Glaze formula and preparation process thereof

A preparation process and glaze technology, which are applied in the field of glaze formulation and preparation process, can solve the defects that appear on the outermost surface of the glaze layer, the glaze flow, the piling glaze and the dry glaze, and the inability to obtain the glaze layer. and other problems, to achieve the effect of improving the thermal insulation effect, the reduction temperature point and the high temperature firing temperature range, and the effect of pure color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present invention also includes a preparation process of glaze, comprising the following steps:

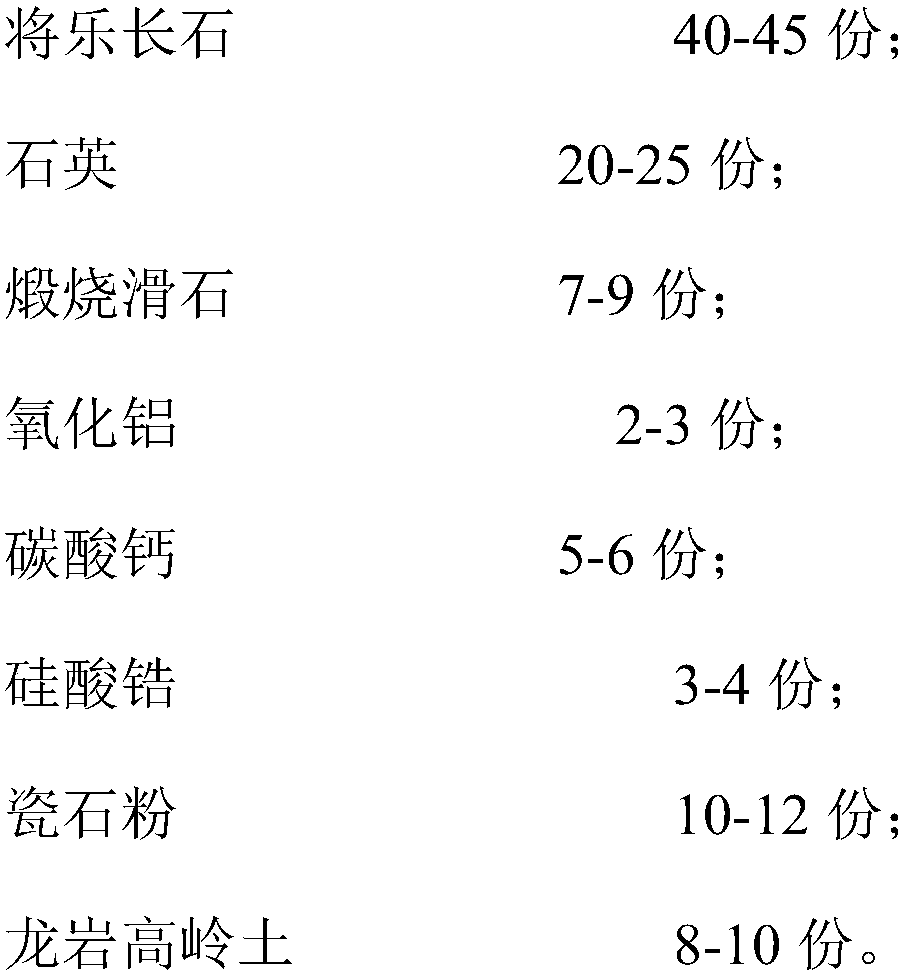

[0039](1) Raw material refining: 40 parts by weight of feldspar are successively subjected to primary grinding, intermediate grinding and advanced grinding; 20 parts by weight of quartz are respectively subjected to primary grinding and intermediate grinding; 7 parts by weight of calcined talc are subjected to primary grinding; 2 parts by weight The aluminum oxide of 3 parts has been through primary grinding, intermediate grinding and advanced grinding successively; The calcium carbonate of 5 parts by weight has been through primary grinding; The zirconium silicate of 3 parts by weight has been through primary grinding, intermediate grinding, advanced grinding and final grinding successively; The porcelain stone powder has undergone primary grinding and intermediate grinding successively; 8 parts by weight of Longyan kaolin has successively undergone primary grinding and...

Embodiment 2

[0047] The present invention also includes a preparation process of glaze, comprising the following steps:

[0048] (1) Raw material refining: 41 parts by weight of feldspar are successively subjected to primary grinding, intermediate grinding and advanced grinding; 22 parts by weight of quartz are respectively subjected to primary grinding and intermediate grinding; 8 parts by weight of calcined talc are processed through primary grinding; 2 parts by weight The aluminum oxide of 3 parts has passed through primary grinding, intermediate grinding and advanced grinding successively; The calcium carbonate of 5 parts by weight has been through primary grinding; The porcelain stone powder has undergone primary grinding and intermediate grinding successively; 9 parts by weight of Longyan kaolin has successively undergone primary grinding and intermediate grinding;

[0049] The step of the primary grinding is: adding the grinding medium and the material to be ground into the ball mil...

Embodiment 3

[0056] The present invention also includes a preparation process of glaze, comprising the following steps:

[0057] (1) Raw material refining: 43 parts by weight of feldspar are successively subjected to primary grinding, intermediate grinding and advanced grinding; 24 parts by weight of quartz are respectively subjected to primary grinding and intermediate grinding; 8 parts by weight of calcined talc are processed through primary grinding; 3 parts by weight 6 parts by weight of alumina have been through primary grinding, intermediate grinding and high-grade grinding; 6 parts by weight of calcium carbonate have been through primary grinding; 4 parts by weight of zirconium silicate have been through primary grinding, intermediate grinding, high-grade grinding and final grinding; 12 parts by weight The porcelain stone powder has undergone primary grinding and intermediate grinding successively; 9 parts by weight of Longyan kaolin has successively undergone primary grinding and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com