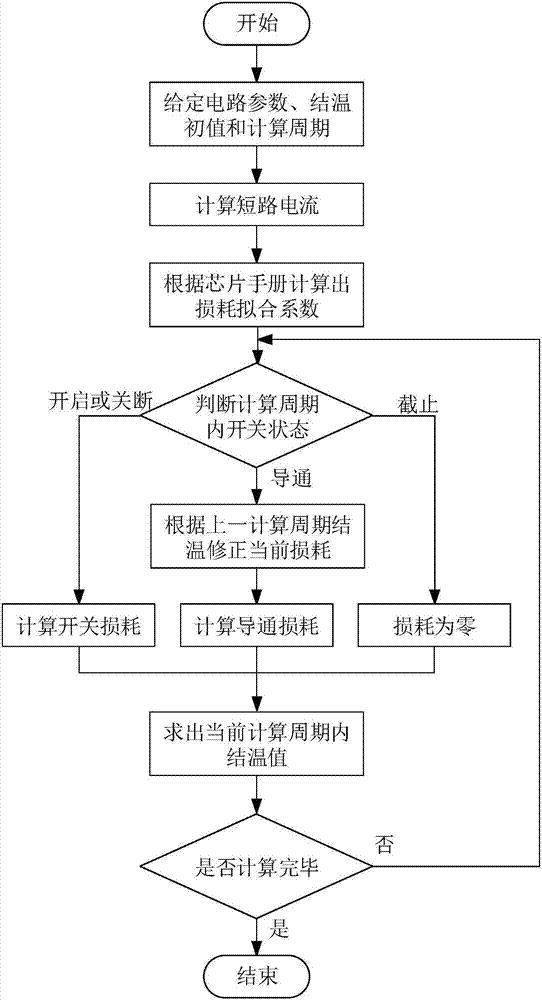

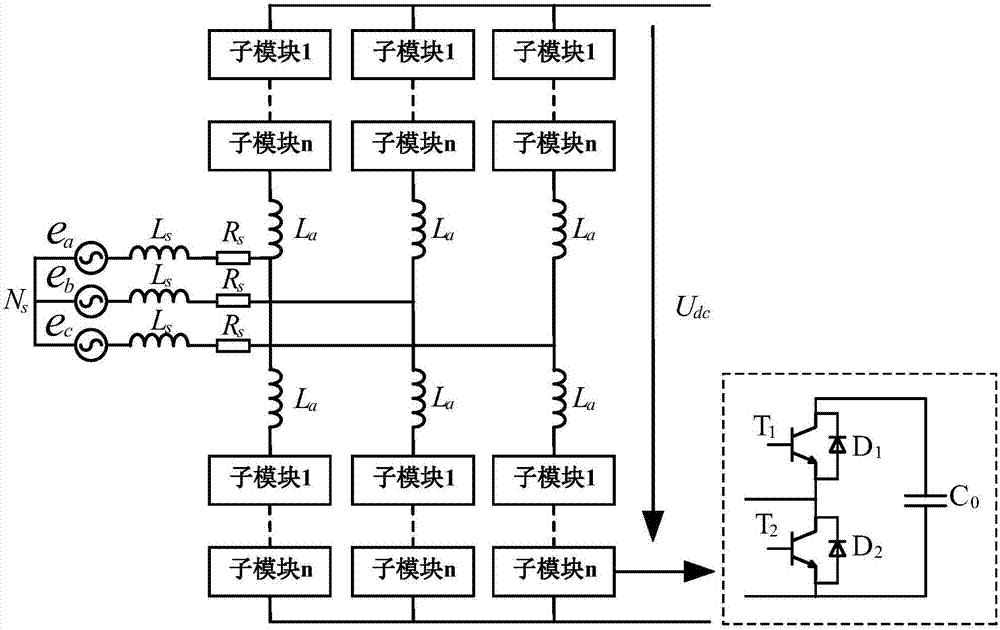

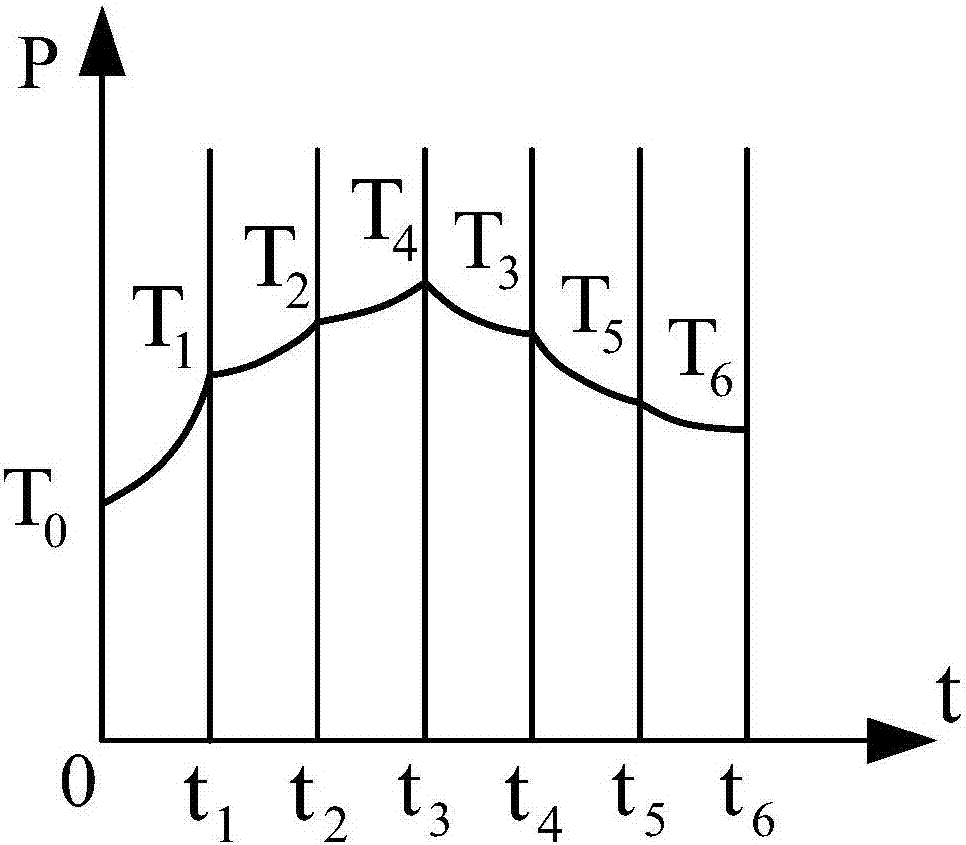

Method for predicting junction temperature of IGBT (Insulated Gate Bipolar Translator) module

ActiveCN107025364AHigh precisionSave resourcesDesign optimisation/simulationSpecial data processing applicationsPower flowJunction temperature

The invention discloses a method for predicting the junction temperature of an IGBT (Insulated Gate Bipolar Translator) module. The method comprises the following steps: 1) according to parameters of a modularized multi-level circuit and the running condition thereof before shortcircuit, calculating an expression of current flowing through the IGBT during direct-current bipolar shortcircuit; 2) according to an IGBT data sheet, fitting relational expressions between the conduction loss and the current flowing through the IGBT and between the switching energy and the current flowing through the IGBT; 3) according to the equivalent switching frequency and the equivalent duty ratio of the IGBT, judging the switching state of the IGBT; 4) according to the switching state of the IGBT, the expression of the current flowing through the IGBT during the direct-current bipolar shortcircuit, and the relational expressions between the conduction loss and the current flowing through the IGBT and between the switching energy and the current flowing through the IGBT, calculating a loss value P of the IGBT; 5) according to the loss value P of the IGBT and a fourth-order Foter heat transfer model of the IGBT module, calculating a distribution value of the junction temperature of the IGBT along with time. The method is applied to the modularized multi-level circuit, and is used for predicting a junction temperature change curve during the direct-current bipolar shortcircuit under different running conditions through calculation; by the method, a reference is provided for main circuit design, protection design and cooling circuit design, and the stability of a system is improved.

