Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

457results about How to "Increase charging rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

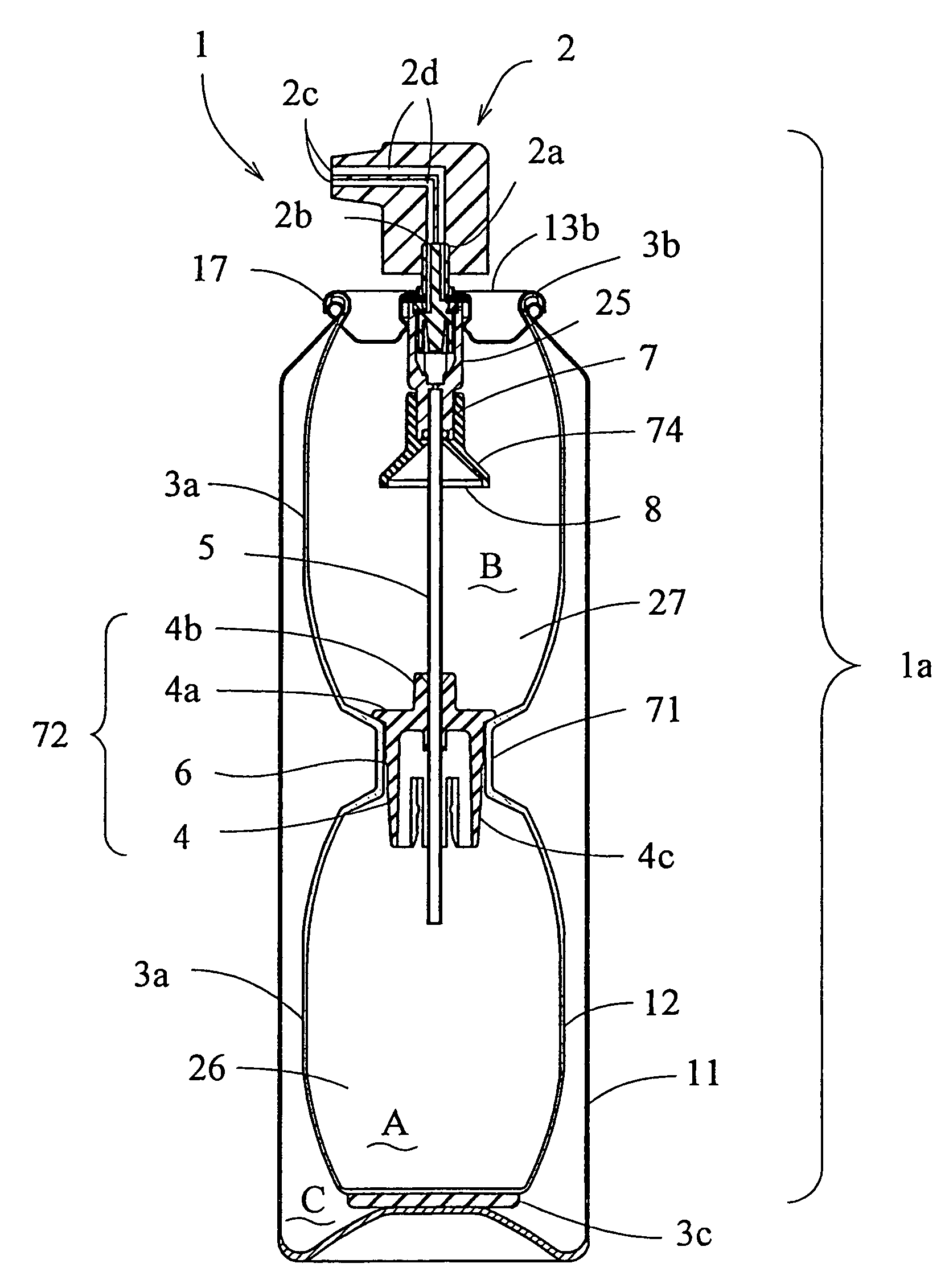

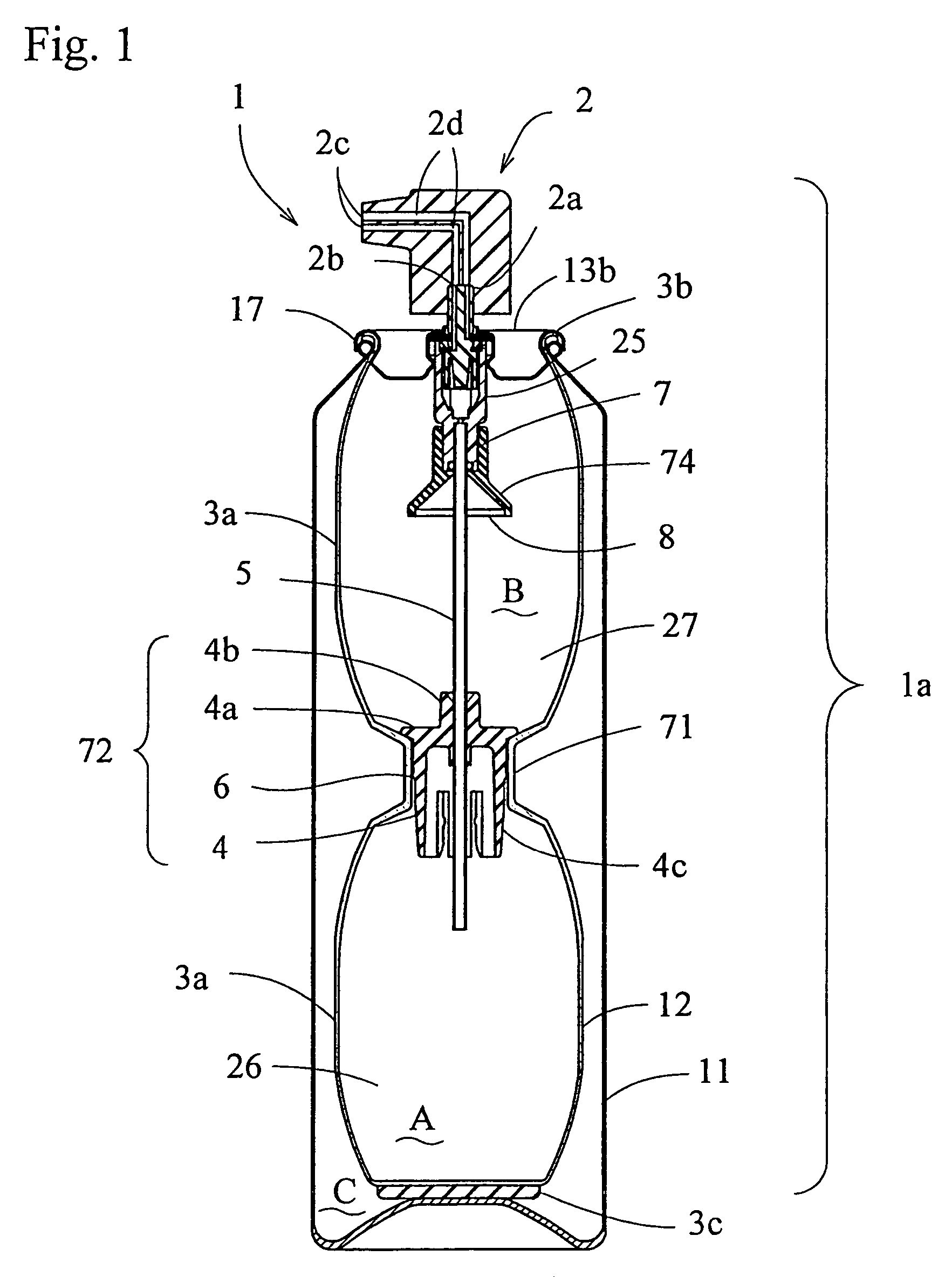

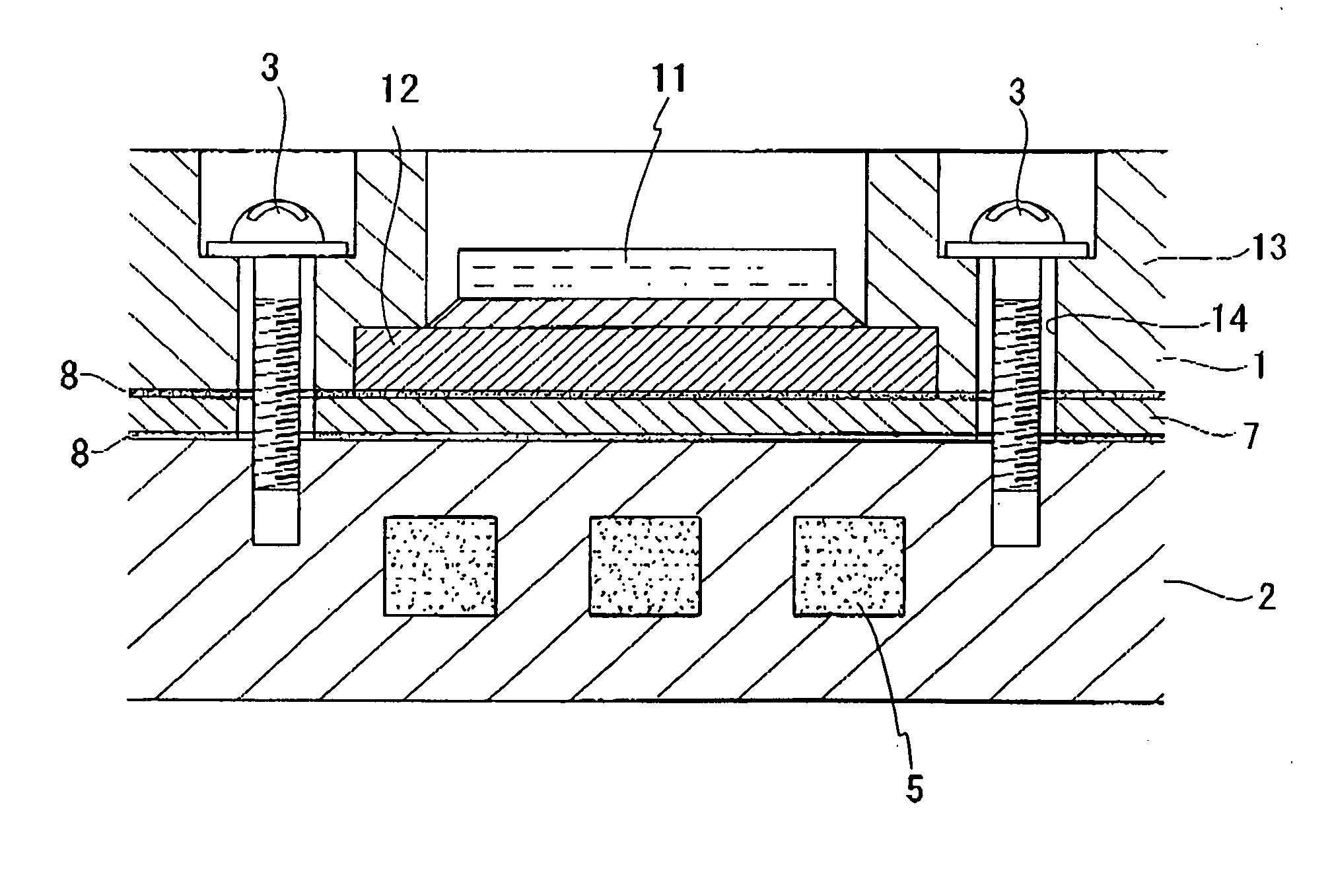

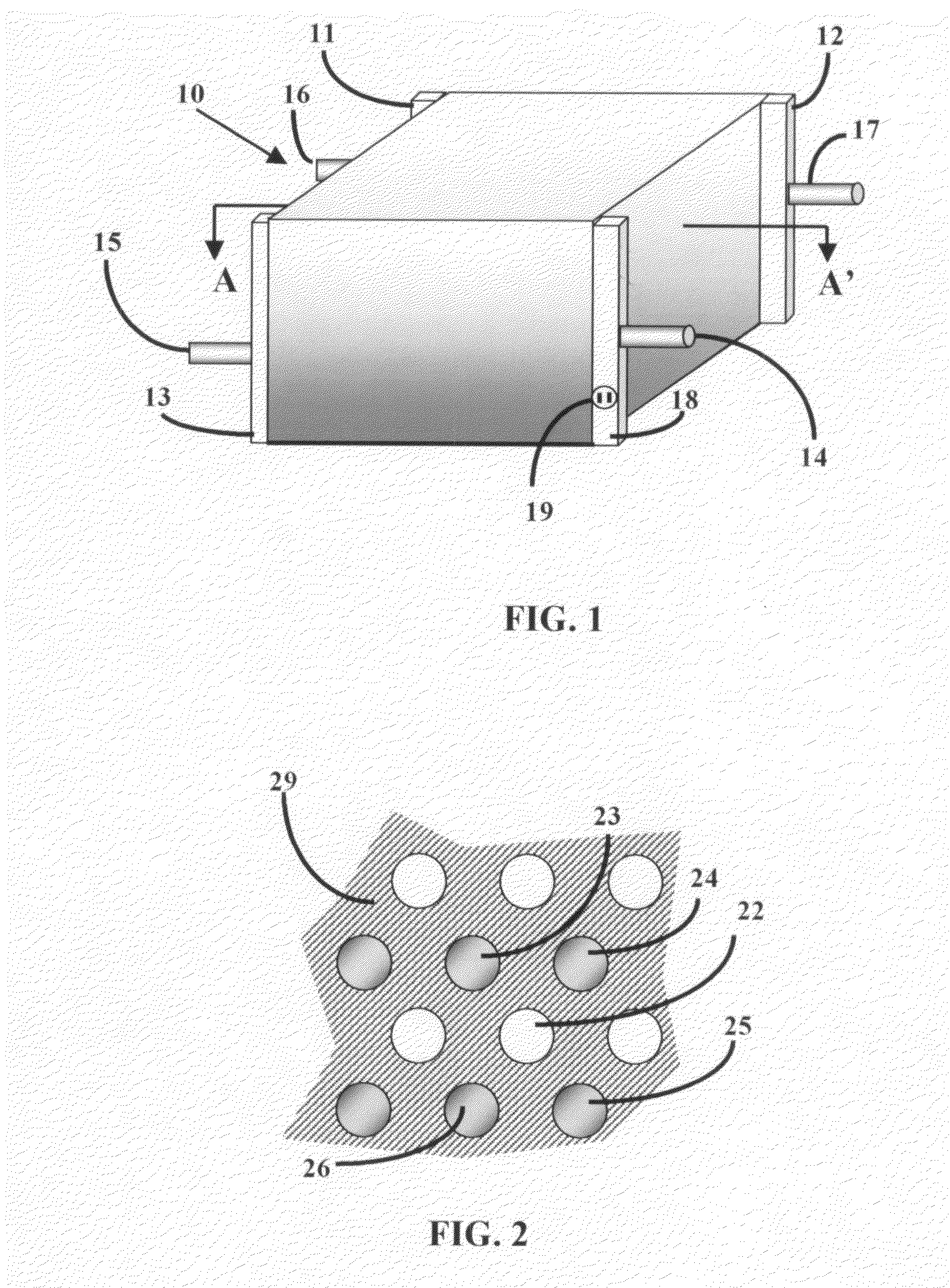

Container for discharging plural contents, a dispenser using the container, and a process for producing the dispenser

InactiveUS7455195B2Easy to splitIncrease charging rateLiquid transferring devicesSingle-unit apparatusHair dyesVitamin Preparations

An aerosol container 190a provided with an outer container 11, a collapsible inner bag 12 inserted in the outer container, and a valve 13. The inner bag 12 comprises an upper and lower chamber 27, 26 and the chambers are divided at a constriction part formed in the middle of the inner bag by a partitioning member 72. The valve 13 has communicating holes that communicates valve 13 with the upper chamber 27 and the lower chamber 26 through a dip tube 28. An inner bag type aerosol product may be obtained by charging different kind of contents A and B into the container. Two-liquid reaction type agents, such as hair dye. enzyme hair dye, hair dress agent or setting agent for hair, reduction of inflammation pain killer, anti-heat flushes, coolants, pack agents, cleansing agents, shaving foams, moisturizers, antipersipirants. vitamin preparations, emollients and etc. may be preferably used for the combination of the contents for aerosol product.

