Heat treatment method of roll shaft

A heat treatment method and roller shaft technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of poor ultrasonic flaw detection, poor mechanical properties, coarse grains, etc., and meet the requirements of no cracking, reduced deformation and cracking, and small transformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

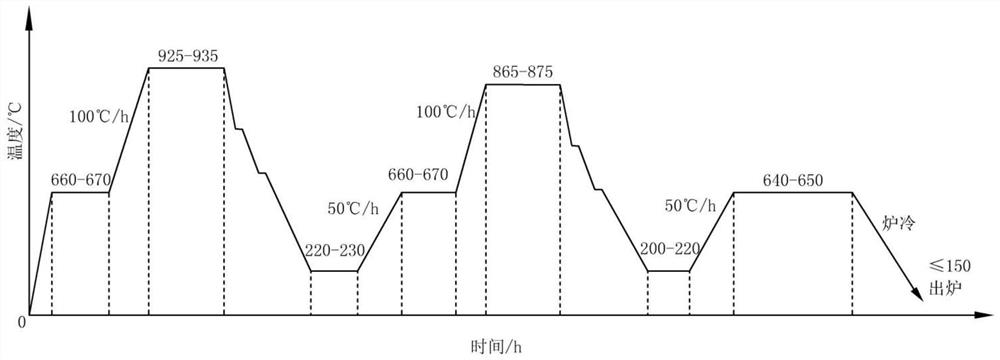

[0018] According to an embodiment of the present invention combined with figure 1 show. A heat treatment method for a roller, comprising the steps of:

[0019] (1) Put the roller shaft into a heat treatment furnace, raise the temperature to 660°C, and keep it warm for 2 hours;

[0020] (2) Raise the furnace temperature to 925°C at a heating rate of 100°C / h and keep it warm for 2 hours;

[0021] (3) Alternately put the roller shaft into brine and air for water cooling and air cooling, and finally put it into quenching oil for oil cooling, so that the temperature of the roller shaft is reduced to 220 ° C, and keep warm for 2 hours;

[0022] (4) Raise the furnace temperature to 660°C at a heating rate of 50°C / h and keep it warm for 2 hours; then raise the furnace temperature to 865°C at a heating rate of 100°C / h and keep it warm for 2 hours;

[0023] (5) Alternately put the roller shaft into brine and air again for water cooling and air cooling, and finally put it into quenchi...

Embodiment 2

[0032] A heat treatment method for a roller, comprising the steps of:

[0033] (1) Put the roller shaft into a heat treatment furnace, raise the temperature to 665°C, and keep it warm for 2.5 hours;

[0034] (2) Raise the furnace temperature to 930°C at a heating rate of 100°C / h and keep it warm for 3 hours;

[0035] (3) Alternately put the roller shaft into brine and air for water cooling and air cooling, and finally put it into quenching oil for oil cooling, so that the temperature of the roller shaft is reduced to 225°C and kept for 2.5 hours;

[0036] (4) Raise the furnace temperature to 665°C at a heating rate of 50°C / h and keep it warm for 2.5 hours; then raise the furnace temperature to 870°C at a heating rate of 100°C / h and keep it warm for 3 hours;

[0037] (5) Alternately put the roller shaft into salt water and air again for water cooling and air cooling, and finally put it into quenching oil for oil cooling, so that the temperature of the roller shaft is reduced t...

Embodiment 3

[0046] A heat treatment method for a roller, comprising the steps of:

[0047] (1) Put the roller shaft in a heat treatment furnace, raise the temperature to 670°C, and keep it warm for 3 hours;

[0048] (2) Raise the furnace temperature to 935°C at a heating rate of 100°C / h and keep it warm for 4 hours;

[0049] (3) Alternately put the roller shaft into brine and air for water cooling and air cooling, and finally put it into quenching oil for oil cooling to reduce the temperature of the roller shaft to 230°C and keep it warm for 3 hours;

[0050] (4) Raise the furnace temperature to 670°C at a heating rate of 50°C / h and keep it warm for 3 hours; then raise the furnace temperature to 875°C at a heating rate of 100°C / h and keep it warm for 4 hours;

[0051] (5) Alternately put the roller shaft into brine and air again for water cooling and air cooling, and finally put it into quenching oil for oil cooling, so that the temperature of the roller shaft is reduced to 220°C and kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com