Owner:XI AN JIAOTONG UNIV

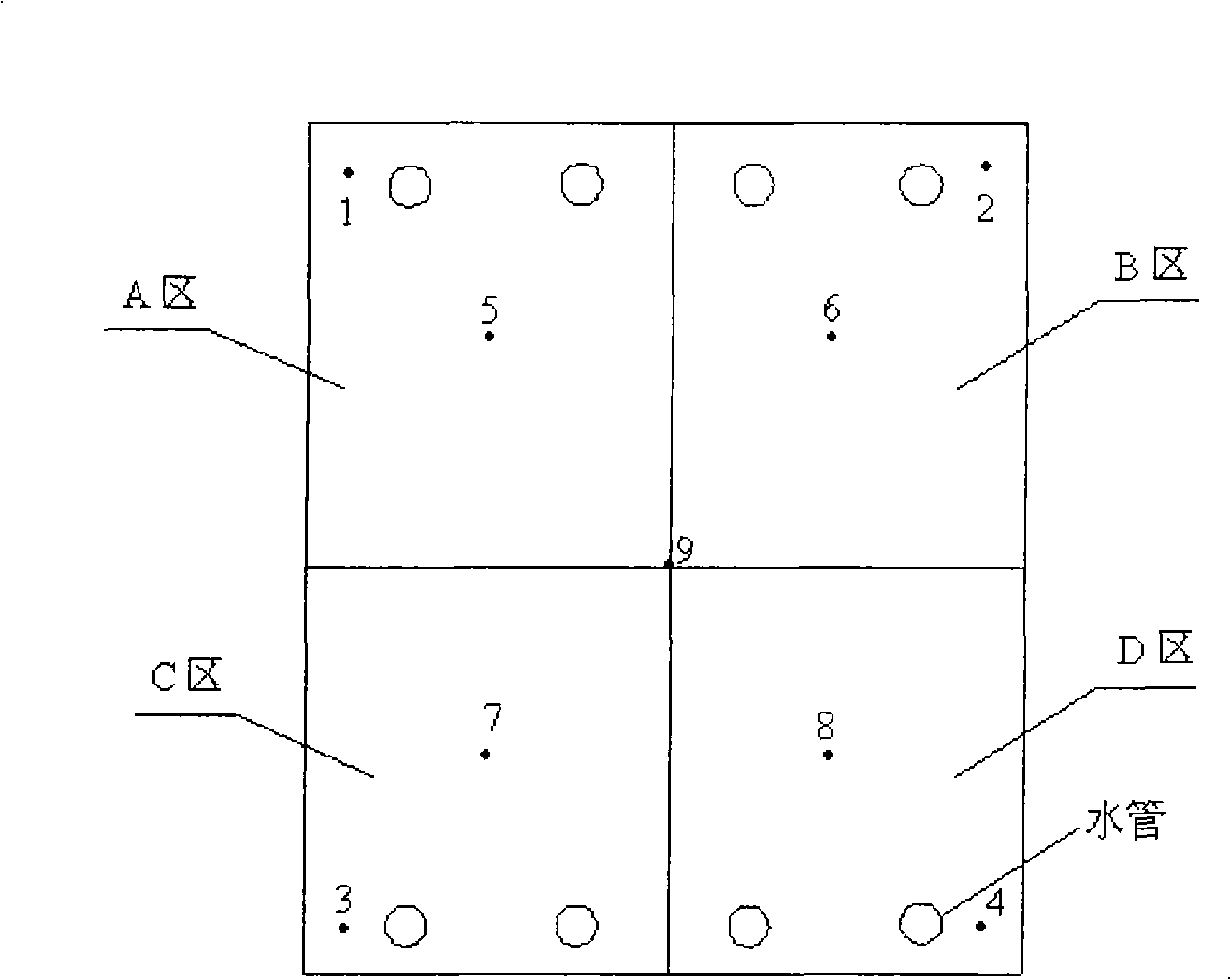

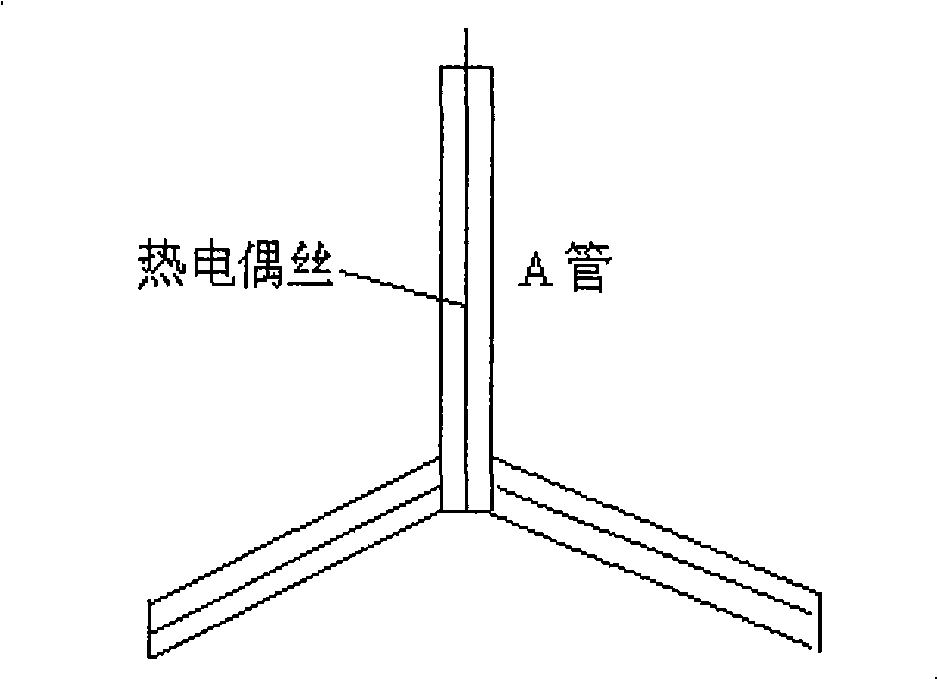

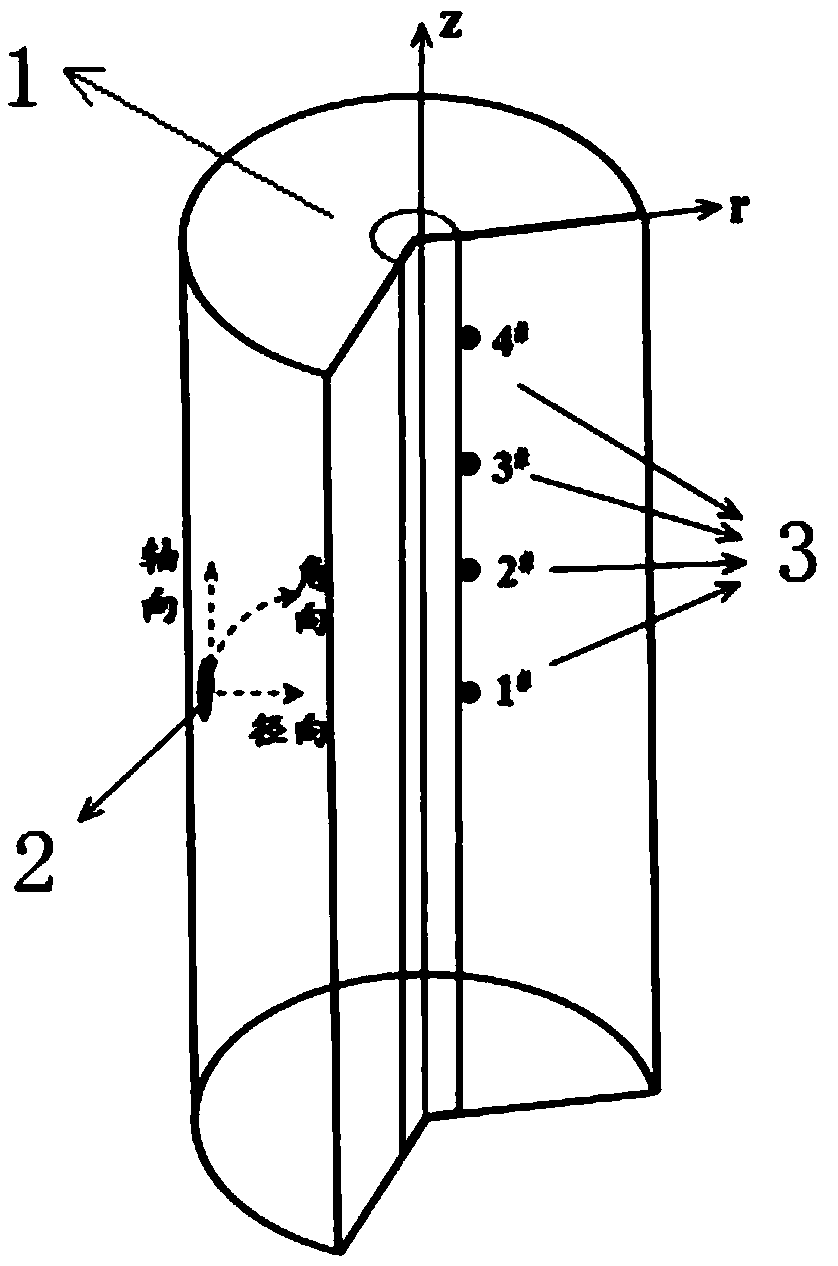

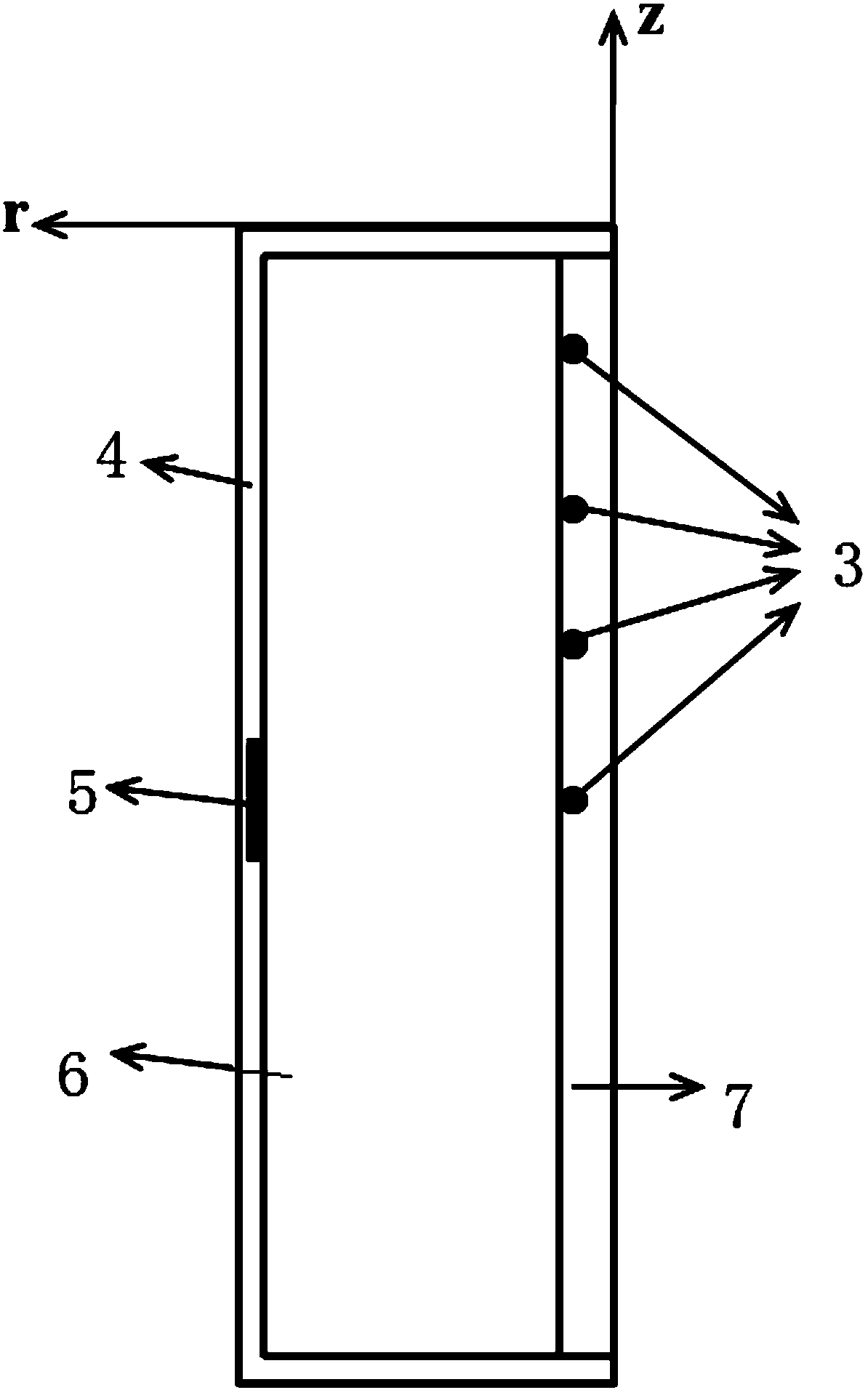

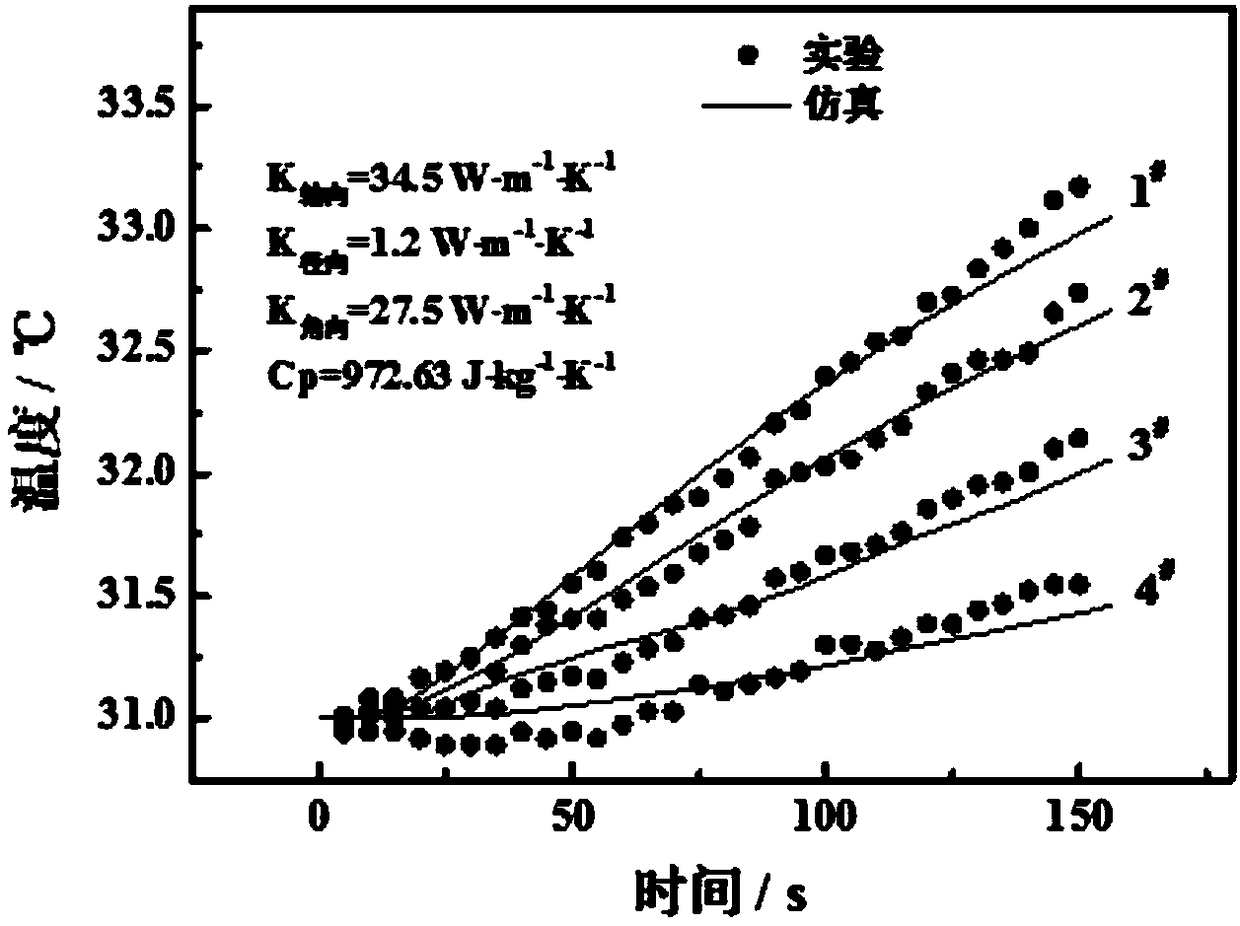

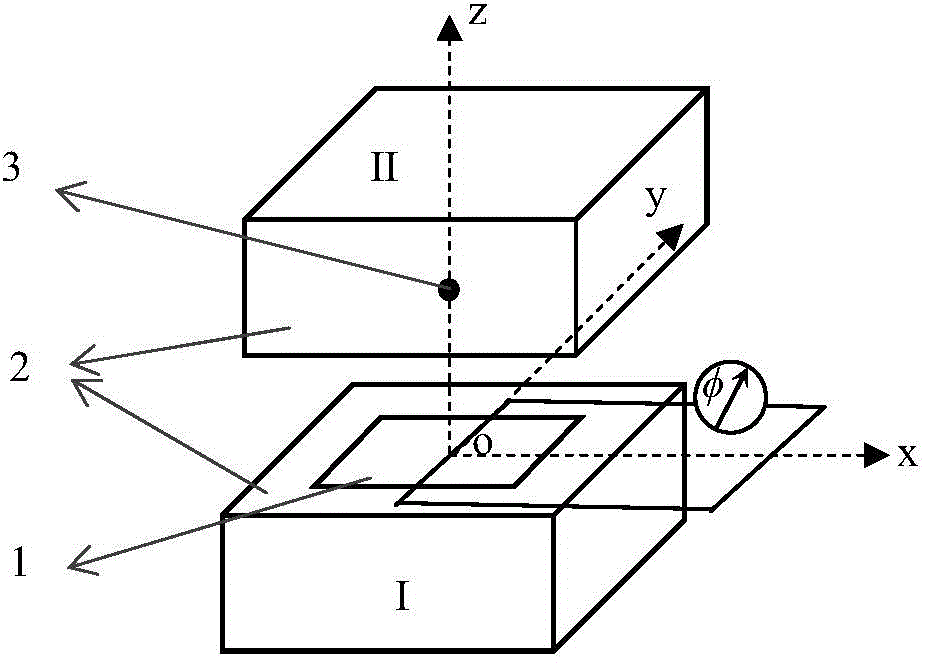

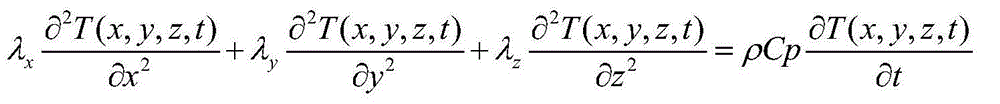

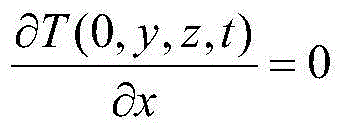

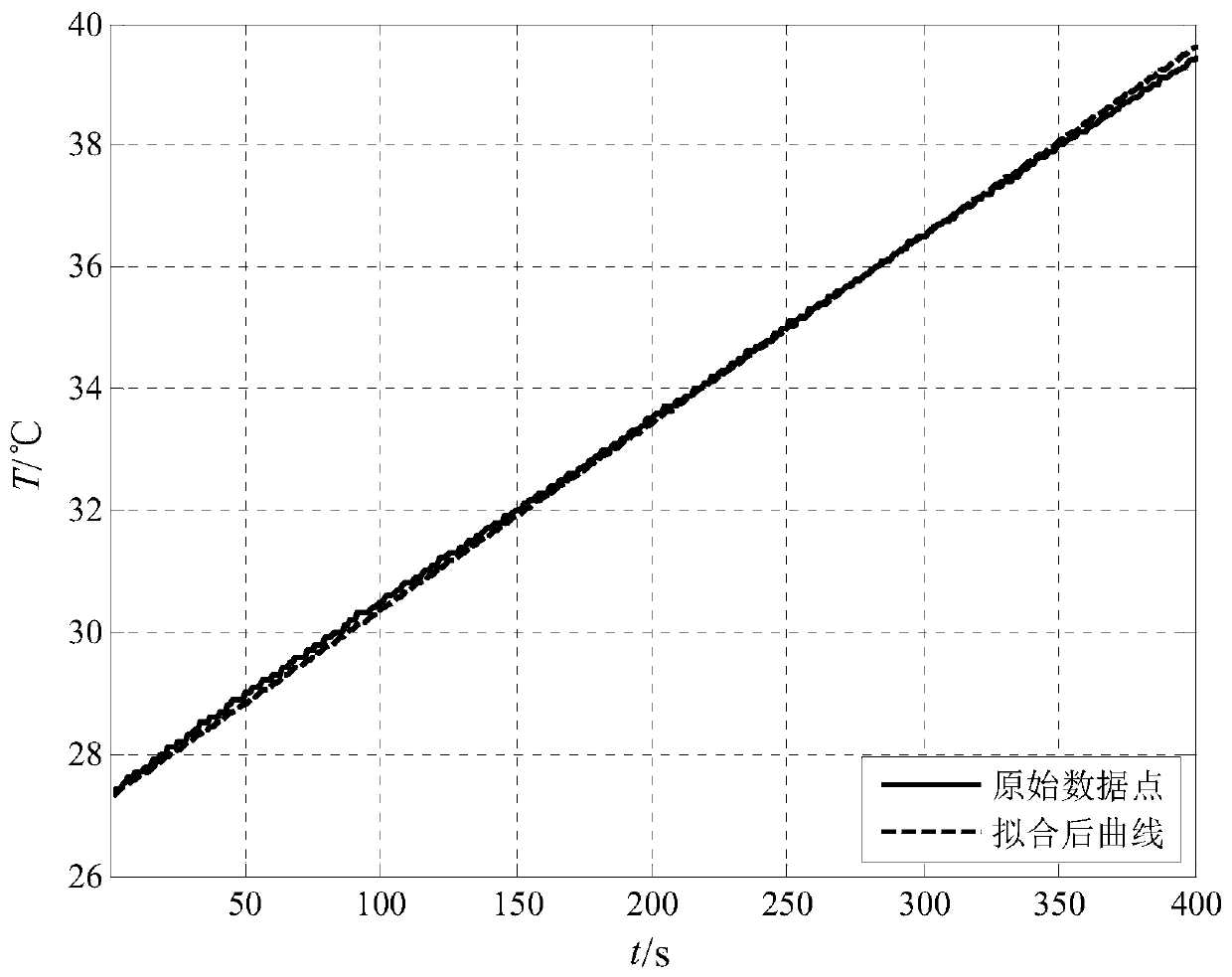

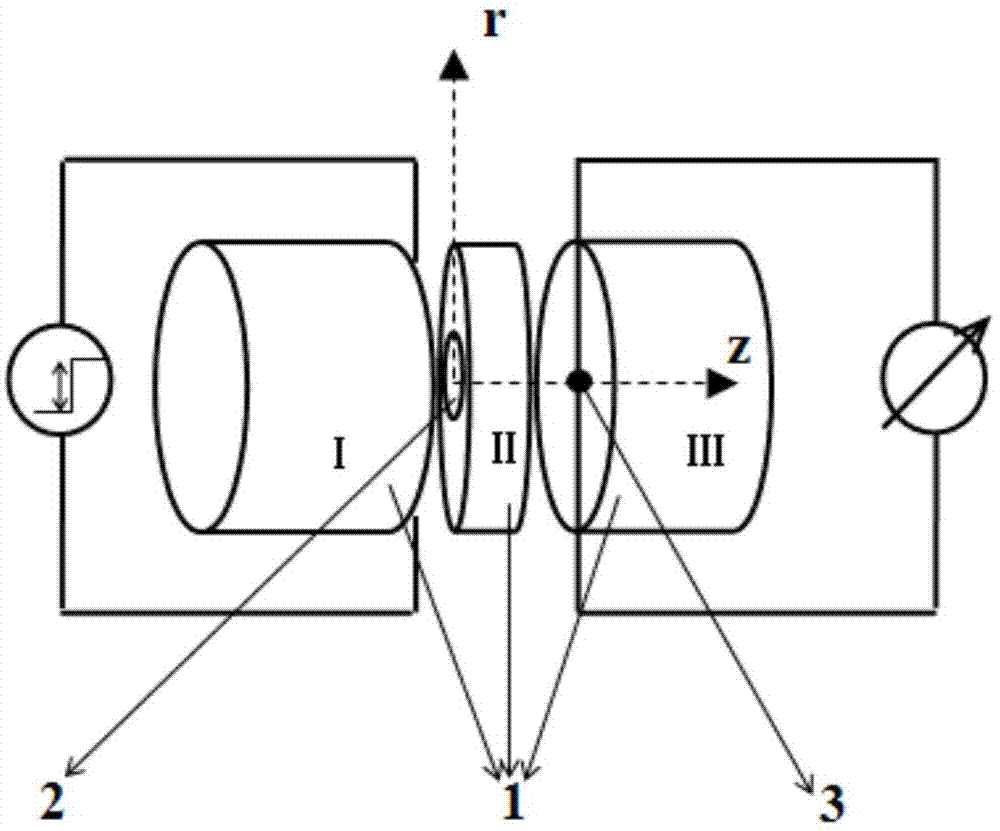

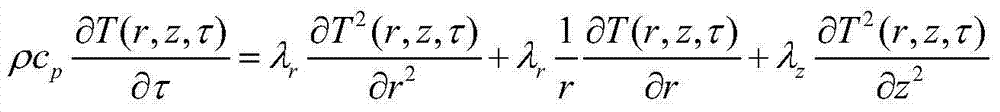

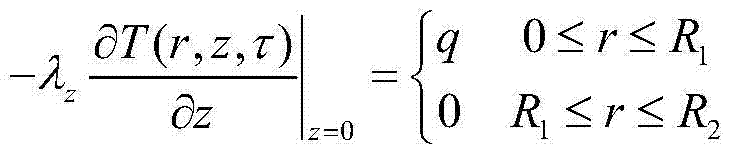

Method for carrying out in-situ solution on thermophysical parameters of cylindrical winding type lithium ion batteries

