Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Guaranteed cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

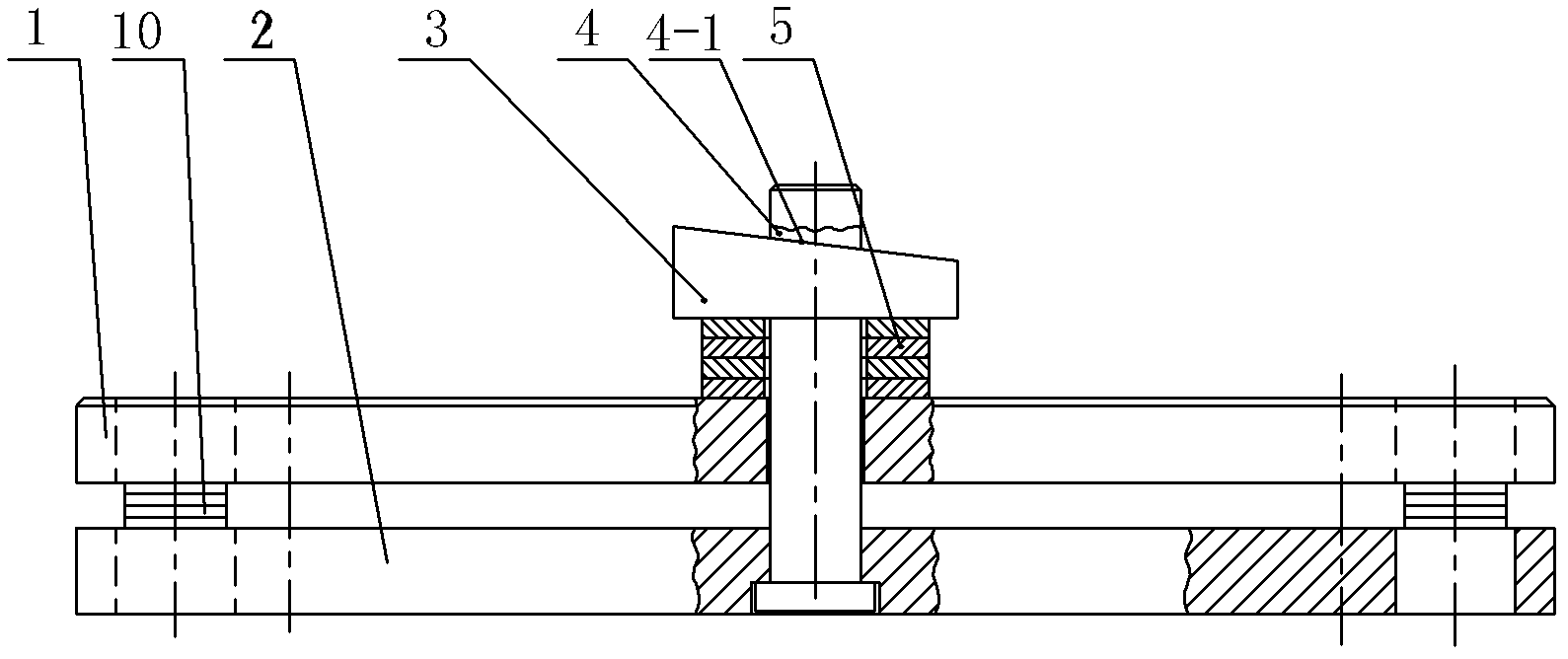

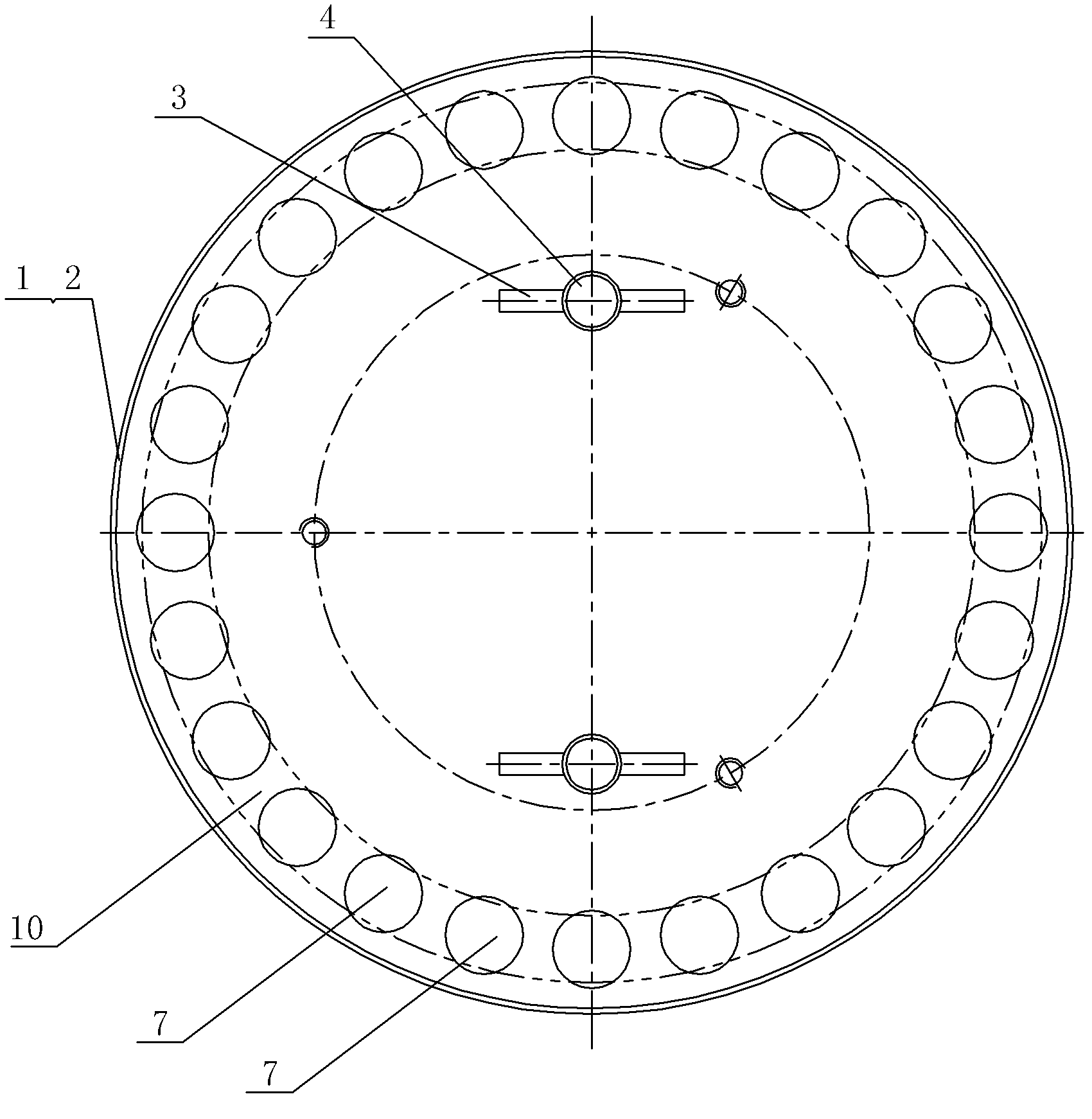

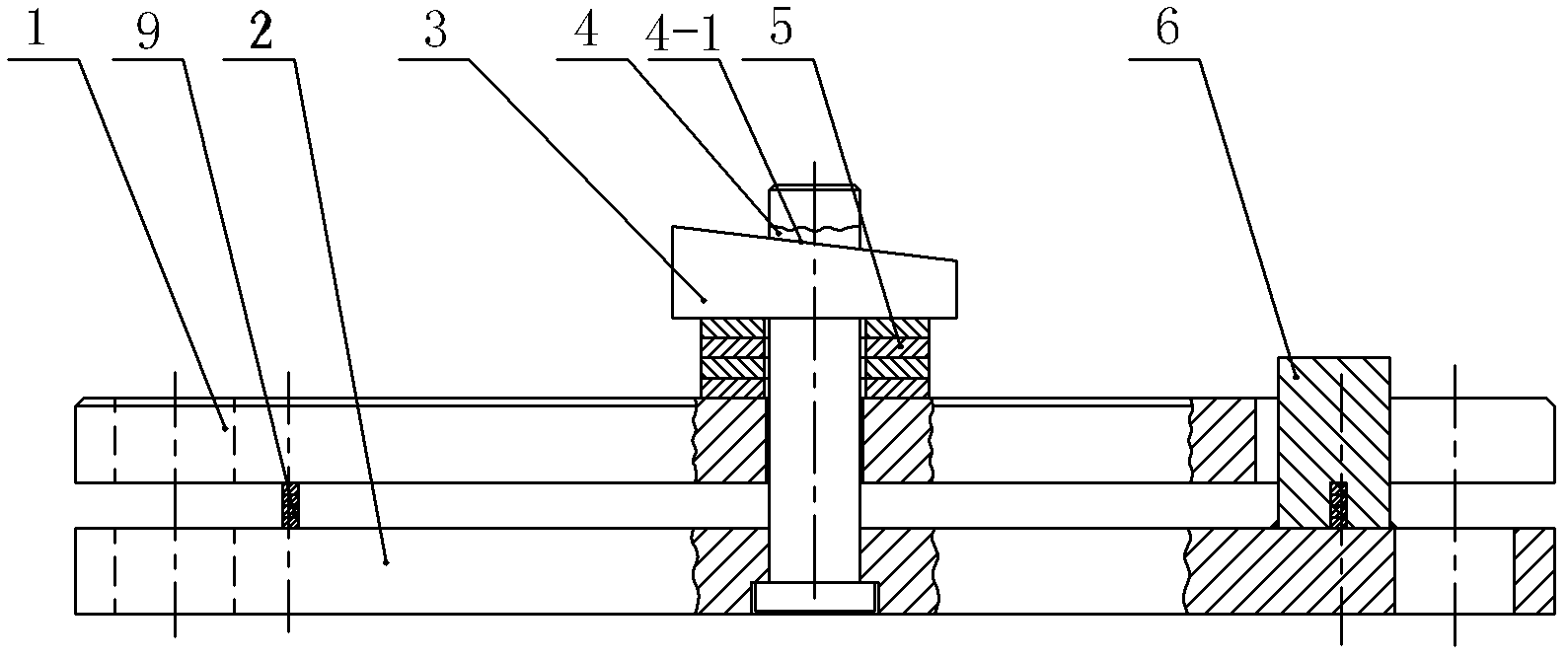

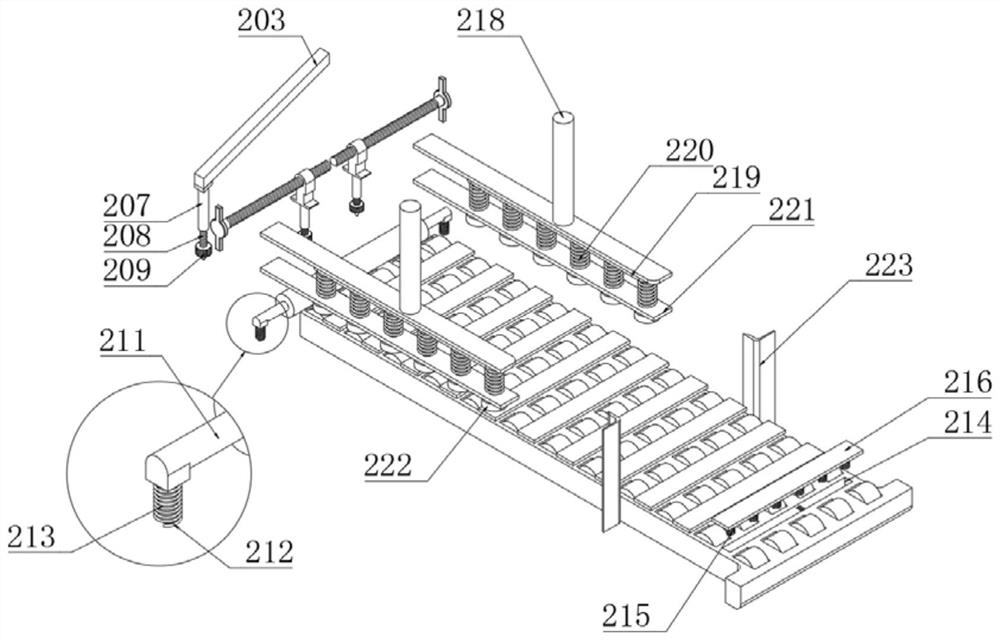

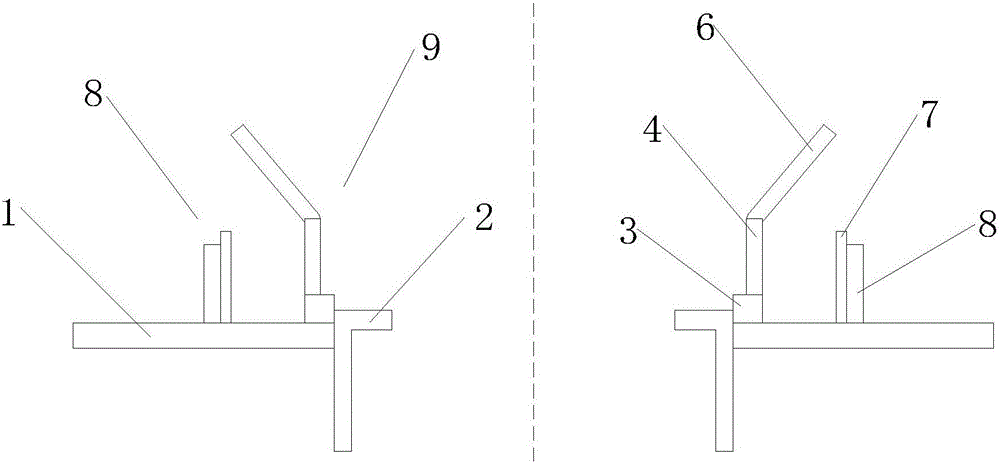

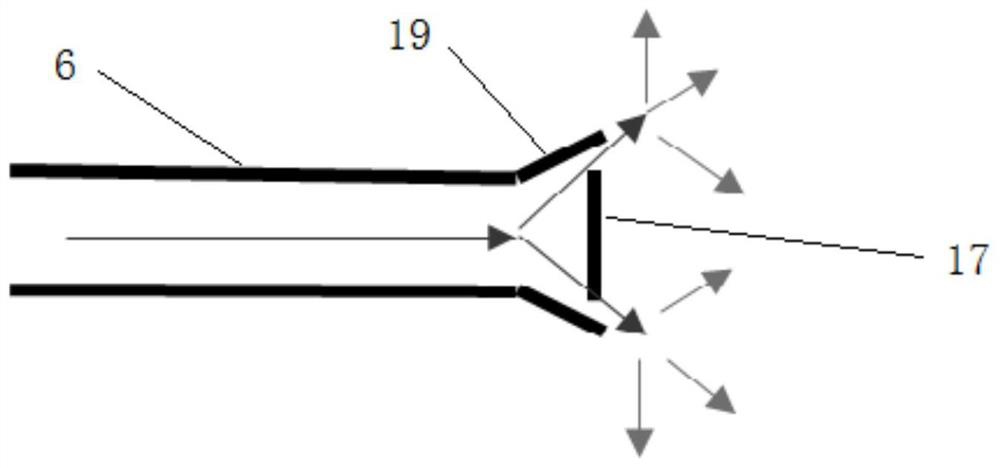

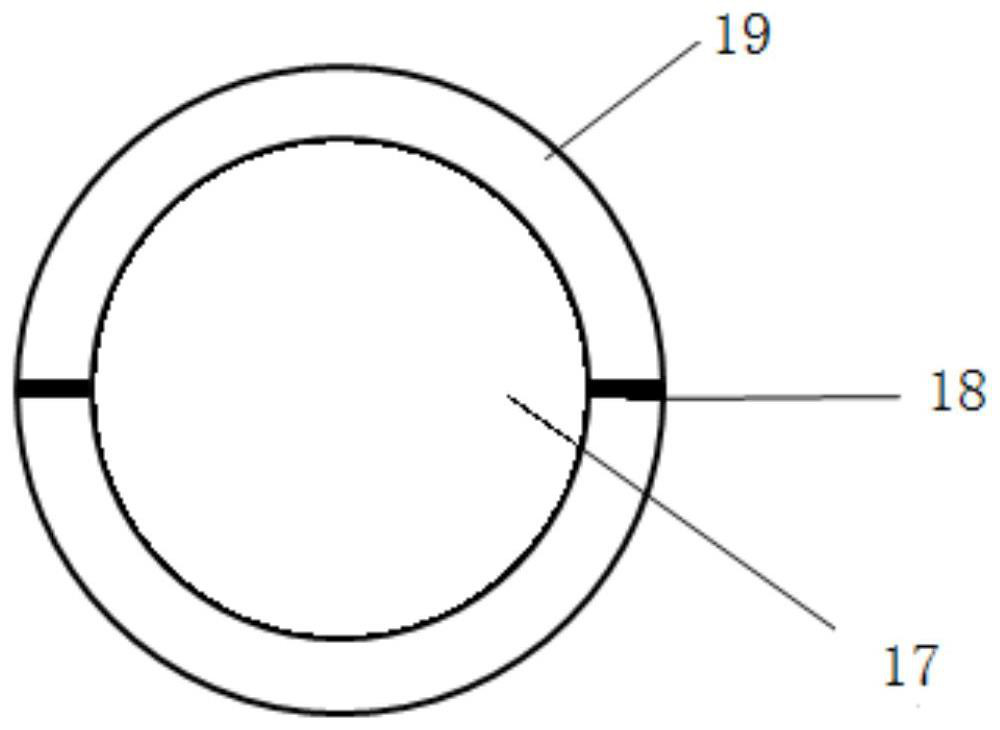

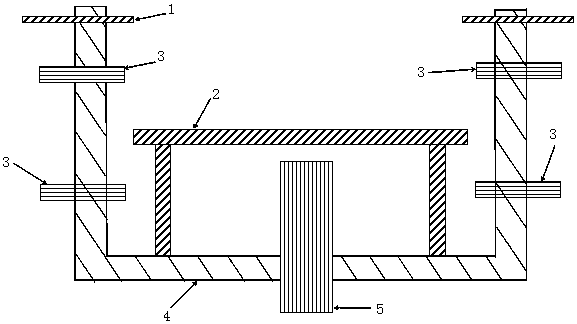

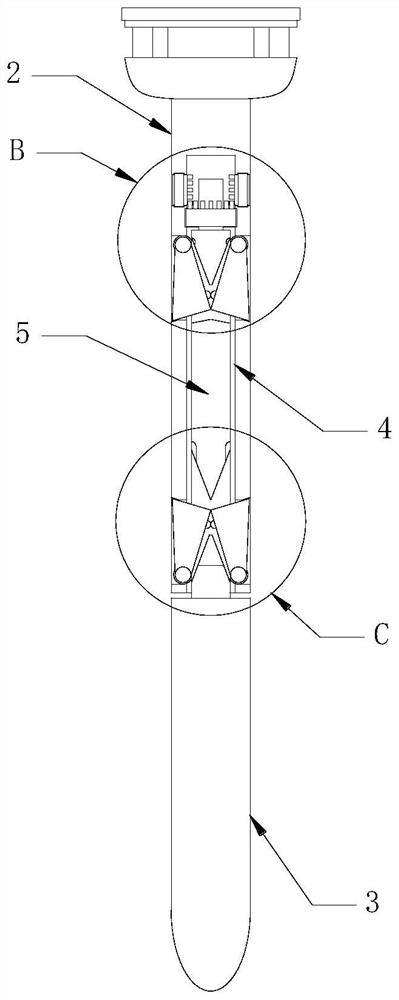

Heat shaping fixture and heat shaping method in quenching process of metal material seal ring

ActiveCN102321796AQuality assuranceEasy to operateFurnace typesHeat treatment furnacesMetallic materialsWaste product

The invention discloses a heat shaping fixture and a heat shaping method in the quenching process of a metal material seal ring, and relates to a heat shaping fixture and a heat shaping method in the quenching process of a seal ring. The invention solves the problems that the integral hardness of a seal ring cannot be improved, the opening size cannot be ensured and waste products are easily produced in the conventional quenching technology. The device comprises that: an upper cover plate and a bottom plate are vertically aligned; a wedge block is nailed in an inclined hole of each shaft; the shaft is sleeved with number adjustable gaskets; the metal material seal ring is arranged between the upper cover plate and the bottom plate; an oil immersion hole on the upper cover plate corresponds to the upper end face of the metal material seal ring; and an oil immersion hole of a lower cover plate corresponds to the lower end face of the metal material seal ring. The method comprises the following steps of: clamping the seal ring in the heat shaping fixture; putting the seal ring and the heat shaping fixture into a heat treatment furnace, and completing quenching and tempering procedures of the heat treatment, which meet the hardness requirement; and detaching the heat shaping fixture and taking the seal ring out. The invention is used for heat shaping in the quenching process of the metal material seal ring.