Owner:DAIZO

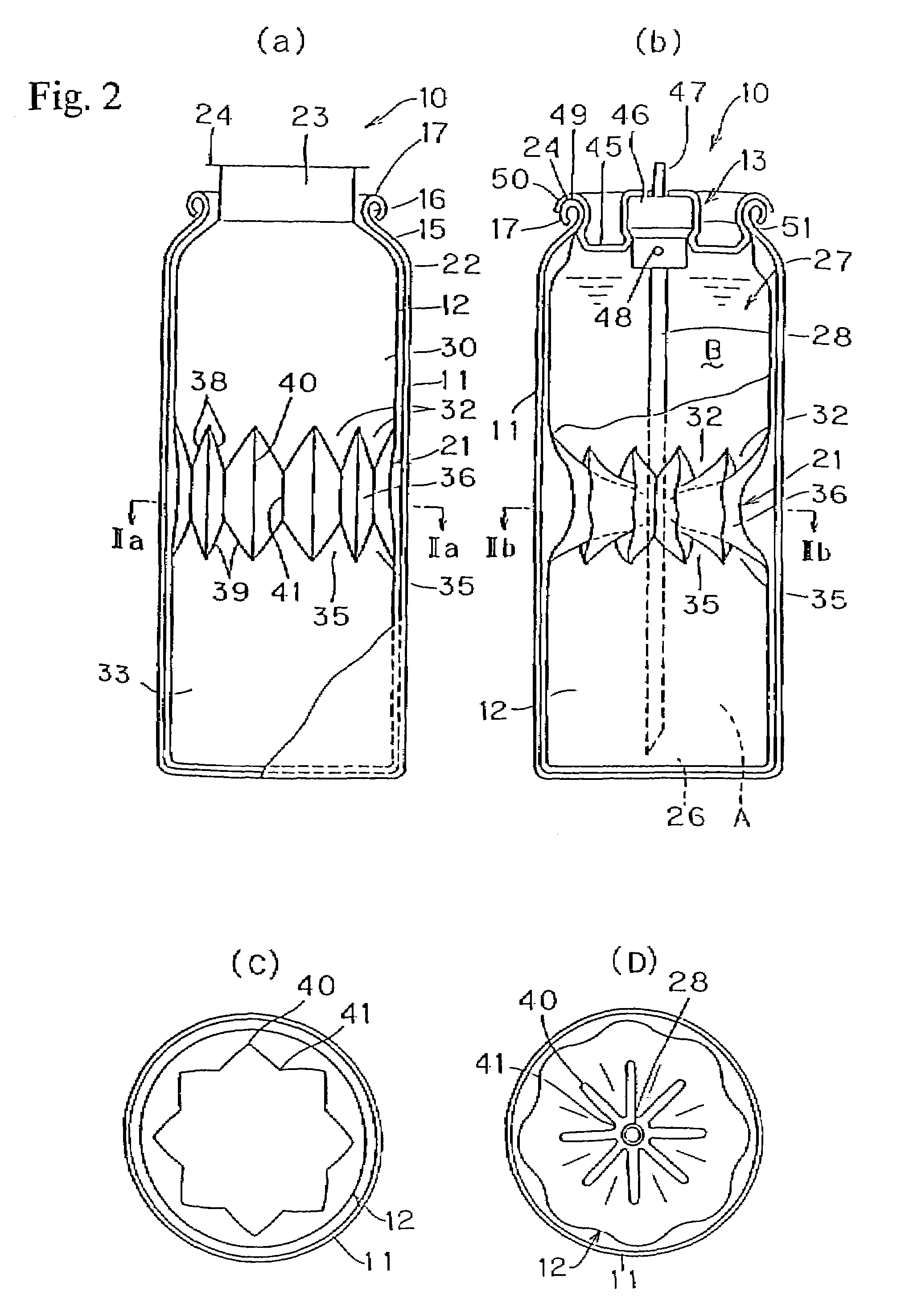

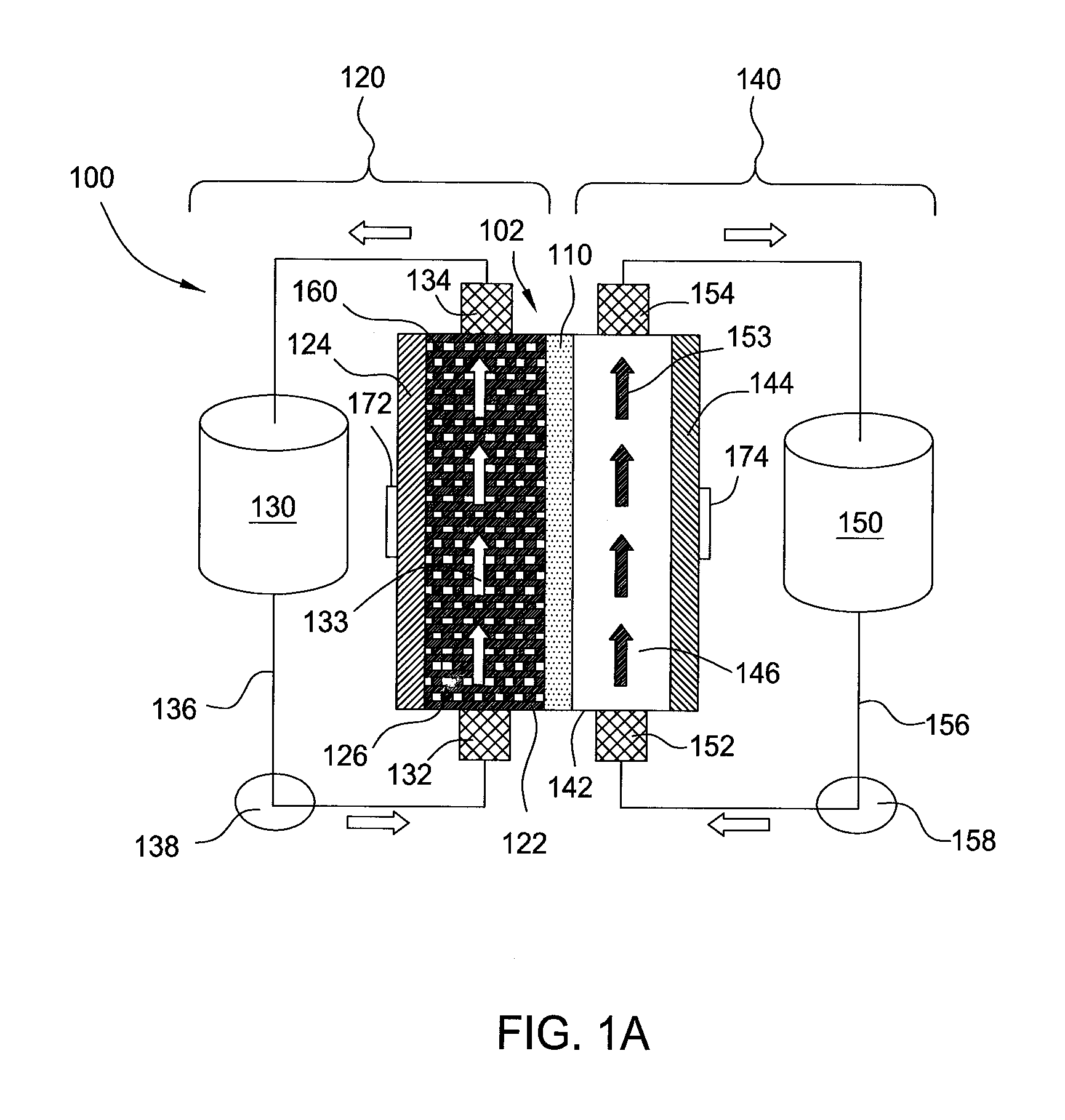

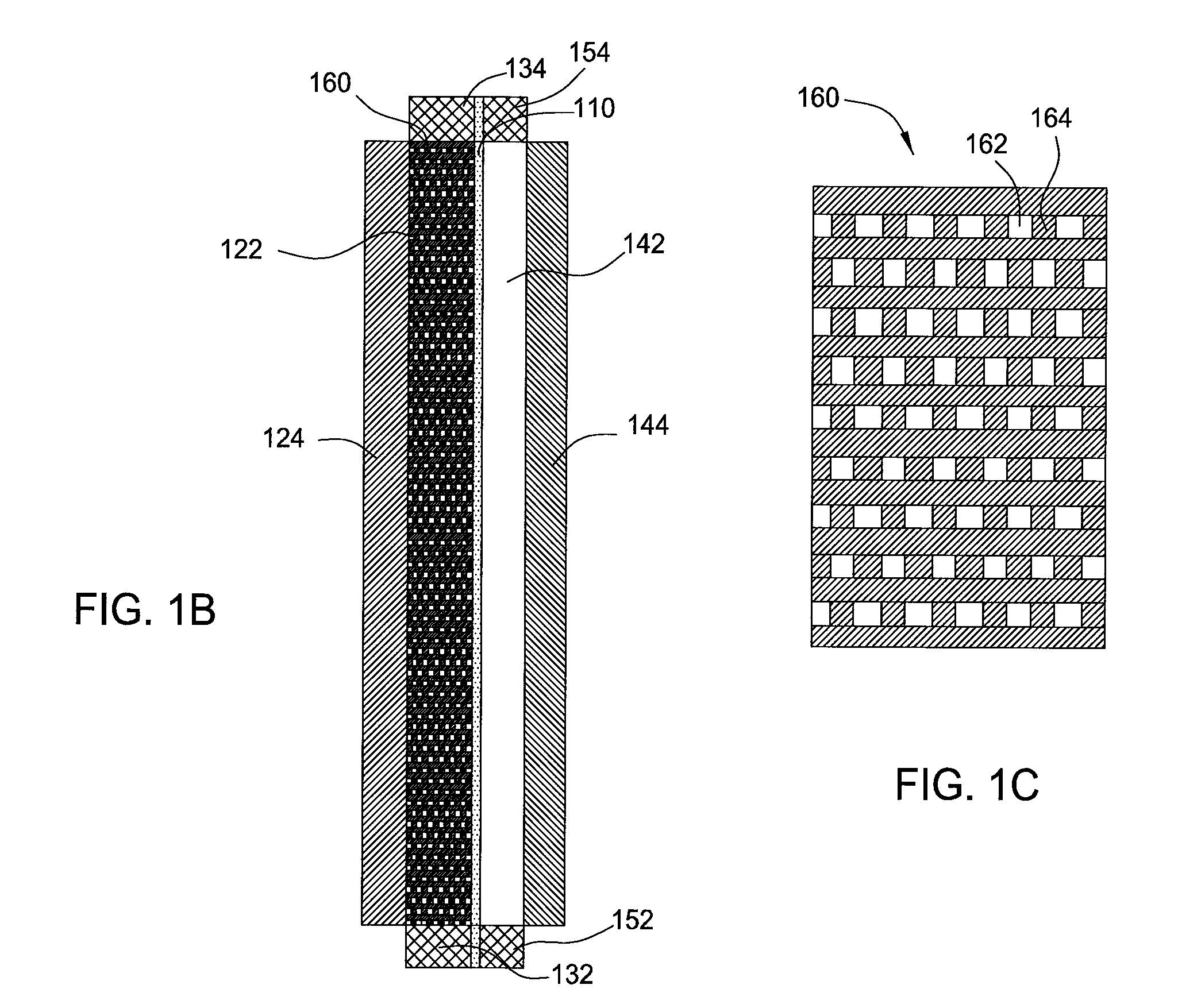

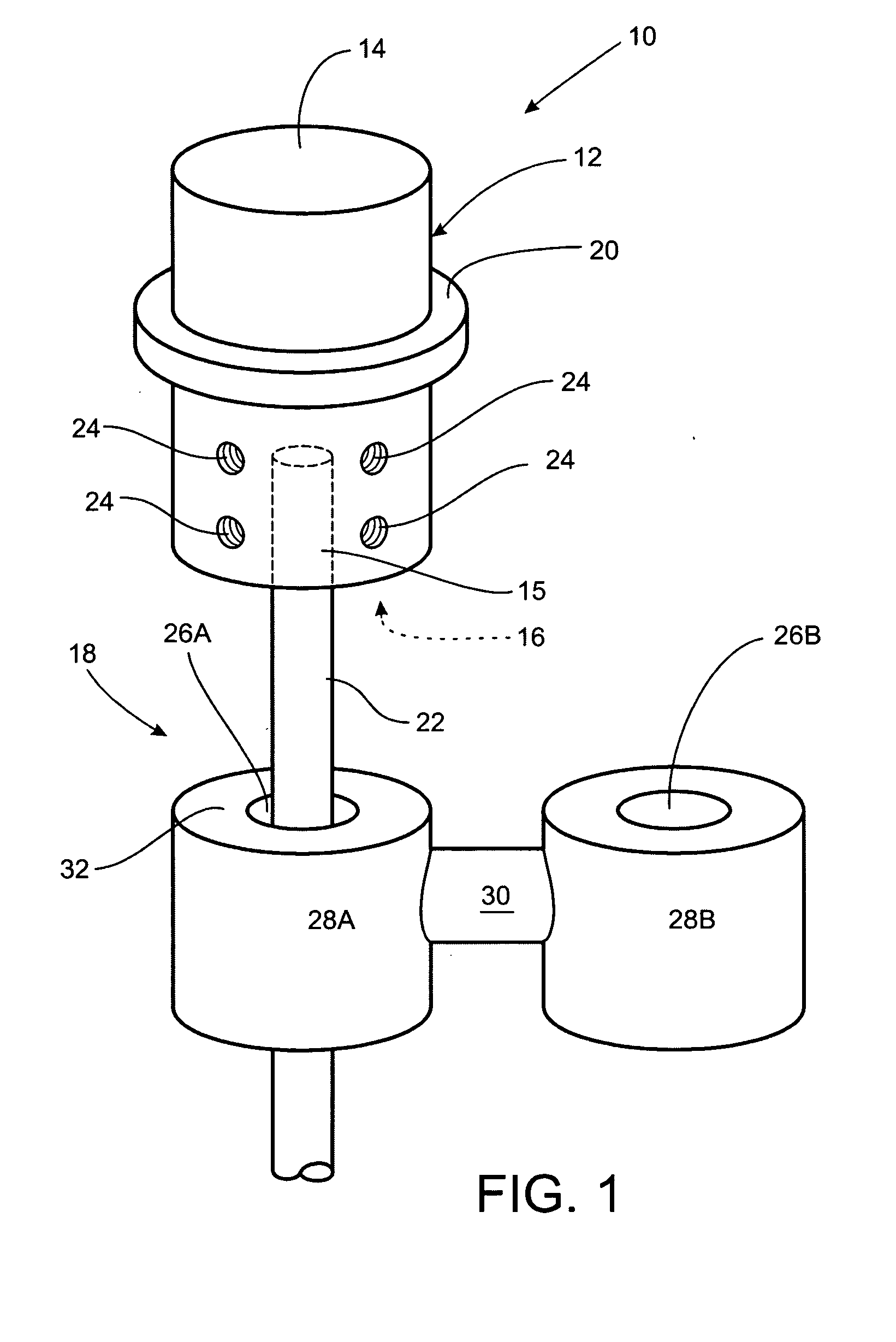

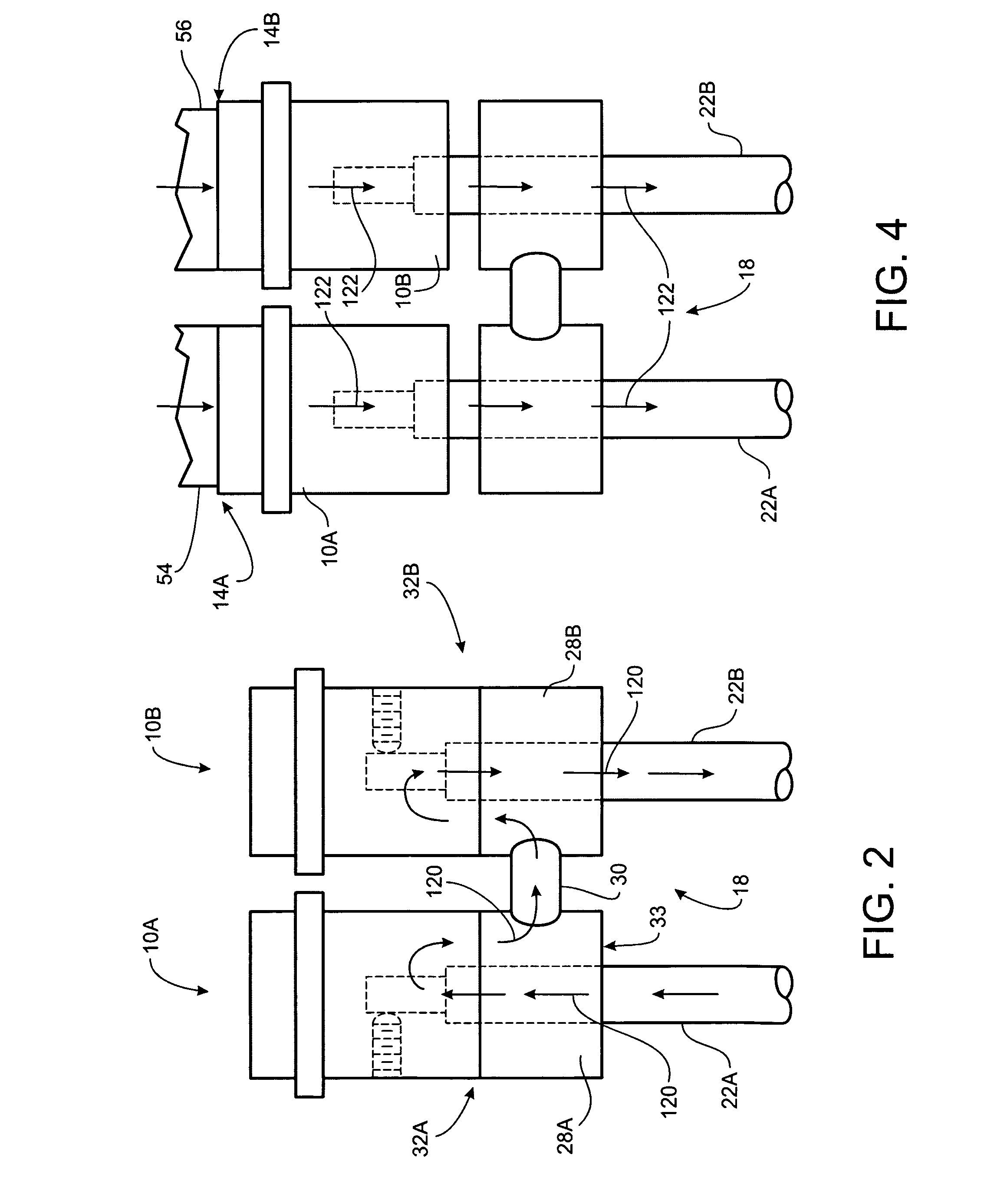

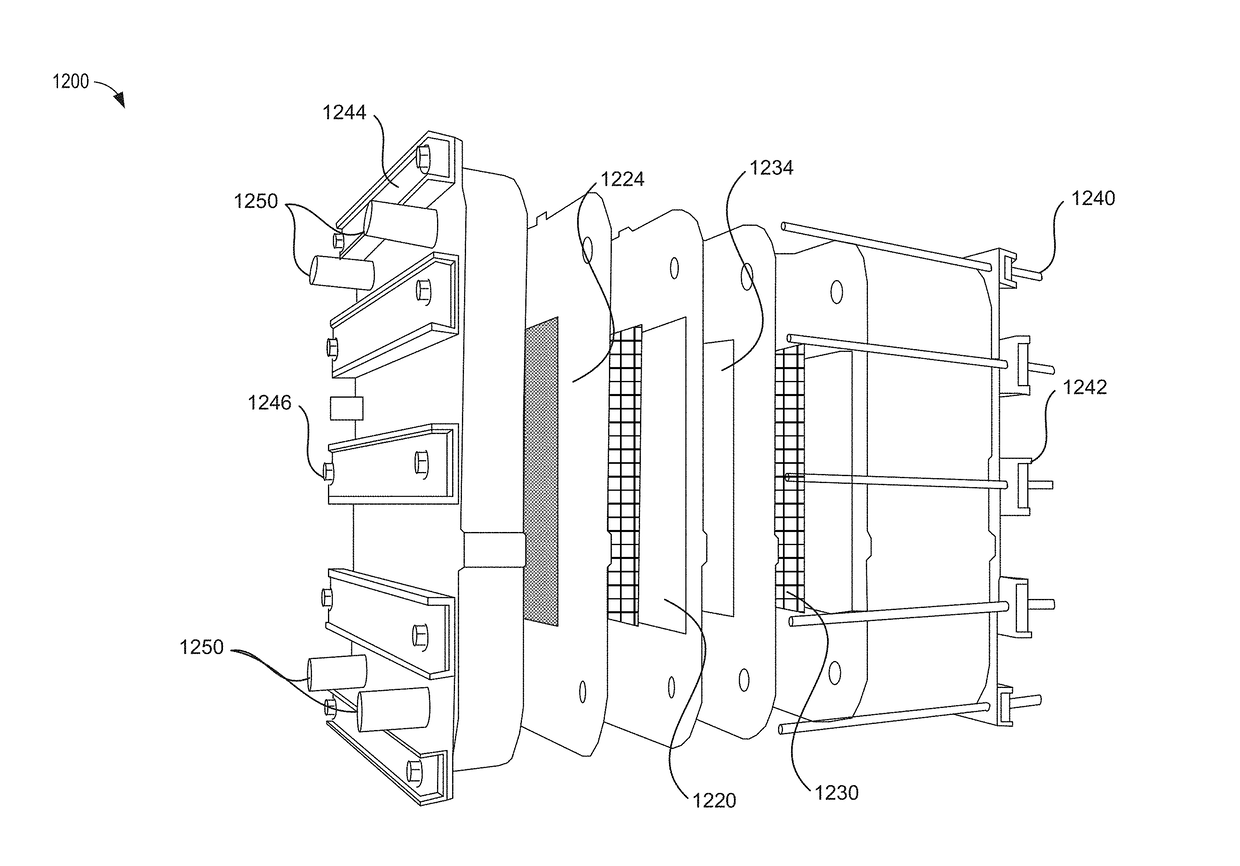

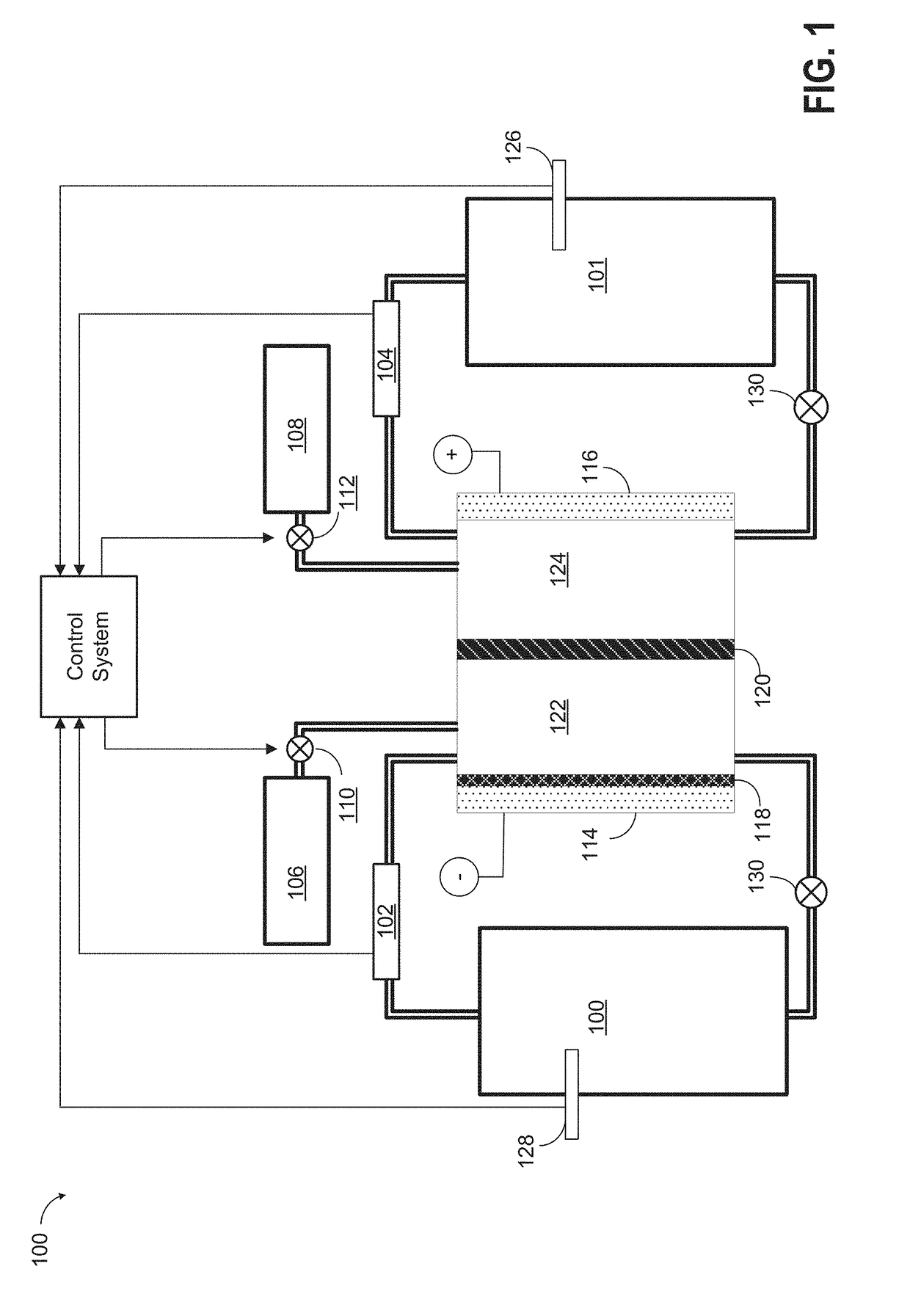

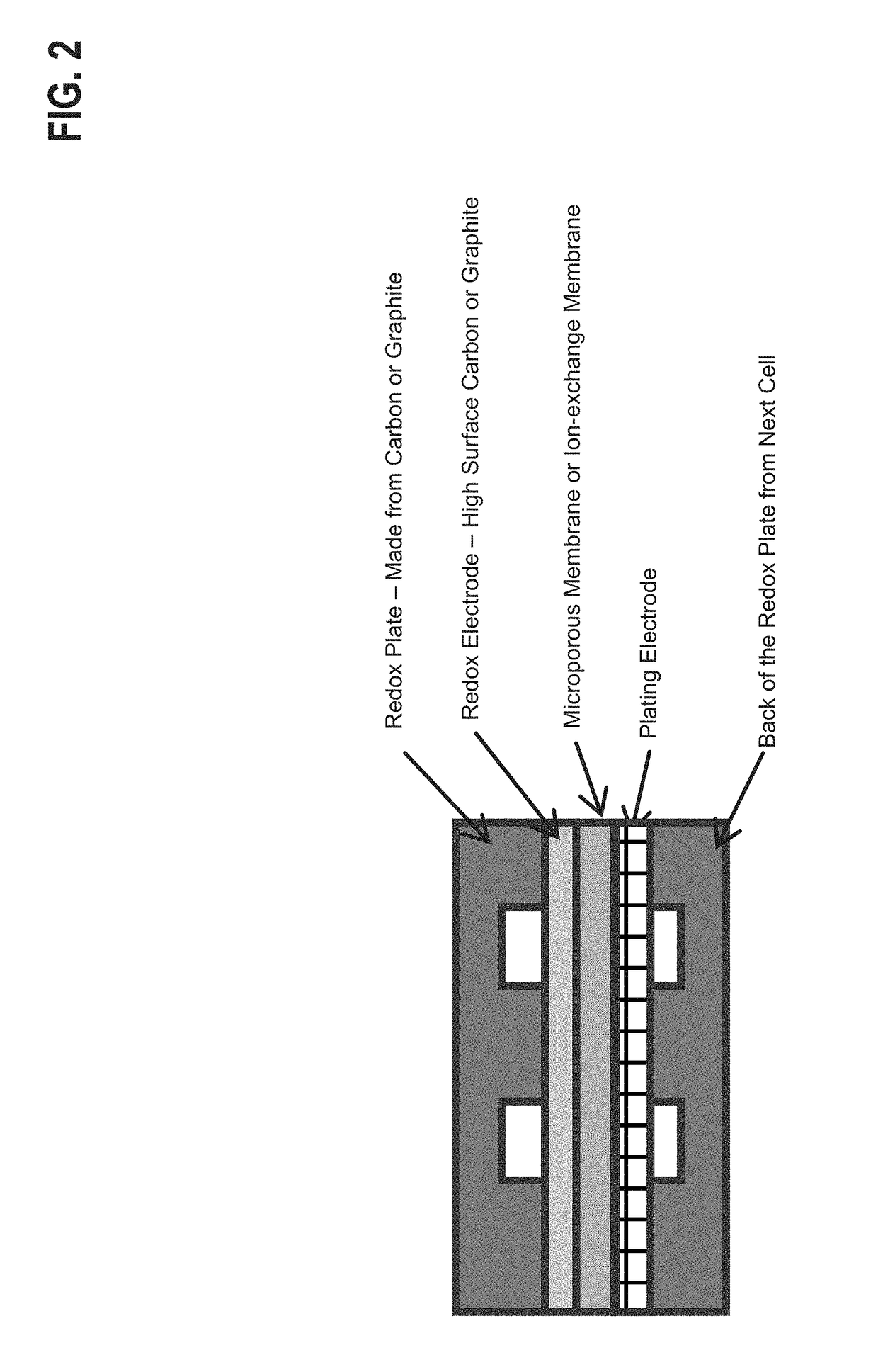

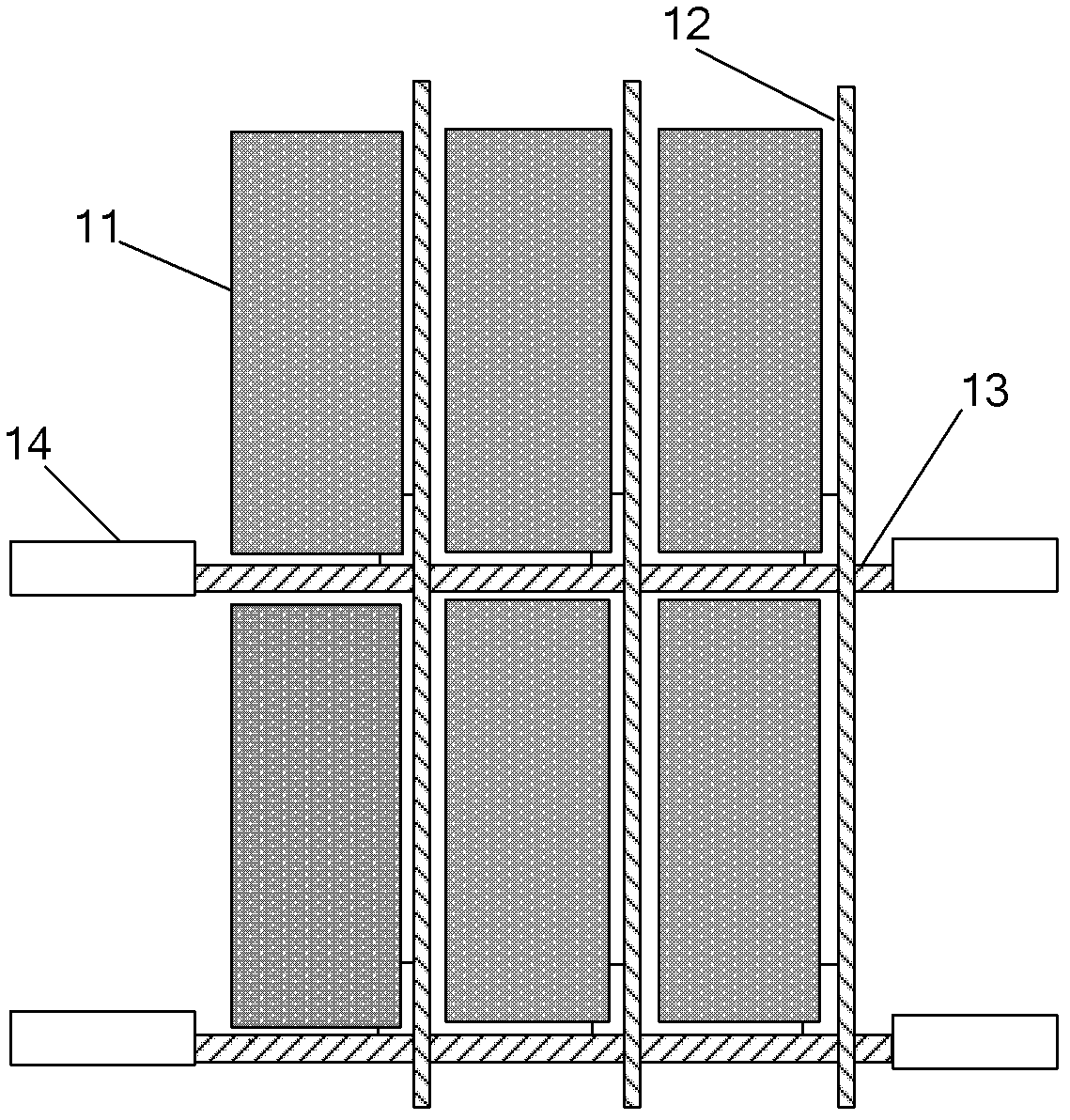

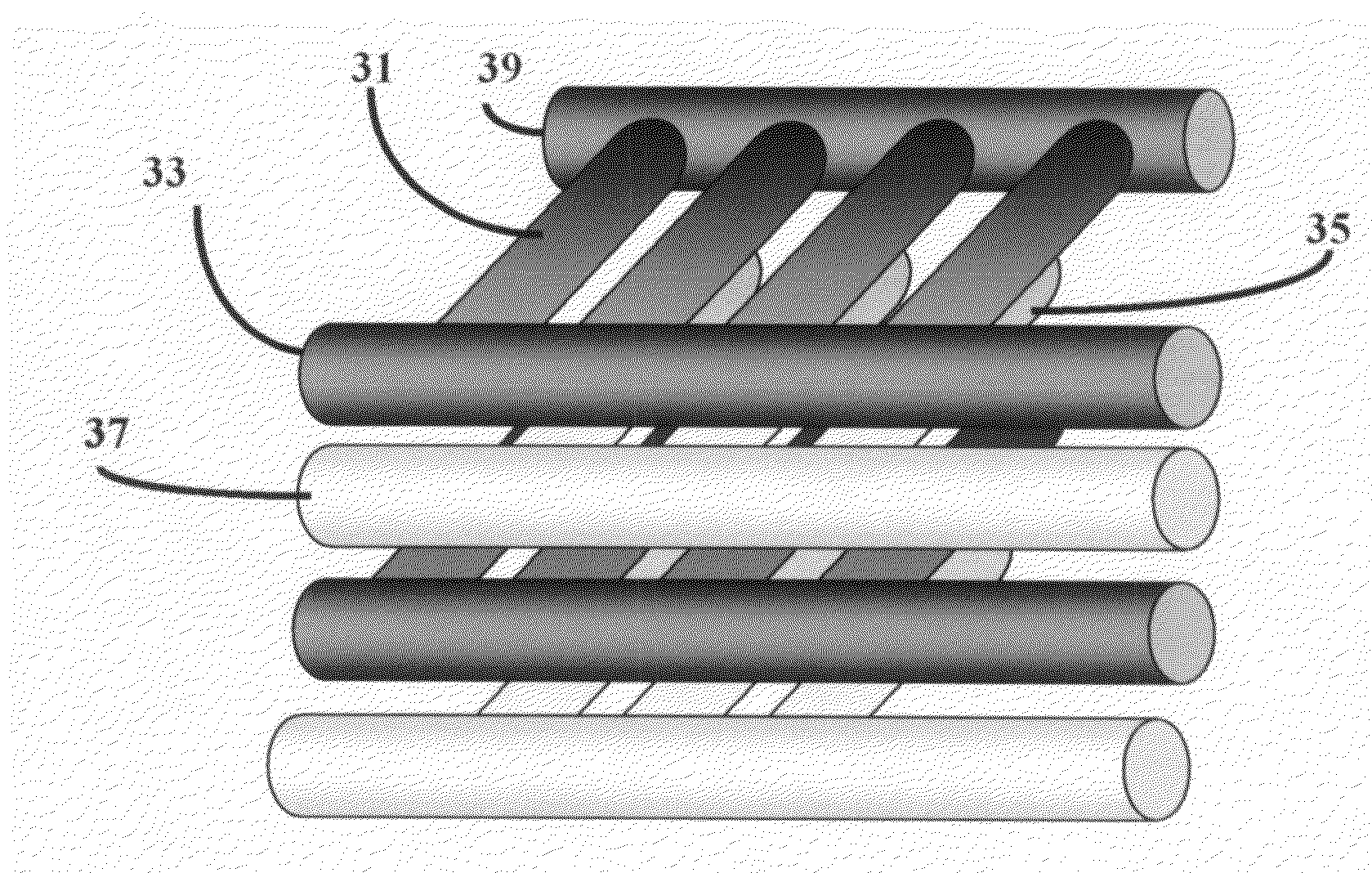

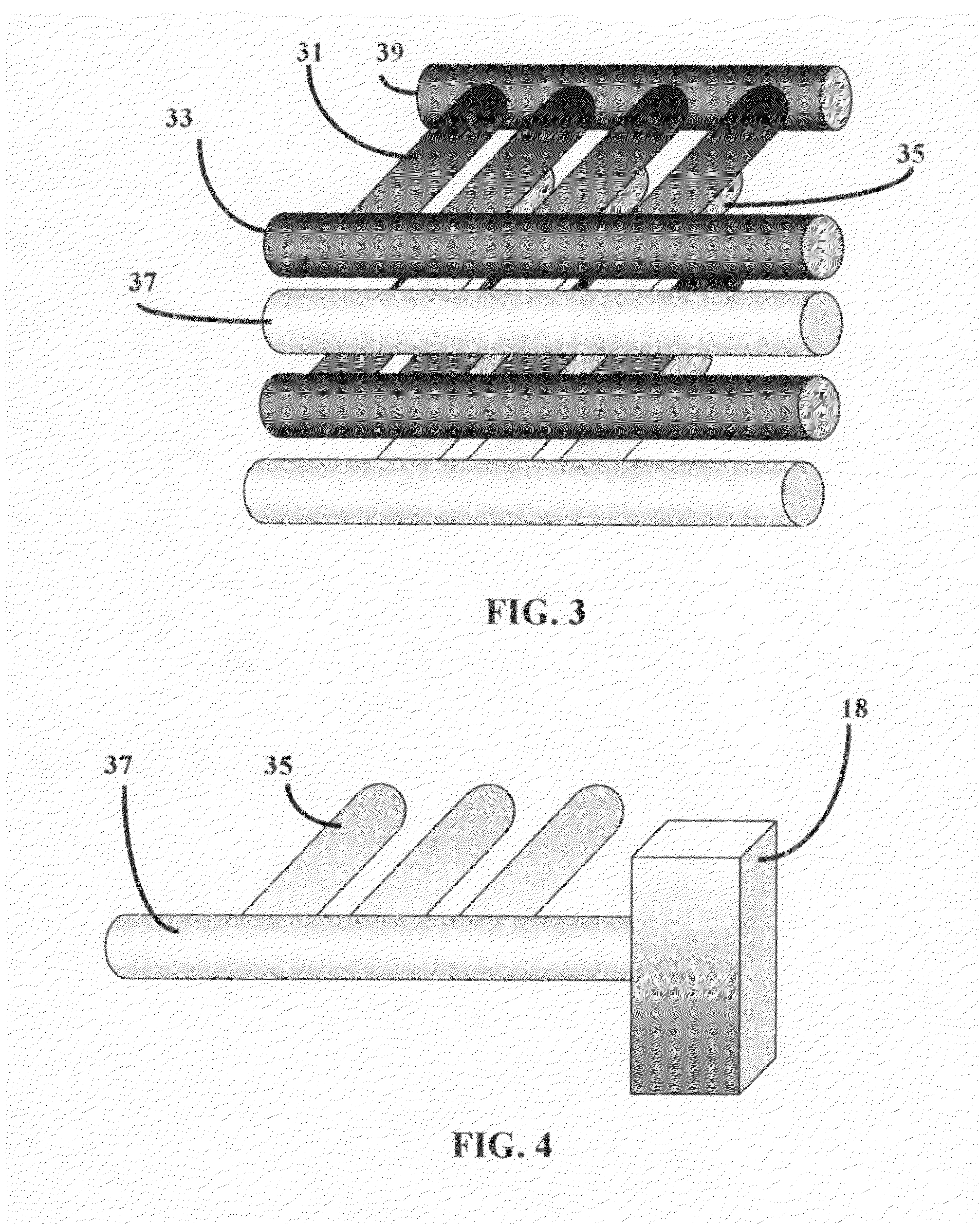

Flow battery systems

ActiveUS20120052347A1Uniform metal platingHigh cell current densityFuel and secondary cellsCell electrodesEngineeringMetal

Embodiments of the invention generally provide for flow battery cells and systems containing a plurality of flow battery cells, and methods for improving metal plating within the flow battery cell, such as by flowing and exposing the catholyte to various types of cathodes. In one embodiment, a flow battery cell is provided which includes a cathodic half cell and an anodic half cell separated by an electrolyte membrane, wherein the cathodic half cell contains a plurality of cathodic wires extending perpendicular or substantially perpendicular to and within the catholyte pathway and in contact with the catholyte, and each of the cathodic wires extends parallel or substantially parallel to each other. In some examples, the plurality of cathodic wires may have at least two arrays of cathodic wires, each array contains at least one row of cathodic wires, and each row extends along the catholyte pathway.

Owner:APPLIED MATERIALS INC

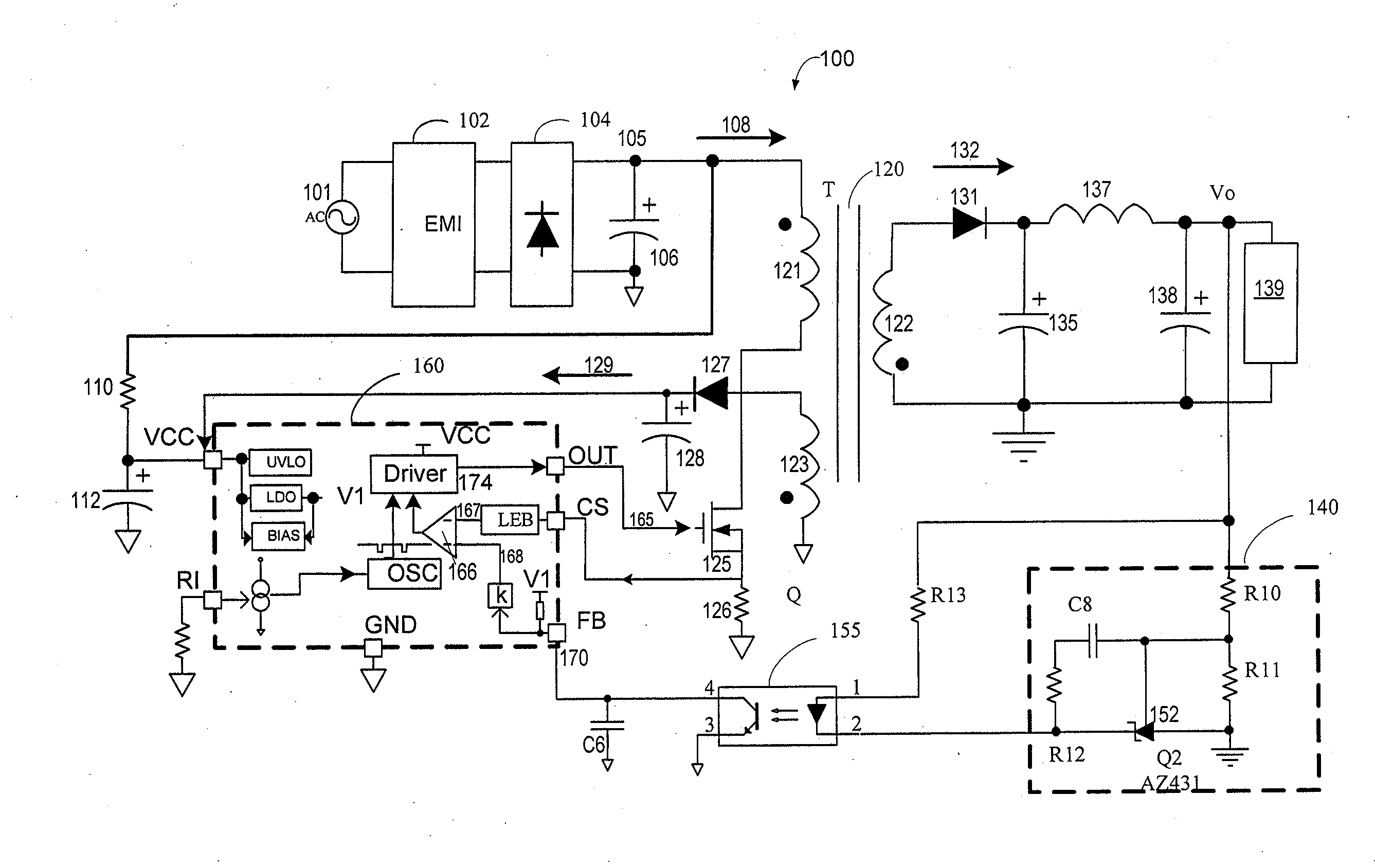

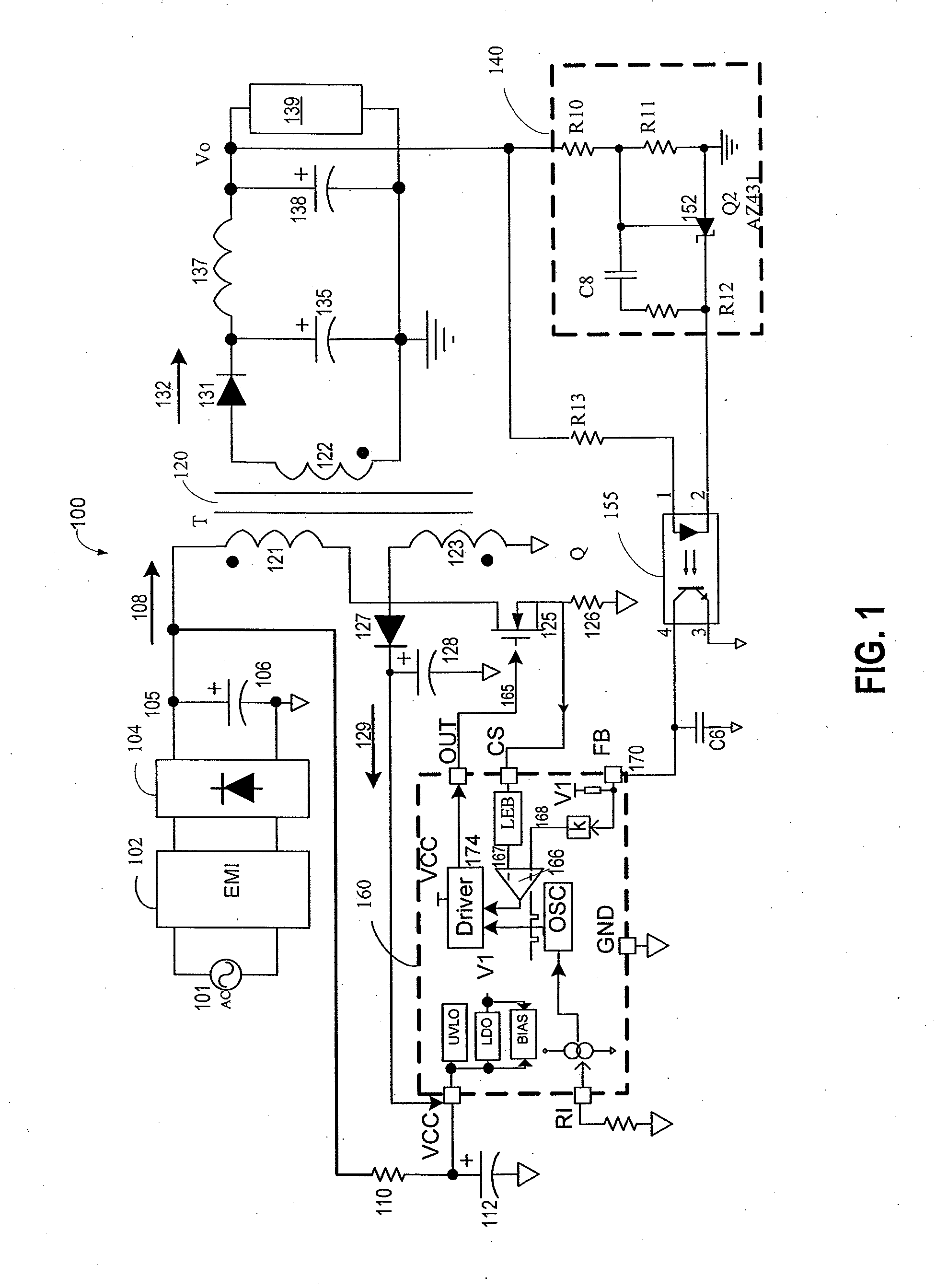

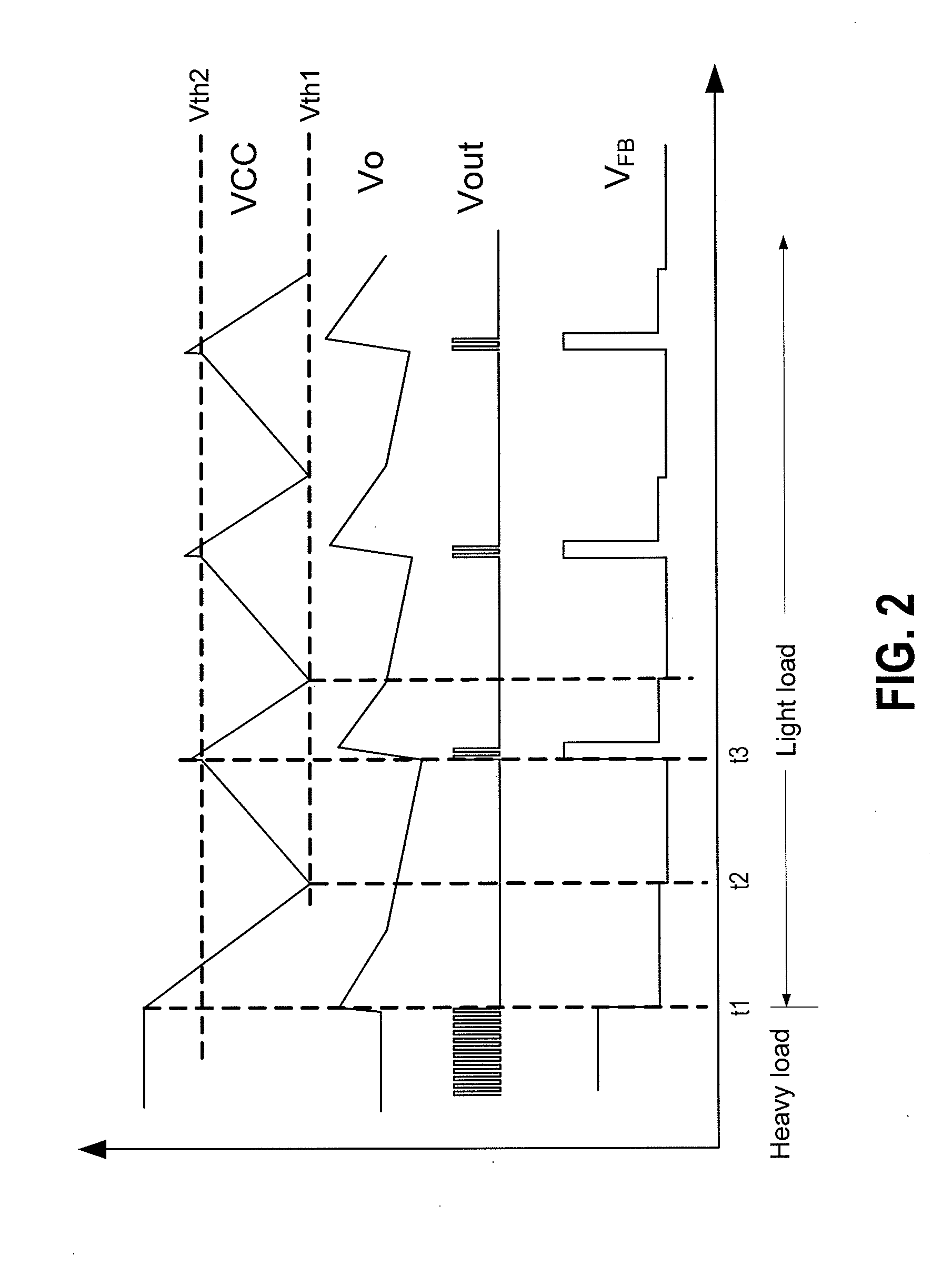

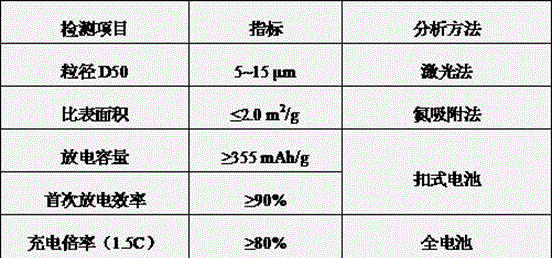

Method and apparatus for a switching mode power supply

ActiveUS20110019446A1Reduce current consumptionMinimizes instabilityEfficient power electronics conversionDc-dc conversionTransformerControl signal

A controller for a switched mode power supply (SMPS) is provided. The SMPS is equipped with a transformer having a primary side winding, a secondary winding, and an auxiliary winding. The controller includes a detection circuit for detecting a transition from a first output load condition to a second output load condition of the SMPS and a control circuit coupled to the detection circuit and being configured to output one or more control signals in response to the detected output load transition. Depending on the embodiment, the one or more control signals include a first control signal for turning on a power switch to cause a current flow in a primary winding of the SMPS and / or one or more second control signals for turning off one or more functional circuit blocks in the controller.