InactiveCN108170914ADesign optimisation/simulationSpecial data processing applicationsElectrical batteryEngineering

The invention discloses a method for carrying out in-situ on thermophysical parameters of cylindrical winding type lithium ion batteries. The method comprises the following specific steps of: firstly,building an experiment device, heating a battery by using an external heat source according to certain power, and measuring different instantaneous temperature changes of a plurality of points on thebattery; secondly, establishing a heat transfer model which comprises heat conductivity coefficient parameters and specific heat capacity parameters of the battery in different directions in simulation software, and calculating a numerical solution of temperature change at each thermocouple measuring points; and finally, fitting measured temperature values and simulated values, and obtaining specific data of thermophysical parameters of the battery. The method has the beneficial effect of considering wet type structures, namely, electrolyte, in real batteries and contact thermal resistance between different structure layers, so as to in-situ and correctly obtain important thermophysical parameters of batteries, such as heat conductivity coefficients and specific heat capacities.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

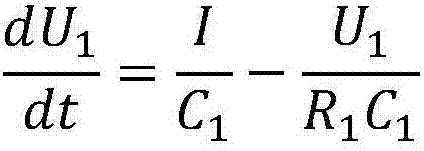

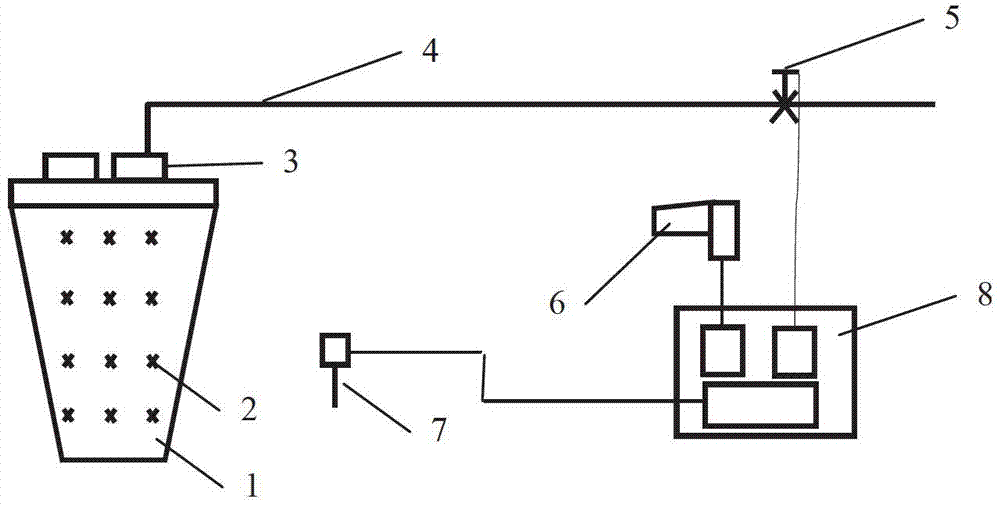

Non-contact tube pass fluid temperature measuring method based on temperature measurement of pipeline outer wall

ActiveCN104062034ARealize non-contact measurementEnables non-destructive measurementsTemperature measurement of flowing materialsThree levelNatural convection

Owner:SHENZHEN TAIKE TEST

Method for measuring anisotropic material heat conductivity based on small-plane heat source

InactiveCN104597078AEasy to implementSimple stepsMaterial heat developmentTime domainLinear correlation

The invention discloses a method for measuring anisotropic material heat conductivity based on a small-plane heat source. The method comprises the following steps: building a three-dimensional heat transfer model of a measured sample in a right-angle coordinate system in a special form under the action of thermal interference; obtaining an analytical solution of temperature change in anisotropic material in a time domain by adopting Laplace transformation, variables separation, transcendental equation solving and inverse Laplace transformation methods; through sensitivity calculation, analyzing linear correlation of sensitivity coefficients of normal heat conductivity and tangential heat conductivity and the effects of parameters on temperature change; building an experiment measurement system, and collecting transient response data of the temperature; and simultaneously determining the normal heat conductivity and the tangential heat conductivity of the measured anisotropic material by an improved Gauss Newton parameter estimation method. The method has the advantages that the transient measurement method which is convenient to implement, fast in measurement and wide in application range and adopts simple steps is provided, and the normal heat conductivity and the tangential heat conductivity of the rectangular anisotropic material can be obtained by once measurement.

