Method for preparing amorphous alloy thin strip through quenching conical single roller quickly

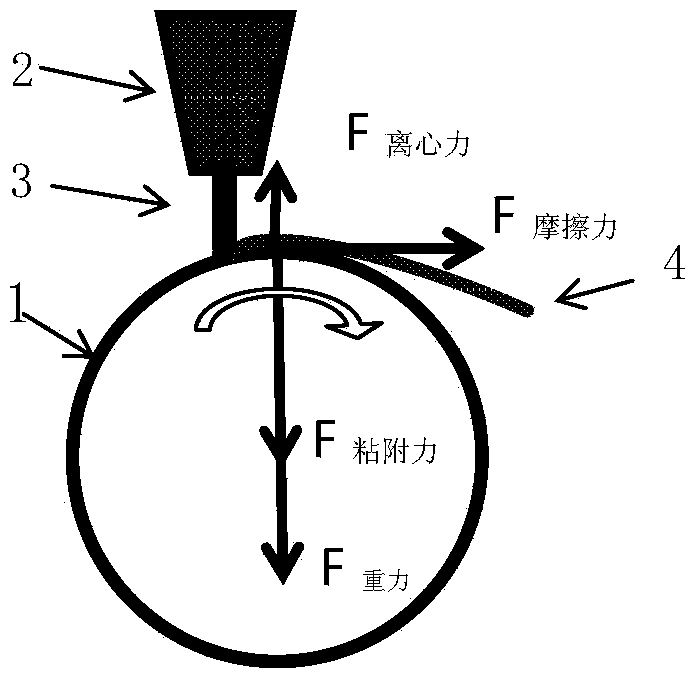

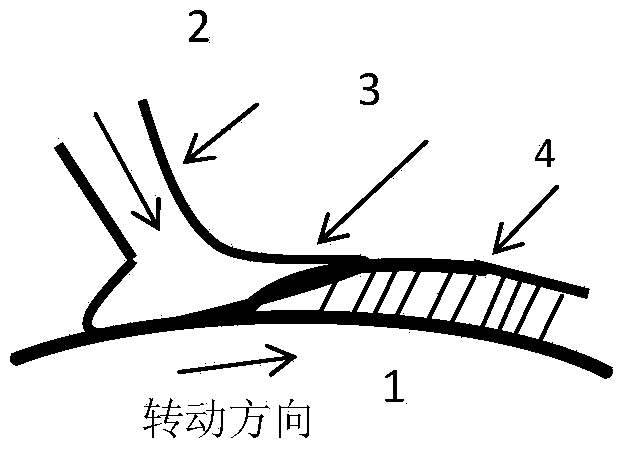

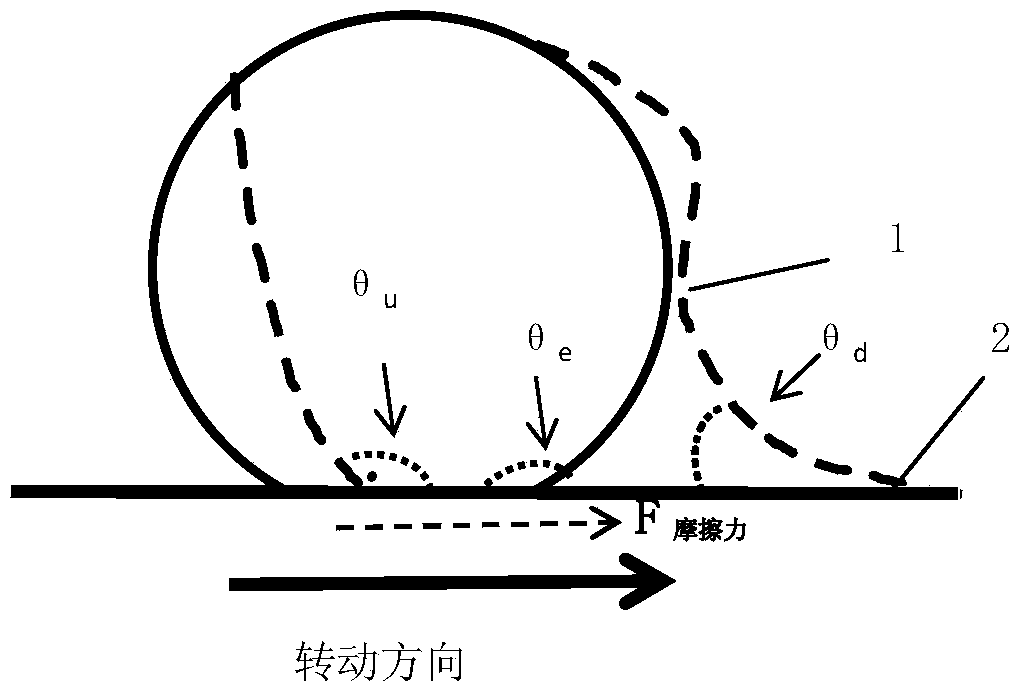

A single-roll rapid quenching and amorphous alloy technology, which is applied in the field of alloy thin strip preparation, can solve the problems of rapid solidification thin strip melt droplet splashing, thin strip Rayleigh defects, and difficulty in forming strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a fast-quenched amorphous alloy thin strip, including batching, smelting, secondary smelting, strip spraying, and harvesting. The mass percentage of its chemical composition is: 21.57%Sm, 72.84%Fe, 1.66%Zr, 3.93%Co.

[0052] Using 99.5% metal samarium, industrial pure iron, metal cobalt, and metal zirconium as raw materials, it is smelted in an intermediate frequency vacuum induction melting furnace. Before smelting, the vacuum chamber is first evacuated, and then high-purity argon is used as a protective gas to avoid alloy oxidation. . The melting temperature is 1600°C. Secondary melting is carried out in the induction ladle, and the spray belt pressure is established in the nozzle package, and the spray belt pressure is 0.05Mpa. The protective atmosphere pressure is 0.01Mpa.

[0053] The conical roller is made of molybdenum, the angle between the conical slope surface and the central axis is 80°, and the inside of the flat roller is cooled by ...

Embodiment 2

[0060] The conical fast-setting thin strip method adopted in this embodiment, the prepared Sm 1.0 Zr 0.3 Fe 8.1 co 0.6 Fast-setting thin zone, the difference is that the angle between the conical slope surface and the central axis is 45°, and other parameters are as in Example 1. Obtain a thin strip with a uniform thickness of 18-19 microns and a Sm with a surface roughness of less than 0.3 microns 1.0 Zr 0.3 Fe 8.1 co 0.6 Fast-setting thin strips are fast-setting thin strips, and there is no splashing phenomenon in the process of throwing the strips. There is no a‐Fe soft magnetic phase in the alloy, and Sm is formed after grinding and nitriding 1.0 Zr 0.3 Fe 8.1 co 0.6 N x , after being made into a bonded magnet, the magnetic property is B r =0.97T, (BH) max =22.3MGOe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com