Fan device for accelerated cooling of special pipe for oil in coating process

A special oil pipe and accelerated cooling technology, which is applied to the components of the pumping device for elastic fluid, pump device, mechanical equipment, etc. Simple, low cost, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

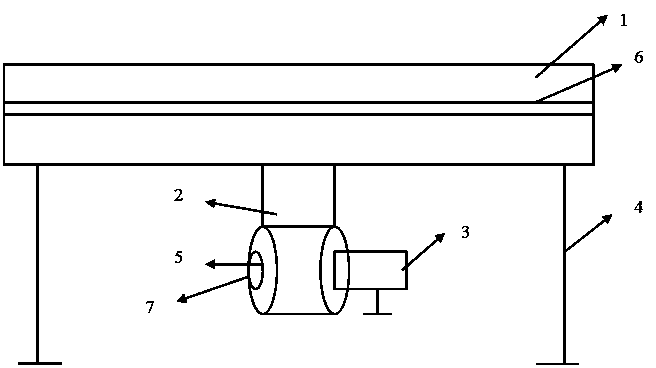

[0011] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] like figure 1 As shown, a fan device for accelerating cooling during the coating process of oil-specific pipes, including a blower box 1, a connecting canvas 2, a fan 3, a support bracket 4, a dust filter 5, an air outlet 6 and an air suction port 7, The two ends of blower box 1 are provided with supporting frame 4, and on its described blower box 1, offer the air outlet 6 that a width is 10mm, the length of air outlet 6 is consistent with the length of described blower box 1, and blower box 1 is a rectangular aluminum structure.

[0013] Simultaneously, blower box 1 is connected with ventilator 3 by connecting canvas 2, and described ventilator 3 is annular structure, and its one side is suction port 7, and the other side is motor, and dust removal filter screen 5 is arranged at this suction port 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com