In-situ TaC particle and iron-based amorphous alloy synergistically strengthened medium-high manganese steel-based composite and preparation method thereof

A technology for iron-based amorphous alloys and composite materials is applied in the field of high-manganese steel-based composite materials and their preparation, and can solve the problems of difficulty in making complex special-shaped parts, low powder core skeleton strength, and high requirements for equipment and process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

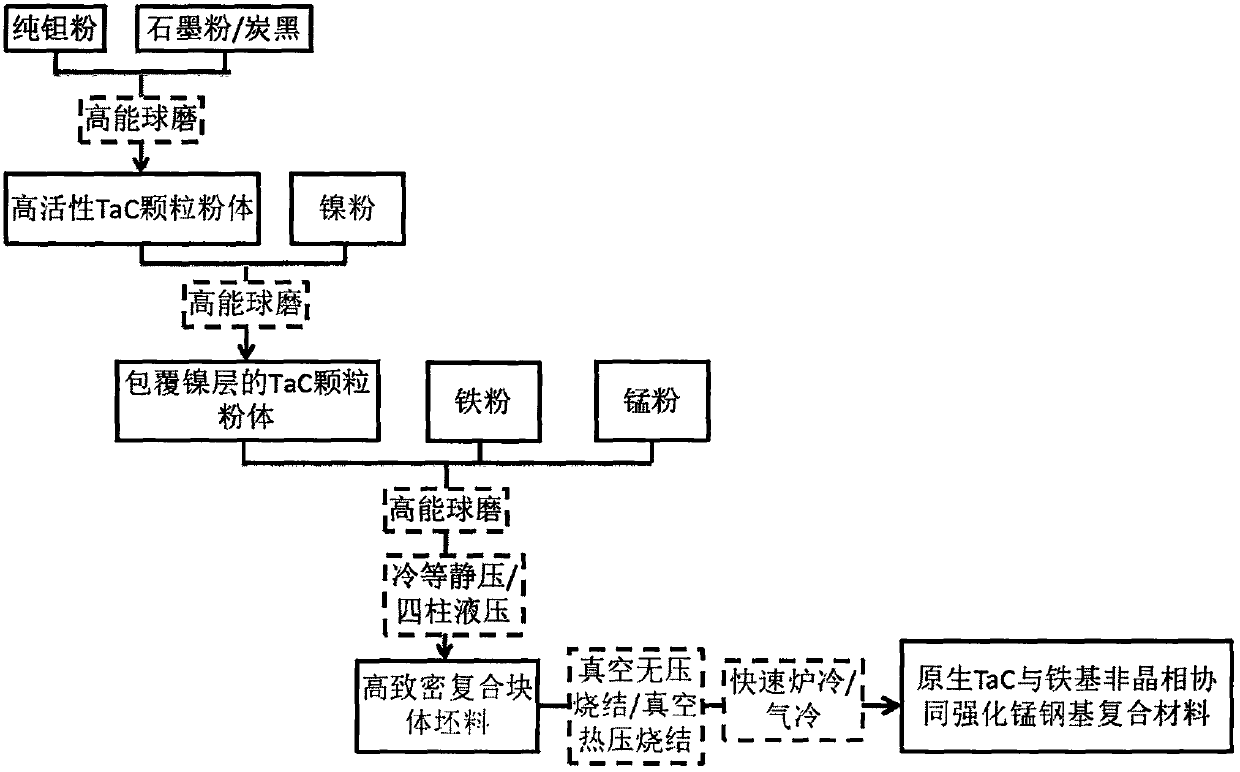

[0022] Step 1. Tantalum powder and graphite powder according to the molar ratio M Ta : M C =1: 1.1 is weighed, then carry out high-energy ball milling (stainless steel ball; stainless steel ball mill tank; ball-to-material ratio is 10:1, rotating speed is 500r / min, and ball milling time is 40h), then obtains the product with high activity, high specific surface area TaC particle powder;

[0023] Step 2. Add a small amount of nickel powder (5% of the quality of the TaC particle powder) in the TaC particle powder obtained in step 1, and then carry out high-energy ball milling (the rotating speed is 300r / min, and the ball milling time is 10h) to obtain coated nickel layer of TaC particle powder;

[0024] Step 3. After step 2 finishes, add stainless steel grinding ball, iron powder and manganese powder (manganese powder accounts for 13% of the total powder quality of iron-manganese, the TaC particle of the coated nickel layer that step 3 obtains in ball mill jar again The powde...

Embodiment 2

[0029] Step 1. Tantalum powder and graphite powder according to the molar ratio M Ta : M C =1: 1.1 is weighed, then carry out high-energy ball milling (stainless steel ball; stainless steel ball mill tank; ball-to-material ratio is 10:1, rotating speed is 500r / min, and ball milling time is 40h), then obtains the product with high activity, high specific surface area TaC particle powder;

[0030] Step 2. Add a small amount of nickel powder (5% of the quality of the TaC particle powder) in the TaC particle powder obtained in step 1, and then carry out high-energy ball milling (the rotating speed is 300r / min, and the ball milling time is 10h) to obtain coated nickel layer of TaC particle powder;

[0031] Step 3. After step 2 finishes, add stainless steel grinding ball, iron powder and manganese powder (manganese powder accounts for 15% of the total powder quality of iron-manganese, the TaC particle of the coated nickel layer that step 3 obtains in ball mill jar again The powde...

Embodiment 3

[0037] Step 1. Tantalum powder and graphite powder according to the molar ratio M Ta : M C =1: 1.1 is weighed, then carry out high-energy ball milling (stainless steel ball; stainless steel ball mill tank; ball-to-material ratio is 10:1, rotating speed is 500r / min, and ball milling time is 40h), then obtains the product with high activity, high specific surface area TaC particle powder;

[0038] Step 2. Add a small amount of nickel powder (5% of the quality of the TaC particle powder) in the TaC particle powder obtained in step 1, and then carry out high-energy ball milling (the rotating speed is 300r / min, and the ball milling time is 10h) to obtain coated nickel layer of TaC particle powder;

[0039] Step 3. After step 2 finishes, add stainless steel grinding ball, iron powder and manganese powder (manganese powder accounts for 18% of the total powder quality of iron-manganese, the TaC particle of the coated nickel layer that step 3 obtains in ball mill jar again The powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com