HY type dry distillation furnace

A dry distillation furnace and dry distillation technology, applied in the field of dry distillation furnaces, can solve the problems of poor material permeability in the furnace and inability to perform dry distillation, and achieve long-term safety, reduce power consumption and operating costs, and prevent furnace clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

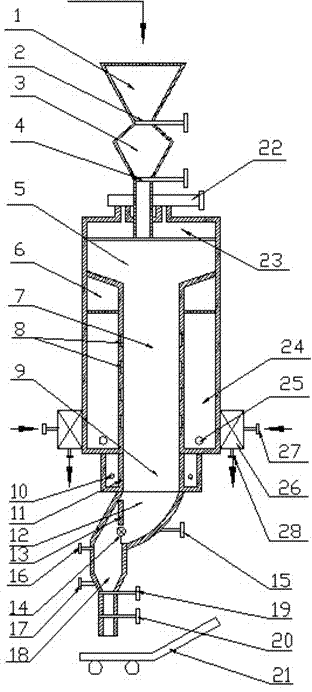

[0038] attachedfigure 1 It is the working principle diagram of HY type retort furnace. The figure shows that the material is fed from the upper part of the retort furnace and enters the silo 1. The I gate valve 2 is opened, and the material enters the hopper 3. When the hopper 3 is full of materials, the I gate valve 2 is closed. , Open the gate valve 4 of the lower II gate of the hopper, and the material falls into the carbonization furnace by its own weight. When not feeding, the Ⅱ gate valve 4 is closed. This double ram blanking method can prevent the gas in the furnace from escaping out of the furnace through the hopper and the air outside the furnace from entering the furnace through the hopper. After the material enters the retort furnace, it first passes through the preheating drying chamber 5. In the preheating drying chamber 5, the material is heated to 200°C-250°C by the retort gas of 500°C-550°C sprayed from the gas chamber 6, and the material contains The water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com