Flameless combustion heat accumulating type flat flame combustion nozzle

A flameless combustion, flat flame burner technology, applied in the direction of burner, combustion ignition, combustion method, etc., can solve the problems of lower performance index, easy direct injection, surrounding parts, easy to brittle cracks, etc., to achieve The effect of reducing NOX emissions, high energy utilization efficiency, and ensuring furnace temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

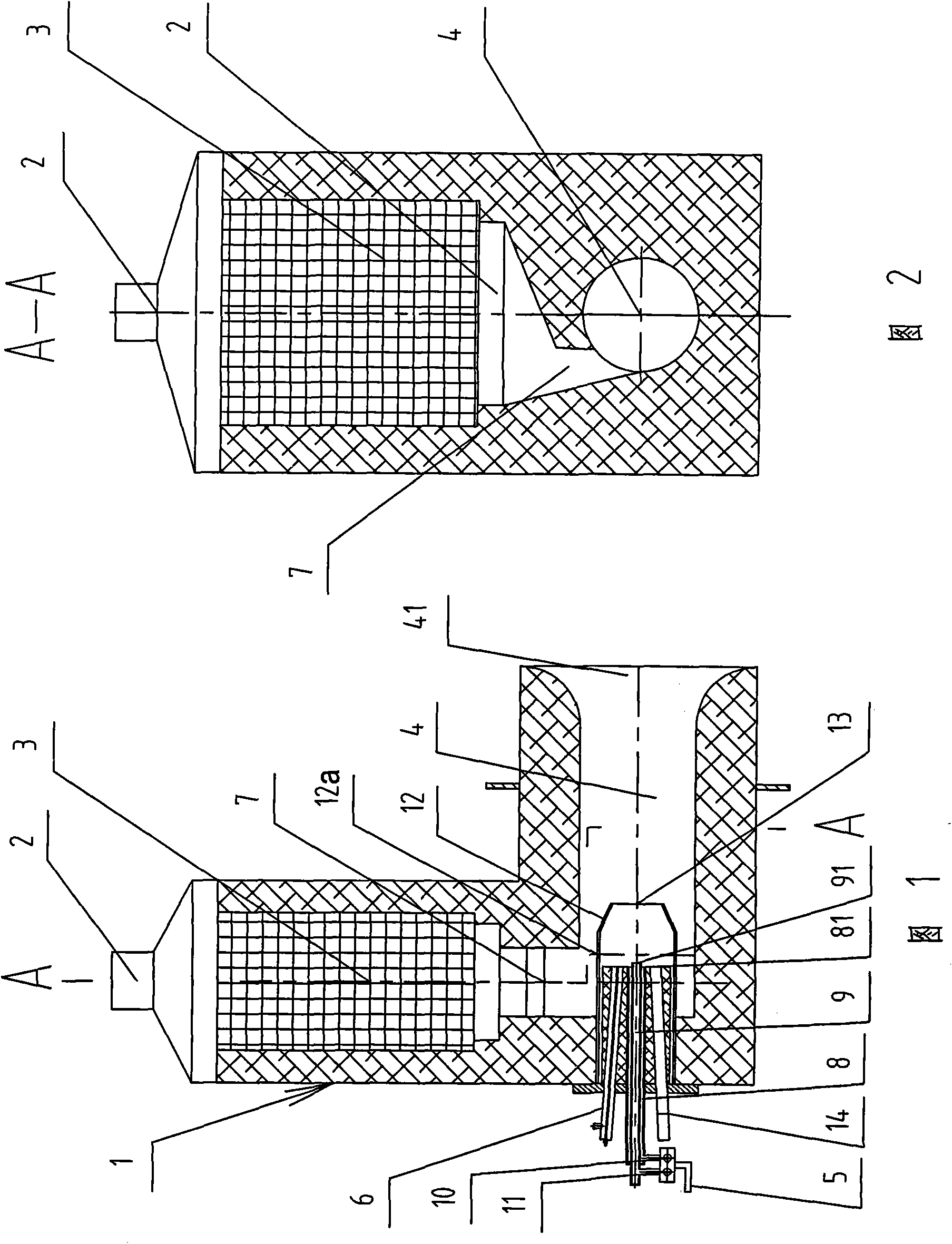

