Quenching chuck for straight section on end portion of automobile plate spring

A technology of automobile steel plate and straight section, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problem of the transformation rate of the leaf spring structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

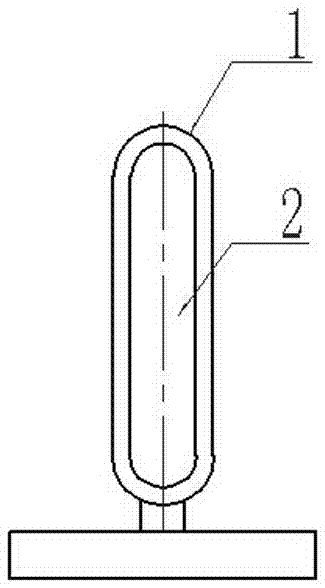

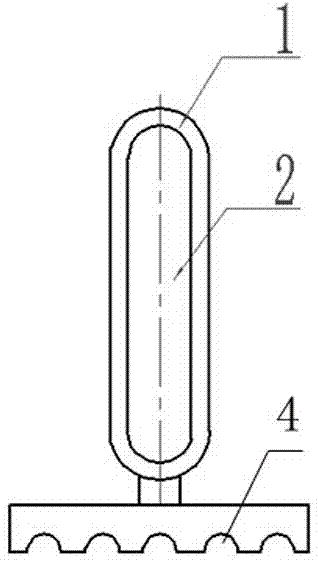

[0014] The present invention as image 3 , 4 shown.

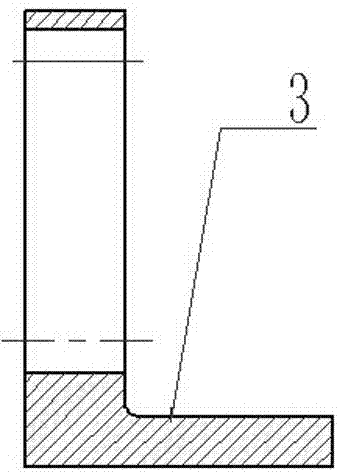

[0015] A quenching collet 1 for the straight section of the end of an automobile leaf spring, comprising a quenching collet 1, a U-shaped mounting hole 2 is vertically provided on the quenching collet 1, and a quenching collet is vertically arranged on the bottom of the quenching collet 1 The straight section 3 at the end of the chuck, the quenching chuck 1 is installed and positioned on the body of the quenching swing machine through the U-shaped mounting hole 2 by bolts, and the straight section 3 at the end of the quenching chuck is evenly equipped with multiple all-through oil grooves 4 .

[0016] The cross-sections of the all-through oil grooves 4 are arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com