Thermal treatment technique of steel wire

A steel wire and process technology, applied in the field of heat treatment of steel wire, can solve the problems of low heat treatment heat utilization rate and production efficiency, environmental pollution, and non-environmental protection, and achieve the effects of stable heat treatment quality, high heat utilization rate, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

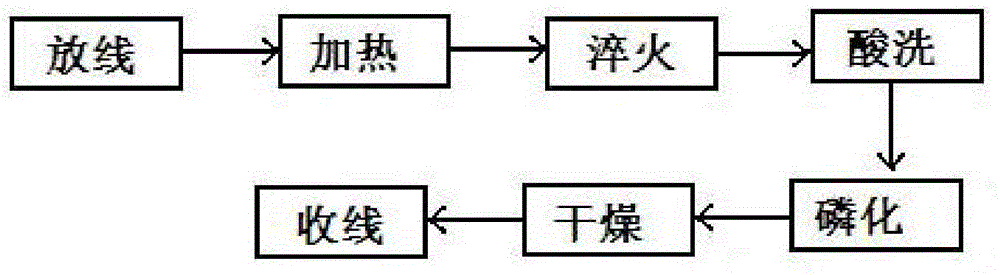

[0026] Such as figure 1 As shown, a steel wire heat treatment process is completed in the same process from wire-feeding to wire-receiving, and the process is specifically carried out in the following steps:

[0027] (1) Heating: The steel wire is unwound through the pay-off rack, and the steel wire is directly fired with natural gas. After one-stage heating at 970-980°C, two-stage heating at 950-960°C, three-stage heating at 940-950°C, and 920-930°C Heating section heating, heating time 1min;

[0028] (2) Quenching: Pass the steel wire heated by natural gas into the quenching pool, and quench it with an aqueous solution of quenching agent.

[0029] The quenching temperature is 90-100°C, the quenching time is 1min, and then rinsed with water, the flushing temperature is 70-80°C, and the flushing time is 0.5min;

[0030] (3) Pickling: Put the quenched steel wire into the sealed pickling tank, the heating method is steam heating, the pickling temperature is 80-90°C, pickling w...

Embodiment 2

[0034] A heat treatment process for steel wire, which is completed in the same process from wire unwinding to wire take-up, and the process is specifically carried out according to the following steps:

[0035] (1) Heating: The steel wire is unwound through the pay-off rack, and the steel wire is directly fired with natural gas. After one-stage heating at 970-980°C, two-stage heating at 950-960°C, three-stage heating at 940-950°C, and 920-930°C Heating section heating, heating time 1.5min;

[0036] (2) Quenching: Put the steel wire heated by natural gas into the quenching pool, and quench it through the quenching agent aqueous solution. The quenching temperature is 90-100°C, and the quenching time is 1.2min. The time is 0.7min;

[0037] (3) Pickling: Put the quenched steel wire into the sealed pickling tank, the heating method is steam heating, the pickling temperature is 80-90°C, pickling with mist hydrochloric acid, the pickling time is 1.5min;

[0038] (4) Phosphating: Pu...

Embodiment 3

[0041] A heat treatment process for steel wire, which is completed in the same process from wire unwinding to wire take-up, and the process is specifically carried out according to the following steps:

[0042] (1) Heating: The steel wire is unwound through the pay-off rack, and the steel wire is directly fired with natural gas. After one-stage heating at 970-980°C, two-stage heating at 950-960°C, three-stage heating at 940-950°C, and 920-930°C Heating section heating, heating time 2min;

[0043] (2) Quenching: Put the steel wire heated by natural gas into the quenching pool, and quench it with a quenching agent aqueous solution. The quenching temperature is 90-100°C, and the quenching time is 1.5min. The time is 1min;

[0044] (3) Pickling: Put the quenched steel wire into the sealed pickling tank, the heating method is steam heating, the pickling temperature is 80-90°C, pickling is carried out with mist hydrochloric acid, and the pickling time is 2 minutes;

[0045] (4) Ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com