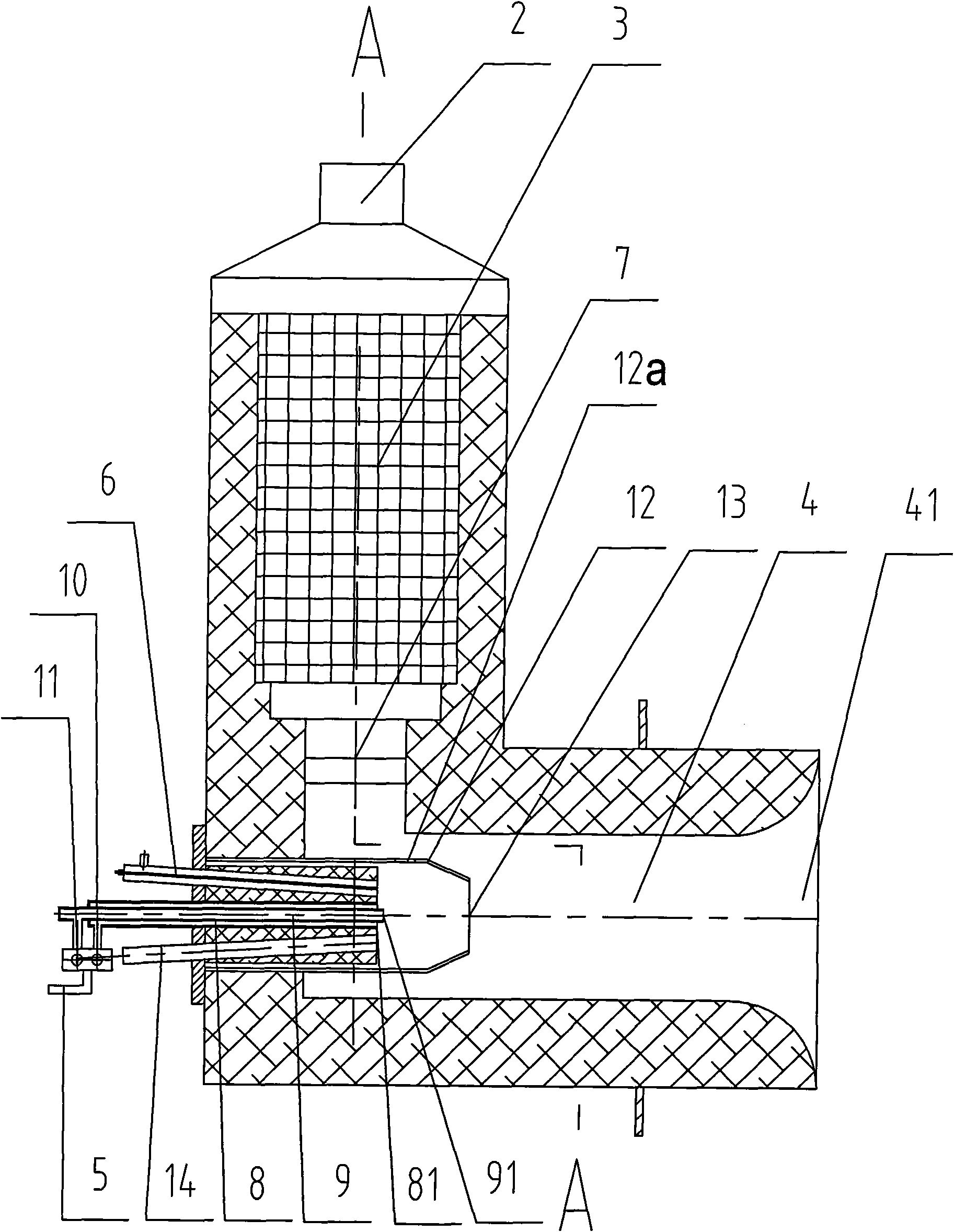

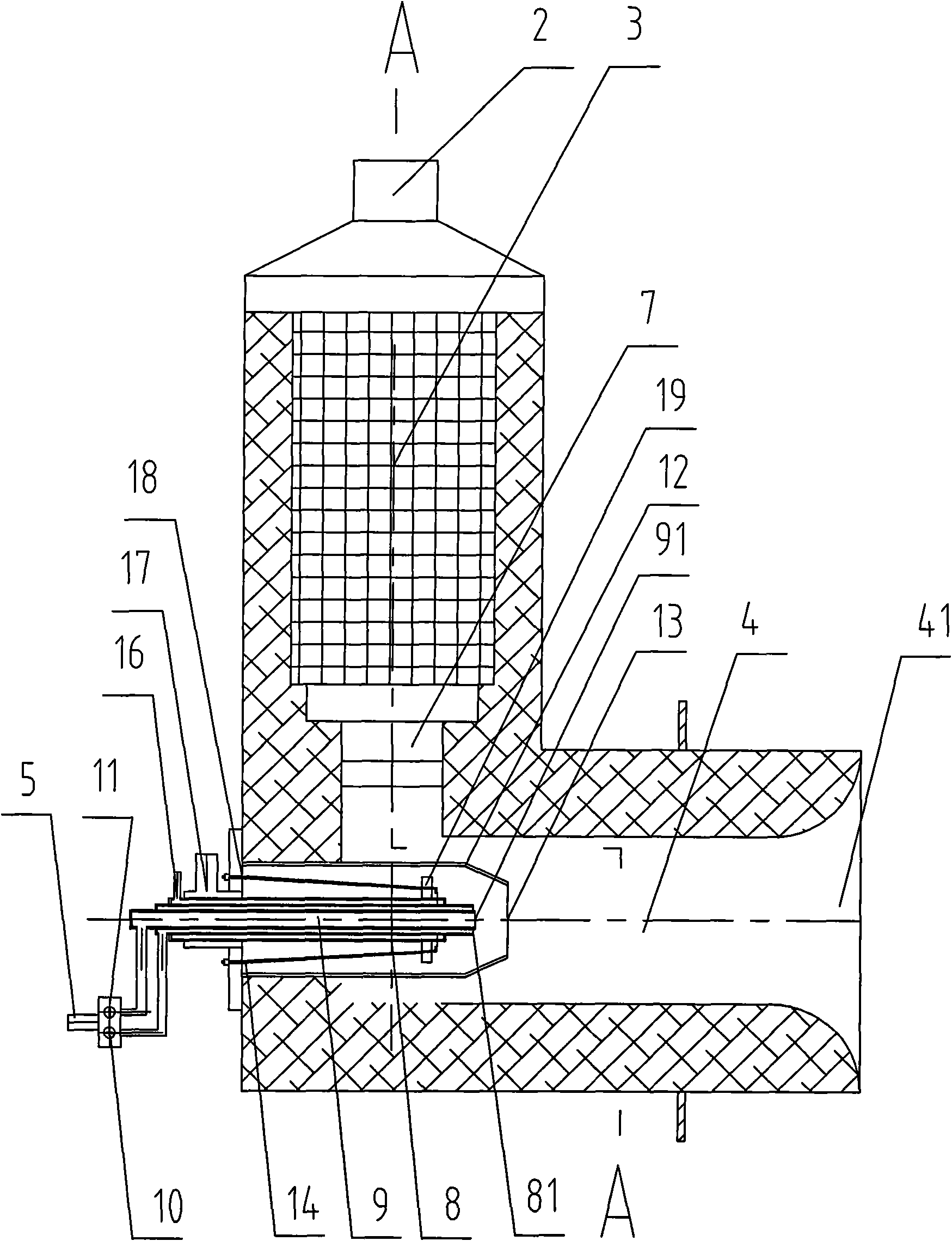

[0024] Such as figure 1 , 2 Among them, the flameless combustion regenerative flat flame burner of the present invention includes a burner body 1, in which an air or flue gas channel 2, a porous heat storage body 3, a combustion cavity 4, and a gas The duct 5 and the ignition device 6, etc., the air or flue gas channel 2 is used as the channel for the combustion-supporting air to enter during combustion, or the flue gas channel for exhausting the flue gas, and the air is input into the burner body 1 (in the combustion cavity 4 and Combustion of gas) or exhaust the flue gas produced by the combustion out of the burner body 1. A porous heat storage body 3 made of refractory materials (such as high-temperature ceramic materials) is arranged in the air or flue gas channel 2 with many The small holes for gas to pass through can exchange heat with the gas when the gas passes; if high-temperature flue gas passes through, the porous heat storage body 3 absorbs the heat of the high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com