Owner:BCD SHANGHAI MICRO ELECTRONICS CO LTD

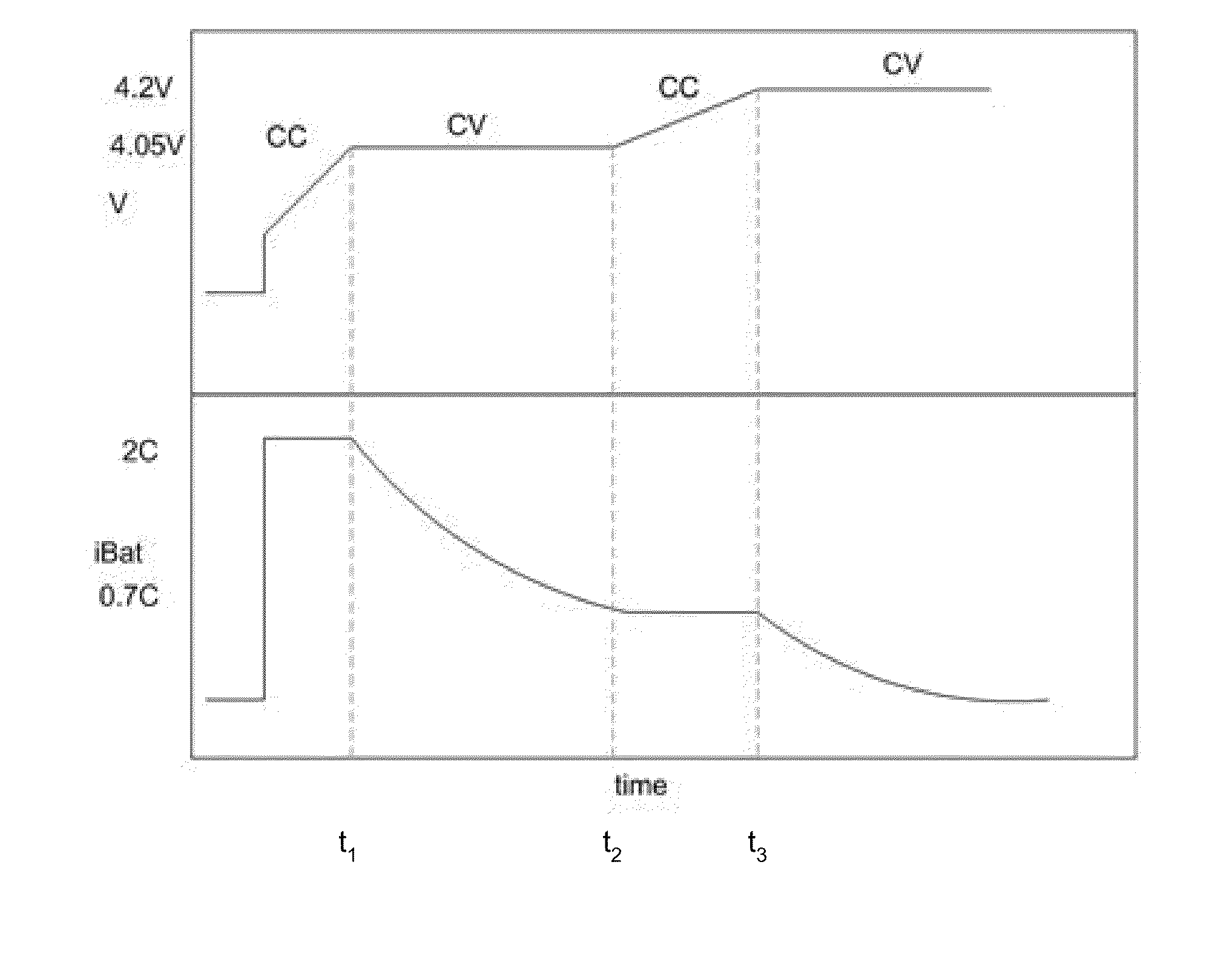

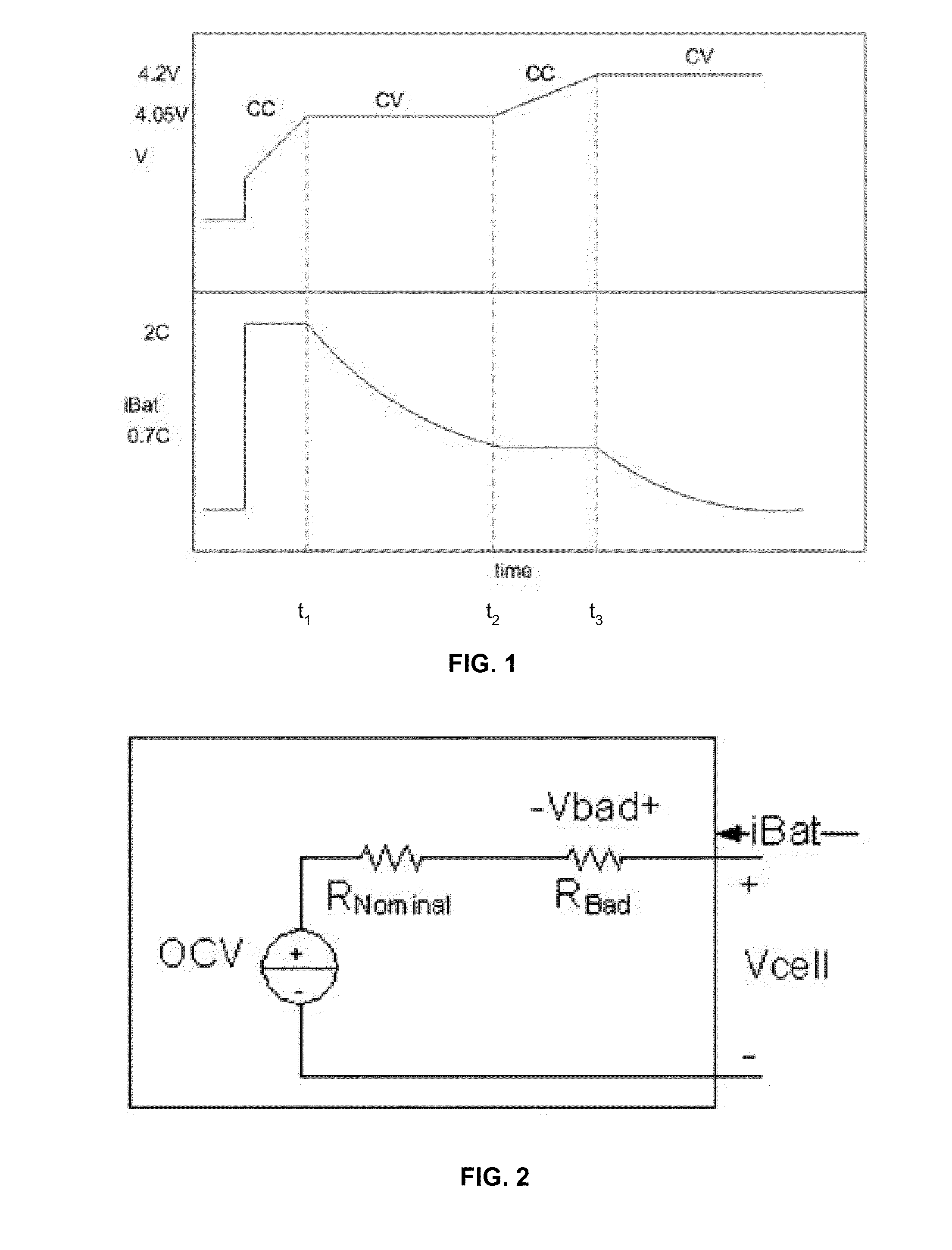

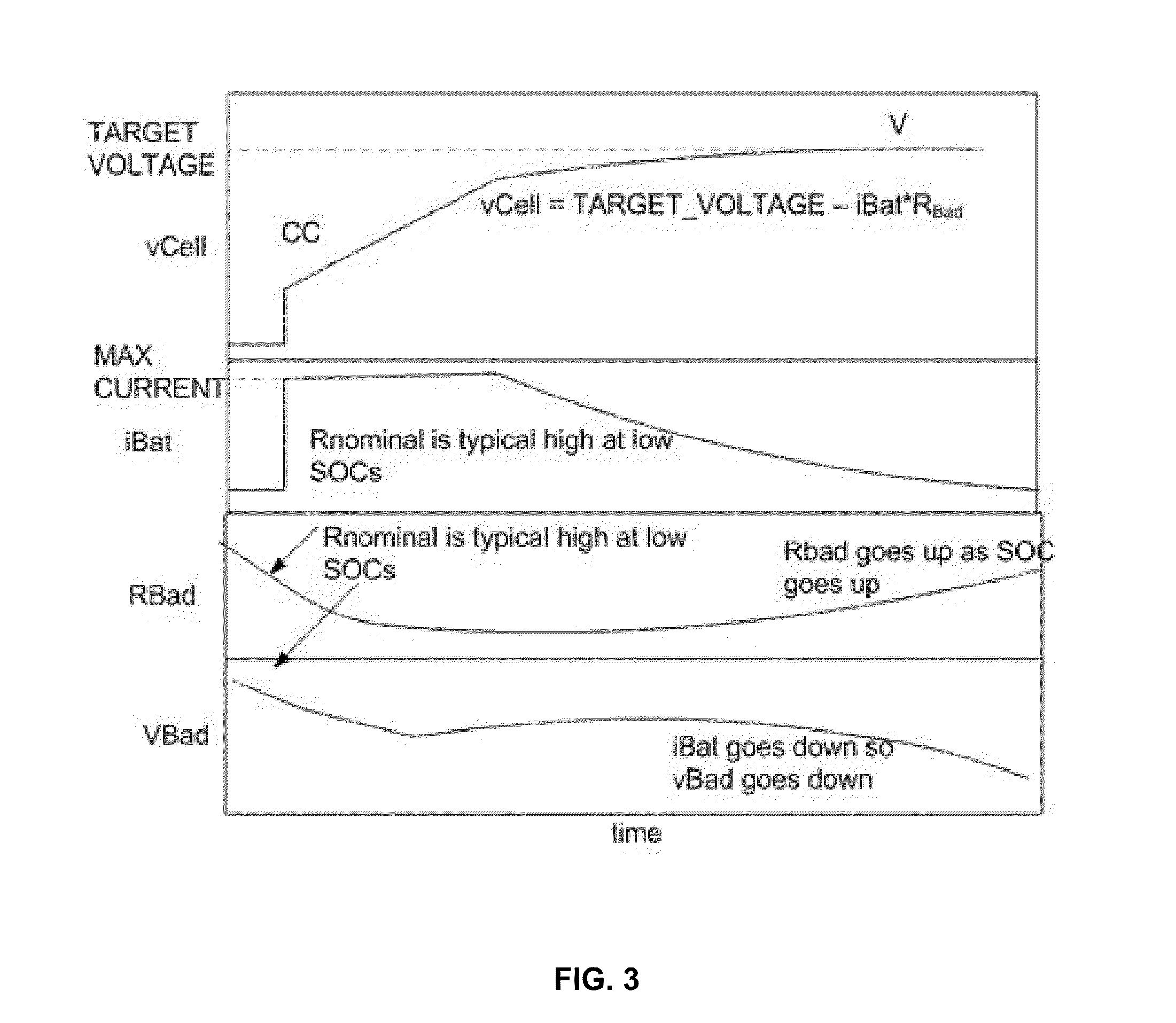

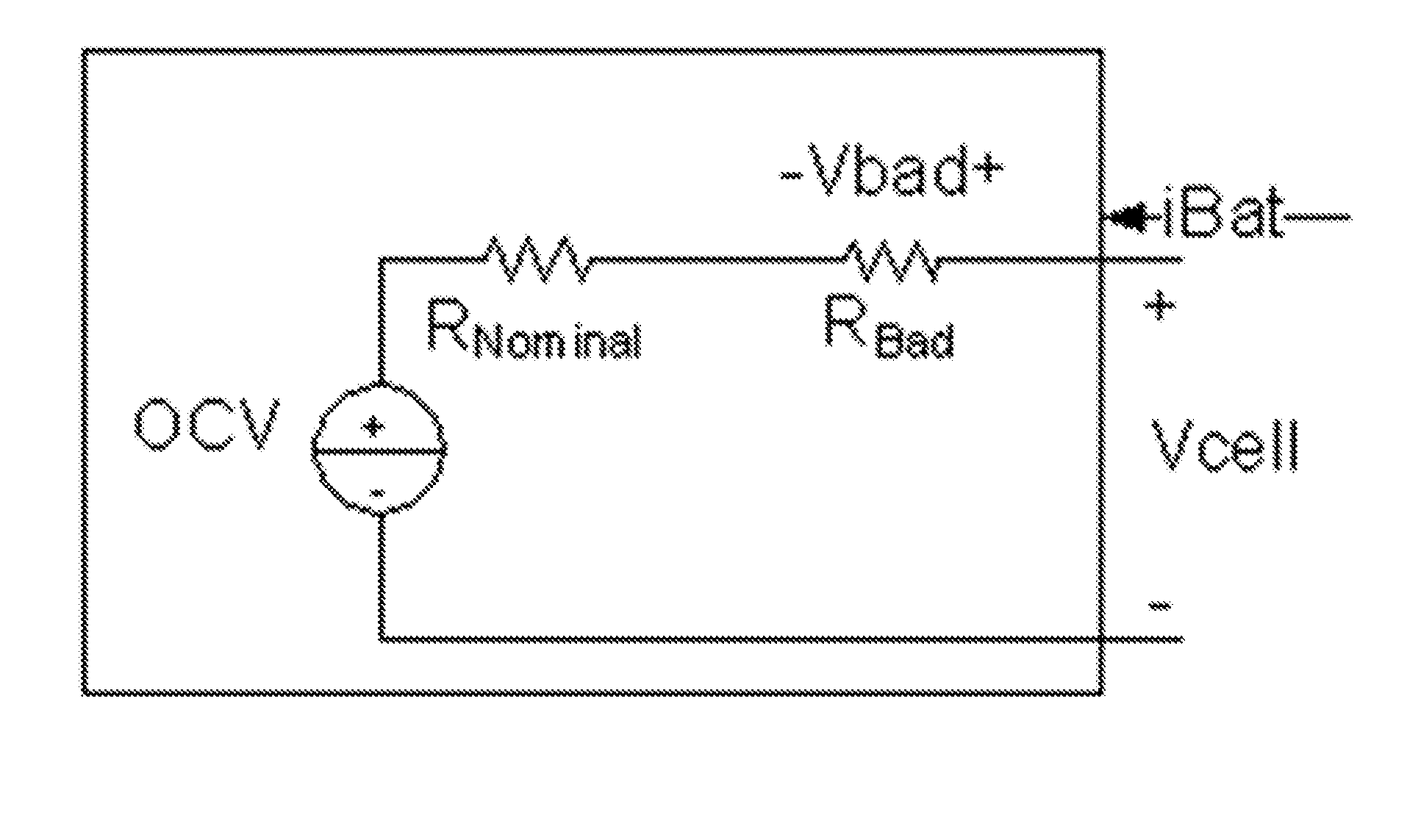

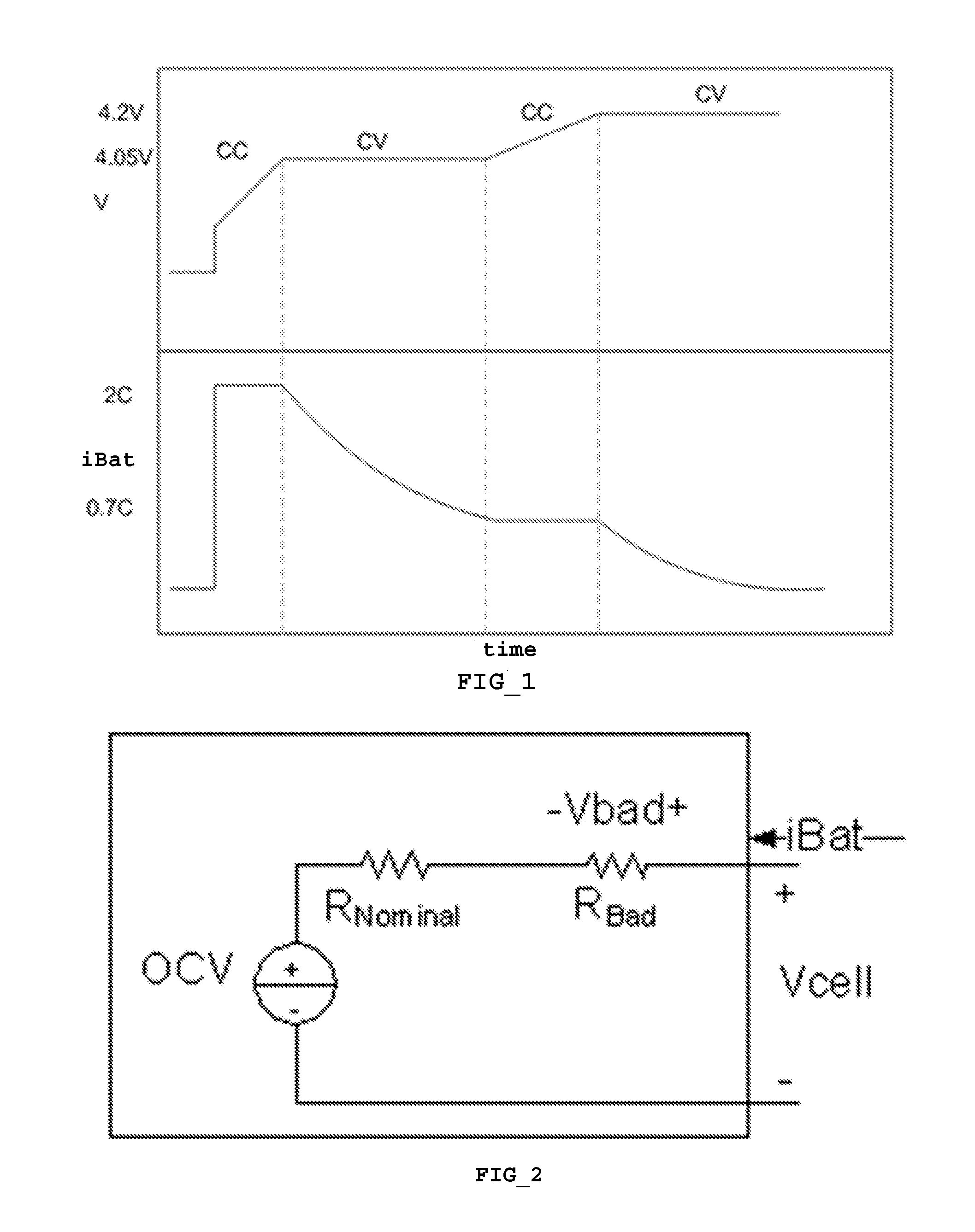

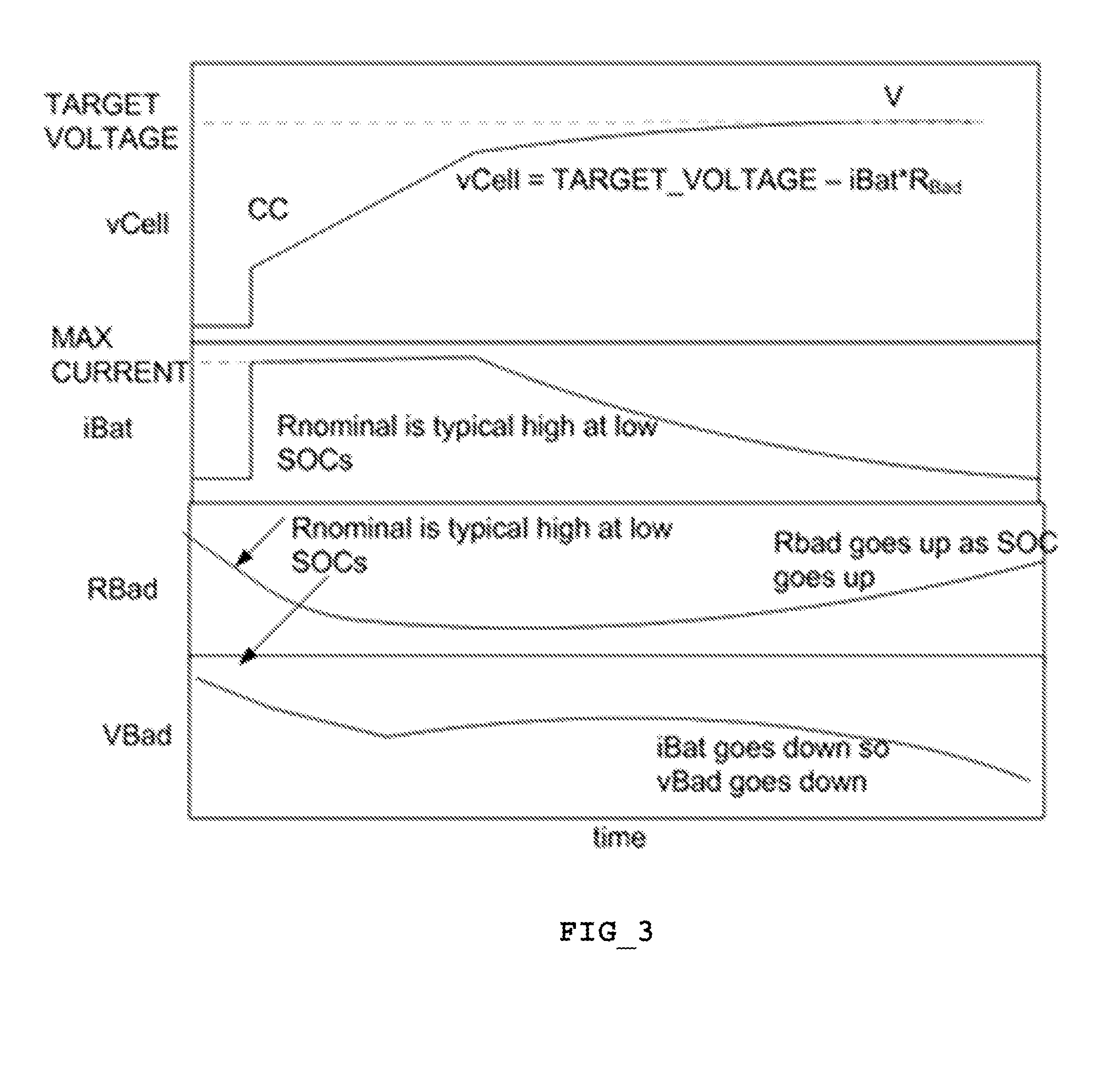

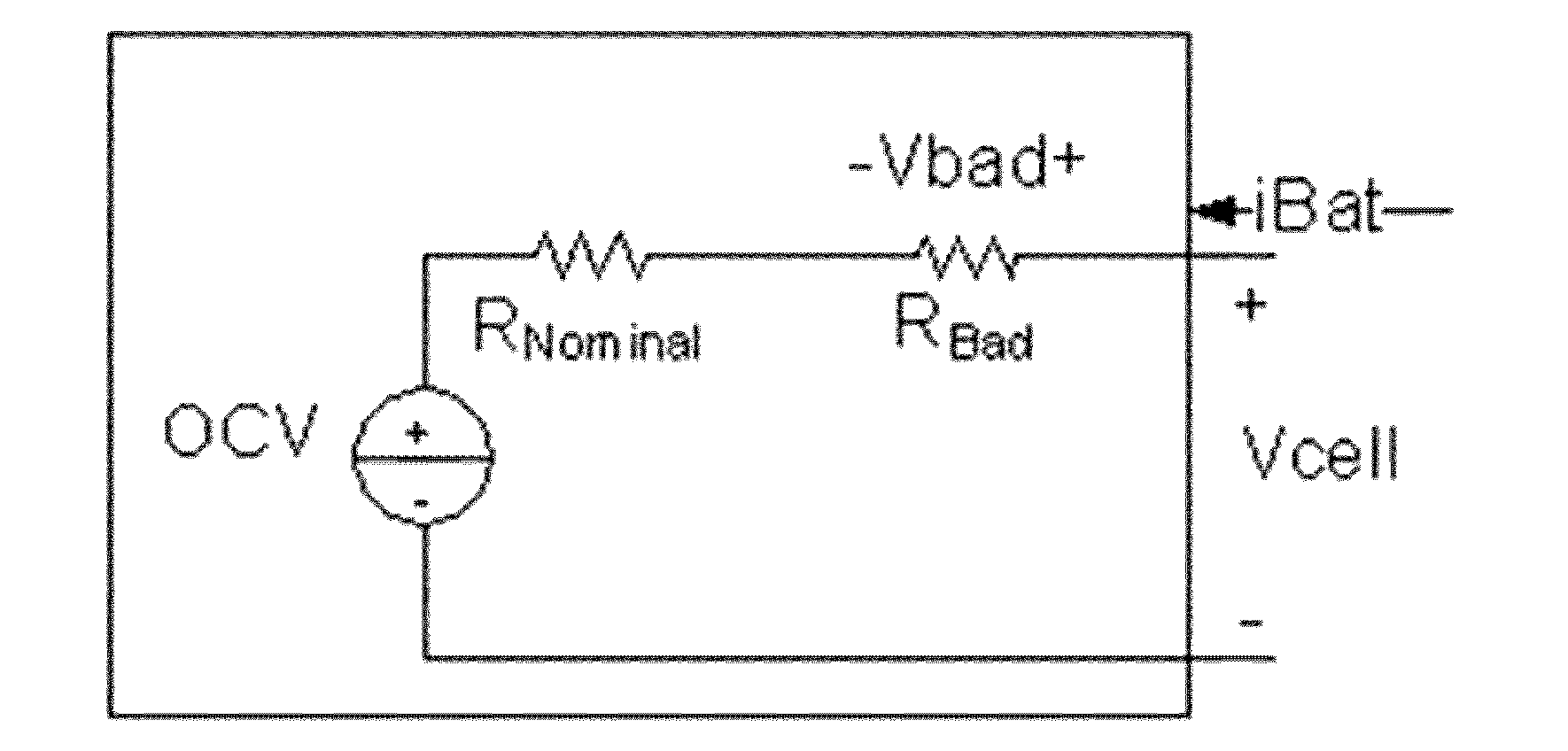

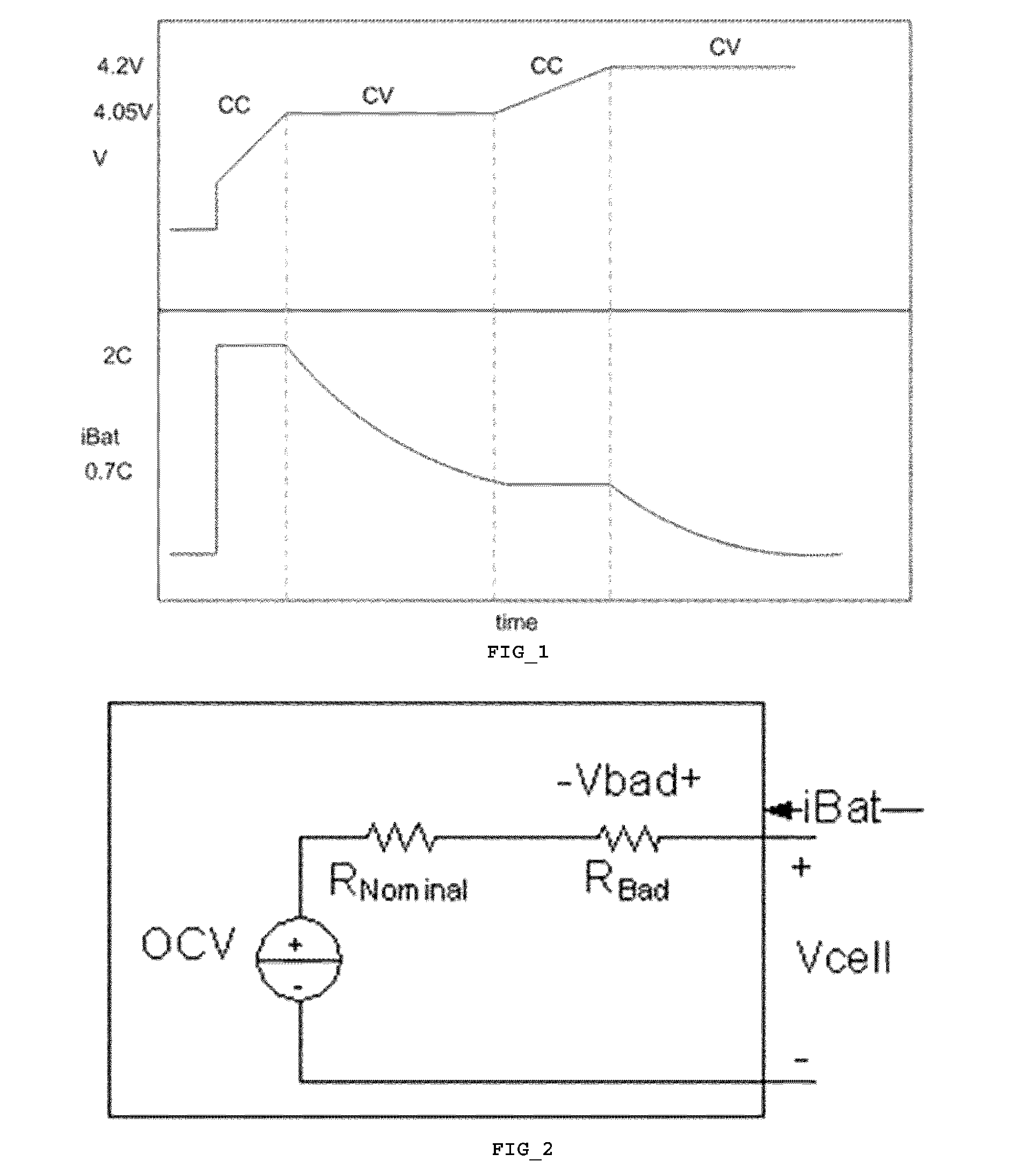

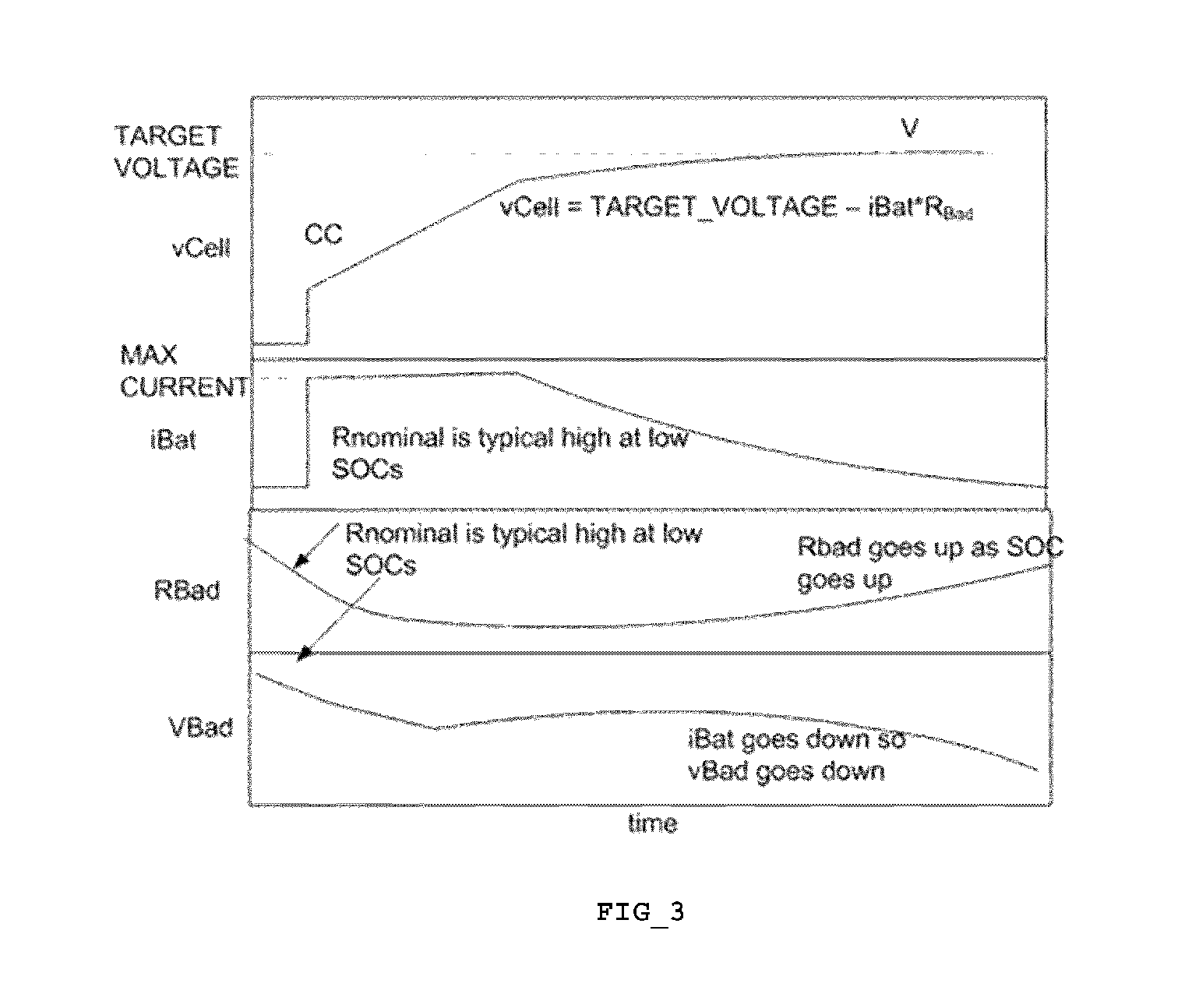

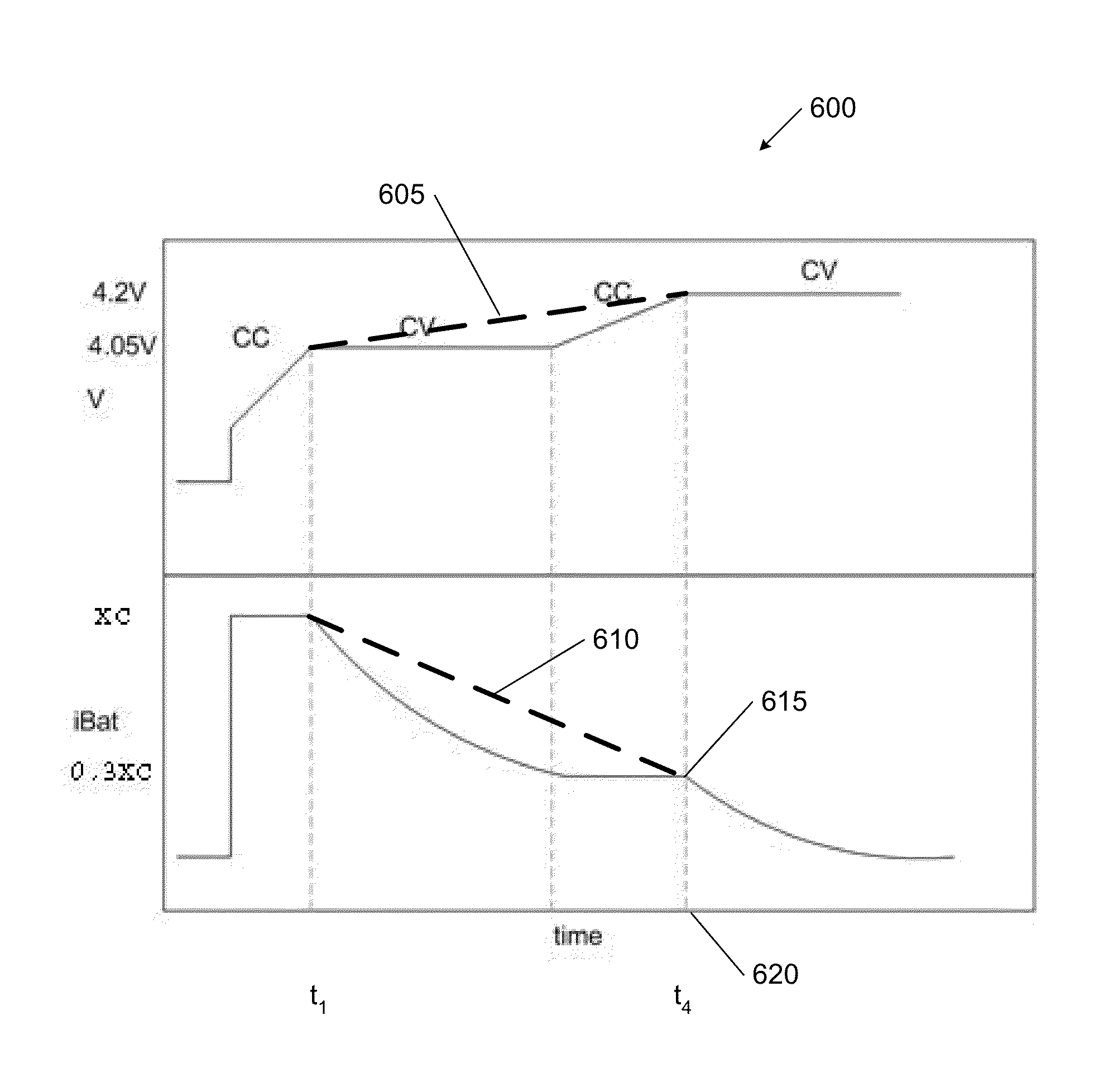

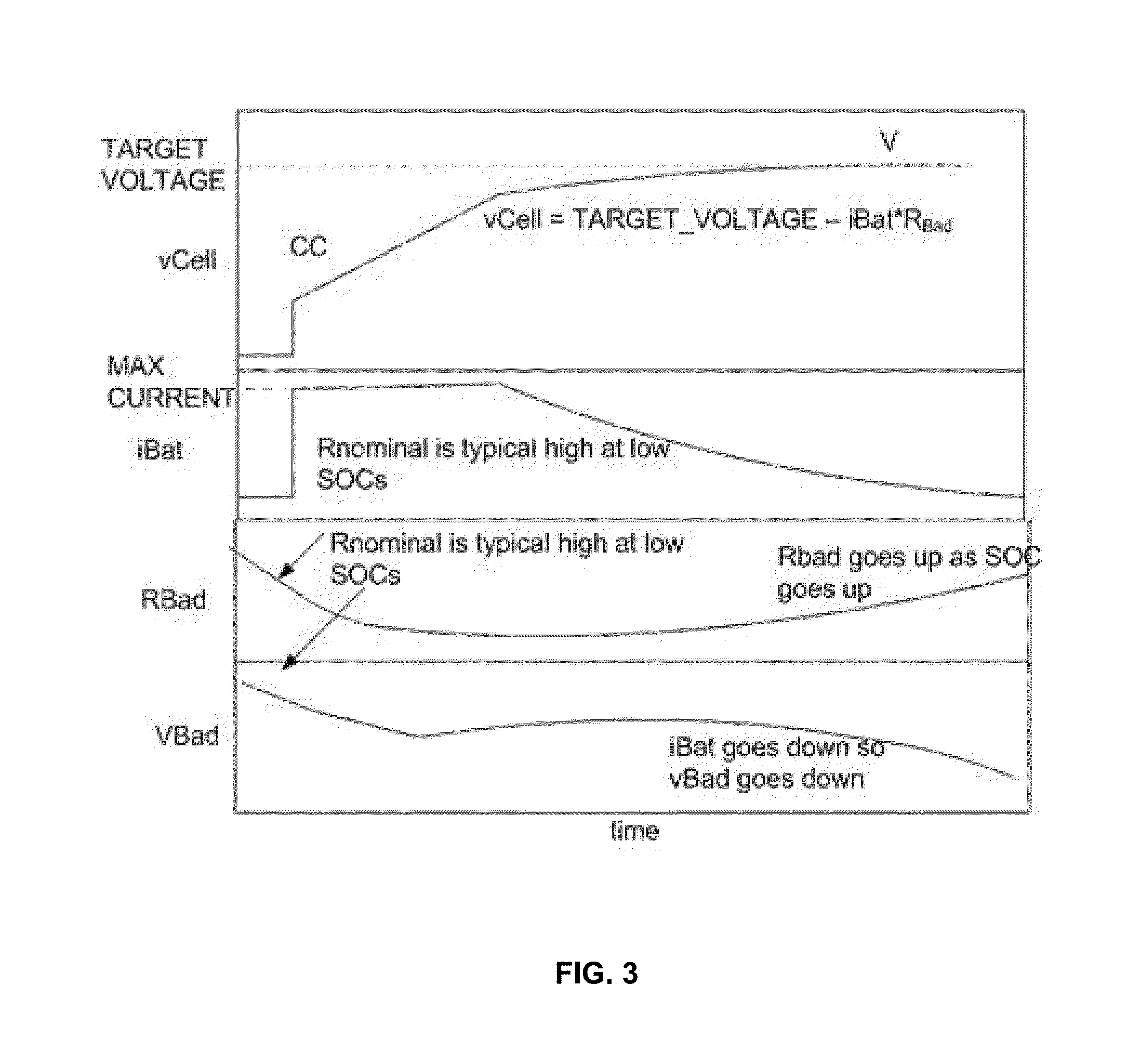

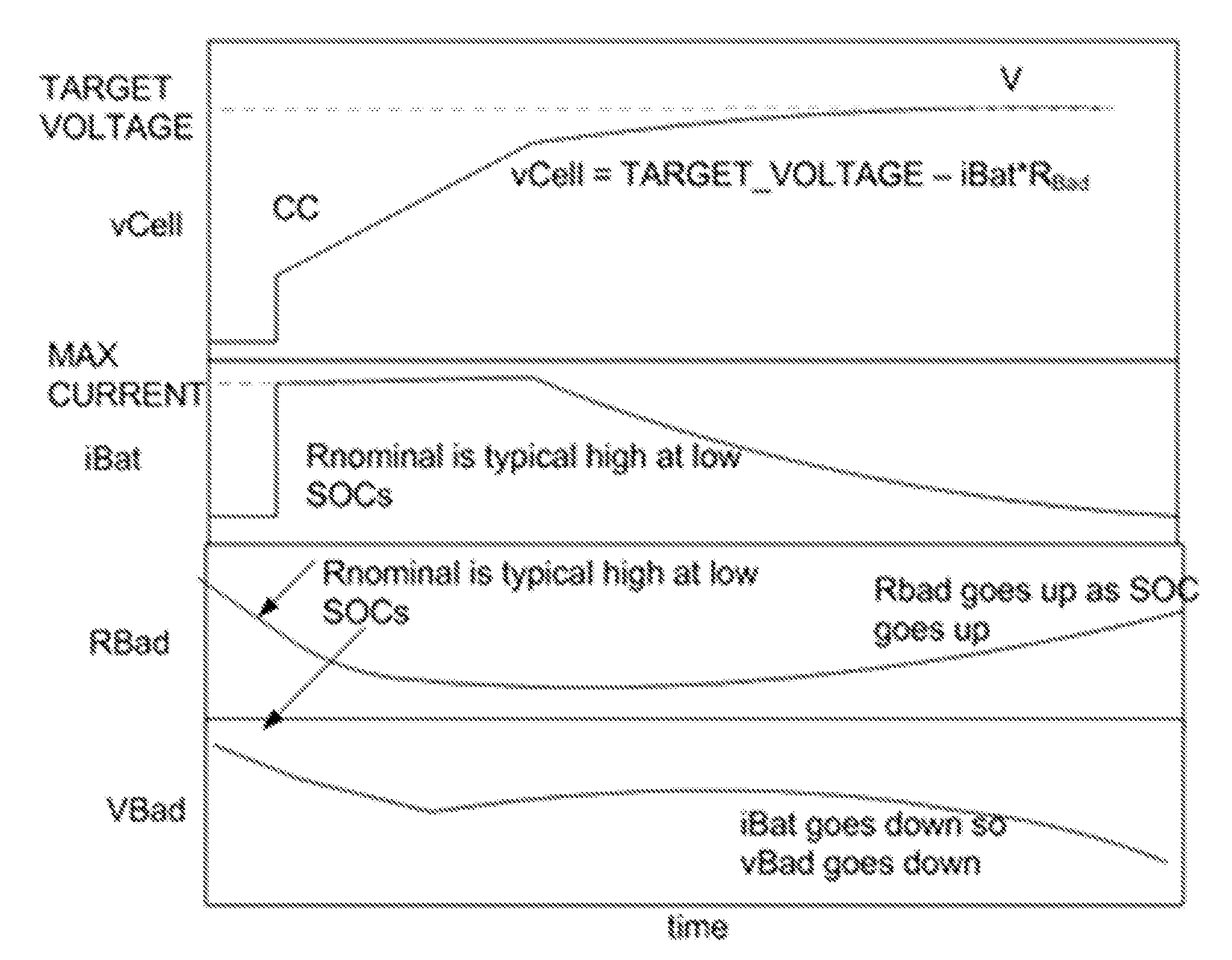

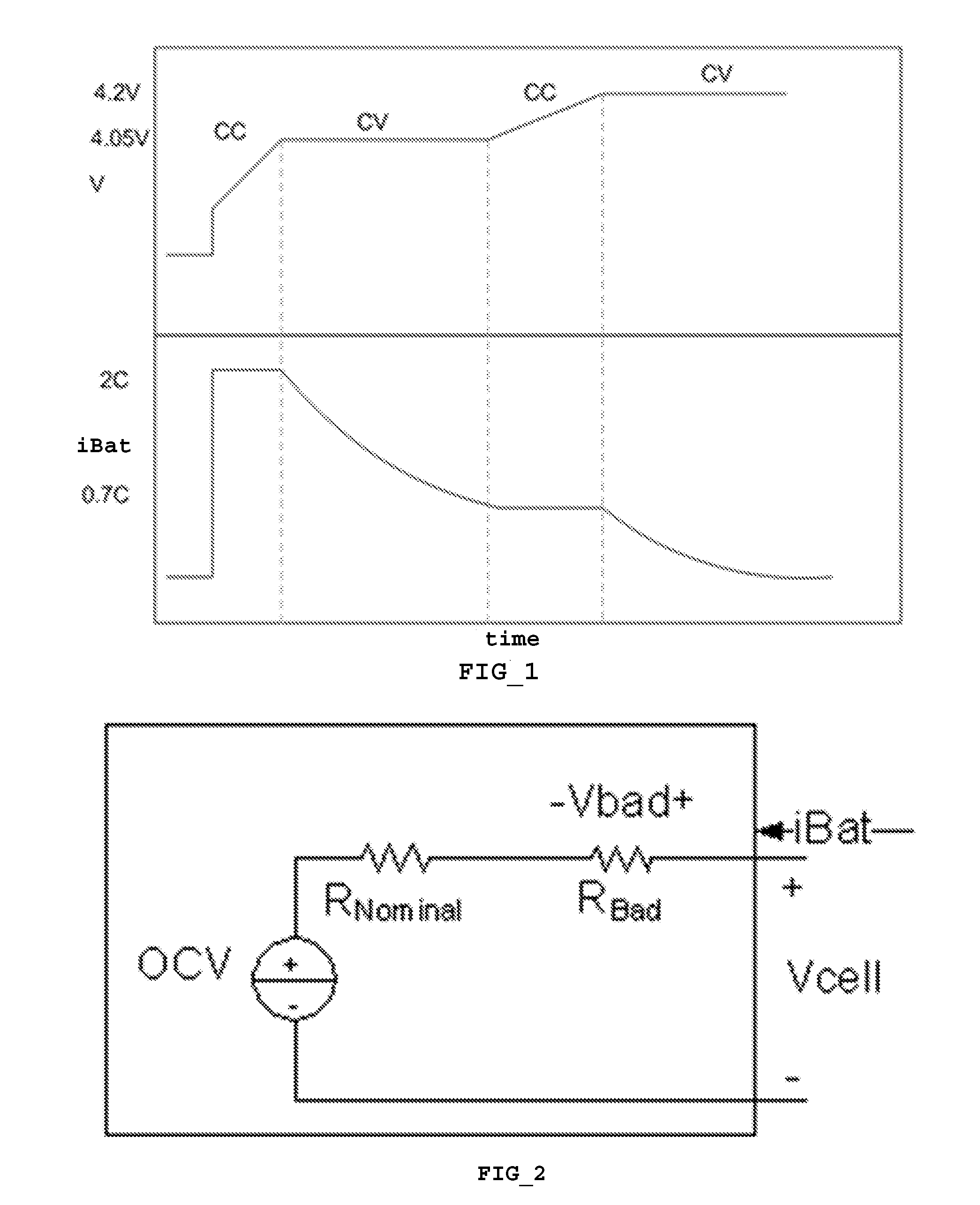

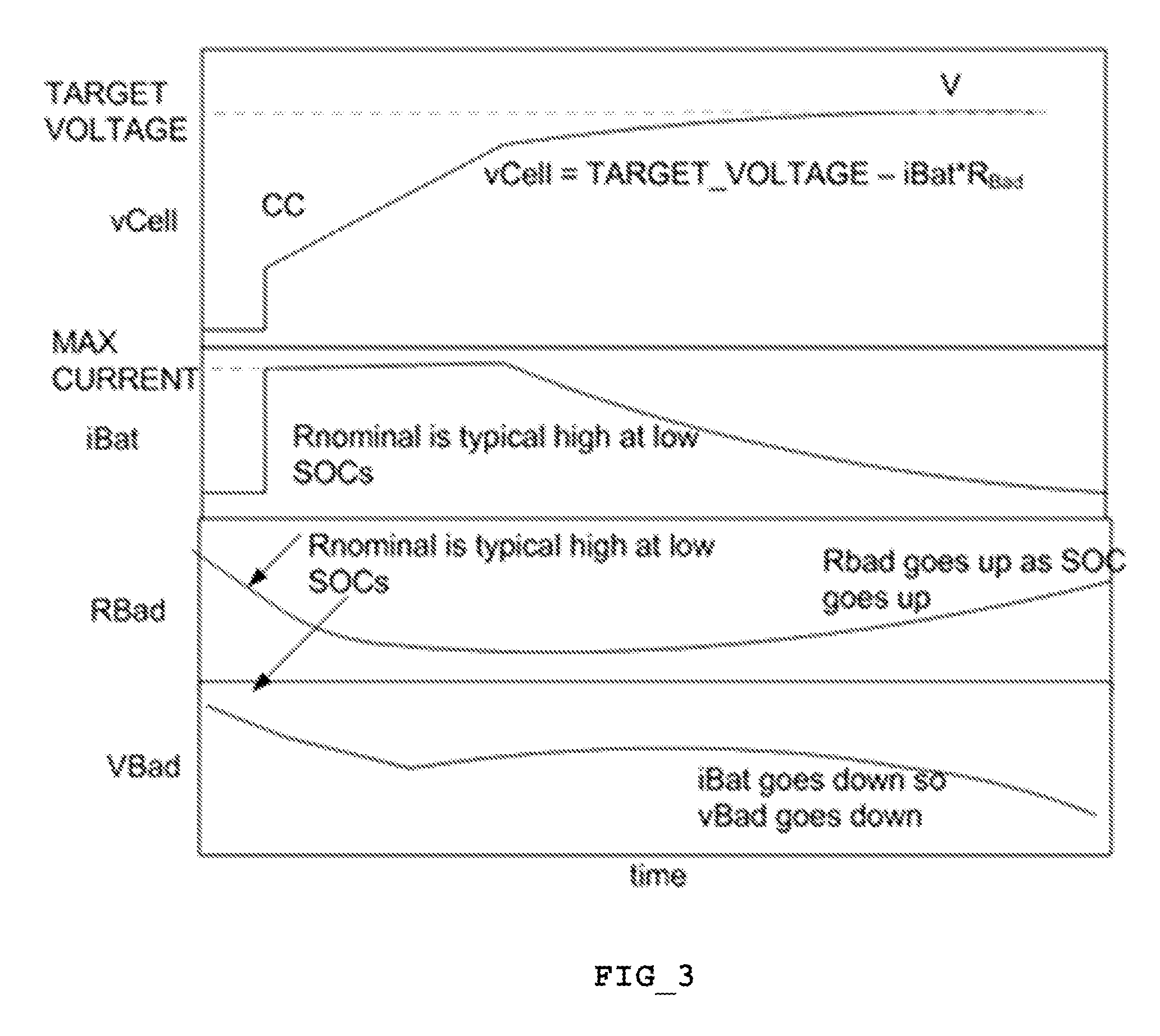

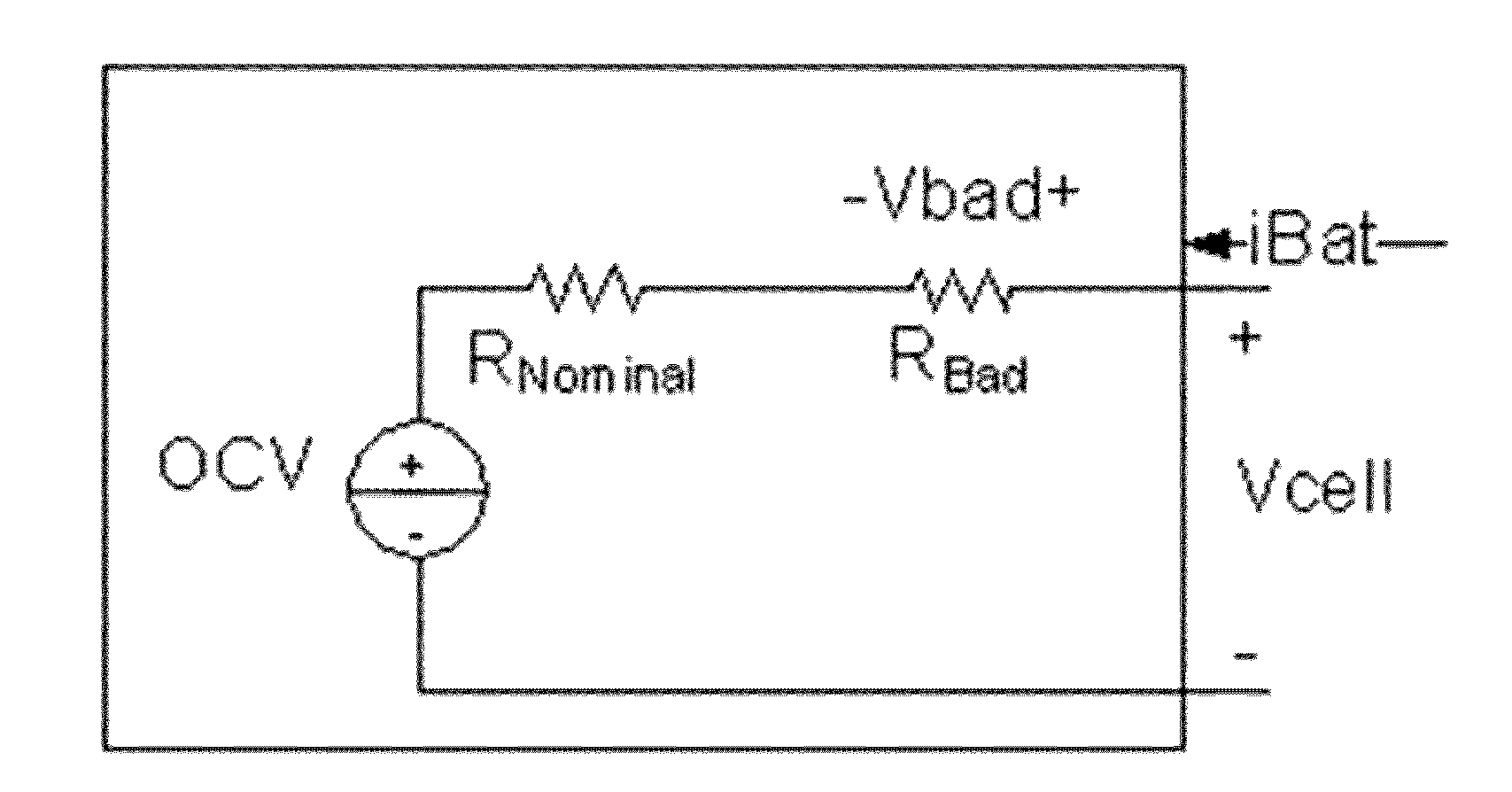

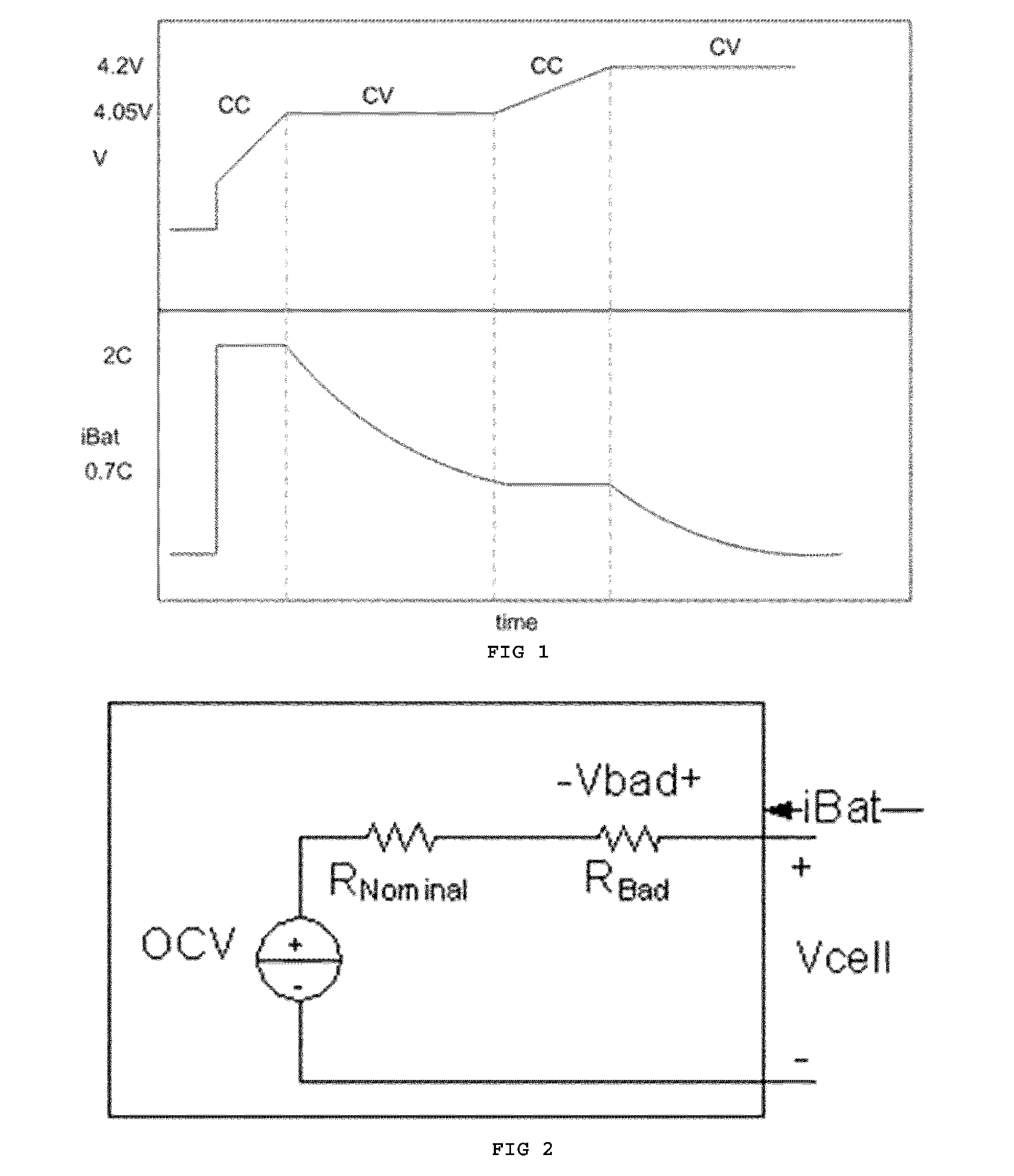

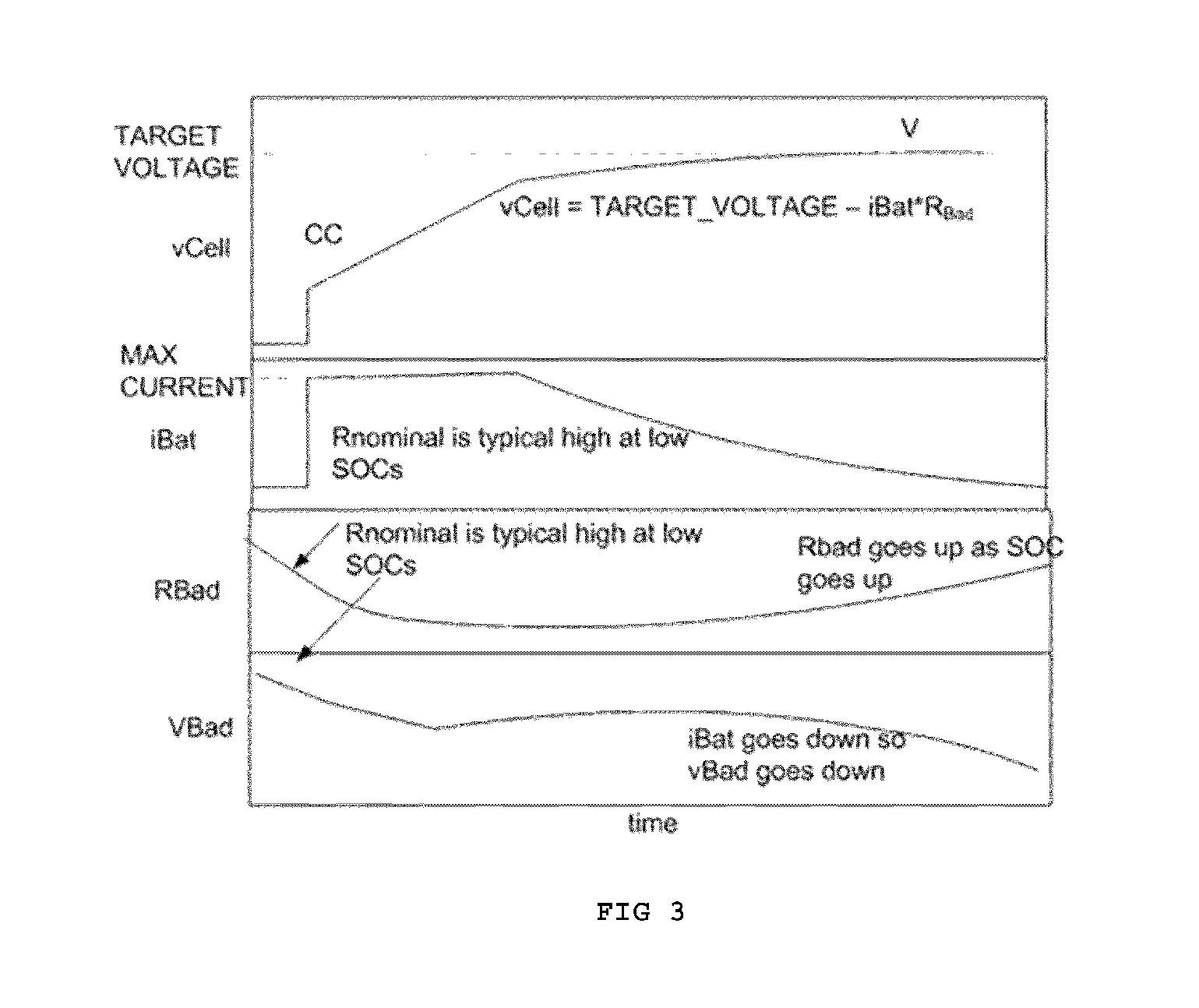

Fast charging with negative ramped current profile

ActiveUS20110156661A1Shorten the timeFast chargingBatteries circuit arrangementsElectric powerPower flowCharge current

A battery cell charging system, including a charger and a controller, for rapidly charging a lithium ion battery cell, the battery cell charging system having a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile includes: a first charging stage with a constant first stage charging current and an increasing battery cell voltage with the first stage charging current provided until the first stage charging voltage is about equal to a first stage complete voltage less than a maximum battery cell voltage; an intermediate ramped charging stage, the intermediate ramped charging stage including both an increasing ramped voltage and a decreasing ramped iBat current for the battery cell for the voltage