Pipe manufacturing machine for metal bellows

A pipe making machine and corrugated technology, which is applied in the field of metal corrugated pipe machines, can solve the problems of poor quality and low production efficiency of corrugated pipes, and achieve the effects of improving quality, improving pipe making efficiency, and easy buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

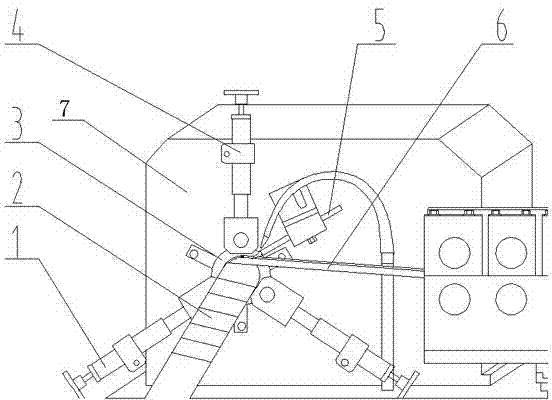

[0010] figure 1 Shows the overall structure diagram of a metal corrugated pipe machine provided by the present invention. The metal corrugated pipe machine is mainly composed of an extrusion device, a buckle wheel 3, and a buckle wheel support frame 2. The buckle wheel 3 is arranged at the top end of the buckle wheel support frame 2, the extrusion device is connected to the casing of the pipe making machine, and the extrusion head is placed near the buckle wheel 3, and the gap is not less than the thickness of the steel strip. The machine is also provided with an edge pin 5, which is connected to the support frame of the buckle wheel 3, the needle head faces the buckle wheel direction, the squeezing device includes a first squeezing device 1, a second The squeezing device 4 and the third squeezing device 7 are movably connected; when the machine starts to work, the steel belt enters the buckle wheel 3, and the buckle wheel 3 starts to buckle. The side needle 5, through the squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com