Dual-seal-head controllable water heat removing reactor

A double-head, reactor technology, applied in the preparation of carbon monoxide or formate reaction, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as large system resistance, low recovery efficiency of sensible heat and latent heat, and large investment in equipment , to achieve the effect of solving the problem of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

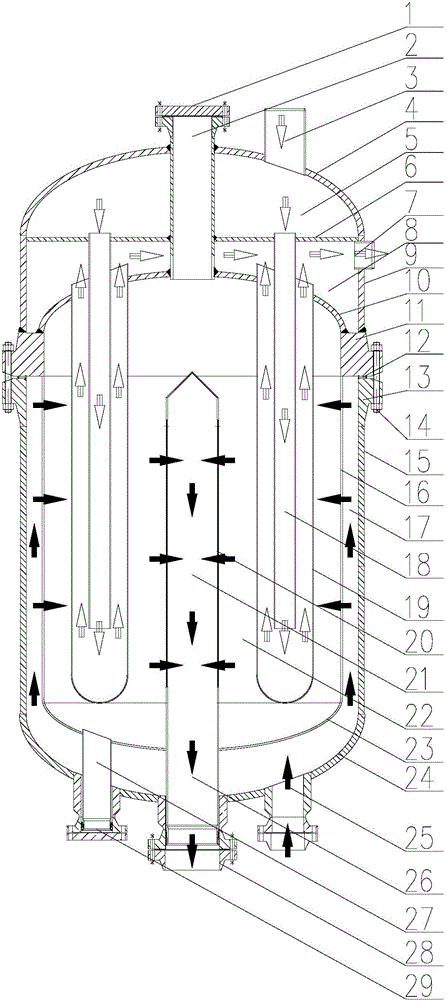

[0030] Such as figure 1 As shown, this embodiment includes a catalyst filling pipe 2, a water inlet pipe 3, an upper and outer sealing head 4, a partition 6, a water outlet pipe 7, a plurality of water guide pipes 18, a plurality of heat exchange pipes 19, an upper inner sealing Head 10, upper flange 11, gas distribution cylinder 16, gas collecting cylinder 20, lower inner head 23 and catalyst self-unloading pipe 27, lower flange 13 connected as one, main cylinder body 15, lower outer head 24, catalyst Self-unloading port 29, air inlet 25 and air outlet 28;

[0031] The water inlet pipe 3 is set on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com