charging range of the first stage complete voltage to about the maximum battery cell voltage; and a final charging stage with a constant final stage charging voltage about equal to the maximum battery cell voltage and a decreasing final stage charging current with the final stage charging voltage provided until the final stage charging current reaches a desired charge complete level.

Owner:TESLA INC

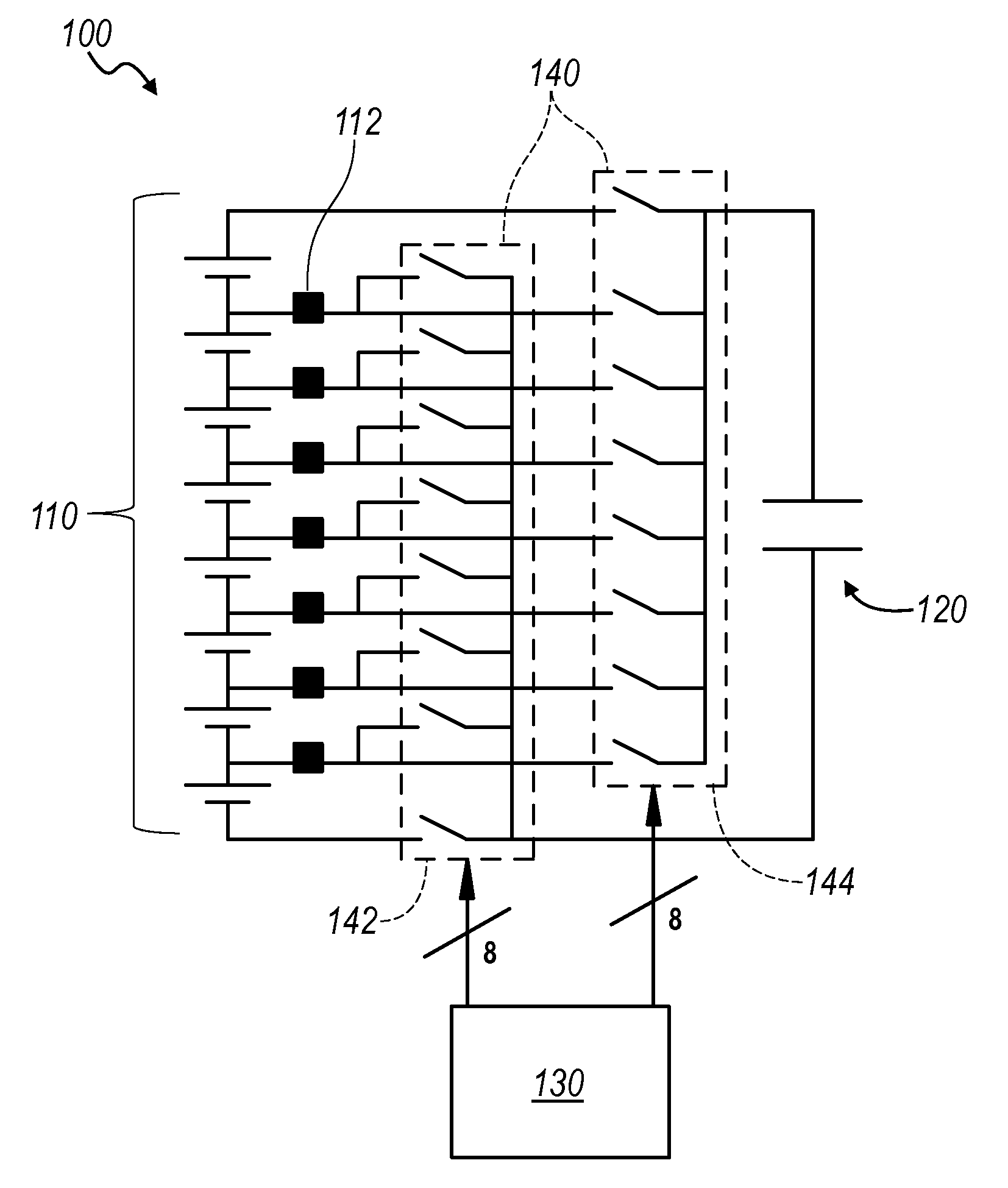

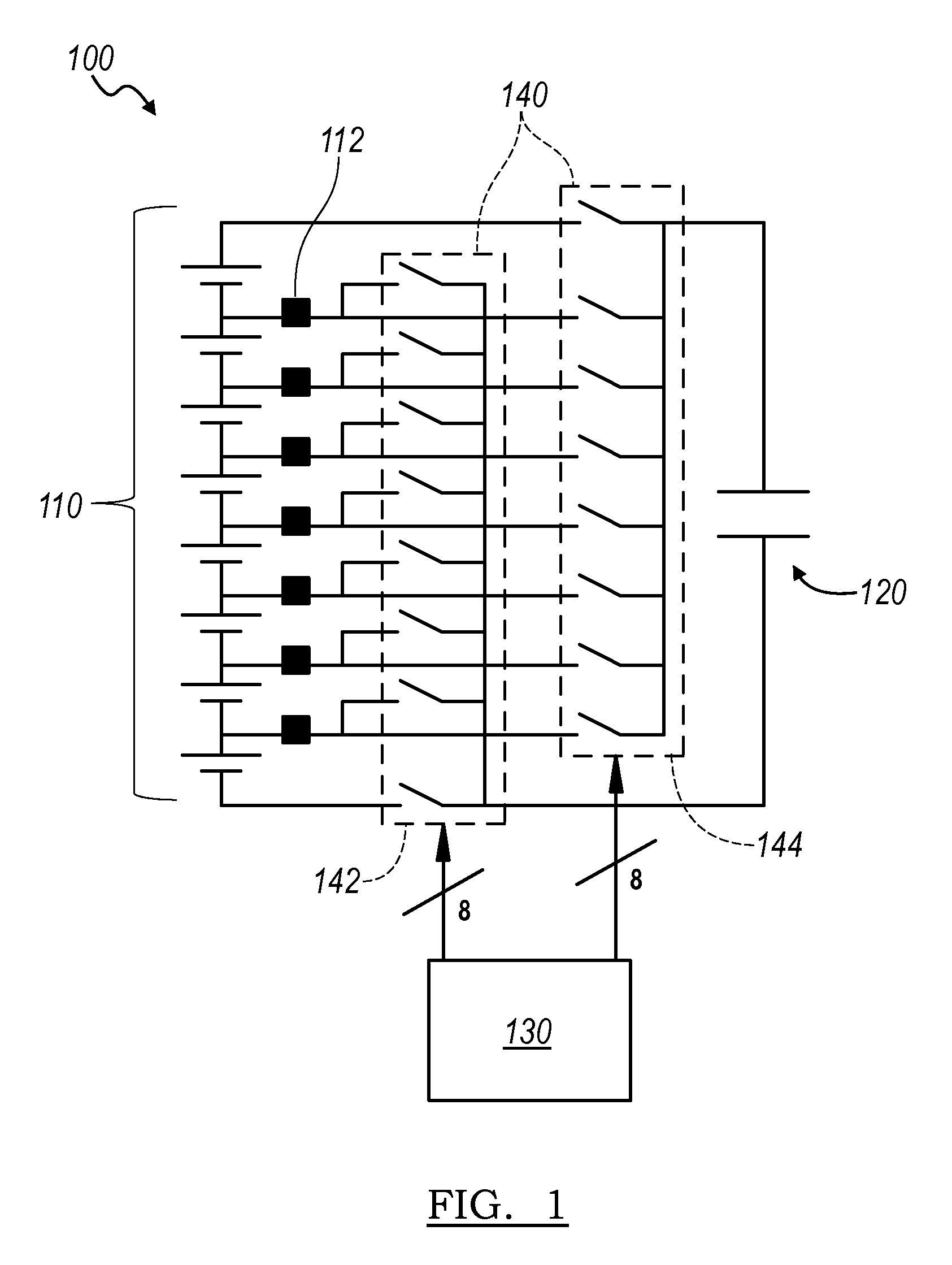

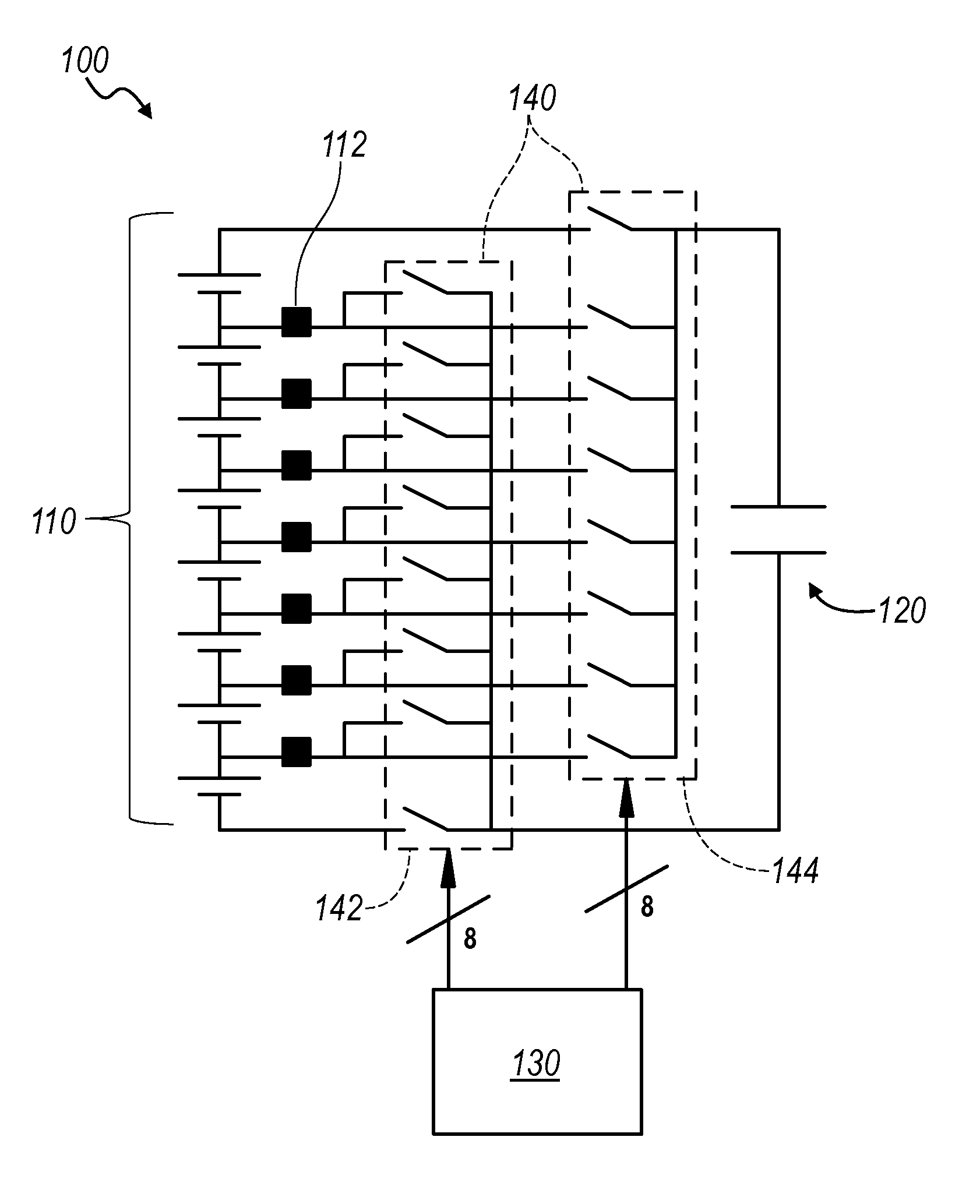

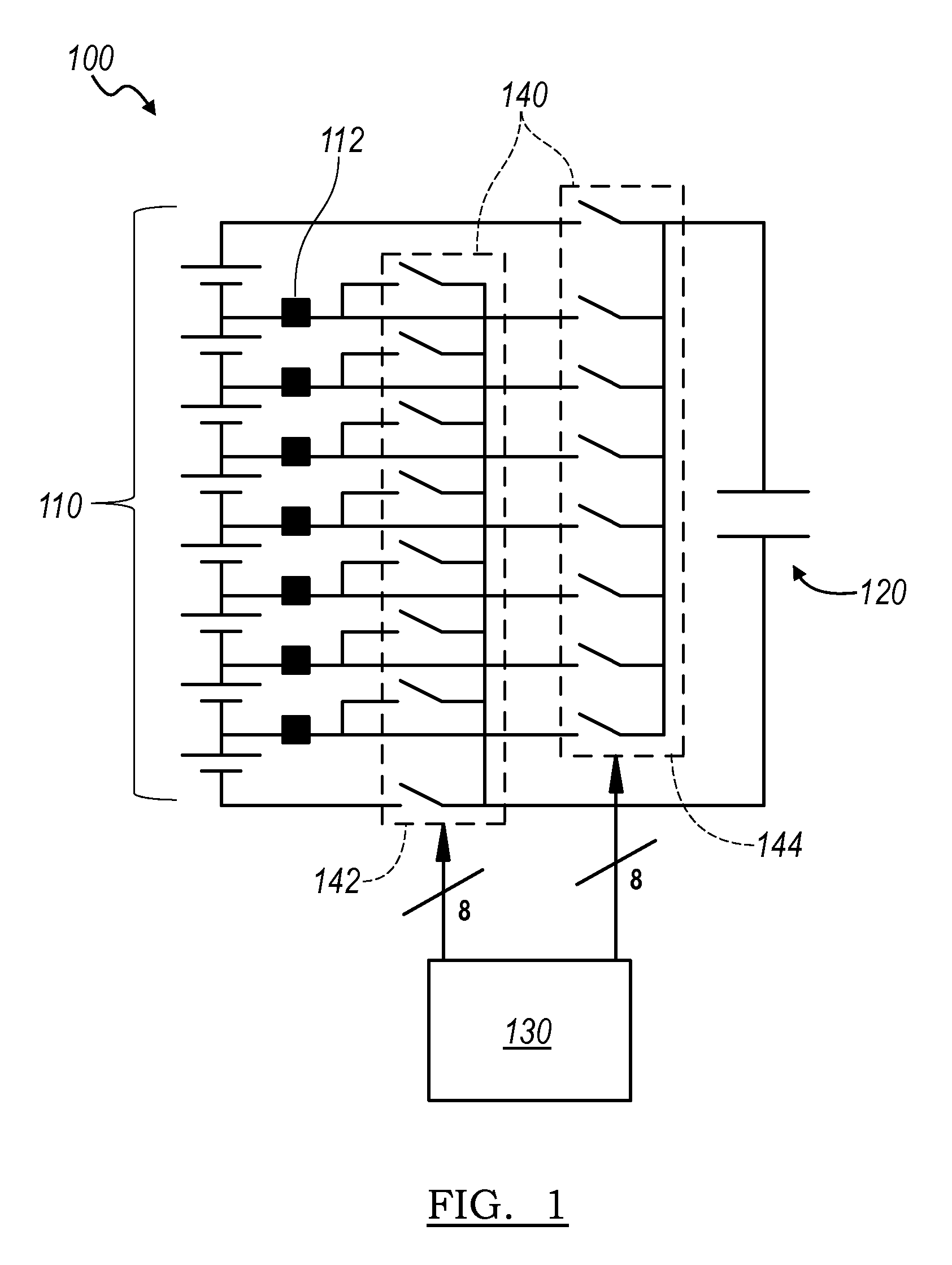

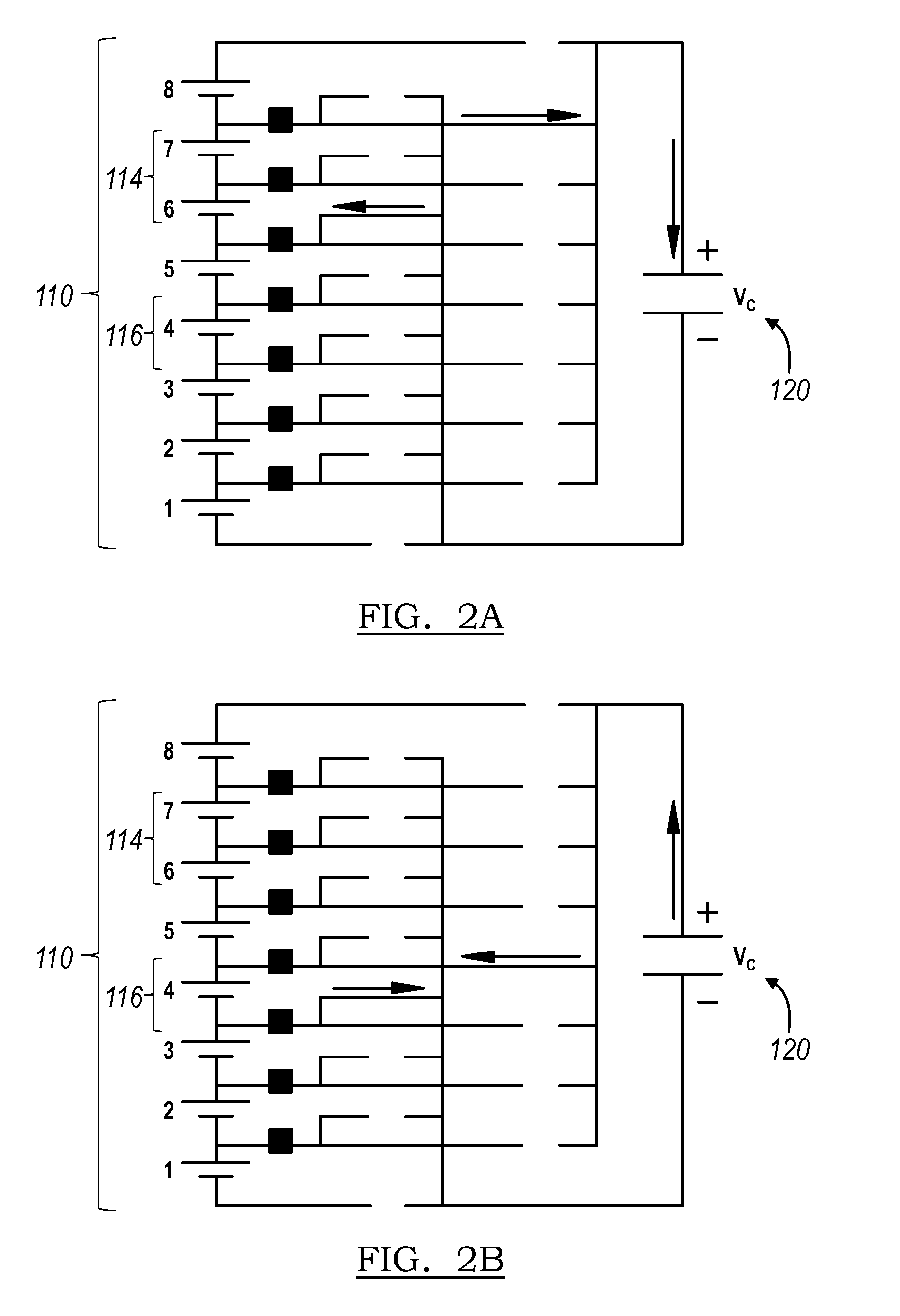

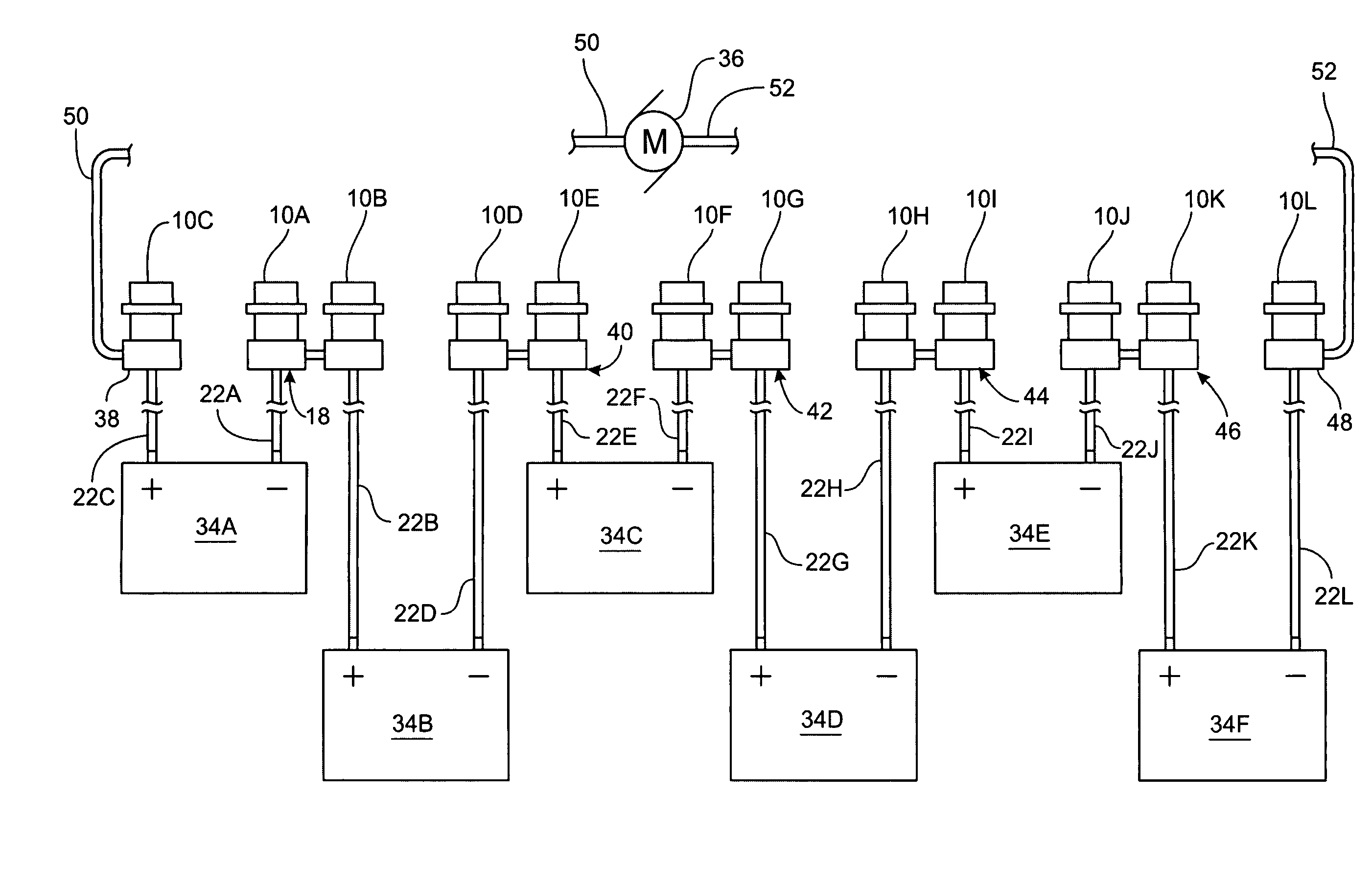

System and Method for Balancing Charge Within a Battery Pack

ActiveUS20100237830A1Increasing initial charge rateFast chargingCharge equalisation circuitElectric powerDonor cellBattery pack

A system for balancing charge within a battery pack with a plurality of cells connected in series, including a capacitor; a processor configured to select a combination of donor cells and receiver cells from the plurality of cells in one of the following two modes: (1) a first mode where the number of donor cells is equal to the number of receiver cells, and (2) a second mode where the number of donor cells is greater than the number of receiver cells; and a plurality of switches that electrically connect the capacitor to the donor cells to charge the capacitor, and that electrically connected the capacitor to the receiver cells to discharge the capacitor. The transfer of charge between cells in the plurality of cells through the capacitor balances the charge within the battery pack.

