A method for predicting fluid temperature distribution in a vertical U-shaped buried pipe of a ground source heat pump under off-design conditions

A fluid temperature, ground source heat pump technology, applied in heat recovery systems, energy-saving heating/cooling, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] This embodiment is aimed at the sandbox experiment under the variable heat flow condition completed by Professor Beier of the United States in 2011, and provides a prediction method for the fluid temperature distribution under the variable heat flow Q(t) condition, and compares the calculated inlet and outlet fluid temperatures with the experimental value Comparing with other model results, the fluid temperature distribution is calculated at the same time.

[0137] By simulating the actual thermal response test, the sandbox experiment was carried out in a room with constant temperature, the sandbox was placed horizontally in the room, and the U-shaped pipe and backfill were placed horizontally in the center of the sandbox. The electric heater is used to heat the fluid, and at the same time, the fluid is driven to circulate in the U-shaped tube, and the inlet and outlet fluid temperature, heat flow, mass flow, etc. are recorded every minute. The experiment lasts 3038 minu...

Embodiment 2

[0153] This embodiment is aimed at the sandbox experiment under the constant heat flow condition completed by Professor Beier of the United States in 2011, and calculates the fluid temperature distribution under the constant heat flow Q(t) condition, and compares the calculated inlet and outlet fluid temperatures with the experimental values and other models The results are compared.

[0154] This experiment is basically the same as the experiment in Example 1, except that the heat flow, mass flow rate and experiment duration are different. The duration of the experiment is 3106 minutes, and the heat flow does not change with time.

[0155] The specific steps of this embodiment are the same as those of Embodiment 1.

[0156] The comparison of the calculated inlet and outlet fluid temperatures with the experimental values and other model results are as follows: Figure 7 with Figure 8 As shown, the comparison between this method and the absolute error of the inlet and o...

Embodiment 3

[0161] This embodiment provides the variable inlet fluid temperature T for the sandbox experiment under the condition of variable inlet fluid temperature completed by Professor Beier of the United States in 2011. in (t) The prediction method of fluid temperature distribution under working conditions, and compare the calculated heat flow and outlet fluid temperature with the experimental value, and calculate the fluid temperature distribution at the same time. This experiment is exactly the same as the experiment in embodiment 2, and the difference between this embodiment and embodiment 2 is as follows: embodiment 2 calculates the inlet and outlet fluid temperature under the condition of known constant heat flow, and this embodiment is known Variable inlet fluid temperature T in Calculate the heat flow and outlet fluid temperature under the condition of (t).

[0162] The concrete steps of this embodiment are as follows:

