Synthetic magnetic field type on-line steel rail welding seam normalizing treatment method and normalizing middle-frequency inductor

A technology of synthetic magnetic field and normalizing treatment, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of poor normalizing quality, low heating efficiency, slow internal heating, etc., to improve the surface quality of rails and the quality of normalizing. , to ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

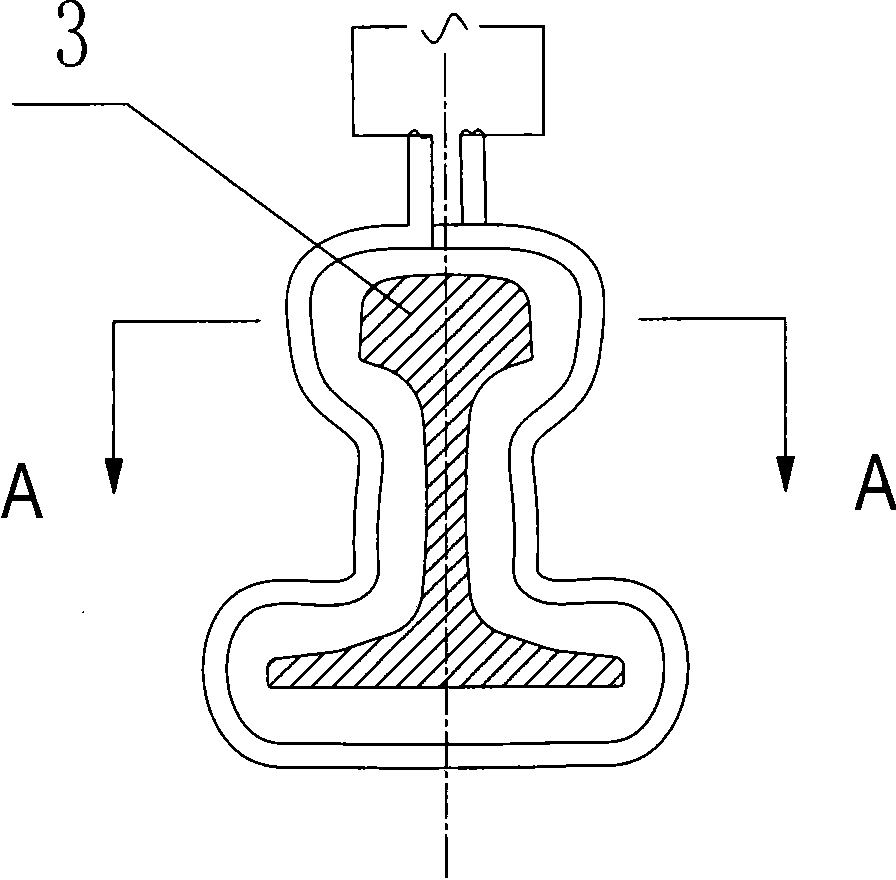

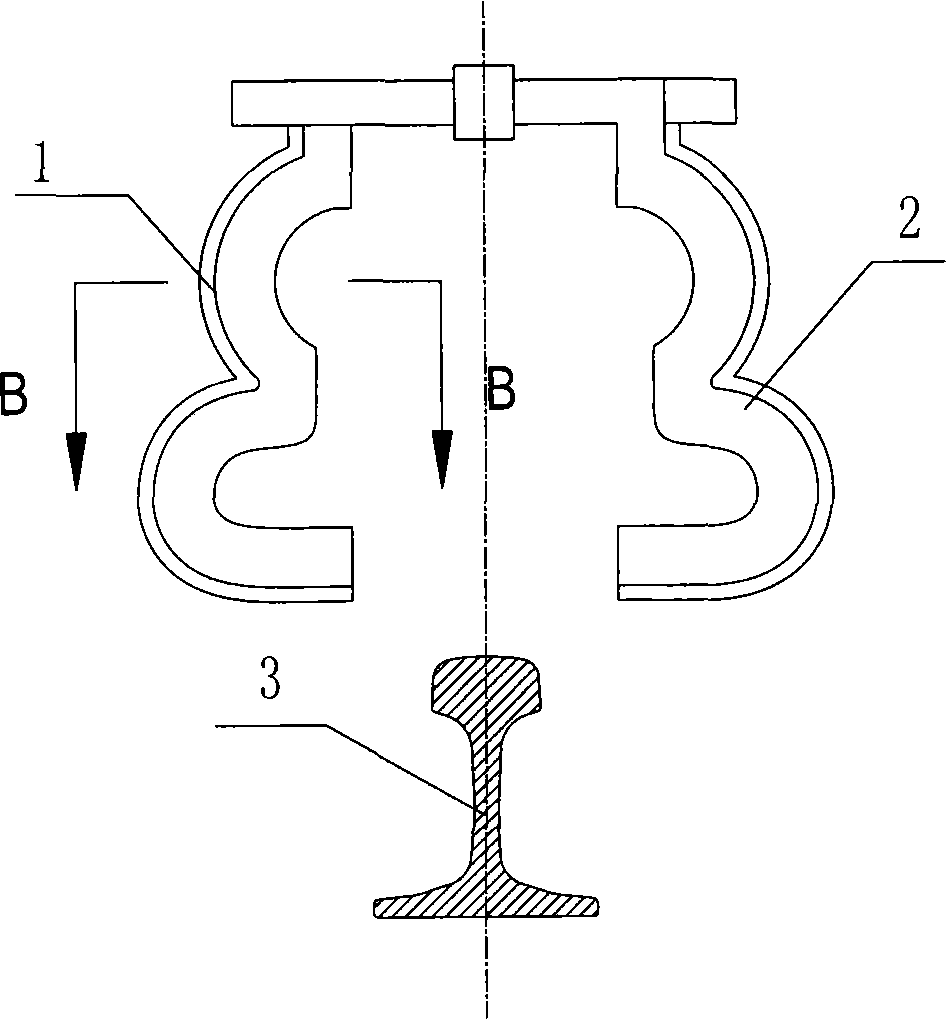

[0031] figure 1 and figure 2 It is a schematic structural diagram of using an annular hollow coil inductor to cover the weld of the rail 3 for electromagnetic induction heating in the existing rail welding workshop. Its working principle has been introduced in detail in the background technology section, so it will not be repeated here.

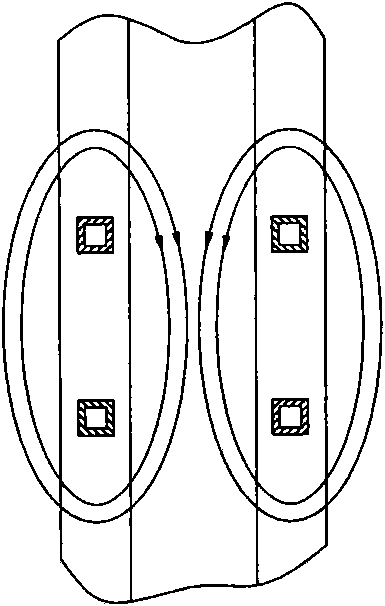

[0032] Since the annular inductor cannot be set on the laid rail 3, the present invention proposes a method of normalizing the online rail by utilizing two sub-inductors that can be separated and closed. The heating process is as follows: two independent and identical sub-inductors are coated on the outer surface of the weld seam of the online rail, and the inner shape of the two sub-inductors after fastening is consistent with the cross-sectional shape of the rail; After covering, the contact surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com