Method for predicting junction temperature of IGBT (Insulated Gate Bipolar Translator) module

A prediction method and junction temperature technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low switching frequency, complex switching behavior of sub-modules, etc., achieve high precision, simple and practical algorithm, and save energy. The effect of software resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited to the examples given.

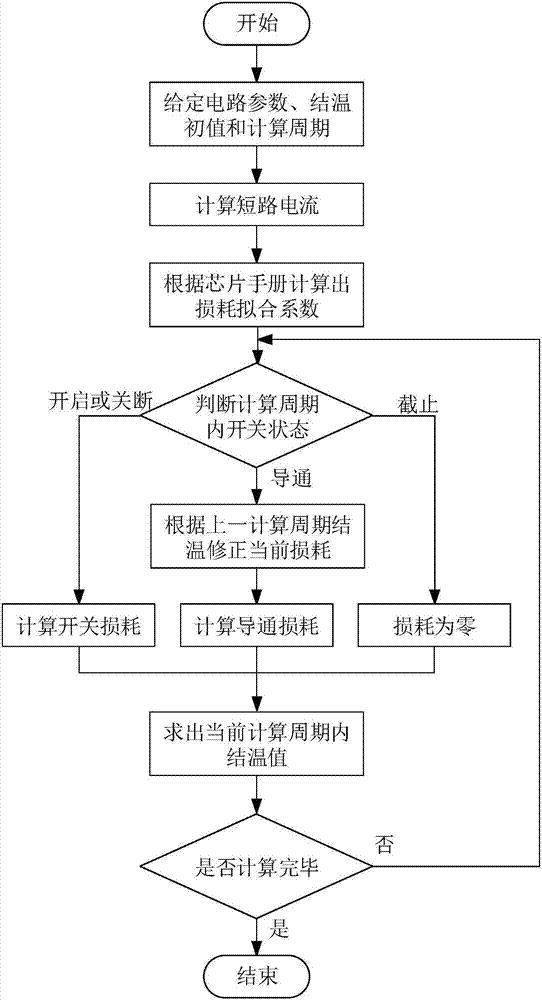

[0051] like figure 1 As shown, a junction temperature prediction method of an IGBT module provided by the present invention comprises the following steps:

[0052]The first step: before calculating, will determine the required parameter value of calculation, in the present invention, these parameters comprise:

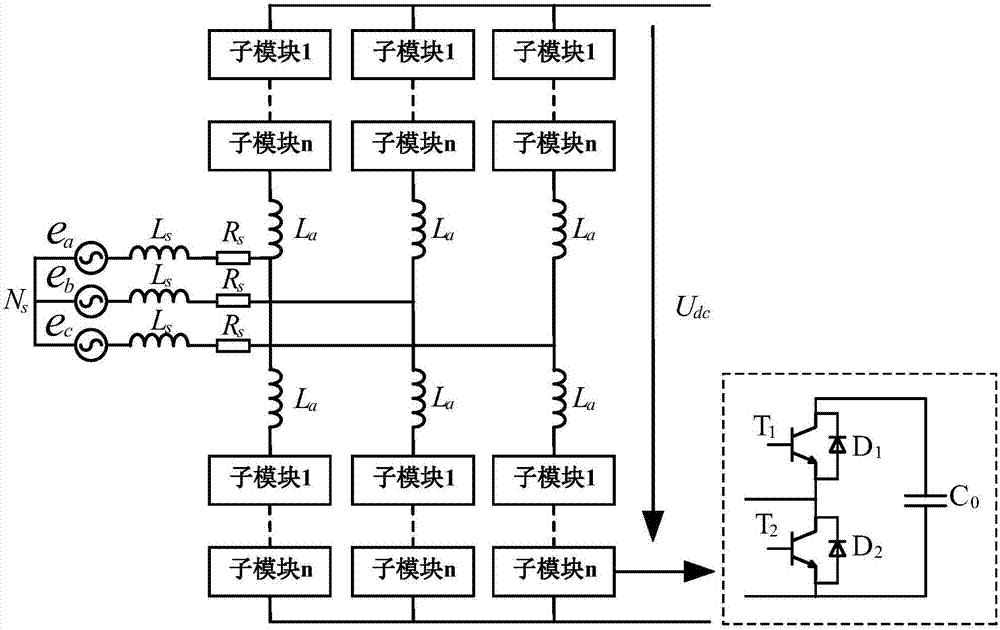

[0053] The parameters of the main circuit, such as figure 2 shown, including the DC side voltage value U dc , the number of sub-modules in half a bridge arm n, the capacitance value of sub-modules C 0 , Bridge arm valve reactor inductance L a , Bridge arm equivalent resistance R st , DC bus equivalent inductance L L and equivalent resistance R L . The bridge arm equivalent resistance includes reactor DC resistance, capacitor series equivalent resistance, line and device equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com