Owner:UNIV OF SCI & TECH BEIJING

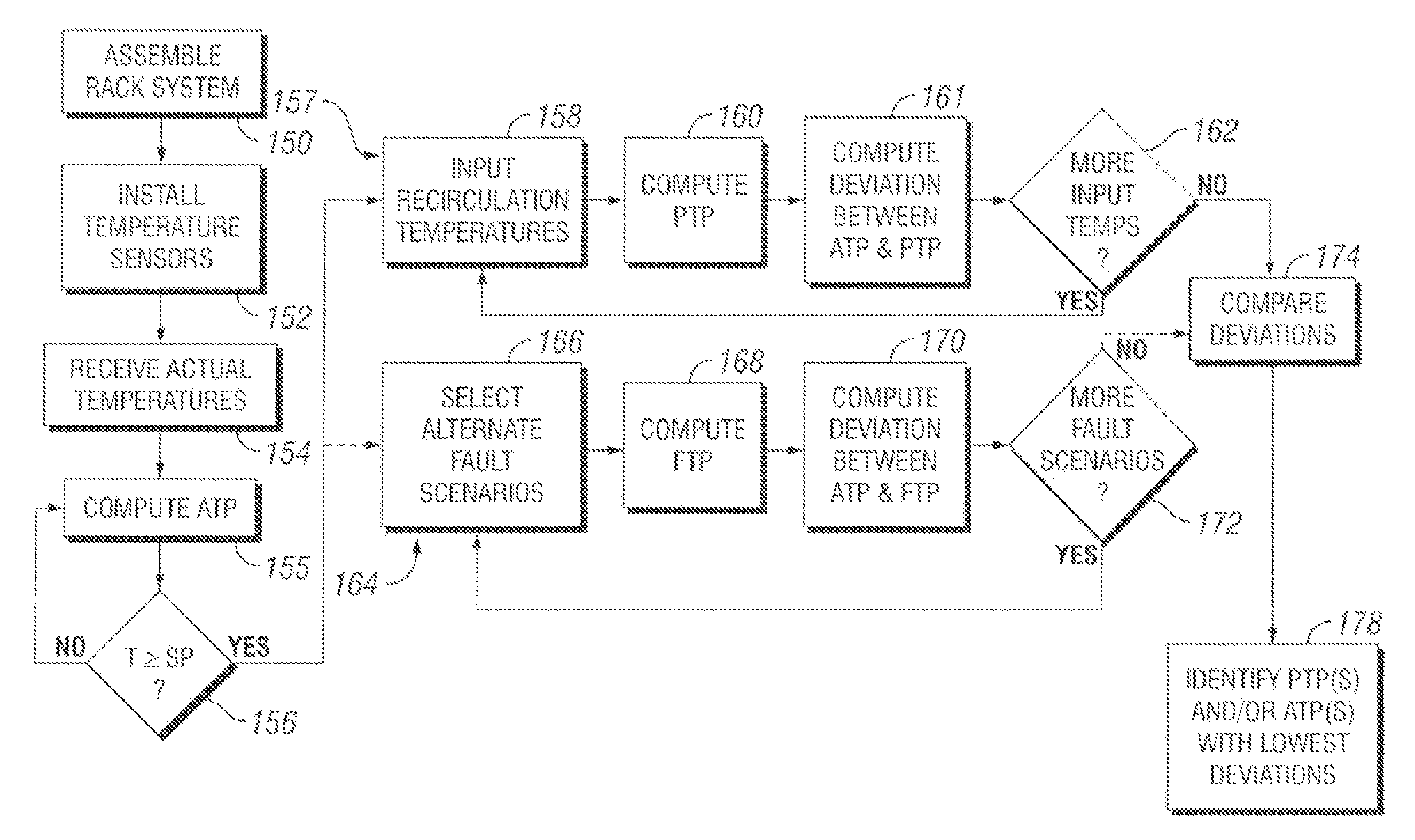

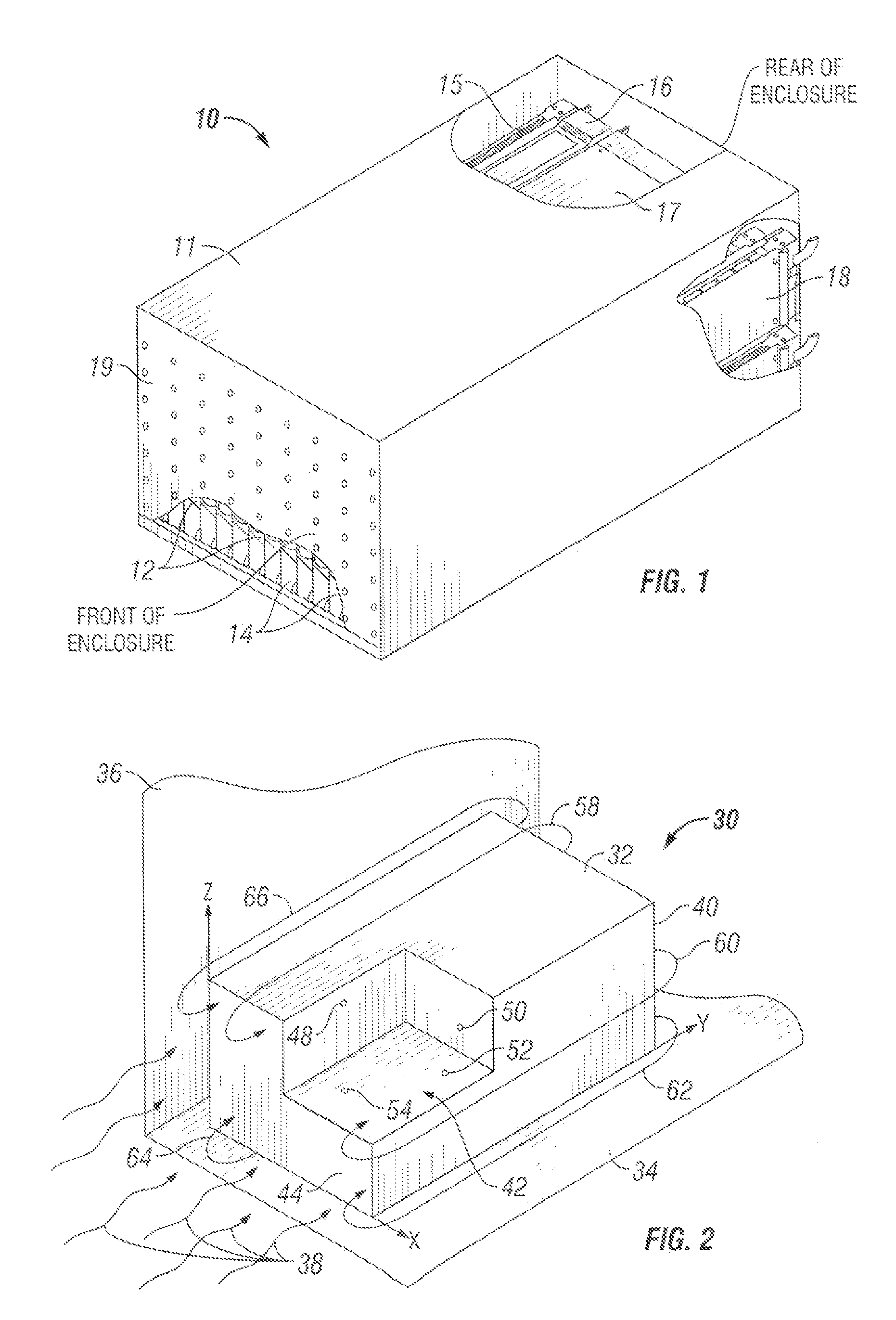

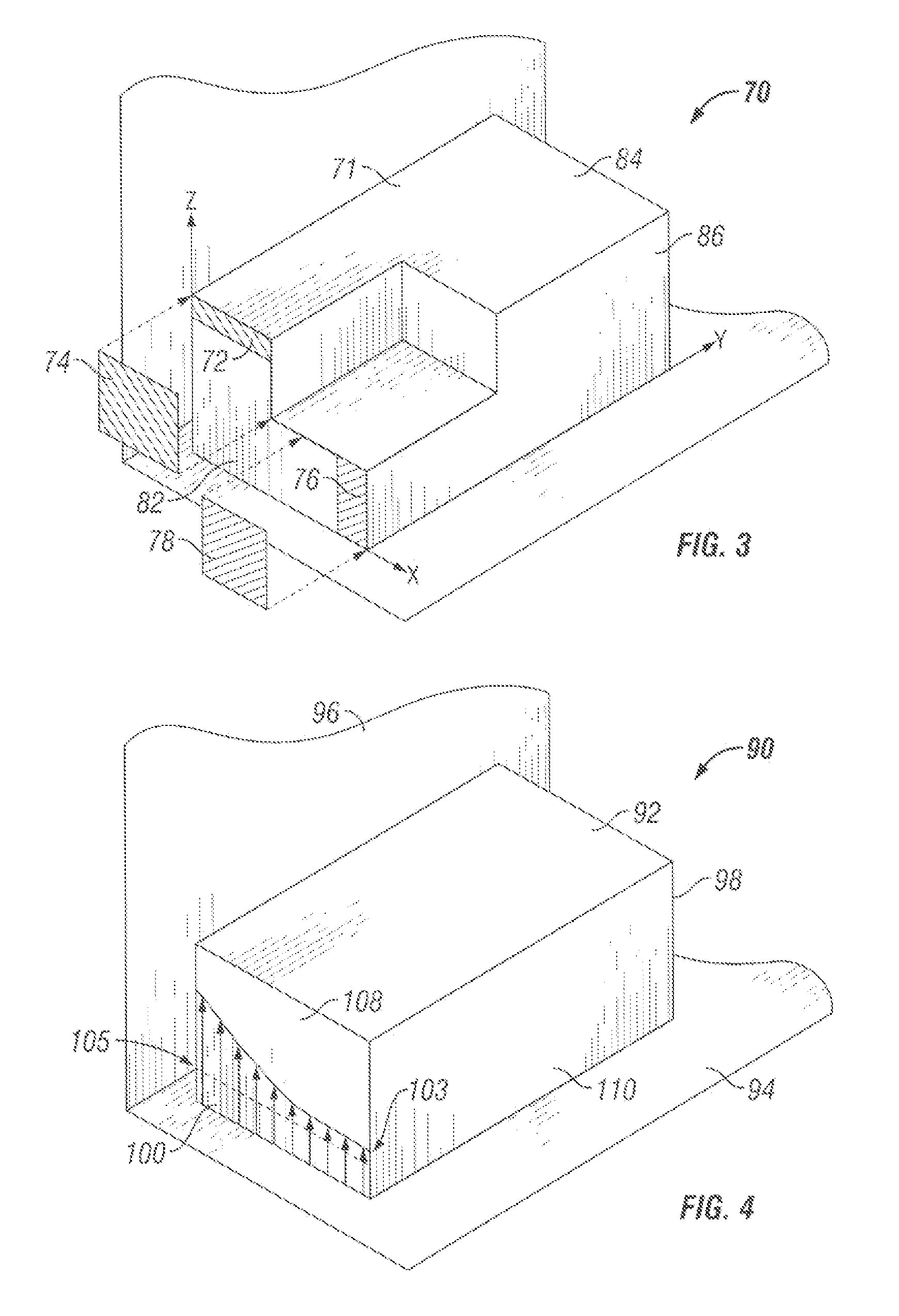

Method of detecting recirculation of heated air within a rack enclosure

Owner:LENOVO GLOBAL TECH INT LTD

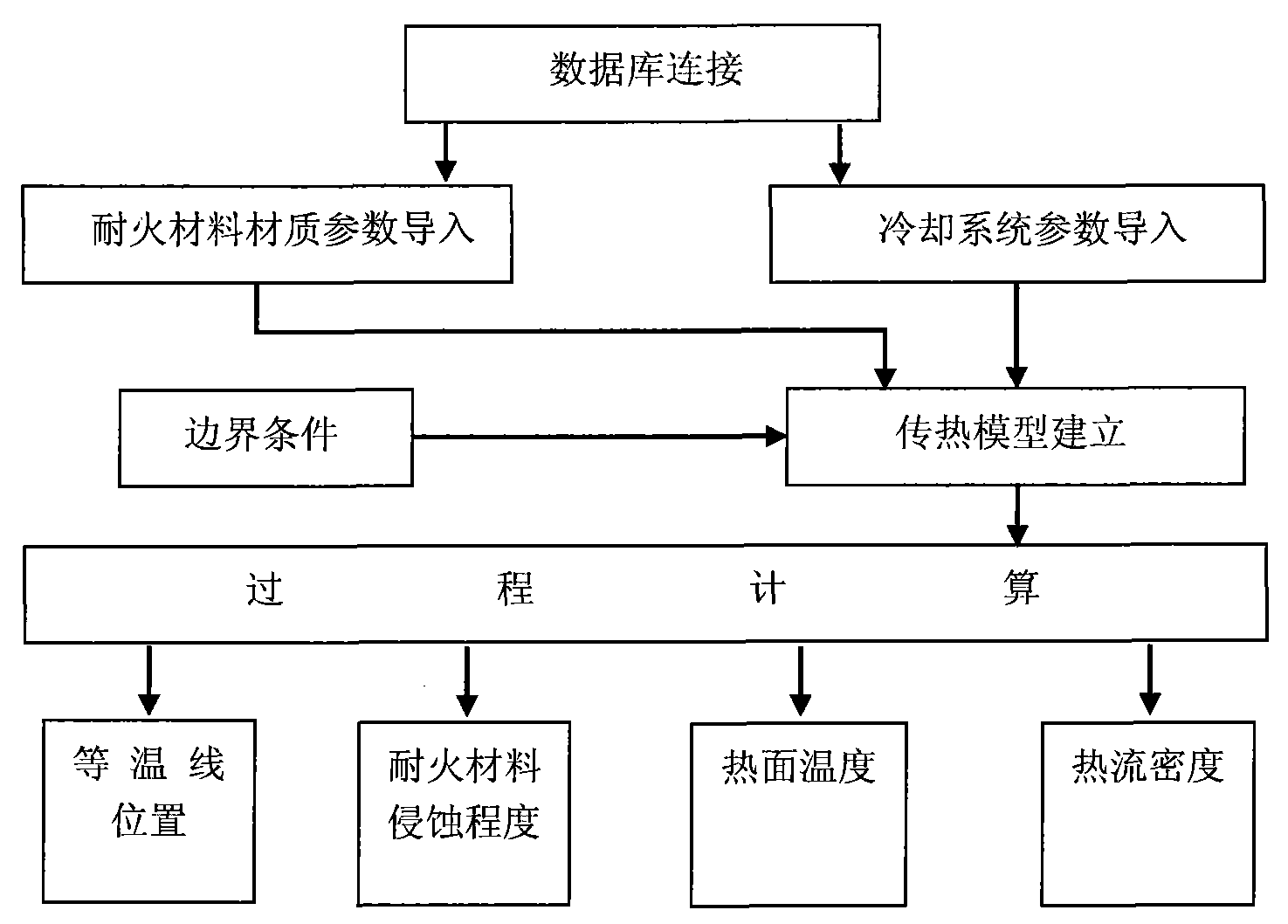

Method for analyzing and monitoring erosion of furnace lining of blast furnace

InactiveCN101812559ALow cost and convenientExtended service lifeBlast furnace detailsChecking devicesBrickQuickening

The invention provides a method for analyzing and monitoring the erosion of a furnace lining of a blast furnace, comprising the following steps of: (1) radially and uniformly arranging thermocouples along a furnace cylinder; (2) establishing database connection and introducing fire-resistant materials and cooling system parameters; (3) establishing a boundary condition and establishing a heat transfer model according to the introduced data in the step (2); (4) analyzing numeric values of the heat transfer model by using a computer according to measuring values of the thermocouples to finally acquire an isotherm position; and (5) writing a model calculation result into the database, displaying the change and the shape of the position of eroded boundary after the computer reads the database in real time, and storing the calculation result to form history data and history curves. The method avoids the quickening of the erosion speed and the ring crack of carbon bricks, simultaneously prevents the furnace cylinder from thickening to influence the smooth operation of the blast furnace, and further prevents piling of the centre of the furnace cylinder and the erosion phenomena of the boundary of the furnace cylinder and the furnace bottom; and simultaneously guides the operation of the blast furnace, in particular to adjustment of cooling water quantity, and ensures that heat flow intensity of the furnace cylinder and the furnace bottom is in the proper range.

Owner:WISDRI ENG & RES INC LTD

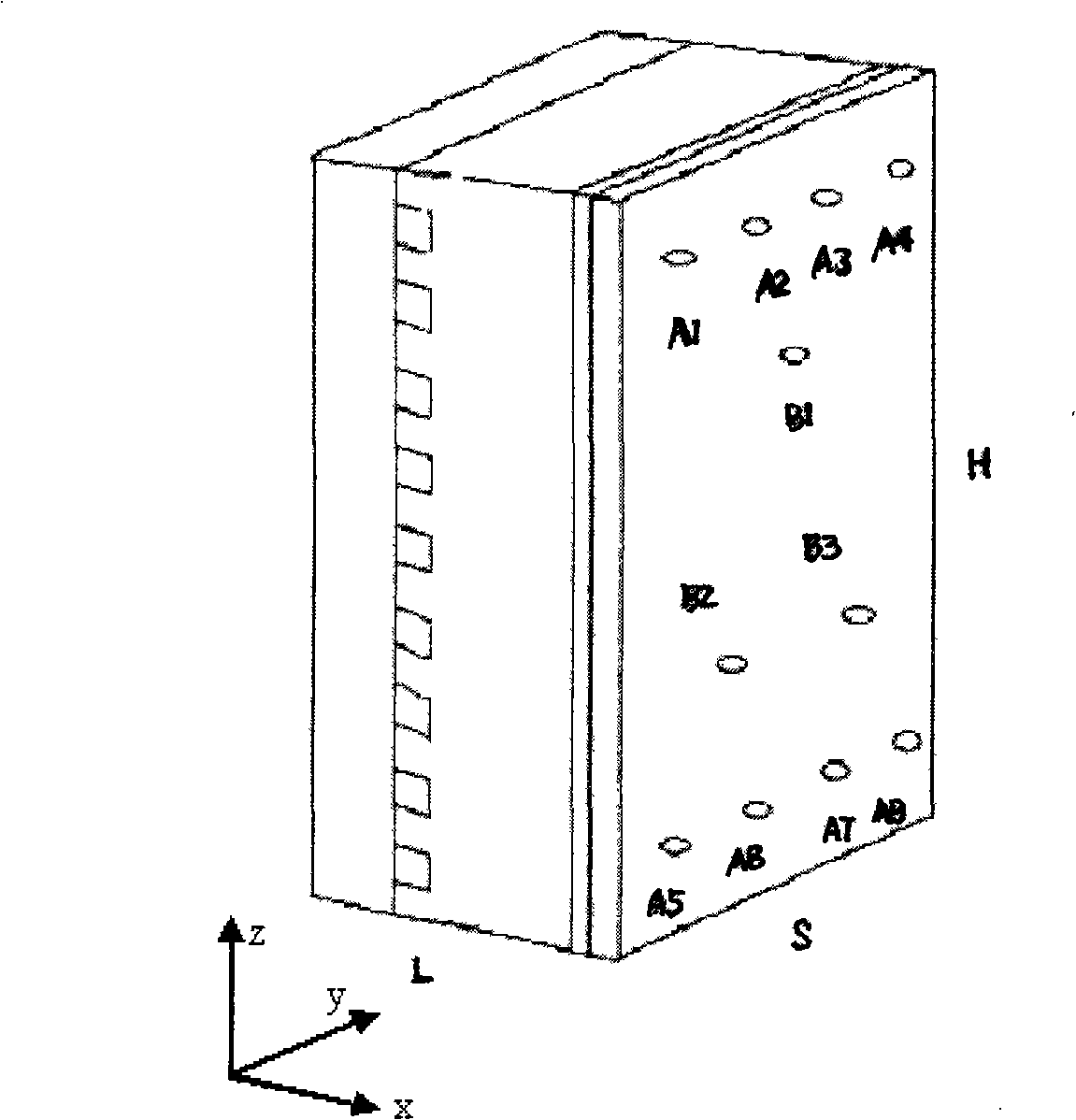

Square lithium ion battery internal thermophysical parameter identification method

ActiveCN109900734ARealize the establishmentAvoid errorsMaterial heat developmentSecondary cellsTwo temperatureEngineering

The invention relates to a square lithium ion battery internal thermophysical parameter identification method and belongs to the field of lithium ion batteries. According to methods for directly obtaining the analytical solutions of heat transfer model equations in existing battery thermophysical parameter identification methods, the overall parameters of batteries are identified, and the internalthermophysical properties of the batteries cannot be identified, while, with the square lithium ion battery internal thermophysical parameter identification method of the invention adopted, the problems in the existing methods can be solved. According to the square lithium ion battery internal thermophysical parameter identification method of the invention, the internal specific heat at constantpressure of a battery is obtained according to battery shell and internal mass, the specific heat at constant pressure of battery shells, heating power and the relation of the temperature of the battery varying with heating time; and the internal longitudinal thermal conductivity coefficient of the battery is obtained according to a heat transfer process, specific heat capacity and boundary conditions; two thermocouples on each battery shell are adopted to obtain two temperatures, and the temperatures of two temperature points at the inner sides of an equal thickness of the lithium ion batteryshells are obtained according to the longitudinal thermal conductivity coefficient and a heat transfer model; and on the basis of the two temperature points and the boundary conditions, the transverse thermal conductivity coefficient of the internal material of the battery is obtained according to the heat transfer model. The method is used to identify the internal thermophysical parameters of the battery.

Owner:HARBIN INST OF TECH

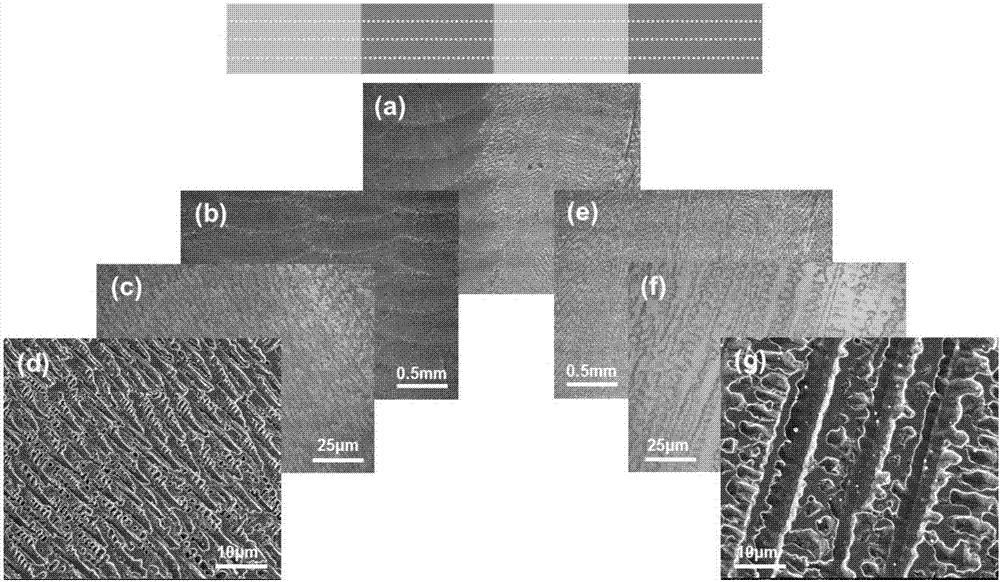

Laser metal 3D printing method capable of achieving customization of local solidification structures of nickel base functional part

ActiveCN107876762ASimple and fast operationEasy to operateAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankMetal

The invention discloses a laser metal 3D printing method capable of achieving customization of local solidification structures of a nickel base functional part. The laser metal 3D printing method comprises the steps of drawing a correspondence relationship diagram of nickel base alloy solidification structures and solidification parameters; acquiring the solidification parameter range corresponding to a local target structure of the part according to the diagram; calculating a molten pool temperature field through a three-dimensional finite element heat transfer model, representing the solidification parameter range, and acquiring technological parameters matched with the target structure; matching all the solidification structures of the part with the technological parameters according tothe process; carrying out single-layer slicing treatment on the part, and acquiring technological parameters, changing along with positions, of a single layer till slicing and setting of technological parameters of all the layers of the part are achieved; and inputting the customized technological parameters into a 3D printing system, carrying out 3D printing, and acquiring the nickel base functional part with the customized solidification structure. According to the laser metal 3D printing method, the customized technological parameters are adopted according to the requirements of the localstructures of the part, and customization of the local solidification structures of the part can be effectively achieved.

Owner:HUNAN UNIV

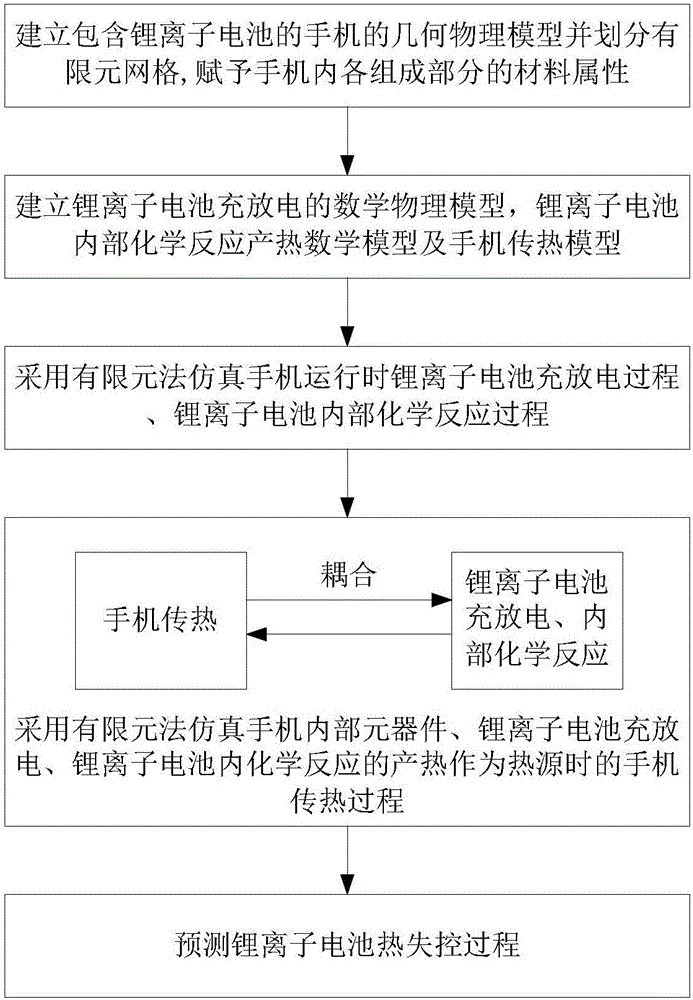

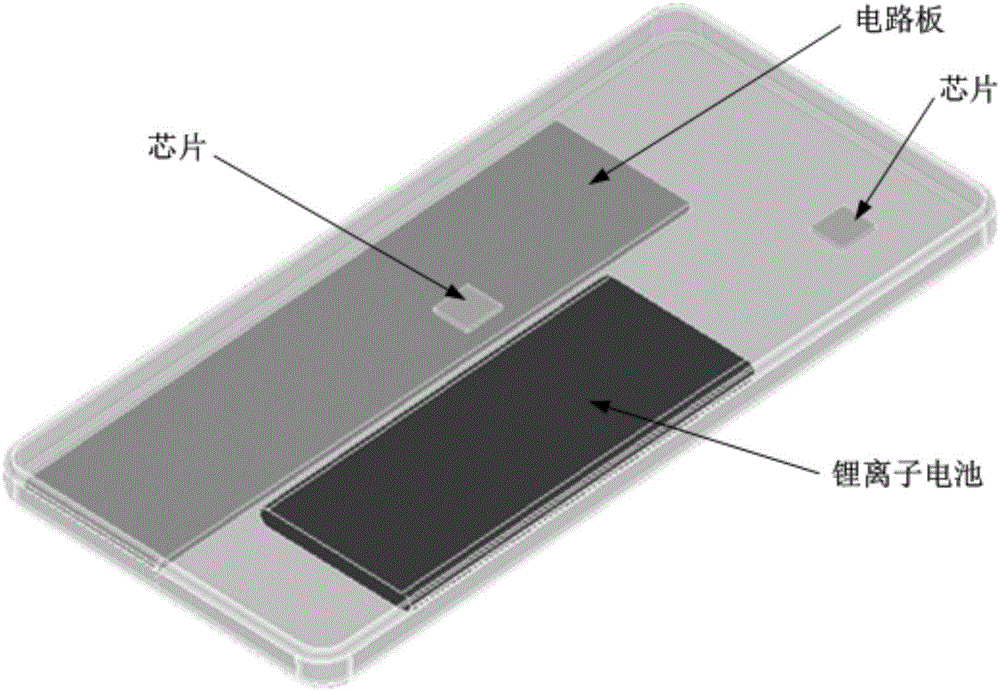

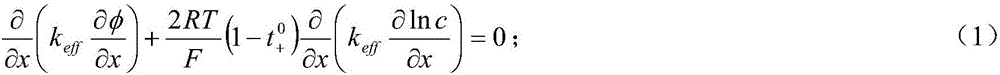

Lithium ion battery thermal runway prediction method in mobile phone operating

InactiveCN106599508APredict thermal runaway processDesign optimisation/simulationSpecial data processing applicationsChemical reactionPredictive methods

The invention discloses a lithium ion battery thermal runway prediction method in mobile phone operating. The lithium ion battery thermal runway prediction method comprises the steps of establishing a geometrical physical model comprising a mobile phone with the lithium ion battery, and dividing finite element grids, and endowing material attribute of each constitute part in the mobile phone; establishing a lithium ion battery charging-discharging mathematical physical model, a lithium ion battery internal chemical reaction heat-producing mathematical model and a mobile phone heat transfer model; performing simulation on a lithium ion battery charging-discharging process and a lithium ion battery internal chemical reaction process in the mobile phone operating by adopting a finite element method; performing simulation on a mobile phone heat production process when heat, produced by the mobile phone internal components, the lithium ion battery charging-discharging process and the lithium ion battery internal chemical reaction process, is adopted as a heat source; and predicting a lithium ion battery thermal runway process. By virtue of the prediction method, the mobile phone heat transfer and lithium ion battery thermal runway are linked together in the mobile phone operating, so that the rapid lithium ion battery thermal runway prediction method in the mobile phone operating is provided.

