Welding method for controlling hardness of weld seam heat-affected zone of low-carbon steel material for casting

A heat-affected zone and welding method technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as not overcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

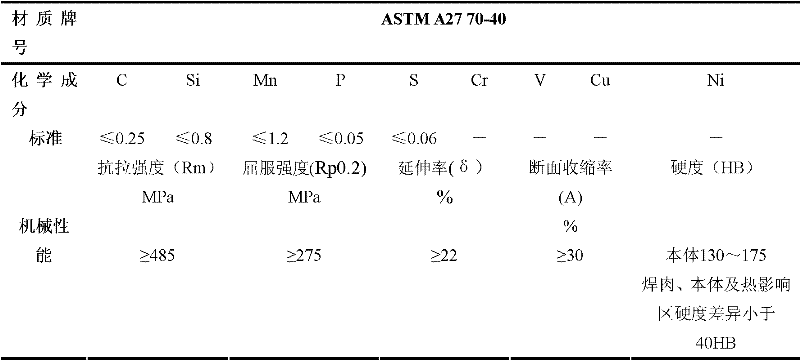

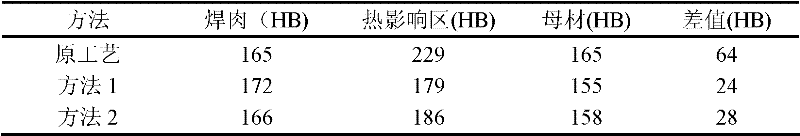

Embodiment 1

[0019] Example 1: A welding method for controlling the hardness of the heat-affected zone of a low-carbon steel weld for casting. The method uses φ4mm and φ5mm AWS 5.1 E7015 electrodes, the minimum preheating temperature is 170°C, the welding current is 175A-240A, and the voltage 20-30V, welding speed 10-25cm / min, welding heat input of 23-27KJ / cm, and tempering weld bead.

Embodiment 2

[0020] Embodiment 2: A welding method for controlling the hardness of the heat-affected zone of a low-carbon steel weld seam for casting. The method uses φ4mm and φ5mm AWS 5.1 E7015 grade electrodes, the minimum preheating temperature is 200°C, the welding current is 175A-240A, and the voltage 20-30V, welding speed 10-25cm / min, welding heat input of 20-25KJ / cm, and tempering weld bead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com