Owner:HARBIN TURBINE

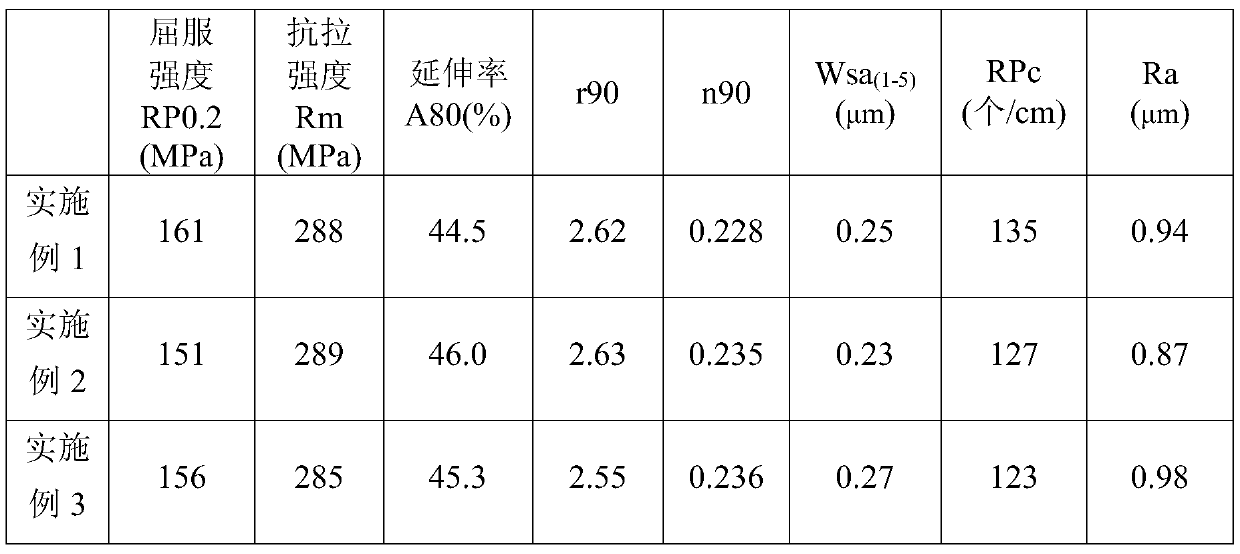

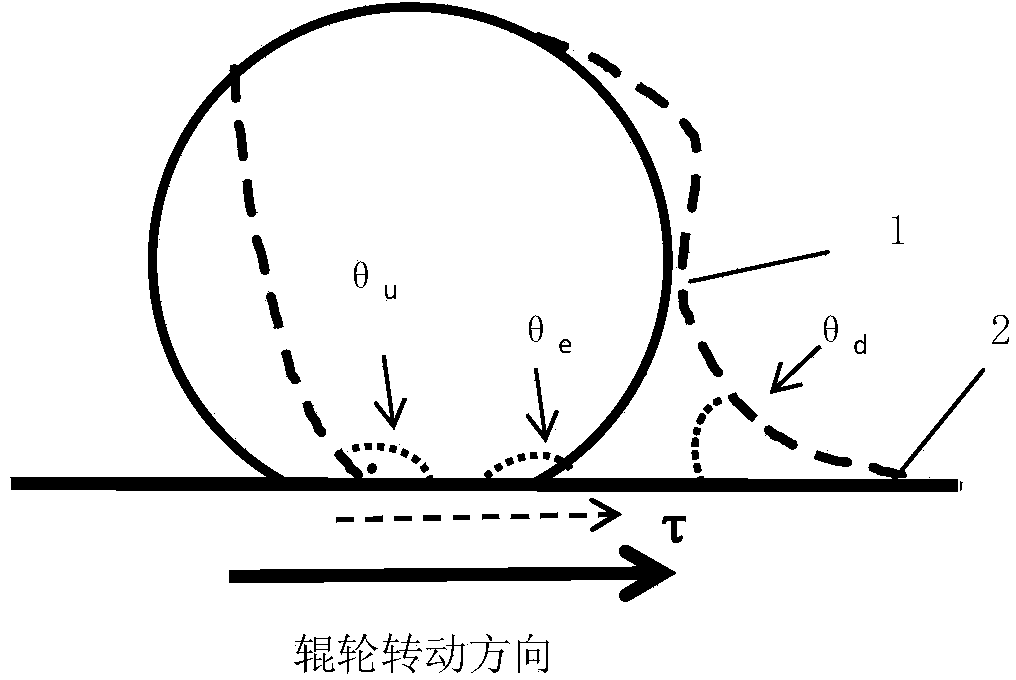

Method for controlling surface appearance of hot-dip galvanized ultra-deep drawing steel for automobile panel

ActiveCN110527921AImprove surface topographyGuaranteed cooling rateHot-dipping/immersion processesSurface roughnessProcess conditions

The invention discloses a method for controlling the surface appearance of hot-dip galvanized ultra-deep drawing steel for an automobile panel. The hot-dip galvanized steel strip comprises the following chemical components in percentage by mass: C is smaller than or equal to 0.0025%, Si is smaller than or equal to 0.020%, Mn is 0.10-0.15%, P is smaller than or equal to 0.012%, S is smaller than orequal to 0.010%, Als is 0.020-0.050%, Ti is 0.055-0.080%, N is smaller than or equal to 0.0040%, and the balance Fe and inevitable impurities. The manufacturing method comprises the steps of smelting, continuous casting, hot rolling, acid continuous rolling, hot galvanizing and the like. By controlling the production process, especially the process conditions of the cold continuous rolling stageand the hot galvanizing stage, the surface roughness and waviness of the hot galvanizing ultra-deep drawing steel can meet the requirements of automobile factories besides good tensile property.