Owner:SHANGHAI ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF P R C

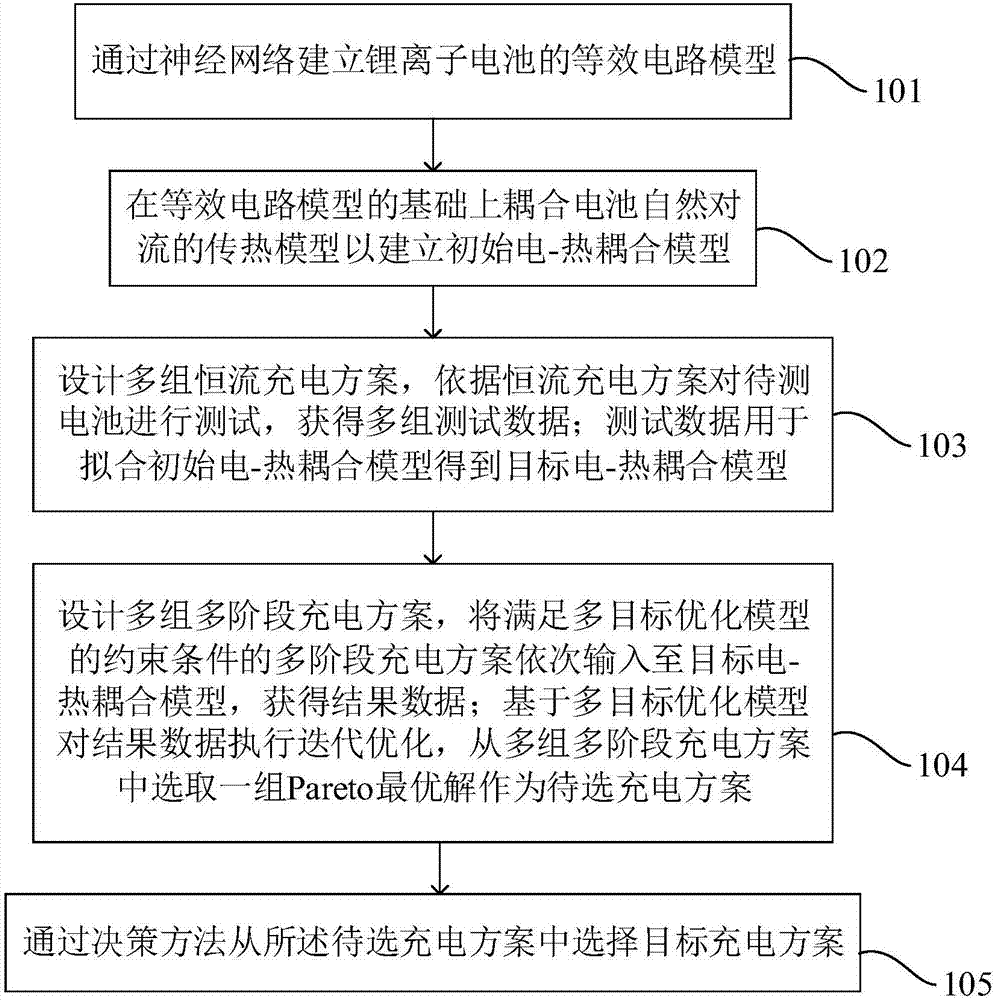

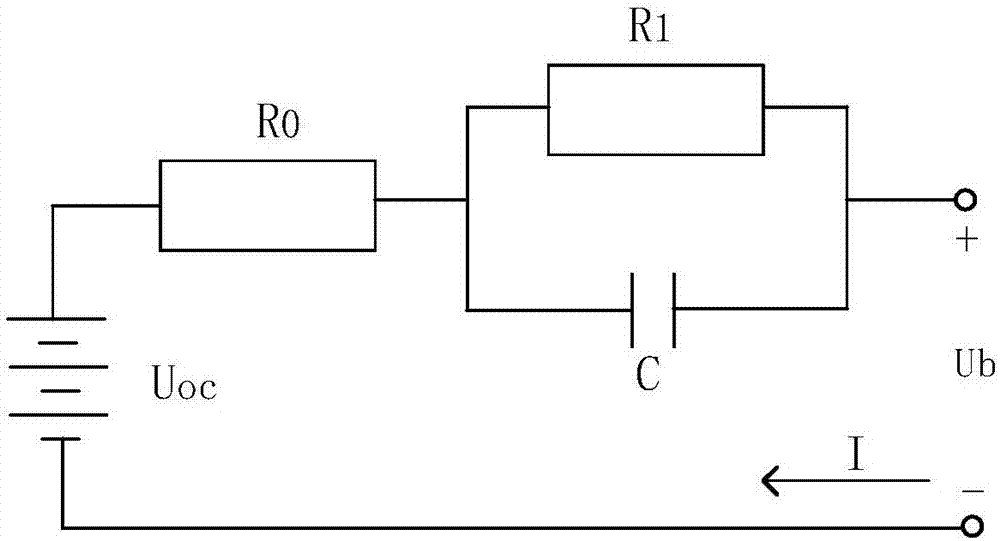

Charging method of lithium ion battery

InactiveCN107171035ATemperature controlIncrease charging rateSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention discloses a charging method of a lithium ion battery. The charging method comprises the following steps: establishing an equivalent circuit model of the lithium ion battery through a neural network; coupling a heat transfer model on the basis of the equivalent circuit model to establish an initial electric-thermal coupling model; designing a plurality of groups of constant-current charging schemes; testing a battery to be detected according to the constant-current charging schemes so as to obtain a plurality of groups of testing data; designing a plurality of groups of multi-phase charging schemes and inputting the plurality of groups of multi-phase charging schemes meeting constraint conditions of a multi-target optimization model into a target electric-thermal coupling model in sequence, so as to obtain result data; carrying out iterative optimization on the result data based on the multi-target optimization model and selecting one group of Pareto optimal solution from the plurality of groups of multi-phase charging schemes as a charging scheme for selecting; and selecting a target charging scheme from the charging scheme for selecting through a decision-making scheme. According to the charging method disclosed by the invention, the optimal charging scheme can be provided for battery charging by utilizing limited experiment times.

Owner:SHANGHAI JIAO TONG UNIV +1

Method and device for rapidly and accurately detecting and controlling baking temperature of ladle

ActiveCN102886500AImprove temperature measurement environmentExtended service lifeMelt-holding vesselsRadiation pyrometryProportion integration differentiationFeedback controller

The invention relates to the temperature measurement field of a high temperature furnace in steel and colored metallurgy industry, in particular to a method and a device for rapidly and accurately detecting and controlling the baking temperature of a ladle. The method and the device are characterized in that a dotty temperature value of the outer surface of the ladle is measured by an infrared temperature measurement instrument, the temperature value of each point of the inner surface of the ladle is calculated by a heat transfer model, the transient temperatures of the inner surface of the ladle at the different depths are calculated by the temperature of the outer surface of the ladle and a convection radiation heat transfer coefficient, a baking air-fuel ratio is adjusted by a proportion integration differentiation (PID) temperature feedback controller so as to realize the automatic baking of the ladle; when the transient temperatures in the ladle reach target values, a heat insulation program is automatically transferred. Compared with the previous technology, the method and the device provided by the invention have beneficial effects that the structure is compact, simple and reasonable, and easy to operate, the temperature measurement environment of the ladle baking is greatly improved, and the service life of the temperature measurement instrument is lengthened, and simultaneously, the accuracy of the temperature measurement is improved, so that a basic data is provided for the accuracy control of thermal regulation of the ladle baking.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

