Production process of elastic paperboard

A production process and cardboard technology, applied in papermaking, paper machines, textiles and papermaking, etc., can solve the problems of less printing times, uneven paper surface warping, uneven thickness, etc., and achieve increased printing times and uniform moisture content , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

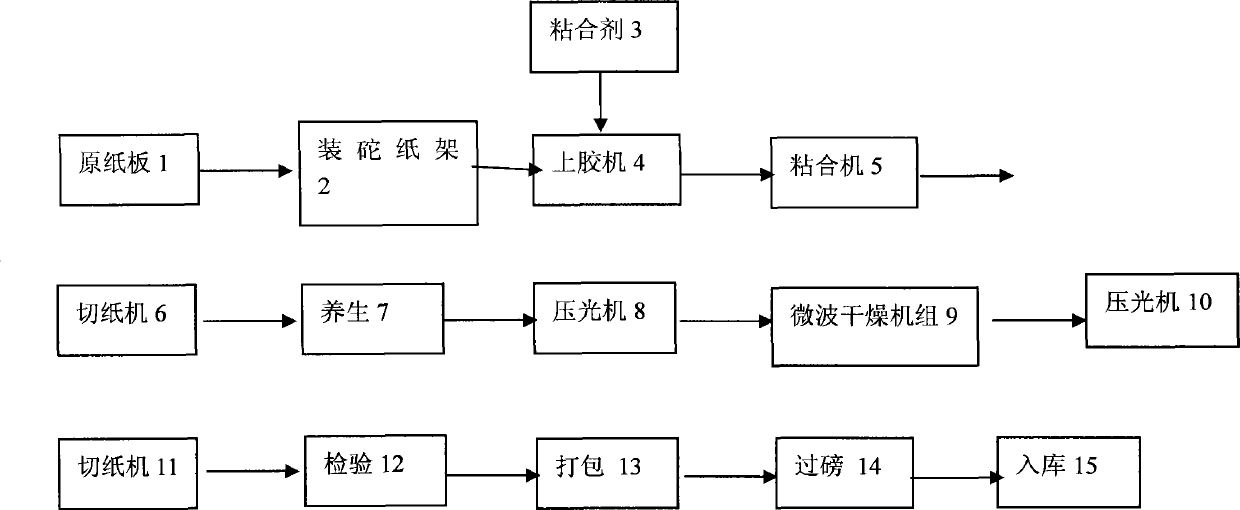

[0009] Such as figure 1 As shown, choose base cardboard 1 refined from high-purity plant fibers, determine the number of layers of base cardboard 1 required according to the thickness required by the elastic cardboard, and hoist the number of base cardboard 1 on the reel according to the required number of layers Go to the weight-loading paper stand 2, inject the adhesive 3 into the gluing machine 4, the raw cardboard 1 passes through the weight-loading paper stand 2, enter the gluing machine 4 for gluing, enter the bonding machine 5 for compounding, and then go to the paper cutter 6. Cut the sheets horizontally into semi-finished products. After periodic health preservation 7, each sheet is put into the calender 8 for calendering to increase the density. The working pressure of the calender 8 is 40Mpa, and it is transported to the microwave drying unit by the conveyor belt. 9 for drying. The operating speed of the microwave drying unit 9 is determined according to the thickne...

Embodiment 2

[0011] Such as figure 1 as shown in figure 1 As shown, choose base cardboard 1 refined from high-purity plant fibers, determine the number of layers of base cardboard 1 required according to the thickness required by the elastic cardboard, and hoist the number of base cardboard 1 on the reel according to the required number of layers Go to the weight-loading paper stand 2, inject the adhesive 3 into the gluing machine 4, the raw cardboard 1 passes through the weight-loading paper stand 2, enter the gluing machine 4 for gluing, enter the bonding machine 5 for compounding, and then go to the paper cutter 6. Cut the sheets horizontally into semi-finished products. After periodic health care 7, each sheet is put into the calender 8 for calendering to increase the density. The working pressure of the calender 8 is 50Mpa, and it is transported to the microwave drying unit through the conveyor belt. 9 for drying. The operating speed of the microwave drying unit 9 is determined accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com