Owner:MOTIV POWER SYST

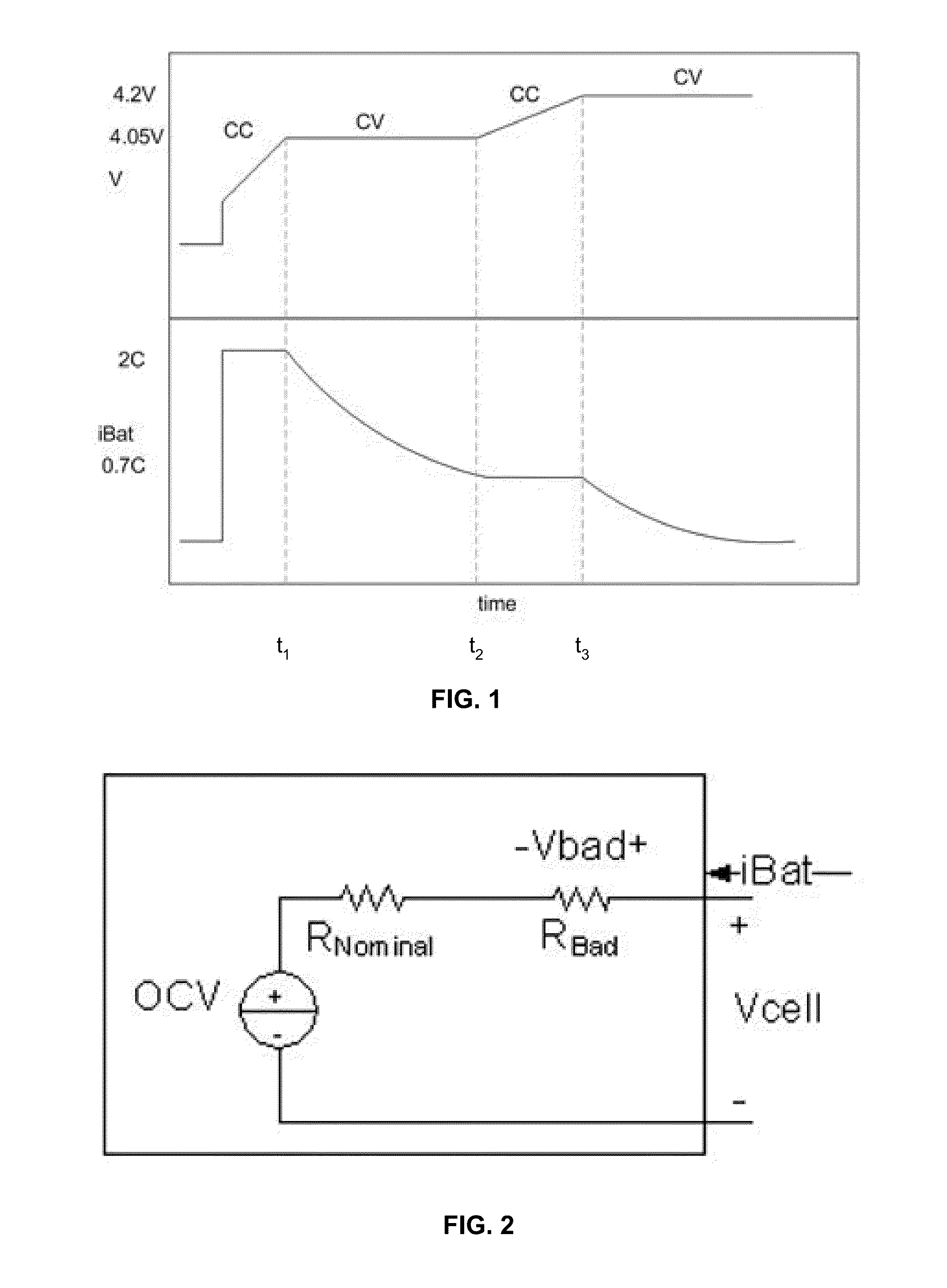

Fast charging of battery using adjustable voltage control

ActiveUS20110012563A1Shorten charging timeReducing/eliminating impactSecondary cells charging/dischargingElectric powerFast chargingEngineering

A battery cell charger for rapidly charging a lithium ion battery cell (or string of series-parallel connected cells) having a maximum battery cell voltage the battery cell charging system including: a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile includes: a first charging stage with a constant first stage charging current and an increasing battery cell voltage with the first stage charging current provided until the first stage charging voltage is about equal to a first stage complete voltage less than the maximum battery cell voltage; one or more intermediate charging stages, each intermediate stage selected from the group consisting of one or more of an intermediate constant voltage stage that provides a decreasing charging current, an intermediate constant current stage that produces an increasing battery cell voltage, and combinations thereof; and a final charging stage with a constant final stage charging voltage about equal to an intermediate stage complete voltage and a decreasing final stage charging current with the final stage charging voltage provided until the final stage charging current reaches a desired charge complete level.

Owner:TESLA INC

Low temperature charging of li-ion cells

ActiveUS20110012562A1Reduce charging currentIncrease charging rateBatteries circuit arrangementsElectric powerCharge currentCelsius Degree

A battery cell charging system, including a charger and a controller, for low-temperature (below about zero degrees Celsius) charging a lithium ion battery cell, the battery cell charging system includes: a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile having: a non-low-temperature charging stage for charging the battery cell using a charging profile adapted for battery cell temperatures above about zero degrees Celsius; and a low-temperature charging stage with a variable low-temperature stage charging current that decreases responsive to a battery cell temperature falling below zero degrees Celsius.

Owner:TESLA INC

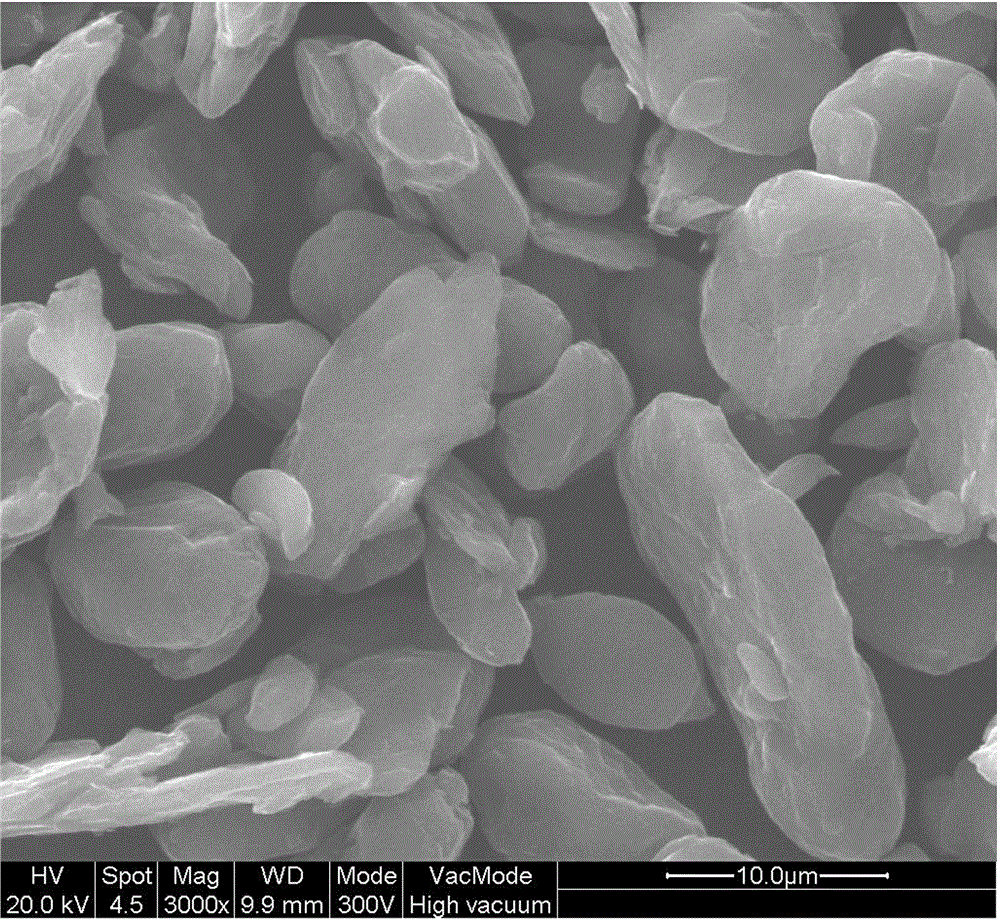

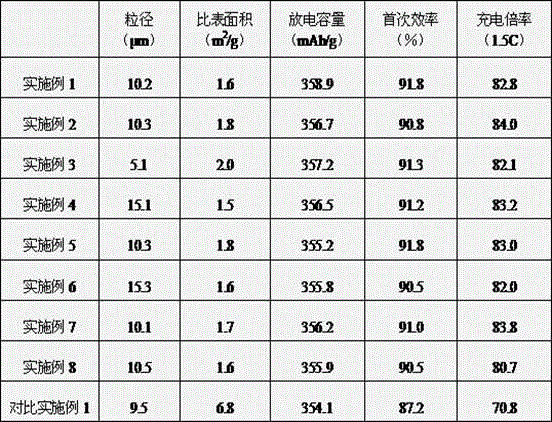

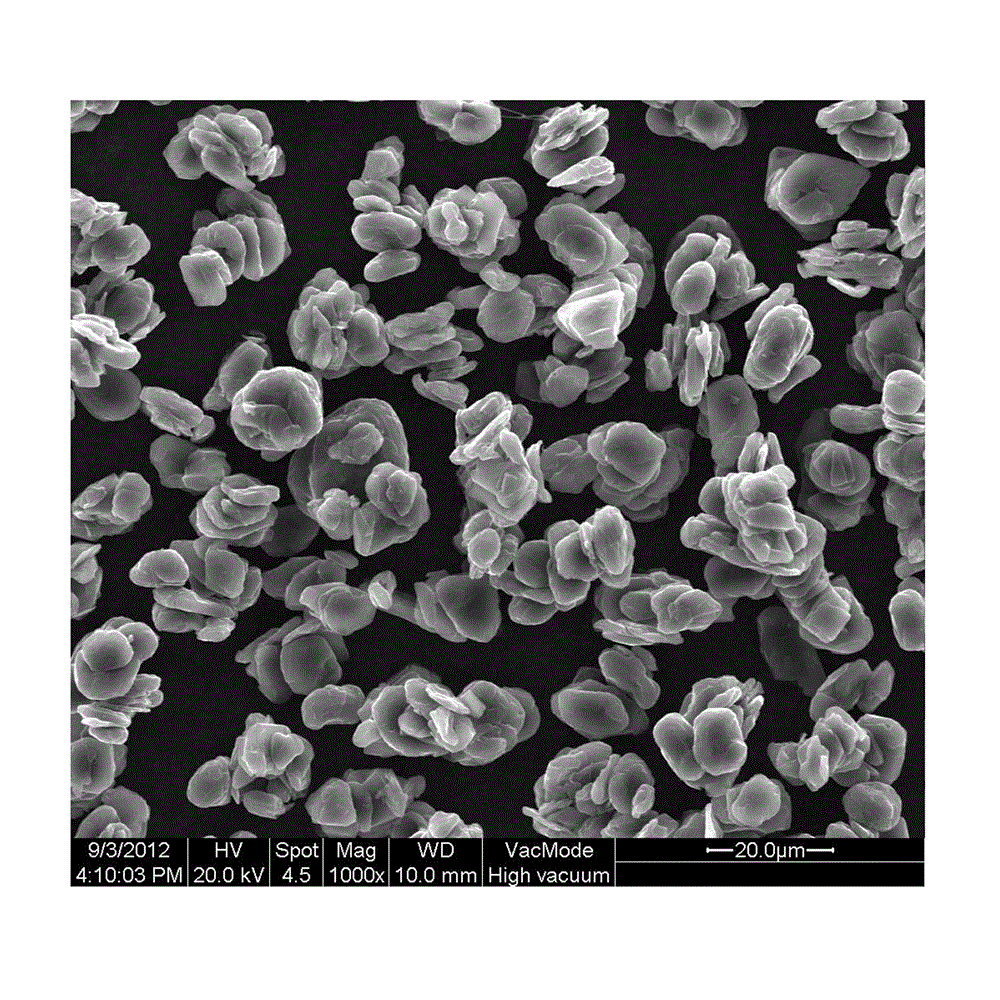

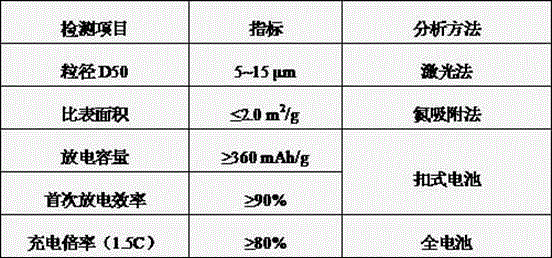

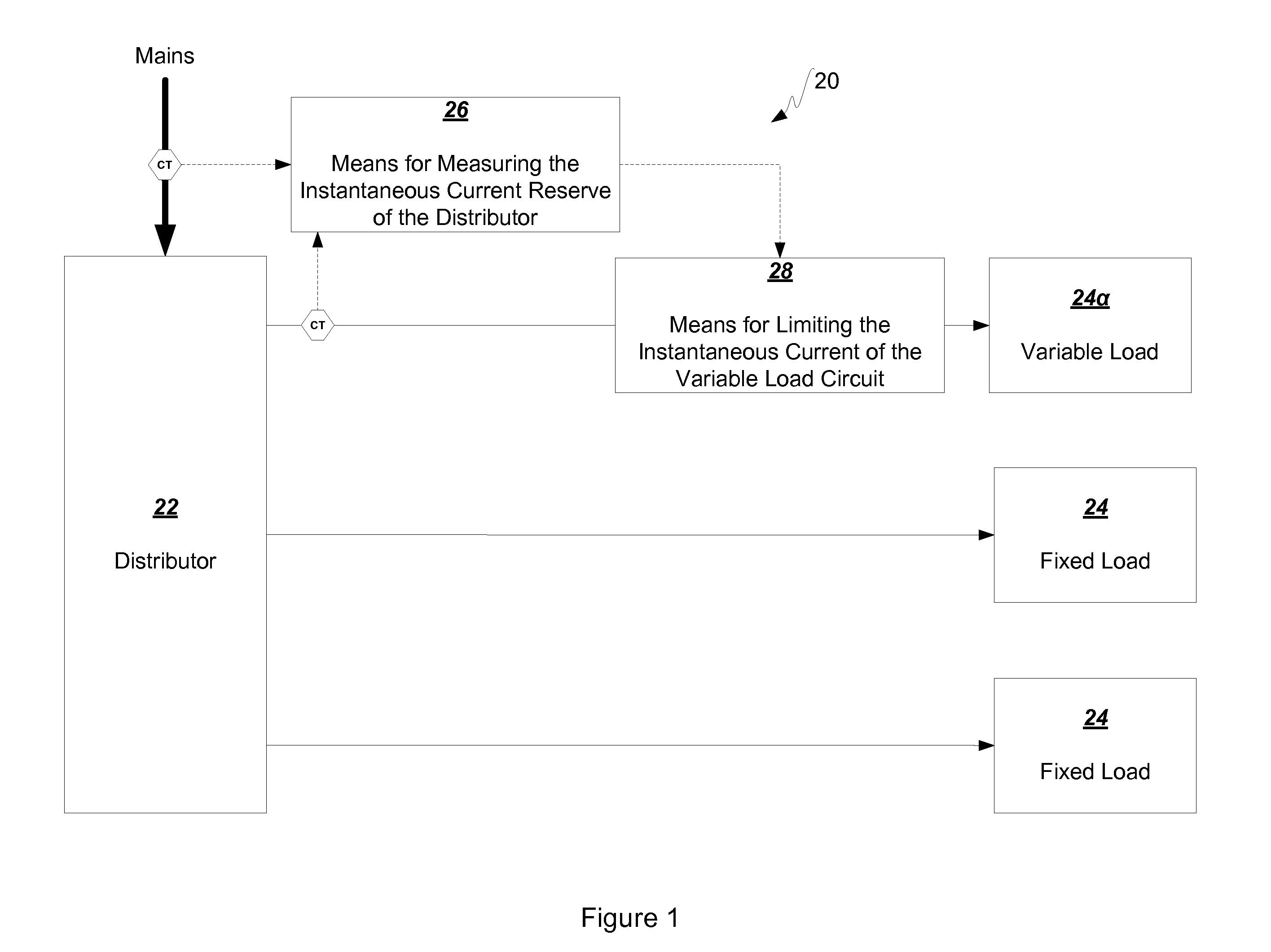

Negative electrode material for quickly rechargeable graphite lithium-ion battery and preparation method of negative electrode material

InactiveCN105024075ASmall specific surface areaIncrease charging rateCell electrodesSecondary cellsDischarge efficiencyElectrical battery

The invention discloses a negative electrode material for a quickly rechargeable graphite lithium-ion battery and a preparation method of the negative electrode material. The preparation method of the negative electrode material for the quickly rechargeable graphite lithium-ion battery comprises the following steps: (1) mixing a mixture containing a graphite precursor and bitumen and heating the mixture for kneading and crushing, wherein the mean grain size D50 of the graphite precursor ranges from 5 to 10 microns, and the mass ratio of the graphite precursor to the bitumen ranges from 50:50 to 90:10; (2) performing heat treatment at a temperature within the range of 300-700 DEG C under the protection of an inert gas; and (3) carrying out graphitizing. The mean grain size D50 of the negative electrode material prepared by use of the preparation method for the quickly rechargeable graphite lithium-ion battery is within the range of 5-15 microns and the specific surface area of the negative electrode material is below 2.0m2 / g; the first discharge capacity of a negative electrode, manufactured by use of the negative electrode material for the quickly rechargeable graphite lithium-ion battery, is more than 355mAh / g, and the initial charge-discharge efficiency of the battery is above 90%; if the battery is quickly charged (1.5C) for 45 minutes, the capacity of the battery can be above 80%; in short, the product is high in discharge capacity and charge / discharge efficiency, and good in rate capability. The invention also relates to a battery comprising the negative electrode material for the quickly rechargeable graphite lithium-ion battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

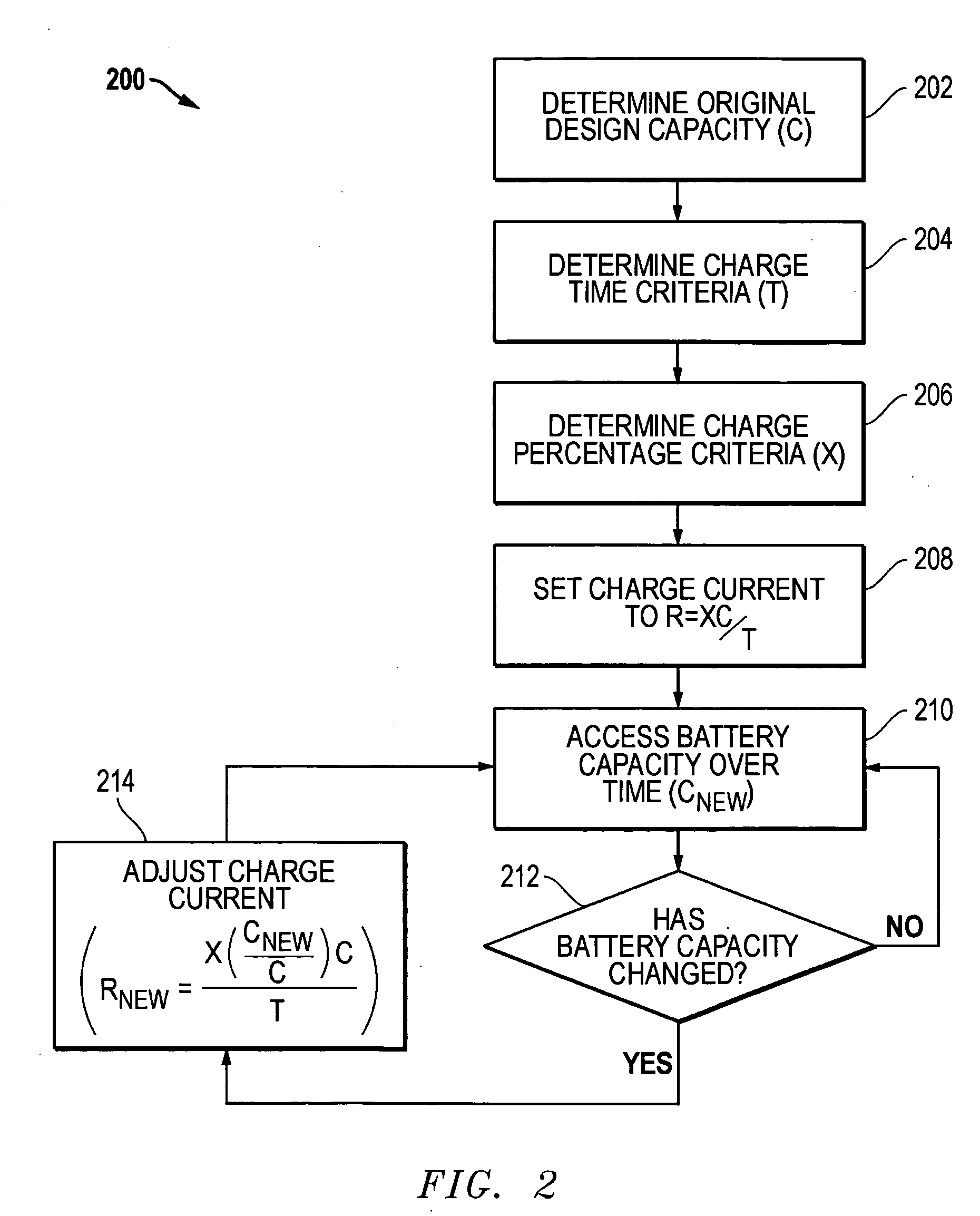

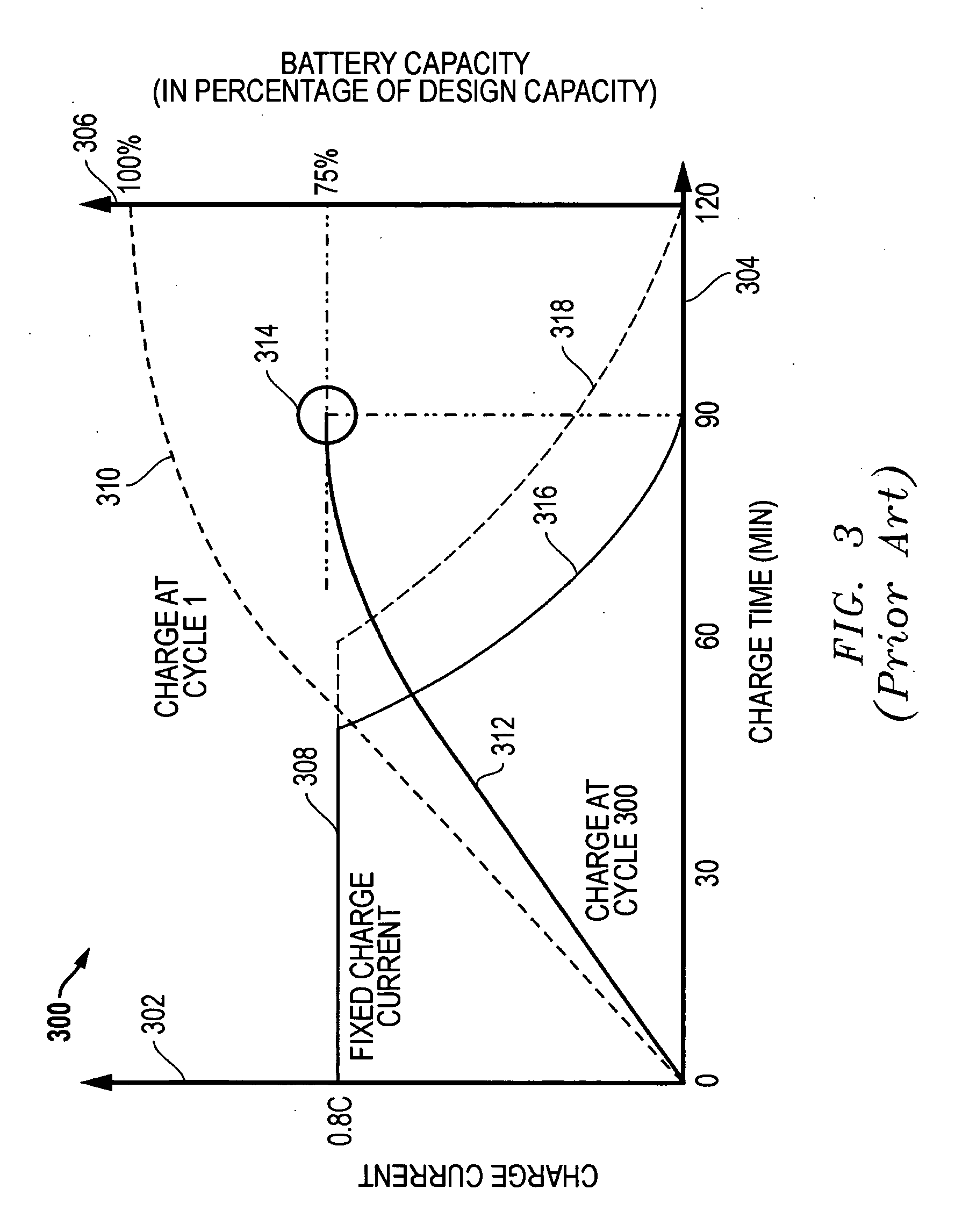

Method and system for charge rate adjustment to enhance battery cycle life

ActiveUS20070139008A1Enhances capacity lifeEnhance battery cycle lifeElectric powerBattery load switchingElectric vehicleCharge rate

Methods and systems are disclosed for charge current adjustment to enhance battery cycle life thereby allowing batteries to be charged quickly without accelerating the aging process of the battery. As the charge capacity of the battery degrades over time, the charge current for the battery charging cycles is also reduced so that the effective charge rate for the battery is adjusted to account for the reduction in charge capacity. In this way, battery capacity life is enhanced by avoiding an accelerated charge rate as the battery capacity drops over the operational life of the battery. The methods and systems disclosed are useful for battery-powered information handling systems, as well as other devices where fast charging and long cycle life is desirable, such as cell phones, personal digital assistants (PDAs), electric vehicles and / or any other battery powered devices.

Owner:DELL PROD LP

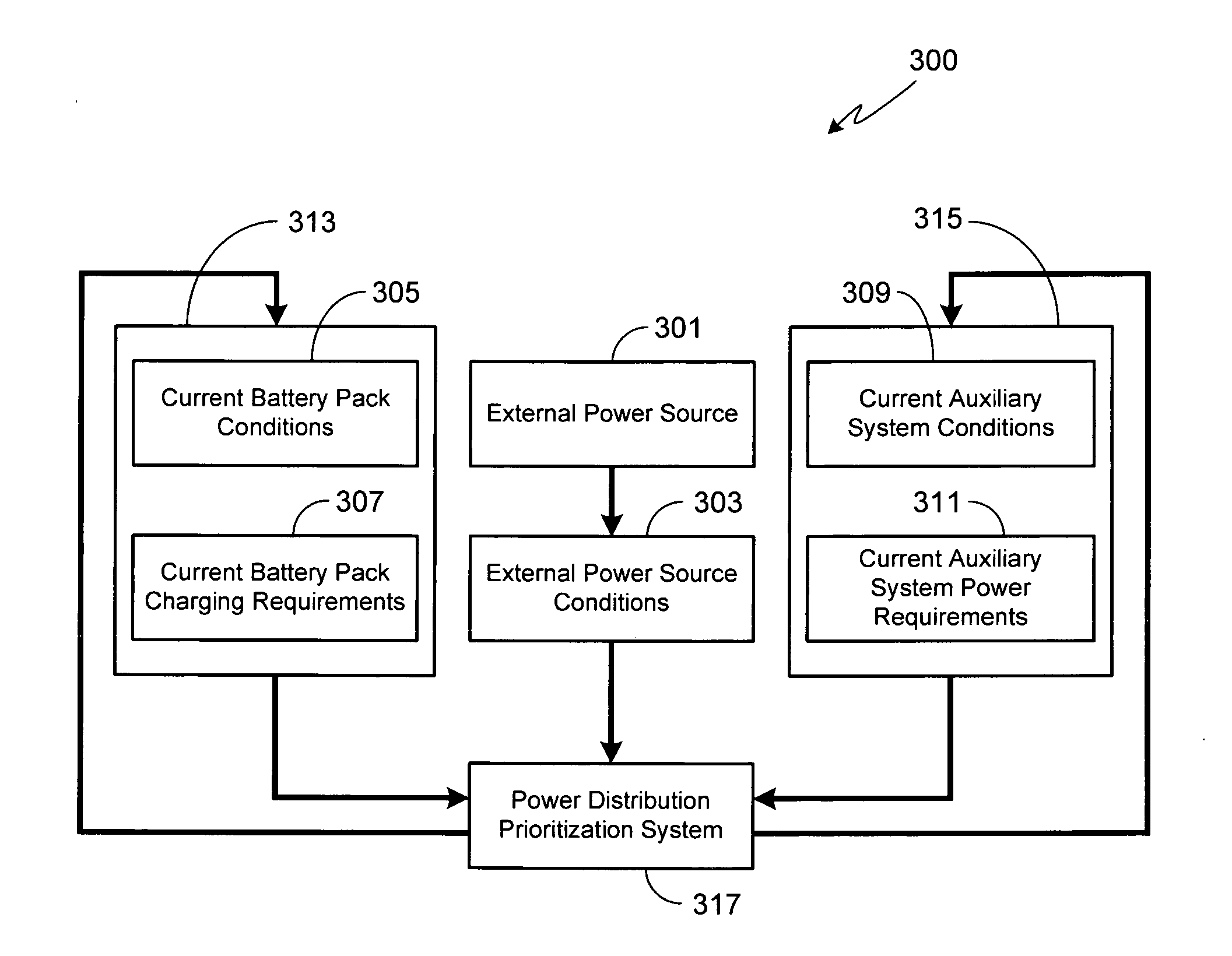

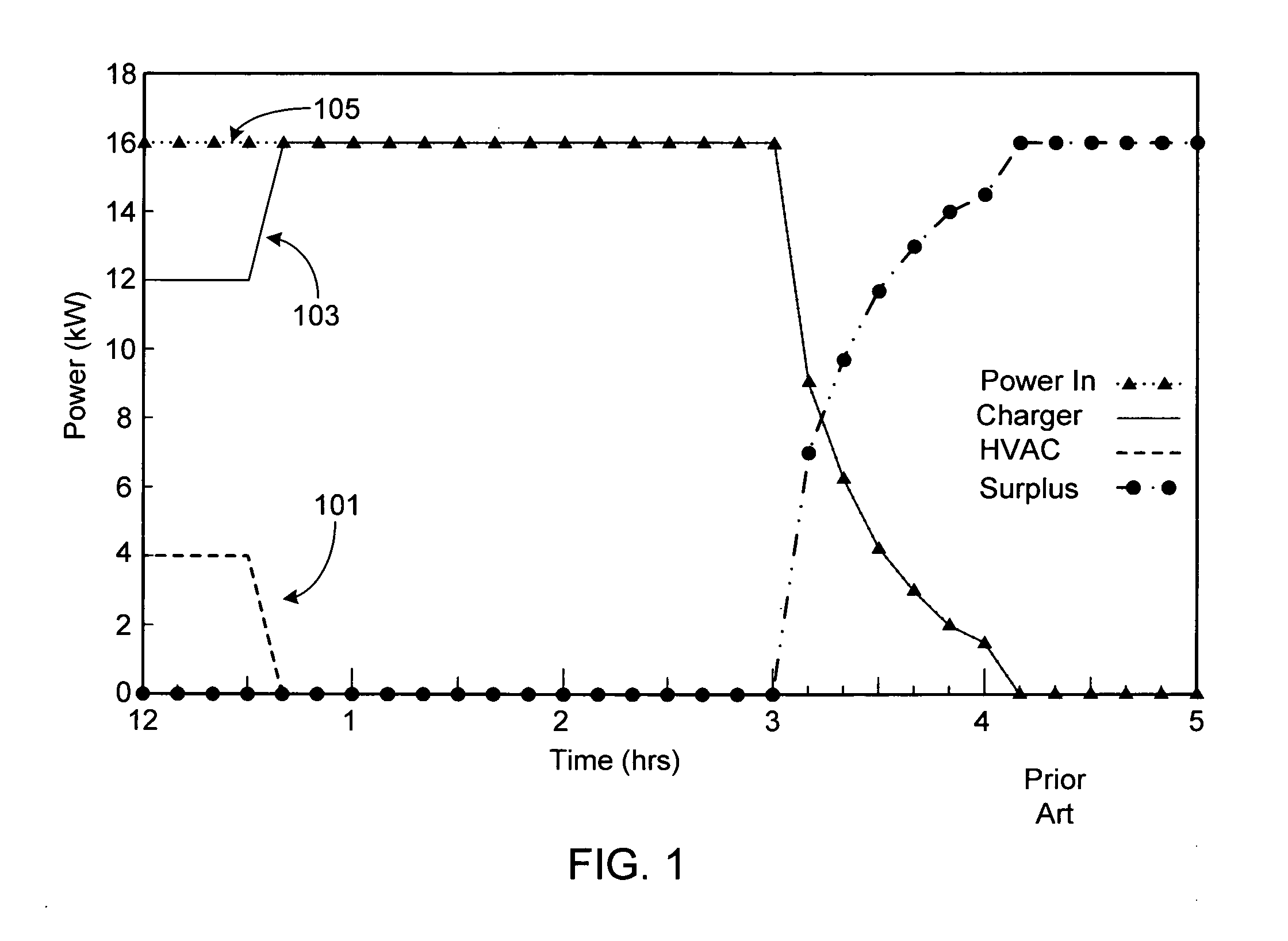

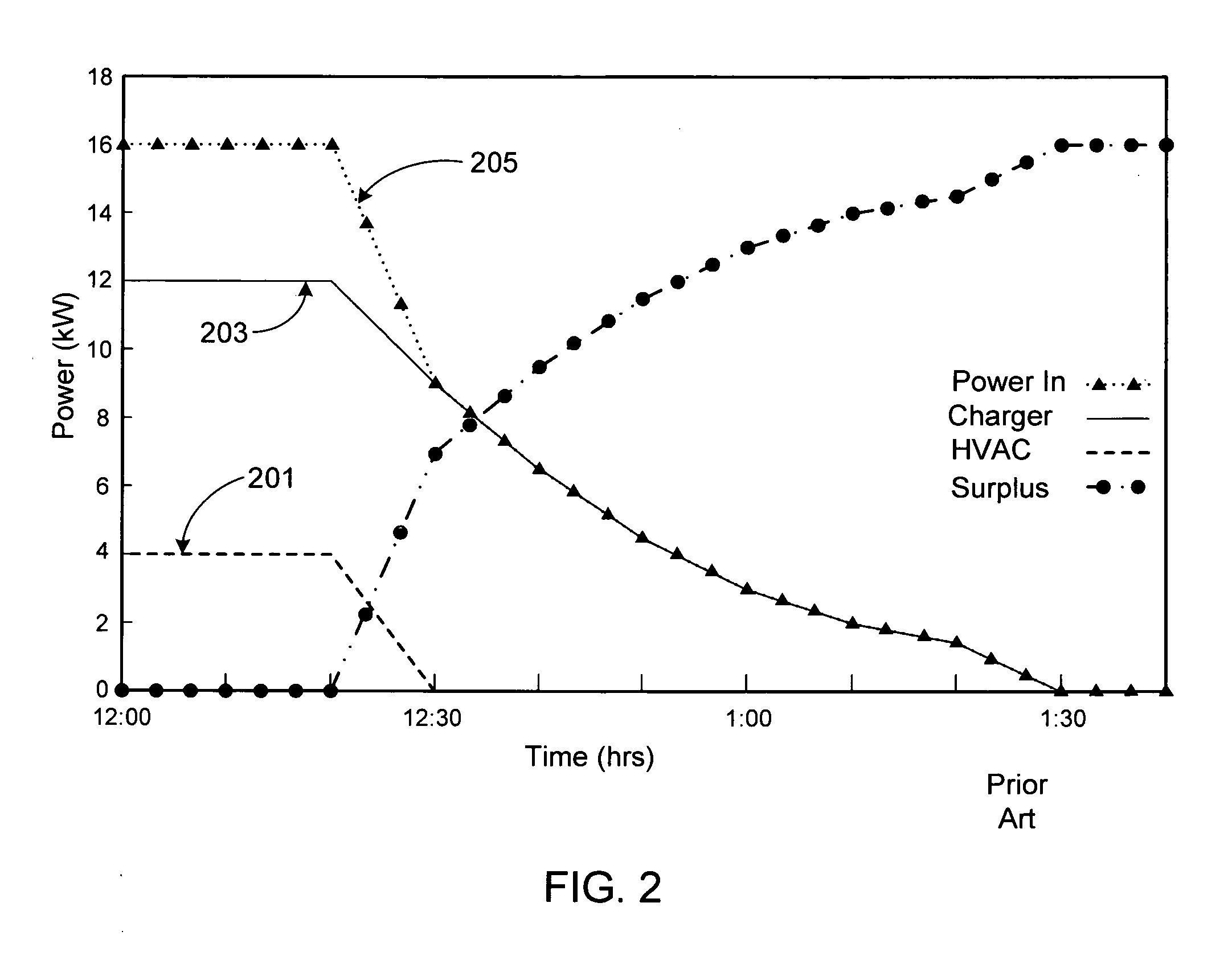

Battery charging time optimization system

ActiveUS20100072954A1Optimizing battery pack chargingLow costPower to auxillary motorsCapacitorsCouplingCharge rate

A system for optimizing battery pack charging is provided. In this system, during charging the coupling of auxiliary systems (e.g., battery cooling systems) to the external power source are delayed so that the battery pack charge rate may be optimized, limited only by the available power. Once surplus power is available, for example as the requirements of the charging system decrease, the auxiliary system or systems may be coupled to the external power source without degrading the performance of the charging system.