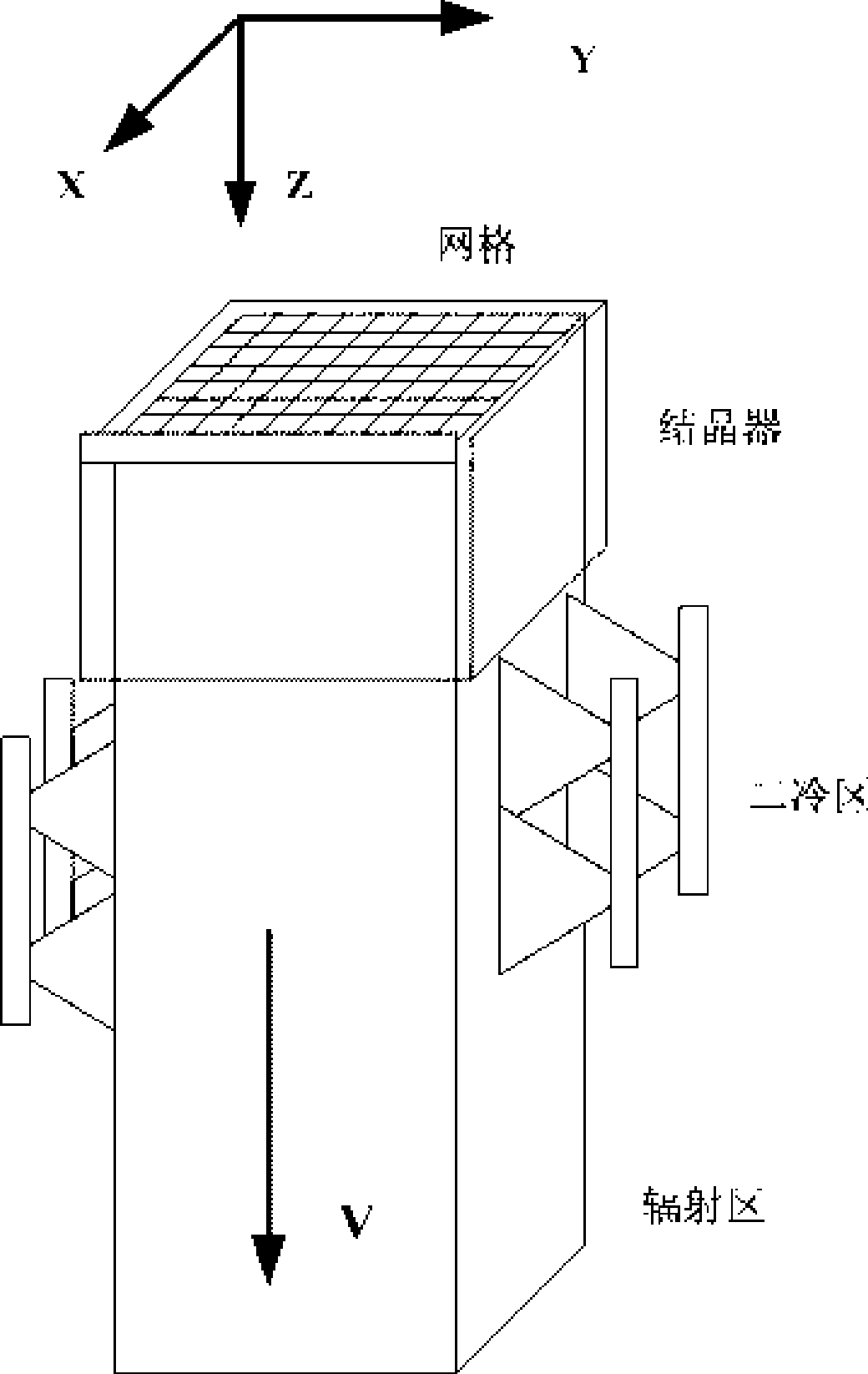

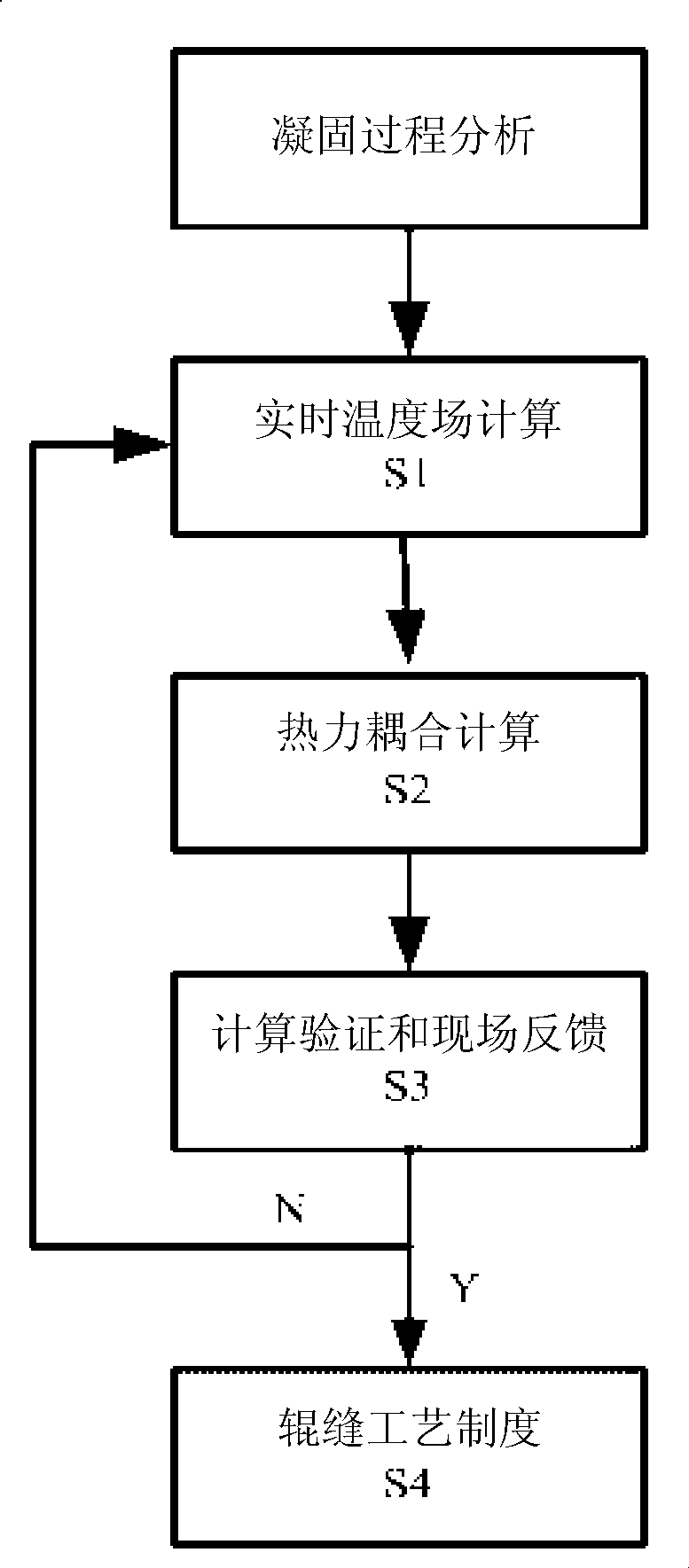

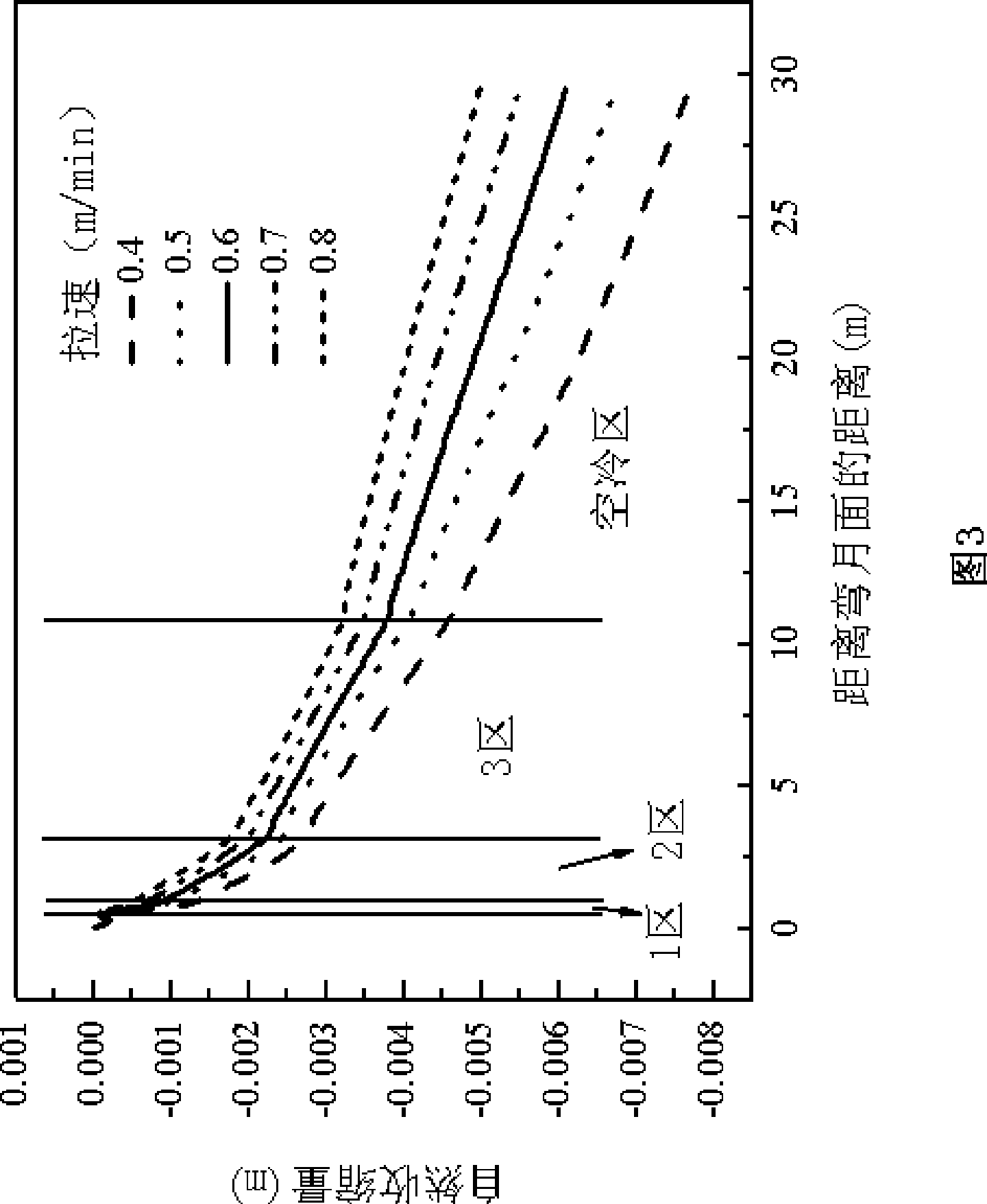

Control method of natural roll-gap thermal-contraction technique based on bloom

The invention discloses a billet continuous casting roll gap technology in metallurgical production and more particularly relates to a control method based on the technology of bloom natural thermal contraction roll gaps. The control process provided by the invention for controlling the roll gaps by the thermal contraction values of casting billets includes the following steps of: (1) the calculation of real-time temperature fields: building a solidification and heat transfer model of casting billets to obtain temperature fields of different times; (2) thermal coupling calculation: obtaining the natural thermal contraction values of casting billets in the direction of the casting billets at different times according to corresponding calculated temperature fields and strain distribution of the casting billets; (3) calculation verification and field feedback: comparing with the actual situations of fields according to results calculated by simulation; and (4) the determination of the system of the roll gap technology: determining the decrease rate and the roll gap difficulty of the roll gaps. The adoption of the control method of the process can effectively avoid the off-square of the casting billets, reduce the billet-drawing resistance and improve the interior defects of the casting billets, such as the central segregation and central porosity, etc.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

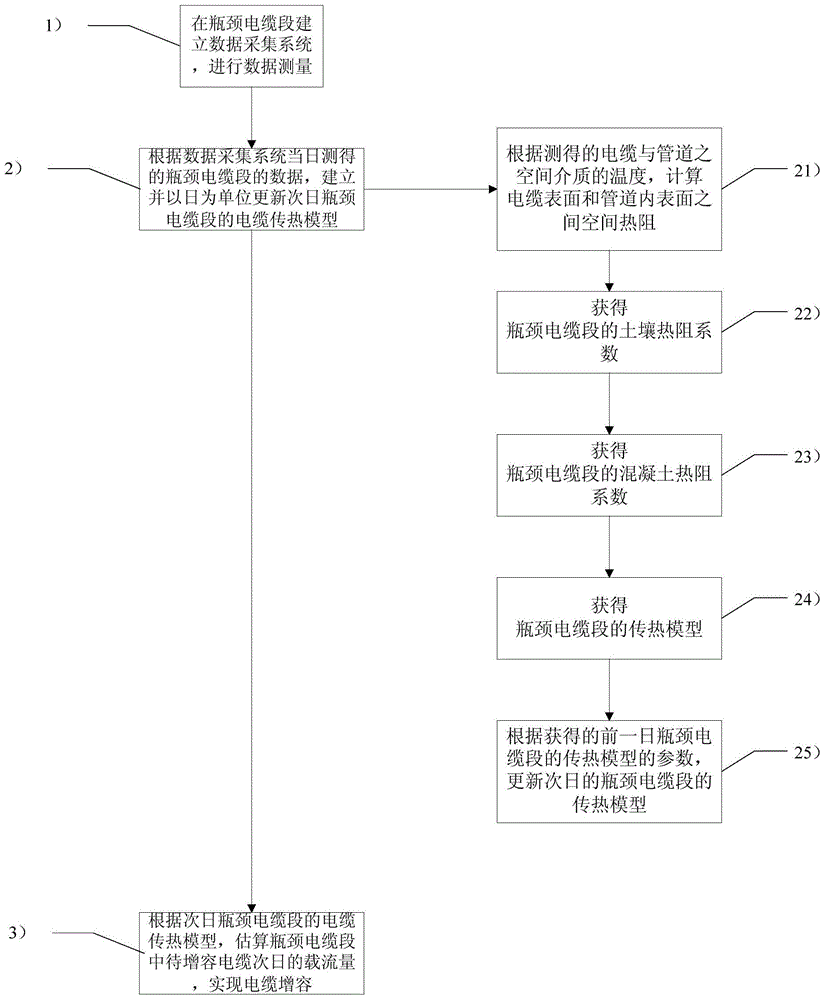

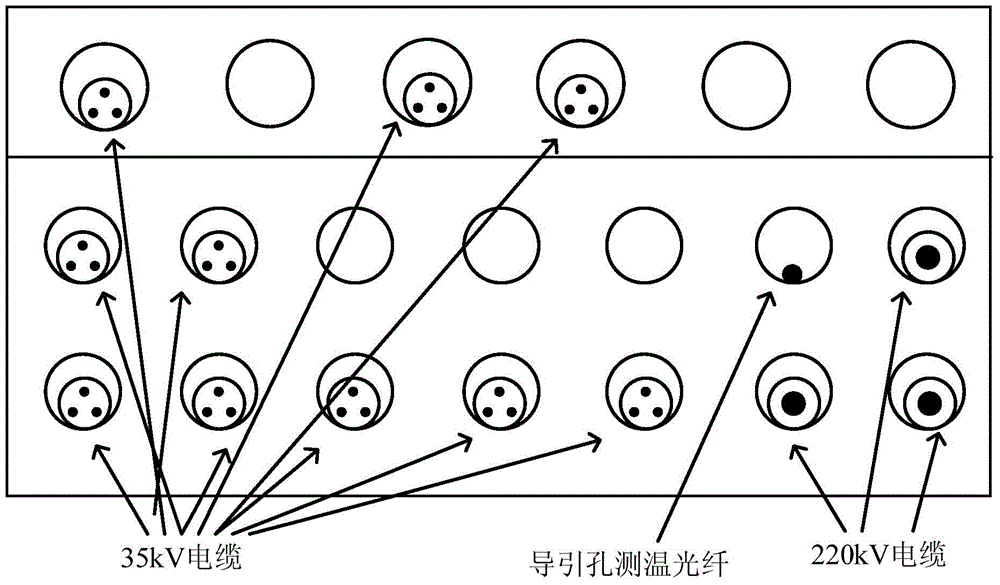

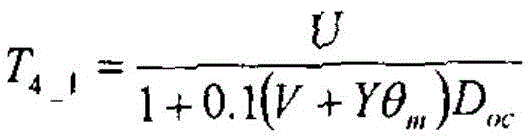

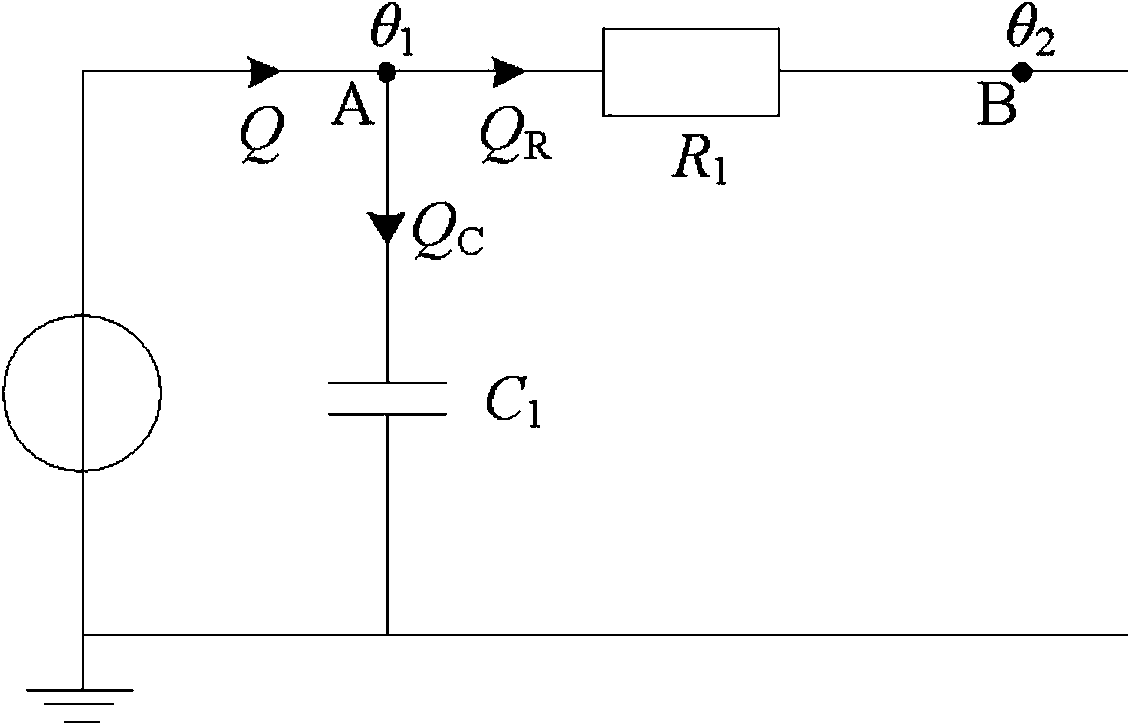

A Quasi-Dynamic Capacity Increase Method Based on Cable Heat Transfer Model

ActiveCN104330659BImprove methodAvoid dealing with complex factors such as heat capacityElectrical testingCarrying capacityData acquisition

A quasi-dynamic compatibilization method based on a cable heat transfer model, used for cable compatibilization inside a calandria. The method includes the following steps: (1) according to a working condition of a total cable line, establishing a data acquisition system at a bottleneck cable section, and carrying out data measurement on the day; (2) according to the data of the bottleneck cable section measured by the data acquisition system on the day, establishing a cable heat transfer model of the bottleneck cable section on the next day, and updating same taking a day as a unit; and (3) according to the cable heat transfer model of the bottleneck cable section on the next day, estimating the current-carrying capacity of a cable to be compatibilized on the next day in the bottleneck cable section, so as to realize cable compatibilization. Compared with the prior art, the method has the advantages of being advanced in method, good in real-time performance and obvious in effect.

Owner:珠海开普检测技术有限公司

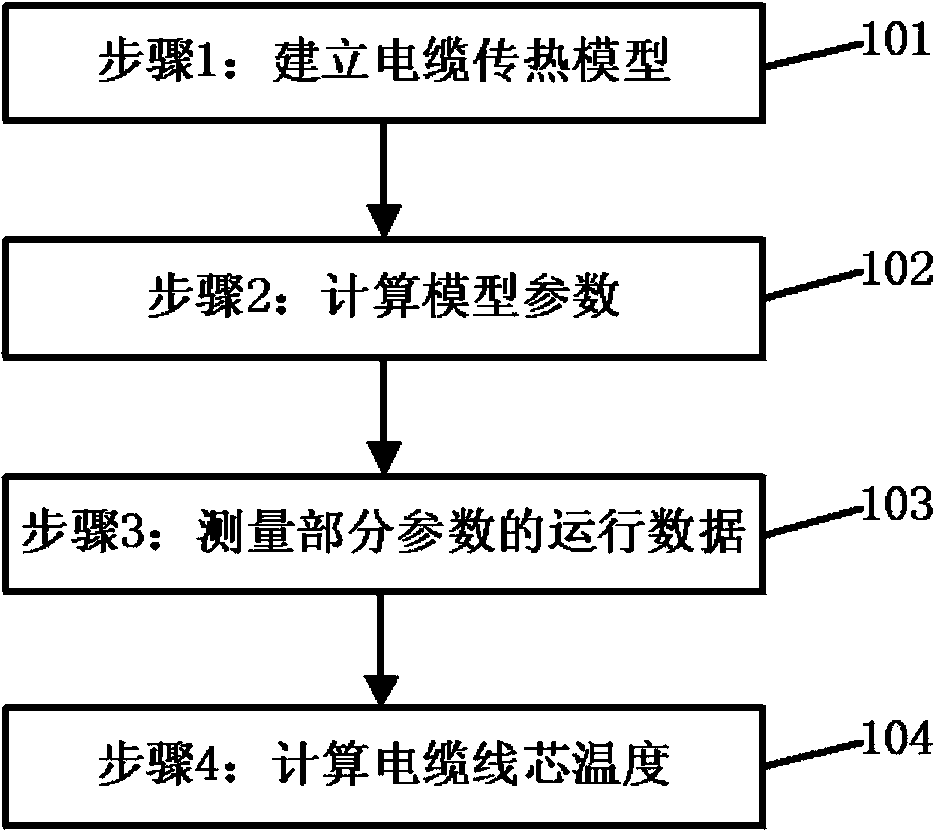

Indirect measuring method for cable core temperature

ActiveCN103808426AEasy to calculatePracticalThermometers using physical/chemical changesCore temperatureEngineering

The invention discloses an indirect measuring method for cable core temperature. The method comprises the following steps: 1, establishing a theoretical heat transfer model of a cable; 2, calculating model parameters in the theoretical model; 3, measuring running data of partial parameters of the cable; 4, calculating the cable core temperature of the cable through the model parameters and the measured running data to finish indirect measurement. The indirect measuring method has the advantages of easiness, rapidness and accuracy.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

