Adhesive film back plate integrated material and preparation process thereof

A preparation process and backplane technology, applied in the field of adhesive film backplane integrated materials and their preparation process, can solve problems such as affecting the quality of the adhesive film, affecting the mechanical properties of the material, losing physical properties, etc., to improve the light transmittance, use Long service life and improved barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

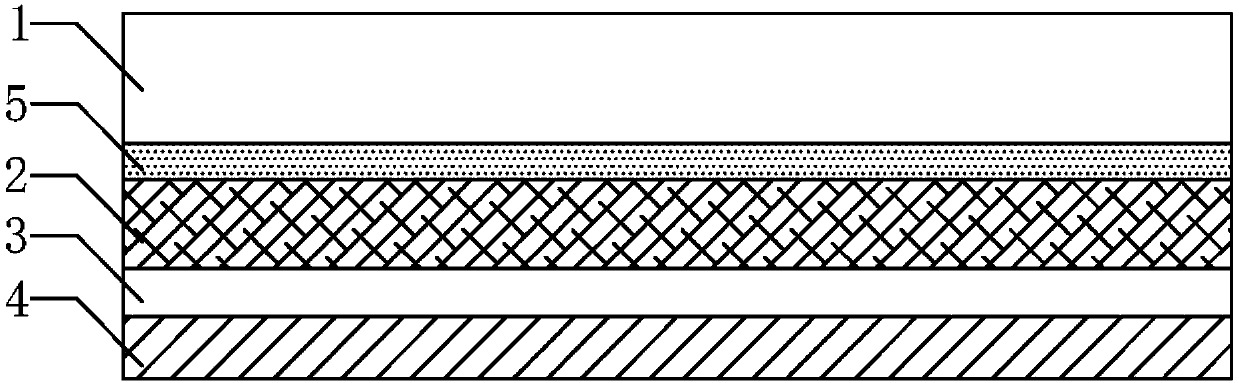

[0056] See figure 1 , an adhesive film backboard integrated material, including an adhesive film layer 1, a structural reinforcement layer 2, an adhesive layer 3 and a weather-resistant layer 4 sequentially connected from the inside to the outside, the adhesive film layer 1 and the structural reinforcement layer There is a frosted layer 5 between the two, and the adhesive film layer 1 is made of modified POE thermoplastic elastomer.

[0057] The thickness of the adhesive film layer is 300 μm, the thickness of the frosted layer is 5 μm, the thickness of the structural reinforcement layer is 400 μm, the thickness of the adhesive layer is 1 μm, and the thickness of the weather-resistant layer is 5 μm.