Owner:SD STEEL RIZHAO CO LTD

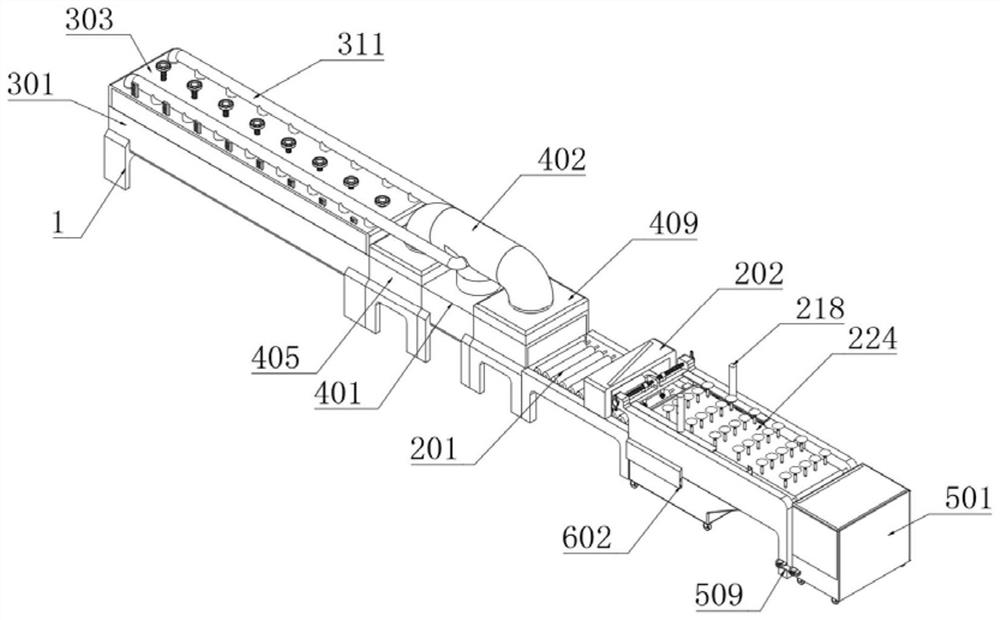

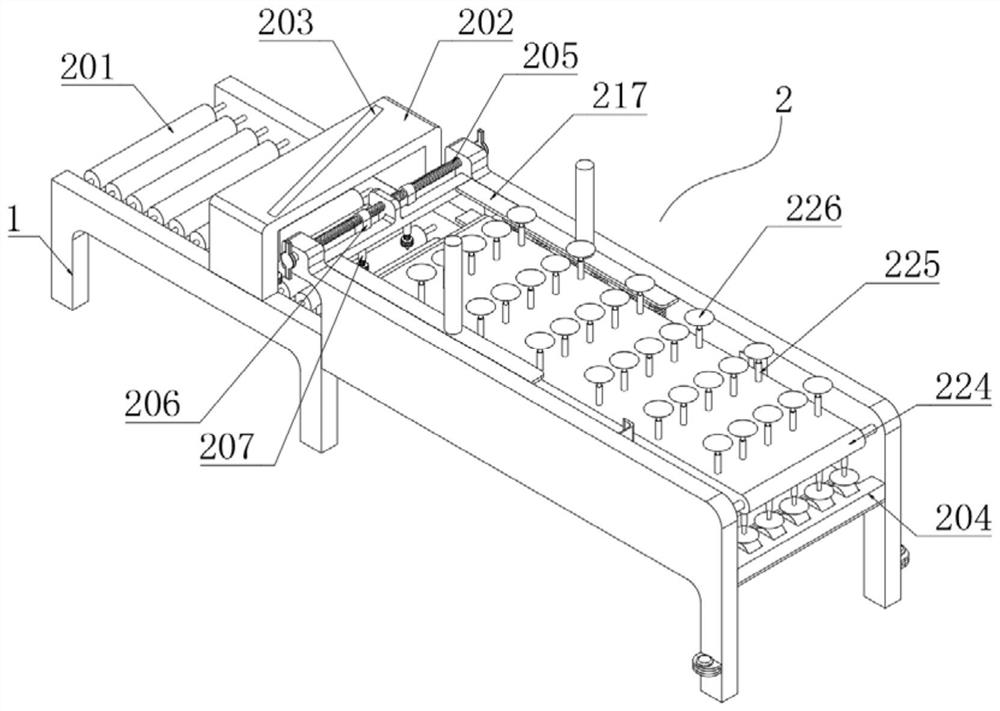

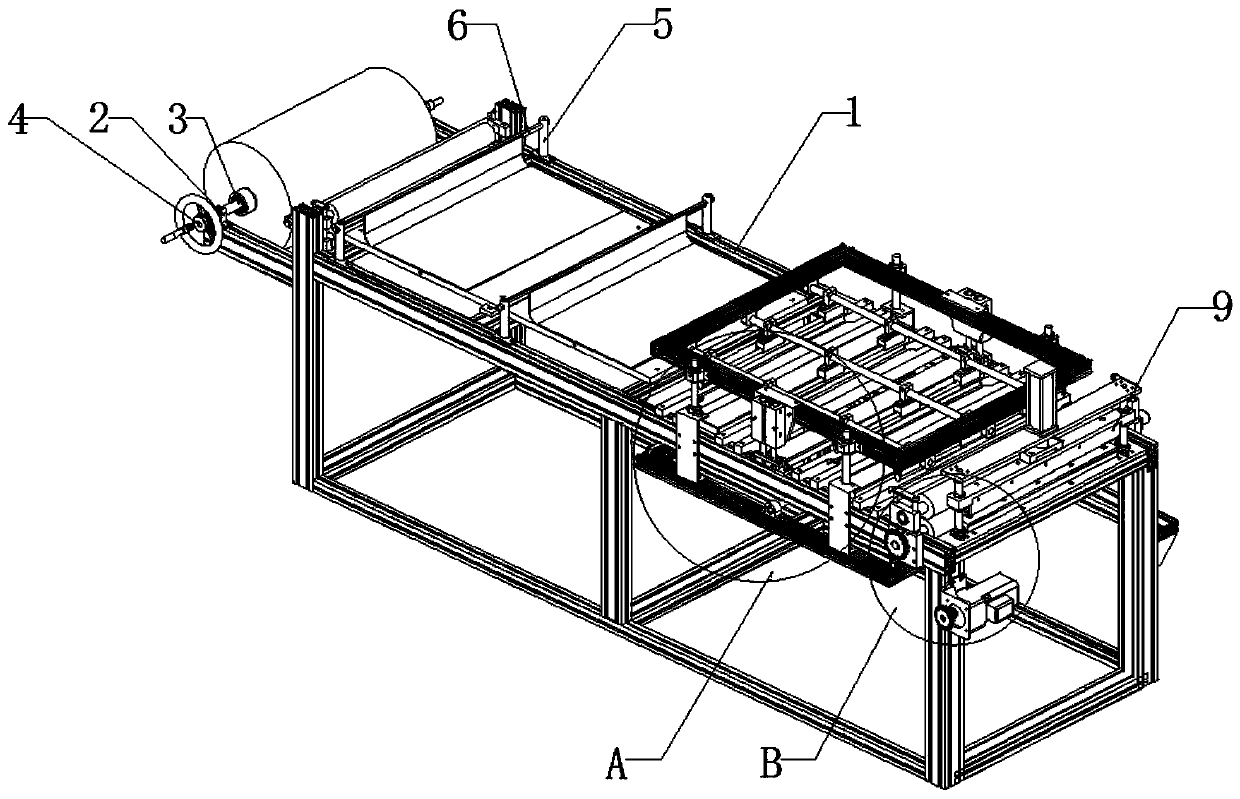

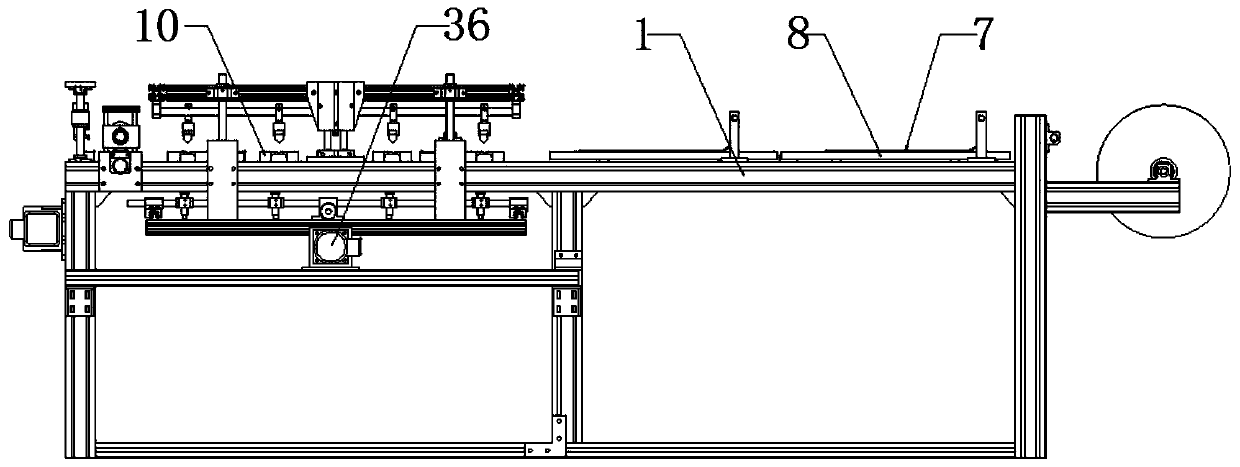

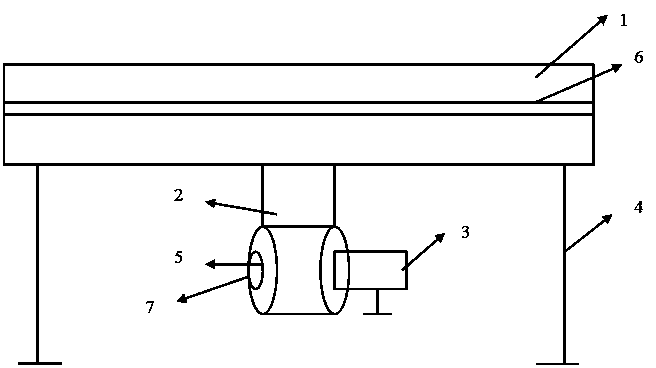

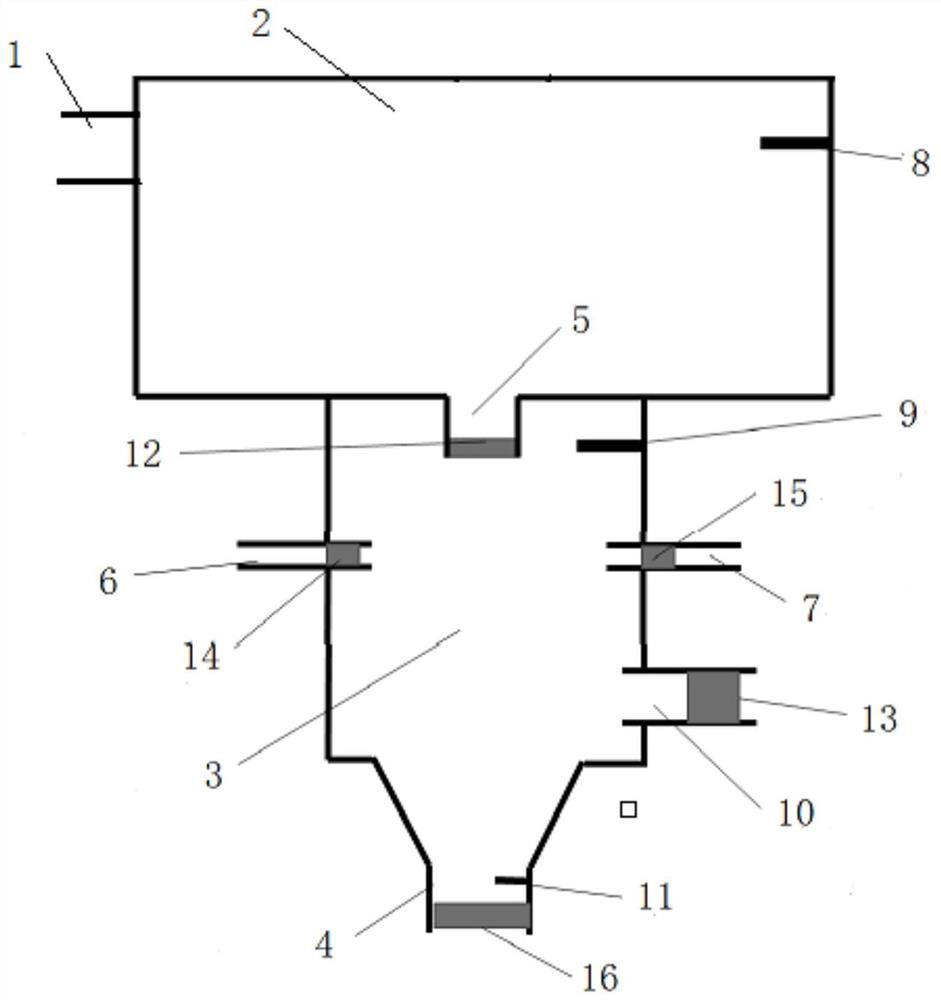

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

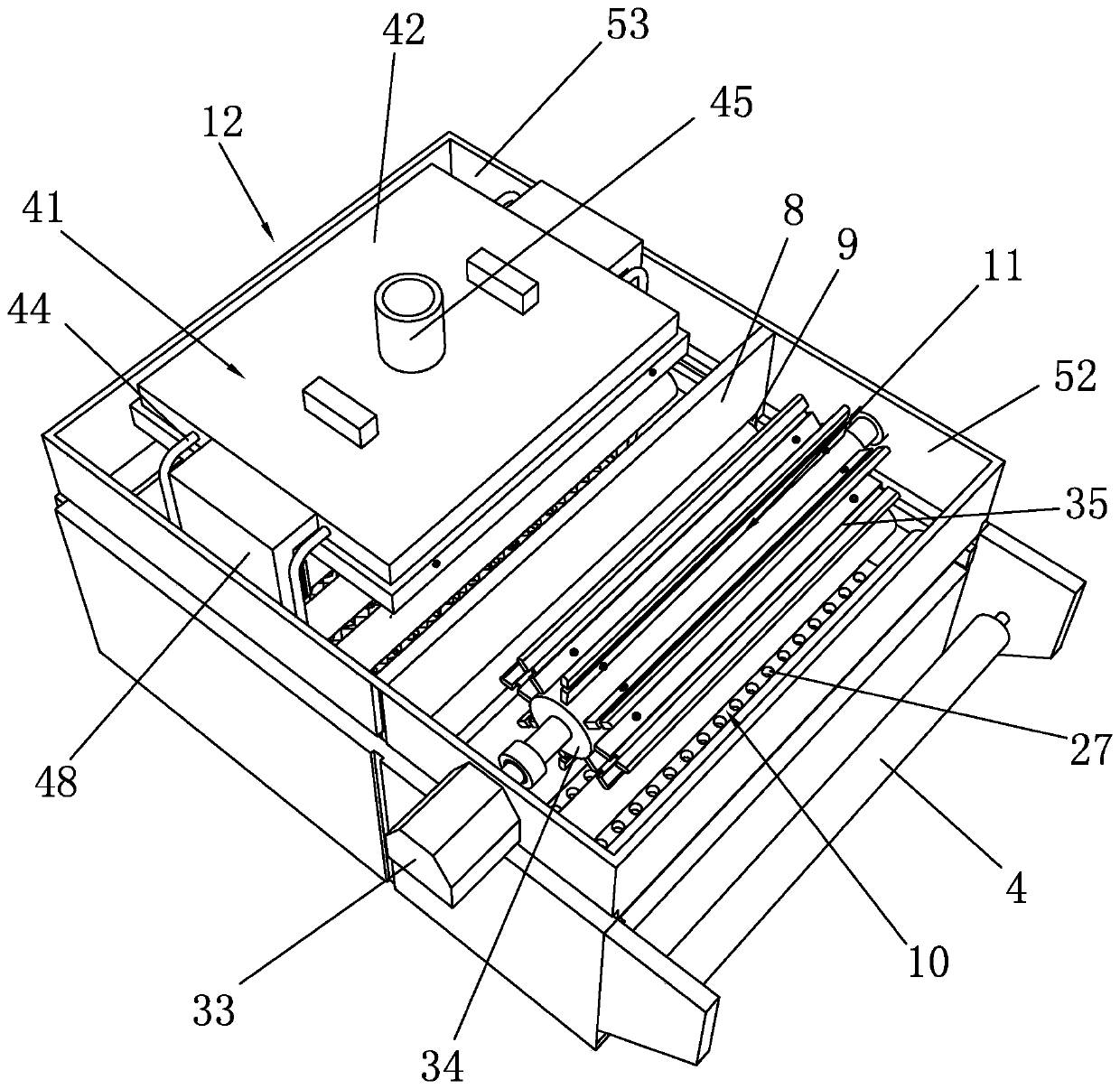

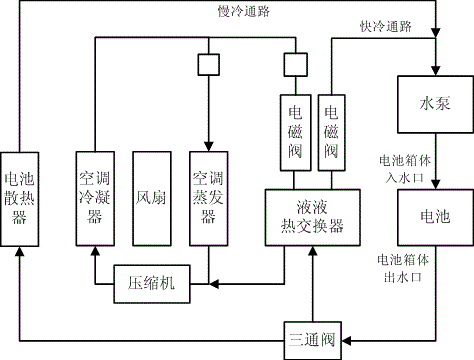

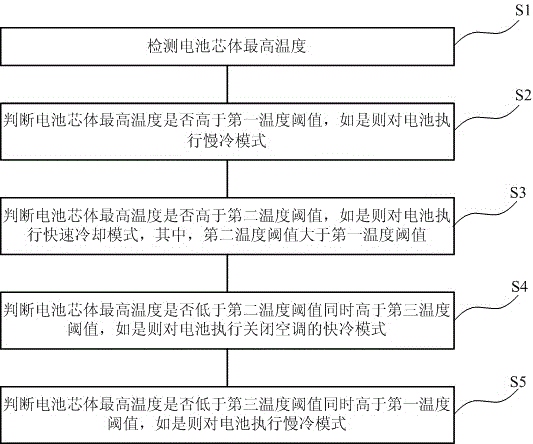

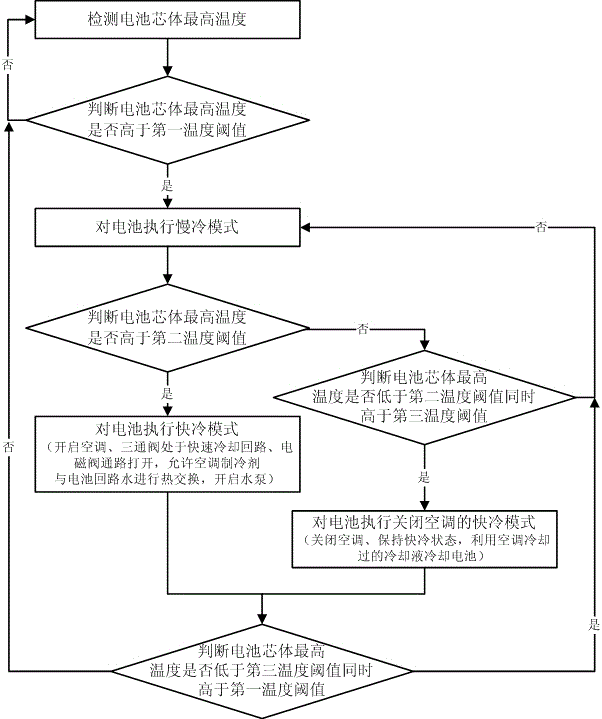

Control method and control system for battery cooling

The invention provides a control method and a control system for battery cooling. The control method comprises the steps of detecting the maximum temperature of a core body of a battery, judging whether the maximum temperature of the core body of the battery is higher than a first temperature threshold, performing a slow cooling mode on the battery if so, judging whether the maximum temperature of the core body of the battery is higher than a second temperature threshold, performing a rapid cooling mode on the battery if so, judging whether the maximum temperature of the core body of the battery is lower than the second temperature threshold and higher than a third temperature threshold, performing an air conditioner closed rapid cooling mode on the battery if so, judging whether the maximum temperature of the core body of the battery is lower than the third temperature threshold and higher than the first temperature threshold, and performing a slow cooling mode on the battery if so. According to the method and the system, the economy, a battery cooling rate and a cooling effect are comprehensively considered according to setting of the temperature thresholds; fuel oil consumption is reduced; an energy source is saved; the battery cooling is realized by cooling a battery circulation waterway coolant with an air conditioner refrigerant; battery overheating can be effectively avoided; and the performance and the safety of a complete vehicle are ensured.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

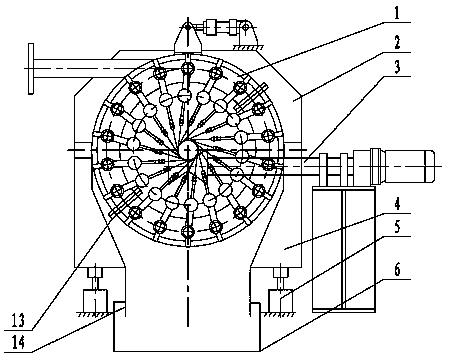

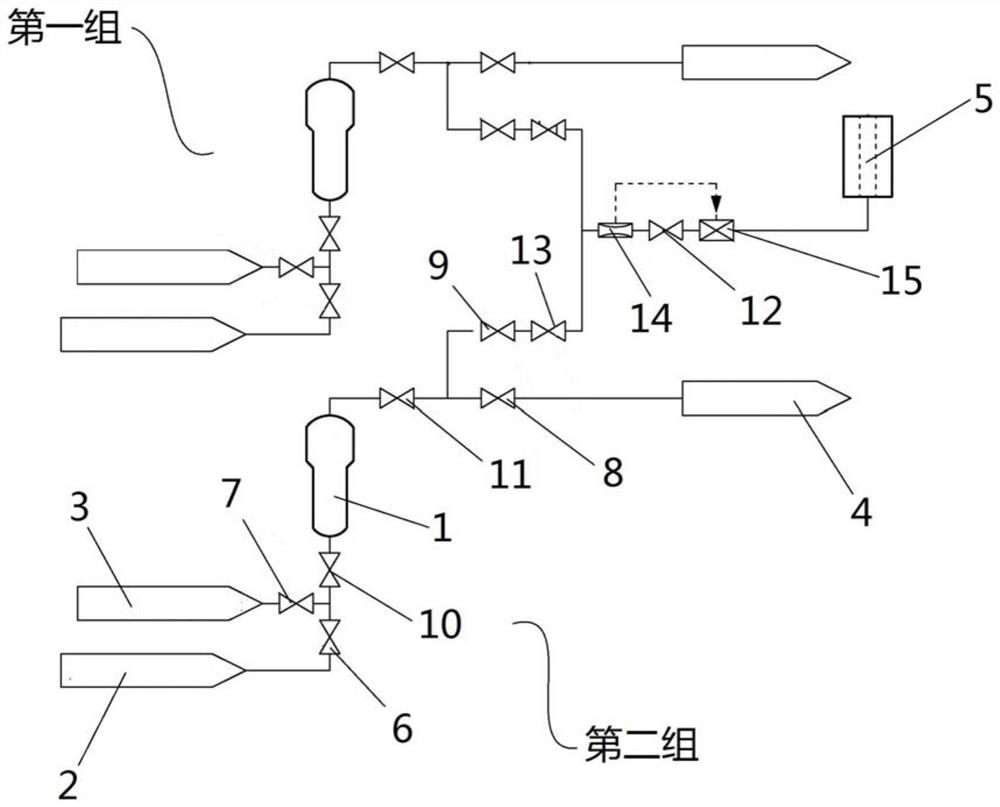

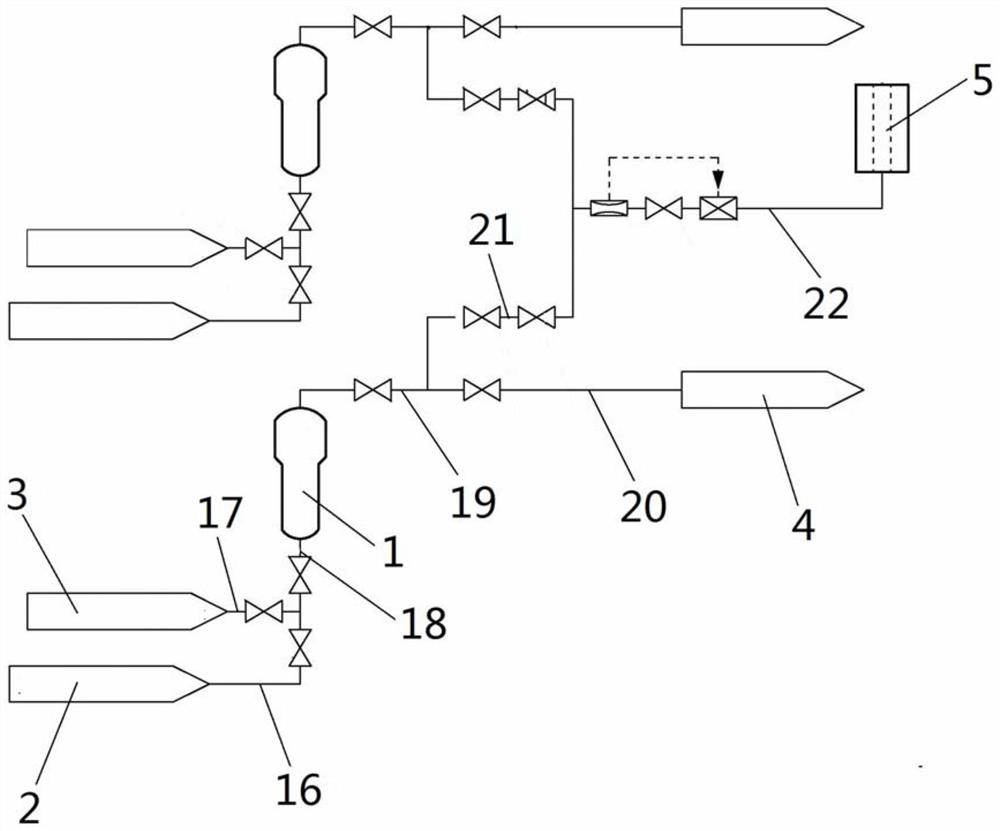

Ringlike quenching device and application method thereof

PendingCN108070701AReduced nozzle unit sizeLow costFurnace typesHeat treatment furnacesQuenchingSteel tube

The invention provides a ringlike quenching device and an application method thereof. The ringlike quenching device comprises water spray rings, a hood, a conveying roller way, a rack, an ascending, descending and guiding device and a water tank. The water tank, the water spray rings and the hood are arranged on the rack. The water spray rings are hooded with the hood and the rack. The lower surface of the rack is connected with the ascending, descending and guiding device. The water tank is located below the rack. The multiple water spray rings are each under independent control, and the water yield of each water spray ring can be adjusted according to the process. By means of the ascending, descending and guiding device, the water spray rings, the hood and the rack can be integrally ascended or descended by a certain distance, and it is guaranteed that the water spray rings are consistent with centers of steel tubes in height. Nozzle devices in the water spray rings can be integrallyrotated by a certain angle, and it is guaranteed that water sprayed out of nozzles is sprayed to the outer surfaces of the steel tubes in the tangential direction; steam films generated on the surfaces are broken up in the quenching process of the steel tubes; the surface heat exchange conditions of the steel tubes are improved; the cooling speed of the steel tubes is increased; it is guaranteedthat a quenching martensitic structure is obtained; and quenching water is prevented from flowing back into a quenching furnace from the inner walls of the steel tubes.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

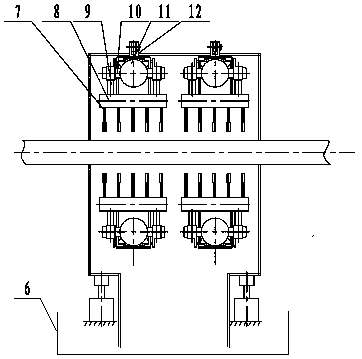

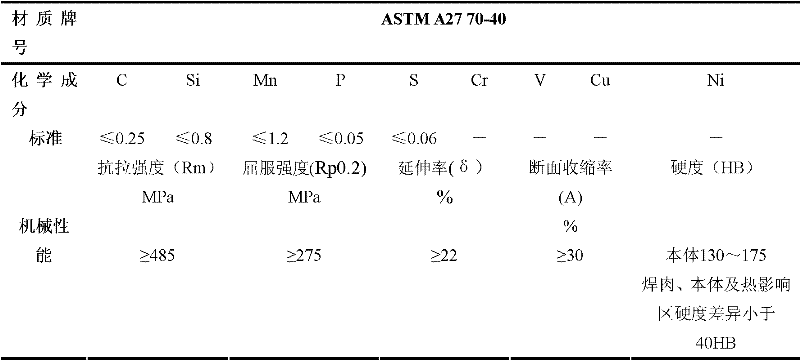

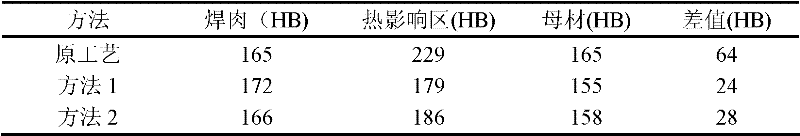

Welding method for controlling hardness of weld seam heat-affected zone of low-carbon steel material for casting

The invention relates to a welding method for controlling hardness of a weld seam heat-affected zone, in particular to a welding method for controlling hardness of weld seam heat-affected zone of a low-carbon steel material for casting. The method is characterized in that the method adopts welding rods of AWS5.1 E7015 with a diameter of 4mm and 5mm, and adopts a temper bead to realize welding under the following conditions: lowest preheating temperature, welding current 175 to 240A, voltage 20 to 30V, and welding speed 10 to 25cm / min. The method provided by the invention is unique, and can control the hardness of a casting body between 160 and 170HB by regulating the chemical components and heat treatment process of a casting. If the hardness of the weld seam heat-affected zone is controlled below 200HB, the hardness difference among the weld seam heat-affected zone, a base material and a weld seam metal can be reduced, and the hardness difference of the weld seam part can be controlled below 40HB.