Owner:TESLA INC

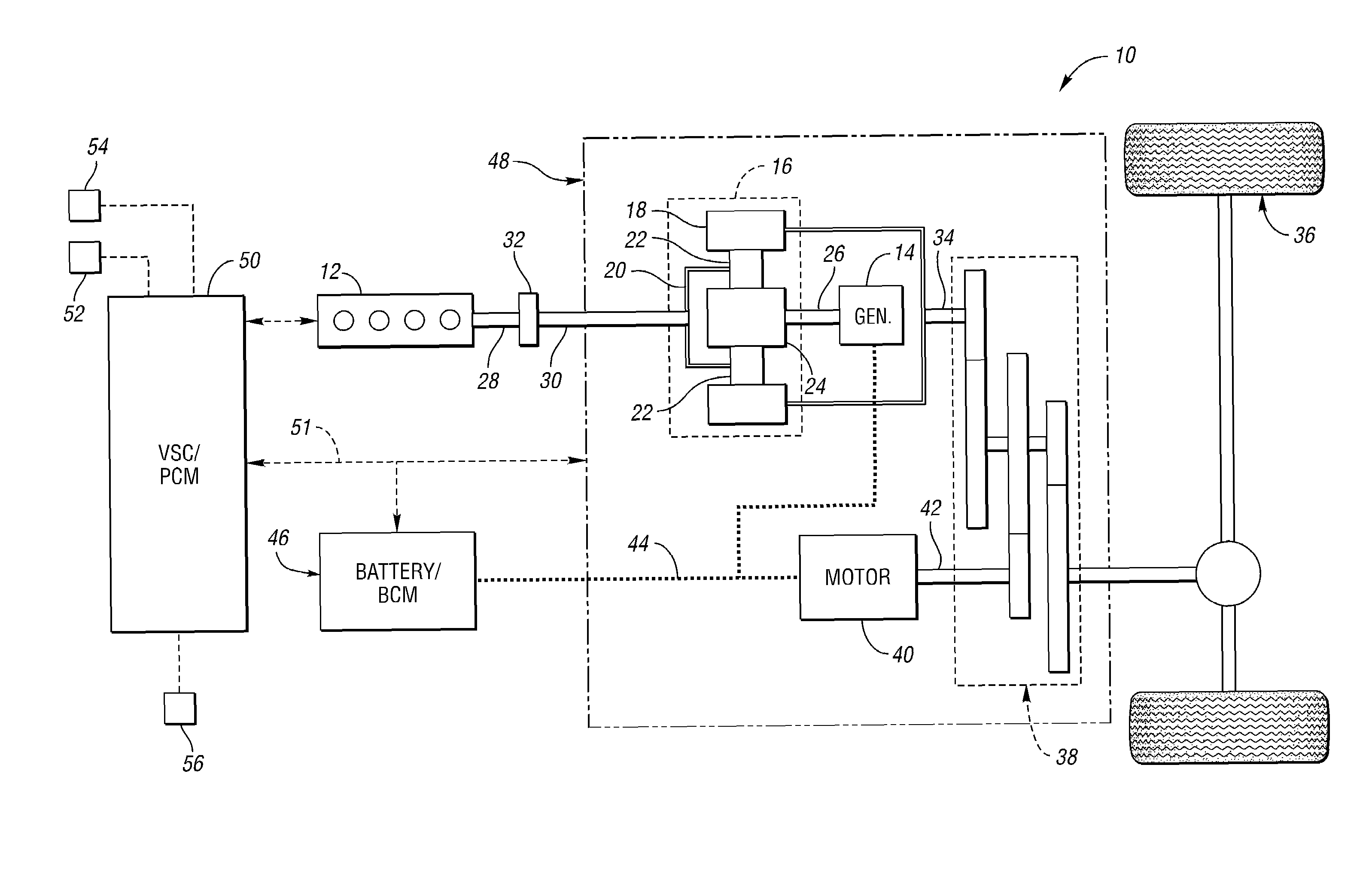

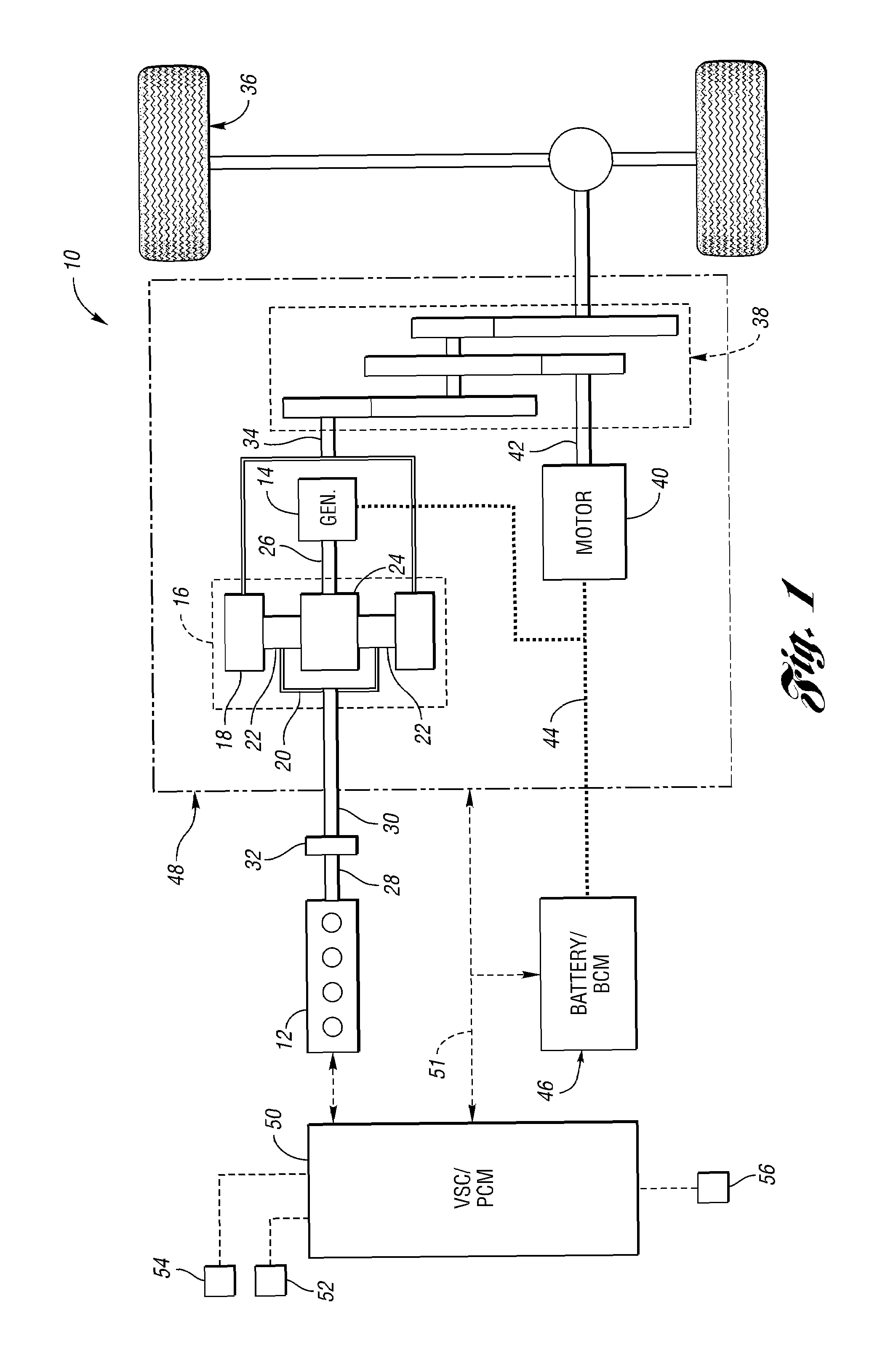

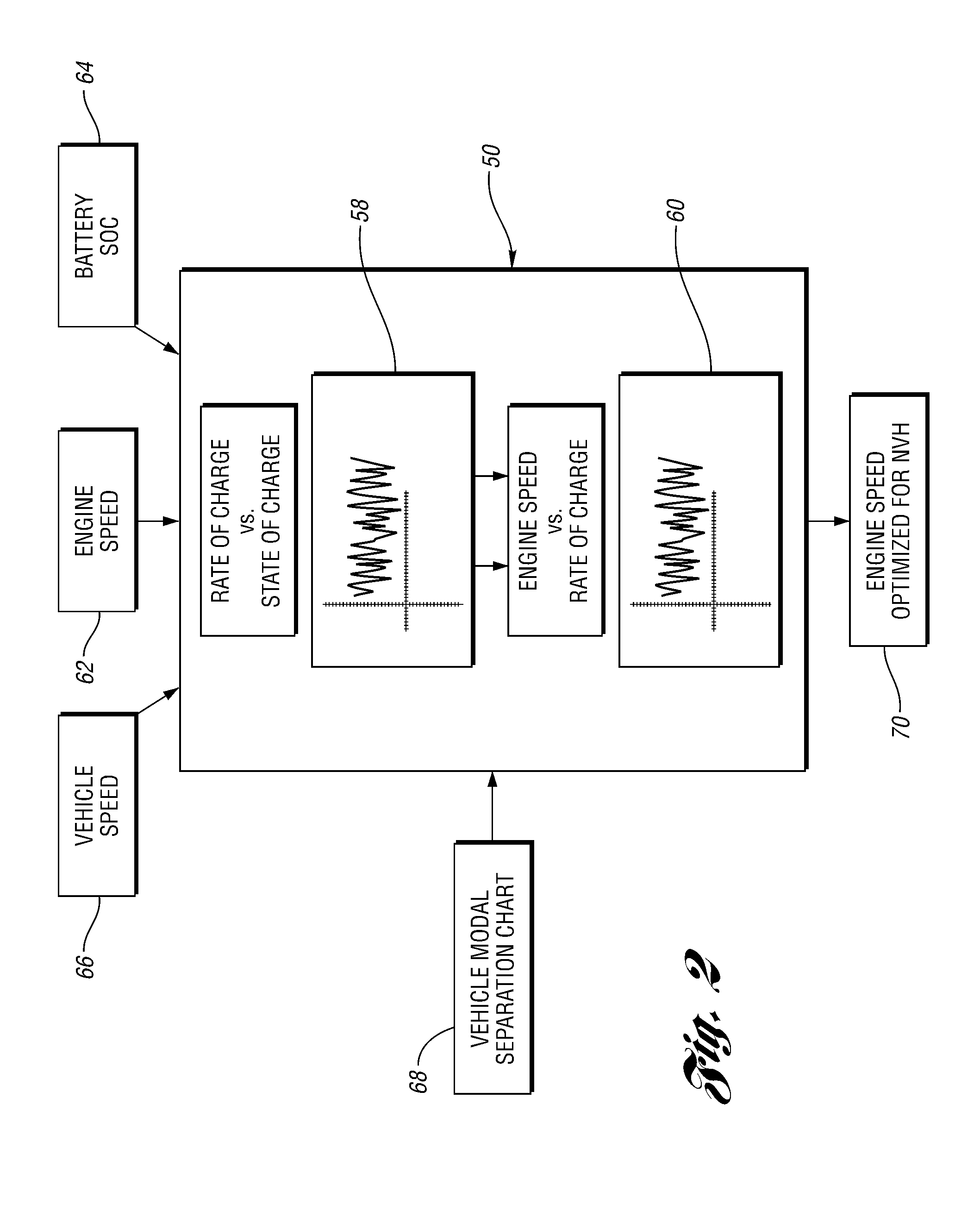

System and method for controlling speed of an engine

ActiveUS7292932B1New noise-vibration level for the vehicle is determinedImprove comfortHybrid vehiclesAnalogue computers for vehiclesNoise levelEngine power

A system and method for controlling the speed of an engine includes determining a desired engine power output and engine speed, and determining whether the desired engine speed is within one of a number of predetermined engine speed ranges. It is then determined whether a noise-vibration level for the vehicle is within a target range when it is determined that the desired engine speed is within one of the predetermined engine speed ranges. The noise-vibration level is a function of at least one of a corresponding vibration level for one or more vehicle mechanical systems, and a noise level for the passenger compartment for the engine operating at the desired engine speed. The engine is then controlled at the desired engine speed when the determined noise-vibration level is within a target range, and it is determined that the desired engine speed is within one of the predetermined engine speed ranges.

Owner:FORD GLOBAL TECH LLC

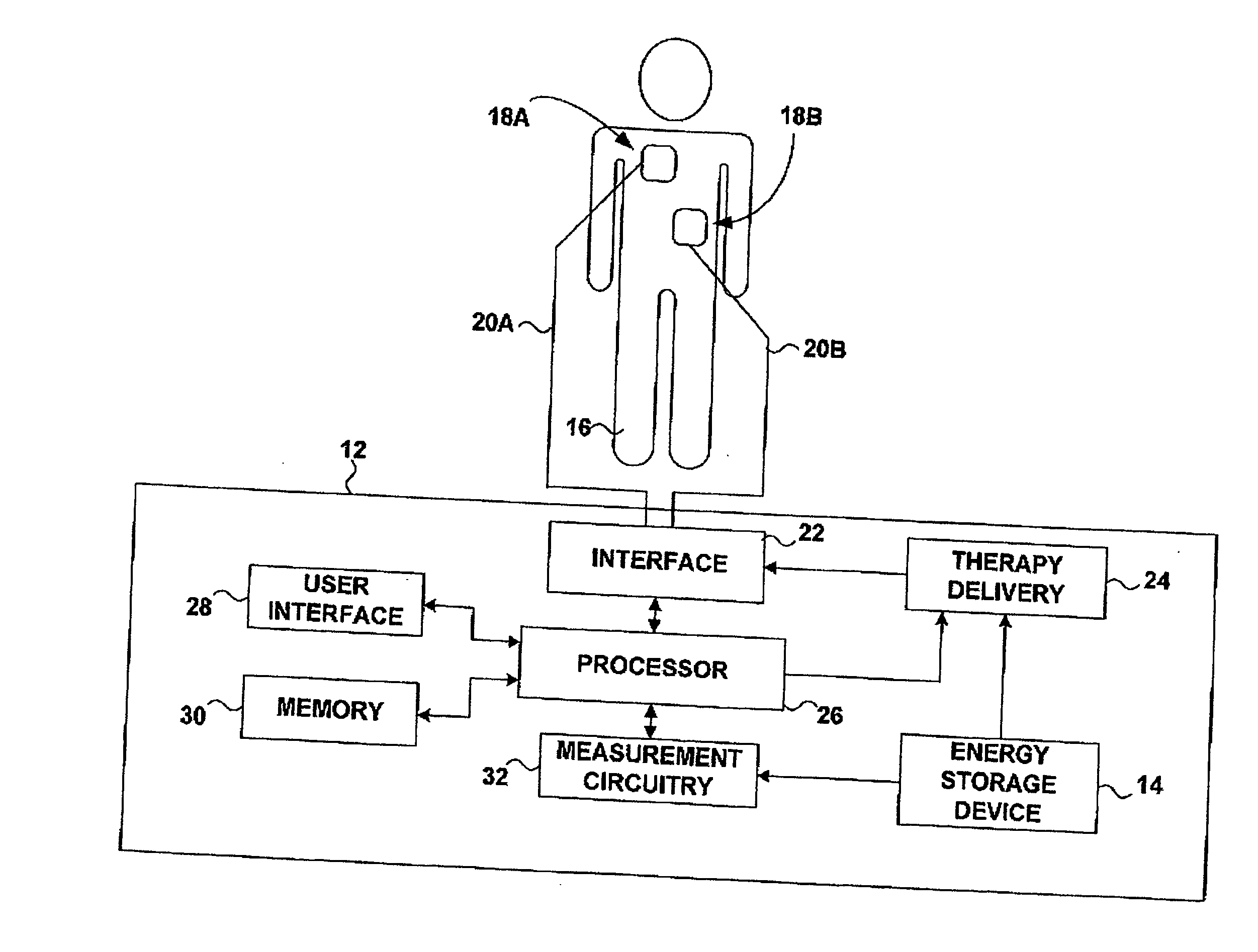

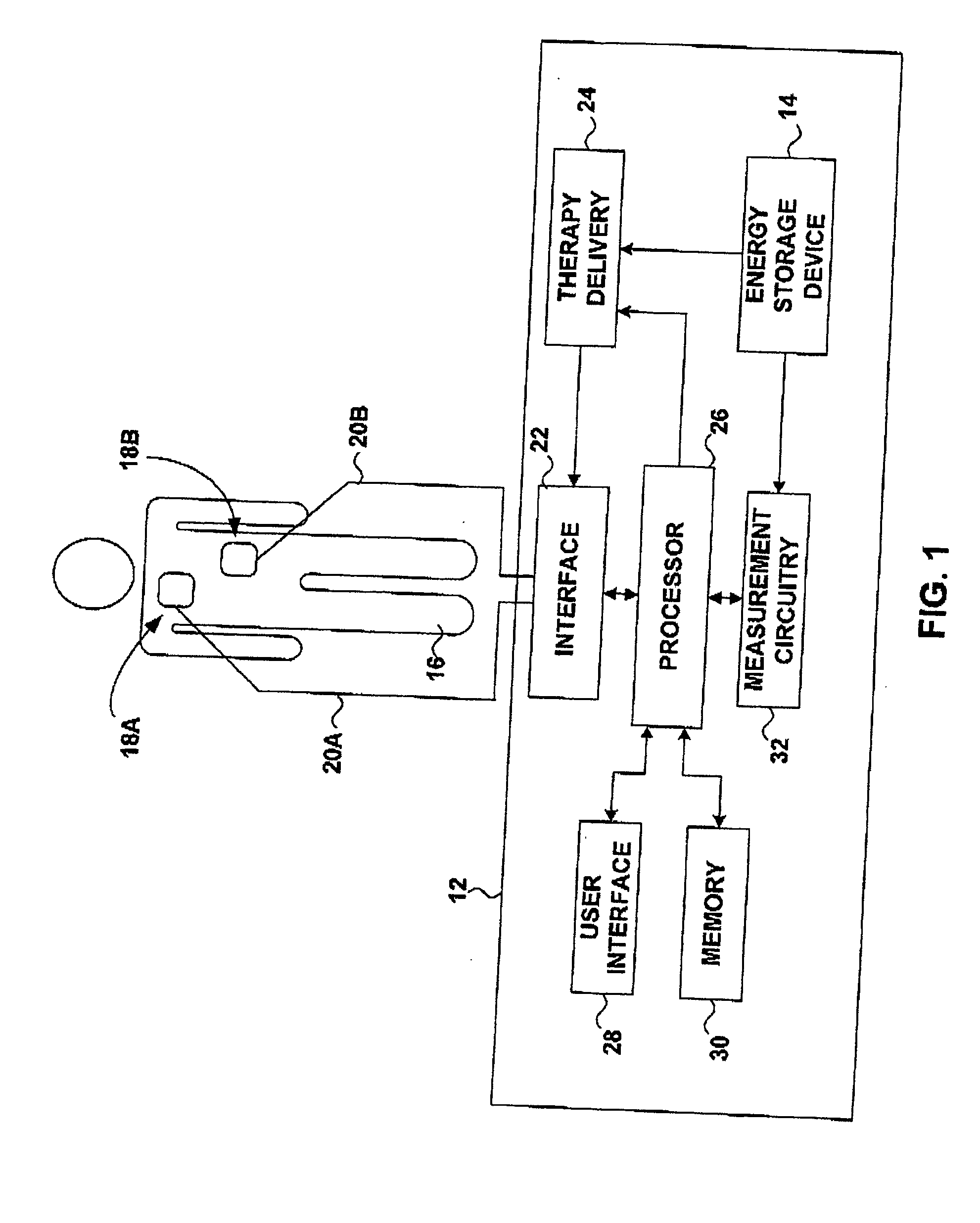

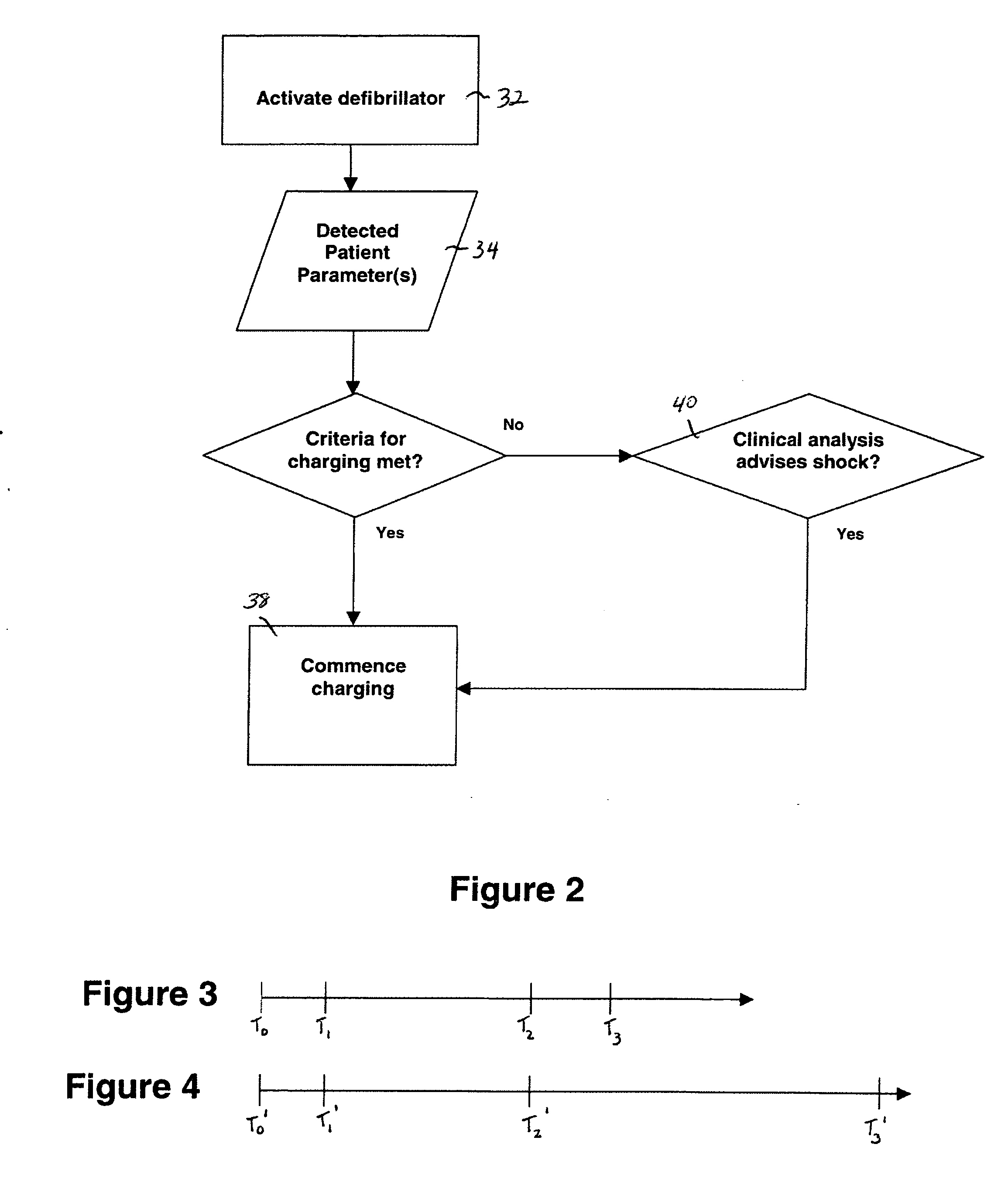

External defibrillator with charge advisory algorithm

A method of delivering electrical therapy to a patient by a medical device includes activating the medical device and performing a first analysis of a first set of data signals sensed by the medical device. If the first analysis shows the first set of data signals meets a first criterion, then charging of an energy delivery circuit is commenced circuit upon completion of the first analysis. A second analysis of a second set of data signals from the patient is performed, and if the second analysis determines that the second set of data signals meet a second criterion, the therapy is delivered. The steps of performing the first analysis and performing the second analysis may be begun at substantially the same time. The step of charging may overlap in time with the step of performing a second analysis. The medical device may be an external defibrillator and the therapy may be a defibrillating shock.

Owner:PHYSIO CONTROL INC

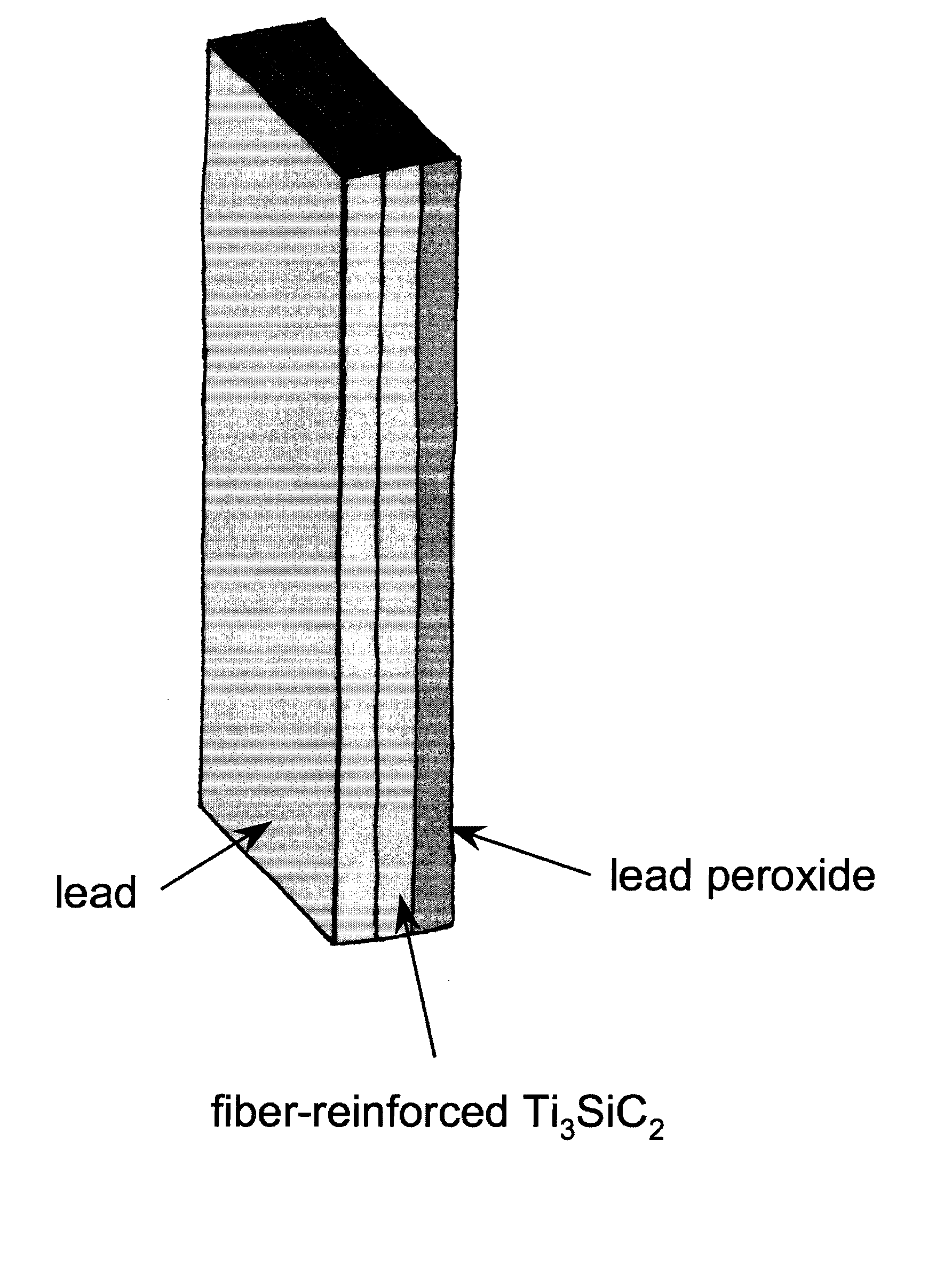

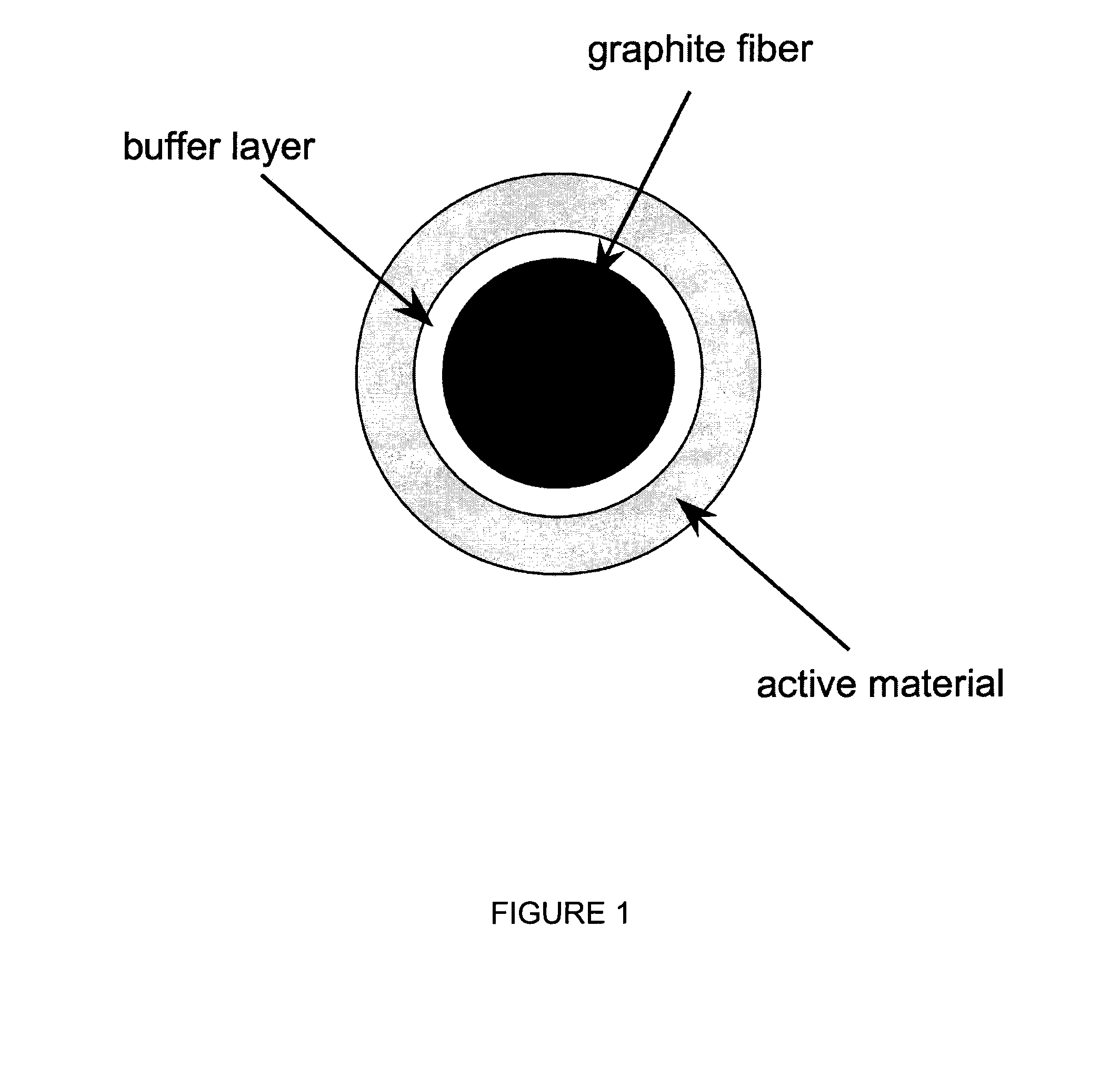

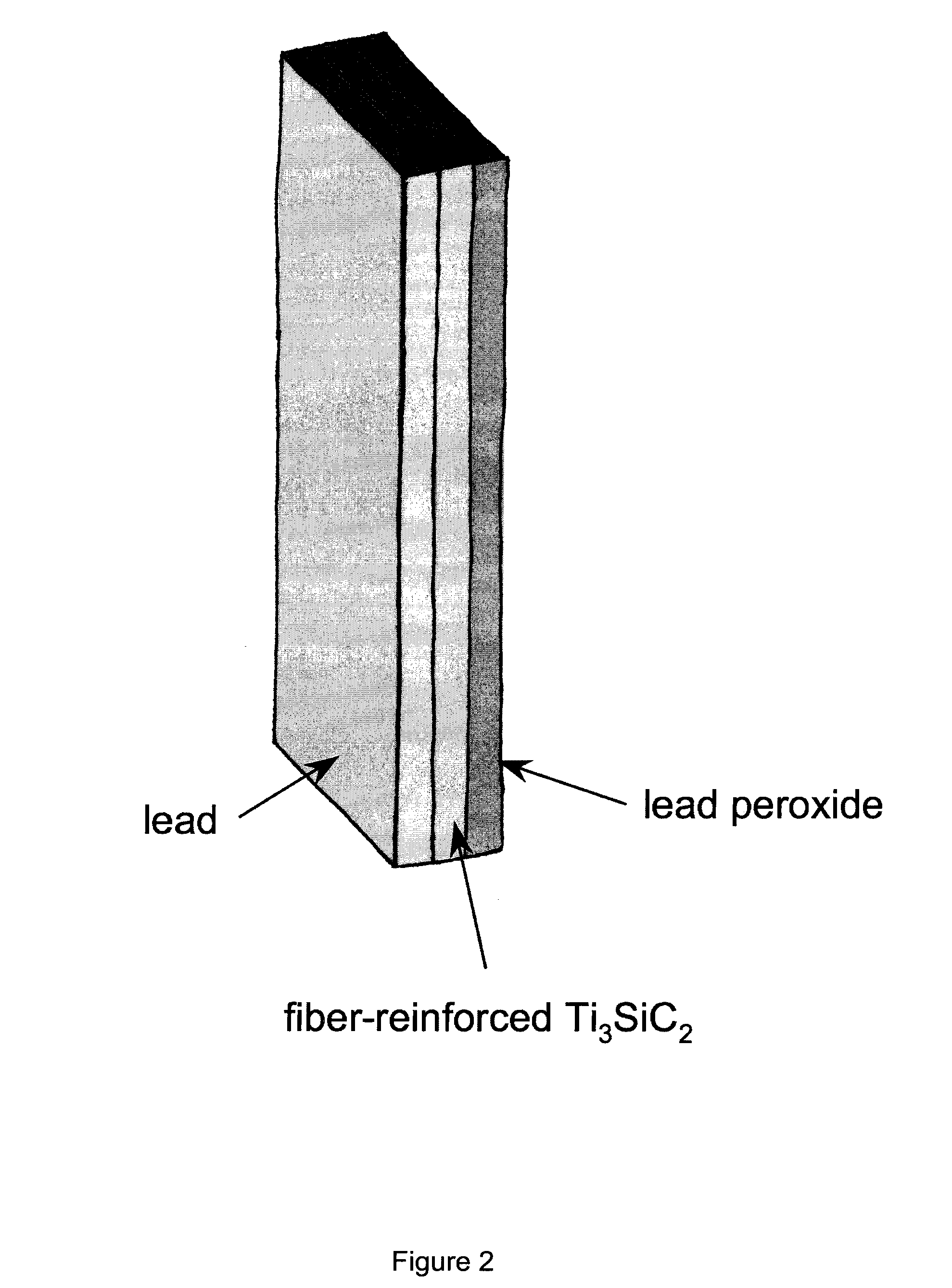

Lightweight, Durable Lead-Acid Batteries

InactiveUS20090269666A1Reduce weightIncrease surface areaFinal product manufactureElectrode carriers/collectorsFiberCarbon fibers

A lightweight, durable lead-acid battery is disclosed. Alternative electrode materials and configurations are used to reduce weight, to increase material utilization and to extend service life. The electrode can include a current collector having a buffer layer in contact with the current collector and an electrochemically active material in contact with the buffer layer. In one form, the buffer layer includes a carbide, and the current collector includes carbon fibers having the buffer layer. The buffer layer can include a carbide and / or a noble metal selected from of gold, silver, tantalum, platinum, palladium and rhodium. When the electrode is to be used in a lead-acid battery, the electrochemically active material is selected from metallic lead (for a negative electrode) or lead peroxide (for a positive electrode).

Owner:UT BATTELLE LLC

Fast charging with negative ramped current profile

ActiveUS8643342B2Shorten the timeFast chargingBatteries circuit arrangementsElectric powerCharge currentFast charging

A battery cell charging system, including a charger and a controller, for rapidly charging a lithium ion battery cell, the battery cell charging system having a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile includes: a first charging stage with a constant first stage charging current and an increasing battery cell voltage with the first stage charging current provided until the first stage charging voltage is about equal to a first stage complete voltage less than a maximum battery cell voltage; an intermediate ramped charging stage, the intermediate ramped charging stage including both an increasing ramped voltage and a decreasing ramped iBat current for the battery cell for the voltage charging range of the first stage complete voltage to about the maximum battery cell voltage; and a final charging stage with a constant final stage charging voltage about equal to the maximum battery cell voltage and a decreasing final stage charging current with the final stage charging voltage provided until the final stage charging current reaches a desired charge complete level.

Owner:TESLA INC

Fast charging of battery using adjustable voltage control

ActiveUS8754614B2Shorten charging timeReducing/eliminating impactIndicating/monitoring circuitsSecondary cells charging/dischargingFast chargingLithium-ion battery

A battery cell charger for rapidly charging a lithium ion battery cell (or string of series-parallel connected cells) having a maximum battery cell voltage the battery cell charging system including: a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile includes: a first charging stage with a constant first stage charging current and an increasing battery cell voltage with the first stage charging current provided until the first stage charging voltage is about equal to a first stage complete voltage less than the maximum battery cell voltage; one or more intermediate charging stages, each intermediate stage selected from the group consisting of one or more of an intermediate constant voltage stage that provides a decreasing charging current, an intermediate constant current stage that produces an increasing battery cell voltage, and combinations thereof; and a final charging stage with a constant final stage charging voltage about equal to an intermediate stage complete voltage and a decreasing final stage charging current with the final stage charging voltage provided until the final stage charging current reaches a desired charge complete level.

