3D amorphous alloy network reinforced boron-steel-based composite material with inlaid in-situ carbide particles, and preparation method of material

A technology of carbide particles and amorphous alloys, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of high equipment and process conditions, low powder core skeleton strength, uneven distribution of columnar carbides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

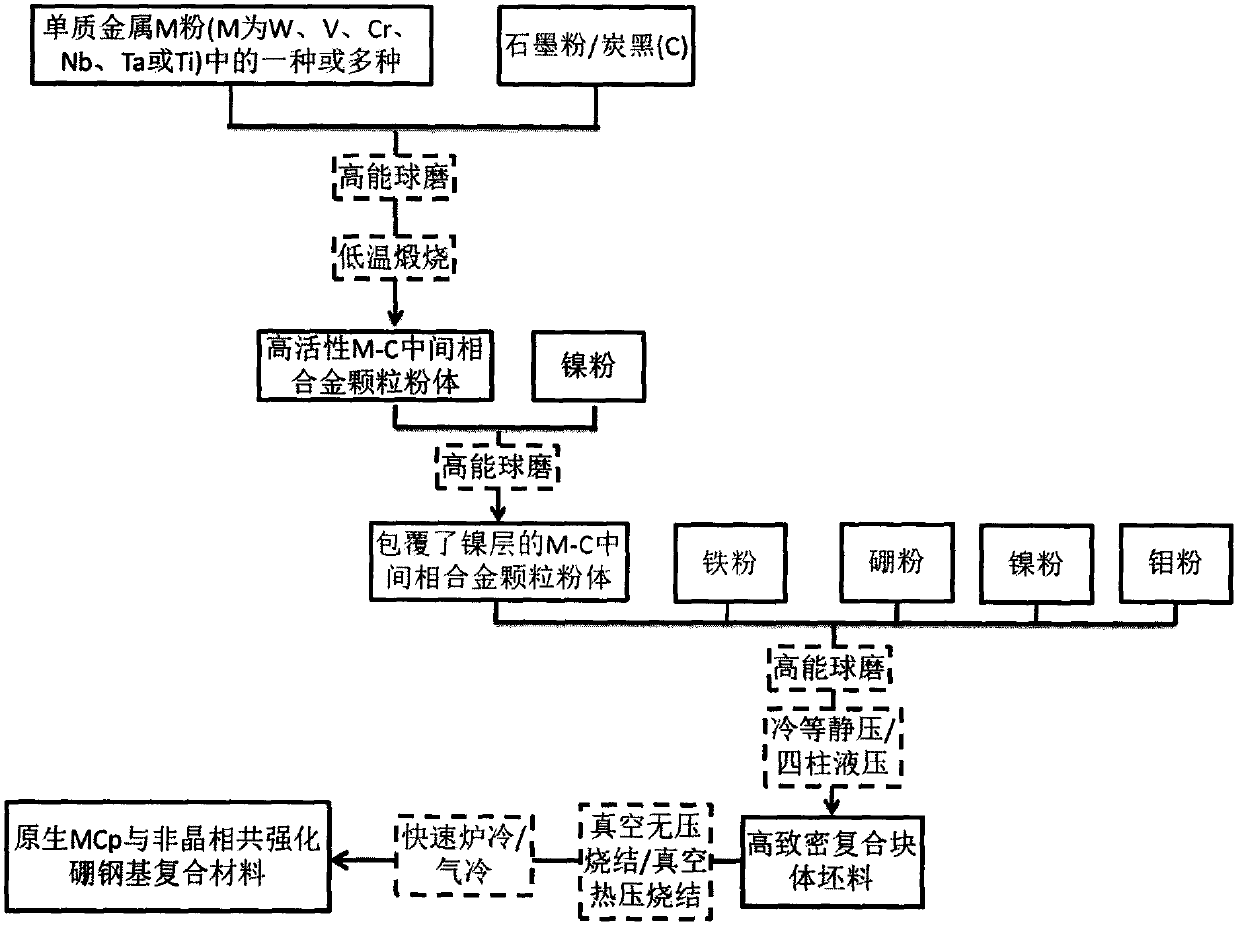

Method used

Image

Examples

Embodiment 1

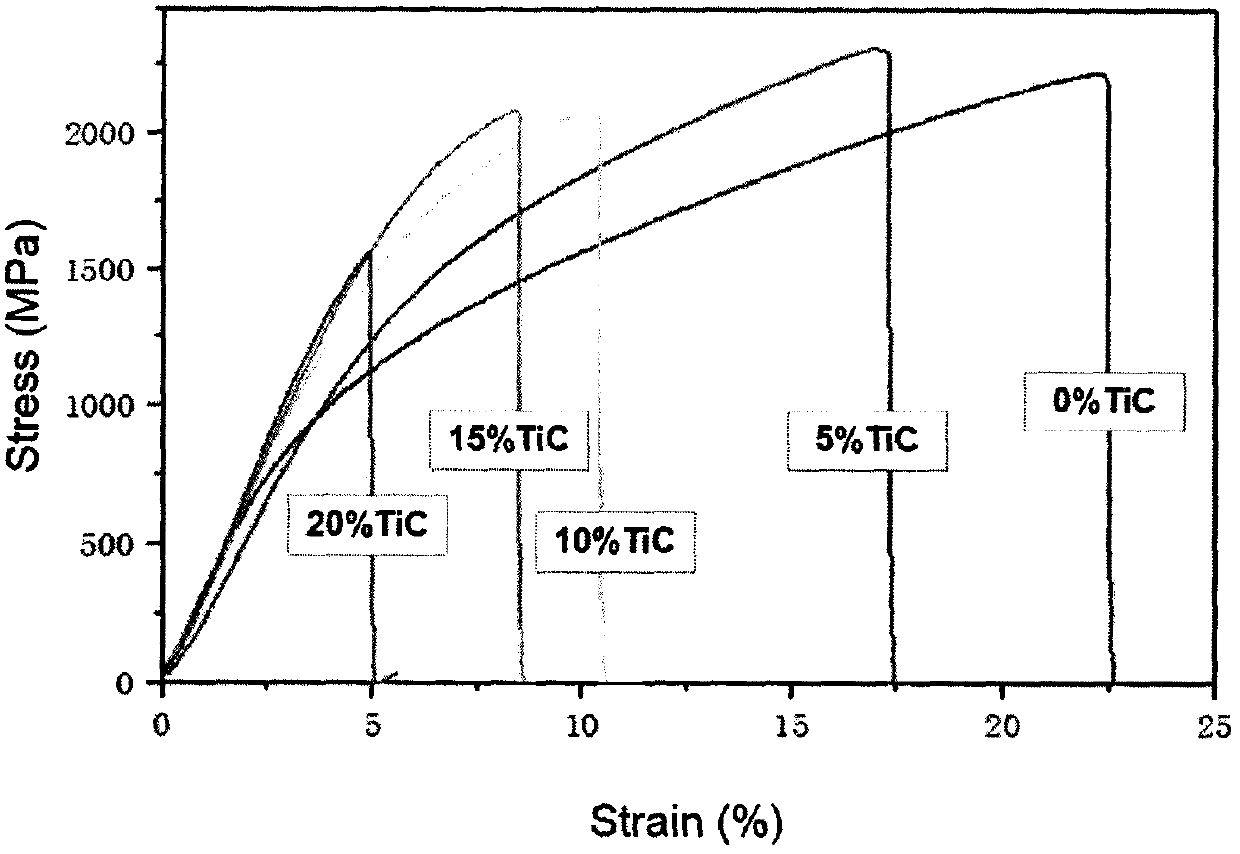

[0026] Example 1: 3D amorphous alloy network reinforced boron steel matrix composite material embedded with in-situ TiC particles

[0027] Step 1. Titanium powder and graphite powder according to the molar ratio M Ti : M C =1: 1.1 is weighed, and then high-energy ball milling (stainless steel balls; stainless steel ball mill tank; the ball-to-material ratio is 10:1, the rotating speed is 500r / min, and the ball milling time is 40h);

[0028] Step 2. Perform low-temperature calcination on the mixed powder obtained after ball milling in step 1. The calcination treatment is carried out under the protection of argon, the calcination temperature is 750 ° C, and the calcination time is 30 minutes, and then Ti-C mesophase alloy particle powder (containing a small amount of elemental Ti and amorphous graphite) with high activity and high specific surface area is obtained;

[0029] Step 3. Add a small amount of nickel powder (5% of the quality of the mesophase alloy particle powder) i...

Embodiment 2

[0034] Example 2: 3D amorphous alloy network reinforced boron steel matrix composite material embedded with in-situ NbC particles