Owner:KOCEL GROUP +1

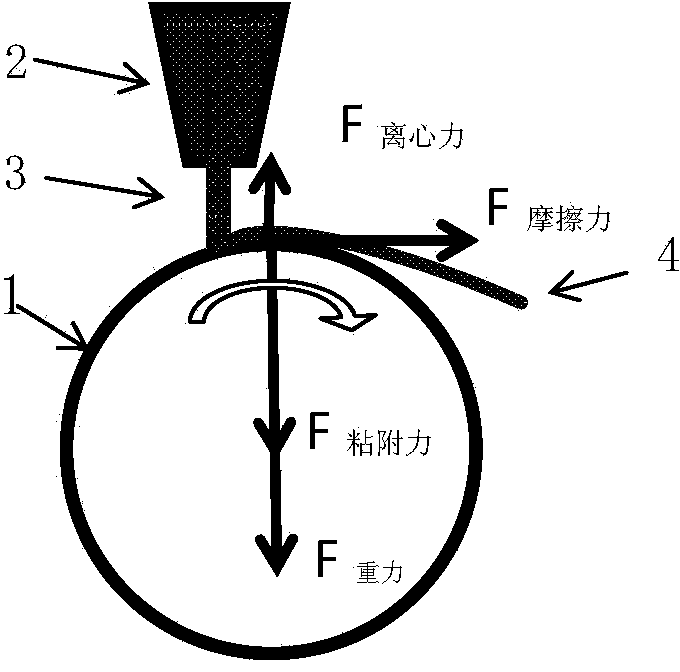

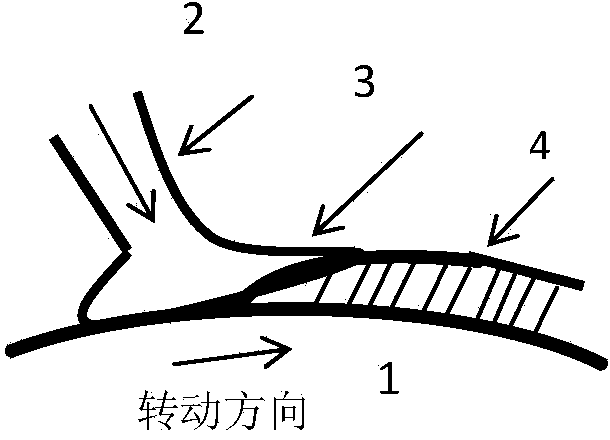

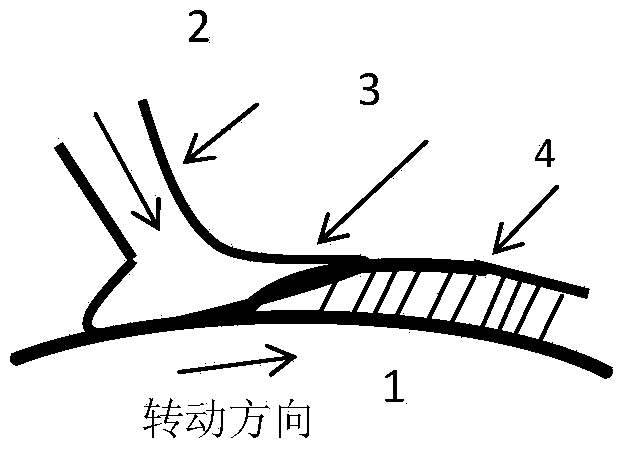

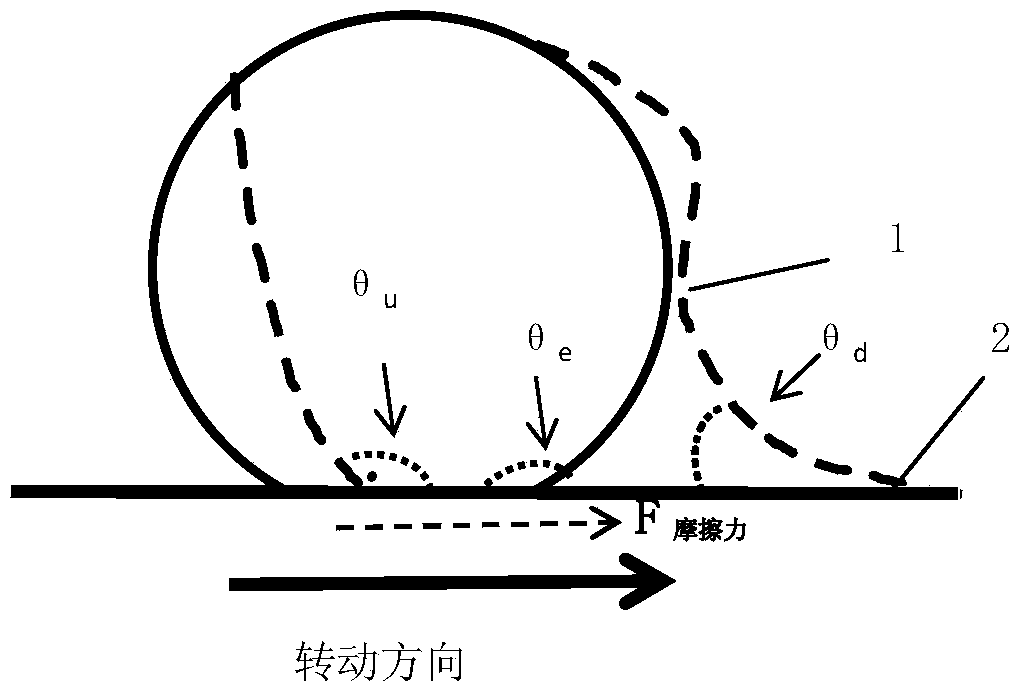

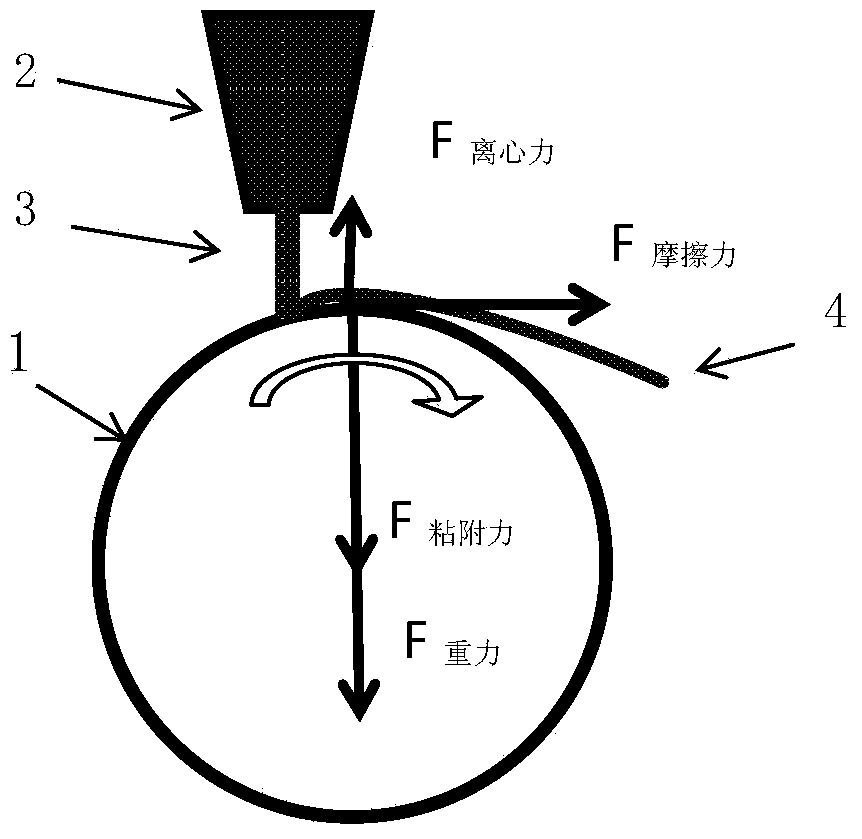

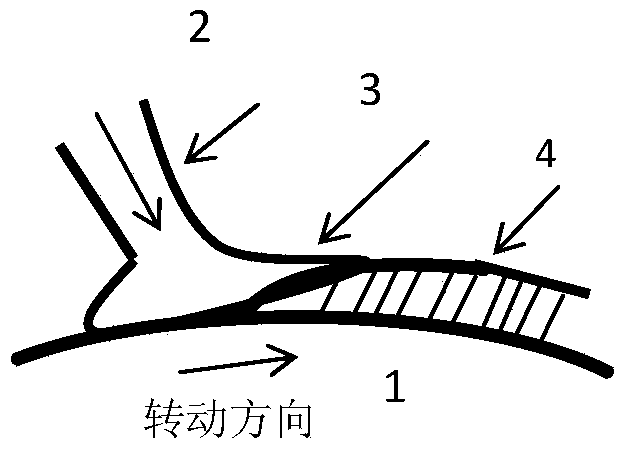

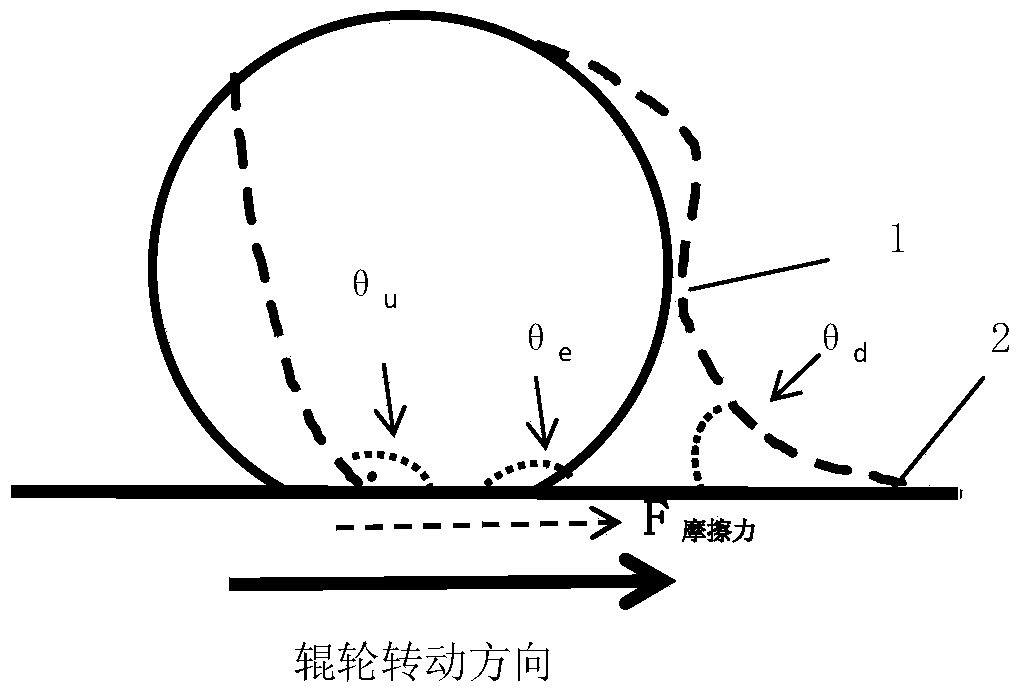

Method for adopting belt spinning of disc-type single roller to prepare amorphous alloy thin belt

ActiveCN103706770ALarge melt spreading areaGood belt forming performanceAmorphous metalSurface smoothness

The invention belongs to the technical field of alloy thin belt preparation and discloses a method for adopting belt spinning of a disc-type single roller to prepare an amorphous alloy thin belt. The method includes adopting the disc-type roller, spraying melt on the surface of a disc rotating around a disc central shaft, enabling a direction in which a centrifugal force is applied on the melt to be parallel to a contact face, namely the surface of the disc, and forming the amorphous alloy thin belt after an amorphous thin belt at the edge of the disc automatically breaks away from the roller under the action of cooling contraction and the centrifugal force. The amorphous alloy thin belt prepared by the method is thinner in size, higher in surface smoothness and better in performance.

Owner:TONGZHOU XINGCHEN MACHINERY

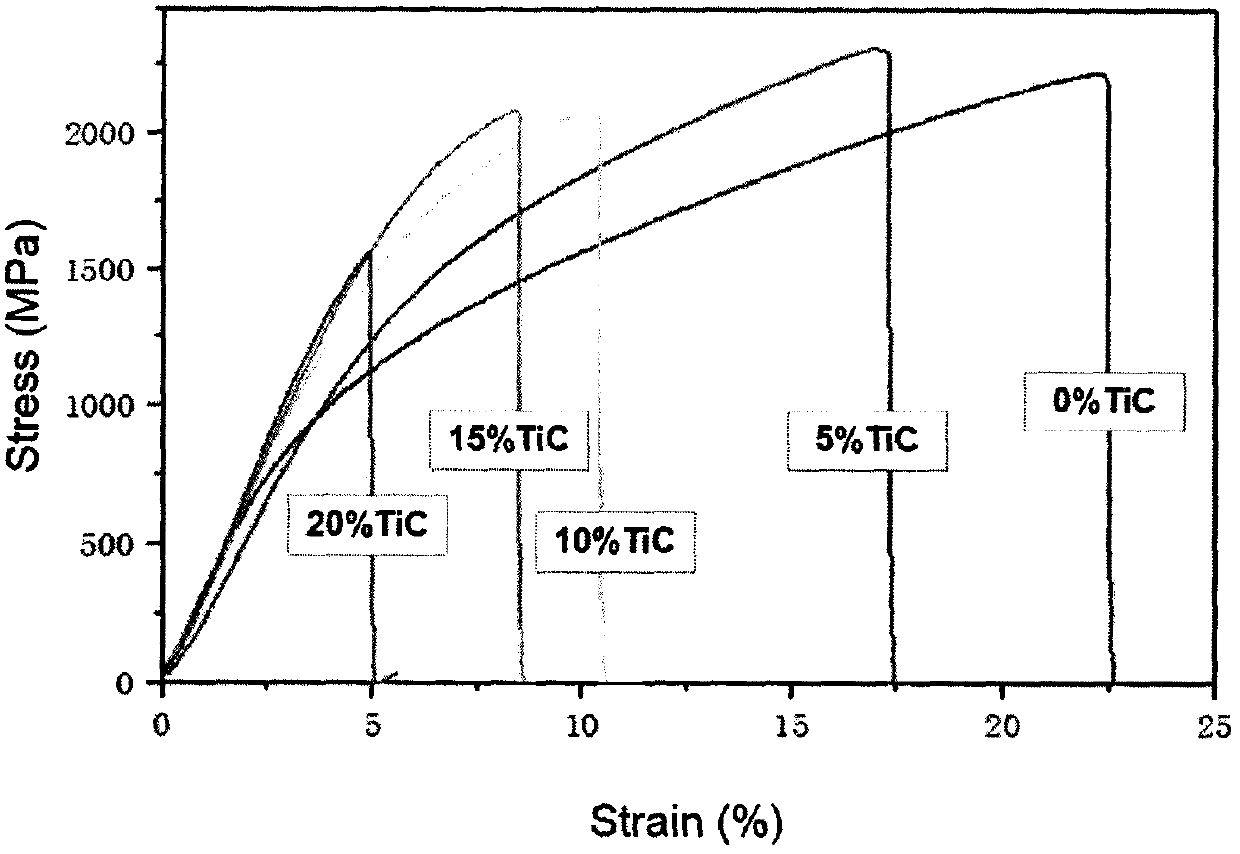

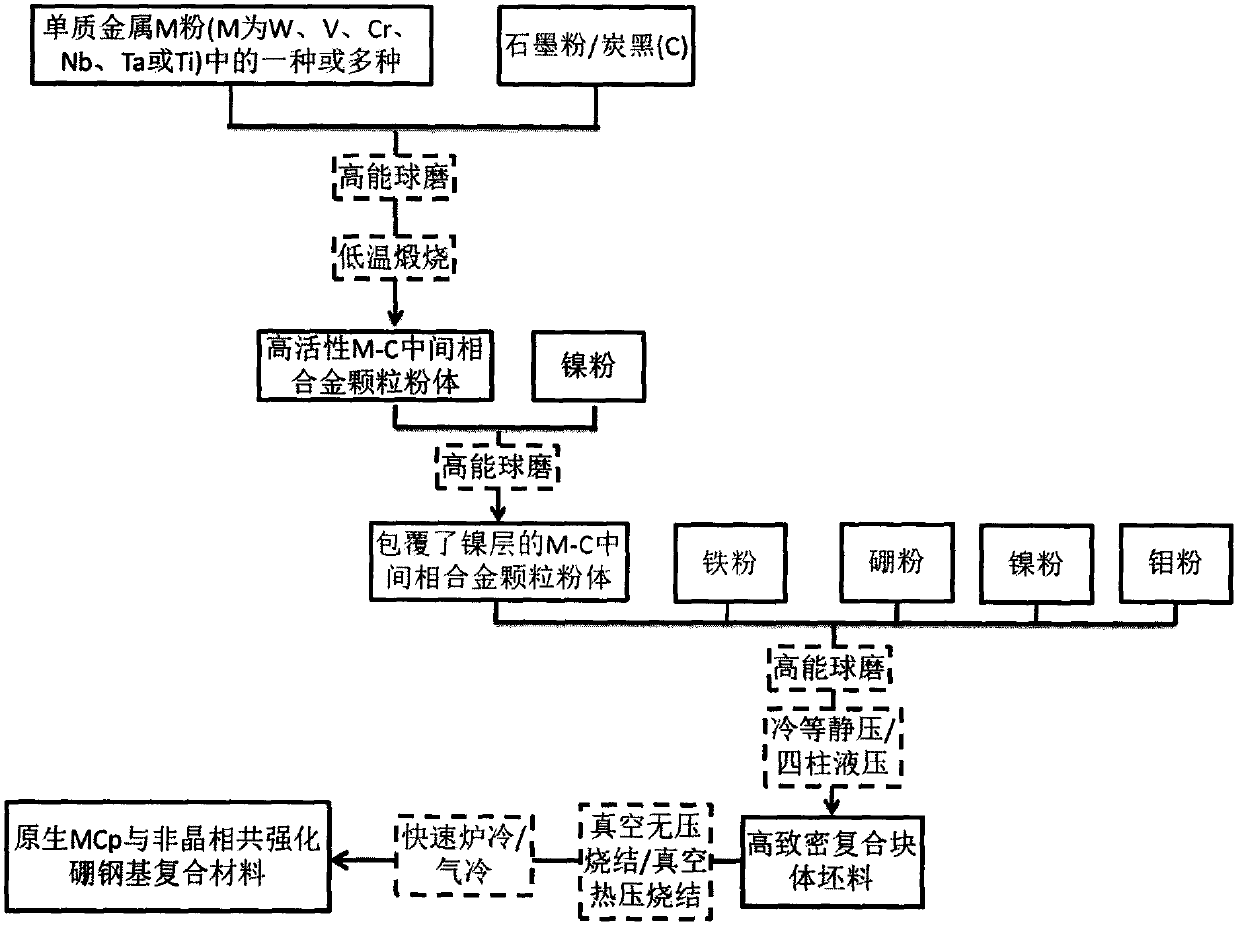

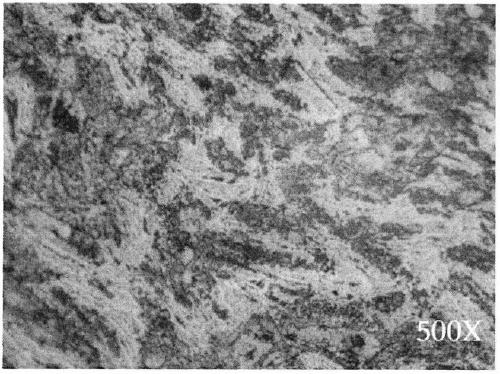

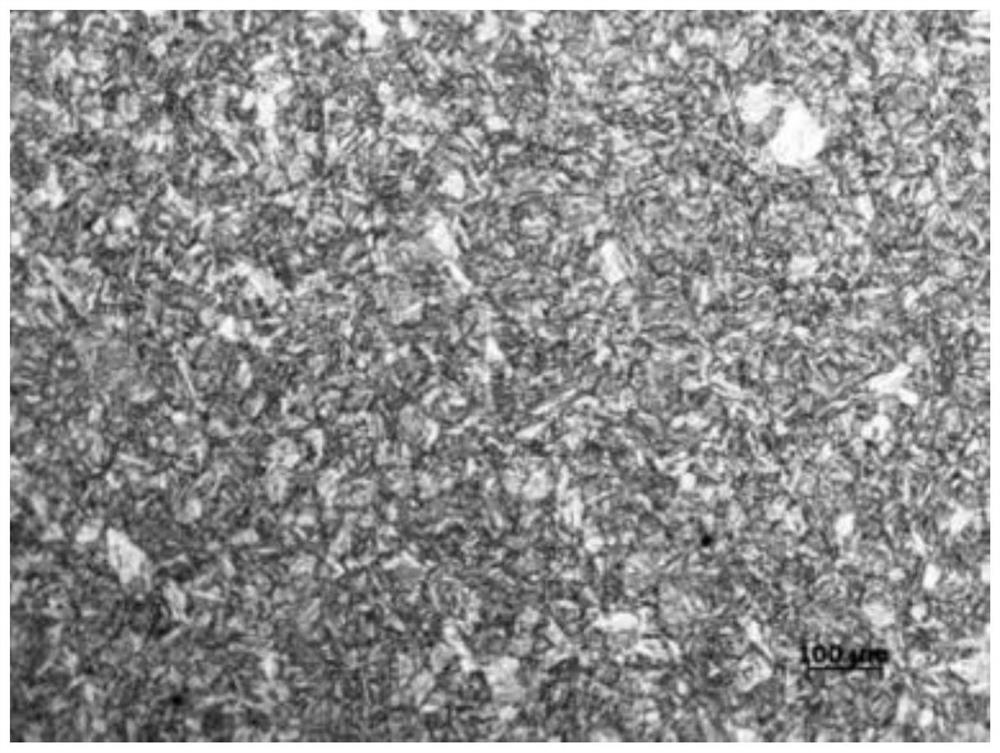

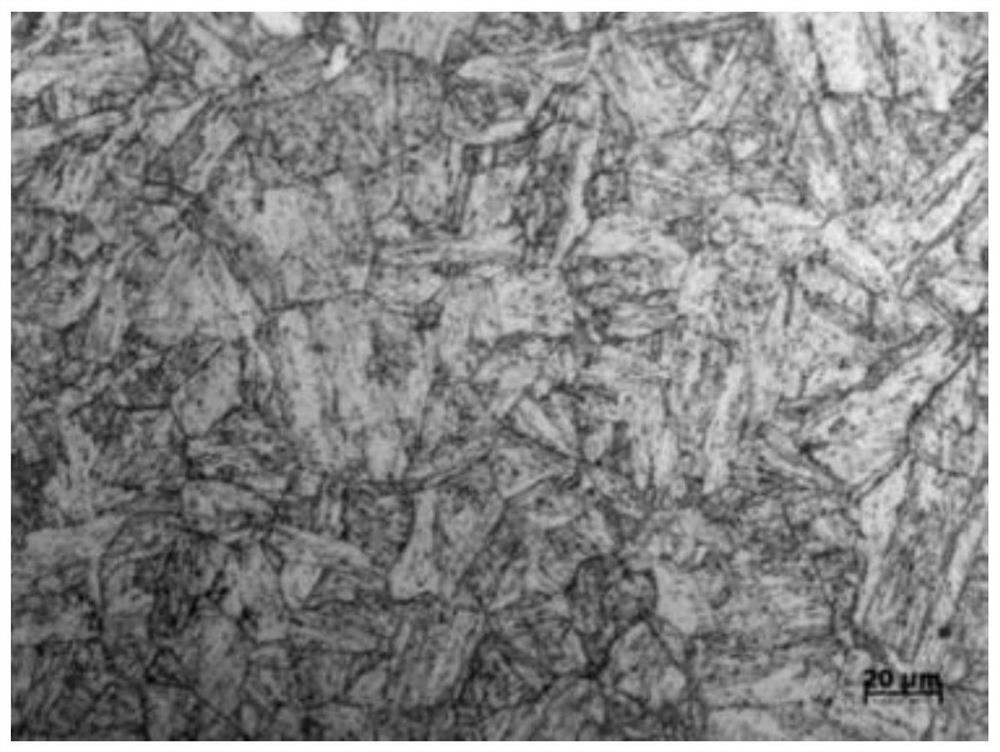

3D amorphous alloy network reinforced boron-steel-based composite material with inlaid in-situ carbide particles, and preparation method of material

InactiveCN111101074AImprove mechanical propertiesGuaranteed cooling rateTransportation and packagingMetal-working apparatusCalcinationHeat treating

The invention discloses a 3D amorphous alloy network reinforced boron-steel-based composite material with inlaid in-situ carbide particles, and a preparation method of the material. The preparation method mainly comprises the preparation process that strong carbide elementary metal powder and carbon black or graphite powder are mixed, are subjected to high-energy ball milling and then are subjected to low-temperature calcination to obtain an intermediate phase alloyed powder with the high reaction activity; high-energy ball milling is used to enable each intermediate phase alloy particle to becladded with a nickel layer on the surface; then iron powder, boron powder, molybdenum powder and nickel powder are added, high-energy ball milling is carried out to make partial iron powder have thenanometer size, and a compact blocky blank is obtained by utilizing high pressure; and the blank is placed into a vacuum dual-chamber thermal treatment furnace for vacuum sintering and is subjected to quick air cooling after sintering is completed, and the final needed composite material is obtained. The 3D amorphous alloy network reinforced boron-steel-based composite material with the inlaid in-situ carbide particles shows ultra-high elastic modulus, strength and hardness, and good plasticity and toughness, is simple in technology and easy for large-scale production to be carried out, and can be suitable for developing products such as gears, bearings, connecting rods, liner plates, rollers, tools and dies, and the products can be long in service life on the working conditions with hightemperature, high stress, hard abrasive wear and the like.