Owner:TESLA INC

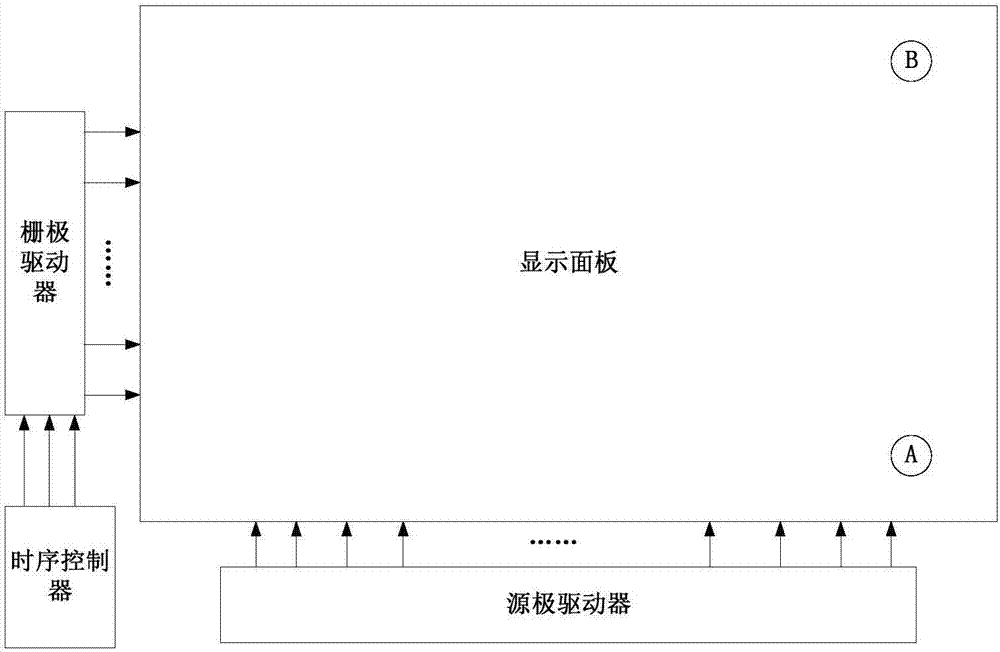

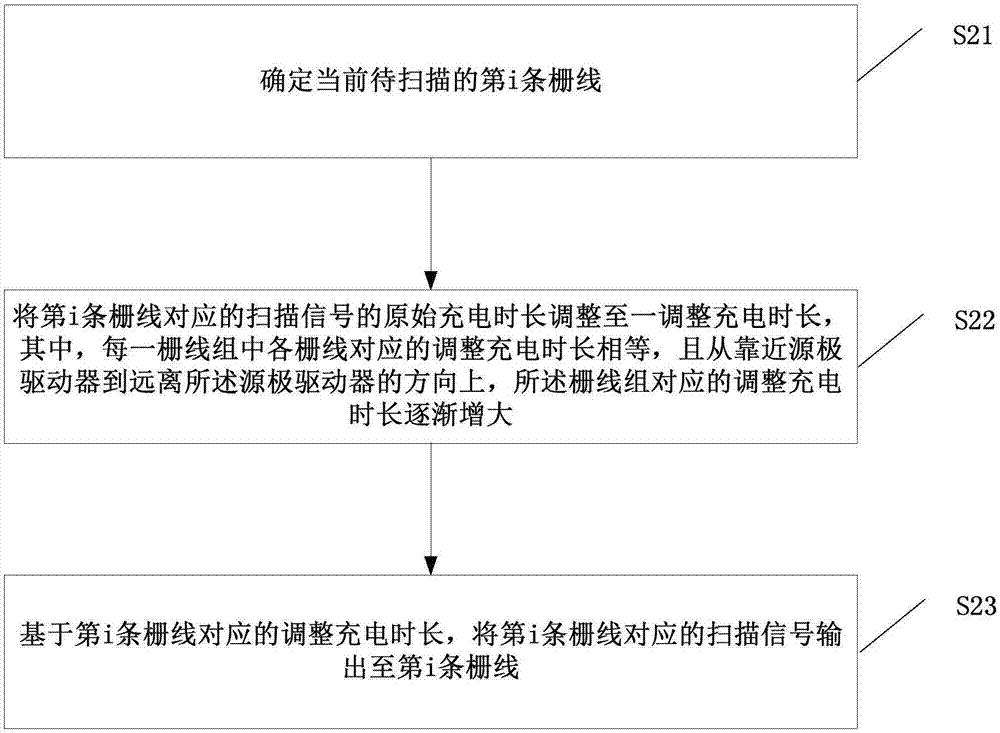

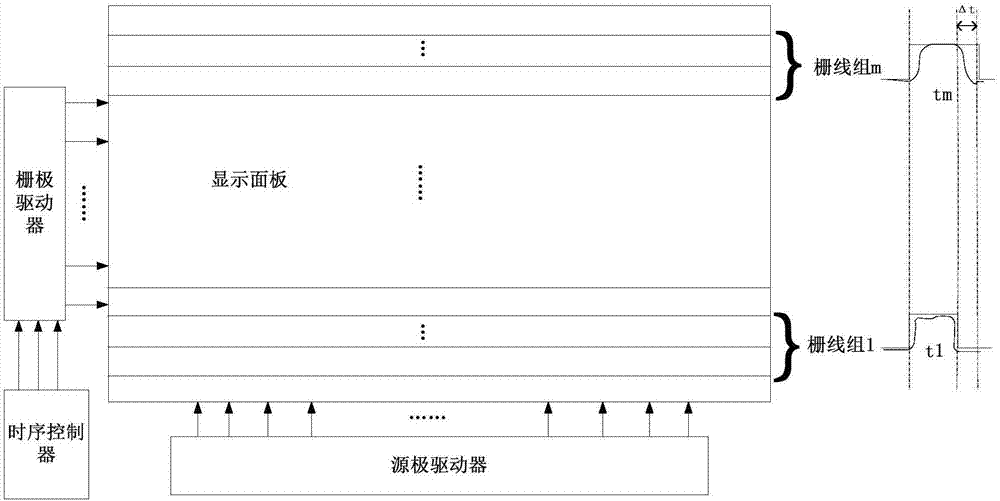

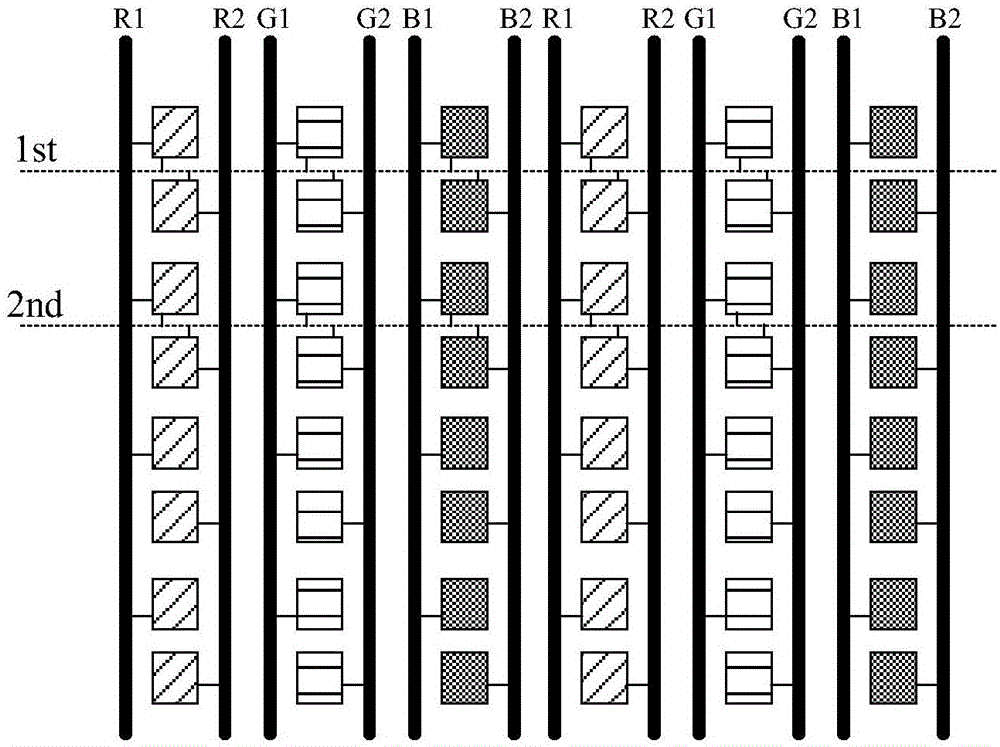

Driving method and driving circuit for display panel, and display device

InactiveCN106875905AIncrease charging rateSolve the problem of poor screen displayStatic indicating devicesCharge rateEngineering

The invention provides a driving method and a driving circuit for a display panel, and a display device. The display panel comprises Y grid lines. According to the scanning sequence of the grid lines, the Y grid lines are divided into multiple grid line groups. Each grid line group comprises at least one grid line. The driving method comprises steps of determining the i-th grid line to be scanned; adjusting the original charging time of the scanning signal corresponding to the i-th grid line to an adjusted charging time, wherein the adjusted charging line corresponding to each grid line in each grid line group is equal, and in a direction gradually away from the source drive, the adjusted charging time corresponding to each grid line group is gradually increased; and based on the adjusted charging time corresponding to the i-th grid line, outputting the scanning signal corresponding to the i-th grid line to the i-th grid line. The charging time corresponding to each grid line is adjusted, the charging rate of the pixel line with the insufficient charging rate is improved, and the charging rate of each line of pixels is enabled to be equal or close.

Owner:BOE TECH GRP CO LTD +1

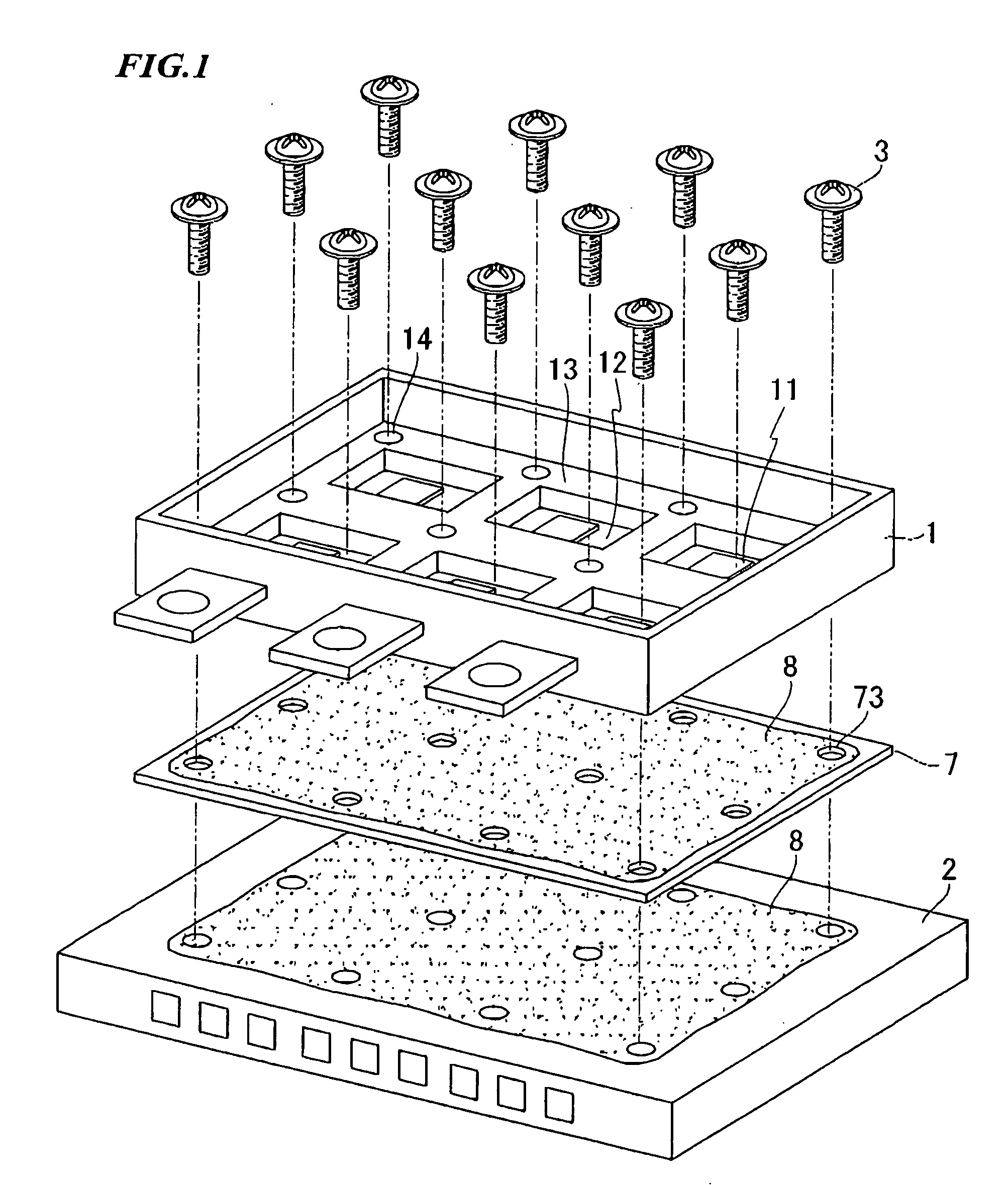

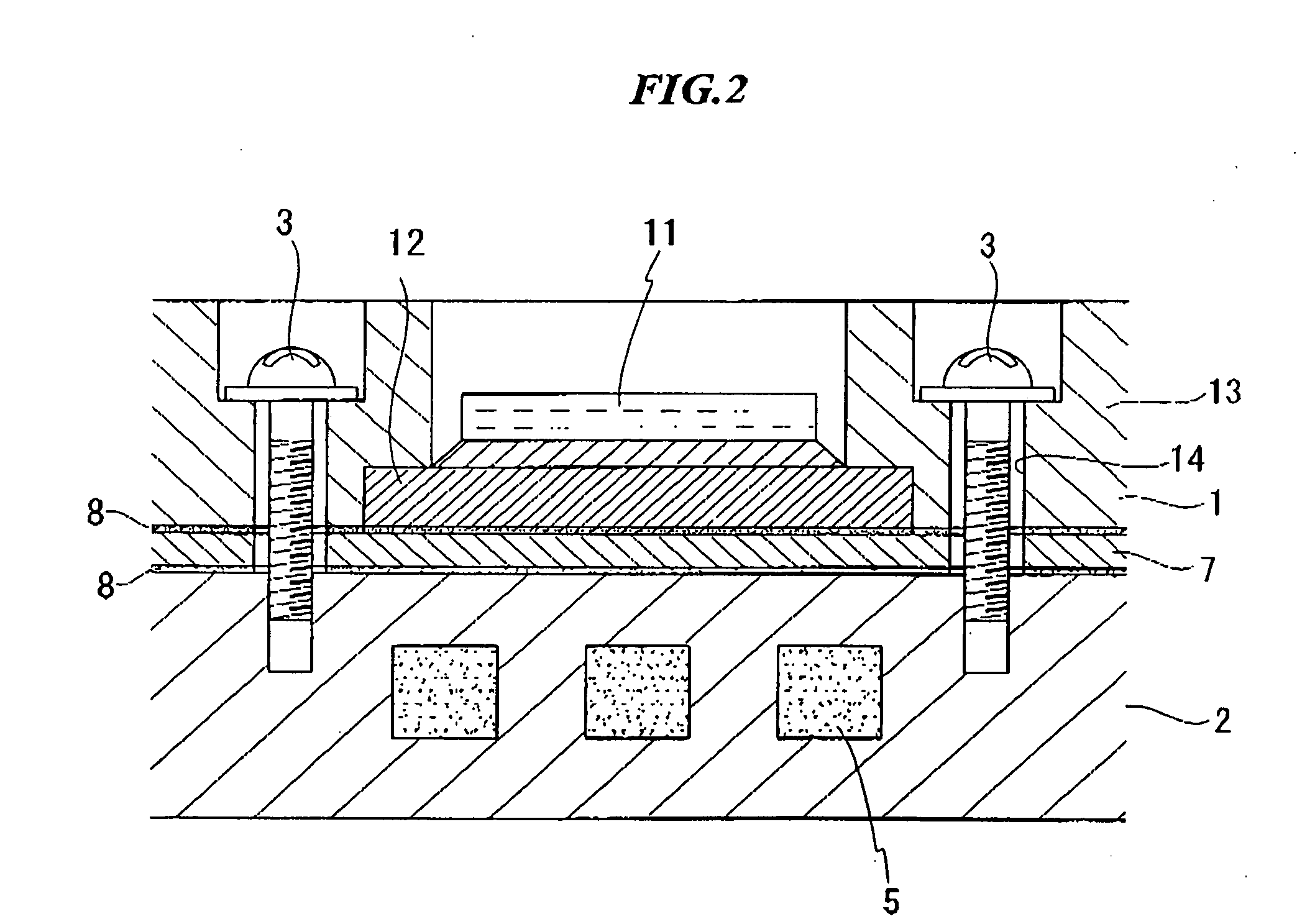

Heat dissipation assembly and method for producing the same

ActiveUS20050205989A1Effective coolingConductible sheet can be preventedSemiconductor/solid-state device detailsSolid-state devicesDevice materialThermal grease

A heat dissipation assembly in which a heat generator and a heat dissipator are integrated via an electrically insulating and thermally conductive sheet, at least one surface of which a thermally conductive grease is applied to, in which the thermally conductive grease is incompatible with the electrically insulating and thermally conductive sheet. Heat from the heat generator such as a semiconductor device or the like can be effectively dissipated while an electrically insulating condition is maintained over a long period of time.

Owner:NISSAN MOTOR CO LTD +2

Low temperature charging of Li-ion cells

ActiveUS8552693B2Total current dropIncrease charging rateBatteries circuit arrangementsElectric powerCharge currentCelsius Degree

A battery cell charging system, including a charger and a controller, for low-temperature (below about zero degrees Celsius) charging a lithium ion battery cell, the battery cell charging system includes: a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile having: a non-low-temperature charging stage for charging the battery cell using a charging profile adapted for battery cell temperatures above about zero degrees Celsius; and a low-temperature charging stage with a variable low-temperature stage charging current that decreases responsive to a battery cell temperature falling below zero degrees Celsius.

Owner:TESLA INC

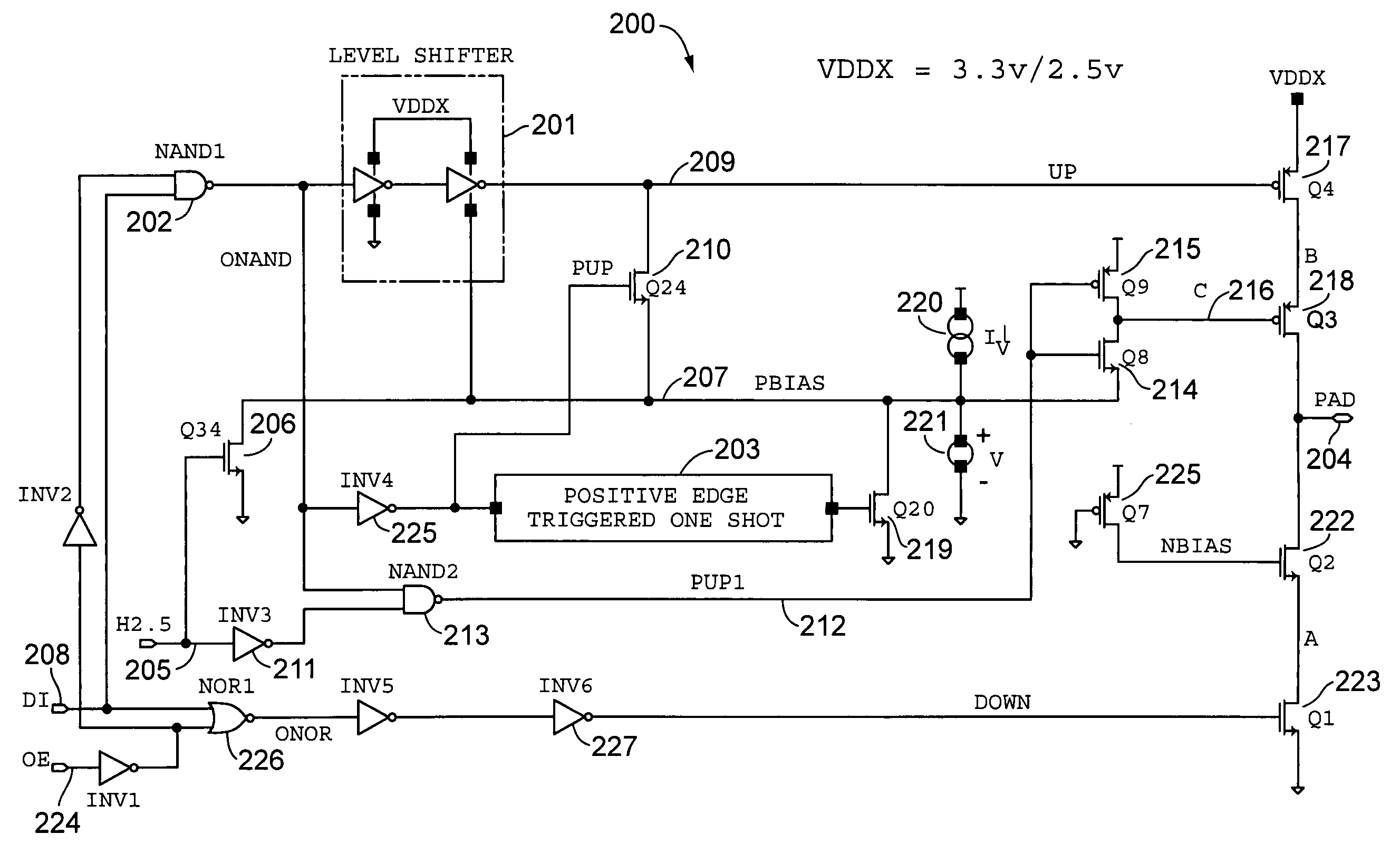

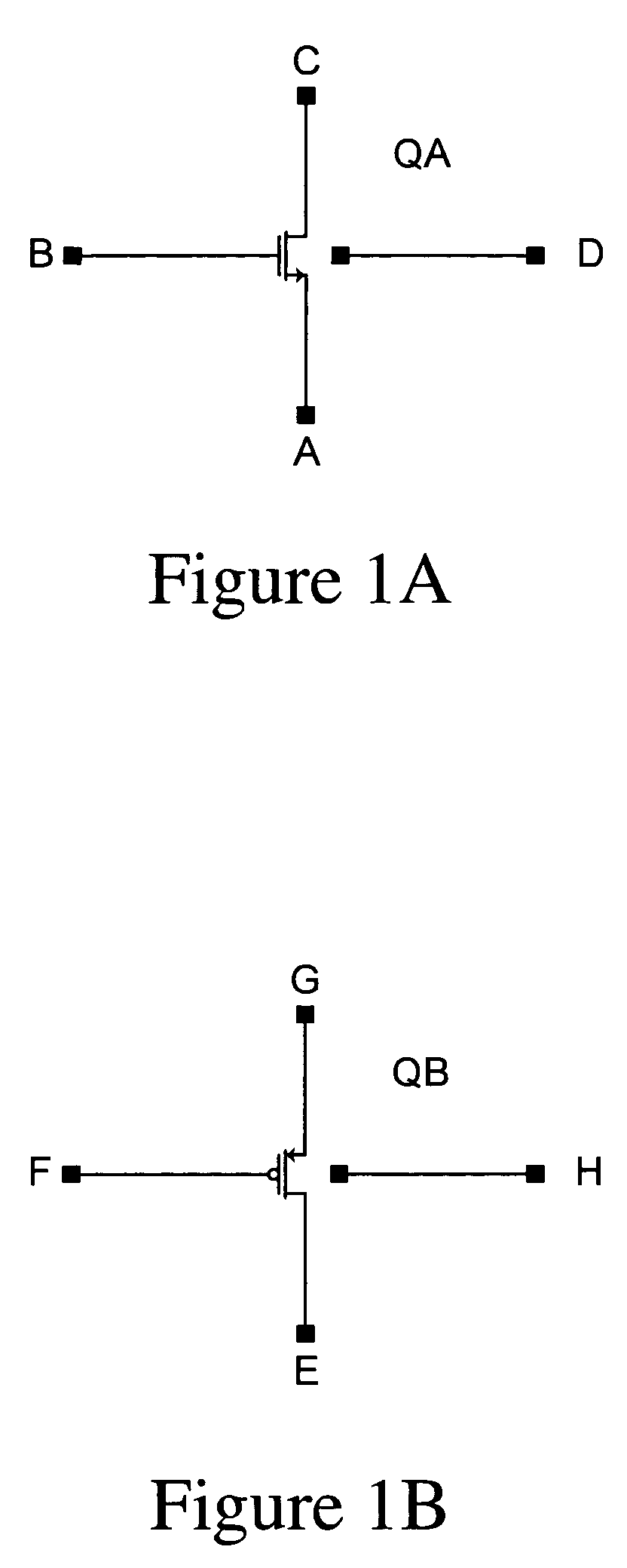

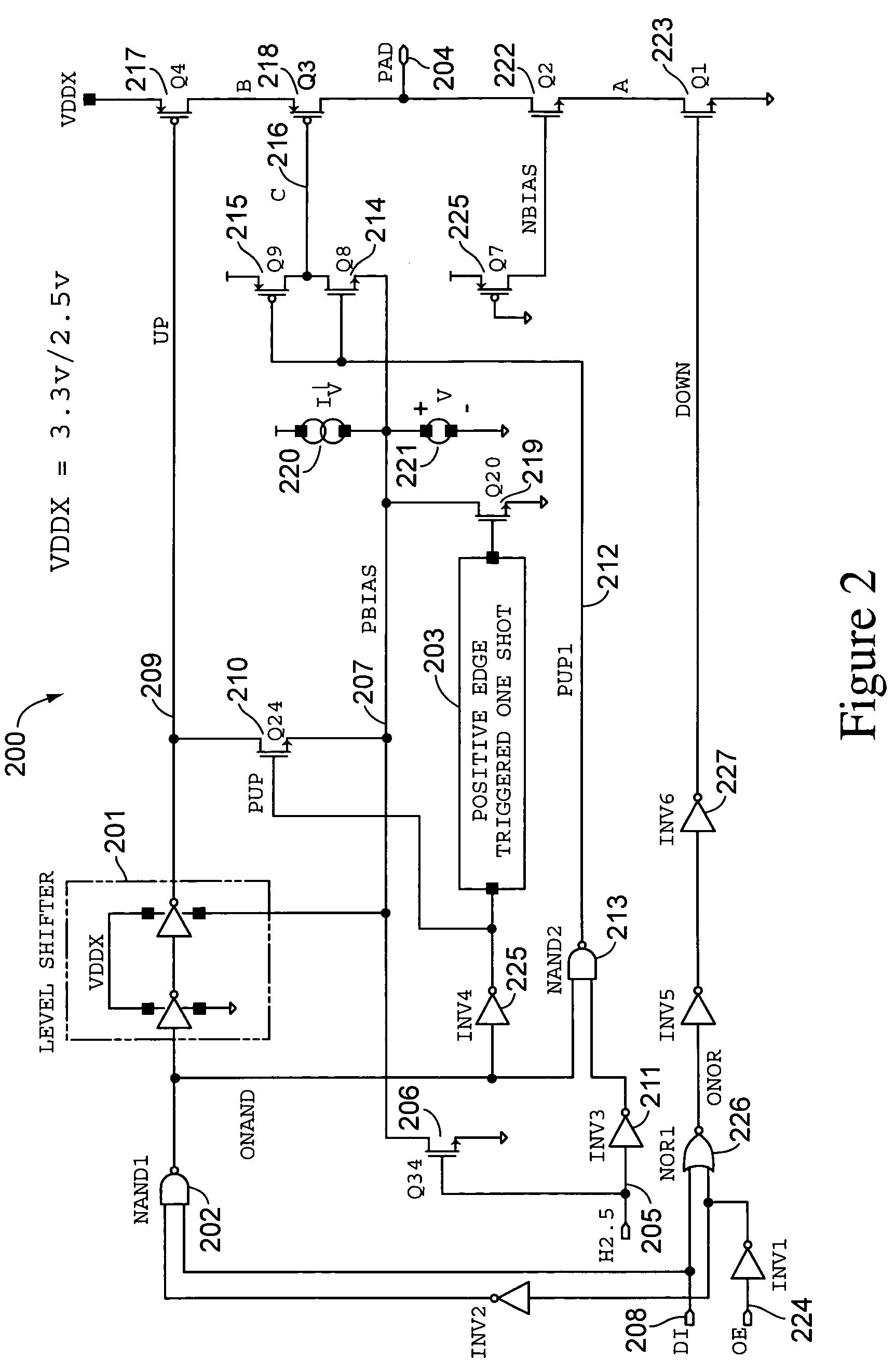

Output drive circuit that accommodates variable supply voltages

ActiveUS7224195B2Increase charging rateSwitching accelaration modificationsLogic circuits coupling/interface using field-effect transistorsDriver circuitEngineering

In accordance with the invention, a driver circuit is described that permits a single thin gate oxide process to be utilized where a dual oxide process may normally be necessary. Circuits employing only thin gate oxide devices are used as the design basis for a single product with a single set of tooling and manufacturing process to operate within the same timing specifications for a core voltage output drive as well as for a higher system drive.

Owner:INTEGRATED DEVICE TECH INC

System and method for balancing charge within a battery pack

ActiveUS8519670B2Decreased battery pack lifetimeEasy to chargeCharge equalisation circuitElectric powerElectricityElectrical battery

A system for balancing charge within a battery pack with a plurality of cells connected in series, including a capacitor; a processor configured to select a combination of donor cells and receiver cells from the plurality of cells in one of the following two modes: (1) a first mode where the number of donor cells is equal to the number of receiver cells, and (2) a second mode where the number of donor cells is greater than the number of receiver cells; and a plurality of switches that electrically connect the capacitor to the donor cells to charge the capacitor, and that electrically connected the capacitor to the receiver cells to discharge the capacitor. The transfer of charge between cells in the plurality of cells through the capacitor balances the charge within the battery pack.

Owner:MOTIV POWER SYST

Rapidly-charged graphite lithium ion battery anode material and preparation method thereof

InactiveCN105024043ASmall specific surface areaIncrease charging rateCell electrodesMicrometerCharge rate

The invention discloses a rapidly-charged graphite lithium ion battery anode material and a preparation method thereof. The preparation method for the rapidly-charged graphite lithium ion battery anode material comprises the following steps of: (1) mixing a mixture containing natural graphite and asphalt, and heating, kneading and smashing the mixture, wherein the average grain size D50 of the natural graphite is 5 to 10 micrometers, and the mass rate of the natural graphite to the asphalt is (50:50) to (90:10); (2) carrying out heat treatment at 300-700 DEG C under the protection of an inert gas; and (3) performing graphitizing. The average grain size D50 of the rapidly-charged graphite lithium ion battery anode material prepared according to the method is ranging from 5 micrometers to 15 micrometers, the specific surface area is less than 2.0 m<2> / g, the initial discharging capacity of the battery prepared from the rapidly-charged graphite lithium ion battery anode material is over 360 mAh / g, the initial charging and discharging efficiency is over 90 percent, the charging rate (1.5C) is over 80 percent, and a product is high in discharging capacity and charging and discharging efficiency and good in rate capability. The invention also relates to a battery, and the battery comprises the rapidly-charged graphite lithium ion battery anode material.

Owner:SHANGHAI SHANSHAN TECH CO LTD

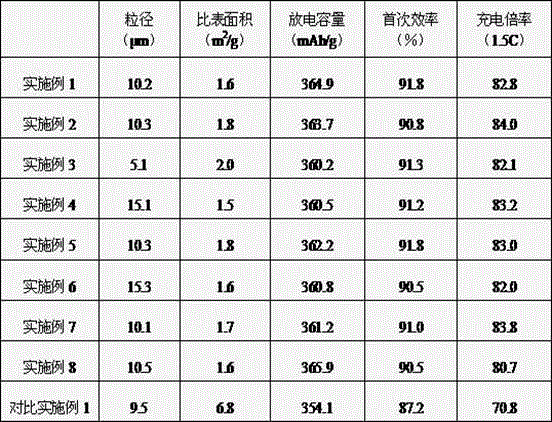

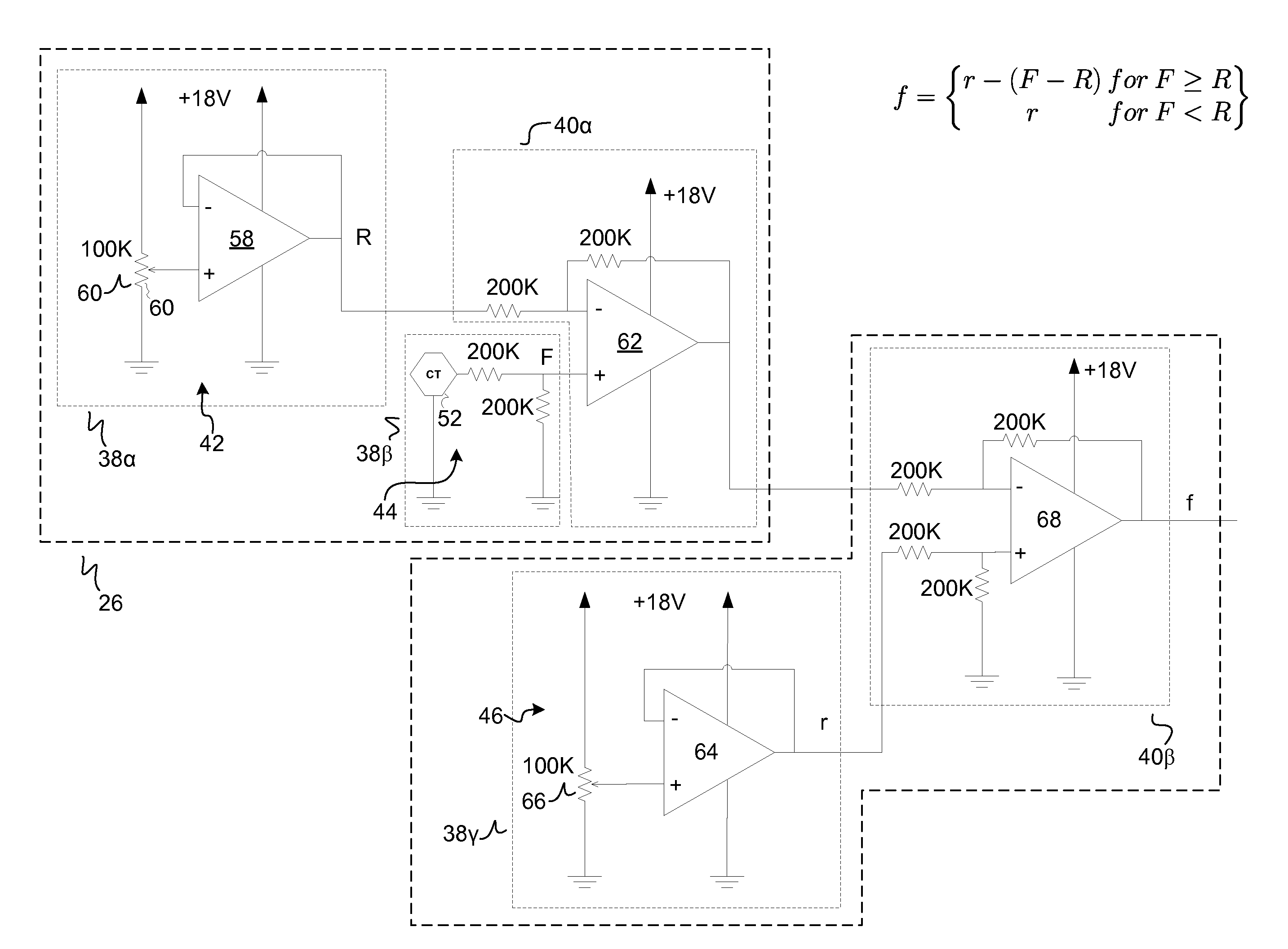

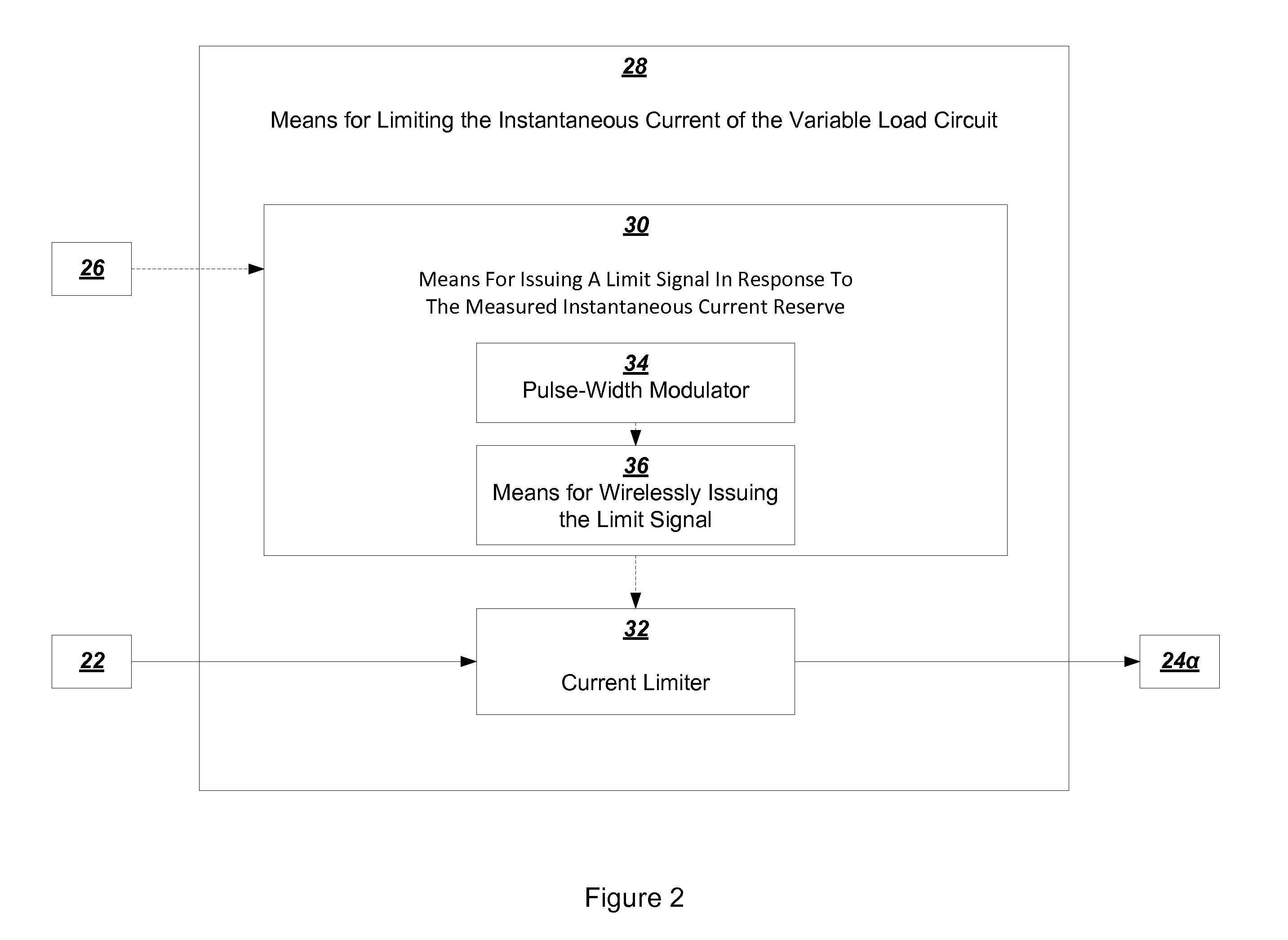

Method and Apparatus for Allocating Electricity from a Distributor

ActiveUS20100066170A1Increase freedomIncrease the rated currentDc network circuit arrangementsPower network operation systems integrationElectricityLoad circuit

The present invention provides a method and apparatus for allocating current (20) from a distributor (22), having a maximum rated current, among a plurality of load circuits (24), including a variable load circuit (24α) that benefits from a full load current allocation but is operable at a lower current allocation. The invention provides for measuring the instantaneous current reserve of the distributor (22) as the maximum rated current of the distributor (22) less the instantaneous current flowing from the distributor (22) to the plurality of load circuits (24), and limiting the instantaneous current of the variable load circuit (24α) to the full load current of the variable load circuit (24α) if the instantaneous current reserve is greater than zero, and the sum of the full load current of the variable load circuit (24α) plus the instantaneous current reserve, if the instantaneous current reserve is less than or equal to zero.