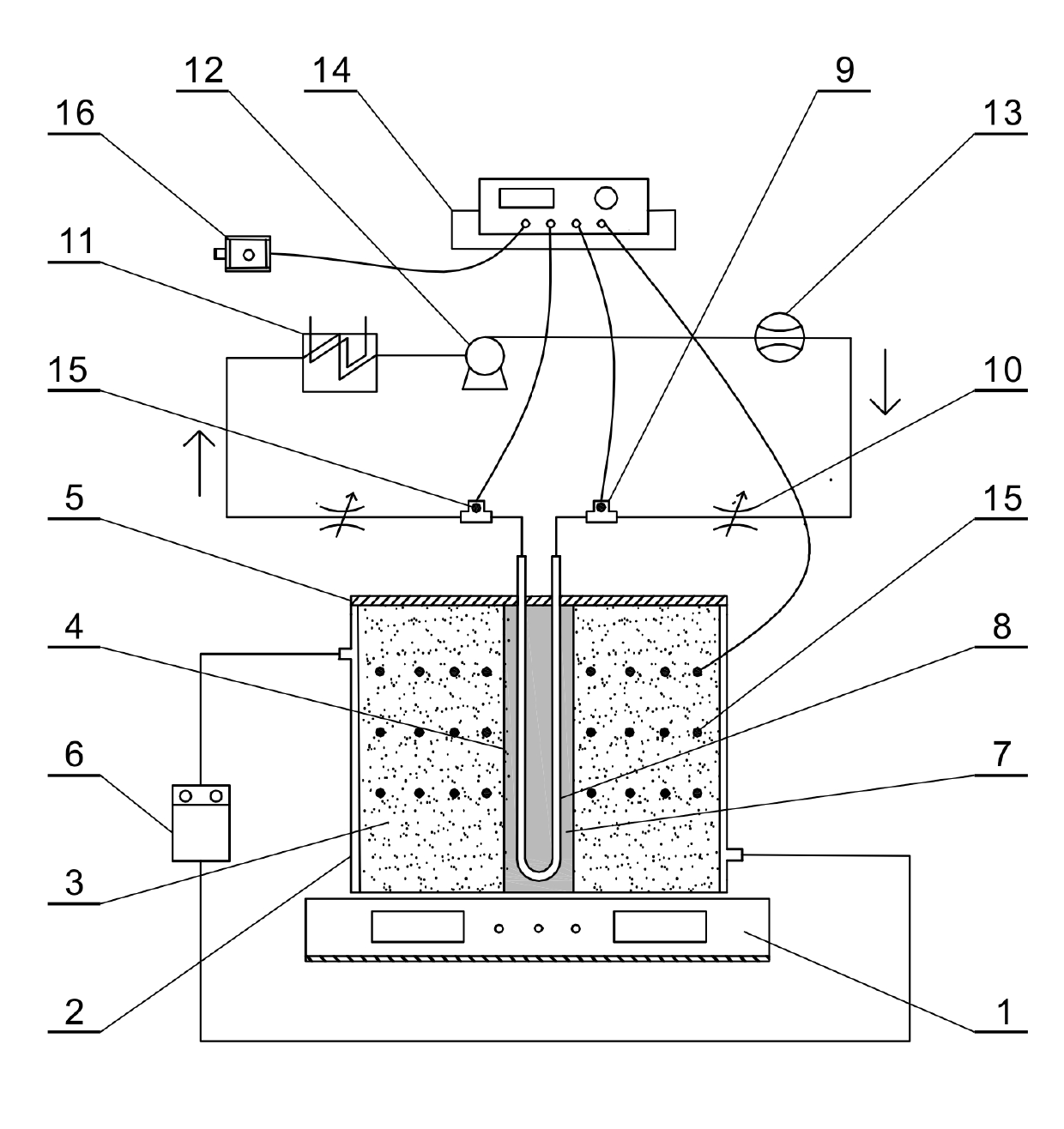

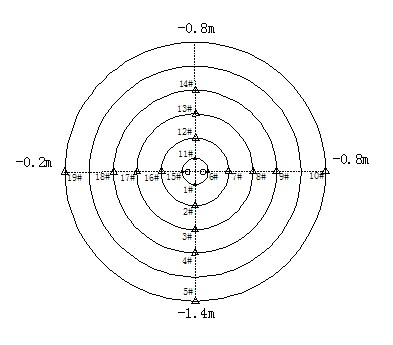

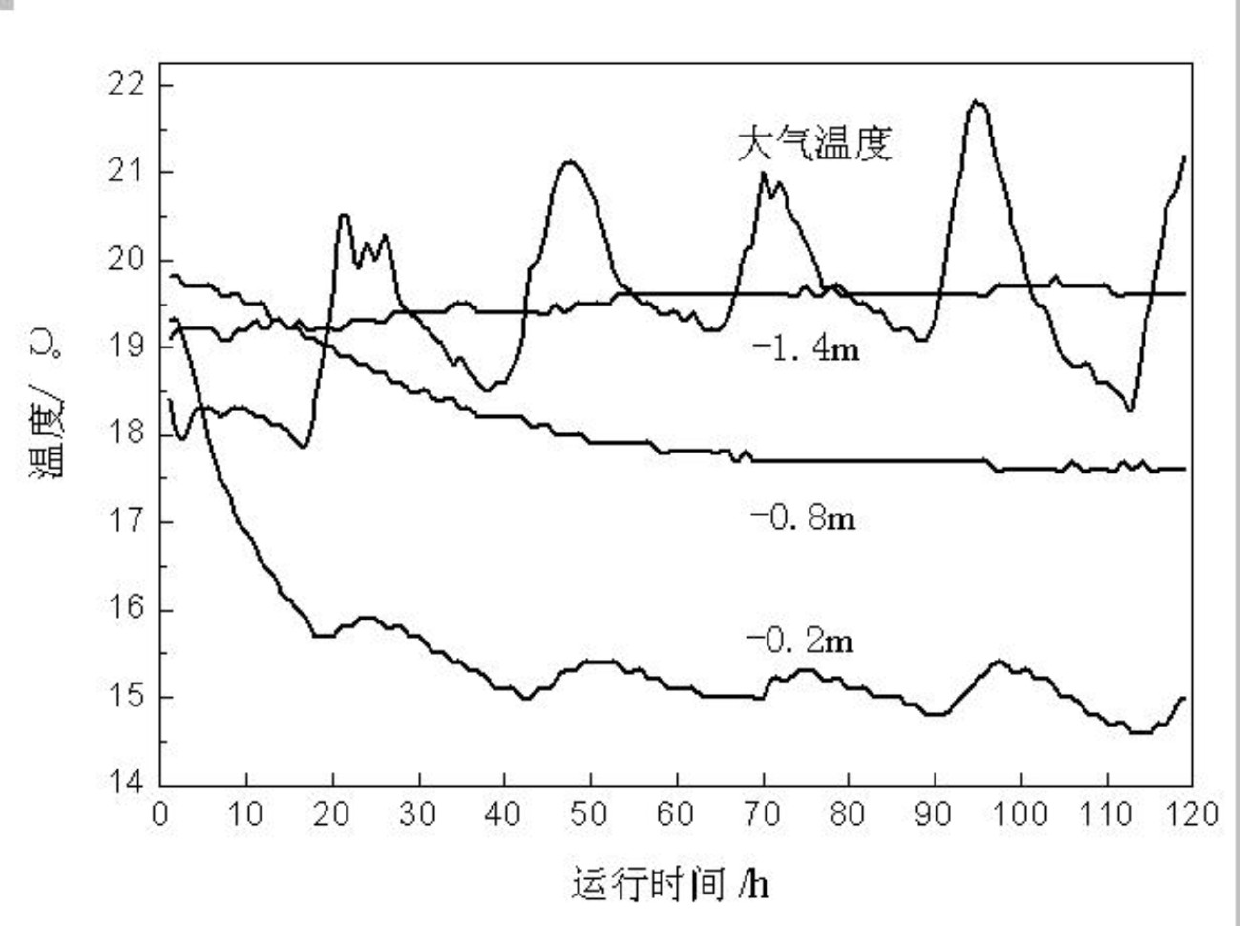

Device for simulating ground source heat pump

InactiveCN102680515ARealize computingRealize verificationMaterial heat developmentWater bathsEngineering

The invention discloses a device for simulating a ground source heat pump. The device comprises a ground layer simulating system, a heat exchanger simulating system and a data collecting system, wherein the ground layer simulating system is composed of a weighbridge, a stainless steel sleeve, soil, a drill hole, a cover board and a constant-temperature water bath kettle; the heat exchanger simulating system is composed of backfill material, an U-shaped pipe, a low-temperature constant-temperature groove, a self-absorption clean water pump, a flowmeter, a tee and a valve; the data collecting system is composed of a temperature / humidity recorder, a PT100-type thermal resistor and a temperature / humidity transducer; the backfill material of the heat exchanger simulating system is arranged in the drill hole of the ground layer simulating system; and the PT100-type thermal resistor of the data collecting system is arranged in the soil of the ground layer simulating system. According to the invention, the device can be used for researching temperature distribution with different depths and different radial soil layers under the action of a buried-pipe heat exchanger and further investigating a heat exchange pattern in the soil so as to realize calculation and verification of a heat transferring model; furthermore, the device can be used for investigating the influence of different backfill materials to the total heat exchange effect and realizing screening and estimation on the backfill materials; in addition, the device also can be used for the research on the influence and the like of different circular water flows to heat exchange quantity in cold or hot working conditions.

Owner:SHANGHAI SUNRISE CHEMISTRY CO LTD

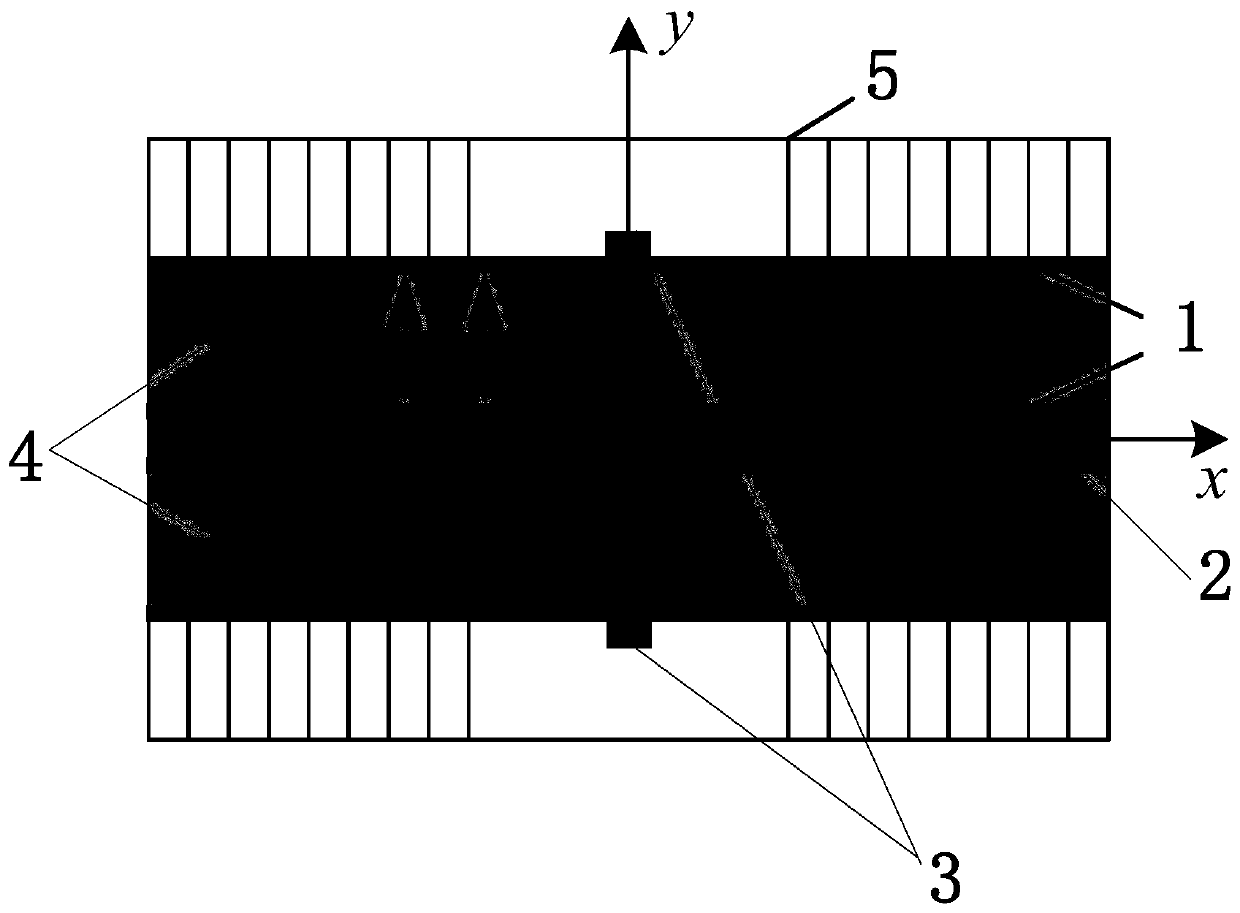

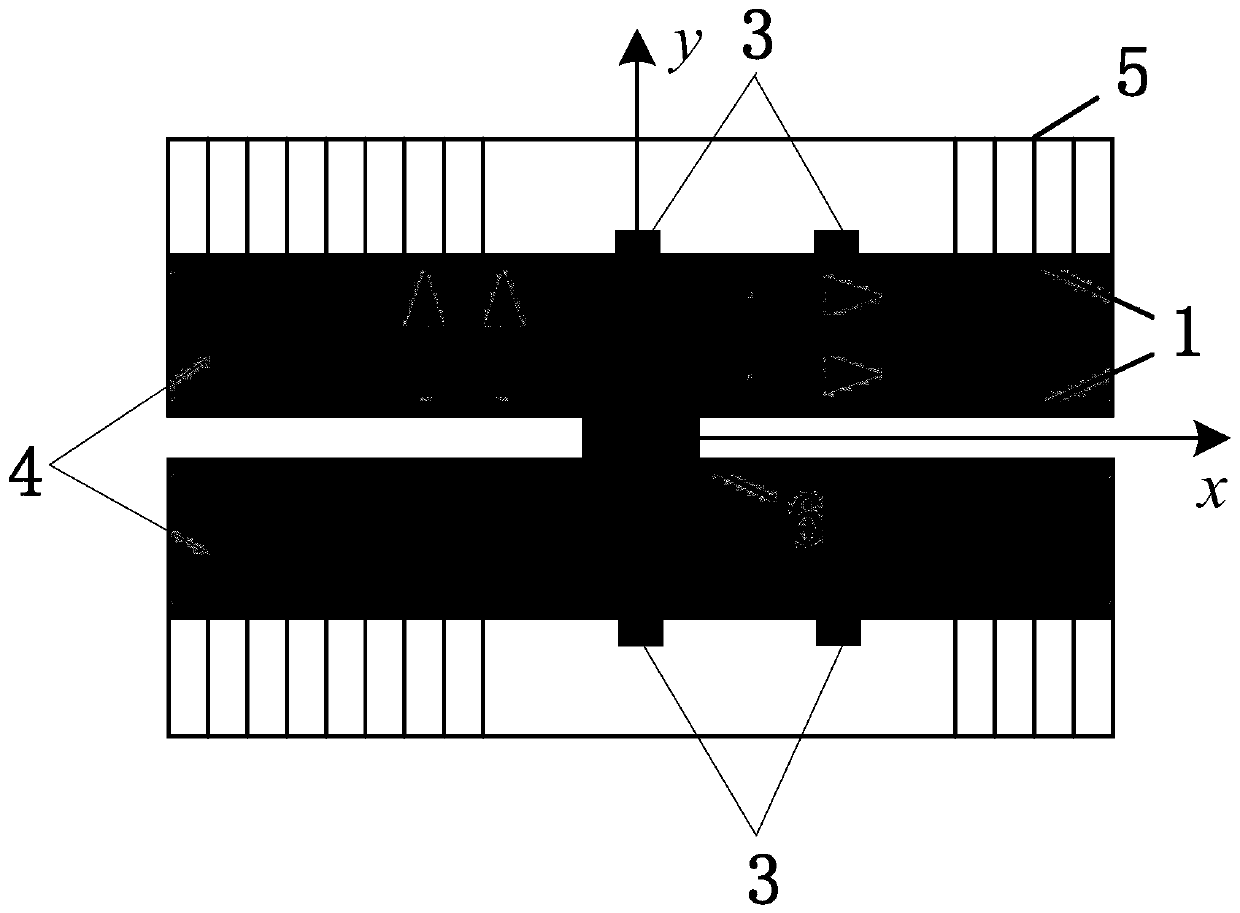

Method for measuring thermophysical property of columnar thermal insulation material

ActiveCN104502402AEasy to implementSimple stepsMaterial heat developmentTime domainEstimation methods

The invention provides a method for measuring thermophysical property of a columnar thermal insulation material, which is used for determining radial heat conductivity, axial heat conductivity and volume heat capacity of the columnar orthotropic thermal insulation material by measuring temperature variation of one point of a tested sample. The method comprises the following steps: establishing a two-dimension cylindrical coordinate heat transfer model under effect of thermal interference of specific form in cylindrical coordinates; obtaining analytical solution of temperature variation of the orthotropic thermal insulation material in the time domain by adopting Laplace transformation, Hankel transformation and Laplace inverse transformation; analyzing correlation among sensitivity coefficients of the radial heat conductivity, the axial heat conductivity and the volume heat capacity and the influences of temperature variation caused by the parameters through calculation on the sensitivity; establishing a corresponding measurement system, and acquiring the transient response data of the temperature in real time; and meanwhile, determining the radial heat conductivity, the axial heat conductivity and the volume heat capacity of the tested orthotropic thermal insulation material by adopting an L-M parameter estimation method. The method provided by the invention is convenient to implement and adopts simple steps, and meanwhile can be used for measuring the radial heat conductivity, the axial heat conductivity and the volume heat capacity of the columnar thermal insulation material.