Owner:QINGHAI UNIV FOR NATITIES

Glass preparation device facilitating edge stripping

InactiveCN112408767AScientific and reasonable structureEasy to useGlass severing apparatusHydraulic cylinderStructural engineering

The invention discloses a glass preparation device facilitating edge stripping. Adjusting screws penetrate through the tops of the two ends of a feeding table, cutters are fixedly connected to the bottom ends of lifting screws in a clamped mode, reset springs are welded to the two ends of a lifting roller, electromagnets are installed at the bottoms of the inner sides of lifting grooves, and limiting fixing plates are welded to the two ends of the feeding table. Impact pressing columns are fixedly connected to the bottom ends of the pressing hydraulic cylinders, buffer springs are welded to the bottom ends of the impact pressing columns at equal intervals, protective rubber pads are bonded to the bottom ends of the impact pressing columns, and the pressing hydraulic cylinders drive the impact pressing columns to impact the corners of the glass. Meanwhile, the impact force borne by the middle of the glass is relieved through the protective springs, the rubber buffer plates and the buffer springs so that the situation that the glass is broken or cracks due to the fact that the impact force at the two ends of the middle is too large is avoided, and burrs on the edge of the glass are repaired through the L-shaped stripping plates after edge stripping is completed; and thus the stripping effect and efficiency of the corners of the glass are ensured.

Owner:洪丽丝

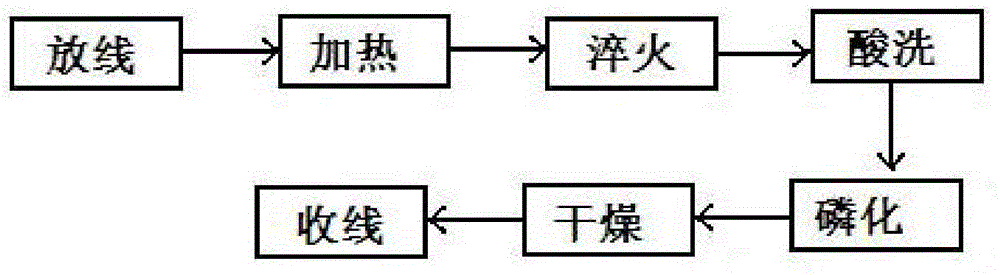

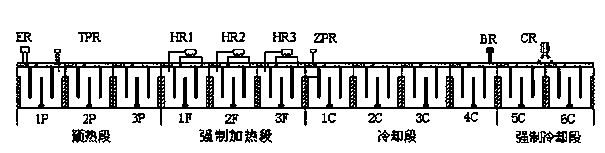

Thermal treatment technique of steel wire

ActiveCN102912109AImprove heat utilizationNo pollution in the processFurnace typesMetallic material coating processesThermal treatmentQuenching

The invention discloses a thermal treatment technique of a steel wire, comprising the following steps of: paying-off the steel wire by a pay-off rack; heating the steel wire by natural gas; putting the heated steel wire in a quenching bath for quenching; washing by water; putting the steel wire a pickling tank and then a phosphating tank; drying in a drying baker; and finally taking up. According to the invention, the whole thermal treatment line is free of pollution, clean and environment-friendly, the utilization rate of the thermal treatment heat is high, and energy is saved.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

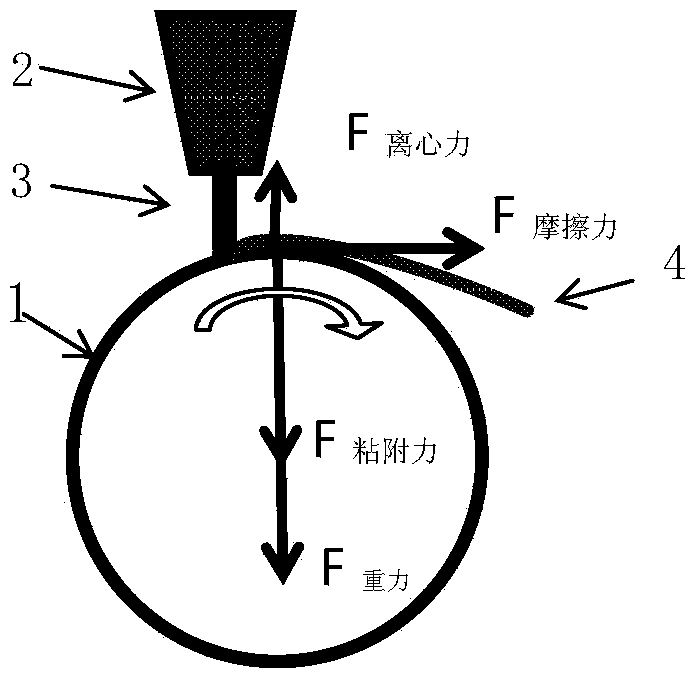

Method for preparing amorphous alloy thin strip through quenching conical single roller quickly

The invention discloses a method for preparing an amorphous alloy thin strip through quenching conical single roller quickly and belongs to the technical field of alloy thin strip preparation. According to the method, a conical roll wheel is adopted, and melt is sprayed to a conical inclined slope face rotating around a conical central shaft and is made to form an included angle with a contact face from being perpendicular to the contact face due to the function of centrifugal force. On the edge of the conical inclined slope face, the amorphous alloy thin strip cools itself, contracts and comes off a roll wheel by itself under the action of centrifugal force. The thin strip prepared through the method in thinner is size, higher in surface smoothness, and better in performance.

Owner:河北聚鑫腾达五金工具有限公司

Special quenching agent for large shaft and preparation method of quenching agent

The invention discloses a special quenching agent for a large shaft and a preparation method of the quenching agent, belonging to the field of quenching agents. The quenching agent is prepared from the following components: sodium chloride, sodium hydroxide, sodium citrate, cis-butenedioic acid, mesotrione, lotus root starch, acrylic acid, p-cresol, metribuzin and water. Through adding reasonable components and strictly controlling the component proportion, when used for quenching a shaft which is made of 45# steel and has the diameter of 1.8-3.5m, the quenching agent has the following advantages that the workpiece cooling speed is high within the temperature range of 650-450 DEG C, and the cooling speed is low at the temperature of below 400 DEG C, so that a favorable quenching effect can be obtained, and a quenching crack condition can also be avoided. The preparation method of the quenching agent has the advantages that all components in the quenching agent are completely dispersed and uniformly distributed by controlling temperatures and adding sequences of raw materials, the quenching agent is similar to a colloid in shape, and the cooling speed at the temperature of below 400 DEG C is lowered.

Owner:深圳市新元特钢有限公司

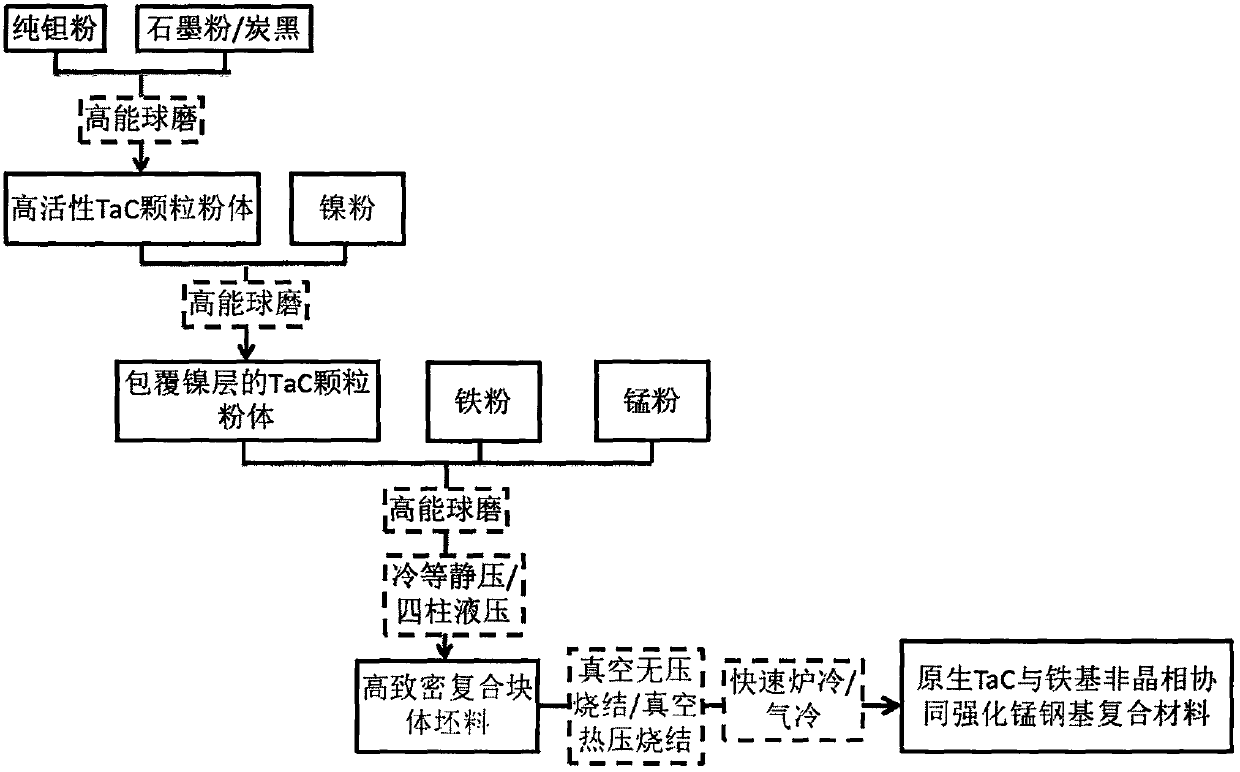

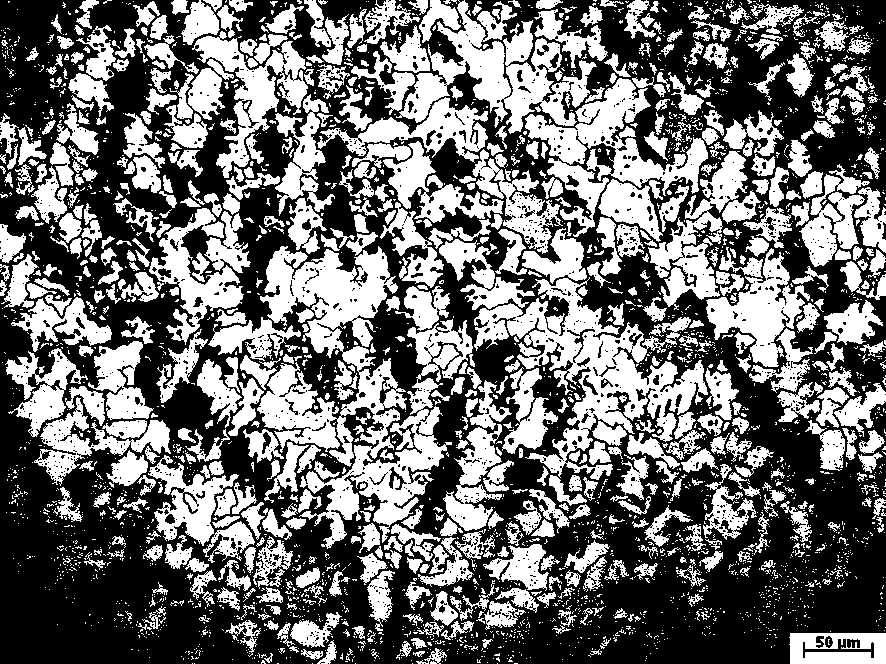

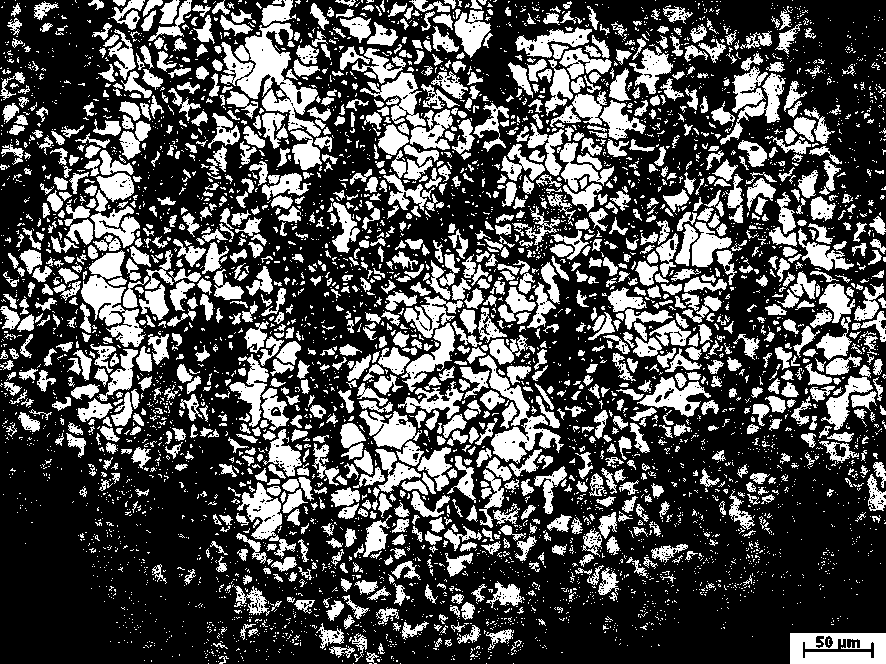

In-situ TaC particle and iron-based amorphous alloy synergistically strengthened medium-high manganese steel-based composite and preparation method thereof

InactiveCN111101048AImprove mechanical propertiesGuaranteed cooling rateMaterials scienceHeat treating

The invention relates to an in-situ TaC particle and iron-based amorphous alloy synergistically strengthened medium-high manganese steel-based composite material and a preparation method thereof. Thepreparation method mainly comprises the following steps that tantalum (Ta) powder is mixed with carbon black or graphite (C) powder, after high-energy ball milling is carried out, Ta-C intermediate phase alloy powders with high reaction activity are obtained; coating nickel layers on the surfaces of intermediate phase alloy particles is carried out by utilizing high-energy ball milling; then ironpowders and manganese powders are added, high-energy ball milling is carried out, enabling part of the iron powders and manganese powders to reach nanoscale is carried out, high-pressure pressing is utilized to obtain a compact block blank; and the blank is put into a vacuum double-chamber heat treatment furnace to perform vacuum sintering, rapid air cooling is carried out after sintering is completed, and the finally needed composite material is obtained. According to the in-situ TaC particle and iron-based amorphous alloy synergistically strengthened medium-high manganese steel-based composite material and the preparation method thereof, the composite material shows ultrahigh elastic modulus, strength and hardness and good plasticity and toughness, the process is simple, scale is easy, and the composite material is suitable for developing products with long service life, such as gears, bearings, connecting rods, lining plates, rollers, cutters, molds and the like, under the working conditions of high temperature, high stress, hard abrasive wear and the like.

Owner:QINGHAI UNIV FOR NATITIES

160mm ultra-thick plate produced under low compression ratio condition and production method of 160mm ultra-thick plate

The invention discloses a 160mm ultra-thick plate produced under a low compression ratio condition and a production method of the 160mm ultra-thick plate. The production method comprises the followingsteps: implementing molten steel rotary furnace smelting, preparing a continuous casting blank by using an LF+RH (Ladle Furnace+Ruhrstahl-Heraeus) refining process, implementing a heating process, and further implementing a rolling process of a period and an on-line swinging type cooling and thermal treatment process, thereby obtaining the ultra-thick plate, wherein the ultra-thick plate consistsof elements of C, Si, Mn, P, S, Nb, V, Ti, Ni, Alt and Fe, and inevitable impurities. The ultra-thick plate produced by using the production method disclosed by the invention is excellent in comprehensive mechanical property, the yield strength of the ultra-thick plate is 313-335MPa, the tensile strength of the ultra-thick plate is 496-516MPa, the elongation rate of the ultra-thick plate is 29-31.5%, the longitudinal impact power at minus 20 DEG C is greater than or equal to 161J, requirements of the standard GB / T 1581-2008 can be met, the cross section shrinkage rate in a thickness directionmeets requirements of Z35 in the standard GB / T 5313-2010, and results of flaw detection based on the standard GB / T 2970-2004 show that the real article quality of the ultra-thick plate meets the requirements of a grade II.