Owner:SCHULER MIKE

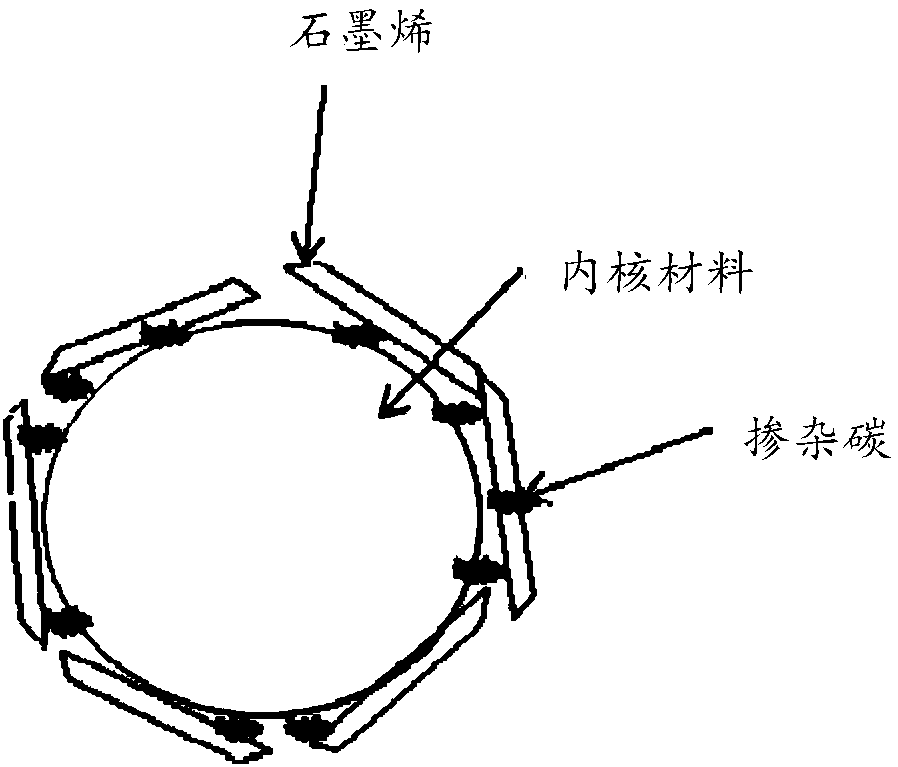

Negative electrode material preparation method, negative electrode material, negative electrode piece and lithium ion battery

InactiveCN108063221AAvoid reunionAvoid large specific surface areaCell electrodesSecondary cellsIonCvd graphene

The invention provides a negative electrode material preparation method, a negative electrode material, a negative electrode piece and a lithium ion battery. The negative electrode material preparation method comprises the following steps: mixing and heating a core material and a heteroelement-containing polymer or a heteroelement-containing ionic liquid; mixing and heating the core material coated with the heteroelement-containing polymer or the heteroelement-containing ionic liquid and functionalized graphene; and sintering the functionalized graphene, the heteroelement-containing polymer orthe heteroelement-containing ionic liquid and the core material to obtain the negative electrode material with the surface of the core material being fixedly coated with the graphene by doping carbon. The negative electrode material preparation method allows the negative electrode material with the core material coated with doped carbon fixed graphene to be obtained through fixing graphene by doping carbon, so graphene is stably fixed on the surface of the core material, and graphene agglomeration is avoided.

Owner:HUAWEI TECH CO LTD

Charging contact array for enabling parallel charging and series discharging of batteries

ActiveUS20110181244A1Reduce charging voltageEliminating high voltage potentialHybrid vehiclesBatteries circuit arrangementsElectrical conductorCharge current

A contact array arrangement which both receives charging current for charging batteries of a battery pack, and which also breaks the parallel charging contact position (contact configuration in which individual batteries of the battery pack are charged in parallel) then reestablishes series connection of the batteries when a charge electrode array is urged against the contact array arrangement and when the charge electrode array is removed. A cover covering the contact array may be connected by throughbolts to a support supporting series connection contacts such that depressing the cover by imposing a downward force (e.g., the weight of a charge electrode array), moves the series connection contacts out of contact with those contacts receiving charge current. Springs return the series connection contacts to the series condition. Charge conductors fixed to the contact array pass through or by the series connection such that a very compact device results.

Owner:BADGER BERKLEY C

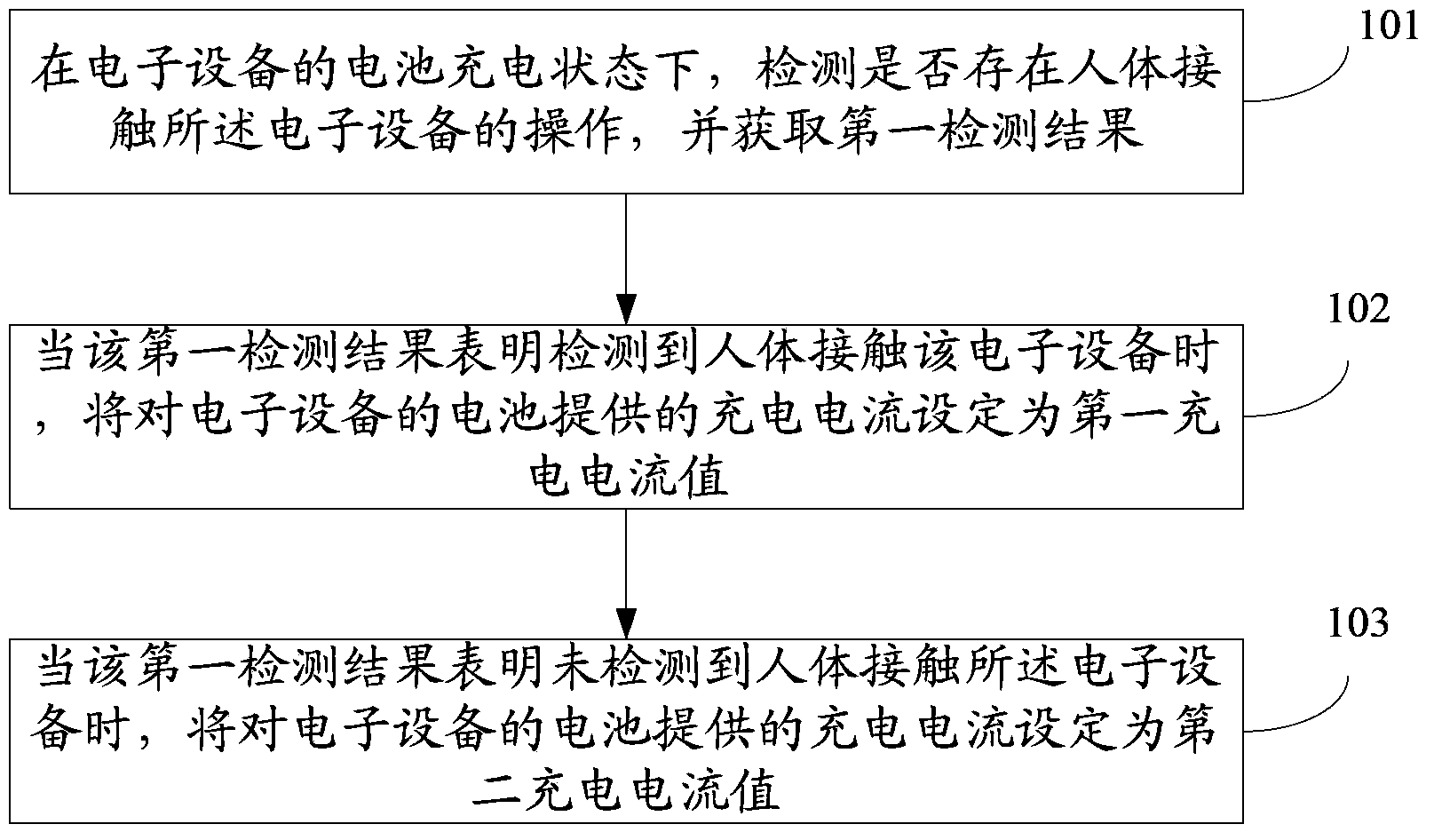

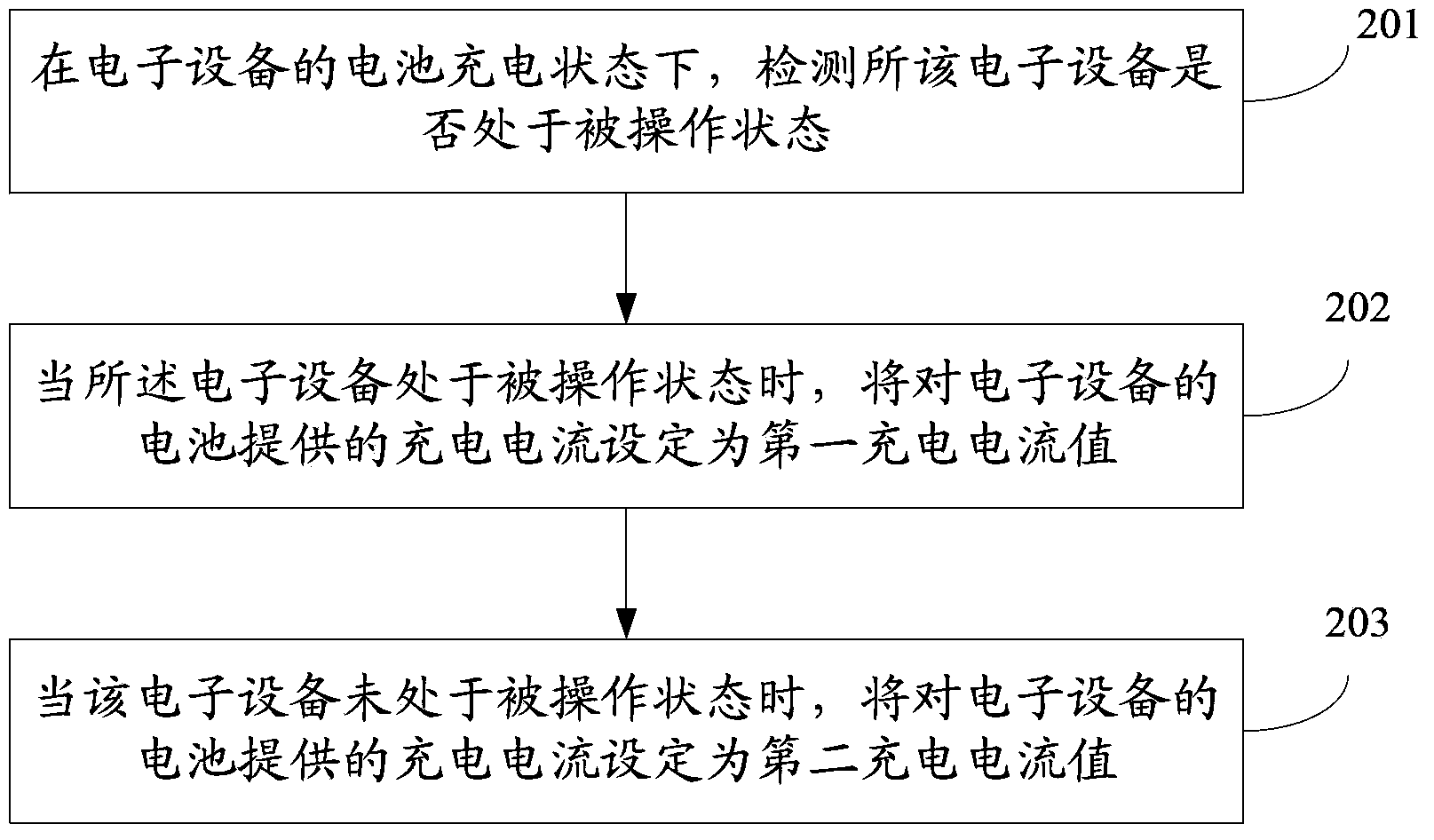

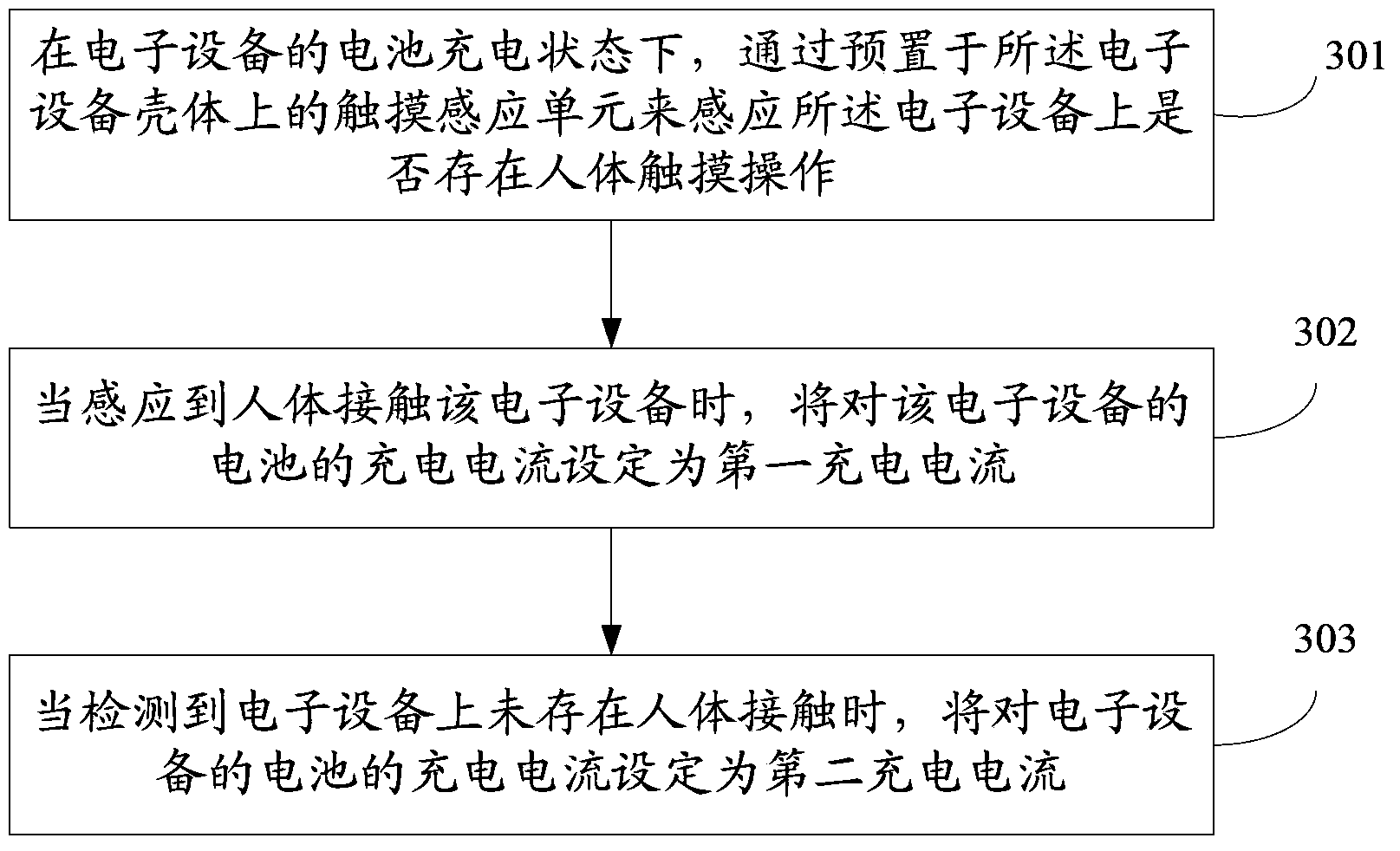

Information processing method and device

ActiveCN103516004AAvoid excessive heatIncrease charging rateBatteries circuit arrangementsElectric powerElectrical batteryBattery charge

The invention discloses an information processing method and device. The method is applied to electronic equipment, and comprises the steps of detecting whether the operation that the human body touches the electronic equipment exists or not in the battery charging state of the electronic equipment; setting a provided charging current on the battery of the electronic equipment as a first charging current value when the fact that the human body touches the electronic equipment is detected; setting the provided charging current on the battery of the electronic equipment as a second charging current value when the fact that the human body does not touch the electronic equipment is detected, wherein the second charging current value is bigger than the first charging current value. The method reduces the influences that operation inconvenience is brought to the using of the electronic equipment by the user in the charging process under the condition that small influences are brought to the charging efficiency of the electronic equipment.

Owner:LENOVO (BEIJING) CO LTD

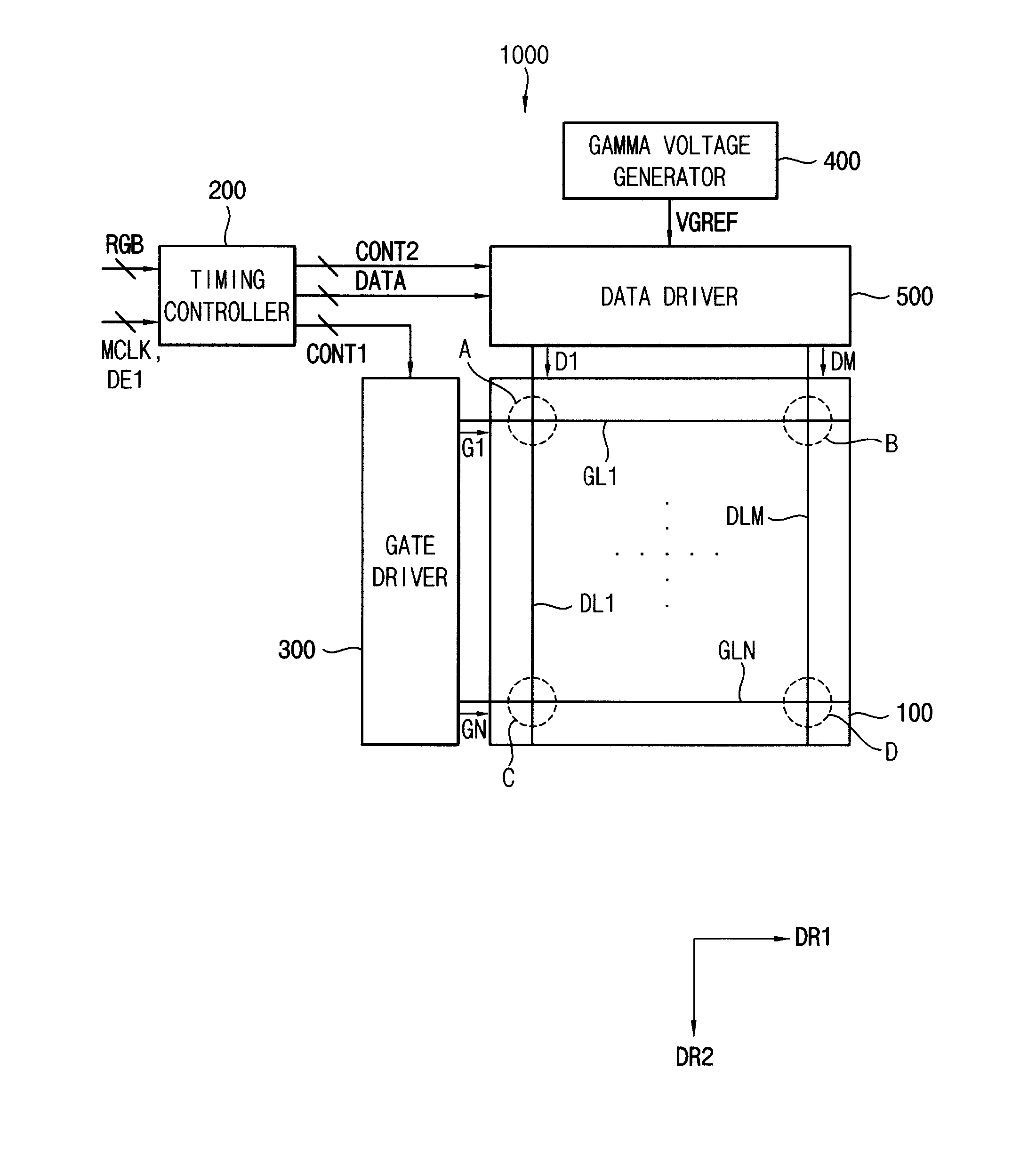

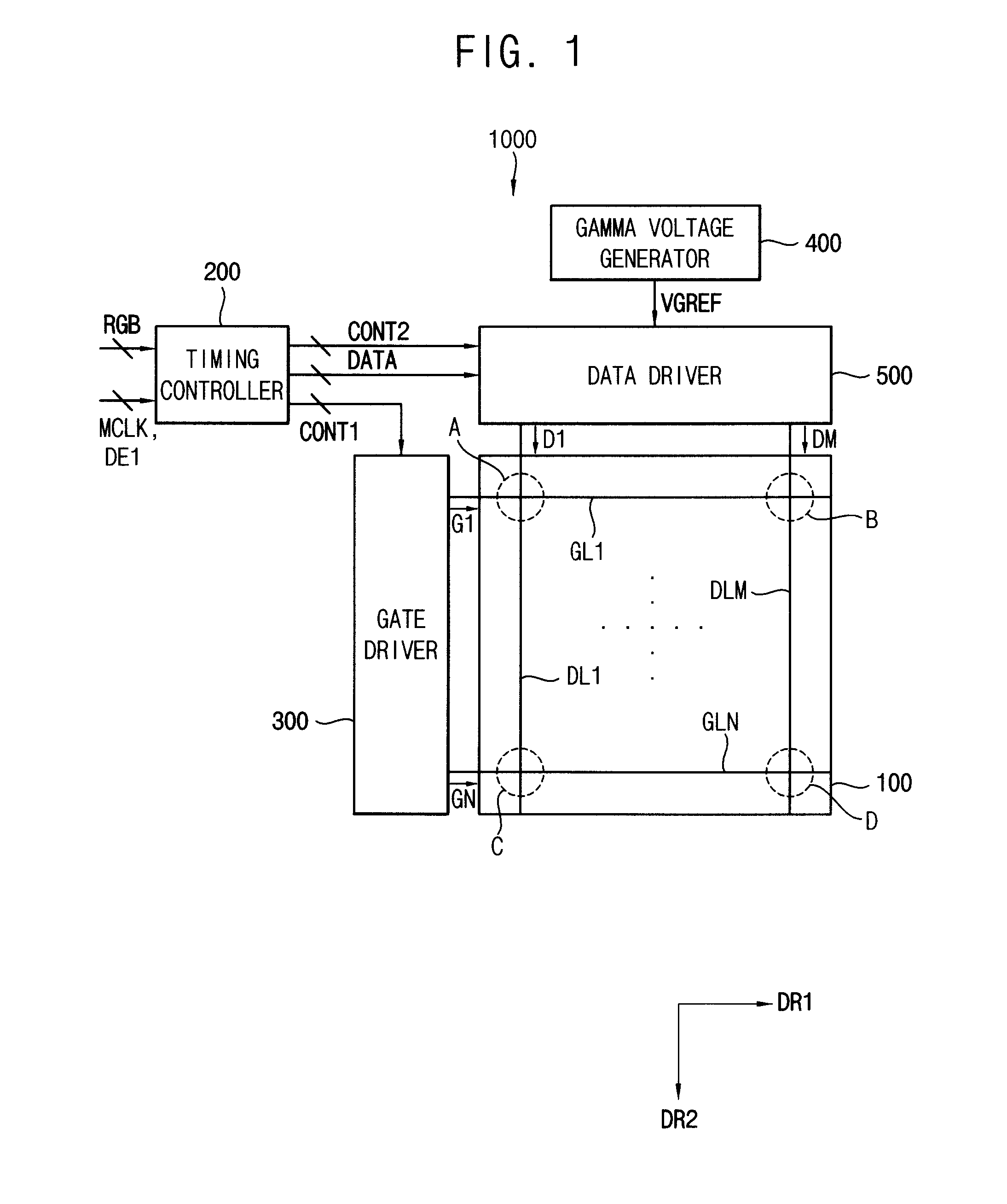

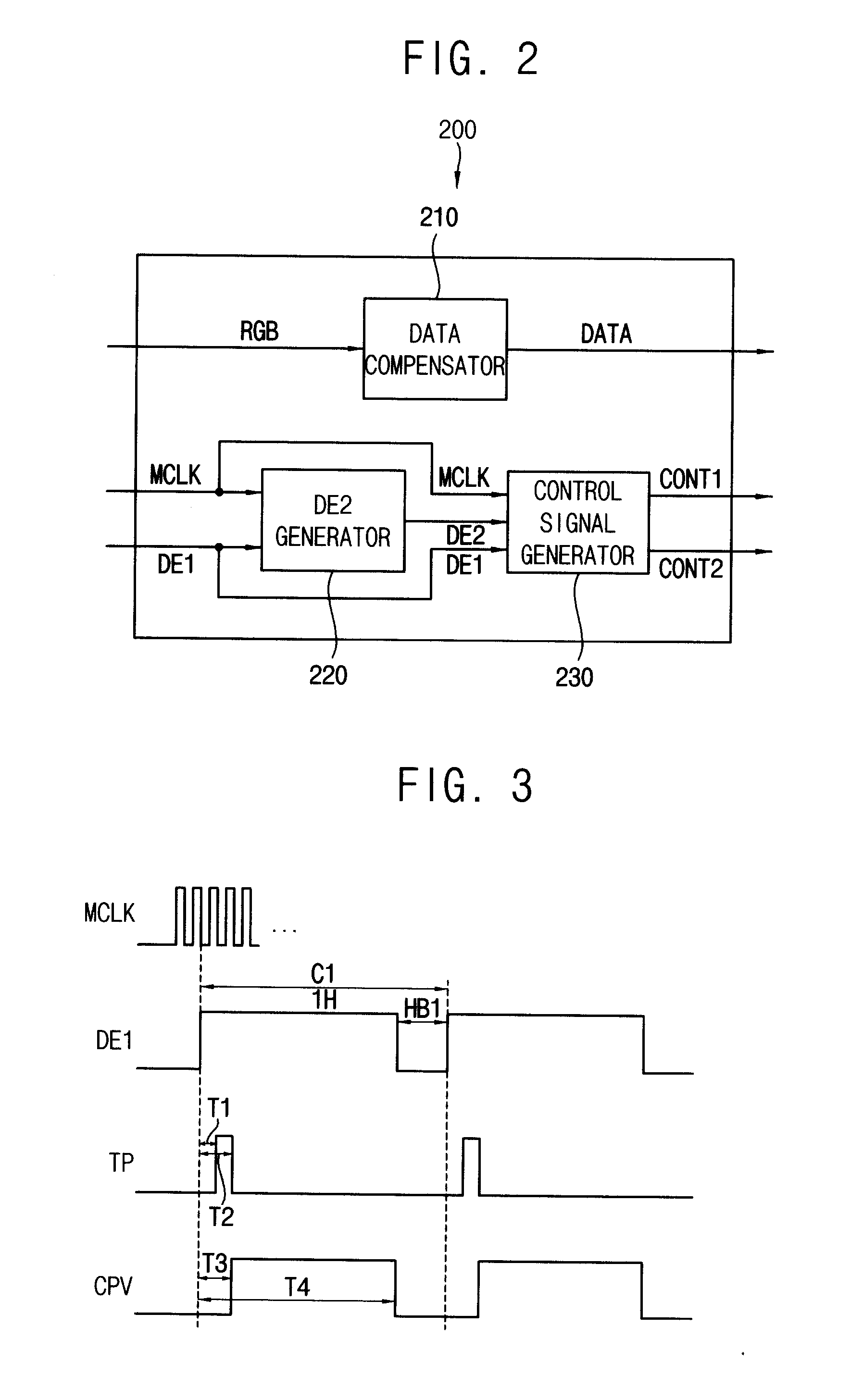

Method of driving display panel and display apparatus for performing the same

ActiveUS20120162185A1Improve display qualityIncrease ratingsCathode-ray tube indicatorsInput/output processes for data processingVoltageData lines

A method of driving a display panel includes converting a first data enable signal including a first cycle based on a compensation parameter to generate a second data enable signal including a second cycle longer than the first cycle, generating a plurality of gate signals based on the second data enable signal to output the gate signals to a plurality of gate lines of the display panel, and generating a plurality of data voltages based on the first data enable signal to output the data voltages to a plurality of data lines of the display panel.

Owner:SAMSUNG DISPLAY CO LTD

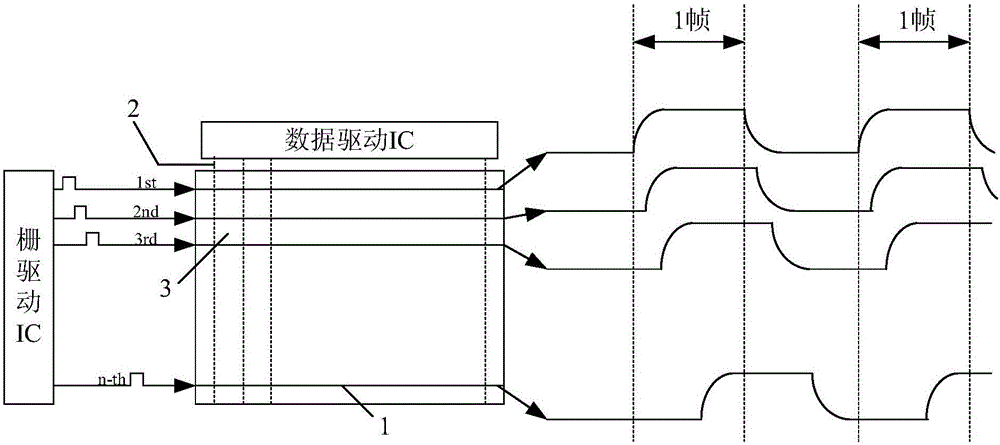

Display substrate as well as driving method and display device

InactiveCN106297712AIncrease the number ofIncrease charging rateStatic indicating devicesCharge rateData signal

The invention provides a display substrate as well as a driving method and a display device, belongs to the technical field of display, and aims to solve the problems that the charge rate of a pixel electrode far away from a signal input end of each data line of a conventional display substrate is reduced, the product productivity can be degraded and the product price is increased. The driving method of the display substrate provided by the invention comprises the following steps of: inputting a grid signal into a grid line so as to power on a switch transistor of a pixel unit controlled by the grid lie; according to the driving signal, inputting a data signal into a data line, so as to enable the data line to output the data signal to the pixel electrode through the switch transistor, wherein the charge time of the pixel electrode far away from the signal input end of the data line is longer than that of the pixel electrode close to the signal input end of the data line.

Owner:BOE TECH GRP CO LTD

Electrolytes for iron flow battery

ActiveUS20170179516A1Rapidly produceHigh charge rateRegenerative fuel cellsIndirect fuel cellsChemistryIron redox

A method of operating an iron redox flow battery system may comprise fluidly coupling a plating electrode of an iron redox flow battery cell to a plating electrolyte; fluidly coupling a redox electrode of the iron redox flow battery cell to a redox electrolyte; fluidly coupling a ductile plating additive to one or both of the plating electrolyte and the redox electrolyte; and increasing an amount of the ductile plating additive to the plating electrolyte in response to an increase in the plating stress at the plating electrode. In this way, ductile Fe can be plated on the negative electrode, and the performance, reliability and efficiency of the iron redox flow battery can be maintained. In addition, iron can be more rapidly produced and plated at the plating electrode, thereby achieving a higher charging rate for all iron flow batteries.

Owner:ESS TECHNOLOGY

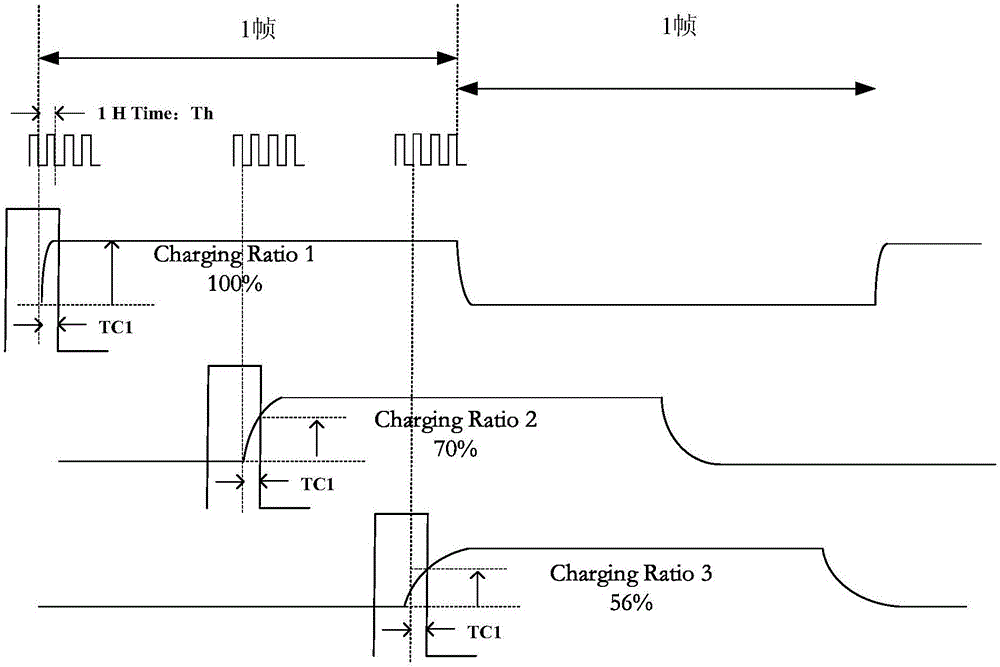

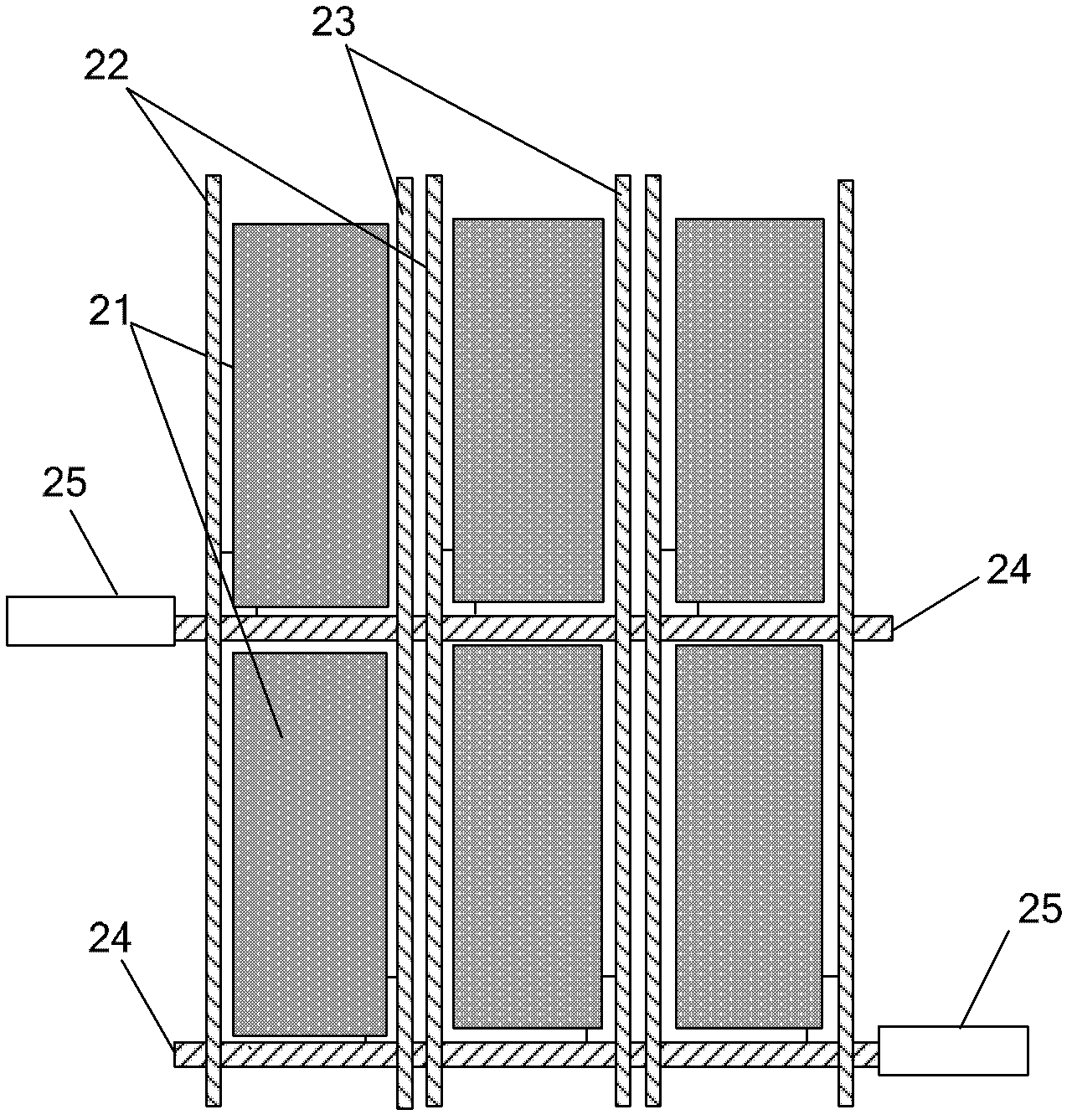

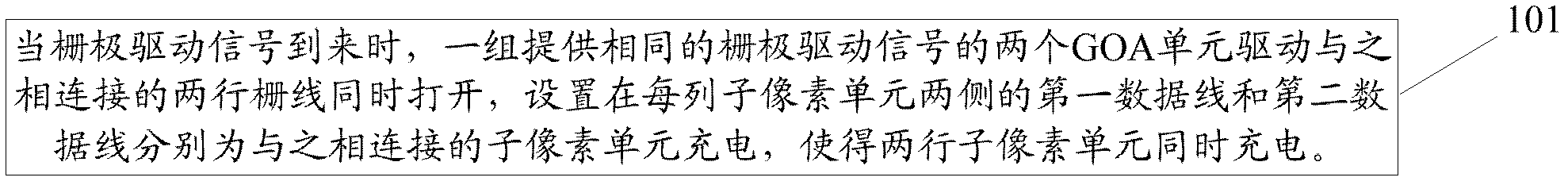

TFT-LCD (thin film transistor-liquid crystal display) panel and driving method thereof

InactiveCN102681273AReduce Logic PowerIncrease charging timeStatic indicating devicesNon-linear opticsLiquid-crystal displayCharge rate

The invention discloses a TFT-LCD (thin film transistor-liquid crystal display) panel and a driving method thereof and relates to the field of liquid crystal displays. Panel power consumption cannot be increased while requirements of pixel charge rate can be met at high refresh frequency. The TFT-LCD panel comprises a plurality of sub-pixel units crosswise defined by several rows of grid lines and several columns of data lines, each row of grid lines is connected with a GOA (gate driver on array) unit used for providing grid driving signals, a first data line and a second data line which are used for providing data to the sub-pixel units in each column are arranged on two sides of each column of the sub-pixel units respectively, each two adjacent sub-pixel units in each column are respectively connected with the first data line and the second data line, each two GOA units provide the same grid driving signals, and one of the two GOA units providing the same grid driving signals is connected with the grid lines in odd rows while the other of the two GOA units is connected with the grid lines in even rows.

Owner:BOE TECH GRP CO LTD

Novel fuel cells and methods of manufacturing the same

InactiveUS20080003481A1Increase charging rateImprove reaction efficiencyElectrolyte holding meansFinal product manufactureFuel cellsElectrolysis

A fuel cell, comprising an electrolyte body and, embedded within it, at least two separate electrodes capable of conducting electrons; the electrodes being sufficiently porous to allow gas flow through them; one electrode being an electrically negative anode and the other electrode being an electrically positive cathode, and the electrolyte body being capable of carrying charged particles between the anode and cathode; the anode and cathode being electrically connected to form an electrical circuit.

Owner:APPLIEDUS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com