Accelerated cooling method after 12Cr2Mo1VR steel plate quenching slot normalizing

A technology of accelerated cooling and quenching tank, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problem of insufficient cooling capacity of the core, achieve the effects of improving water temperature uniformity, accelerating cooling speed, and reducing performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

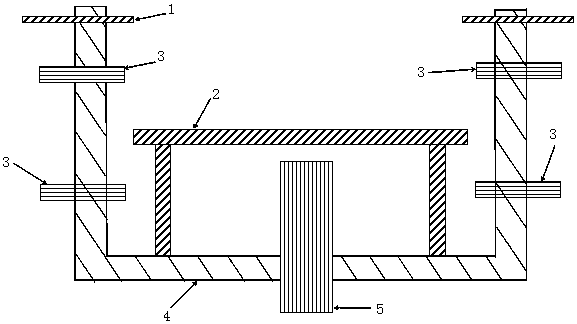

Method used

Image

Examples

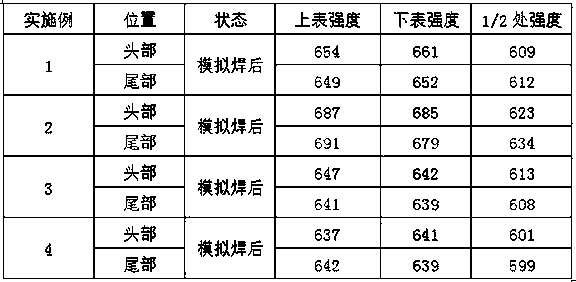

Embodiment 1

[0022] The specification of the large thickness 12Cr2Mo1VR steel plate in this example is 162*1850*13450mm, the chemical composition and mass percentage of the steel plate are: C: 0.13%, Si: 0.05%, Al: 0.024%, Mn: 0.58%, Cr: 2.36% , Mo: 1.03%, V: 0.32%, P: 0.005%, S: 0.003%, As: 0.007%, Sn: 0.005%, Sb: 0.001%, and the balance is Fe and unavoidable impurities.

[0023] In this embodiment, the production method of accelerated cooling after normalizing the large thickness 12Cr2Mo1VR steel plate in the quenching tank is as follows:

[0024] When the steel plate is normalized and cooled for the first time, the water temperature in the quenching tank is 30°C. The time for the steel plate to enter the water from the furnace is 60s. After the steel plate enters the water, the air stirring is turned on immediately, and the water volume in the upper part of the quenching tank is 500m 3 / h, the water entering the bottom is 1500m 3 / h, the water temperature in the quenching tank during t...

Embodiment 2

[0028] The specification of the large thickness 12Cr2Mo1VR steel plate in this example is 190*2000*9850mm, the chemical composition and mass percentage of the steel plate are: C: 0.12%, Si: 0.08%, Al: 0.019%, Mn: 0.54%, Cr: 2.41% , Mo: 1.02%, V: 0.35%, P: 0.006%, S: 0.002%, As: 0.006%, Sn: 0.002%, Sb: 0.001%, and the balance is Fe and unavoidable impurities.

[0029] In this embodiment, the production method of accelerated cooling after normalizing the large thickness 12Cr2Mo1VR steel plate in the quenching tank is as follows:

[0030] When the steel plate is normalized and cooled for the first time, the water temperature in the quenching tank is 28°C. The time for the steel plate to enter the water from the furnace is 49s. After the steel plate enters the water, the air stirring is turned on immediately, and the water volume in the upper part of the quenching tank is 510m 3 / h, the water entering the bottom is 1530m 3 / h, the water temperature in the quenching tank during th...

Embodiment 3

[0034] The specification of the large thickness 12Cr2Mo1VR steel plate in this example is 180*1760*10440mm, the chemical composition and mass percentage of the steel plate are: C: 0.14%, Si: 0.06%, Al: 0.021%, Mn: 0.54%, Cr: 2.40% , Mo: 1.01%, V: 0.34%, P: 0.006%, S: 0.004%, As: 0.005%, Sn: 0.003%, Sb: 0.001%, and the balance is Fe and unavoidable impurities.

[0035] In this embodiment, the production method of accelerated cooling after normalizing the large thickness 12Cr2Mo1VR steel plate in the quenching tank is as follows:

[0036] When the steel plate is normalized and cooled for the first time, the water temperature in the quenching tank is 30°C. The time for the steel plate to enter the water from the furnace is 53s. After the steel plate enters the water, the air stirring is turned on immediately, and the water volume in the upper part of the quenching tank is 550m 3 / h, the water entering the bottom is 1570m 3 / h, the water temperature in the quenching tank during t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com