Owner:HUNAN UNIV OF TECH

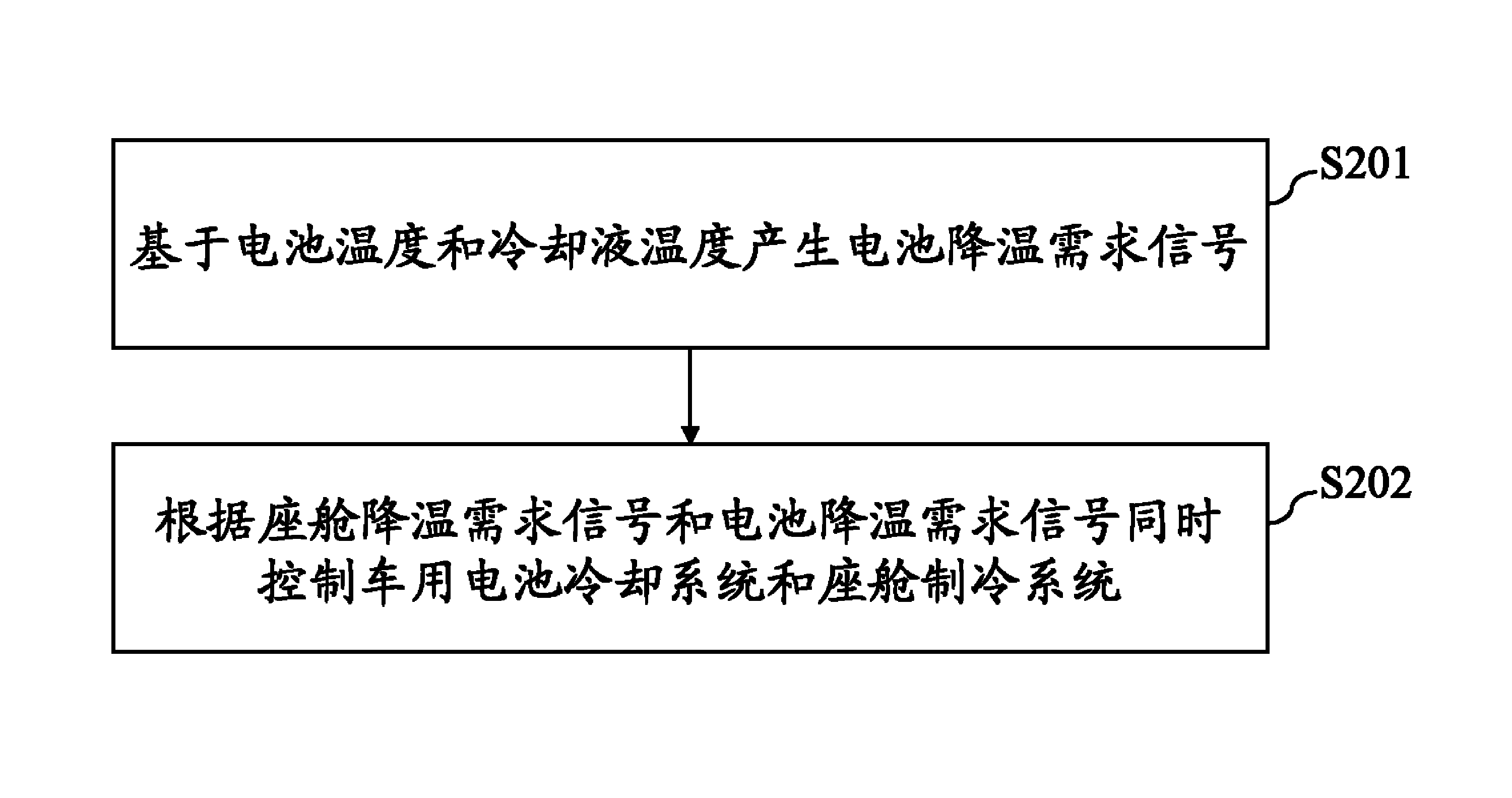

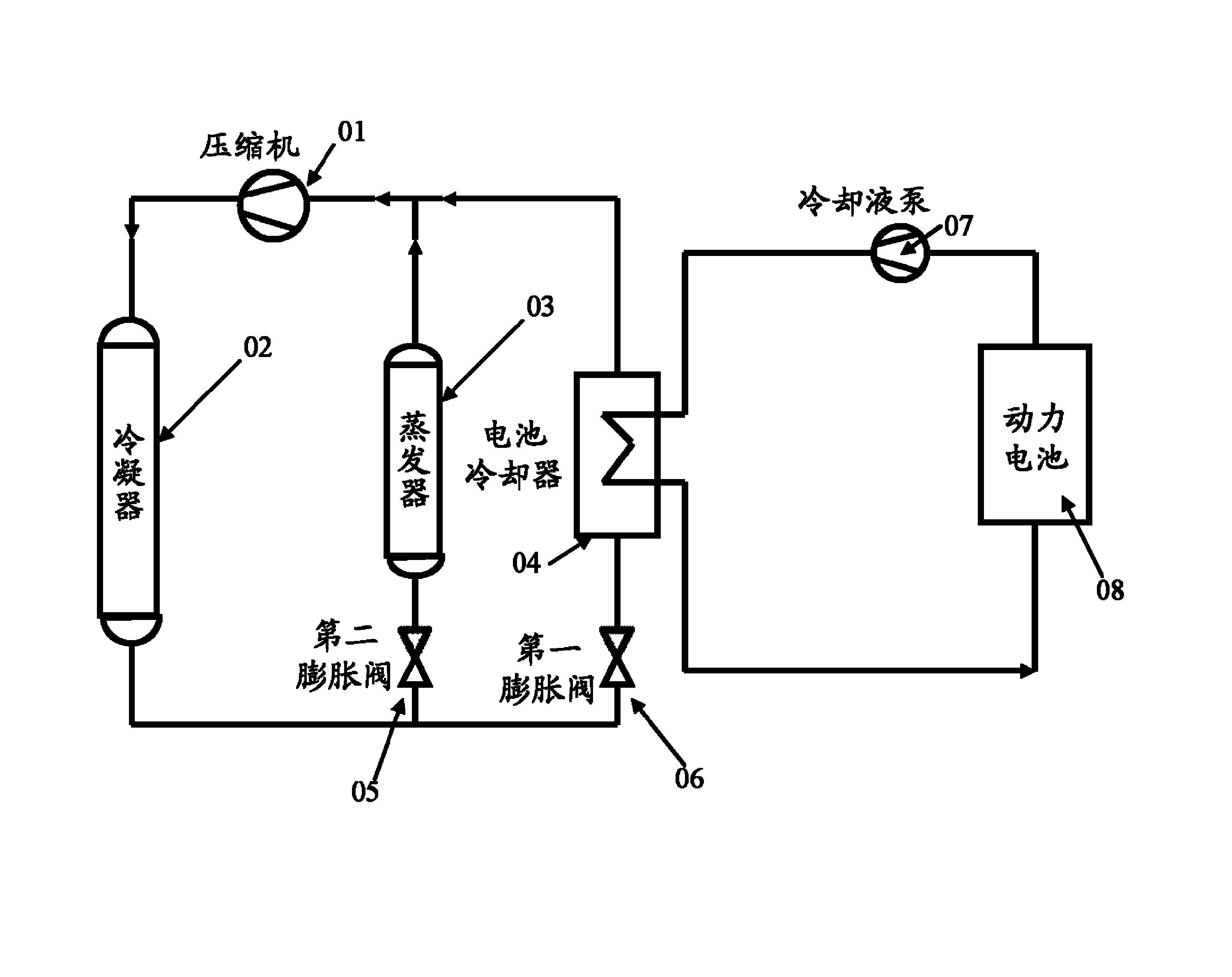

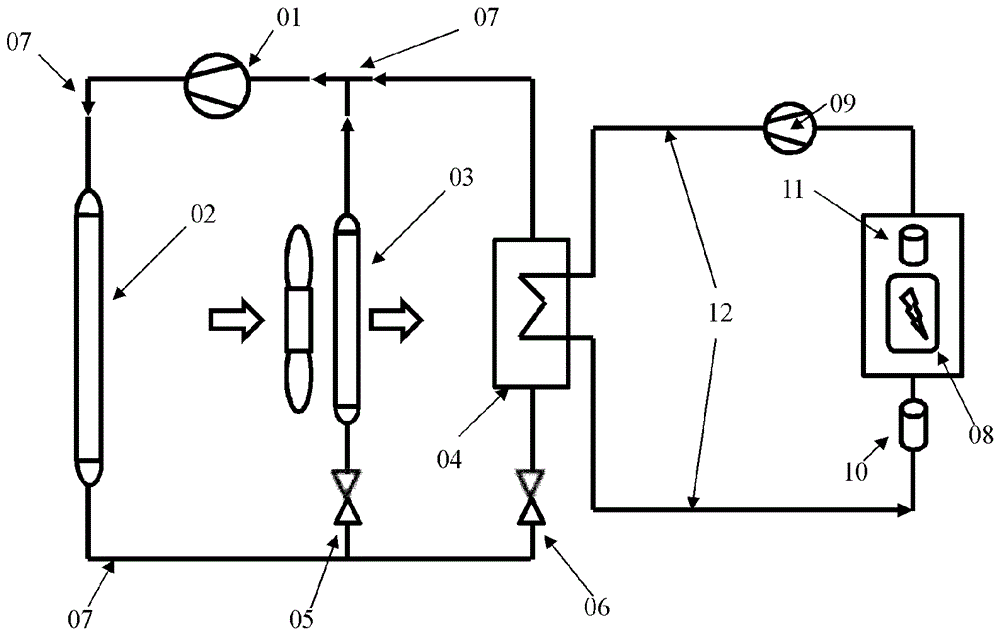

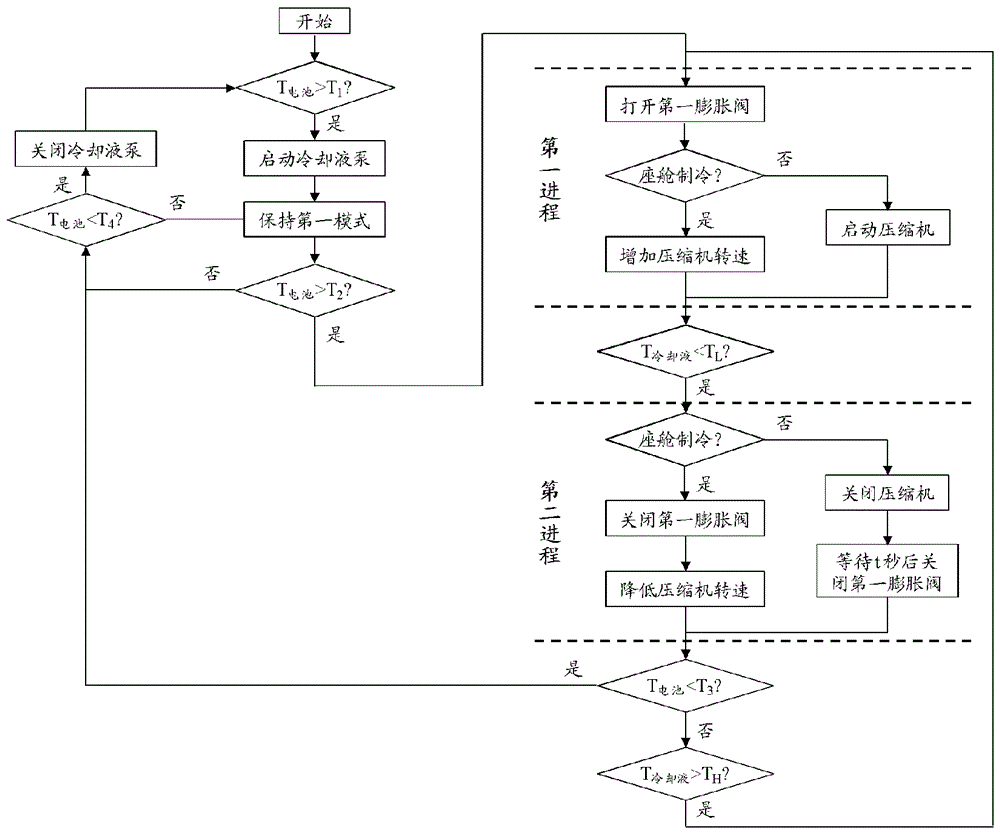

Control method for vehicular battery cooling system

ActiveCN104108293AOptimum temperature working rangeSave time at workAir-treating devicesCell temperature controlCoolant temperatureCoolant pump

The invention relates to a control method for a vehicular battery cooling system. The vehicular battery cooling system comprises a battery cooler, a coolant pump, a first expansion valve and an electric compressor. The electric compressor is shared by the vehicular battery cooling system and a cabin refrigerating system, and the cabin refrigerating system comprises a second expansion valve. The method includes: simultaneously controlling the vehicular battery cooling system and the cabin refrigerating system according to cabin cooling demand signals and battery cooling demand signals; when the battery temperature is larger than a first battery temperature threshold TBSH or the coolant temperature is larger than or equal to a first coolant temperature threshold TBCH, generating a battery cooling demand signal which indicates cooling demand of a battery; when the battery temperature is smaller than a second battery temperature threshold TBSL or the coolant temperature is smaller than or equal to a second coolant temperature threshold TBCL, generating a battery cooling demand signal which indicates no cooling demand of the battery.

Owner:SAIC MOTOR

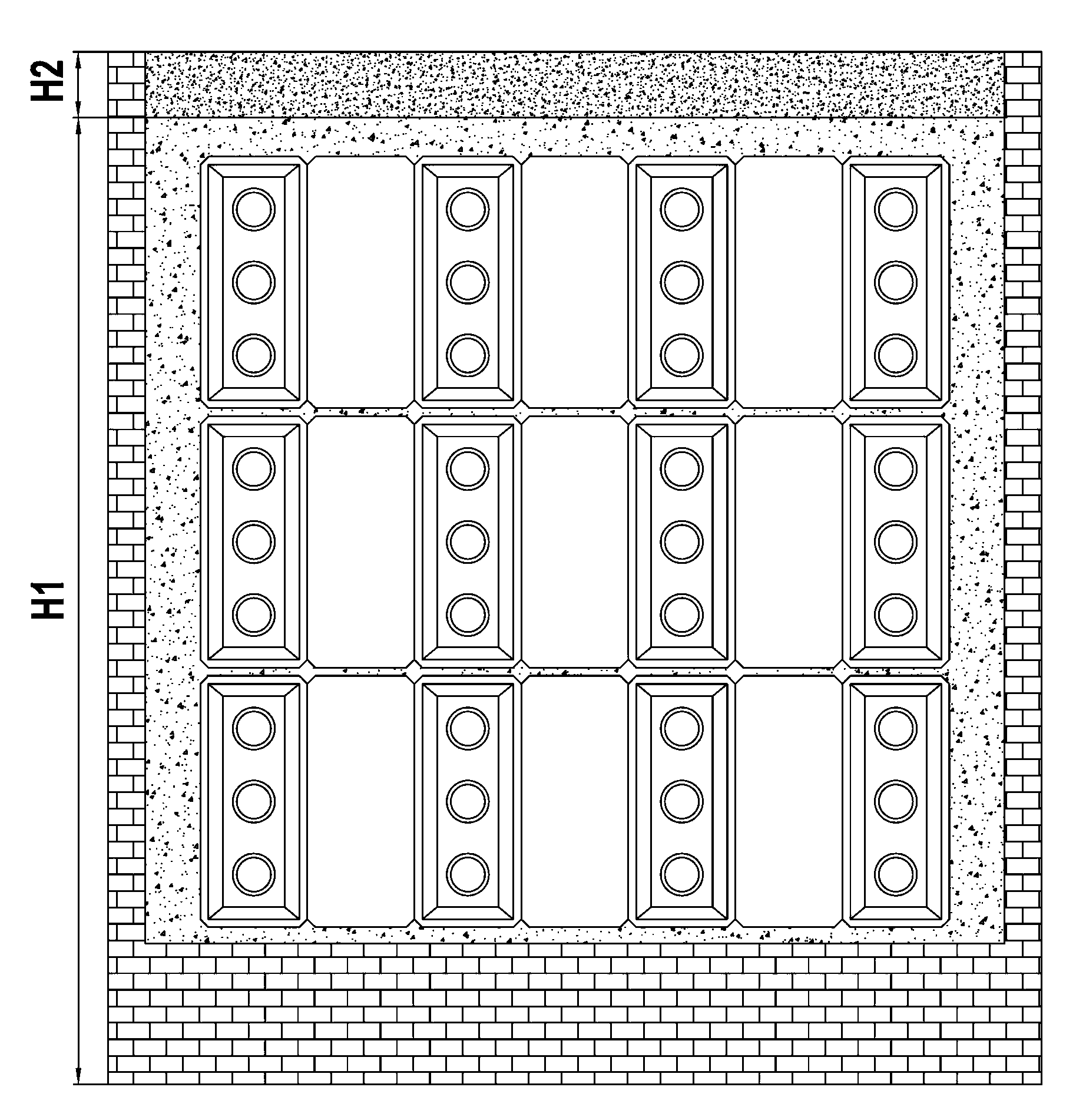

Aluminum alloy laminar flow distribution plane solidification casting device and casting method thereof

ActiveCN106238716AAchieve laminar distributionAvoid local overheatingMolten metal pouring equipmentsIngot castingWater spray

The invention discloses an aluminum alloy laminar flow distribution plane solidification casting device and a casting method thereof, and belongs to the technical field of aluminum alloy ingot blank casting. The device comprises a support. A translation flow distribution mechanism capable of moving horizontally is arranged on the upper portion of the support. A flow control mechanism is arranged at an outlet of the translation flow distribution mechanism. A casting tank is arranged below the translation flow distribution mechanism. A water spraying system and a cooling plate system are arranged below the casting tank. The method includes the steps that the cooling plate system rises into the casting tank, and molten aluminum alloy enters a flow distribution groove and then enters a guide rod sleeve; a second motor is started to control flow of the molten aluminum alloy; a first motor is started, a movable plate drives the flow distribution groove to move horizontally, and the molten aluminum alloy flows to a cooling plate upper plate body in a laminar mode; when an aluminum alloy solidification layer can be supported, a cooling plate oil cylinder is started, and thus the cooling plate system descends; then the water spraying system is pushed in, and sprayed water is cooled; the descending speed of a main oil cylinder is controlled until casting reaches a preset thickness; and after all the cooling is completed, water spraying is stopped, the water spraying system is extracted, ingot castings are taken out, and accordingly casting is completed.

Owner:NORTHEASTERN UNIV

Fiberglass mesh cloth forming device and operation method thereof

InactiveCN109825979AImprove work efficiencyEasy to useSevering textilesHeating/cooling textile fabricsFiberglass meshDrive wheel

The invention discloses a fiberglass mesh cloth forming device and an operation method thereof. The fiberglass mesh cloth forming device comprises a profile support, a fixed base, a roller, a slide rail, a first slider, a threaded rod, a second driven wheel, a second slider, a first support rod, a cooling nozzle, a second supporting rod, a slide clamping base, a design finalizing knife, a second server motor and a second driving wheel. After an aluminum heating plate is rapidly heated, design finalizing is rapidly conducted on fiberglass mesh cloth through an adjustable design finalizing baseand the vertically-moving design finalizing knife, and the work efficiency is rapid; meanwhile, through an air-cooling mechanism at the bottom, the air cooling of the fiberglass mesh cloth is rapidlycompleted, the work efficiency is improved, and the quality of the finished product is ensured; the fiberglass mesh cloth is pressed and conveyed under a first servo motor through a first pressing roller and a second pressing roller with an adjustable distance; through a cutting mechanism, the formed fiberglass mesh cloth can be sequentially cut.

Owner:常小琼

Suspended air purifying equipment

ActiveCN109681979AThe installation is firm and stableGuaranteed cooling effectLighting and heating apparatusSpace heating and ventilation detailsPunchingAir purification

The invention discloses suspended air purifying equipment. The suspended air purifying equipment comprises an equipment body and a suspension frame; the equipment body is located in the suspension frame; the suspension frame comprises a bottom bracket, a top pressing assembly and an upper baffle; the bottom bracket comprises a first bracket assembly and a second bracket assembly; the top pressingassembly is located on the upper portion of the equipment body; and the top pressing assembly is connected with the upper baffle. Through the design of the suspension frame, suspension mounting of theequipment body is more convenient, operations such as punching do not need to be conduct on the equipment body, meanwhile, the equipment body can be fully supported and clamped up and down,, back andfront, and left and right, the fastness of the equipment body after suspension is effectively ensured, through the suspension frame, suspension and fixing of the equipment body are achieved, and theequipment body is protected against dust, the service life of the equipment body is further prolonged, through the whole suspension frame, the contact area between the equipment body and air can be ensured, and thus the radiating rate of the equipment body is effectively ensured.

Owner:苏州乐赢科技咨询有限公司

A control method of a vehicle battery cooling system

InactiveCN103855440BReduce energy consumptionSave time at workSecondary cellsPropulsion coolingEngineeringCoolant temperature

The invention relates to a control method of a vehicle battery cooling system. The battery cooling system includes a battery cooler, a cooling liquid pump, a first expansion valve and an electric compressor shared with an air conditioning system for cabin refrigeration. The method comprises the following steps: when battery temperature is greater than a first temperature threshold, the first cooling mode is adopted, wherein the first cooling mode includes starting of the cooling liquid pump to cool the battery through the cooling liquid at the current temperature; and when the battery is in the first cooling mode and the battery temperature is greater than a second temperature threshold, a second cooling mode is further adopted, wherein the second cooling mode includes the implementation of a first process of the electric compressor to provide a refrigerant for the battery cooler, in order to reduce the temperature of the cooling liquid, and the second temperature threshold is determined according to whether the battery is in a charging state.

Owner:SAIC MOTOR

Inner roller type single roller rapid quenching amorphous ribbon preparation method

The invention provides an inner roller type single roller rapid quenching amorphous ribbon manufacturing method, and belongs to the technical field of preparation of amorphous ribbons. An inner roller type roller is adopted and is of a hollow straight barrel structure, melt is ejected to the inner surface of the inner roller type roller which rotates around a center shaft, the inner surface of the inner roller type roller is of a straight barrel type, and the direction of centrifugal force applied to the melt changes from the direction perpendicular to a contact surface and upward into the direction perpendicular to the contact surface and towards the interior of the contact surface. The ribbons prepared through the method are thinner in size, higher in surface smoothness, and better in performance.

Owner:TONGZHOU XINGCHEN MACHINERY

Single-crystal thermal field gradient additional adjustment system

PendingCN106435715AGuaranteed cooling rateLow costPolycrystalline material growthBy pulling from meltSingle crystalEngineering

The invention discloses a single-crystal thermal field gradient additional adjustment system which is arranged on an upper cover plate of a single crystal furnace and is arranged in a manner of surrounding an inner flow guide barrel, and consists of a plurality of annular components including a first component, a second component, a third component, a fourth component and a fifth component; the first component, the second component and the third component are set to be temperature adjustment parts in sequence from top to bottom; the temperature adjustment parts form an included angle of 160 to 180 degrees relative to the inner flow guide barrel; a heat insulation part is arranged on the outer side of each temperature adjustment part; the heat insulation parts are formed by stacking fourth components and fifth components in the horizontal direction from inside to outside; the adjustment of the adaptability to the gradient of a thermal field at the upper part of the single-crystal thermal field guarantees smooth transition of the gradient of the thermal field and enables a required temperature region of a crystal rod to be in a proper temperature gradient so as to control the crystal rod to be at a cooling speed of the certain temperature region; meanwhile, the single-crystal thermal field gradient additional adjustment system can rectify gas.