Owner:UNIV OF SCI & TECH BEIJING

Data heat transfer model-based testing device and testing method thereof

InactiveCN102128853AGet rid of dependenceSimple structureMaterial heat developmentPower sensorEngineering

The invention discloses a data heat transfer model-based testing device and a testing method thereof. The device consists of a water tank, a thermostatic heating pipe, a water pump, a valve, a thermometer, a temperature sensor, a pressure gauge, a flow meter, an electric power sensor, a U-shaped embedded pipe, a data processor and a control switch. The thermal physical parameters of tested rock soil can be obtained according to the water temperature change values of an inlet and an outlet of the U-shaped embedded pipe, flow and pressure values of water and original soil temperature value acquired by the temperature sensor through a one-dimensional unsteady state value model by adopting a comprehensive calculation method.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

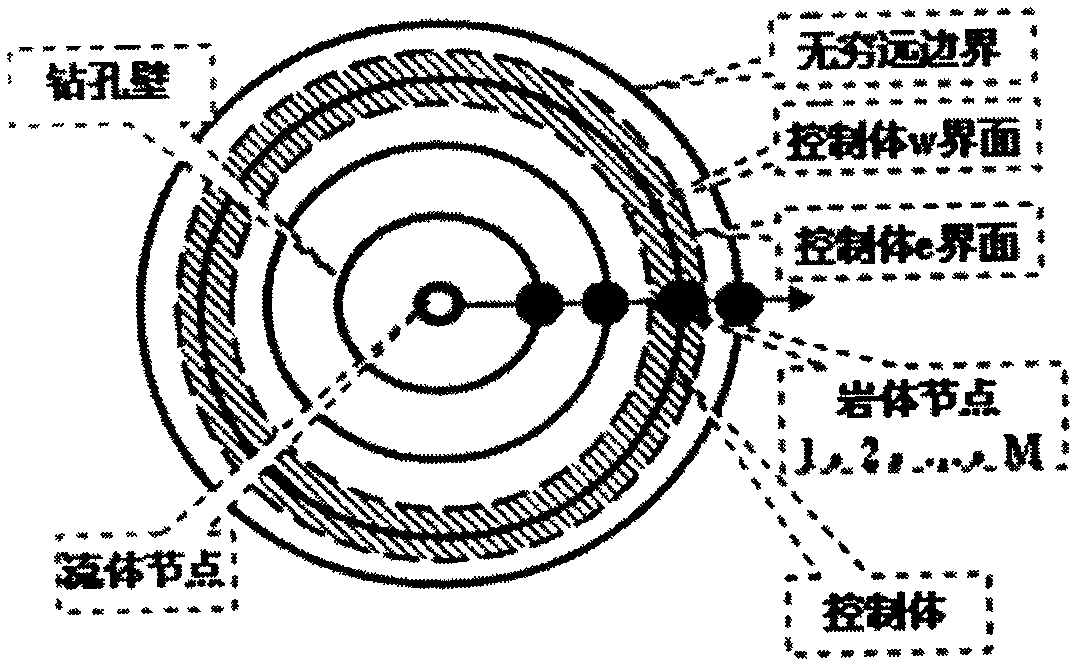

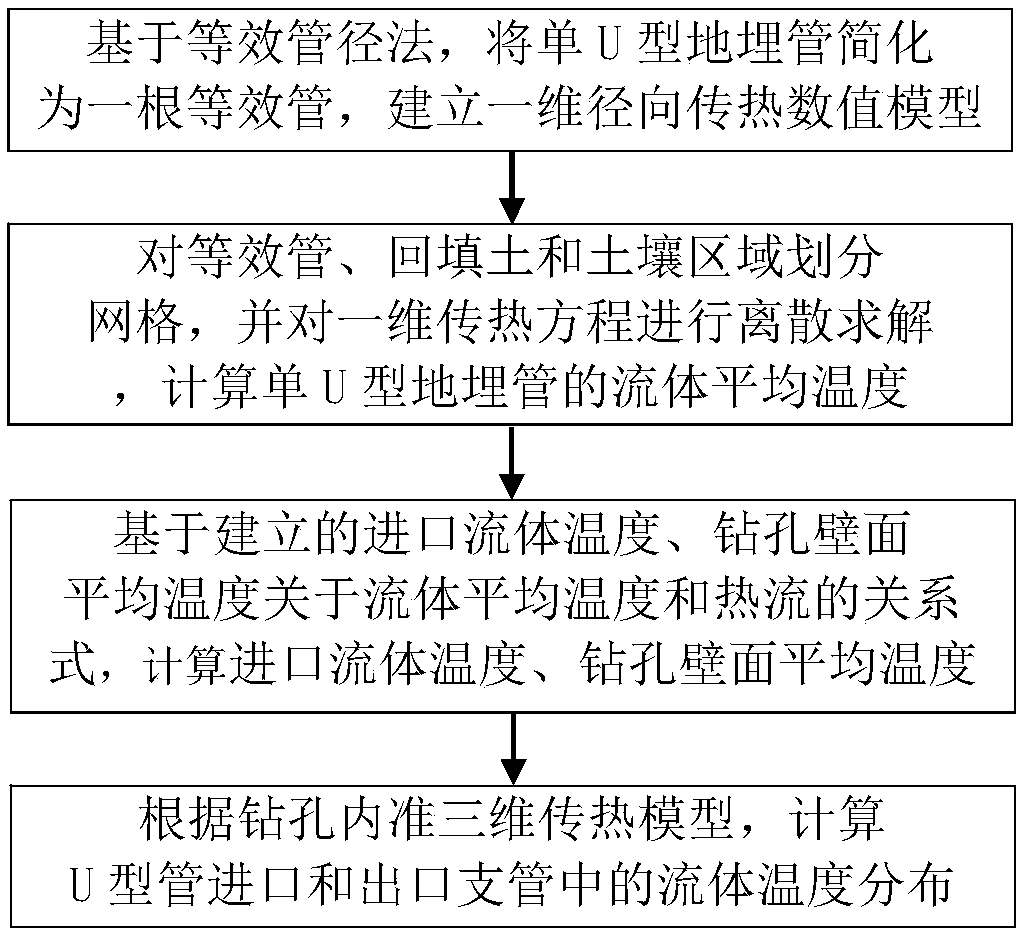

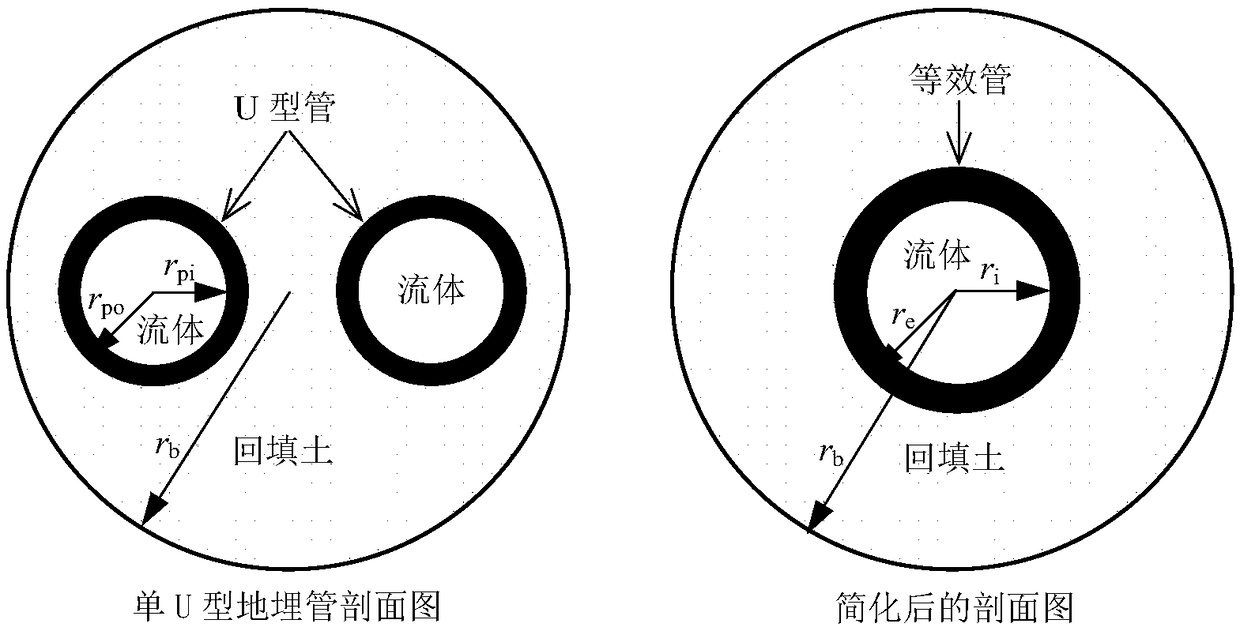

A method for predicting fluid temperature distribution in a vertical U-shaped buried pipe of a ground source heat pump under off-design conditions

ActiveCN109086560AAccurate predictionHigh precisionHeat recovery systemsGeothermal energy generationHeat fluxOff design

A method for predicting fluid temperature distribution of a vertical single U-shaped buried pipe of a ground source heat pump under variable operating conditions belongs to that field of ground sourceheat pump, and is used for calculating fluid temperature distribution in U-shaped pipe under variable heat flux or variable inlet fluid temperature operating conditions. Firstly, a single U-shaped buried pipe is simplified to an equivalent pipe based on the equivalent pipe diameter method, and a one-dimensional radial heat transfer numerical model including fluid, equivalent pipe, backfill and soil is established, and the heat transfer equation is discretely solved to calculate the average temperature of the fluid in the single U-shaped buried pipe. The results show that the average temperature of the fluid in the U-shaped buried pipe is higher than that in the single U-shaped pipe. Then, based on the quasi-three-dimensional heat transfer model in the borehole, the relationship between the inlet fluid temperature and the average wall temperature of the borehole with respect to the average fluid temperature and heat flux is established, and the fluid temperature distribution in the U-tube under the conditions of variable heat flux or variable inlet fluid temperature is calculated. This method has the advantages of less computation, high precision and strong generality.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

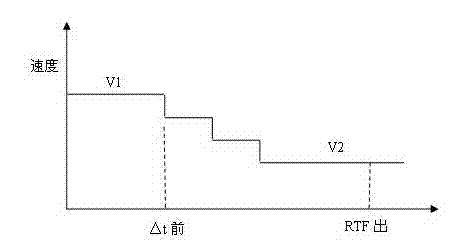

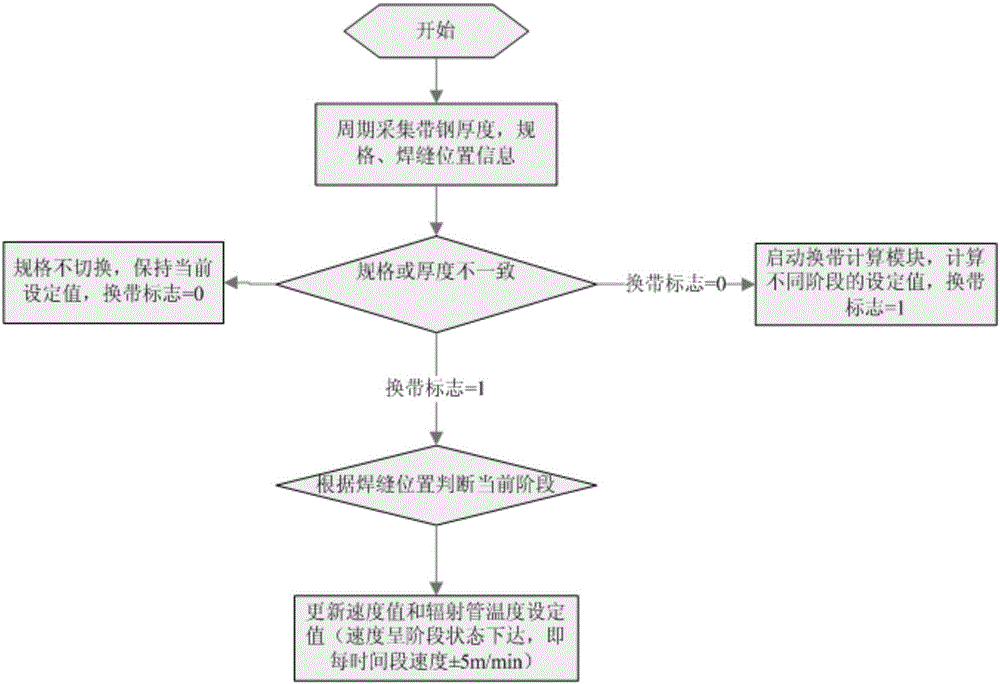

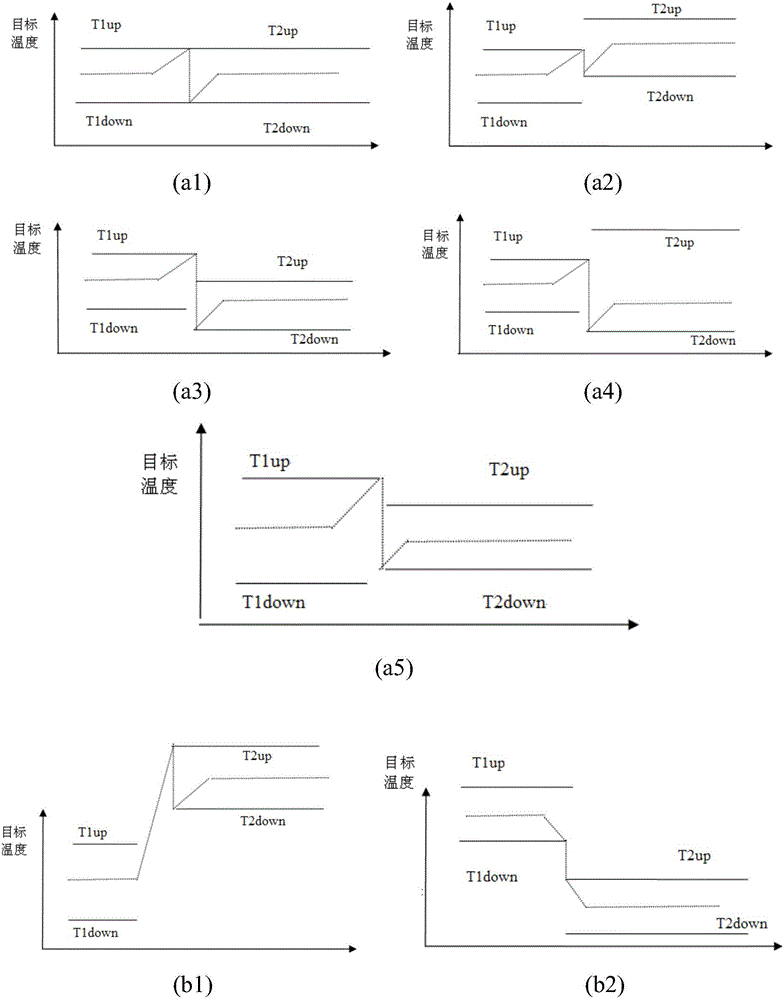

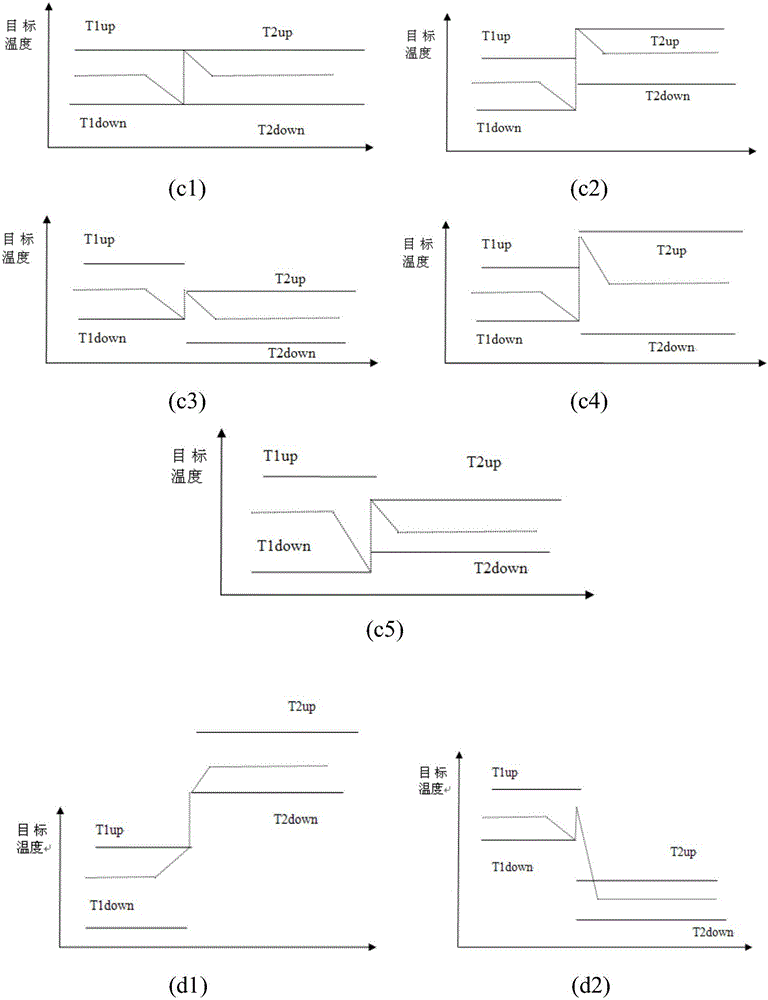

Control method of vertical annealing furnace based on band steel switching specifications

ActiveCN106119521ASimple structureVarious control methodsFurnace typesHeat treatment process controlAutomatic controlStrip steel

The invention discloses a control method of a vertical annealing furnace based on band steel switching specifications, belonging to the technical field of automatic control. The control method comprises the following steps: firstly judging whether the types, thickness and target temperature intervals of two kinds of band steel in front of and behind a weld joint are consistent to determine the types of replacing bands by periodically acquiring the specifications of the two kinds of band steel subjected to band replacement and the weld joint location information; then determining the band replacing target temperature according to the types of the replacing bands and computing the band steel velocity set values and radiant tube temperature set values at different stages during band replacing according to combined action of a velocity model and a heat transfer model; finally judging different stages during band replacing according to the weld joint location and giving the band steel velocity set values and radiant tube temperature set values at corresponding stages, thus achieving the aim of stable control. The perfect control method can be formed and is applicable to online band replacing control of the vertical annealing furnace.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com