Ceramic heating piece for laser printer and manufacturing process thereof

A technology of ceramic heating sheet and laser printer, which is applied in the direction of electric recording process applying charge pattern, equipment of electric recording process applying electric charge pattern, heating element material, etc., can solve the problems of high cost printer and inability to change temperature, etc. , to achieve the effect of easy production, omitting the surface treatment process, and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

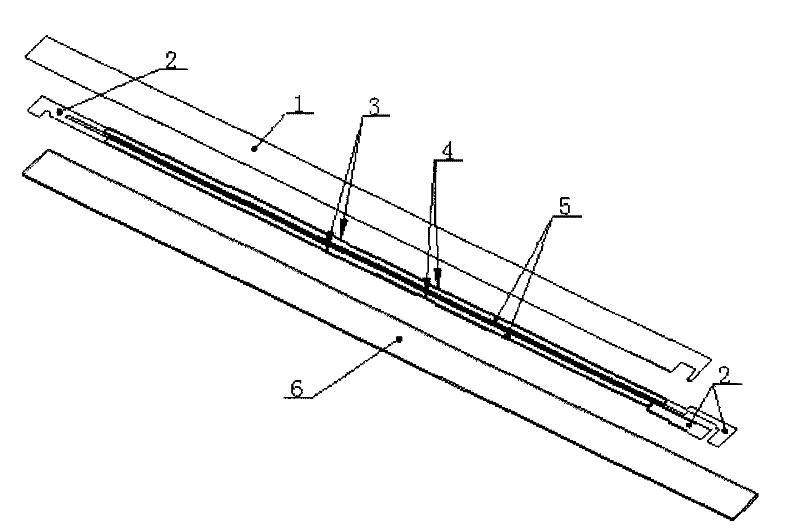

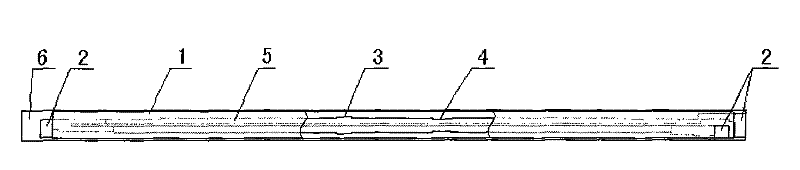

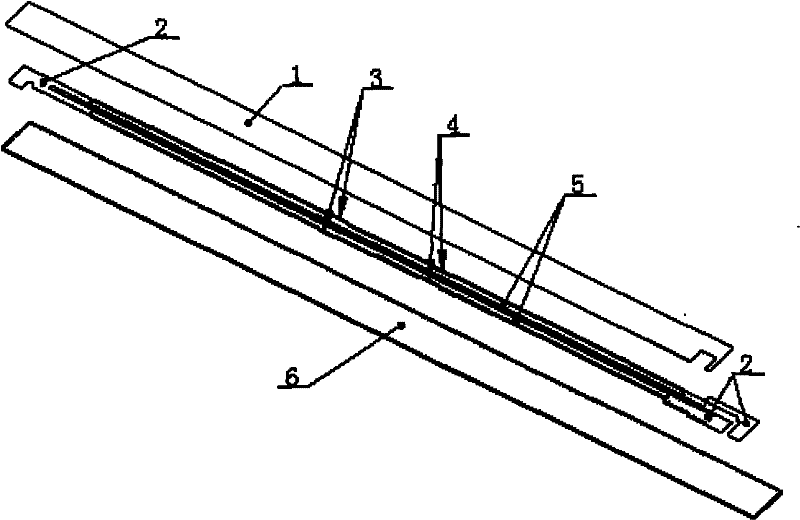

[0021] see figure 1 with figure 2 , a ceramic heating sheet for laser printers in the present invention, a thin film heating wire 5 is sintered on a ceramic substrate 6, lead-out electrodes 2 are arranged at both ends of the thin film heating wire 5, and a dielectric covering layer is arranged outside the thin film heating wire 5 1, it is characterized in that: described ceramic substrate 6 is the Al2O3 substrate of 96% (remaining 4% is made of SiO 2 Or / and MgO as an additive, the function is to increase the roughness of its surface, to improve the adhesion firmness with the film heating wire 5 and the medium cover layer 1), and the cover layer 1 is a glass glaze film.

[0022] Widening lines 3 and narrowing lines 4 for changing temperature are provided on the film heating lines 5 . The working principle of the widening line 3 and narrowing line 4 is:

[0023] 1. First of all, when the thin film heating wire 5 used as a heating element is uniform in thickness and equal in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com