Multilevel wheel-type draught fan

A multi-level, stage-wheel technology, which is applied to wind turbines, wind turbines that are in the same direction as the wind, and wind turbine components, etc., can solve the problems of low blade conversion rate, difficult transportation and installation, high noise, etc. The effect of low rate, simple installation and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

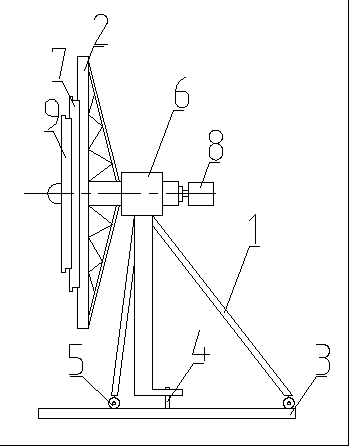

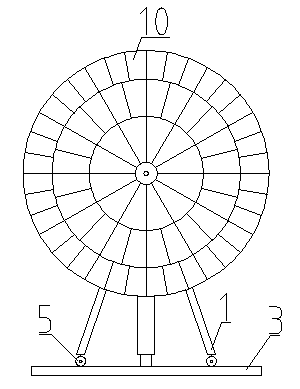

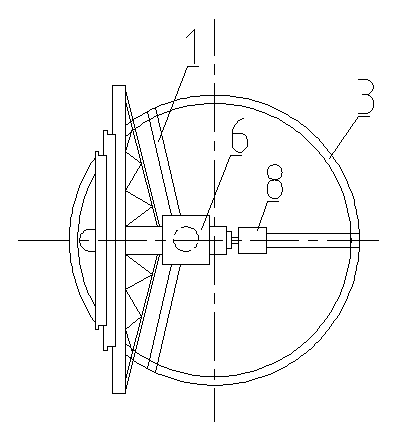

[0011] Specific embodiment 1: Take the 3-level roulette as an example: by Figure 1~3 It can be seen that the inner sleeve of the big roulette (2) is connected with the coaxial center of the roulette (7), the small roulette (9), the shaft of the big roulette (2) and the roulette (7) and the roulette (7) and the small wheel The discs (9) are fitted in turn through the rollers between the shafts; behind the shaft is the gear set (6), so that the forces of the large disc (1), the disc (7) and the small disc (9) are gathered together, and the The generator (8) is connected; the oblique support (1) is connected to the wheel, and the bottom of its long side is connected to the roller (5), and the shaft (4) is fixed by the track in the center of the circular guide rail (3), which can realize different wind directions. , the fan rotates on the circular guide rail (3) and rotates against the wind.

[0012] Because this fan adopts a multi-level wheeled fan, so that the three wheels rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com