Owner:保山新澳泰能源有限公司

Method of opening type roasting filling material filling

ActiveCN103134327AImprove sealingGuaranteed burning lossEnergy inputCharge manipulationCold airGranularity

The invention relates to a method of filling material filling, in particular to a method of opening type roasting filling material filling used for a carbon industry. An area with a standing seam in a fire way wall is filled by the filling material with a regular granularity. An area without a standing seam of the fire way wall on the upper portion of a material box is filled by a layer of fine filling materials and the fine filling materials are concentratedly to be operated in and out of a furnace. Convenience and feasibility of the operation are guaranteed. The method of the opening type roasting filling material filling has the advantages that the filling materials with different granularities are filled in the upper position and the lower position of the opening type roasting furnace material box, thus the good sealing effect of the material box is achieved. The fact that oil tar and volatile matter in a heating stage of a roasting product which smoothly enter the fire way to burn is guaranteed. A Cold air quantity leaking in the fire way from the material box is reduced. A pre-heating air quantity which enters the material box from the fire way after the roasting product enters the cooling state is reduced. Regular temperature rising speed in the heating stage and cooling speed in the cooling stage of the roasting product are guaranteed. Burning losses of the filling materials in the cooling stage of the roasting product are reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Fan device for accelerated cooling of special pipe for oil in coating process

InactiveCN104005970ASimple structureLow costPump componentsPump installationsDust controlEngineering

The invention relates to a fan device for accelerated cooling of a special pipe for oil in a coating process. The fan device comprises a blast box, connecting canvas, a ventilator, supporting frames, a dust removal filtering screen, air outlets and an air suction opening. The two ends of the blast box are provided with the supporting frames, one or more air outlets are formed in the blast box, the length of the air outlets is equal to the length of the blast box, meanwhile, the blast box is connected with the ventilator through the connecting canvas, the air suction opening is formed in one side of the ventilator, and the dust removal filtering screen is arranged at the position of the air suction opening. The cooling device is simple in structure, low in cost and easy to popularize; when a large number of pipes need to be cooled, the cooling rate can be guaranteed, the production efficiency can be improved, and coating can be conducted smoothly.

Owner:山西海隆石油技术有限公司

Method and device for preparing high-purity silicon monoxide in batches

PendingCN114180585AAvoid lostUniform particle sizeProcess control/regulationSilicaSilicon monoxidePhysical chemistry

The invention provides a method and a device for preparing high-purity silicon monoxide in batches. The method comprises the following steps: uniformly mixing silicon powder and silicon dioxide powder, carrying out heating and heat preservation treatment to generate silicon monoxide steam, collecting the silicon monoxide steam, and instantly condensing and depositing the silicon monoxide steam by adopting cooling gas to obtain high-purity silicon monoxide. The device comprises a feed port, a reaction zone, a deposition zone and a discharge port, the feed port is connected with the reaction zone, the discharge port is connected with the deposition zone, the reaction zone is communicated with the deposition zone through a silicon monoxide gas transfer port, and the deposition zone is further provided with a cooling device. The silicon monoxide powder material prepared by adopting the method and the device disclosed by the invention is uniform in granularity, high in purity and free from agglomeration, meanwhile, the preparation process of the silicon monoxide powder is shortened, the cost is saved, and the method is suitable for large-scale industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

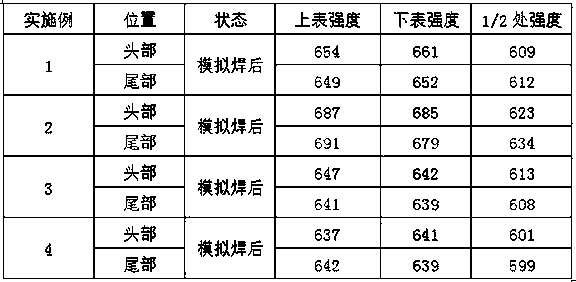

Accelerated cooling method after 12Cr2Mo1VR steel plate quenching slot normalizing

InactiveCN108239692AImprove water temperature uniformityIncrease temperatureFurnace typesHeat treatment furnacesWater entryQuenching

The invention discloses an accelerated cooling method after 12Cr2Mo1VR steel plate quenching slot normalizing. The method comprises the following steps of: controlling a water temperature of a quenching slot, controlling time from tapping to water entry of a steel plate, and controlling to start an air stirring process and a secondary normalizing pre-turnover process, wherein during the secondarynormalizing pre-turnover process, the steel plate needs to be normalized twice, and turnover needs to be firstly performed before secondary normalizing. After the method is adopted for normalizing, a12Cr2Mo1VR steel plate with a thickness greater than and equal to 150 mm is cooled in an accelerated mode, so that surface and core performances as well as die-welding performance of the treated steelplate can meet GB713-2014 requirements and are relatively stable, and performance difference among upper and lower surfaces as well as a head and a tail of the steel plate is relatively small.

Owner:WUYANG IRON & STEEL

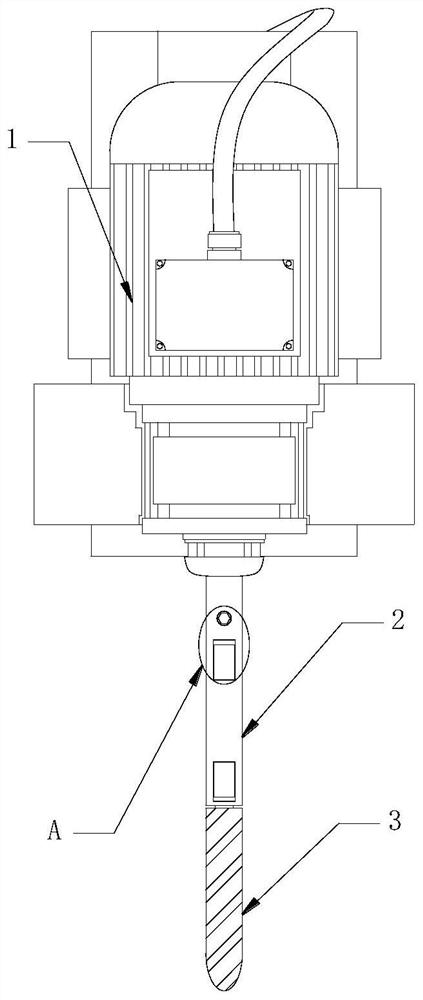

Positioning and punching device for building steel formwork production and machining and punching method

InactiveCN113843623AEasy to operateIncrease productivityOther manufacturing equipments/toolsPunchingStructural engineering

The invention relates to the technical field of building steel formwork production, in particular to a positioning and punching device for building steel formwork production and machining and a punching method. The positioning and punching device comprises an electric control drilling machine, a connecting rod is fixedly installed at the rotating end of the electric control drilling machine, and a drill bit is arranged at the bottom end of the connecting rod. According to the positioning and punching device for building steel formwork production and machining and the punching method, an upper grinding device and a lower grinding device are arranged to be matched, an upper scraping block and a lower scraping block can be cut out and then driven by the electric control drilling machine, the upper scraping block and the lower scraping block make contact with the hole edges on the upper side and the lower side of a punched hole, so that convex edges generated by punching at the hole edges are scraped away, the operation is easy and rapid, grinding equipment does not need to be independently used for re-machining, the production efficiency is improved, in the process of grinding the convex edges of the punched hole, the upper scraping block and the lower scraping block which rotate at a high speed are used for disturbing airflow, so that air flow in the hole punching area is accelerated, cooling of the hole punching area of the steel formwork is accelerated, and the safety is better.