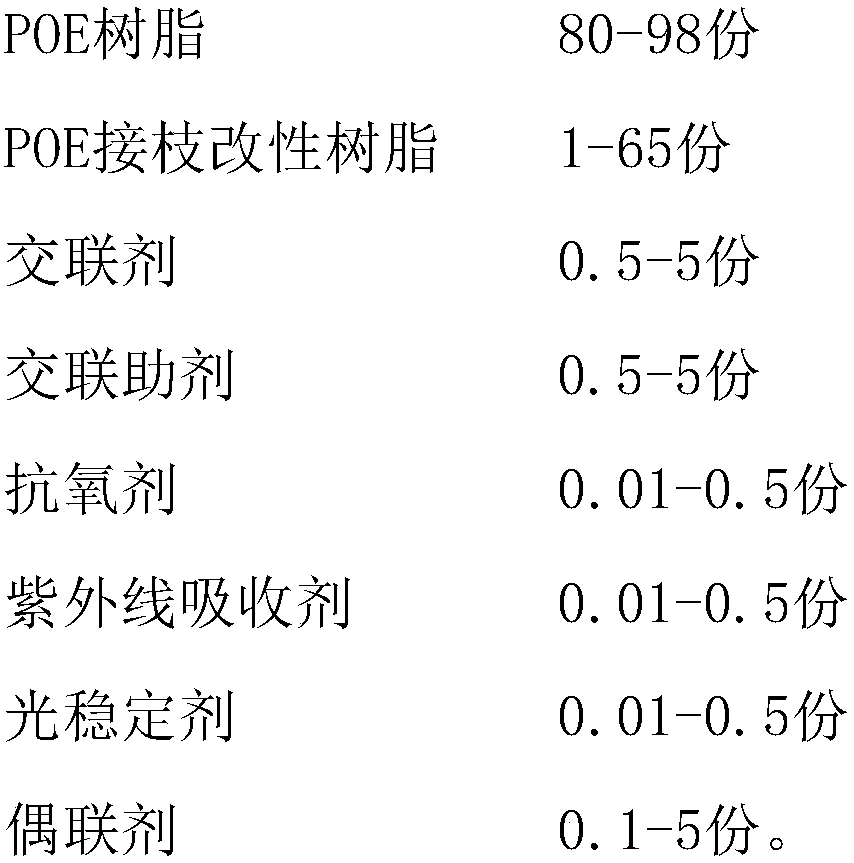

[0058] The modified POE thermoplastic elastomer includes the following raw materials in parts by weight:

[0059]

[0060] The weight content of the octene monomer in the POE resin is 25%, the melt flow rate of the POE resin is 10g / 10min, and the light transmittance is greater...

Embodiment 2

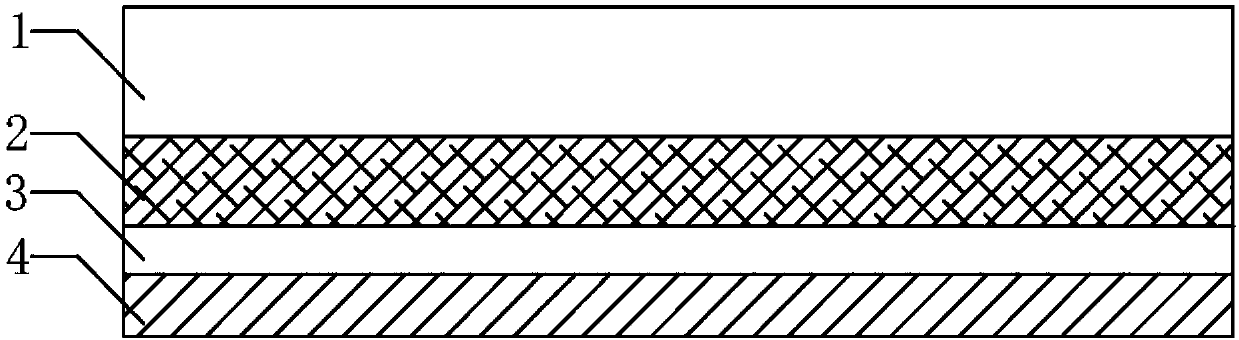

[0074] The difference between this embodiment and above-mentioned embodiment 1 is:

[0075] The thickness of the adhesive film layer is 400 μm, the thickness of the frosted layer is 8 μm, the thickness of the structural reinforcement layer is 315 μm, the thickness of the adhesive layer is 7 μm, and the thickness of the weather-resistant layer is 15 μm.

[0076] The modified POE thermoplastic elastomer includes the following raw materials in parts by weight:

[0077]

[0078]

[0079] The weight content of the octene monomer in the POE resin is 27%, the melt flow rate of the POE resin is 17g / 10min, and the light transmittance is greater than 83%.

[0080] The POE grafted modified resin is a mixture made of POE, maleic anhydride and dicumyl peroxide in a weight ratio of 95:1.3:0.12, which is blended and extruded at a temperature of 183°C. .

[0081] The crosslinking agent is peroxy-2-ethylhexyl tert-butyl carbonate; the crosslinking assistant is trimethylolpropane triacr...

Embodiment 3

[0088] The difference between this embodiment and above-mentioned embodiment 1 is:

[0089] The thickness of the adhesive film layer is 500 μm, the thickness of the frosted layer is 10 μm, the thickness of the structural reinforcement layer is 225 μm, the thickness of the adhesive layer is 13 μm, and the thickness of the weather-resistant layer is 27.5 μm.

[0090] The modified POE thermoplastic elastomer includes the following raw materials in parts by weight:

[0091]

[0092] The weight content of the octene monomer in the POE resin is 29%, the melt flow rate of the POE resin is 25g / 10min, and the light transmittance is greater than 86%.

[0093] The POE grafted modified resin is a mixture made of POE, maleic anhydride and dicumyl peroxide in a weight ratio of 100:1.5:0.1, and prepared by blending, extrusion and granulation at a temperature of 185°C .

[0094] The cross-linking agent is 3,3-di(tert-butyl peroxy) ethyl butyrate; the cross-linking assistant is triallyl i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com