Novel tea knead entwist machine

A kneading machine and tea technology, which is applied in the field of new tea kneading machines, can solve problems such as difficult separation of broken tea and finished tea, unbalanced kneading force, and unreasonable setting of ribs, so as to prevent bones from becoming brittle, operate smoothly, and facilitate The effect of collection processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

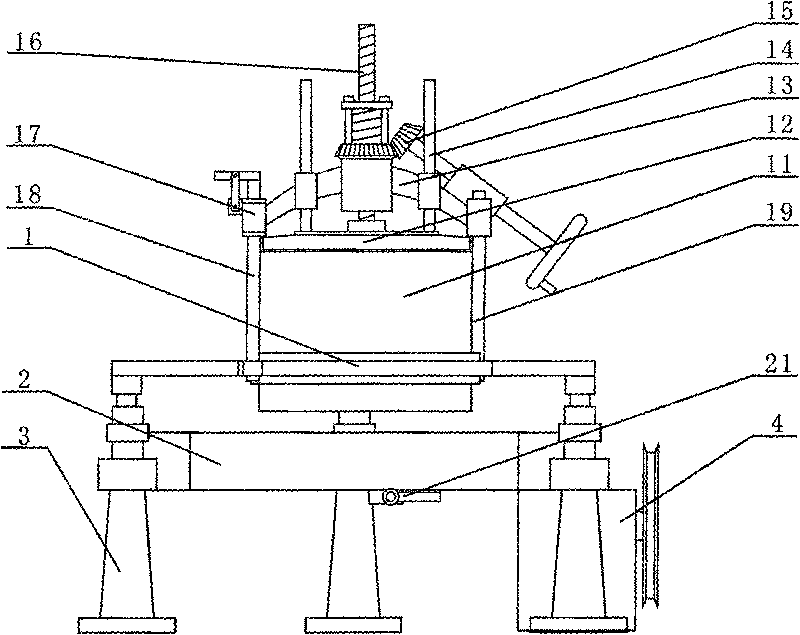

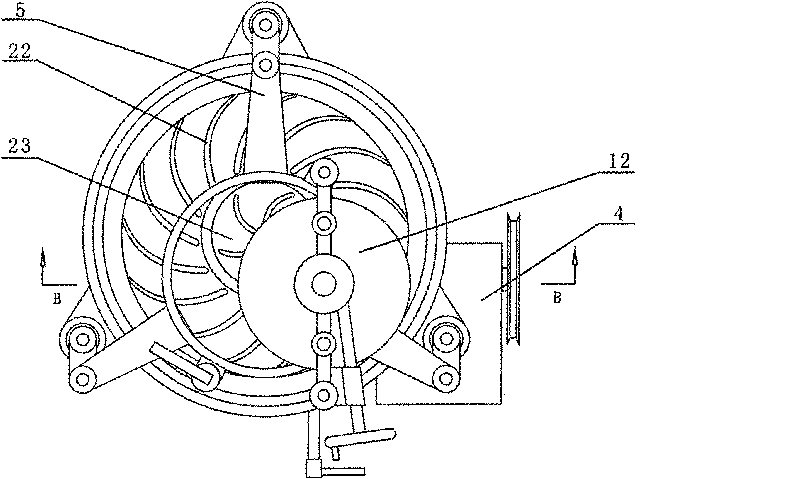

[0025] Such as figure 1 and figure 2 Among them, a novel tea rolling machine comprises a bracket 3, on which a transmission mechanism 4 is arranged, a kneading disk 2 is fixedly mounted on the bracket 3, and a kneading device 1 is installed on the bracket 3 through a plurality of crank rocker mechanisms 5, wherein A crank rocker mechanism 5 is connected with the transmission mechanism 4 .

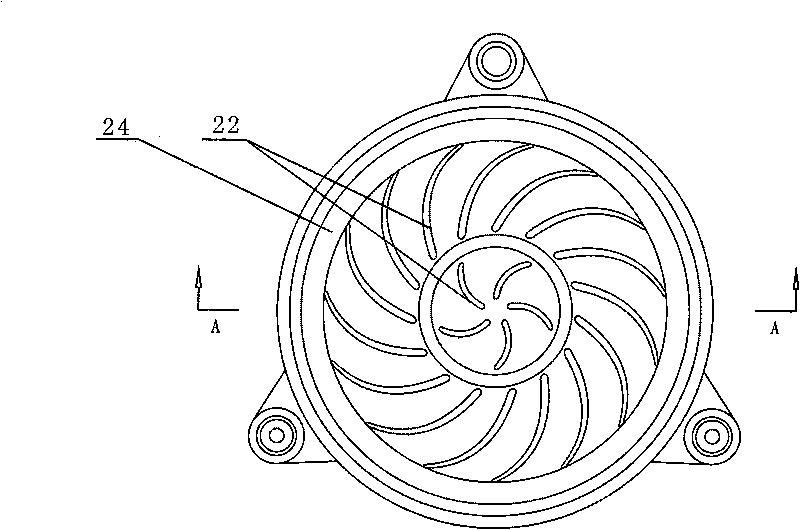

[0026] Such as Figure 4 Among them, the kneading plate 2 is divided into a crushed tea platform 24 and a kneading area 25, and the angle between the kneading area 25 and the horizontal plane is 3°-8°, and the angle adopted in this example is 5°.

[0027] Such as figure 1 and figure 2 Among them, a discharge tray 23 is arranged in the middle of the kneading disc 2, and the discharge tray 23 is connected with a discharge switch 21.

[0028] Such as image 3 , Figure 6 Among them, the kneading disc 2 and the discharge disc 23 are provided with a plurality of ribs 22, and the plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com