Owner:溆浦县贺老九钢结构有限公司

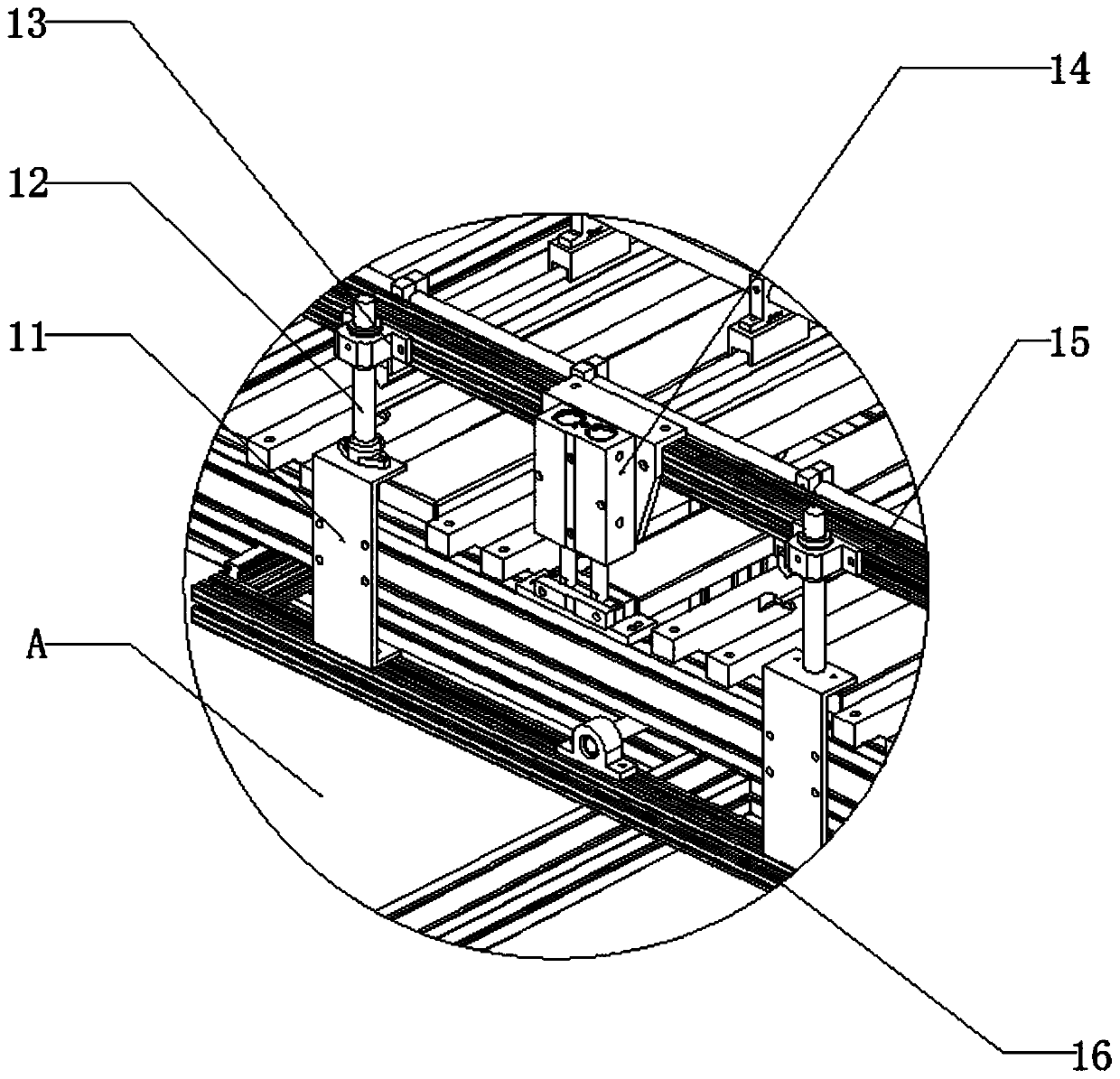

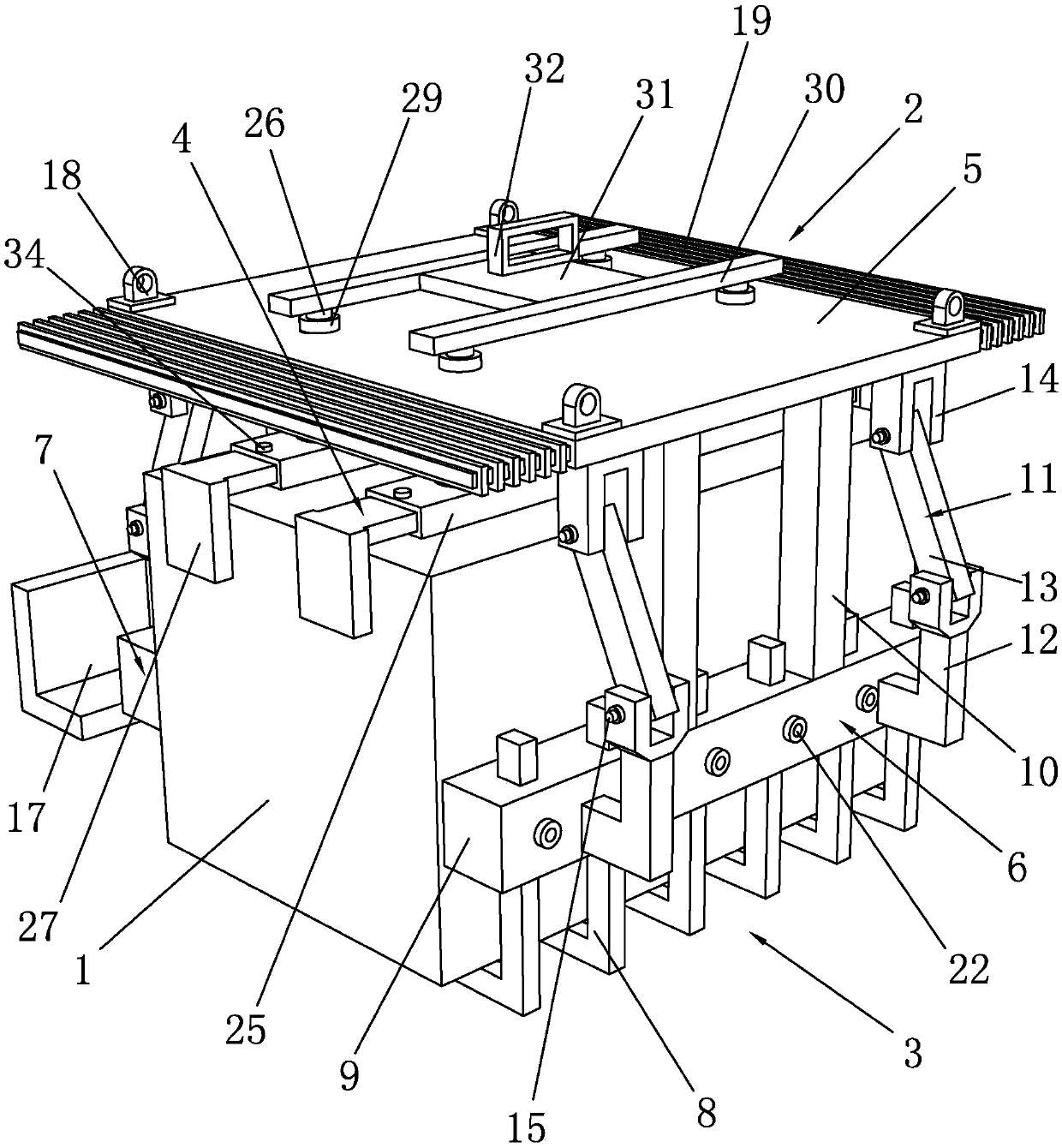

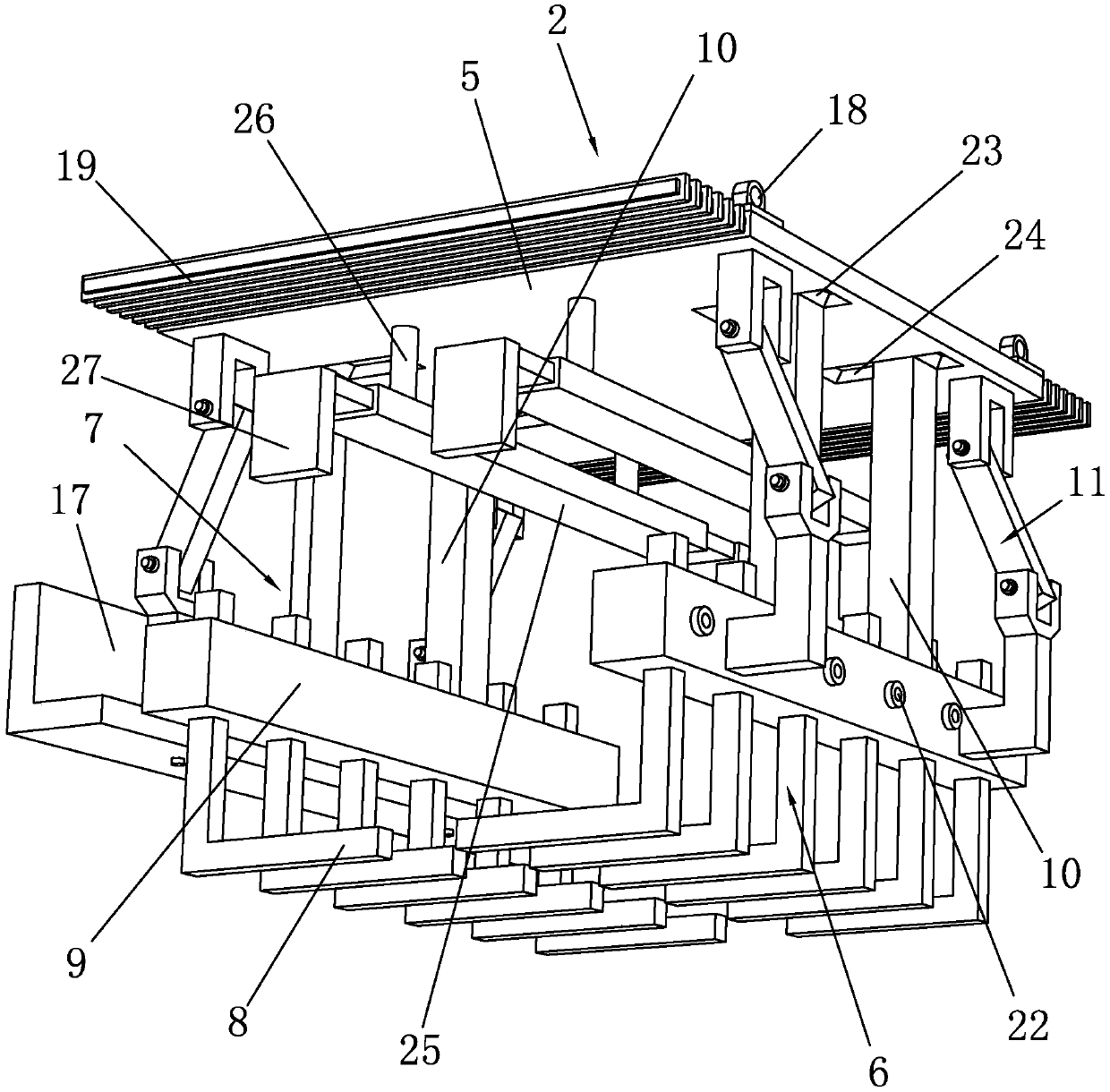

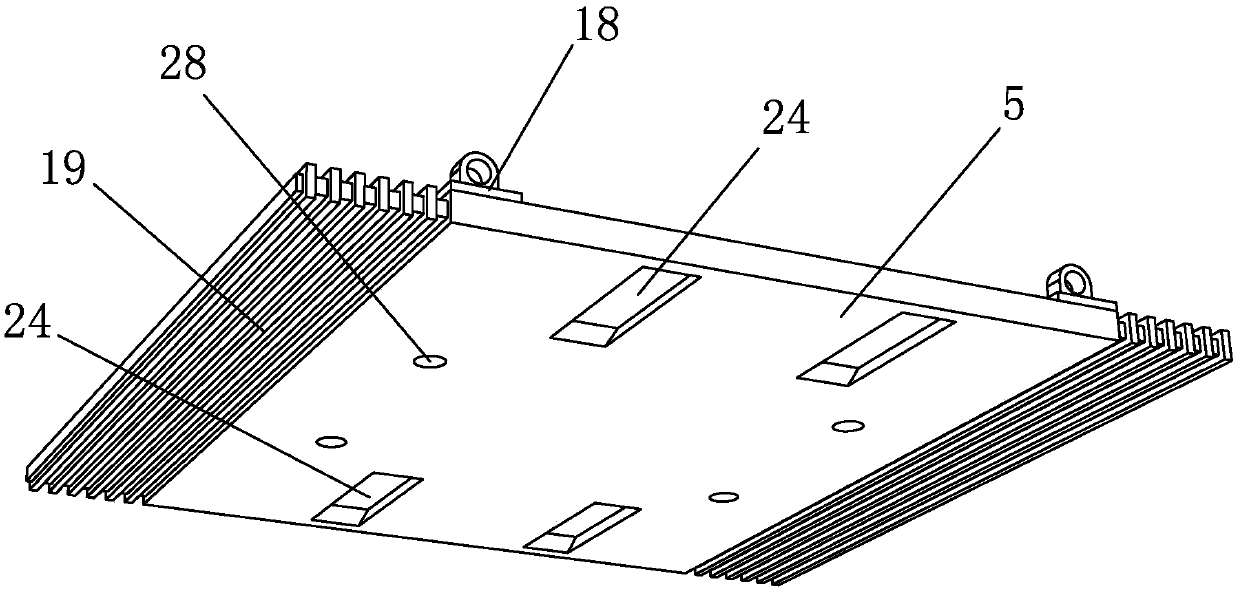

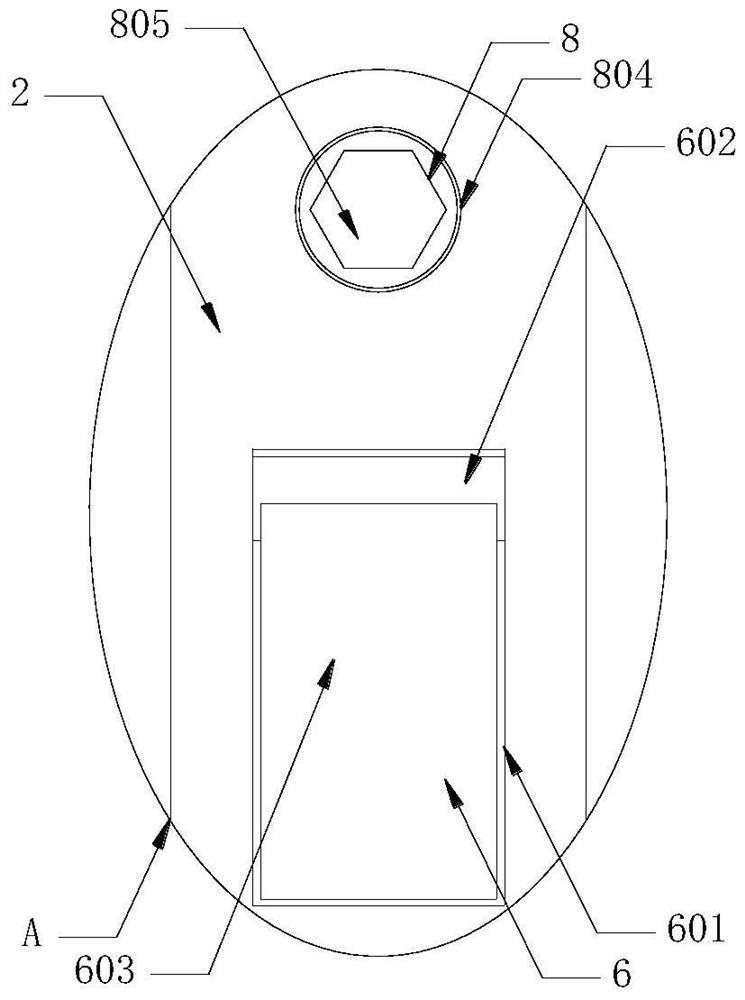

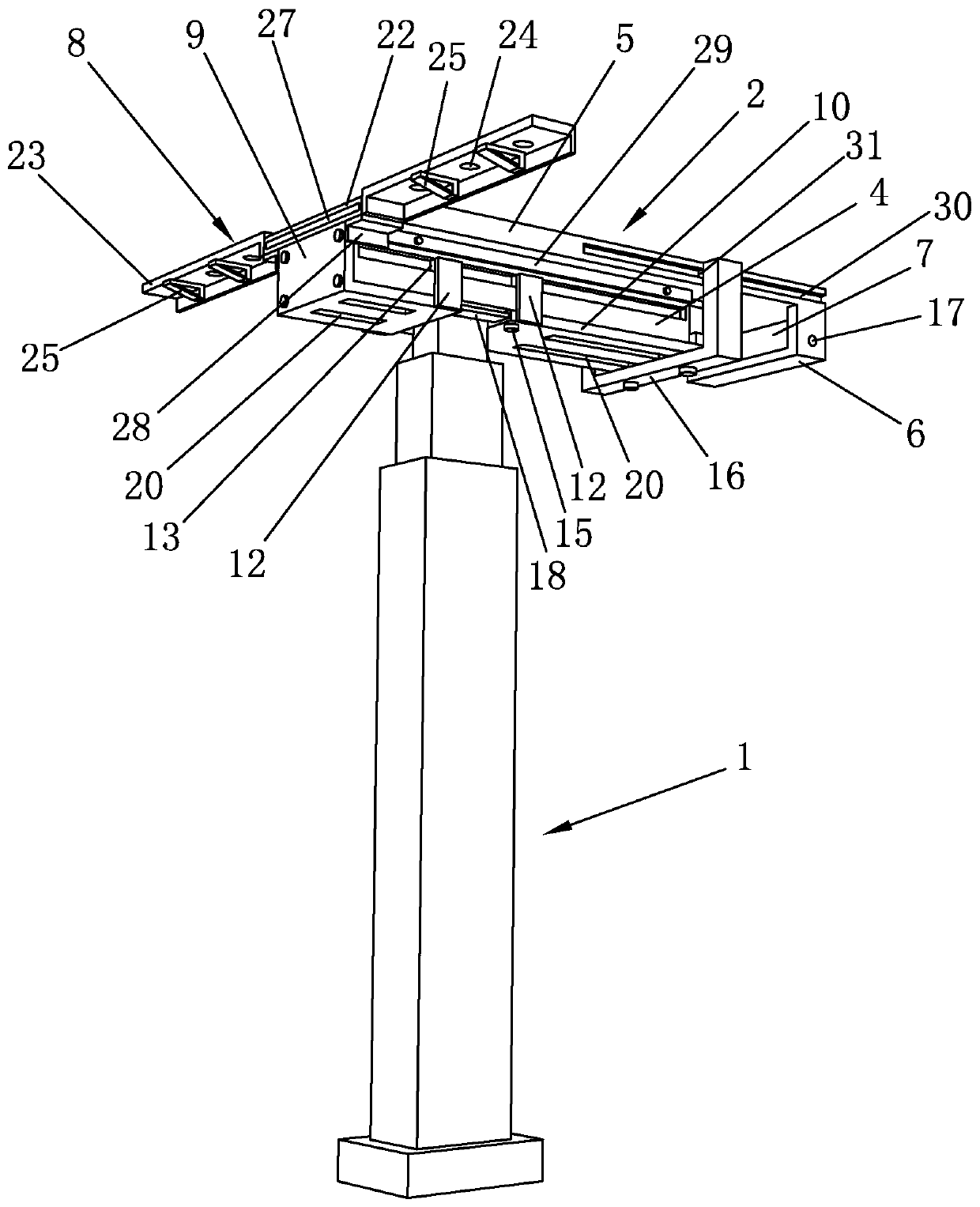

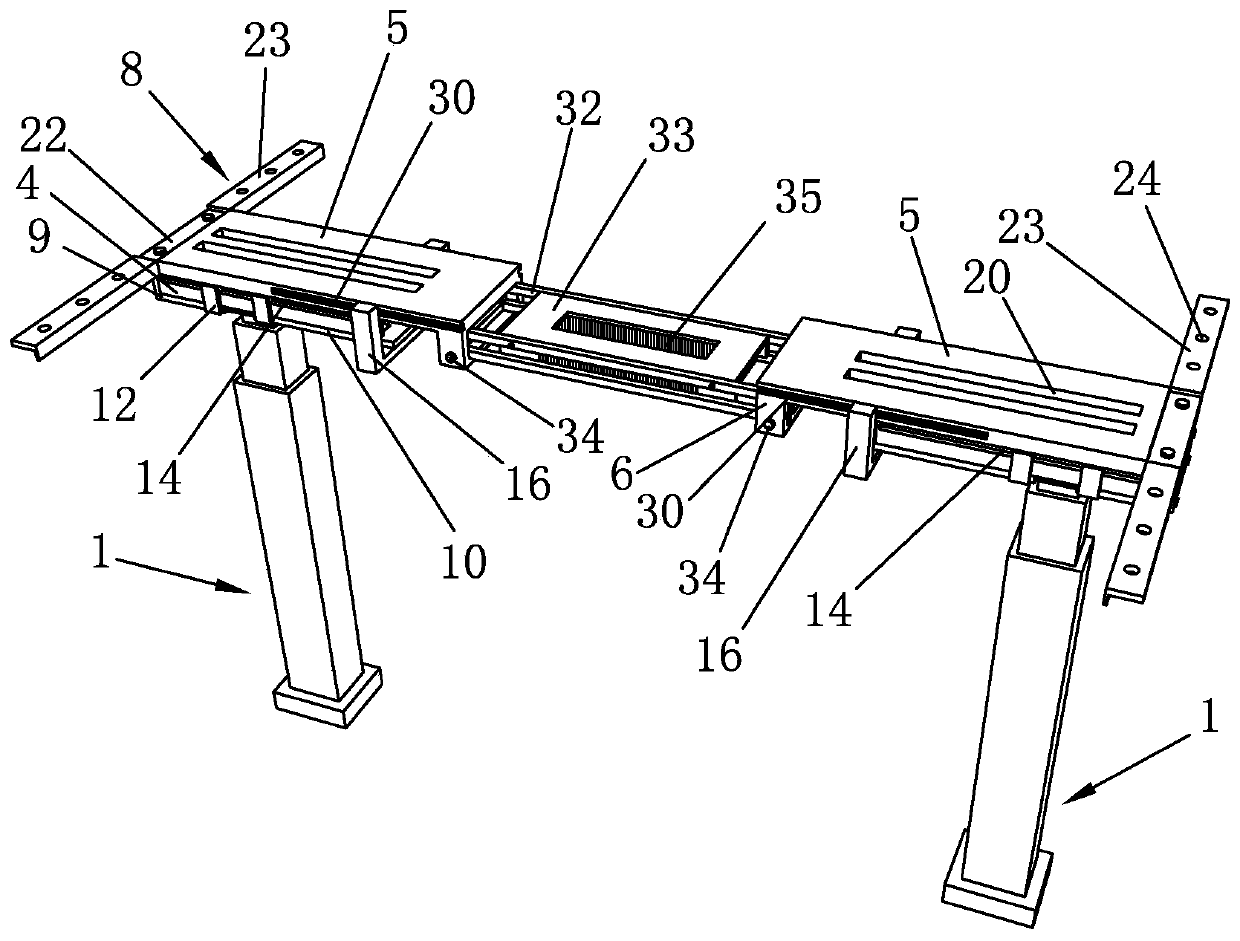

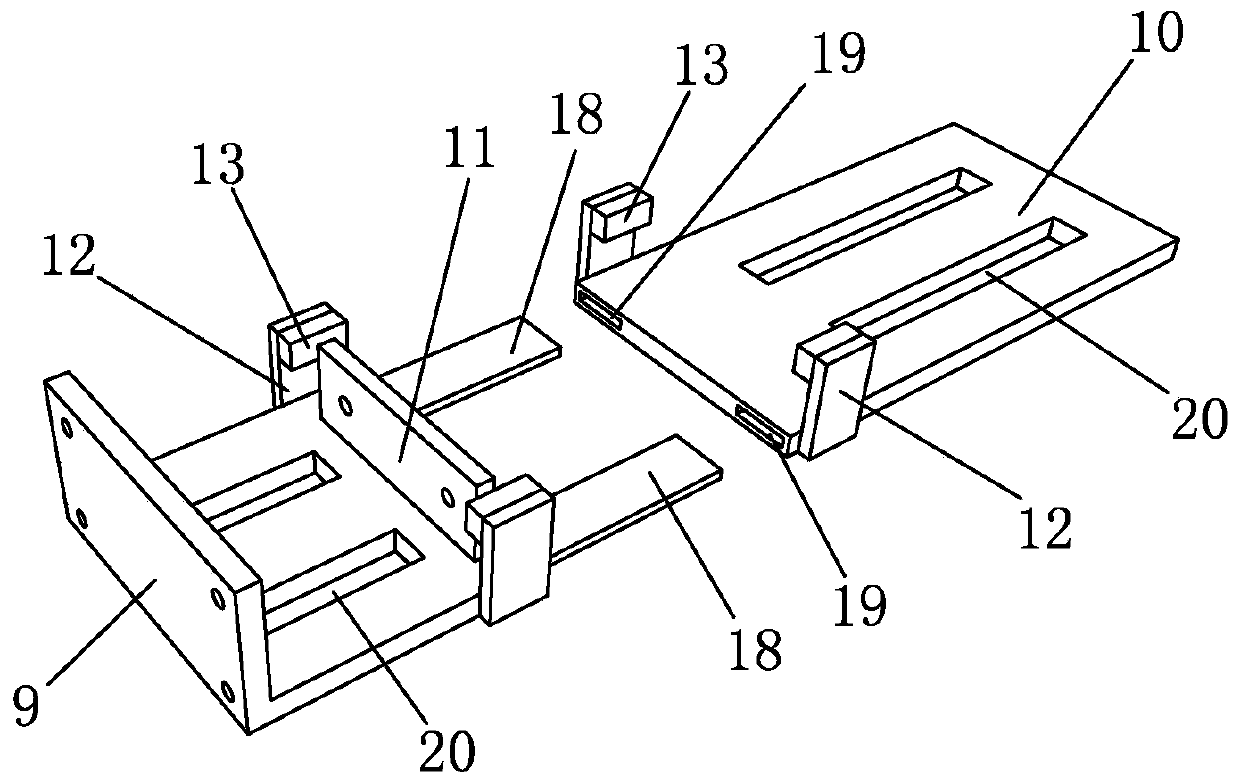

Quenching chuck for straight section on end portion of automobile plate spring

InactiveCN106987696AFix low conversion ratesIncrease contact areaFurnace typesHeat treatment furnacesSlow coolingStraight segment

The invention relates to a quenching collet used for the straight section of the end of an automobile leaf spring, comprising a quenching collet, a U-shaped installation hole is vertically arranged on the quenching collet, and a quenching collet is vertically arranged on the bottom of the quenching collet The straight section at the end, the quenching chuck is installed and positioned on the body of the quenching swinging machine by the bolt through the U-shaped mounting hole, and the straight section at the end of the quenching chuck is evenly equipped with multiple full-through oil grooves with arc-shaped cross-sections . The invention solves the problem that the cooling speed of the leaf spring end is slowed down due to the contact surface during quenching and forming, resulting in a lower quenching structure conversion rate. Through the multi-channel all-through oil grooves uniformly arranged under the straight section of the end of the quenching chuck, It can increase the contact area between the quenching medium and the end of the leaf spring, and ensure the cooling rate so as to solve the problem of the transformation rate of the quenching structure.

Owner:东风汽车悬架弹簧有限公司

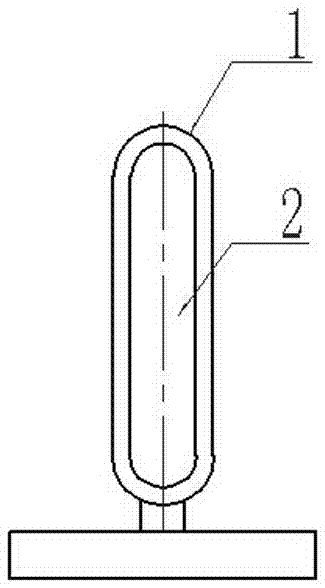

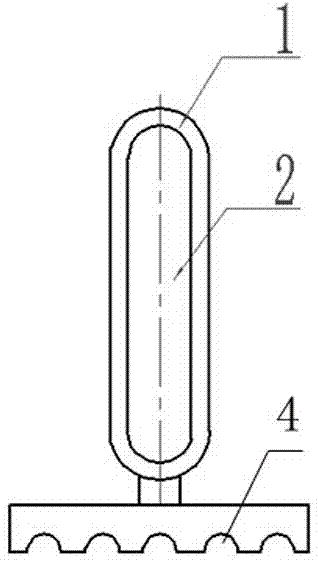

High-thrust lifting upright structure and mounting method thereof

Owner:绍兴蒂尔莱特科技有限公司

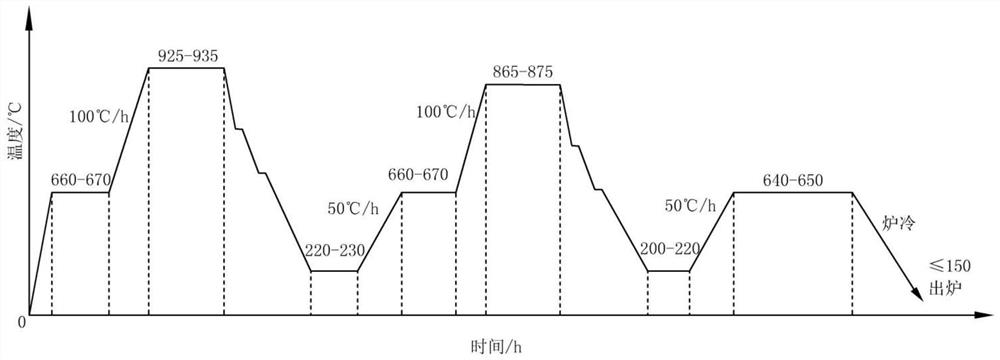

Heat treatment method of roll shaft

PendingCN113667800AReduce distortionReduced tendency to crackFurnace typesQuenching agentsFurnace temperatureHeat conservation

The invention provides a heat treatment method of a roll shaft. The heat treatment method comprises the following steps of heating the roll shaft to 660-670 DEG C, and keeping the temperature for 2-3 hours; raising the furnace temperature to 925-935 DEG C, and keeping the temperature for 2-4 hours; alternately carrying out water cooling and air cooling on the roll shaft, finally conducting oil cooling, reducing the temperature of the roll shaft to 220-230 DEG C, and keeping the temperature for 2-3 hours; raising the furnace temperature to 660-670 DEG C, and keeping the temperature for 2-3 hours; raising the furnace temperature to 865-875 DEG C, and keeping the temperature for 2-4 hours; alternately carrying out water cooling and air cooling on the roll shaft again, finally carrying out oil cooling, enabling the temperature of the roll shaft to be reduced to 200-220 DEG C, and keeping the temperature for 2-3 hours; raising the furnace temperature to 640-650 DEG C, and keeping the temperature for 3-4 hours; and then performing whole-course furnace cooling, reducing the temperature to 150 DEG C, and conducting discharging . According to the heat treatment method, the thermal stress during water cooling is reduced, and the deformation and cracking tendency of the roll shaft is reduced.

Owner:南京联银重型机械有限公司

Cooling system of high-temperature gas cooled reactor nuclear power station

PendingCN114017759AQuick startImprove economyNuclear energy generationBoiler controlNuclear powerProcess engineering

The invention provides a cooling system of a high-temperature gas cooled reactor nuclear power station, and belongs to the technical field of nuclear power. The cooling system comprises: a steam generator; a main water supply device; an auxiliary steam generating device; a main steam device; and an auxiliary steam receiving device. According to the cooling system of the high-temperature gas cooled reactor nuclear power station, the cooling steam supply pipeline is additionally arranged between the main water supply device and the water supply device between the steam generator, and cooling steam with certain parameters is provided for the steam generator after the reactor is shut down emergently; a cooling steam discharging pipeline is additionally arranged on a steam conveying pipeline of the steam generator; and through the structure, the cooling time of the steam generator is shortened from about 20 days during natural cooling to about 52 hours, so that a reactor can be quickly started after emergency shutdown, and the operation efficiency and the economical efficiency of a power plant are greatly improved.

Owner:HUANENG SHANDONG SHIDAO BAY NUCLEAR POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com