Electric cooker and heating control method thereof

A technology for electric cookers and control chips, applied in heating devices, household appliances, kitchen appliances, etc., can solve problems such as insufficient temperature, increased heat loss of silicon controlled silicon, and large volume of electric cookers, so as to avoid excessive temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

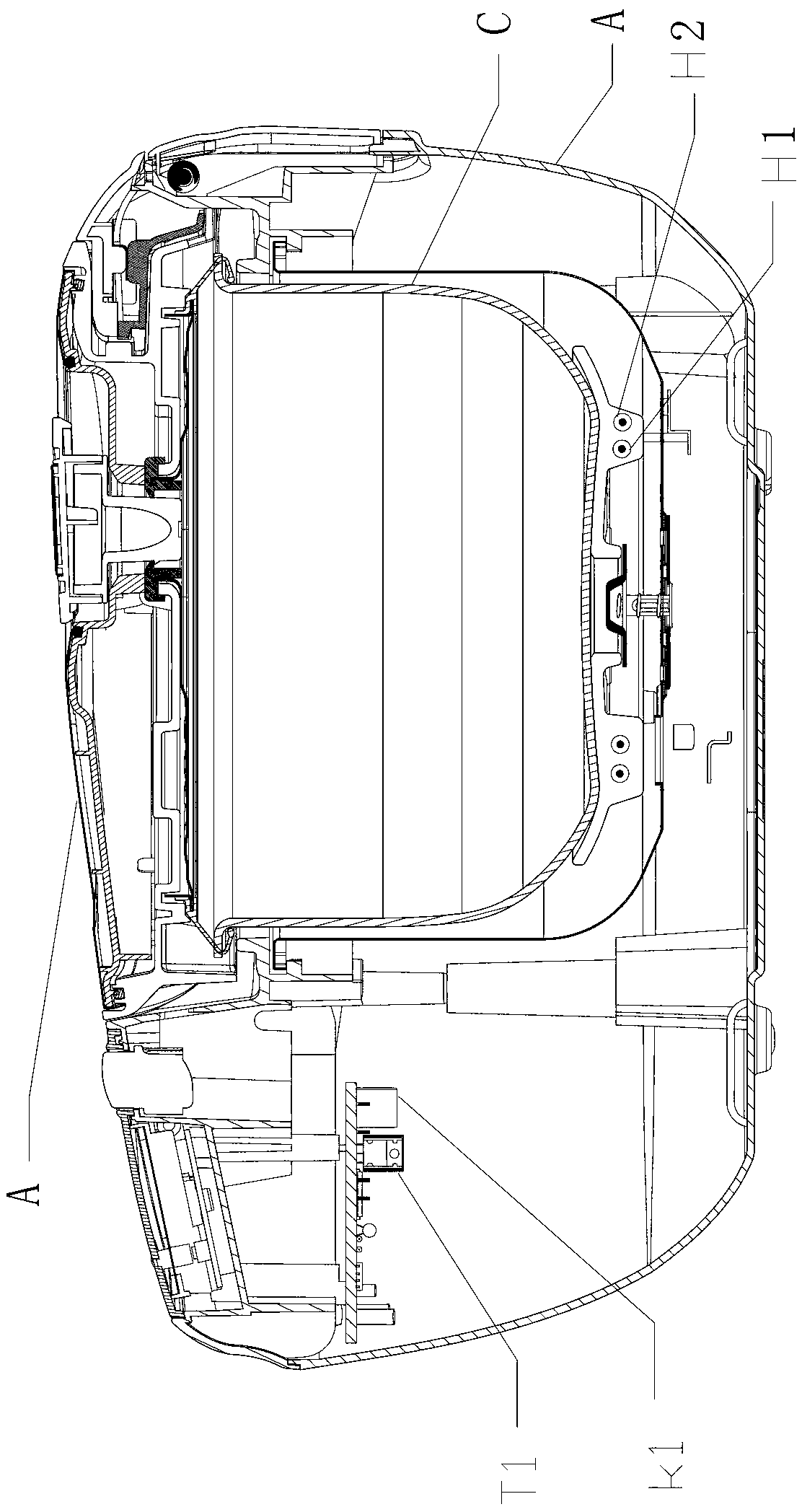

[0030] refer to Figure 1-4

[0031] Electric cooker, including pot body A, pot cover B, inner pot C, heating device, control device and switching power supply, heating device includes relay temperature control mechanism and thyristor temperature control mechanism, relay temperature control mechanism includes relay K1 and relay The connected first heating tube H1, the thyristor temperature control mechanism includes the thyristor T1 and the second heating tube H2 controlled by the thyristor, the relay K1 and the thyristor T1 are controlled by the control device; the relay temperature control The mechanism and the thyristor temperature control mechanism cooperate to provide heating power.