[0035] Step 1. Niobium powder and graphite powder according to the molar ratio M Nb : M C =1: 1.1 is weighed, and then high-energy ball milling (stainless steel balls; stainless steel ball mill tank; the ball-to-material ratio is 10:1, the rotating speed is 500r / min, and the ball milling time is 40h);

[0036] Step 2. Perform low-temperature calcination on the mixed powder obtained after ball milling in step 1. The calcination treatment is carried out under the protection of argon, the calcination temperature is 750 ° C, and the calcination time is 30 minutes, and then the Nb-C mesophase alloy particle powder (containing a small amount of elemental Nb and amorphous graphite) with high activity and high specific surface area is obtained;

[0037] Step 3. Add a small amount of nickel powder (5% of the quality of the mesophase alloy particle powder...

Embodiment 3

[0043] Example 3: 3D amorphous alloy network reinforced boron steel matrix composite material embedded with in-situ WC particles

[0044] Step 1. Tungsten powder and graphite powder according to the molar ratio M W : M C =1: 1.1 is weighed, and then high-energy ball milling (stainless steel balls; stainless steel ball mill tank; the ball-to-material ratio is 10:1, the rotating speed is 500r / min, and the ball milling time is 40h);

[0045] Step 2. Perform low-temperature calcination on the mixed powder obtained after ball milling in step 1. The calcination treatment is carried out under the protection of argon, the calcination temperature is 750°C, and the calcination time is 30 minutes, and then the W-C mesophase alloy particle powder with high activity and high specific surface area is obtained;

[0046] Step 3. Add a small amount of nickel powder (10% of the mass of the mesophase alloy particle powder) to the W-C mesophase alloy particle powder obtained in step 2, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com