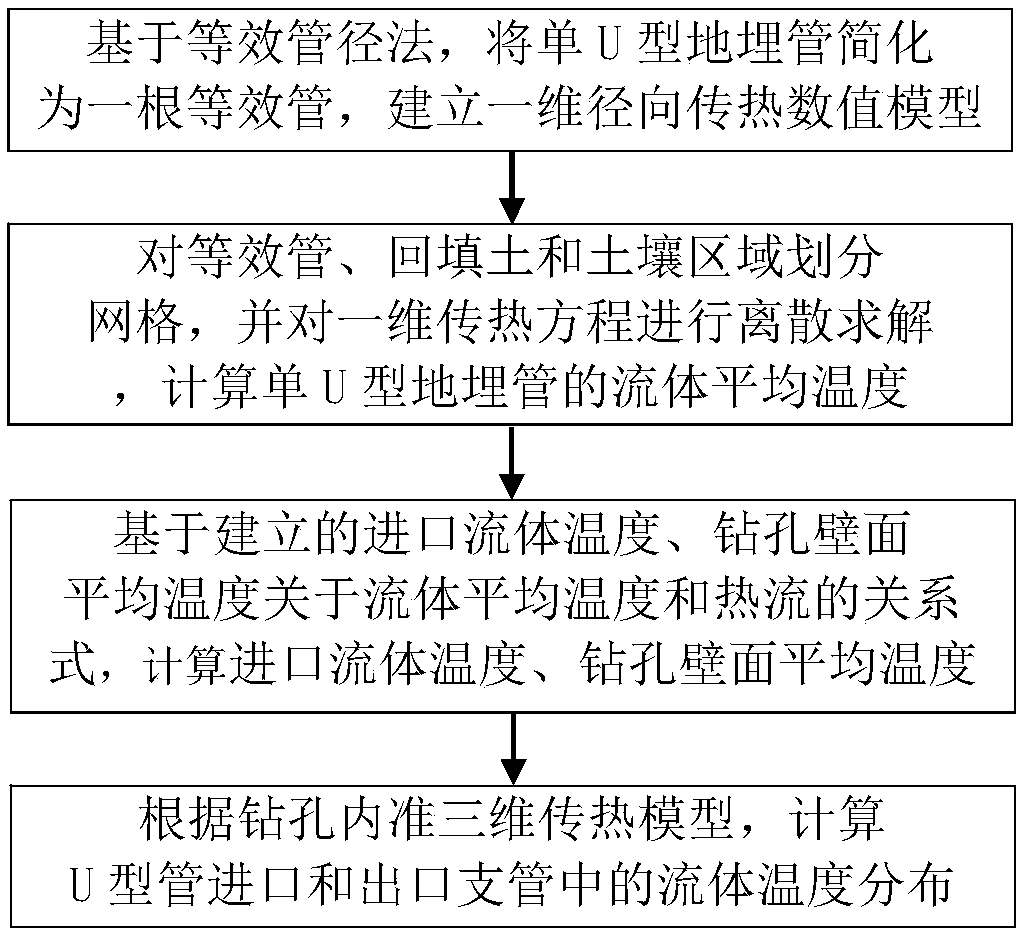

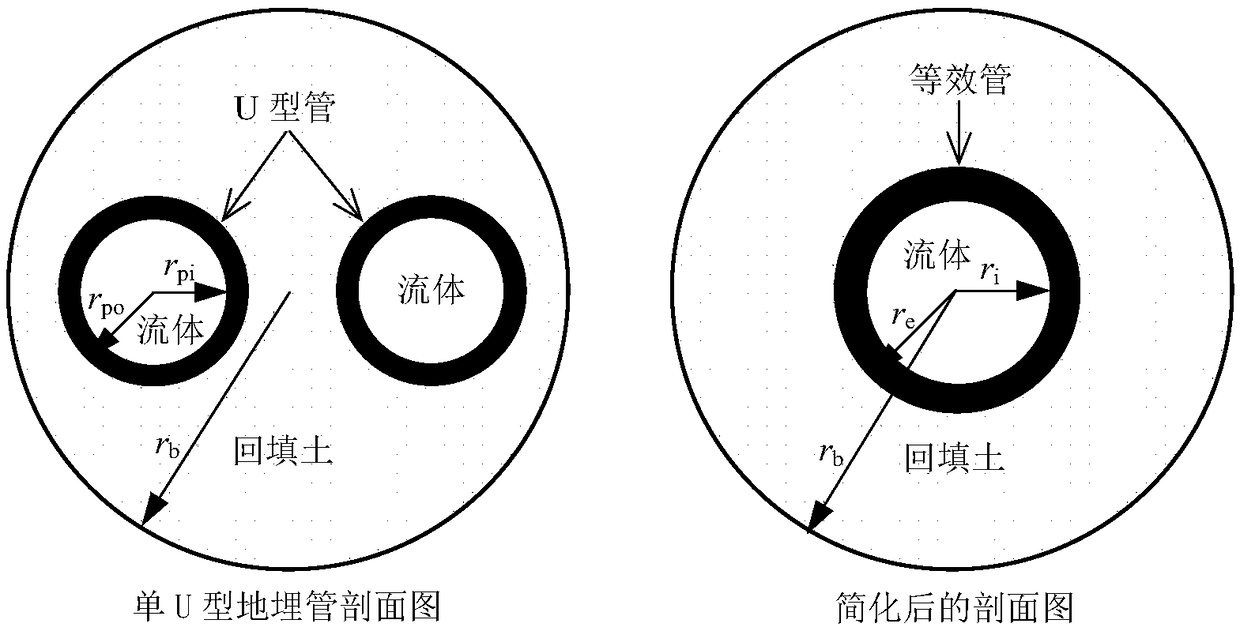

[0163] Step 1: If figure 2 As shown, the single U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com