[0032] The relay temperature control mechanism can be composed of a relay K1 and a first heating tube H1; it can also be composed of multiple relays K1 and multiple first heating tubes H1, and each relay K1 controls a corresponding first heating tube H1 . When the relay temperature contro...

Embodiment 2

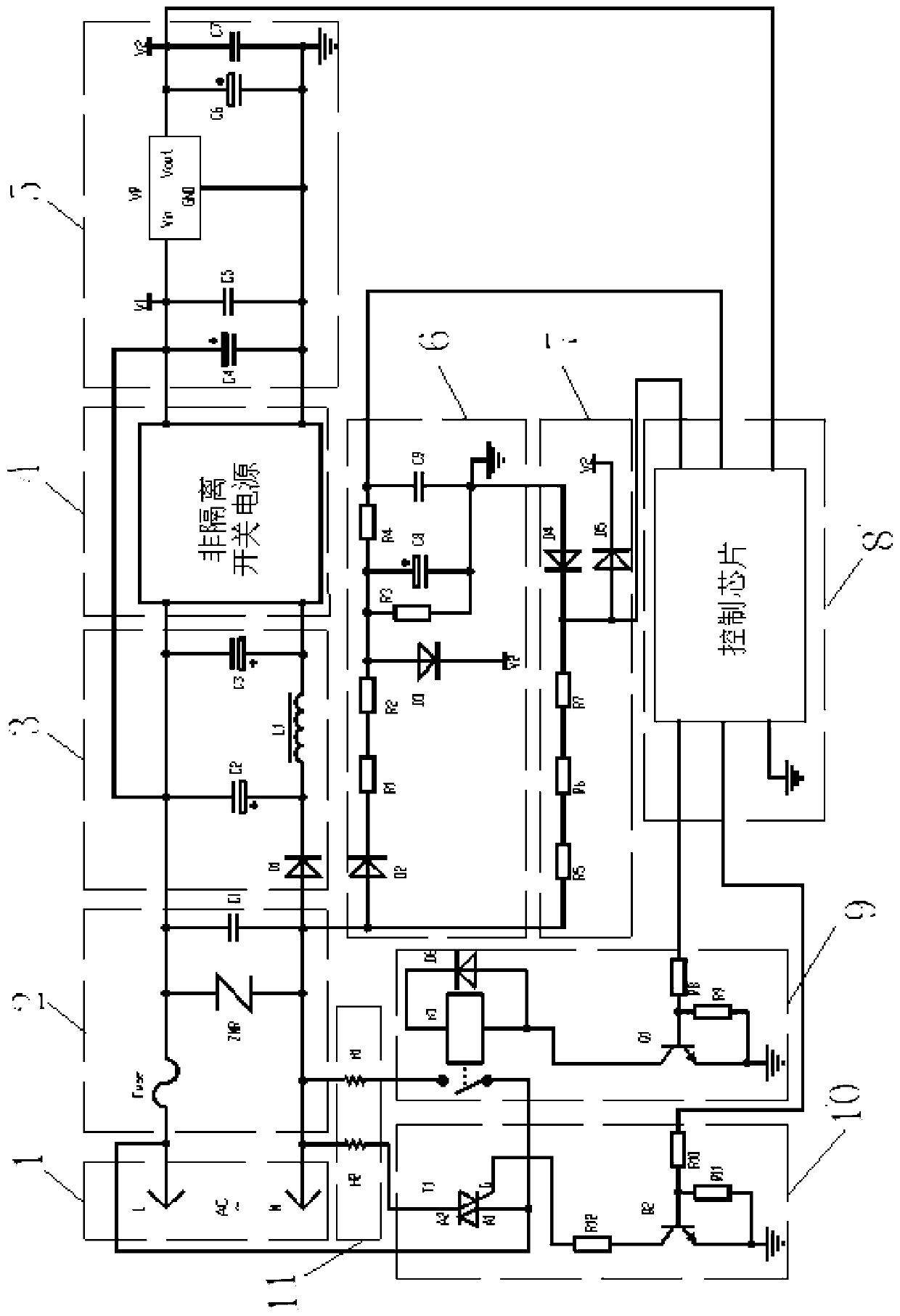

[0052] refer to Figure 5

[0053] The heating control method of the electric cooker comprises the following steps:

[0054] 1), the control chip 8 sets the corresponding output power P according to the cooking mode and cooking stage selected by the user 0 , the output power P 0 pre-stored in the storage unit of the control chip 8;

[0055] 2) The current voltage is measured by the voltage effective value detection circuit 6, and the current voltage is input into the control chip 8. The first calculation unit calculates the power Pr of the first heating tube H1 under the current voltage, and the second calculation unit calculates the second power Pr under the current voltage. Heating tube H2 power Pt;

[0056] 3) The comparison unit compares P 0 and Pr, calculate P 0 The difference from Pr, and the ratio of the difference to Pt , and finally will Converted to the half-wave number N triggered by the thyristor T1;

[0057] 4) When the thyristor T1 is turned on, the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com